Volvo 供应商25大培训_01 MSA

- 格式:pdf

- 大小:1.28 MB

- 文档页数:45

2015 Supplier training-MSA 85710Jie ZhouManufacturing Site Assessment (MSA)2015 Supplier training-MSA 85710Jie Zhou•General understanding 概述•Elements Description 条款讲解2015 Supplier training-MSA 85710Jie ZhouGeneral understanding概述2015 Supplier training-MSA 85710Jie ZhouVQE VQE AWARD Customer SatisfactionSourcing with QualityProgram Development &Changes1.CBP , Commodity Business Plan2.SFQ, Sourcing for Quality Process, Supplier Evaluation3.SCM, Supplier Choice Meeting1.APQP , Advanced Product Quality Planning2.SEP , Supplier Engagement Process3.PPAP , Production Part Approval Process4.Product and Process Changes.1.Concern resolution, FASS process, 8D-, DMAIC-methods2.MSA/LDA Manufacturing Site Assessment/Lean Deployment Assessment3.Supplier Escalation processLessons Learned and Continuous Improvement Ongoing ProductionSourcing Program Development and Changes Ongoing Production2015 Supplier training-MSA 85710Jie ZhouMSA is about….▪Review if supplier fulfil customer requirements –examples:TS16949, Volvo Customer Specific requirements. 体系及沃尔沃特殊要求符合性.▪To improve the supplier by assessing if the supplier is working in a systematic way.系统化评审并敦促改善工具▪Supplier self evaluation –to improve daily business. 自审▪To evaluate new potential suppliers (“Light MSA” –short version). 潜在供应商考察.2015 Supplier training-MSA 85710Jie ZhouA “Second-Party Audit ” which is conducted by parties having an interest in the organization such as customers, or by other persons on their behalf. 客户/二方审核A systematic , documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which audit criteria are fulfilled. 系统性的/存档的2015Suppliertraining-MSA85710Jie Zhou Elements Description条款讲解2015 Supplier training-MSA85710Jie Zhou There are 16 elements in MSA.1. Planning for Manufacturing Process Capability 制造过程能力策划2. PFMEAs/Control Plans 潜在失效模式分析/控制计划3. Employee Readiness/Training Review 员工资质及培训4. APQP / Launch / PPAP and Run-at-Rate Review 产品质量先期策划/投产/批准/节拍5. Manage the change 变更管理6. Sub-supplier Quality Management 分供方质量管理7. Control of Incoming Quality 来料质量管理8. Process Variability Monitoring/Reduction 过程变异监控/消减9. Measurement System 测量系统10. Control of Parts/Part Identification/Packaging/Shipping 追溯/标示/包装/发运11. Testing/Engineering specification 检测/工程规范12. Maintenance / Housekeeping 维护保养/厂务13. Manufacturing Flow / Process Engineering / 6 Sigma and Lean Manufacturing Metrics 精益生产14. Problem Solving / Corrective actions 纠正与改善措施15. Health and Safety 健康与安全16. Risk management 风险管理Elements layout2015 Supplier training-MSA 85710Jie ZhouElements layout2015 Supplier training-MSA85710Jie Zhou Commodity Specific AssessmentAnd 9 Commodity Specific Assessment (CSA)1.Tightness Leakage Test密封泄漏测试2.Casting 铸造3.Fasteners紧固件4.Machining机加工5.Painting & Electroplating喷涂&电镀6.Plastics Molding塑料注塑7.Stamping冲压8.Welding焊接9.Electrical*电子*2015 Supplier training-MSA85710Jie Zhou Manufacturing Site AssessmentYou can check out specific guide line and work sheet at supplier portal: https:///EN/SupplierQuality/MSA/Pages/default.aspx2015 Supplier training-MSA85710Jie Zhou 1. Planning for Manufacturing Process CapabilitySupplier´s quality system is third party certified to TS 16949 and ISO 14001.三方认证TS及ISO证书Supplier has a process to identify and regularly update customer and internal expectations, objectives, and requirements into measurable.有识别,定期更新内部及外部客户期望,目标和需求并做量化管理的过程Supplier has a defined organization and a systematic process for managing the company including;* process to follow up VSIM metrics and other targets. 管理目标与沃尔沃供应商信息系统•Result from customer survey/satisfaction (Manufacturing, Logistic, SQM, Buyer, R&D, etc.) 客户满意度调查,需要涵盖沃尔沃的所有相关部门.* management team is following monthly continuous improvement plans and have assigned responsible person for each measurable/activity. 管理层月度评审,和推进符合跟进活动.•Trend/performance charts demonstrate effectiveness of improvement activities 图形化* monthly and yearly evaluating the performances 月度及年度绩效评估过程Non-conformances identified in internal audits are not repeated. 反复发生的内审不符.Supplier has a defined organization and a systematic process for managing that parts will comply with all Legal Requirements. 法律法规符合性管理.2015 Supplier training-MSA85710Jie Zhou1. Planning for Manufacturing Process Capability??Customer 客户Tire-1 一级供应商Tire-2 二级供应商Management review 管理层评估团队参与闭环改善2015 Supplier training-MSA85710Jie Zhou Organizations meet the requirements according to AIAG FMEA Handbook and for the Control Plan ISO/TS 16949 Annex A and AIAG APQP for Control Plan (AIAG=Automotive Industry Action Group, /scriptcontent/index.cfm ) 符合手册要求All parts have documented DFMEA, PFMEA and Control plans. 每个产品的必要文件There is a robust and systematic process in place for continuously improving the process in order to reduce and eliminate potential failure modes. It‘s important to focus on 1) Severity, 2) Criticality –severity x Occurrence and 3) to identify high RPNs. 不能仅将RPN 值作为持续改善的优先级因子FMEAs are reviewed annually or as issues arise. All error detection areas are reviewed and, where feasible, plans exist to move to error prevention devices (Poka Yoke). 防错应用Error-proofing and Poka Yoke methods are documented and tested for effectiveness and defined in preventive maintenance plan. 防错装置的预防性维护Supplier together with VCC identifies all Special Characteristics and Pass-Through characteristics and implement to* Special Characteristic Agreement (SCA) 特殊特性清单* PFMEAs 潜在失效模式分析* Control Plans 控制计划* Operator instructions 作业员指导书* Maintenance plan and instructions 维护保养计划及作业指导书All process or product characteristics being used are identified in the Control plan and operator instructions. Reaction plans are clearly defined and protect VCC from non-conforming materials.过程和产品特性控制应在控制计划和作业指导书里体现,反应计划定义保护不符件流入客户端.2015 Supplier training-MSA 85710Jie ZhouWeak PFMEAsAgreement of ”Special Characteristics” is missing (SCA –Special Characteristics Agreement ) 无特殊特性清单Supplier is not aware how customer is assembling part in engine or vehicle plant. 供应商不了解客户端该部件组装过程It‘s not included in maintenance plan/instructions and operator instructions. 没有维护保养计划及作业指导书Pass Through Characteristics (PTC) are missing. 没有识别传递传导特性Failure modes are missing 漏注失效模式not working as a cross functional team 非团队输出not reviewing the PFMEA on the shop floor 无现场评审PFMEA is not updated when process or the layout are changed 过程变更时不更新Involved people are not enough PFMEA trained. Maintenance people are not participate in the PFMEA teams 参与人员资质能力,无设备工程参与PFMEAs don‘t include; internal transportation, storage, labeling and rework. 忽略内部物料部件传递传输,存储,返工过程PFMEA is filled in wrong way, misunderstanding for failure mode, effect and cause, wrong occurrence rating, not separated cause analysis. 不规范Not including process and product requirements 产品和过程要求或规范PFMEA is not used as a tool for improvements –all failure modes needs to be evaluated and actions need be implemented to reduce risks 忽略改善目的Wrong focus of potential failure modes –Supplier is focusing on RPN to improve the process. Must instead focus on Severity and Criticality 改善方向The potential risks in the PFMEA must be verified and detected in the EOL Test, Trusting too much in End of Line Test (EOL) 对最终检的错误认识.Not updating PFMEA in a systematic way …… 忽视规范系统管理2015 Supplier training-MSA85710Jie ZhouIs this included in the PFMEA?Incoming goods Parts ready for shipment ReworkTool change!Stop!ScrapBreakdown!1234The whole process –all steps!Manual work A clear Process chart will be key preliminary document!2015 Supplier training-MSA85710Jie Zhou Maintenance plan and instructions 维护保养与FMEA PFMEAIdentifying Special Characteristics and Pass ThroughCharacteristics Tool FMEA MachineFMEADesign FMEA Maintenance Instr Maintenance PlanOperator InstrControl Plan Often missing to notifyimportant characteristicsin ….YS YC2015 Supplier training-MSA85710Jie Zhou 3. Employee Readiness/Training ReviewThe supplier ensures that only trained and qualified personnel are involved in all aspects of the manufacture or design (as appropriate) of VCC parts. 资质考核和培训过程Supplier has a training program for all departments and can demonstrate compliance to training plans. 培训计划及实施Training is part of the supplier objectives. 培训在管理过程的量化体现Supplier identifies operator skill set and training requirements and has a selection criteria to assign skilled operators to a given function.作业员技能管理.(Operators are not trained enough to have the right mindset regarding “Zero defects”) 零缺陷理念推进2015 Supplier training-MSA85710 Jie Zhou 3. Employee Readiness/Training ReviewPotential improvement areas –Quality mindsetDefinition of -ZERO defectsTo care about….!To use common sense!Realizing the risks and minimize them!Accordingto specificationCustomer Satisfaction2015 Supplier training-MSA85710Jie Zhou 4. APQP / Launch / PPAP and Run-at-Rate Review Supplier has a system to manage new vehicle program launches and an APQP tracking routine in place. 项目系统管理The supplier complies with the AIAG Production Part Approval Process (PPAP) manual and VCC customer specific requirements. Supplier follows VCC "Phased PPAP Requirement Handbook:Run-at-Rate (Phase 0) and capacity verification (Phase 3) must be performed and supports the confirmed NWC (Normal Weekly Capacity) program requirements for all VCC parts. 节拍及产能验证Supplier monitors customer demands and has a process to ensureon-going sufficient capacity, incl sub supplier´s capacity. 供应链产能管理Suppliers require that sub-suppliers have a process that takes care of PPAP requirements. 分供方2015 Supplier training-MSA85710Jie Zhou 5. Manage the changeSupplier has a documented process to effectively implement changesregarding design, process and volume changes. 受控过程管理变更Supplier effectively reviews and updates its quality supporting documentation (Process Flow Diagrams, FMEAs, Control Plans,Operator Instructions and Visual Aids.) 变更时对产品过程文档评审Supplier follows a documented process to ensure that proper Volvo approvals for design changes(SREA-Supplier Request For Engineering Approval). 遵守沃尔沃变更申请和批准流程Supplier follows a documented process to ensure that proper Volvo approvals for process changes, change of sub-suppliers and transfer of production from one location to another(SRICA-Supplier Request For Industrial Change Approval).遵守沃尔沃变更申请和批准流程2015 Supplier training-MSA85710Jie Zhou Supplier requires sub-supplier to have a Quality System that is fulfillingISO/TS 16949 or VDA or ISO 9001. 管理体系要求Supplier has defined process to evaluate and selection of new sub-suppliers 新供应商遴选过程Supplier has a process for managing its supply base including identification of those with high impact to quality. 分级分类的供应商管理Supplier requires PPAP for all parts from sub-suppliers. Supplier verifies PPAP compliance of requirements by on-site visit of high impact/new projects sub-supplier facilities. 生产件批准全覆盖,对重点件现场评审批准Supplier is responsible for transfer of any engineering requirements stated in the Part Folder for Suppliers (PFFS) when defined by VCC. 传递并贯彻相关沃尔沃产品技术标准和工程规范Where pass-through characteristics (PTC) are identified; 传递特性管理supplier has a process to identify/analyze and handle sub-supplier PTCs, utilizing robust controls and error-proofing methods.PTCs must be integrated both at supplier´s and sub-supplier´s PFMEA, control plan through the VCC`s SCA process.2015 Supplier training-MSA85710Jie Zhou Supplier requires annual dimensional and functional verification (re-PPAP) for all parts from sub-suppliers if not other is stated. 产品年度评审Supplier has a procedure in place that defines how to assure implementation of corrective actions across sub-supplier facilities for all issues through a robust 8D process 整改纠正需分供方提交8D 报告Sub-suppliers have a documented problem solving methodology and using qualified people for investigating root causes related to customer concerns. 根本原因分析需要运用系统方法及合格人员.Supplier has appropriate resources to manage sub supplier quality incl on site assessment of high impact sub-supplier facilities. 分供方管理资源配备.Supplier has a process to obtain VCC approval prior to implementation of any sub-supplier (tier 2 or tier 3, etc.) changes per the SREA process (Supplier Request for Engineering Approval) or the SRICA process (Supplier Request for Industrial Change Approval). 变更管理When the supplier submits PPAP documentation to VCC, it contains sub-suppliers ´PPAP information and/or it is available for review. 分供方提交PPAP 存档以备沃尔沃评审.2015 Supplier training-MSA85710Jie Zhou 6. Sub-supplier Quality ManagementWeak control of 2nd tier supplier…..Weak control of 2nd Tier Supplier. 40-60% of VCC´s rejects are related to 2nd tier!!!!数据统计,四到六成问题来源于二级供应商!1st Tier Supplier doesn't have SQM organization.-2nd Tier Supplier is often managed by the buyers or projectpeople at 1st Tier. Competence skills are missing to performing 8D and PPAP reviews. 分供方管理人员能力-1st Tier is very seldom visiting 2nd Tier Supplier to makereview of Flow chart, PFMEA and Control plan.忽略分供方项目文件的现场评审-Poor evaluation of new potential 2nd tier糟糕的新供应商遴选过程Pass Through Characteristics are not/seldom identified between 1st Tier and 2nd Tier Supplier (SCA). 缺失传递特性的识别1st Tier supplier doesn‘t have any procedure/guide line how to prioritize 2nd tier suppliers. 缺失供应商分级分类管理1st Tier supplier doesn‘t evaluate problems from 2nd tier suppliers every year.2015 Supplier training-MSA85710Jie Zhou 7. Control of Incoming QualitySupplier has included in organization structure a department for Incoming Quality management within sufficient resources and a defined process. 组织,过程,资源.•Supplier has a strategy for receiving inspection and how to minimize it with preventive activities. 减少来料检验的策略•Incoming quality requirements are part of a control plan;-If incoming quality inspections are made, there isevidence/records of the specification/results and complianceto the specification. 检验记录保存和符合性-If no incoming inspections are made, there is a rationale forqualifying sub-suppliers 免检的分供方质量保证•Supplier has a procedure for parts marking and handling in Incoming area and also assurance to protect parts mixing. 检验区域的标示管理.2015 Supplier training-MSA85710Jie Zhou 8. Process Variability Monitoring/Reduction •A key aspect of defect prevention is process variability reduction and the use of SPC or an equivalent process monitoring method to indicate when action is necessary. 统计过程控制的目的理解.•For characteristics covered in SCA, the supplier demonstrates process capability using the Cpk process capability index as defined in VCS 5060.19. The capability demand is Cpk>1,33 during long time study. 了解并实施特殊特性清单特性过程能力管控.For characteristics not covered in SCA, appropriate characteristics are chosen for SPC monitoring/control in all processes (if applicable).不仅限特殊特性清单特性.•The control charts are reviewed by the operator and appropriate actions are taken directly and recorded.作业员对控制图理解和采取行动能力.•The reaction plan in the control plan clearly describes the method for the operator to communicate issues to process owner. 控制计划需要定义作业员与工艺负责人的反馈和报告要求.•AIAG Statistical Process Control (SPC) manual is followed in all aspects.•符合手册2015 Supplier training-MSA85710Jie Zhou From VCS 5060,39 Classification of requirementsConsequence class [1] 关键特性For requirements where non-compliance leads to the following:-Risking life and limb-Non-compliance with legal or governmental requirements-Direct failure of function-Considerably shortened life-Process (at subsequent stages) made impossibleConsequence class [3] 特殊特性For requirements where non-compliance leads to the following:-Risk of non-compliance with legal or governmental requirements-Risk of disturbed function-Risk of shortened life2015 Supplier training-MSA85710Jie ZhouProcess expectations Consequence class Expectation for PSW approval Expectation for running production [1] or CC Capability Cpk>1,67 and Poka-Yoke.Long time ongoing capability Cpk>1,33 and Poka-Yoke.[3] or SC Capability Cpk>1,67.Long time ongoing capabilityCpk>1,33 or Annual short timecapability Cpk>1,67 evaluation orPoka-Yoke.Pass-ThroughPTC Poka-Yoke preventing parts from being produced out of specificationPoka-Yoke.For Cpk capability evaluation, see VCS 5060,19 Capability requirements.Capability should be evaluated based on at least 25 parts, sampled out of a 8h production run.Poka-yoke devices should be validated regularly.Consequence Class2015 Supplier training-MSA85710Jie Zhou 9. Measurement SystemAll gauges used for checking components/parts per the control plan have a gauge R&R performed in accordance with the appropriate methods described by the latest AIAG Measurement Systems Analysis Manual to determine measurement capability. 控制计划中的量具Gauge masters are traceable to a national or international equivalent standard. Gauge calibration and maintenance is performed on an appropriate schedule and per specification. 量具校准Supplier conducts regular evaluation of error proofing devices. Evidence is requested 防错装置定期验证Variable gauges are used for all characteristics mentioned in SCA, when ever possible. 特殊特性检测需要计量型量具2015 Supplier training-MSA85710Jie Zhou 10. Control of Parts/Part Identification/Packaging/ShippingSupplier has a documented processes in place for part identification and part control in all stages of production including rework, repair, scrap, non-conforming parts, testing, laboratories, storage areas, office areas, etc.追溯/标示管理过程Work instructions for management of rework, repair, scrap, etc., have all of the necessary details, including quality acceptance criteria, process and product control parameters, reference to product drawing release level and date, specific/special gauges and tools required. 返工,维修,报废现场管理Applicable service processes should be followed regarding the re-use of parts if an assembly is disassembled and re-assembled for any reason (e.g., rework). 回用物料质量控制.Supplier ensures that rework operation does not by-pass any quality operation performed in the original process and assures that part conforms to customer requirements. 返工过程应可靠,保证符合客户要求和相应规范.Supplier evaluate if further traceability is required for reworked components. 返工追溯All PFMEAs address the risk of part getting wrong part number marking and different parts getting mixed in the same box. 混料错料潜在失效模式分析Supplier has appropriate traceability of product shipped to customer, including ingoing products. 全工序适当追溯性All PFMEAs address the risks of handling, storage and transporting.拿取,存储,运送中的潜在失效模式分析.Volvo Packaging guidelines are available for use and followed as required; -“Terms & Conditions” and “Container Selection Process” available through VCC Supplier Portal. 包装物流规划符合沃尔沃合同条款,包装箱选取过程要求(相关规范在沃尔沃供应商门户网站可查询)2015 Supplier training-MSA85710Jie Zhou 11. Testing/Engineering specificationAll inspections, measurements, and tests including Volvo specification stated in ”Part Folder for Suppliers” are performed according to documented control plans, instructions and/or procedures to ensure product requirements are met 检测需符合PFFS•Appropriate reaction plans address what actions should take place if there is a test or inspection failure 当检测失败,恰当的反应计划定义•For commodities defined by SQM, supplier demonstrate compliance to CQI-9"Special Process: Heat Treat System Assessment" available through AIAG / Assessment is done yearly and is valid also for sub-suppliers. 热处理工艺CQI-9年度评审.2015 Supplier training-MSA85710Jie Zhou 12. Maintenance / Housekeeping(Many of our concerns are related to maintenance –the trend is increasing!)数据统计表明,与维护保养相关的供应商质量抱怨正在增加.Supplier has a defined organization with sufficient resources and process for managing maintenance including; 组织和资源配备* vision and strategy -moving from reactive to preventive and predictive.愿景策略* process to define and follow up targets (like OEE, Downtime, Mean Timebetween Failure, Mean Time to Repair, etc) 指标量化管理* monthly and yearly evaluating performances incl action plans定期绩效评审和改善推进* Trend/performance charts demonstrate effectiveness of preventivemaintenance program 图形化的改善效果验证Supplier has a list of all spare parts with defined most critical parts, defined minimum of parts on stock, defined process for spare parts order, timing for delivering of spare parts. 备件管理,关键备件Preventive maintenance 预防性维护All machines; have a preventive maintenance action list, are included in a PM time scheduleand the plan is monitored and reviewed monthly by management.Tooling Management模具工装夹具管理Supplier has a process for tooling management, including history, identification, storage andcleaning of tooling.2015 Supplier training-MSA85710Jie Zhou 12. Maintenance / HousekeepingHousekeeping and 5S -Supplier has a defined organization and a systematic process for plant cleanliness, housekeeping, ergonomics and working conditions including; 组织和资源-vision and strategy 愿景和策略-process to define and follow up targets 跟进达成目标的过程-monthly and yearly evaluating performances by the management team 管理团队的定期绩效评估-Trend/performance charts demonstrate effectiveness of the improvement activities. 图形化的改善效果验证evidence that the management team is following the plans for above.管理层参与There are monthly audits of 5S and housekeeping progress.定期的5S 及常务现场审核.2015 Supplier training-MSA85710Jie Zhou 13. Manufacturing Flow / Process Engineering / 6 Sigma and Lean Manufacturing Metrics Supplier includes key manufacturing and Six Sigma-typemeasurable within its QOS. A minimum of two lean-and Six Sigma-type measurable show trends or history of improvement in the past six months. Lean and Six Sigma measurable -include some of the following; First Time Through (FTT), Overall Equipment Effectiveness (OEE), Dock To Dock (DTD) and Percent of Value ADD (PVA)精益生产指标量化管理要求•Additional VCC has a document called LDA (Lean Deployment Assessment)2015 Supplier training-MSA85710Jie Zhou Supplier uses a structured and systematic problem solving method (e.g. Global 8D) to address customer concerns and complaints. Involved personnel are trained and qualified in problem solving methodologies (example; 5xWhy analysis, fishbone diagram, Is/Is not analysis, etc). 使用包含结构化和系统化工具如“5个为什么”,“鱼骨图”,“是非图”等的8D过程分析问题.•Methods are established to communicate quality concerns to the supplier´s production and support personnel. Root cause analysis and corrective actions are submitted to the supplier management team for review. The corrective actions are communicated to and replicated in all affected areas in the supplier´s organization (including other plants).质量投诉的问题分析过程,纠正改善措施内部宣导,培训.管理层团队评审,姊妹工厂的交流.•Supplier has a process in place to address customer plant concerns in a timely and thorough manner 规范的客户投诉处理流程•Supplier reviews quality concerns and program launches and incorporate lessons learned into the Quality system (e.g. work instructions, procedures, standards, guidelines, processes, etc) to achieve future flawless launch.运用质量投诉经验教训,改进质量体系,建立无差错过程.2015 Supplier training-MSA85710Jie Zhou Poor 8D resolution: 糟糕的8D 运用1. Just a few people are involved in the team –not working cross functional. 非团队参与,个人拍脑袋2. General bad/complicated description of the different steps, D0-D8. 8D 理解错误3. Root causes are not found –related to Design, Process and ”Strategic” (Quality system, procedures/routines, instructions, checklists, standards, communication, etc) 错误的根本原因识别4. Supplier creates a database where all 8D reports are stored. 经验教训积累和分享-Problem when having new projects people must read Lessons Learnt (LL). –How can this be secured? (Recipe!)-How to transfer LL to other sites?5. There is no/weak link between root causes and corrective actions 根本原因和纠正措施不相关6. Normally, after a customer concern, a supplier is investigating potential root causes for instance using an Ishikawa diagram. Supplier is not checking if those potential root causes are included in the PFMEA.忽略PFMEA7. Repeated failures due to;重复发生8. Robust ”Permanent Corrective Actions” (PCA) is not always implemented. 永久措施久拖不决9. Poka Yoke or Error Proofing is not implemented –only training of operators again and again and again and again ……. 不使用防错方法,反复培训人员10. Weak training in using the 8D tool (incl 5xwhy analysis) in cross functional teams No deeply involvement from Senior Management team –is not challenging the teams to find the root causes. 8D 问题分析工具培训不够,没有管理层参与.11. Supplier is not measuring reaction time related to VCC requirements 反应时间缓慢.2015 Supplier training-MSA85710Jie Zhou 15. Health and Safety•The aim is to have supplier 3rd party certified according to OHSAS 18001 or equivalent.•Supplier‘s QOS has safety, tracks injuries related to ergonomic issues as one of the metrics 安全,工伤量化指标管理•Supplier has a process in place to assess physical and chemical risk to workers as well as appropriate health and safety measures in place to reduce risk. 伤害风险和化学品风险识别管理过程•Emergency systems are in place and well communicated to employees. 应急系统工作正常,员工培训到位.•A risk assessment is always done before implementing new chemicals into production. 新化学品采购前需要风险评估过程.2015 Supplier training-MSA85710Jie Zhou 16. Risk Management•The supplier has an appointed risk manager (safety engineer) or organization with risk management tasks. 组织资源配置•The supplier has and follows procedures with consideration how to manage: 有管理流程•Loss of communication, to suppliers and VCC. 供应链通讯中断•Logistic chain. 物流•The supplier has possibilities for alternative production in case of a problem, e.g. on site 替代生产应急方案•The supplier must make sure that software used for production is protected from unauthorized changes and that there is appropriate storage for backups. 软件知识产权•The supplier has a back up system in case of loss of power, server breakdowns 备用电源,UPS2015 Supplier training-MSA85710Jie Zhou Manufacturing Site Assessment Any questions or comments –please contact your corresponding Site SQM engineer2015 Supplier training-MSA85710Jie Zhoug/Y/R definition2015 Supplier training-MSA85710Jie Zhou Manufacturing Site Assessment-guide lineAbout SQM concurrence 供应商质量管理团队采购定点意见What can be a concern from SQM, and give no! 以下关注点且不限于•Choose direct 2nd tier without a clean strategy, need to be either cost benefitor technology that we want to control. 指定二级供应商•Project skills or project resources at supplier is poor. 项目能力及资源不足•Technical skills poor at supplier 技术力量薄弱•Poor MSA result without an strong action plan 糟糕的MSA评审结果且没有强力行动计划•Supplier site in a dangerous area (ex; part of Mexico) 外部安全环境考虑•High warranty data/claim on specific commodity, on proposed supplier 售后质量记录•Earlier poor project track record 糟糕的前项目记录•Too many projects at the same time is a huge risk and can be a stopper. 同一供应商在一时间段接到项目较之前数量大大增加•Others…..2015 Supplier training-MSA85710Jie ZhouMSA & CSA in supplier portal and VSIM。

![沃尔沃培训内训教材[优质PPT]](https://uimg.taocdn.com/ec315b55b52acfc788ebc949.webp)

VOLVO汽车4S店售后服务--客户服务礼仪培训课件(可编辑)VOLVO汽车4S店售后服务--客户服务礼仪培训课件客户服务礼仪培训培训师翟铂服务理念客户至上服务至上作为商务服务的宗旨充分反映了企业对我们的期望讲求礼仪是企业对商务职员的基本要求也是体现企业服务宗旨的具体表现服务理念个人行为表现代表企业形象能否对客户进行良好的服既使有再好的商品而对客户的服务不佳也会导致企业的信务影响到企业的形象誉不佳业绩不振文明待客实际操作要求来有迎声问有答声去有送声自我介绍,推荐自己介绍的内容公司名称职位姓名要领介绍自己前问候对方明朗爽快速度稍慢流畅而不可炫耀给对方一个自我介绍的机会您好我是请问应该怎样称呼您呢介绍他人为他人中汽南方的销售顾问我叫陈某架起沟通的桥梁原则尊者有知情权仪态标准站姿手掌五指并拢掌心朝上指向被介绍人握手时的姿态女士握位食指位男士握位整个手掌一般关系一握即放屈前相握名片交换的时间方式途径勿把自己的名片强递给每一个见面的高级主管除非他主动向你索取勿太早递出你的名片尤其是面对完全陌生的人和偶然认识的人勿在一大堆陌生人中散发你的名片应在商业性社交场合交换名片参加同业会议时交换名片通常是在会议开始时进行有时在结束时进行勿把有缺点过时或肮脏的名片给人用餐期间一般不要交换名片在参加社交性晚宴时不论女士或男士都应该带着名片电话是企业内对外沟通最常使用的工具从电话的接听挂断等小小动作上能评断出这家公司的员工是否经过良好的训练也同时可以看出这家公司的管理是否有效率您已是企业内的一份子您每一次电话的应对都影响着企业的声誉希望您能注意电话的使用技巧拨电话的流程接电话的流程重点注意事项 1态度上应谨慎礼貌亲切 2声调音量适中速度不急不慢试想我们嘴巴说谢谢心里却把对方恨得牙痒痒的受话者必也能感觉出您的心不甘情不愿同样是一句话何不说得漂亮一些让人心情舒畅呢 3常将请谢谢对不起挂在嘴边 4常说您取代你多说我们公司咱们公司少说你们公司让对方有一种被认同的感觉一下子缩短了彼此的距离相信要做进一步的深谈要求都会比较容易 5拨电话时电话接通后应告知自已的部门姓名小组1小组2 来电接听小组3 代接电话来电找的人不在小组4 代接电话来电找的人正在接电话办公室日常礼仪 ,真诚相待 ,成为大家的一份子 ,多与同事沟通,不传闲话鞠躬标准的站姿要求要有美感 ,帮助周围的人 ,好的度量端立身直肩平正视悍然抢行阻挡道路不守秩序蹦蹦跳跳奔来跑去制不当行姿横冲直撞造噪音步态不雅错误的坐姿礼仪规范微笑最能赋予人好感增加友善和沟通愉悦心情的表情方式第一影响往往在几秒钟形成而想改变它却需付出很长时间的努力仪容仪表员工礼仪行为十点通笑容多一点嘴巴甜一点想得细一点说得清一点站得直一点坐得正一点走得快一点穿得雅一点态度诚一点应变活一点正确的走姿走姿要求注意稳重与干炼得体的做法行走时头部要抬起目光平视前方双臂自然下垂手掌心向内并以身体为中心前后摆动行走时应伸直膝盖尤其是前足着地和后足离地时膝部不能弯曲男士步幅以一脚半距离为宜女士步幅以一脚距离为宜抬脚时脚尖应正对前方不能偏斜沿直线行走即两脚内侧应落在一条直线上双臂以身为轴前后摆动幅度30,35度正确的蹲姿 1适用的情况整理工作环境给予客人帮助提供必要服务捡拾地面物品自我整理装扮 2注意事项不要突然下蹲不要距人过近不要方位失当不要毫无遮掩不要蹲着休息正确的蹲姿说明一脚在前一脚在后两腿向下蹲前脚全着地小腿基本垂直于地面后腿跟提起脚掌着地臀部向下错误的握手表情神态礼仪 2微笑先要放松自己的面部肌肉然后使自己的嘴角两端平均地微微向上翘起让嘴唇略呈弧形微笑时应当目光柔和发亮双眼略为睁大眉头自然舒展眉毛微微向上扬起迷人的笑容来自刻苦的训练哟课程大纲 1我们的学习目标 2接待处迎客技巧 3服务的仪态 4服饰仪容礼仪耳环发型妆容指甲口袋裙子鞋子丝袜上衣每日对镜点检职场女性服饰仪容发型短发或束发禁染奇异的颜色或怪异发型饰品小而精美的耳环只戴婚戒禁夸张前卫的饰品指甲短干净透明色甲油禁长或脏的指甲艳色的甲油鞋妆容淡妆禁浓装前卫装子与服装相配色的皮鞋禁不干净裤边口袋领子皮鞋口气领带头发扣子职场男性服饰仪容发型短发并保持干净整洁禁留鬓角脸注脸每日对镜点检意脸部清洁并经常剃须并保持口气清新指甲短干净禁长或脏的指甲服装穿着整洁干净搭配得当裤子烫出裤边扣子完好并扣整齐禁口袋放过多物品衬衫衬衫领口干净与领带颜色搭配得当鞋子与服装相配色的皮鞋并保持干净 1我们的学习目标 2接待处迎客技巧 3服务的仪态 4服饰仪容礼仪课程大纲课程大纲 1我们的学习目标 2接待礼仪 3服务的仪态 4服饰仪容礼仪接待的工作要点正确的姿态整理来宾的名单电话应对柜台经常保持清洁整齐注意服务仪容接待访客时要注意访客的心理及顺应访客的要求进行服务最影响你接待水准的是第一是你的接待态度第二是你的服装打扮及礼貌第三是你的说话技巧 1必要的心理准备 2确保贵宾从入口进来后能清楚知道接待处的位置 3整齐清洁 4借齐需要的小册子 5时钟及日历表 6花瓶 7安排好当天的工作程度表 8你的服饰要整齐第一步具体而完善的准备 1以愉快的心情向来访者打招呼 1必须站起来向到访者的人说声欢迎2中午十一点前可以说声早安 3午后可以说一声你好第二步主动招呼来访者不能忽视的要点是引领开始时向访客说一声对不起令你久候了场所的不同引领访客时的要点也不同 1走廊上走在访客侧前方两至三步当访客走在走廊的正中央时你要走在走廊上的一旁偶尔向后望确认访客跟上当转弯拐角时要招呼一声说往这边走 2楼梯上先说一声在X楼然后开始引领访客到楼上上楼时应该让访客先走因为一般以为高的位置代表尊贵在上下楼梯时不应并排行走而应当右侧上行左侧下行 3电梯内首先你要按动电梯的按钮同时告诉访客目的地是在第几层如果访客不只一个人或者有很多公司内部的职员也要进入电梯并站在一角按着开启的掣引领访客进入然后再让公司内部职员进入即是说访客先进入以示尊重离开电梯则刚好相反按着开启的掣让宾客先出如果你的上司也在时让你的上司先出然后你才步出第三步引领访客第四步入座备茶会客室的准备工作窗户是否通风地上是否有烟灰纸屑会客桌是否已抹干净沙发是否整齐墙上挂钟的时间是否正确这些重要的细节是否被你乎视掉了呢清洁开门后接待人员站在门的侧面说请进请客人进去进门后随手关门请客人进入接待室后便请他坐上座并说声请稍等一会安排入座当客人在接待室入座后立即准备弄茶第五步当访客准备离开时 1通常情况下当客人正要离去时向他们说一声谢谢您的来临 2需特别的送客则带领客人到电梯前替客人按钮当客人进入电梯后在门未关闭前向客人告别 3利用车辆接送客人 A 如果客人需要你帮助叫出租车你应先将客人带至门前等候你截停车后替客人打开车门然后一手固定车门一手示意他们进入说请客人入座后指把车门关上这时最好不要立即离去应站在原地与客人挥手告别直到汽车远去 B如果需要你亲自送客时同样乘车也有座位的次序司机后面的座位为上座司机旁边为次上座位三人同时乘坐时后面两个为上座位司机旁边为次上座位是助手座位为安全起见法律规定坐在司机旁边座位上的人必须系上安全带1事前的准备前往会客室接见客人时别忘记接待礼仪之一介绍礼仪带干净的新名片把名片放在上衣的袋内或裤袋中都不好应把名片存放在名片夹内平时准备多些名片不要在客人面前出现名片已用光的情况2交换名片时的礼仪用双手拿着名片的两角名片的正面向上面向对方并说我是XX请多指教一般来说来访者或地位较低的要先拿出名片 3收下对方名片时礼仪用双手接取对方递交的名片接受时点头示意并拿着名片的空白部分把名片接过来后念名片在会唔中如有很多名片同时交换时可在桌上将客人的名片逐一与他们的座位对应排好便于认识客人 4事后的整理当会客完毕送走客人后返回自己座位将刚才的名片拿出来整理后才保存下来接待礼仪之三名片交换礼仪接待礼仪之五电话礼仪等对方放下电话后再轻轻放回电话机上 6放回听筒语气诚恳态度5结束语对时间地点数字等进行准确和蔼谢谢麻烦您了那就拜托您了等的传达说完后可总结所说内容的要点打电话是想向您咨询一下关于??事必须要确认电话的对方如与要找的人接通电话后应重新问候请4电话内容问?先生在吗 3确认对象一定要报出自己的姓名讲话时要有礼貌您好我是? ?公司? ?部的? ? 2问候告知自己姓名确认对方的姓名明确通话的目的准备好要讲的内容说话的顺序 1准备注意事项基本用语顺序 6放回电话听简请放心我一定转达谢谢再见等 5结束语确认时间地点对象和事由如是传言必须记录下电话时间和留言人这件事情我已经明白了还有什么需要帮助您的 4确认来电事宜必要时应进行记录是这样的是的好的 3听取来电用意必须对对方进行确认请问您是哪一位您好 2确认对方接电话时不使用喂回答告知对方自己的姓名您好中汽南方??部??? 1拿起听筒告知自己的姓名注意事项基本用语顺序 1电话铃响在3声之内接起 2告知对方自己的姓名 3电话机旁准备好纸笔进行记录 4确认记录下的时间地点对象和事件等重要事项 5使用礼貌语言 6打错电话要有礼貌地回答让对方重新确认电话号码以小组为单位讨论并演练电话接听流程时间3分钟角色A× ×部新员工角色B人力资源部事由询问新员工参加培训的时间和地点课程大纲 1我们的学习目标 2接待处迎客技巧 3服务的仪态 4服饰仪容礼仪鞠躬一般分为三项点头礼即十五度鞠躬普通的鞠躬中礼即三十度鞠躬恭敬的鞠躬及敬礼即四十五度鞠躬顺应不同的时间及场合来做在街上或公司遇见上司或公司的前辈时只需点头礼便可以到对方的公司访谈的时候或接待初次访客时要行鞠躬礼正确的做法 1必须伸直腰脚跟靠拢双脚尖处微微分开目视对方 2然后将伸直的腰背由腰开始的上身向前弯曲当低下头时头部垂低背部微呈圆弯形状 3弯腰速度适中之后将垂下的头再次抬起时动作可慢慢做这样会令人感觉很舒服礼貌地鞠躬可改变对方对你的印象错误示范正确的站姿站姿站姿的基本要求是挺直舒展站得直头部抬起面部朝向正前方双眼平视下颌微微内立得正线条优美精神焕发收劲部挺直双肩放松保持水平腰部直立女性双臂自然下垂处于身体女性两腿呈V字形立正时双膝与双脚的跟部两侧右手搭在左手上贴在腹部靠紧两脚尖之间相距一个拳头的宽度两腿呈T字形立正时右脚后跟靠在左足弓处男性双手相握可叠放于腹前或者相握于身后男性双脚叉开与肩平行身体的重心放在两脚之间正确的坐姿坐姿坐姿的基本要求是端庄文雅得体大方 1入坐的要点在他人之后入坐从座位左侧就座毫无声息地就座以背部接近座椅得体的坐法先则身走近座椅背对其站立右腿后退一点以小腿确认一下座椅然后随势坐下必要时可以一手手扶座椅的把手坐好后占椅面34左右若着裙装应用手将裙子稍向前拢一下不宜将裙子下摆东撩西扇也不许当从整理服饰。

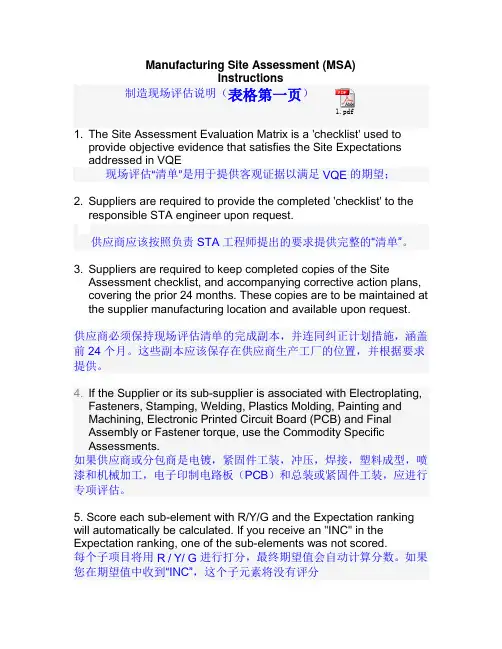

Manufacturing Site Assessment (MSA)Instructions制造现场评估说明(表格第一页)1.pdf1. The Site Assessment Evaluation Matrix is a 'checklist' used toprovide objective evidence that satisfies the Site Expectationsaddressed in VQE现场评估“清单”是用于提供客观证据以满足VQE的期望;2. Suppliers are required to provide the completed 'checklist' to theresponsible STA engineer upon request.供应商应该按照负责STA工程师提出的要求提供完整的“清单”。

3. Suppliers are required to keep completed copies of the SiteAssessment checklist, and accompanying corrective action plans, covering the prior 24 months. These copies are to be maintained at the supplier manufacturing location and available upon request.供应商必须保持现场评估清单的完成副本,并连同纠正计划措施,涵盖前24个月。

这些副本应该保存在供应商生产工厂的位置,并根据要求提供。

4. If the Supplier or its sub-supplier is associated with Electroplating,Fasteners, Stamping, Welding, Plastics Molding, Painting andMachining, Electronic Printed Circuit Board (PCB) and FinalAssembly or Fastener torque, use the Commodity SpecificAssessments.如果供应商或分包商是电镀,紧固件工装,冲压,焊接,塑料成型,喷漆和机械加工,电子印制电路板(PCB)和总装或紧固件工装,应进行专项评估。