(整理)微型山地履带拖拉机传动简图

- 格式:doc

- 大小:27.50 KB

- 文档页数:3

履带拖拉机变速器改进设计Ⅳ摘要随着农业的不断进步发展,农业生产机械化、规模化及生产资料和农田建设材料等各种物资运输量越来越大,农民越来越需要拖拉机的帮助,因此,农用拖拉机的发展前景很广阔,会有较大的发展。

满足拖拉机的动力性和经济性指标,这与变速器的档数、传动比的范围和各档传动有关。

拖拉机工作的道路条件越复杂、比功率越小,变速器的传动比范围越大。

变速器与主减速器及发动机参数作优化配置,可得到良好的动力性和经济性。

变速器的结构对动力性,经济性,操纵的可靠性与轻便性,工作噪声等都有直接影响。

变速器主要用来改变发动机传到驱动轮上的转矩和转速,目的是在起步、爬坡、转弯、加速等各种行驶工况下,获得不同的牵引力和速度,同时使发动机在最有利的工况下范围工作,设有空档和倒档。

本次设计按照传统设计方法,本着半经验半理论的设计原则通过类比法确定方案,参照已有车型变速器结构,最后以机械零件的强度和刚度理论对确定的形状和尺寸进行必要的计算和校核,以满足约束条件,进而缩短设计周期,降低设计成本。

关键词:变速器,传动比,设计,计算,校核TRACKED TRACTOR TRANSMISSION IMPROVEDDESIGN ⅣABSTRACTWith the continuous progress of agricultural development, agricultural production mechanization, the scale of the means of production and agricultural land and building materials and other goods traffic increasing, more and more farmers need the help of tractors, therefore, farm tractors development prospects are broad, there will be greater development.Tractors to meet the power and economic indicators, and transmission of the file, the transmission ratio of the scope and the transmission of the file. Tractor work of the road conditions more complex than the smaller power, the transmission of the transmission ratio greater. Reducer and the main transmission and engine parameters to optimize the allocation and availability of power and good economy.In order to make it come true that the transmission is adapted to the engine and its structure is sound, I pay close attention to the development of the clutch transmission shaft and collectivity arranging designers in my design, and have a repeating discussion with them .For shifting gear steadily , fourth and third gear have synchrotron ,and in consideration of the simplicity and reliability .According to the traditional mean of design ,part experience and theory and analogism ,the blue print come into being .by virtue of tradition transmission I verify the size of element which have been chosen, according to mechanical theory, in consideration of the qualification bringing down the cost and cycle time.KEY WORD:Transmission, transmission ratio, design, calculations, checking符号说明A中心距D 直径E弹性模量i传动比gf 挠度δ转角M 弯矩m汽车总质量kgg重力加速度N/kgψ道路最大阻力系数maxr驱动轮的滚动半径mm rT发动机最大扭矩N·m emaxi主减速比η汽车传动系的传动效率i一档传动比gIG汽车满载载荷N 2ϕ路面附着系数K中心距系数Am直齿轮模数tα齿轮压力角°β斜齿轮螺旋角°b齿轮宽度mmZ齿轮齿数xσ齿轮弯曲应力MPa Wσ齿轮接触应力MPa jF齿轮所受圆周力Nta F 轴向力 Nr F 径向力 Ng T 计算载荷 N ·mσK 应力集中系数f K 摩擦力影响系数E 齿轮材料的弹性模量 MPaK ε 重合度影响系数z r 主动齿轮节圆半径mm b r 从动齿轮节圆半径mm z ρ 主动齿轮节圆处的曲率半径mm b ρ 从动齿轮节圆处的曲率半径mm T τ 扭转切应力MPa T W 轴的抗扭截面系数3mm G 轴的材料的剪切弹性模量MPa P I 轴截面的极惯性矩4mm c f 垂直面内的挠度mm s f 水平面内的挠度mm目录第一章绪论 (1)第二章变速器传动方案的研究与改进 (9)§2.1 变速器的功用与要求9§2.2 变速器的种类10§2.3 课题变速箱存在的问题与解决方案11§2.4 变速器改进方案的确定12第三章变速器传动方案与参数的确定 (14)§3.1 变速器档位与传动比的初定 14§3.1.1 最高档传动比的选择14§3.1.2 最低档传动比的选择14§3.1.3 各档位传动比的分配15§3.2 变速箱外形尺寸的初定15§3.2.1 变速箱齿轮中心距的确定15§3.2.2变速箱的轴参数确定16§3.3 变速器各项参数的最终确定 16§3.3.1齿轮齿数及其参数的确定16§3.3.2 齿轮模数确定17§3.3.3 齿轮其他参数的计算18§3.3.4 齿形、压力角α、螺旋角β21§3.3.5 齿宽的确定21§3.3.6 中心距的最后确定22第四章齿轮与轴的校核 (23)§4.1 齿轮的校核23§4.1.1齿轮的损坏形式23§4.1.2 齿轮的强度校核与计算 23§4.2 轴的校核 25§4.2.1轴刚度的校核25§4.2.2 轴的强度校核26第五章轴承的校核 (28)第六章啮合套的设计 (29)§6.1 换挡机构形式29§6.2 防脱挡措施29第七章变速器操纵机构设计 (32)第八章结论 (33)参考文献 (34)致谢 (36)第一章绪论随着社会经济展和农业机械化水平的提高,拖拉机保有量迅猛增长,同时对拖拉机性能和质量提出了更高的要求。

352履带拖拉机(中央传动及转向离合器设计)摘要中央传动用来增加传动系的传动比,以达到减速增扭的目的,通常还用来改变转矩的传递方向,使转矩从纵置的变速箱输出轴传递给横置的中央传动两侧输出轴。

中央传动应有适当的传动比,以保证拖拉机具有良好的牵引性与经济性;结构应紧凑,以减小后桥尺寸和和质量,保证后桥有足够的离地间隙;齿轮装置应有足够的承载能力和支承刚度,如系锥齿轮副,则还应便于调整。

中央传动的齿轮形式目前主要有圆柱齿轮和圆锥齿轮。

圆柱齿轮结构简单,加工较容易,在传动时不致产生轴向力。

但仅适用于采用横置变速箱的拖拉机。

而圆锥齿轮应用则较为广泛。

履带拖拉机在行使过程中,需要经常改变行驶方向,这就需要有一套能够按照司机意志来改变或恢复拖拉机行驶方向的专设机构,它将司机踩下转向离合器踏板的动作转变为车轮的偏转动作,这就是所谓的转向系统。

转向性能是保证车辆安全,减轻驾驶员劳动强度和提高作业效率的重要因素。

转向离合器转向系统由于构造简单,制造方便,维修容易,在拖拉机上广泛采用。

它具有转向半径小,直线行驶性好等优点。

但由于传递的转矩较大,只得采用多片式离合器,而多片式离合器分离彻底性比较差。

这对转向离合器来说,除了使摩擦面的磨损略微增大外,对整机性能没有太大影响,不像主离合器分离不彻底会造成换档困难。

关键词:中央传动,转向离合器,锥齿轮,转向系统352 TRACKED TRACTOR(CENTRAL TRANSMISSION AND STEERING CLUTCH DESIGN)ABSTRACTCentral spread to use to increase to spread to move to fasten of spread and move ratio, the purpose that to attain to decelerate to increase to twist, usually return to use to change the torque to deliver the direction, make torque place become soon the box outputs the stalk to deliver to horizontal place central to spread to move the two sides exportation stalk.Central spread to move and should have appropriate of spread and move ratio, with the assurance that the tractor has to lead the sex and economy goodly; structure should tightly packed, after to let up the bridge size and and quantity, the assurance is behind the bridge has to leave a ground of cleft enough;The wheel gear device should have the enough loading ability and pay to accept just degree, return if department the bevel gears is vice, should easy to adjustment.Central spread the dynamic wheel gear form to mainly have the cylinder wheel gear and the bevel gearses currently.The cylinder wheel gear structure is simple, processing to compare easily, produce the stalk toward dint unlikely while spread move.But be applicable to the adoption only horizontal place to become soon the tractor of the box.But the cone wheel gear the application then compare extensively.The track tractor professional makes in the process, needing to usually change to drive the direction, this need to be have a set of can change or recover the tractor to drive the particularly establish of the direction organization according to the driver will, it deflect the action change that the driver tramples bottom to change direction the clutch pedal for the felloe action, this is to change direction the system so calledly.Change direction the function is to guarantee the vehicle safety, easing the pilot the labor strength and raise important factor of the homework efficiency.steering mechanism changes direction the system because of structure in brief, make convenience, maintain easily, in the dalliance on board extensivedoption.It has the radius of change direction small, drive sex good etc. advantage straightly.But because the torque that deliver compare greatly, have to several type clutches of adoption, but several types clutch separate thoroughly sex is worse.This says towards steering mechanismcome, in addition to making rub to face of wearing away the inching aggrandizement, having no to the whole machine function to affect too greatly, be unlike the main clutch separation ill success and will result in shift gear the difficulty.Key words: Central transmission , steering clutch ,bevel gears, steering system目录第一章前言 (1)第二章中央传动及转向离合器概论 (2)§2.1 履带拖拉机转向机构概述 (2)§2.2 中央传动的概述 (3)第三章中央传动及转向离合器方案分析 (5)§3.1 转向离合器方案分析 (5)§3.2 中央传动方案分析 (10)第四章转向系统设计计算 (14)§4.1 螺旋锥齿轮的计算 (14)§4.2 转向离合器设计计算 (17)§4.3 带式制动器的设计计算 (19)第五章主要零件的强度校核与计算 (21)§5.1 螺旋锥齿轮的承载能力计算 (21)§5.2 轴强度计算 (22)§5.3 轴承寿命计算 (24)第六章结论 (28)参考文献 (29)致谢 (30)第一章前言拖拉机的主要任务是用来拖带农机具进行各种田间作业(如翻地、播种、中耕等);也可作为其他农业机械(如脱谷机、扬场机等)的动力;另外拖带拖车可进行运输作业。

微型山地履带拖拉机传动简图传动路线:Ⅰ档:Z34/Z14→Z23/Z35→Z51/Z22Ⅱ档:Z32/Z13→Z23/Z35→Z51/Z22Ⅲ档:Z31/Z12→Z23/Z35→Z51/Z22倒档:Z41/Z14→Z33/Z41→Z23/Z35→Z51/Z22传动比:Ⅰ档:Z34/Z14→Z23/Z35→Z51/Z22=46/20×50/20×66/20=18.975Ⅱ档:Z32/Z13→Z23/Z35→Z51/Z22=40/26×50/20×66/20=12.69Ⅲ档:Z31/Z12→Z23/Z35→Z51/Z22=32/34×50/20×66/20=7.765倒档:Z41/Z14→Z33/Z41→Z23/Z35→Z51/Z22=22/20×41/22×50/20×66/20=16.91已知条件:发动机:常柴牌L12柴油机额定功率:8.8KW 额定转速:2400 r/min一级带传动:B型V带(GB/T 1371-98)大小带轮的计算直径:D=212mm d=85mm传动比:i带= 2.49一级带传动效率:η1=0.96一对滚动轴承的效率:η2 =0.99柱齿轮8级精度一般齿轮传动效率:η3 =0.97联轴器效率:η4=0.99 (以上数据从【1】p5 表1-7查的)柴油机输出转矩:T=9.55×p/n=9.55 =3.5拖拉机的速度:Ⅰ档:24.67 m/minⅡ档:35.00 m/minⅢ档:55.00 m/min倒档:27.83 m/min[1]吴宗泽,罗圣国主编.机械设计课程设计手册.高等教育出版社.2008[2]邱宣怀主编.机械设计(第四版). 高等教育出版社.2007[3]吴宗泽主编.机械零件设计手册.机械工业出版社.2007[4]杨福增,杜白石主编.2007。

履带拖拉机无级变速器设计(换档离合器设计)摘要本文介绍了设计的内容和设计指导思想,本次设计的内容是设计履带拖拉机无级变速器—换档离合器设计,重点介绍和分析研究了离合器,并在设计中根据不同的工况进行的设计,特别介绍了一种新型的无级变速装置—液压机械无级传动,也是一种双功率流无级传动系统,具有无级调速、高效率的特性,是大功率车辆较理想的传动方式。

液压机械无级变速器是一种液压功率流与机械功率流并联的新型传动装置,通过机械传动实现传动高效率,通过液压传动的可控调速与机械传动相结合实现无级变速。

该装置的采用能大幅度地提高车辆的动力性、经济性和操作自动化水平。

湿式多片离合器是动力换档拖拉机传动装置中主要部件之一。

湿式多片换档离合器是动力换档拖拉机传动装置中主要部件之一。

对该离合器结构设计特点做了系统地论述,对摩擦片、回位弹簧、快速排油阀等关键部件进行了设计,对冷却润滑的实现及密封装置的选择,并对离合器的扭矩容量、热容量及其寿命进行了分析计算。

关键词:拖拉机,液压机械传动,负载换挡,湿式多片离合器DESIGN OF CONTINUOUSLY VARIABLETRANSMISSION OF TRACKED TRACTOR (DESIGN OF WET SHIFT CLUTCH)ABSRACTThe design content and the design guiding ideology are introduced in this paper. T his design content is the design wet shift clutch of tracked tractor stepless transmission gearbox. The hydro-mechanical continuously variable transmission (HMCVT) is a new type transmission device, which consists of a mechanical transmission (MT) combined in parallel with a hydrostatic transmission (HST) featuring a pair of hydraulic units. The HMCVT has a continuously variab le shifting ratio by the combination of HST and MT and achieves high efficiency by MT. This device can greatly improve power and fuel economy characteristics and operation automation level of vehicle.The wet multi-disk shifting clutch is one of main parts of power-shift tractor’gearing. This paper discusses systematically the structural design features of this clutch, including the design of key parts such as friction plate, return spring and quick draining oil valve, the implementation of cooling and lub rication and the selection of sealing devices. The analysis and calculation of torque capacity, heat capacity and service life of this clutch are also carried out.Key words:tractor, hydo-mechanical stepless transmission, load shift, wet multiple disc shift clutch目录第一章前言 (1)第二章液压无级变速器传动方案的设计 (3)§2.1 设计任务及已知条件 (3)§2.2 液压无级变速传动方案的选择 (3)§2.3 传动参数的确定 (4)§2.3.1 中心距和各对齿轮传动比的确定 (4)§2.3.2 离合器的状态 (5)§2.3.3 液压泵及液压马达的选择 (6)§2.4 无级调速特性 (7)第三章液压无级变速器换档机构—离合器的设计 (9)§3.1离合器概论 (9)§3.1.1 离合器的功用与分类 (9)§3.1.2 影响离合器选择的因素 (10)§3.2 离合器的设计要求和选型 (11)§3.2.1 离合器的设计要求 (11)§3.2.2 离合器的选型 (11)§3.2.3 湿式摩擦式离合器润滑油的选择 (12)§3.2.4 湿式摩擦式离合器的润滑方式 (12)§3.3 湿式多片离合器主要参数的选择 (13)§3.4 湿式多片换档离合器的设计计算 (15)§3.4.1 摩擦片的设计计算 (15)§3.4.2 回位弹簧的设计计算 ... . . .. . .. (21)§3.4.3 快速排油阀的设计计算 (30)第四章结论 (36)参考文献 (37)致谢 (39)第一章前言液压式无级变速器是由液压传动和机械传动有机的结合而成,兼有液压传动与无级调速的特点。

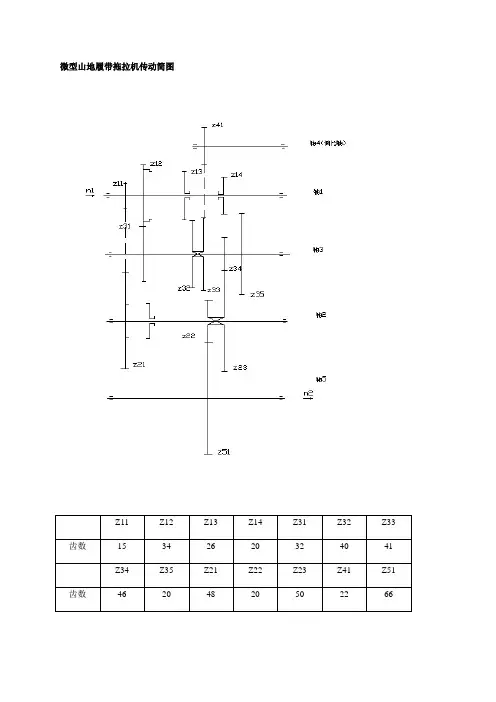

微型山地履带拖拉机传动简图

传动路线:

Ⅰ档:Z34/Z14→Z23/Z35→Z51/Z22

Ⅱ档:Z32/Z13→Z23/Z35→Z51/Z22

Ⅲ档:Z31/Z12→Z23/Z35→Z51/Z22

倒档:Z41/Z14→Z33/Z41→Z23/Z35→Z51/Z22

传动比:

Ⅰ档:

Z34/Z14→Z23/Z35→Z51/Z22=46/20×50/20×66/20=18.975

Ⅱ档:

Z32/Z13→Z23/Z35→Z51/Z22=40/26×50/20×66/20=12.69

Ⅲ档:

Z31/Z12→Z23/Z35→Z51/Z22=32/34×50/20×66/20=7.765

倒档:

Z41/Z14→Z33/Z41→Z23/Z35→Z51/Z22=22/20×41/22×50/20×66/20=16.91

已知条件:

发动机:常柴牌L12柴油机

额定功率:8.8KW 额定转速:2400 r/min

一级带传动:B型V带(GB/T 1371-98)

大小带轮的计算直径:D=212mm d=85mm

传动比:i带= 2.49

一级带传动效率:η1=0.96

一对滚动轴承的效率:η2 =0.99

柱齿轮8级精度一般齿轮传动效率:η3 =0.97

联轴器效率:η4=0.99 (以上数据从【1】p5 表1-7查的)

柴油机输出转矩:T=9.55×p/n=9.55 =3.5

拖拉机的速度:

Ⅰ档:24.67 m/min

Ⅱ档:35.00 m/min

Ⅲ档:55.00 m/min

倒档:27.83 m/min

[1]吴宗泽,罗圣国主编.机械设计课程设计手册.高等教育出版社.2008

[2]邱宣怀主编.机械设计(第四版). 高等教育出版社.2007

[3]吴宗泽主编.机械零件设计手册.机械工业出版社.2007

[4]杨福增,杜白石主编.2007。