VESTAS风机介绍

- 格式:ppt

- 大小:1.50 MB

- 文档页数:18

国外主要风力发电机组制造商基本情况调查一、国外企业1.Vestas(丹麦维斯塔斯)丹麦vestas公司的风机制造始于1979年,于1998年在哥本哈根股票交易市场上市,2008年以其19.8%的市场占有率名列全球第一大风力发电机制造商,预计2009年全年营业额约72亿欧元。

公司现拥有9500余名员工,设在丹麦的总部有员工2300多人,其中技术开发人员160人,维斯塔斯公司在荷兰设有分公司,在西班牙有2个厂,意大利1个厂,印度1个厂,英国1个厂,中国天津有3个厂,内蒙古1个厂,员工达到1000人,在北京设有办事处。

在美国科罗拉多州建造了叶片、机舱和塔架工厂。

2009年关闭了在英国的工厂。

1987年,Vestas开始专注于风能利用的研究,2003年12月与丹麦NEG Micon 合并成立了世界上最大的风机制造公司——新威斯塔斯公司,而丹麦NEG Micon公司是1997年由Nordtank公司与Micon公司合并组成,是当时世界上规模最大的风力发电机制造厂,还是丹麦唯一有自己的桨叶制造及其它非标部件生产制造能力的企业,其在变桨距叶片设计和制造方面具有技术优势。

该公司产品的单机容量分别为850kW、1.5MW、2MW和3MW。

2002年5月研制V90 /3MW 风力发电机样机, 2004年批量生产。

2009年36台V90-3MW风力发电机组安装在壳牌风能公司位于距离荷兰EAZ岸边10公里处的海上风电场。

该机为3叶片, 风轮直径90 m, 重量40吨,切入风速4m / s, 额定风速15 m/s, 两级行星增速齿轮箱,增速比为:4极双馈异步发电机,额定电压1000V。

V90 /3MW机组为紧凑型结构,取消了低速轴。

2009年7月与比利时-荷兰投资者集团的Belwind N.V.公司签约,为坐落于比利时比利时泽布鲁日海岸46公里外的Bligh Bank海上风电场提供55台V90-3.0兆瓦风机,这些风机将于2010年交付和安装。

丹麦vestas公司是世界风力发电工业中技术发展的领导者,其核心业制造风力发电机,并且自此在动力工业商起到了积极作用。

1987年, Vestas开始专门集中力量于风能的利用研究,此后便从一个行业先锋发展至在全球设有60个高科技的市场领军团队、员工逾9500人(至2004年6月)的大型企业。

生产车间遍布丹麦、德国、印度、意大利、苏格兰、英格兰、西班牙、瑞典、挪威及澳大利亚。

MW级风力机2004年全球销售量为8154 MW,Vestas(incl. associated company)的销售量为2784MW,2004年占据市场份额34.1%;至2004年底,全球安装量为47912 MW,Vestas (incl. associated company)的安装量为17538MW,占据市场份额36.7%[2]。

在欧洲专利局网站上以 VESTAS WIND SYSTEMS AS为申请人的公开专利有98篇(至2005年7月)。

1979年,维斯塔斯安装了它的第一台风机,从此,维斯塔斯便开始在快速发展的风电行业中发挥出积极的作用。

1987年,维斯塔斯还只是一个拥有60名雇员的行业先锋,如今,维斯塔斯已经成为了市场领先的拥有13,500名雇员的全球集团,是高科技风电解决方案的领先生产商。

下面是维斯塔斯更多的有趣而丰富多彩的发展历史。

1898年:一切开始的一年。

这一年,铁匠H.S.Hanse 走下火车,踏上丹麦 lem 车站的站台,并于不久后开办他的第一家工坊。

由于 Hansen 源源不断的创意和无所畏惧的开创精神,他的“Hansen 铁匠铺”从建立之初就非常成功。

他的精神似乎也鼓舞激励了他的助手们,因为他们中很多人后来都建立了自己的公司。

Lem 镇渐渐发展成为一个铁匠工艺聚集的中心地带。

1928: Dansk Staalvindue Industri 的成功“铁匠Hansen ”和他的儿子 Peder Hansen建立了Dansk Staalvindue Industri-一家为工业建筑生产钢窗框的公司。

VestasWindSystemA/S集团是一个跨国公司,创建于1945年。

Vestas于1979年开始制造风力发电机,并且自此在动力工业商起到了积极作用。

1987年,Vestas开始专门集中力量于风能的利用研究,此后便从一个行业先锋发展至在全球设有60个高科技的市场领军团队、员工逾9500人(至2004年6月)的大型企业。

生产车间遍布丹麦、德国、印度、意大利、苏格兰、英格兰、西班牙、中国、瑞典、挪威及澳大利亚。

Vestas公司是世界风力发电工业中技术发展的领导者,位于世界上最大的10大风机设备供应商之首,占有2005年世界风机新增容量的27.9%的市场份额。

其核心业务包括开发、制造、销售和维护风力发电系统。

产品的单机容量范围从850kW到3MW,即将推出4.5MW产品。

VestasTechnology公司在丹麦、德国、意大利、印度和苏格兰生产风电机组。

VestasWindSystemA/S公司是哥本哈根股票市场的上市公司。

在欧洲专利局网站上以VESTASWINDSYSTEMSAS为申请人的公开专利有98篇(至2005年7月)。

维斯塔斯公司在风电技术领域是居于世界领先的厂商。

作为一个国际化的供应商,维斯塔斯针对各种需求提供风电技术,包括对主要的交钥匙工程提供风电单机。

同时,维斯塔斯公司非常注重新产品的开发。

维斯塔斯公司八个国家设有合资企业,为世界上30多个国家提供产品和服务。

维斯塔斯公司的业务包括风机的开发、销售、生产以及支持服务。

维斯塔斯在丹麦、瑞典、荷兰、美国和德国设有机构,在印度、意大利和西班牙设有合资厂。

维斯塔斯始终跻身于行业前列,已经在全球安装了26,000多台风机发电,是世界上最大的风电系统供应商,也是最早开始制造风机的公司之一。

今天,以二十多年丰富经验和不断创新的公司精神为后盾,维斯塔斯风机以其先进、高效和实证的可靠性而闻名于世。

然而,开发和制造高质风机仅仅是维斯塔斯业务范围的一部分。

ATTACHMENT 1WIND TURBINE SAFETY CONSIDERATIONSVestas is one of the leading wind turbine manufacturers, with approximately 70% market share worldwide. Based on its prominence in the world market, the Vestas Safety Manual (32 pages) is a credible source of safety information. Nordex is another well know manufacturer of wind turbines. Its Safety Manual (130 pages) likewise is considered a credible source of information on the subject of safety.On page 3 of the Vestas Safety Regulations for Operators and Technicians Manual, point # 2. – Stay and Traffic by the Turbine, Vestas personnel are instructed to stay away from a turbine by 400 m (1312 ft) unless it is necessary. Taken in context, this distance would apply to normal operating conditions. (See Exhibit 1)Under abnormal operating conditions, Vestas expands this distance in consideration of the safety of its employees. This is evidenced by the Vestas Confidential Health and Safety Instruction manual for a Falmouth MA wind farm. Page 10 of this manual addresses the situation of a free spinning “runaway turbine”. In that manual, instructions are for no one to be allowed within a 1640 feet (500 m) radius. (See Exhibit 2)The Nordex Safety Manual also addresses safety in the context of a fire. On page 52, under section 9.3 Fire, it states:DANGER FALLING TURBINE PARTS In case of a fire in the nacelle or on the rotor, parts may fall off the wind turbine. In case of a fire, nobody is permitted within a radius of 500 m from the turbine. (See Exhibit 3)Given that these standards apply to employees who are familiar with the safety implications of wind turbines and are equipped to deal with abnormal conditions, it is indefensible, from a safety perspective alone, to specify in a wind ordinance designed to protect the public health, safety and welfare a setback that is less than 1640 feet.Item no.: 960314.R5 Date 2006-09-11Issued by: Technology Class: IIType: MAN Page 3 of 32Safety Regulations for Operators and TechniciansV90 – 3.0MW/V100 – 2.75MWVestas Wind Systems A/S · Alsvej 21 · 8900 Randers · Denmark · 1. IntroductionA turbine connected to the grid implies certain elements of danger if it is handled without exercising proper caution.For safety reasons, at least two persons have to be present during a work procedure. The work must be properly carried out in accordance with this manual and other related manuals. This implies, among other things that personnel must be instructed in and familiar with relevant partsof this manual.Furthermore, personnel must be familiar with the contents of the “Substances and Materials” regulations.Caution must especially be exerted in situations where measurement and work is done in junction boxes that can be connected to power.Consequently the following safety regulations must be observed.2. Stay and Traffic by the TurbineDo not stay within a radius of 400m (1300ft) from the turbine unless it is necessary. If you have to inspect an operating turbine from the ground, do not stay under the rotor plane but observe the rotor from the front.Make sure that children do not stay by or play nearby the turbine. If necessary, fence the foundation. The access door to the turbine must be locked in order to prevent unauthorized persons from stopping or damaging the turbine due to mal-operation of the controller.3. Address and Phone Number of the TurbineNote the address and the access road of the turbine in case an emergency situation should arise. Theaddress of the turbine can often be found in the service reports in the ring binders next to the groundcontroller. Find the phone number of the local life-saving service.Vestas advises to “evacuate by running upwind …access to the surrounding area in a radius of at least 500 meters [1640 ft.] must berestricted.”Revision 04 / 2011-07-18 Safety ManualThe WT itself is adequately protected against damage by comprehensive lightning protection measures. However, persons inside or in the proximity of a WT are still at risk. ■ Initially, proceed as in a grid failure ■ Leave and lock the WT ■ Wait at a safe distance from the WT until the thunderstorm has passed Do not re-enter the WT until the thunderstorm has passed.9.3FireDANGERFALLING TURBINE PARTSIn case of a fire in the nacelle or on the rotor, parts may fall off the wind turbine. In case of a fire, nobody is permitted within a radius of 500 m from the turbine.NOTE The WT is equipped with ABC powder fire extinguishers for fighting incipient fires. At least one fire extinguisher is located in the tower base near the door and another in the nacelle near the Topbox. This makes it possible to extinguish burning solids and liquids, as well as fires in electrical systems of up to 1,000 V. These fire extinguishers are not suitable for extinguishing a fire on the high-voltage elements, see Chapter 9.3.2 "Fire in medium- voltage switchgear or transformer".9.3.1 Fire in the WT■ R emove any persons from the danger area ■ If possible, disconnect the burning object from the gri d ■ Fight the fire with available means if there is any chance of success ■ If the fire cannot be extinguished or if there is no chance of success, call the fire department ■ Inform the responsible Remote MonitoringPage 52 of 130 NALL01_011010_EN Fire。

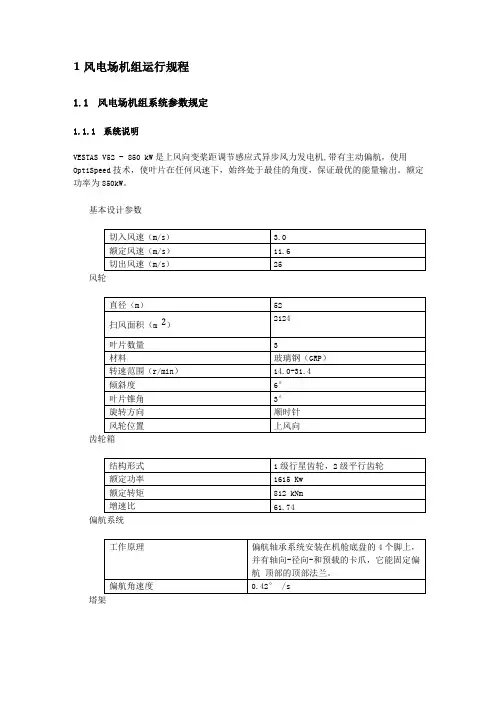

1风电场机组运行规程1.1风电场机组系统参数规定1.1.1系统说明VESTAS V52 - 850 kW是上风向变桨距调节感应式异步风力发电机,带有主动偏航,使用OptiSpeed技术,使叶片在任何风速下,始终处于最佳的角度,保证最优的能量输出。

额定功率为850kW。

基本设计参数风轮齿轮箱偏航系统塔架1.2风电场机组正常运行的监视1.2.1电力参数运行监视1.2.1.1电压监视:a.定子电压。

b.电网电压。

c.总线电压。

1.2.1.2电流监视(波动范围必须在额定值的+10%至-10%以内)。

1.2.1.3频率监视(变化范围+2至-3Hz):a.定子频率。

b.电网频率。

c.电网和定子相差。

1.2.1.4功率因数和功率监视。

1.2.1.5功率:a.发电机有功功率。

b.发电机无功功率。

c.电网有功功率。

d.电网无功功率。

1.2.1.6发电机组各部温度监视。

1.2.1.7各风机用电动机实际运行状态和控制画面一致性的监视。

1.2.1.8控制电源处于接通位置;控制计算机显示处于正常状态;各项保护装置均在投位置,且保护定值均与批准设定的值相符。

1.2.2风电场机组运行监视1.2.2.1风电场机组运行监视一般规定:a.值班人员每天应按时收听和记录当地天气预报,做好风电场机组安全运行的事故预想和对策。

b.值班人员每天应定时通过主控室计算机的屏幕监视风电机组各项参数变化情况。

c.值班人员应根据计算机显示的风电机组运行参数,检查分析各项参数变化情况,发现异常情况应通过计算机屏幕对该机组进行连续监视,并根据变化情况作出必要处理。

同时在运行日志上写明原因,进行故障记录与统计。

1.2.2.2风电场机组的定期巡视:a.值班人员应定期对风电机组、风电场测风装置、巡回检查,发现缺陷及时处理,并登记在缺陷记录本上。

b.检查风电机组在运行中有无异常声响、叶片运行状态、调向系统动作是否正常,电缆有无绞缠情况。

c.检查风电机组各部分是否漏油;液压装置的油压、油位和油温在规定范围;润滑油油压、油位和油温在规定范围;齿轮箱油位和油温在正常范围。

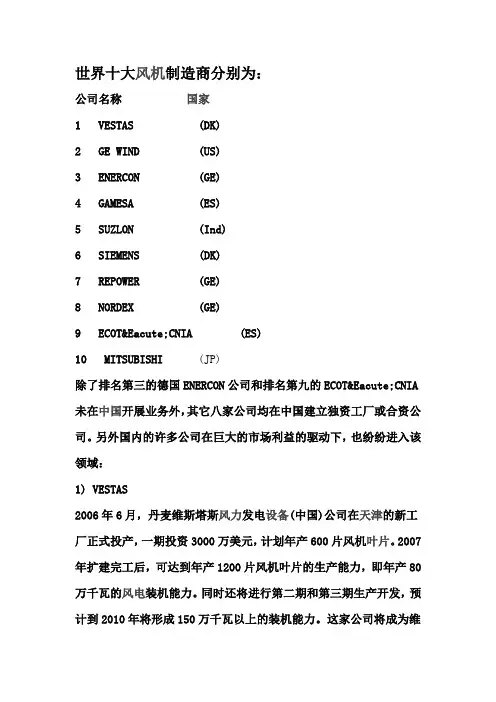

世界十大风机制造商分别为:公司名称国家1 VESTAS (DK)2 GE WIND (US)3 ENERCON (GE)4 GAMESA (ES)5 SUZLON (Ind)6 SIEMENS (DK)7 REPOWER (GE)8 NORDEX (GE)9 ECOTÉCNIA (ES)10 MITSUBISHI (JP)除了排名第三的德国ENERCON公司和排名第九的ECOTÉCNIA 未在中国开展业务外,其它八家公司均在中国建立独资工厂或合资公司。

另外国内的许多公司在巨大的市场利益的驱动下,也纷纷进入该领域:1) VESTAS2006年6月,丹麦维斯塔斯风力发电设备(中国)公司在天津的新工厂正式投产,一期投资3000万美元,计划年产600片风机叶片。

2007年扩建完工后,可达到年产1200片风机叶片的生产能力,即年产80万千瓦的风电装机能力。

同时还将进行第二期和第三期生产开发,预计到2010年将形成150万千瓦以上的装机能力。

这家公司将成为维斯塔斯集团在亚太地区的生产基地之一,为我国以及国际市场提供产品和服务。

2) GE WIND美国GE能源集团在中国的首个风机组装厂在沈阳正式宣布成立。

通用电气能源(沈阳)有限公司由GE公司全资所有,生产1.5兆瓦风机。

第一台风机已在2006年3月末装配完成,2006年7月将首次交付当地组装的机组。

预计到2010年将形成120万千瓦的风电装机能力。

3) GAMESA西班牙歌美飒公司将中国市场列为仅次于美国的第二大海外风机市场。

2006年9月,西班牙歌美飒公司在天津设立的风力发电机生产基地正式投产,2008年前总投资额将达6000万欧元。

歌美飒天津基地现在年组装能力为820台,装机容量70万千瓦,预计2010年生产能力将提升到120万千瓦,2020年实现4万兆瓦的目标。

4) SUZLON印度企业Suzlon风机公司位列世界风机厂商第五,其投资6000万美元在天津的工厂已于2006年3月开工建设,于2006年8月投产,主要生产1.5MW的风机,预计年生产容量将达80万千瓦。

Appendix A: Vestas 126, 3.45 MW Series Wind Turbine BrochureWind energy means the world to us. And we want it to mean the world to our customers, too, by maximising your profits and strengthening the certainty of your investment in wind power.That’s why, together with our partners, we always strive to deliver cost-effective wind technologies, high quality products and first class services throughout the entire value chain. And it’s why we put so much emphasis on the reliability, consistency and predict-ability of our technology.We have more than 35 years’ experience in wind energy. During that time, we’ve delivered more than 70 GW of installed capacity in 75 countries. That is more than 15 per cent of total wind tur-bine capacity installed globally – and over 15 GW more than our closest competitor. We currently monitor over 28,000 wind tur-bines across the globe. All tangible proof that Vestas is the right partner to help you realise the full potential of your wind site.What is the 3 MW Platform today?The 3 MW platform was introduced in 2010 with the launch of the V112-3.0 MW®. Over 8 GW of the 3 MW platform has been installed all over the world onshore and offshore making it the obvious choice for customers looking for highly flexible and trustworthy turbines.Since then the 3 MW platform was upgraded and new variants were introduced utilising untapped potential of the platform.All variants carry the same nacelle design and the hub design has been re-used to the largest extend possible. In addition, our engineers have increased the nominal power across the entire platform improving your energy production significantly.With this expansion, the 3 MW platform covers all IEC wind classes with a variety of rotor sizes and a higher rated output power of 3.45 MW.Y ou can choose from the following turbines on the 3 MW platform:·V105-3.45 MW™ – IEC IA·V112-3.45 MW™ – IEC IA·V117-3.45 MW™ – IEC IB/IEC IIA·V126-3.45 MW™ – IEC IIB·V126-3.45 MW™ – IEC IIA·V136-3.45 MW™ – IEC IIIAAll variants of the 3 MW platform are based on the proven technology of the V112-3.0 MW® with a full-scale converter, providing you with superior grid performance.Our 3 MW platform is designed for a broad range of wind and site conditions, enabling you to mix turbines across your site or port-folio of sites, delivering industry-leading reliability, serviceability and exceptional energy capture optimising your business case.All turbine variants are equipped with the same ergonomically designed and very spacious nacelle which makes it easier for maintenance crews to gain access, so they can reduce the time spent on service while maximizing the uptime without compro-mising safety. All turbines can be installed and maintained using standard installation and servicing tools and equipment further reducing the operation and maintenance costs by minimising your stock level of spare parts.Are you looking for the maximum return on your investment in wind energy?How does our technology generate more energy?More power for every wind siteV112-3.45 MW™, V117-3.45 MW™, V126-3.45 MW™ andV136-3.45 MW™ are available with several noise modes to meet sound level restrictions with an optimised production. The power system enables superior grid support and it is capable of maintaining production across severe drops in grid voltage, while simultaneously minimising tower and foundation loads. It also allows rapid down-rating of production to 10 per cent nominal power.Proven technologies - from the company that invented themThe 3 MW platform is a low-risk choice. It is based on the proven technologies that underpin more than 56,000 Vestas turbines installed around the world. Using the best features from across the range, as well as some of the industry’s most stringently tested components and systems, the platform’s reliable design minimises downtime – helping to give you the best possible return on your investment.With an operating range that covers all wind classes, our 3 MW platform delivers unrivalled energy production. The proven blade technology from the V112-3.0 MW® is used on theV105-3.45 MW™, the V112-3.45 MW™ and on the V117-3.45 MW™. The industry known structural shell blades are used on the V126-3.45 MW™ and V136-3.45 MW™- a technology which is also used on the 2 MW V110-2.0 MW™ variant.Reliable and robustThe Vestas Test Centre is unrivalled in the wind industry. We test most nacelle components using Highly Accelerated Life Testing (HALT) to ensure reliability. For critical components, HALT identi-fies potential failure modes and mechanisms. Specialised test rigs ensure strength and robustness for the gearbox, generator, yaw and pitch system, lubrication system and accumulators. Our quality-control system ensures that each component is manufactured to design specifications and performs at site. We systematically monitor measurement trends that are critical to quality, locating defects before they occur.Is the 3 MW platform the optimal choice for your specific site?One common nacelle – five different rotor sizesThe wind conditions on a wind project site are often not identical. The 3 MW platform features a range of turbines that cover all wind classes and combined across your site they can maximise the energy output of your wind power plant.Tip-height restrictions and strict grid requirementsWith a rotor size of 105 m, the V105-3.45 MW™ IEC IA is the turbine that fits the most severe wind conditions. It has an ex-tremely robust design for tough site conditions and is especially suited for markets with tip-height restrictions and high grid requirements.Like all the other 3 MW turbines, the V105-3.45 MW™ is equipped with a full-scale converter ensuring full compliance with the challenging grid codes in countries like the UK and Ireland.Cold climatesThe V112-3.45 MW™, V117-3.45 MW™ , V126-3.45MW™and V136-3.45 MW™ can be combined with Vestas De-Icing and Vestas Ice Detection ensuring optimum production in cold climates.excellent turbine choices. A combination of the variants can optimise your site layout and improve your production signifi-cantly on complex sites.Low-wind sitesBuilt on the same proven technology as the V112-3.0 MW®,the V136-3.45 MW™ IEC IIIA is our best performer on low-wind sites. The larger rotor enable greater wind capture, which in turn produces more energy to reduce levelised cost of energy (LCOE). The result is exceptional profitability in areas with low wind, and new frontiers for wind energy investment.Large Diameter Steel Towers (LDST) support the added rotor size and rating of Vestas turbines to increase Annual Energy Production on low-wind sites.LDST is specially designed with a larger diameter in the bottom section that allows for optimal strength at high hub heights.Maximising old permitsAlthough the V136-3.45 MW™ is one of the highest producing low wind turbine available, some old permits may simply be tooKnowledge about wind project planning is key Getting your wind energy project up and operating as quickly as possible is fundamental to its long-term success. One of the first and most important steps is to identify the most suitable location Would you benefit from uninterrupted control of wind energy production?The complexity and specific requirements of grid connections vary considerably across the globe, making the optimal design of electrical components for your wind power plant essential. By identifying grid codes early in the project phase and simulating+28,000 The Vestas Performance and Diagnostics Centre monitors more than 28,000 turbines worldwide. We use this information to con-tinually develop and improve our products and services.monitor performance and produce detailed, tailored reports from anywhere in the world. The VestasOnline® Power Plant Controller offers scalability and fast, reliable real-time control and features customisable configuration, allowing you to implement any control an early stage and monitor any damage. This information allows pre-emptive maintenance to be carried out before the compo-nent fails, reducing repair costs and production loss.IEC IAFacts & figuresPOWeR ReGuLaTiOn Pitch regulated withvariable speedOPeRaTinG daTaRated power3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed25 m/s Re cut-in wind speed23 m/s Wind class IEC IA Standard operating temperature range from -20°C* to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter105 m Swept area8,659 m²Air brake full blade feathering with3 pitch cylinderseLeCTRiCaLFrequency50/60 Hz Converter full scaleGeaRbOXType two planetary stages andone helical stageTOWeRHub height72.5 m (IEC IA)naCeLLe diMensiOnsHeight for transport 3.4 m Height installed(incl. CoolerTop®) 6.9 m Length12.8 m Width 4.2 m Hub diMensiOnsMax. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOnsLength51.2 m Max. chord 4 mMax. weight per unit fortransportation70 metric tonnesTuRbine OPTiOns· Power Optimised Mode· Condition Monitoring System· Service Personnel Lift· Vestas Ice Detection· Low Temperature Operation to -30°C· Fire Suppression· Shadow Detection· Increased Cut-In· Nacelle Hatch for Air Inlet· Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOny early average wind speed m/s 14.016.018.012.010.08.06.04.02.06.08.010.09.07.0■V105-3.45MW™IEC IA GWhIEC IAFacts & figuresPOWeR ReGuLaTiOn Pitch regulated withvariable speedOPeRaTinG daTaRated power3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed25 m/s Re cut-in wind speed23 m/s Wind class IEC IA Standard operating temperature range from -20°C* to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter112 m Swept area9,852 m²Air brake full blade feathering with3 pitch cylinderseLeCTRiCaLFrequency50/60 Hz Converter full scaleGeaRbOXType two planetary stages andone helical stageTOWeRHub height69 m (IEC IA) and 94 m (IEC IA)naCeLLe diMensiOnsHeight for transport 3.4 m Height installed(incl. CoolerTop®) 6.9 m Length12.8 m Width 4.2 m Hub diMensiOnsMax. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOnsLength54.7 m Max. chord 4 mMax. weight per unit fortransportation70 metric tonnesTuRbine OPTiOns· Power Optimised Mode· Condition Monitoring System· Service Personnel Lift· Vestas Ice Detection· Vestas De-Icing· Low Temperature Operation to - 30°C· Fire Suppression· Shadow detection· Increased Cut-In· Nacelle Hatch for Air Inlet· Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOny early average wind speed m/s 14.016.018.012.010.08.06.04.02.0■V112-3.45MW™IEC IA GWh6.08.010.09.07.0IEC IB/IEC IIA Facts & figuresPOWeR ReGuLaTiOn Pitch regulated withvariable speedOPeRaTinG daTaRated power3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed25 m/s Re cut-in wind speed23 m/s Wind class IEC IB/IEC IIA Standard operating temperature range from -20°C* to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter117 m Swept area10,751 m²Air brake full blade feathering with3 pitch cylinderseLeCTRiCaLFrequency50/60 Hz Converter full scaleGeaRbOXType two planetary stages andone helical stage TOWeRnaCeLLe diMensiOnsHeight for transport 3.4 m Height installed(incl. CoolerTop®) 6.9 m Length12.8 m Width 4.2 m Hub diMensiOnsMax. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOnsLength57.2 m Max. chord 4 mMax. weight per unit fortransportation70 metric tonnesTuRbine OPTiOns· Power Optimised Mode· Condition Monitoring System· Service Personnel Lift· Vestas Ice Detection· Vestas De-Icing· Low Temperature Operation to - 30°C· Fire Suppression· Shadow detection· Increased Cut-In· Nacelle Hatch for Air Inlet· Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOny early average wind speed m/sHub heights80 m (IEC IB), 91.5 m (IEC IB)and 116.5 m (IEC IB/IEC IIA/DIBtS)14.016.018.012.010.08.06.04.02.0GWh6.08.010.09.07.0■V117-3.45MW™IEC IB/IEC IIAIEC IIBFacts & figuresPOWeR ReGuLaTiOn Pitch regulated withvariable speedOPeRaTinG daTaRated power3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed22.5 m/s Re cut-in wind speed20 m/s Wind class IEC IIB Standard operating temperature range from -20°C* to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter126 m Swept area12,469 m²Air brake full blade feathering with3 pitch cylinderseLeCTRiCaLFrequency50/60 Hz Converter full scaleGeaRbOXType two planetary stages andone helical stage TOWeRnaCeLLe diMensiOnsHeight for transport 3.4 m Height installed(incl. CoolerTop®) 6.9 m Length12.8 m Width 4.2 m Hub diMensiOnsMax. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOnsLength61.7 m Max. chord 4 mMax. weight per unit fortransportation70 metric tonnesTuRbine OPTiOns· Power Optimised Mode· Condition Monitoring System· Service Personnel Lift· Vestas Ice Detection· Vestas De-Icing· Low Temperature Operation to - 30°C· Fire Suppression· Shadow detection· Increased Cut-In· Nacelle Hatch for Air Inlet· Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOny early average wind speed m/sHub heights87 m (IEC IIB), 117 m (IEC IIB) and137 m (IEC IIIA)14.016.018.012.010.08.06.04.02.0GWh6.08.010.09.07.0■V126-3.45MW™IEC IIBIEC IIAFacts & figuresPOWeR ReGuLaTiOn Pitch regulated withvariable speedOPeRaTinG daTaRated power3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed22.5 m/s Re cut-in wind speed20 m/s Wind class IEC IIA Standard operating temperature range from -20°C* to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter126 m Swept area12,469 m²Air brake full blade feathering with3 pitch cylinderseLeCTRiCaLFrequency50/60 Hz Converter full scaleGeaRbOXType two planetary stages andone helical stage TOWeRnaCeLLe diMensiOnsHeight for transport 3.4 m Height installed(incl. CoolerTop®) 6.9 m Length12.8 m Width 4.2 m Hub diMensiOnsMax. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOnsLength61.7 m Max. chord 4 mMax. weight per unit fortransportation70 metric tonnesTuRbine OPTiOns· Power Optimised Mode· Condition Monitoring System· Service Personnel Lift· Vestas Ice Detection· Vestas De-Icing· Low Temperature Operation to - 30°C· Fire Suppression· Shadow detection· Increased Cut-In· Nacelle Hatch for Air Inlet· Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOny early average wind speed m/sHub heights87 m (IEC IIA), 117 m (IEC IIA/DIBtS),137 m (IEC IIIA/DIBtS), 147 m (IEC IIIA),149 m (DIBtS) and 166 m (DIBtS)14.016.018.012.010.08.06.04.02.0GWh6.08.010.09.07.0■V126-3.45MW™IEC IIAIEC IIIAFacts & figuresPOWeR ReGuLaTiOnPitch regulated withvariable speedOPeRaTinG daTa Rated power 3,450 kW Cut-in wind speed 3 m/s Cut-out wind speed 22.5 m/s Re cut-in wind speed 20 m/s Wind class IEC IIIA Standard operating temperature range from -20°C * to +45°C with de-rating above 30°C*subject to different temperature optionssOund POWeR(Noise modes dependent on site and country)ROTORRotor diameter 136 m Swept area 14,527 m²Air brakefull blade feathering with3 pitch cylinderseLeCTRiCaL Frequency 50/60 Hz Converter full scaleGeaRbOX Typetwo planetary stages andone helical stageTOWeR naCeLLe diMensiOns Height for transport 3.4 m Height installed (incl. CoolerTop ®) 6.9 m Length 12.8 m Width4.2 mHub diMensiOns Max. transport height 3.8 m Max. transport width 3.8 m Max. transport length 5.5 mbLade diMensiOns Length 66.7 m Max. chord4.1 mMax. weight per unit for transportation70 metric tonnesTuRbine OPTiOns· Condition Monitoring System · Service Personnel Lift · Vestas Ice Detection · Vestas De-Icing· Low Temperature Operation to - 30°C · Fire Suppression · Shadow detection · Increased Cut-In· Nacelle Hatch for Air Inlet · Aviation Lights· Aviation Markings on the Blades· Obstacle Collision Avoidance System (OCAS™)annuaL eneRGy PROduCTiOnHub heights82 m (IEC IIIA), 112 m (IEC IIIA), 132 m (IEC IIIA/DIBt2) and 149 m (DIBtS)14.016.018.012.010.08.06.04.02.00■ V136-3.45MW™IEC IIIA GWh6.08.010.09.07.0Vestas Wind Systems A/SHedeager 42 . 8200 Aarhus N . Denmark Tel: +45 9730 0000 . Fax: +45 9730 0001 *****************© 2015 Vestas Wind systems a/s. all rights reserved.。

维斯塔斯风机高压电缆参数表摘要:一、引言二、维斯塔斯风机简介三、高压电缆参数表概述1.电缆类型2.电缆规格3.电缆长度4.电缆额定电压5.电缆工作温度四、高压电缆参数表在维斯塔斯风机中的应用五、总结正文:一、引言维斯塔斯风机作为风力发电领域的知名品牌,其产品质量及技术水平在全球范围内具有较高的声誉。

本文将重点介绍维斯塔斯风机高压电缆参数表的相关内容,以帮助大家更好地了解这一产品。

二、维斯塔斯风机简介维斯塔斯风机(Vestas Wind Systems A/S)成立于1979年,总部位于丹麦,是全球领先的风力发电设备制造商。

维斯塔斯风机凭借其卓越的技术实力、丰富的行业经验以及优质的售后服务,为全球各地的风电项目提供了大量高性能的风力发电机组。

三、高压电缆参数表概述1.电缆类型维斯塔斯风机高压电缆主要采用三相交联聚乙烯绝缘铜芯电缆。

这种电缆具有良好的电气性能、耐热性能和耐候性能,能适应各种恶劣环境。

2.电缆规格电缆规格主要包括截面积、芯数等。

不同的规格适用于不同功率的风力发电机组,需根据实际需求进行选择。

3.电缆长度电缆长度根据项目现场的具体情况定制,一般包括陆地电缆和海上电缆两种类型。

陆上电缆长度通常为几百米至数千米,而海上电缆长度可达数十千米。

4.电缆额定电压维斯塔斯风机高压电缆额定电压通常为3kV、6kV、10kV等,根据风力发电机组的功率等级进行选择。

5.电缆工作温度电缆工作温度范围较广,一般为-40℃至+90℃,适用于各种气候条件。

四、高压电缆参数表在维斯塔斯风机中的应用维斯塔斯风机高压电缆参数表是选购和配置风力发电机组的重要参考依据。

通过对比分析参数表,用户可以选择合适的电缆规格和类型,确保风力发电机组的正常运行。

五、总结维斯塔斯风机高压电缆参数表对于选购和配置风力发电机组具有重要意义。

用户可以根据参数表中的各项指标,选择合适的电缆类型、规格和工作温度,确保风力发电机组的稳定运行。