CNC加工中心-常用球刀精加工参数表

- 格式:xls

- 大小:30.00 KB

- 文档页数:2

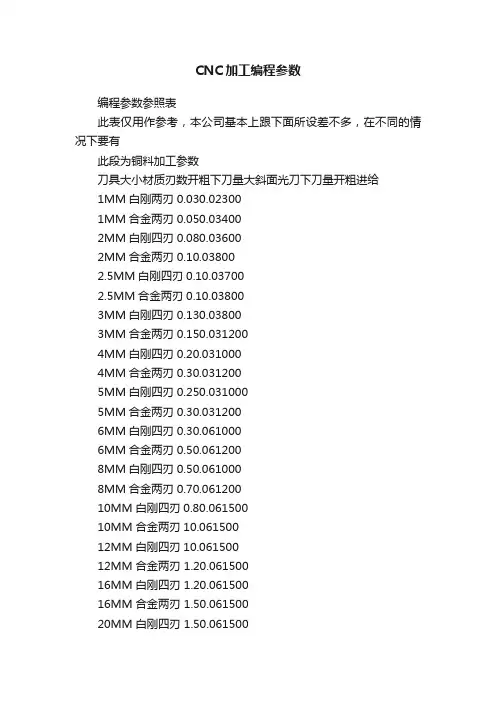

CNC加工编程参数编程参数参照表此表仅用作参考,本公司基本上跟下面所设差不多,在不同的情况下要有此段为铜料加工参数刀具大小材质刃数开粗下刀量大斜面光刀下刀量开粗进给1MM白刚两刃0.030.023001MM合金两刃0.050.034002MM白刚四刃0.080.036002MM合金两刃0.10.038002.5MM白刚四刃0.10.037002.5MM合金两刃0.10.038003MM白刚四刃0.130.038003MM合金两刃0.150.0312004MM白刚四刃0.20.0310004MM合金两刃0.30.0312005MM白刚四刃0.250.0310005MM合金两刃0.30.0312006MM白刚四刃0.30.0610006MM合金两刃0.50.0612008MM白刚四刃0.50.0610008MM合金两刃0.70.06120010MM白刚四刃0.80.06150010MM合金两刃10.06150012MM白刚四刃10.06150012MM合金两刃 1.20.06150016MM白刚四刃 1.20.06150016MM合金两刃 1.50.06150020MM白刚四刃 1.50.06150020MM合金两刃 1.50.06150025MM白刚四刃 1.50.06150025MM合金两刃 1.50.061500飞刀刀具刀具大小材质刃数开粗下刀量大斜面光刀下刀量开粗进给R6合金刀粒两刃0.450.151500R8合金刀粒两刃0.50.21500R10合金刀粒两刃0.60.2150012R0.4合金刀粒一刃0.70.1120016R0.4合金刀粒两刃0.70.1150020R0.4合金刀粒两刃0.70.1150025R0.8合金刀粒两刃10.1150030R5合金刀粒两刃0.60.31600球刀刀具刀具大小直径材质刃数开粗下刀量斜面光刀下刀量R0.51MM合金两刃0.020.02R11MM合金两刃0.040.05R1.53MM合金两刃0.060.07R24MM合金两刃0.150.1R2.55MM合金两刃0.20.1R36MM合金两刃0.30.12R48MM合金两刃0.30.12R510MM合金两刃0.50.15R612MM合金两刃0.50.15R816MM合金两刃0.60.2R1020MM合金两刃0.60.2编程参数参照表此表仅用作参考,本公司基本上跟下面所设差不多,在不同的情况下要有此段为钢料加工参数刀具大小材质刃数开粗下刀量大斜面光刀下刀量开粗进给2MM白刚四刃0.020.034002MM合金两刃0.040.035002.5MM白刚四刃0.020.034002.5MM合金两刃0.040.035003MM白刚四刃0.030.034003MM合金两刃0.050.036004MM白刚四刃0.050.036004MM合金两刃0.050.036005MM白刚四刃0.050.036005MM合金两刃0.050.038006MM白刚四刃0.060.066006MM合金两刃0.060.068008MM白刚四刃0.080.068008MM合金两刃0.10.06110010MM白刚四刃0.10.0680010MM合金两刃0.150.06110012MM白刚四刃0.130.07120012MM合金两刃0.150.07130016MM白刚四刃0.150.11300 16MM合金两刃0.20.11300 20MM白刚四刃0.20.11200 20MM合金两刃0.250.11200 25MM白刚四刃0.20.11200 25MM合金两刃0.250.131200飞刀刀具刀具大小材质刃数开粗下刀量大斜面光刀下刀量开粗进给R6合金刀粒两刃0.40.151500 R8合金刀粒两刃0.40.21500 R10合金刀粒两刃0.50.21500 12R0.4合金刀粒一刃0.20.11200 16R0.4合金刀粒两刃0.250.11500 20R0.4合金刀粒两刃0.30.11500 25R0.8合金刀粒两刃0.30.21500 30R5合金刀粒两刃0.50.31600 40R6合金刀粒两刃0.50.31500 63R5合金刀粒六刃0.60.31300球刀刀具刀具大小直径材质刃数开粗下刀量斜面光刀下刀量R11MM合金两刃0.030.03 R1.53MM合金两刃0.060.07R24MM合金两刃0.150.1 R2.55MM合金两刃0.20.1 R36MM合金两刃0.30.12 R48MM合金两刃0.30.12 R510MM合金两刃0.50.15 R612MM合金两刃0.50.15 R816MM合金两刃0.60.2 R1020MM合金两刃0.60.2下要有不同的改变光平面进给光斜面进给开粗转数光刀转数15030050006000150400550060002005004000450020050042005000200600350040002006004000450020060035004000200650400045002506003000350025065035004000250600300035003006503500400025060028003200300700300040002506002200250030080022003000300600220025004008002200300030060022002500400800220030004008001200120045010001200150040080010001000450100012001200400800800-100800450100010001000光平面进给光斜面进给开粗转数光刀转数150025003000150021002500150020002500500110022003000600120018003000600120018003000600130018002800700120016002000开粗进给光斜面进给开粗转数光刀转数300350550060006005004500450070060042004500110090040004500120080040004200150012003000380015001300300035001700150026003000180015002500300018001500250030001800150025002800下要有不同的改变光平面进给光斜面进给开粗转数光刀转数光侧面进给斜面转速2004503000320025050032003500200450300032002505003200350020045025002800250500260030002004502200250025050025003000250500180025003006502200280025050015002200300600200025002506001300230030080030080018002300300800300600120020002508004008001800200025080030080012001600250800400800150018002508004008007001200230400450100080012002504004008006001000200300450100060010002003004008005008002002504501000500800200250光平面进给光斜面进给开粗转数光刀转数15002500300015002100250015002000250050011002200300060012001800300060012001800300060013001800280070012001600200080012001600200010001200700-10001500开粗进给光斜面进给开粗转数光刀转数40040035004500 70060035004000 110090035004000 120080035004000 1500120025003000 1500130025003000 1700130022002800 1800150022002800 1800150020002600 1800150018002300。

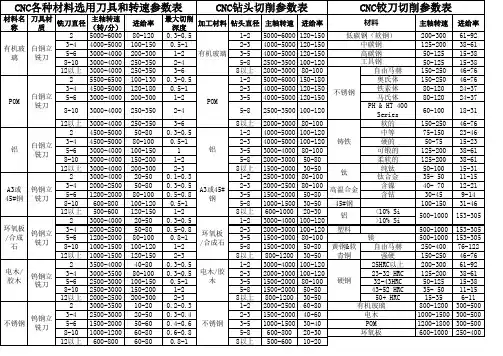

CNC各种材料选用刀具与转速参数表

内容来源网络,由“深圳机械展(11万㎡,1100多家展商,超10万观众)”收集整理!

更多cnc加工中心、车铣磨钻床、线切割、数控刀具工具、工业机器人、非标自动化、数字化无人工厂、精密测量、3D打印、激光切割、钣金冲压折弯、精密零件加工等展示,就在深圳机械展.

内容来源网络,由“深圳机械展(11万㎡,1100多家展商,超10万观众)”收集整理!

更多cnc加工中心、车铣磨钻床、线切割、数控刀具工具、工业机器人、非标自动化、数字化无人工厂、精密测量、3D打印、激光切割、钣金冲压折弯、精密零件加工等展示,就在深圳机械展.。

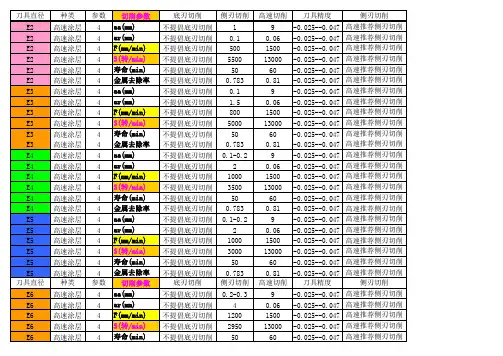

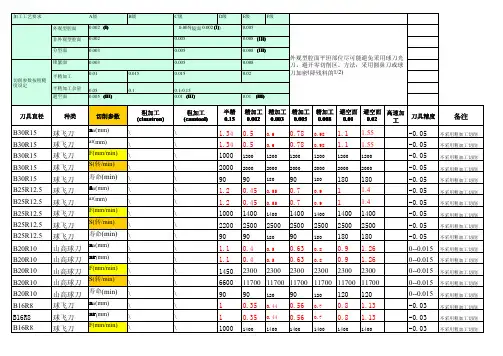

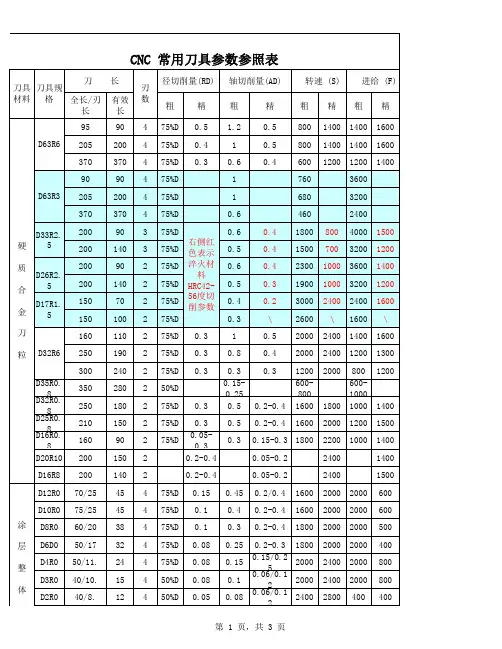

B16R8球飞刀S(转/min)\\2000320032003200320032003200-0.03不采用粗加工切削B16R8球飞刀寿命(min)\\909012090120120120-0.03不采用粗加工切削B16R8球飞刀a a (mm)\\10.350.440.560.70.8 1.13-0.03高速加工B16R8球飞刀ar (mm)\\10.350.440.560.70.81.13-0.03高速加工B16R8球飞刀F(mm/min)\\2000350035003500350035003500-0.03高速加工B16R8球飞刀S(转/min)\\4500800080008000800080008000-0.03高速加工B16R8球飞刀寿命(min)\\-0.03高速加工B16r8黛杰球刀aa(mm)\\0.350.440.560.70.8 1.13B16r8黛杰球刀ar(mm)\\0.350.440.560.70.8 1.13B16r8黛杰球刀F(mm/min)\\400040004000400040004000B16r8黛杰球刀S(转/min)\\900090009000900090009000B16r8黛杰球刀寿命(min)\\B16r8山高球刀aa(mm)\\10.350.440.560.70.8 1.13B16r8山高球刀ar(mm)\\10.350.440.560.70.8 1.13B16r8山高球刀F(mm/min)\\1450230023002300230023002300B16r8山高球刀S(转/min)\\6600117001170011700117001170011700B16r8山高球刀寿命(min)\\60180180180180180180B12R6合金球刀a a (mm)\\0.850.30.380.50.620.70.980.380--0.051B12R6合金球刀ar (mm)\\0.850.30.380.50.620.70.980.380--0.051B12R6合金球刀F(mm/min)\\140014001400140014001400140018200--0.051B12R6合金球刀S(转/min)\\180018001800180018001800180041000--0.051B12R6合金球刀寿命(min)\\90909090909090600--0.051B12R6山高球刀a a (mm)\\0.850.30.380.50.620.70.98B12R6山高球刀a r (mm)\\0.850.30.380.50.620.70.98B12R6山高球刀F(mm/min)\\18004200420042004200B12R6山高球刀S(转/min)\\810018000180001800018000B12R6山高球刀寿命(min)\\90120120120120B12R6高速涂层a a (mm)0.31.20.850.30.380.50.620.70.980--0.02B12R6高速涂层ar (mm)1 2.50.850.30.380.50.620.70.980--0.02B12R6高速涂层F(mm/min)2200155030003000260030002600260026000--0.02B12R6高速涂层S(转/min)6850620068506850685068506850685068500--0.02B12R6高速涂层寿命(min)1201201801201801801800--0.02B10R5合金球刀a a (mm)\\0.770.280.350.450.560.630.90.380--0.051B10R5合金球刀ar (mm)\\0.770.280.350.450.560.630.90.380--0.051B10R5合金球刀F(mm/min)\\130013001300130013001300130018000--0.051B10R5合金球刀S(转/min)\\180022002000220020001800180065000--0.051B10R5合金球刀寿命(min)\\90909090909090900--0.051B10R5山高球刀a a (mm)\\0.770.280.350.450.560.630.9B10R5山高球刀a r (mm)\\0.770.280.350.450.560.630.9B10R5山高球刀F(mm/min)\\20004500420045004200B10R5山高球刀S(转/min)\\1000019000190001900019000B10R5山高球刀寿命(min)\\90180180180180B10R5高速涂层a a (mm)0.510.770.280.350.450.560.630.90--0.02B10R5高速涂层ar (mm)2 2.20.770.280.350.450.560.630.90--0.02B10R5高速涂层F(mm/min)3000180026002600260026002600260026000--0.02B10R5高速涂层S(转/min)9500760095009500950095009500950095000--0.02B10R5高速涂层寿命(min)9090180901801201200--0.02B8R4合金球刀a a (mm)\\0.70.250.30.40.50.560.80.150--0.051B8R4合金球刀ar (mm)\\0.70.250.30.40.50.560.80.30--0.051B8R4合金球刀F(mm/min)\\110012001200120012001200120016000--0.051B8R4合金球刀S(转/min)\\220022002200220022002200220060000--0.051B8R4合金球刀寿命(min)\\60606060609090900--0.051B8R4高速涂层a a (mm)0.50.80.70.250.30.40.50.560.8\B8R4高速涂层ar (mm)1.6 1.70.70.250.30.40.50.560.8\B8R4高速涂层F(mm/min)300020002400300030003000300030003000\B8R4高速涂层S(转/min)10000900010000100001000010000100001000010000\B8R4高速涂层寿命(min)909018090180180180\B8R4山高球刀a a (mm)\0.70.250.30.40.50.560.8B8R4山高球刀a r(mm)\0.70.250.30.40.50.560.8B8R4山高球刀F(mm/min)\23005000500050005000B8R4山高球刀S(转/min)\1300020000200002000020000B8R4山高球刀寿命(min)\\180180180180B6R3合金球刀a a(mm)\0.60.210.260.350.440.50.70.150--0.051 B6R3合金球刀ar(mm)\0.60.210.260.350.440.50.70.210--0.051 B6R3合金球刀F(mm/min)\120012001200120012001200120015000--0.051 B6R3合金球刀S(转/min)\260026002600260026002600260078000--0.051 B6R3合金球刀寿命(min)\60606060609090600--0.051 B6R3高速涂层a a(mm)0.30.60.60.210.260.350.440.50.7\B6R3高速涂层ar(mm) 1.2 1.20.60.210.260.350.440.50.7\B6R3高速涂层F(mm/min)300022003000260026002600260030003000\B6R3高速涂层S(转/min)130001030013000130001300013000130001300013000\B6R3高速涂层寿命(min)909015090150150150\B4R2合金球刀a a(mm)\\0.50.180.220.280.350.40.560.180--0.051 B4R2合金球刀ar(mm)\\0.50.180.220.280.350.40.560.180--0.051 B4R2合金球刀F(mm/min)\\55075075075075055055010000--0.051 B4R2合金球刀S(转/min)\\300030003000300030003000300064000--0.051 B4R2合金球刀寿命(min)\\50506050606060600--0.051 B4R2高速涂层a a(mm)0.20.40.50.180.220.280.350.40.56\B4R2高速涂层ar(mm)0.80.80.50.180.220.280.350.40.56\B4R2高速涂层F(mm/min)200023502000200020002000200020002000\B4R2高速涂层S(转/min)150001200015000150001500015000150001500015000\B4R2高速涂层寿命(min)909012090120120120\B3R1.5合金球刀a a(mm)\\0.420.150.180.240.30.350.480.10--0.051 B3R1.5合金球刀ar(mm)\\0.420.150.180.240.30.350.480.10--0.051 B3R1.5合金球刀F(mm/min)\\4005505505505505505508000--0.051 B3R1.5合金球刀S(转/min)\\240030003000300030003000300080000--0.051 B3R1.5合金球刀寿命(min)\\40404040404040600--0.051 B3R1.5高速涂层a a(mm)0.20.30.420.150.180.240.30.350.48\B3R1.5高速涂层ar(mm)0.50.60.420.150.180.240.30.350.48\B3R1.5高速涂层F(mm/min)200023501800200020002000200020002000\B3R1.5高速涂层S(转/min)165001250016500165001650016500165001650016500\B3R1.5高速涂层寿命(min)606012060120120120\B2R1高速涂层a a(mm)0.150.20.050.030.030.030.030.030.03\ B2R1高速涂层ar(mm)0.420.420.350.120.150.20.250.280.4\ B2R1高速涂层F(mm/min)200023501750160016001600160016001600\ B2R1高速涂层S(转/min)130001325018000180001800018000180001800018000\ B2R1高速涂层寿命(min)30606012060120120120\ B2R1合金球刀a a(mm)\\0.050.050.050.050.050.050.050.03\ B2R1合金球刀ar(mm)\\0.150.120.150.150.150.150.150.1\ B2R1合金球刀F(mm/min)\\350400400400400400400600\ B2R1合金球刀S(转/min)\\300030003000300030003000300010000\ B2R1合金球刀寿命(min)\\\\\\\\\\ B1R0.5高速涂层a a(mm)\\0.050.050.050.05\\\\ B1R0.5高速涂层ar(mm)\\0.10.080.10.1\\\\ B1R0.5高速涂层F(mm/min)\\900900900900\ B1R0.5高速涂层S(转/min)\\18000180001800018000\ B1R0.5高速涂层寿命(min)\\60606060\ B0.5R0.25高速涂层a a(mm)\\\0.02\\\\\\ B0.5R0.25高速涂层ar(mm)\\\0.05\\\\\\ B0.5R0.25高速涂层F(mm/min)\\\400\\\\\\ B0.5R0.25高速涂层S(转/min)\\\18000\\\\\\ B0.5R0.25高速涂层寿命(min)\\\\\\\\\\。

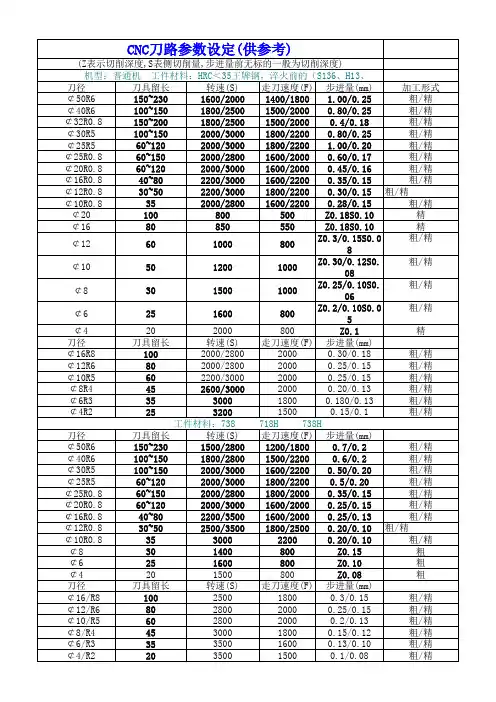

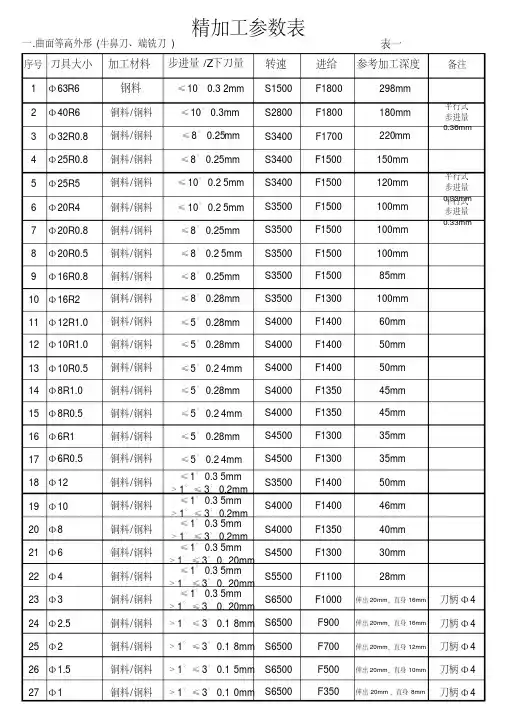

表一序号刀具大小加工材料步进量/Z 下刀量转速进给参考加工深度备注1Ф63R6钢料≤10°0.32mm S1500F1800298mm 2Ф40R6铜料/钢料≤10°0.3mm S2800F1800180mm 平行式步进量0.36mm3Ф32R0.8铜料/钢料≤8°0.25mm S3400F1700220mm 4Ф25R0.8铜料/钢料≤8°0.25mm S3400F1500150mm 5Ф25R5铜料/钢料≤10°0.25mm S3400F1500120mm 平行式步进量0.33mm 6Ф20R4铜料/钢料≤10°0.25mm S3500F1500100mm 平行式步进量0.33mm7Ф20R0.8铜料/钢料≤8°0.25mm S3500F1500100mm 8Ф20R0.5铜料/钢料≤8°0.25mm S3500F1500100mm 9Ф16R0.8铜料/钢料≤8°0.25mm S3500F150085mm 10Ф16R2铜料/钢料≤8°0.28mm S3500F1300100mm 11Ф12R1.0铜料/钢料≤5°0.28mm S4000F140060mm 12Ф10R1.0铜料/钢料≤5°0.28mm S4000F140050mm 13Ф10R0.5铜料/钢料≤5°0.24mm S4000F140050mm 14Ф8R1.0铜料/钢料≤5°0.28mm S4000F135045mm 15Ф8R0.5铜料/钢料≤5°0.24mm S4000F135045mm 16Ф6R1铜料/钢料≤5°0.28mm S4500F130035mm 17Ф6R0.5铜料/钢料≤5°0.24mm S4500F130035mm 18Ф12铜料/钢料≤1°0.35mm ﹥1°≤3°0.2mm S3500F140050mm 19Ф10铜料/钢料≤1°0.35mm ﹥1°≤3°0.2mm S4000F140046mm 20Ф8铜料/钢料≤1°0.35mm ﹥1°≤3°0.2mm S4000F135040mm 21Ф6铜料/钢料≤1°0.35mm ﹥1°≤3°0.20mm S4500F130030mm 22Ф4铜料/钢料≤1°0.35mm ﹥1°≤3°0.20mm S5500F110028mm23Ф3铜料/钢料≤1°0.35mm ﹥1°≤3°0.20mm S6500F1000伸出20mm ,直身16mm 刀柄Ф424Ф2.5铜料/钢料﹥1°≤3°0.18mm S6500F900伸出20mm ,直身16mm刀柄Ф425Ф2铜料/钢料﹥1°≤3°0.18mm S6500F700伸出20mm ,直身12mm刀柄Ф426Ф1.5铜料/钢料﹥1°≤3°0.15mm S6500F500伸出20mm ,直身10mm 刀柄Ф427Ф1铜料/钢料﹥1°≤3°0.10mmS6500F350伸出20mm ,直身8mm刀柄Ф4精加工参数表一.曲面等高外形(牛鼻刀、端铣刀)精加工参数表表二序号刀具大小加工材料步进量/Z 下刀量转速进给1R10铜料/钢料0.20mm S3000F16002R8铜料/钢料0.18mm S3500F15003R6铜料/钢料0.17mm S4000F14504R5铜料/钢料0.16mm S4000F14505R4铜料/钢料0.15mm S4600F13506R3铜料/钢料0.13mm S5000F13007R2铜料/钢料0.11mm S5500F11008R1.5铜料/钢料0.09mm S6000F10009R1铜料/钢料0.08mm S6500F70010R0.75铜料/钢料0.07mm S6500F65011R0.5铜料/钢料0.05mmS6500F350备注:②粗公的步进量在以上基础加0.03mm ;③以上R 刀用“等高外形”加工曲面时,Z 深度(步进量)在以上基础上加0.05mm ;序号刀具大小加工材料转速进给参考加工深度1Ф25铜料S450F250125mm 2Ф20(白钢)铜料S650F350100mm 3Ф20(合金)铜料S2500F85085mm 4Ф16(白钢)铜料S850F40075mm 5Ф16(合金)铜料S2800F80065mm 6Ф12铜料S2400F75050mm 7Ф10铜料S2800F75046mm 8Ф8铜料S3000F75040mm 9Ф6铜料S3200F70035mm 10Ф25R0.8钢料S1800F700150mm 11Ф20R0.8钢料S2000F700100mm 12Ф16R0.8钢料S2200F70085mm①以上参数是相对普通机床对钢料和铜公幼公的加工,高速机的步进量按以上参数,转速、进给以2号机、伸出20mm ,直身10mm 伸出20mm ,直身8mm3号机刀库表为准;④曲面光刀时尽量用“最佳等高”方式加工。

加工中心切削参数文档编制序号:[KKIDT-LLE0828-LLETD298-POI08]加工中心.数控铣床.刀具名称.转速进给、下刀量例:立铣刀必备知识(按照加工45号钢材)刀具名称、转速(/min)、进给(mm/min)、下刀量(mm)63R6(刀片) 600 2500-300050R6(刀片) 650-850 2500-3000 刀片) 1200 2000-2500 刀片) 700-1200 2000-2500 刀片) 2000-2500 2000-3000 刀片) 2200-2500 2200-3000 球头刀2000-2500 2000 球头刀 2200-2500 2000-3000 10(球头刀 2500 1800-2000 球头刀 2500-2800 1500-18006(球头刀 4000 1500-1800 球头刀 5000-6000 18003(球头刀 7000 1500-1800 球头刀 12000 1500-2000 球头刀 16000 1200-15001(球头刀 20000 1200(球头刀 20000 500(球头刀 7000 150030R5(平底立铣)720-1000 2000-3000 平底立铣) 300-600 2000-2500 平底立铣) 600-1000 2000-2500 平底立铣) 1600 2000-2500 平底立铣) 2000-2200 2000-2500 平底立铣) 2200-2500 2000-2500 平底立铣) 2500 1500-2000 平底立铣) 3000 1500-2000 平底立铣) 3500-4000 1500-20003(平底立铣) 6000 1500-1800 平底立铣) 9000 1500 平底立铣) 12000 1200-1500 平底立铣) 18000 1000-1500 铣刀大体上分为:1.平头铣刀.进行粗铣.去除大量毛坯.小面积水平平面或者轮廓精铣2.球头铣刀.进行曲面半精铣和精铣.小刀可以精铣陡峭面/直壁的小倒角。

数控加工参数表 The manuscript was revised on the evening of 2021一、主轴转速n(r/min)主轴转速一般根据切削速度V来选定,计算公式为:n=1000V/(π×d)式中,d为刀具直径(mm),V为刀具切削速度(m/min)。

对于球头铣刀,工作直径要小于刀具直径,故其实际转速应大于计算转速n。

表1铣刀的切削速度V(单位:m/min)二、进给速度V f (mm/min)Vf = fz×z×n式中n为主轴转速,z为铣刀齿数,f z为每齿进给量(mm/齿).每齿进给量fz的选取主要取决于工件材料的力学性能、刀具材料、工件表面粗糙度等因素。

工件材料的强度和硬度越高,f z越小;反之则越大。

硬质合金铣刀的每齿进给量高于同类高速钢铣刀。

工件表面粗糙度要求越高,f z就越小。

1.铣削加工表2 铣刀每齿进给量f z (单位:mm/齿)2.镗削加工表3 镗孔切削用量3、攻螺纹攻螺纹前底孔直径的确定:攻米制螺纹螺距P<1mm:d0=d-PP>1mm:d0=d-(~)P式中P —螺距(mm)d0 —钻头直径(mm)d—螺纹公称直径(mm)攻不通孔螺纹钻孔深度=所需螺孔深度- d表4 攻普通螺纹前的底孔直径表5 攻英制螺纹前的底孔直径表6 攻螺纹切削速度(单位:m/min)4、钻孔加工表7 用高速钢钻头钻孔切削用量(f单位:mm/r)5、铰孔加工铰孔属于精加工工序,加工过程中应合理选择铰刀的类型及材质,高速钢铰刀属于通用铰刀,硬质合金铰刀一般用于加工钢、铸钢、灰铸铁和冷硬铸铁。

为了达到较高的孔径精度和表面质量,应采用较低的切削速度和进给量并合理选择切削液。

铰孔前应留有铰削余量,一般为~底孔直径=铰刀直径-(~)mm铰削加工时切削速度V取3~15m/min进给量f取~r注意:在正式加工之前应试铰,并检验孔径及粗糙度是否符合要求。

三、切削液的选择注:以上各表是加工中心和数控铣床常用的加工参数,供参考。