molecular distillation(分子蒸馏)

- 格式:doc

- 大小:45.00 KB

- 文档页数:5

分子蒸馏及其在多不饱和脂肪酸中的应用摘要阐述了分子蒸馏的基本原理及其主要特点。

介绍了分子蒸馏在不饱和脂肪酸方面的应用研究成果。

关键词分子蒸馏多不饱和脂肪酸应用分子蒸馏(Molecular distillation)是一种在高真空度下进行的液液分离操作的连续蒸馏过程。

其分离原理是基于在一定的温度和真空度下不同物质的分子平均自由程差异,在远低于其沸点的温度下将其分离。

分子蒸馏技术特别适应于高沸点,热敏性以及易氧化物料的分离纯化,可降低高沸点物料的分离成本,保护热敏物料的特点品质。

该技术已经广泛应用于石油化工、食品香料等领域,特别是天然物质的提取与分离。

1 分子蒸馏的基本原理分子蒸馏不同于一般的蒸馏技术,他是运用不同物质分子运动自由程的差别而实现物质的分离。

所谓自由程,即是一个分子在相邻两次分子碰撞之间所经过的路程。

任一分子在运动过程中都在不断变化自由程,而在一定的外界条件下,不同物质的分子其自由程各不相同。

在某时间间隔内自由程的平均值,叫做平均自由程(mean free path)。

分子蒸馏能够实现远离沸点下操作。

根据分子运动理论,液体混合物的分子受热后运动加剧,会从液面逸出而成为气体分子,随着液面上气体分子的增加,有一部分其他分子就会返回液体,在外界温度保持恒定的情况下,最终达到液——气的动态平衡。

Juraj Lutisan和Jan Cvengros 运用理想气体动力学理论导出分子平均自由程公式,提出分子蒸馏的分离作用是利用液体分子受热会从液面逸出,而且不同种类分子逸出后其平均自由程不同来实现的。

λm=Vm/f式中:λm——分子的平均自由程;Vm——某一分子的平均速度;f——碰撞频率。

由分子平均自由程的公式可知,不同的分子由于其运动速度和有效分子直径不同,他们的平均自由程是不相同的,轻分子的平均自由程大,重分子的平均自由程小,分子蒸馏的分离作用就是利用不同分子的平均自由程不同来实现的。

2 分子蒸馏的特点分子蒸馏在低氧惰性条件下蒸馏具有如下特点:2.1 蒸馏温度低普通蒸馏在沸点温度进行,分子蒸馏是在低于蒸馏物质沸点的任何温度下进行,被分离物质只要存在着温度差,就能达到分离目的。

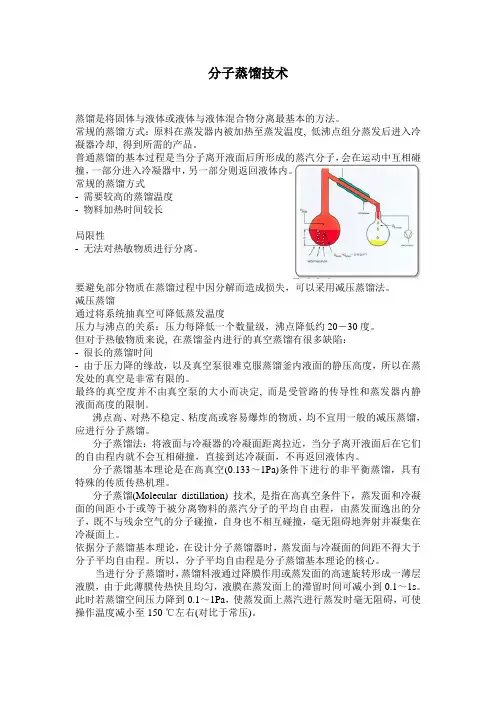

分子蒸馏技术蒸馏是将固体与液体或液体与液体混合物分离最基本的方法。

常规的蒸馏方式:原料在蒸发器内被加热至蒸发温度, 低沸点组分蒸发后进入冷凝器冷却, 得到所需的产品。

普通蒸馏的基本过程是当分子离开液面后所形成的蒸汽分子,会在运动中互相碰撞,一部分进入冷凝器中,另一部分则返回液体内。

常规的蒸馏方式- 需要较高的蒸馏温度- 物料加热时间较长局限性- 无法对热敏物质进行分离。

要避免部分物质在蒸馏过程中因分解而造成损失,可以采用减压蒸馏法。

减压蒸馏通过将系统抽真空可降低蒸发温度压力与沸点的关系:压力每降低一个数量级,沸点降低约20-30度。

但对于热敏物质来说, 在蒸馏釡内进行的真空蒸馏有很多缺陷:- 很长的蒸馏时间- 由于压力降的缘故,以及真空泵很难克服蒸馏釜内液面的静压高度,所以在蒸发处的真空是非常有限的。

最终的真空度并不由真空泵的大小而决定, 而是受管路的传导性和蒸发器内静液面高度的限制。

沸点高、对热不稳定、粘度高或容易爆炸的物质,均不宜用一般的减压蒸馏,应进行分子蒸馏。

分子蒸馏法:将液面与冷凝器的冷凝面距离拉近,当分子离开液面后在它们的自由程内就不会互相碰撞,直接到达冷凝面,不再返回液体内。

分子蒸馏基本理论是在高真空(0.133~1Pa)条件下进行的非平衡蒸馏,具有特殊的传质传热机理。

分子蒸馏(Molecular distillation) 技术, 是指在高真空条件下,蒸发面和冷凝面的间距小于或等于被分离物料的蒸汽分子的平均自由程,由蒸发面逸出的分子,既不与残余空气的分子碰撞,自身也不相互碰撞,毫无阻碍地奔射并凝集在冷凝面上。

依据分子蒸馏基本理论,在设计分子蒸馏器时,蒸发面与冷凝面的间距不得大于分子平均自由程。

所以,分子平均自由程是分子蒸馏基本理论的核心。

当进行分子蒸馏时,蒸馏料液通过降膜作用或蒸发面的高速旋转形成一薄层液膜,由于此薄膜传热快且均匀,液膜在蒸发面上的滞留时间可减小到0.1~1s。

此时若蒸馏空间压力降到0.1~1Pa,使蒸发面上蒸汽进行蒸发时毫无阻碍,可使操作温度减小至150 ℃左右(对比于常压)。

分子蒸馏技术1、分子蒸馏技术的原理分子蒸馏技术(Molecular distillation technology)是一种新型的液-液分离或精制技术,是利用混合物组分中不同分子运动的平均自由程的差异不同而进行分离的。

其特征是蒸发面与冷凝面之间的距离小于被分离物料分子的平均自由程,根据被分离物系各组分的分子量不同,分子平均自由程的差别进行分离。

分子蒸馏又叫短程蒸馏(Short-pathdistillation)。

根据分子平均自由程公式知,不同种类的分子,由于其分子有效直径不同,故其平均自由程也不同,即不同种类分子,从统计学观点看,其逸出液面后不与其它分子碰撞的飞行距离是不相同的。

分子蒸馏的分离作用就是利用液体分子受热会从液面逸出,而不同种类分子逸出后其平均自由程不同这一性质来实现的。

液体受热后,轻分子的平均自由程大,重分子的平均自由程小,在离液面小于轻分子的平均自由程而大于重分子平均自由程处设置一捕集器,使得轻分子不断被捕集,从而破坏了轻分子的动态平衡而使混合液中的轻分子不断逸出,而重分子因达不到捕集器很快趋于动态平衡,不再从混合液中逸出,这样,液体混合物便达到了分离的目的。

2、分子蒸馏技术的特点与常规的普通蒸馏技术相比,短程分子蒸馏技术具有明显特点[1-8]。

2.1操作温度低普通蒸馏是在沸点温度进行,而分子蒸馏是根据不同种类的分子逸出液面后的平均自由程不同的性质来实现的,因而分子蒸馏是在低于蒸馏物质沸点的温度下进行,被分离物质只要存在着温度差,就能达到分离目的。

2.2蒸馏真空度高分子蒸馏由于其特殊的结构,系统内真空度较高,压强只有0.5-1Pa,因而分子蒸馏分离可有效避免易氧化物质的氧化分解。

另外,对于混合液中的低分子物质(如有机溶剂、臭味物质等)的脱除,分子蒸馏较常规蒸馏有效得多。

2.3受热时间短分子蒸馏装置加热面与冷凝面的距离小于轻分子的平均自由程,液面逸出的轻分子几乎未经碰撞就达到冷凝面,所以受热时间很短。

分子蒸馏原理及优缺点

分子蒸馏(Molecular Distillation, MD),又称短程蒸馏(Shot-Path Distillation),是一种利用不同物质分子的平均自由程的差别,在高真空度下进行分离精制的连续蒸馏过程。

原理:根据分子运动理论,液体混合物分子受热后运动加剧,当接受足够能量后,就会从表面逸出成为气相分子(蒸发),随着逸出分子不断增加,逸出分子发生碰撞,发生碰撞的分子重新聚集而落回液面,

小分子)时,

分子蒸馏可以在0.013-1.33Pa 的压强条件下进行蒸发。

使在常压条件下,沸点较高的分子,降低沸点。

如鱼油乙酯230℃→120℃优缺点:

A适于高沸点、热敏性、易氧化物料(蒸馏温度低)

B可有选择性地蒸出目的产物(利用多级分子蒸馏同时分离两种以上物

质)

C工艺简单,溶剂污染少(分离过程为物理过程,不需要使用溶剂) D单纯的分离技术,不具备提取功能

E进样物料及分离后的组分必须为低极性液态

F设备、技术要求高,初期投入较大,生产能力有限。

分子蒸馏流程五个过程英文回答:Molecular Distillation Process.Molecular distillation is a separation process that utilizes the difference in volatility and molecular weight of components in a mixture to achieve separation. The process involves the following steps:1. Evaporation: The feed mixture is heated until the more volatile components vaporize. This is done in a vacuum chamber under low pressure to reduce the boiling points of the components.2. Condensation: The vapor from the feed mixture then passes through a condenser, where the vapor condenses back into a liquid.3. Collection: The condensed liquid is collected in aseparate vessel.4. Fractionation: The condensed liquid is then fractionally distilled to further separate the components based on their boiling points.5. Purification: The final step is to purify the collected fractions to remove any remaining impurities. This can be done through a variety of methods, such as crystallization, filtration, or chromatography.中文回答:分子蒸馏流程。

现代分离技术综述分离技术是研究生产过程中混合物的分离、产物的提取或纯化的一门新型学科,随着社会的发展,对分离技术的要求越来越高,不但希望采用更高效的节能、优产的方法,而且希望所采用的过程与环境友好。

正是这种需求,推动了人们对新型分离技术不懈的探索。

近十余年来,新型分离技术发展迅速,其应用范围已涉及化工、环保、生化、医药、食品、电子、航天等领域,不少技术已趋成熟。

本文对分子蒸馏技术、膜分离技术、超临界萃取技术、新型生物膜技术进行综述。

1、分子蒸馏技术1.1分子蒸馏过程技术的基本原理分子蒸馏(molecular distillation)是指在高真空的条件下,液体分子受热从液面逸出,利用不同分子平均自由程差导致其表面蒸发速率不同,而达到分离的方法[1]。

分子分离过程如图1所示,经过预热处理的待分离料液从进料口沿加热板自上而下流入,受热的液体分子从加热板逸出。

由于冷凝和蒸发表面的间距一般小于或等于蒸发分子的平均自由程,逸出分子可以不经过分子碰撞而直接到达冷凝面冷凝,最后进入轻组分接收罐。

重组分分子由于平均自由程小,不能到达冷凝板,从而顺加热板流入重组分接收罐中,这样就实现了轻重组分的分离[2]。

图1分子蒸馏过程1.2分子蒸馏过程理论的研究国内外许多学者在过去几十年里,尝试建立了两种不同方法来研究分子蒸馏过程。

一种是蒸发系数法,即把各种阻力对分子蒸馏速率的影响归纳于参数蒸发系数E,但是由于在某种条件下得到的E值并不能用于另一种条件下的分子蒸馏速率的预测,所以采用该方法研究分子蒸馏并无太多的现实意义。

另一种方法是数学模型化法,即对分子蒸馏过程各个阶段产生的阻力进行研究,分别建立数学模型并求解,计算出分子蒸馏的速率。

Rees G J[3~4]针对离心式分子分馏器从传质传热机理出发,建立了一维数学分析模型,提出了蒸发面温度、液膜厚度与蒸发速率相关联的有限元方程,从微观方面分析了分子蒸馏过程。

M等[5]用高质量流量下膜理论描述了静止式分子蒸馏器液体内部传递过程对液相温度和组成分布的影响,理论和实验结果取得了一致。

超临界流体萃取技术和分子蒸馏技术传统的植物有效成分的提取方法,主要有水提法、水蒸气蒸馏法和有机溶剂萃取法。

它们都有明显的缺陷,如水提法浓缩困难且提取选择性不高,往往会将许多物质提取出而给后续纯化工作带来困难;水蒸气蒸馏法由于温度较高,会引起一些热敏性成分的热分解和易水解成分的水解;有机溶剂萃取法除了面临大量的溶剂筛选工作外,萃取所得产品还必需经过一系列的脱溶剂操作,才能得到最终产品,而且,产品中不可避免的会含有残余的有机溶剂,产品的使用范围受到很大的限制。

在崇尚“回归自然”的今天,天然食品日益受到人们的欢迎,而在传统的加工过程中致使热敏性的营养素受到破坏或残留有害的化学物质,导致加工的食品失去其天然性。

因此寻求新的提取分离技术以解决这些问题,成为当务之急,也是当前一个新的研究领域。

通过不懈的努力,研究者们提出了超临界流体萃取(supercritical fluid extraction,SFE)技术和分子蒸馏(Molecular distillation)技术。

一、超临界流体萃取(SFE)技术1、超临界流体萃取(SFE)技术原理超临界流体萃取,是指处于临界温度(T C)和临界压力(P C)下的一种物质状态,P C和T C称为临界点。

在临界点附近的范围内,流体的密度变化非常大,气体与液体之间的区别消失,不会发生冷凝或蒸发,只能以流体的形式存在,处于临界状态的流体,其物理化学性质与在非临界状态下相比有显著不同,其密度接近于液体,有较大的溶解能力,其扩散系数接近于气体,传质非常快,因而可以作为萃取溶剂。

超临界流体温度和压力的轻微改变,都可导致物质物理化学性质如密度、介电常数、扩散系数、粘度、溶解度的巨大变化,导致溶剂和溶质的分离。

由于其具有低能耗、无污染和适合于处理易热分解和易氧化物质等特性,在化学工业、能源工业和医药工业中引起广泛的兴趣和应用。

2、超临界流体萃取(SFE)技术萃取剂的选择常见SFF萃取剂有CO2、SO2、NH3、CH3CH3、CH2=CH2等,但在食品工业中,以CO2作为超临界流体的应用最为广泛。

分子蒸馏分子蒸馏(molecular distillation )也称短程蒸馏(short- path distillation ),是一种在高真空下(残气分子的压力<0.1Pa)进行的连续蒸馏过程,属于高真空蒸馏。

它的本质特征在于蒸发器与冷凝器之间的距离小于分子间的平均自由程,一般为10-2~0.2m。

液相表面压力为0.1333Pa,如果其设备设计的比较好,则此压力还可降到6.666×10-3Pa。

在分子蒸馏过程中,分子的运动是无障碍的,各组分之间的相对挥发度增加,操作温度及物料受热时间也大大降低,它既不同于简单蒸馏,也不同于一般的蒸发,它是一种完全非平衡蒸馏。

分子蒸馏过程与传统的蒸馏过程不同,传统蒸馏是在沸点温度下进行分离的,蒸发与冷凝过程是可逆的,液相与汽相间会形成平衡状态。

分子蒸馏过程是一个不可逆的,并且在远离物质常压沸点温度下进行的蒸馏过程,更确切地说,它是分子蒸发的过程。

由于其操作温度远低于物质常压下的沸点温度,同时物料被加热的时间非常短,不会对物质本身造成破坏,因此分子蒸馏广泛应用于化工、医药、轻工、石油、油脂、核化工等工业中,用于浓缩或纯化高分子量、高沸点、高粘度的物质及热稳定性较差的有机化合物。

分子蒸馏的基本原理1.1 分子碰撞分子之间存在着相互作用力,当两分子离得较远时,其作用力主要表现为吸引力,但当两分子接近到一定程度后,分子之间的排斥力迅速增加.当两分子接近到一定程度时,排斥力使两分子分开.这种由接近而至排斥分离的过程就叫分子的碰撞过程。

1.2 分子的平均自由程一个分子在相邻两次碰撞之间所经过的路程叫分子的自由程.任一分子在运动过程中,其自由程都在不断地变化,而在一定的外界条件下,不同物质分子的自由程各不相同.在某时间间隔内,自由程的平均值称为平均自由程。

设νm 为任一分子的平均速度;ƒ为碰撞频率;λm为平均自由程.则有λm =νm/ƒ(1)所以ƒ=νm /λm(2)由热力学原理可知:(3)式中 d一分子有效直径;p一分子所处空间压力;T一分子所处环境温度;k一波尔兹曼常数.对比式(2)和式(3)可得(4)分子运动自由程的分布规律可用概率公式表示为:F = 1一e-λ/λm(5)F一自由程小于或等于平均自由程的概率;λ一分子运动自由程.由(4)式可看出,在一定条件下,某一分子的平均自由程与该分子所处体系的温度成正比,而与体系的压力和该分子的有效直径成反比.1.3 分子蒸馏基本原理依据分子运动理论,液体混合物受热后分子运动会加剧,当某些分子吸收到足够的能量时,就会从液面逸出成为气相分子.随着逸出分子的增多,有一部分气相分子又会返回液相,在外界条件保持恒定的情况下,最终达到分子运动的动态平衡.根据分子运动平均自由程公式(4),不同种类的分子,由于其分子有效直径不同,故其平均自由程也不同.从统计学的观点看,不同种类分子逸出液面后不与其它分子碰撞的飞行距离是不同的,分子蒸馏的分离作用就是依据此原理实现的.如图1所示.图1 分子蒸馏原理示意图待分离混合液体在加热板上被加热,吸收到足够能量的分子逸出液面.轻分子的分子运动平均自由程大,重分子的分子运动平均自由程小.在离液面距离小于轻分子运动自由程而大于重分子运动自由程处,设置一冷凝板.气体中的轻分子能到达冷凝板上,且不断被冷凝,从而破坏了体系中轻分子的动态平衡,而使混合液中的轻分子不断逸出.相反,气体中重分子因不能到达冷凝板,很快与液相中重分子趋于动态平衡,表现上似乎重分子不再从液相逸出,从而达到液体混合物的分离。

分子蒸馏技术在石油化工中的应用213000常州海鸥化工设计研究院有限公司摘要:分子蒸馏技术具有加热温度低,过程温和,受热时间短等优点,适合于高沸点和热敏性物质的分离﹐特别适合应用于油脂的精深加工。

本文从分子蒸馏技术的基本原理,特点,操作过程,设备四方面阐述了分子蒸馏技术在处理石油化工产生的渣油.回收废润滑油、生产高粘度润滑油以及分离催化剂与产品等方面的应用。

关键词:分子蒸馏技术;石油化工;应用分子蒸馏(Molecular Distillation)是一项利用高真空条件下不同物质内部分子间的自由程差实现的新技术,其实质为“分子气化”。

由于具有高真空度,低蒸馏温度,短加热时间,高分离度,因此能够显著地减少高沸点材料的分离费用,更好地保障热敏材料的品质,特别适用于分离、萃取和提纯高沸点、高热敏性和易氧化物质,可以将许多传统的分离方法难以处理的问题都处理掉。

目前,如今,其在医药、食品、精细化工、石油化工、塑料等行业中得到了广泛的应用,具有很大的技术应用前景。

在我国日益枯竭的背景下,在日益增长的环境保护意识和持续高涨的原油价格背景下,如何有效地提高原油的使用率已成为国际社会关注的焦点。

分子蒸馏是一种新型的物理化学方法,具有绿色、洁净等优点,在石化行业具有广阔的发展前景。

一、分子蒸馏的基本原理1.1分子运动平均自由程范德华力和电荷力是两种不同性质的力量,液体的运动幅度比气体的要小,这是因为液体的力量和气体的力量都是一样的,如果两个液体的力量很大,那么两个分子就会慢慢的靠近,但是如果两个分子的距离很近,那么这两个分子之间的力量就会变成一种斥力,这种斥力的力量会随着距离的靠近而快速的增加,最终导致两个分子分离。

1.2分离原理分子蒸馏是基于组分间挥发性的差异,在较高的真空环境中进行的一种非平衡蒸馏。

在混合工质的沸点温度下,根据各工质分子的平均自由程差异,在高真空条件下对各工质进行分离。

在装置的凝结面和蒸发面之间存在温差的情况下,可以进行分离作业。

Molecular distillation ProfileMolecular distillation is a distillation method operated in high vacuum, At this time, the mean free path of steam molecules is greater than the distance between evaporation surface and condensation surface, liquid mixtures can be separated because of the difference of evaporation rate of each component in liquid.Under certain temperature, the lower the pressure, the gas molecule mean free path greater. When the pressure of evaporation space (10-2 ~ 10-4 mmHg) is very low, and evaporation surface is near condensation surface, the vertical distance between them is less than the mean free path of steam molecules , gas molecules can reach condensation surface and condensate without collisions.The working principle of molecular distillationMolecular distillation is a special kind of liquid - liquid separation technology, which is different from the traditional distillation separation principle. Separation can be achieved because of the difference of the mean free path of the different molecules. When the liquid mixture flows along the heating plate and is heated, light and heavy liquid molecules escape into the gas phase because of the difference of the mean free path of the light and heavy molecules, the moving distance of the different molecules after escaping from liquid surface. If a condensation plate can be set up properly, the light molecules can reach condensation surface and condensate and be exhausted, the heavy molecules can not reach condensation surface and be exhausted. In this way, the purpose of the separation material is achieved. The difference of pressure between the boiling film and the condensation surface is the driving force whose the steam flows, the small pressure drop will cause the flow of steam. It is required that the distance between boiling surface and condensation surface is very short under the pressure of 1mbar, the stills based on the principle is namedshort-path distillation device. Still short-range (molecular distillation)has a built-in condenser in the opposite surface of heating surface which makes operating pressure reduce to 0.001mba Short-path distillation is a process of thermal separation technology under the pressure of 1 ~ 0.001mbar, which has the lower boiling temperature, is ideal for heat-sensitive, high boiling point materials. Its basic components: the cylinder cylindrical with a heating jacket, the rotor and the built-in condenser, the scraping membrane device, anti-splash installment. The built-in condenser is located in the center of the evaporator, the rotor between the cylinder and condenser.Distillation process: the materials are added from the top of the evaporator and are distributed uniformly, continuously on heating surface by the liquid distributor. the scraping membrane device make the liquid materials into a single very thin liquid film like turbulence, and advance downward spirally. In the process, the light molecules escaping from the heating sarurface reach the built-in condenser and condense into fluid through a short line and almost without a collision . It flow along the condenser tube, is exhausted through the exhaust pipe at the bottom of the evaporator; the residues(the heavy molecules ) are collected in a circular path under the heating zone, flow out through the side of the pipe.The process of molecular distillationShort-path distillation is also suitable for molecular distillation. The flow is from the surface of the heating zone directly to the condenser’s surface. Molecular distillation process can be ma de up ofthe following four steps:1, The molecules proliferate from the main body of liquid phase to the evaporating surface. Typically, in the liquid phase, the proliferation rate is the primary factor of controlling the molecular distillation speed, therefore, the thickness of the thin liquid layer should be reduced and the flow of liquid should be enhanced.2, the free evaporation of the molecules on the liquid’s surfaceWith temperature rises, the evaporation rate enhances, but in some instances, the separation factor decreases. Therefore, based on the thermal stability of the material the economic rational temperature of distillation is chose, which based on the thermal stability of the material.3, the molecules fly from the evaporation surface to the condensation surfaceIn the process, the molecules may collide one another and may collide with the residual air molecules between the two sides in the air. The evaporated molecules are far more heavier than air molecules, so the collision of their own has little effect on evaporation rates and the flying direction. The hot campaign of the residual gas molecules between two sides is chaotic state. so the number of residual gas molecules is the main factor influencing evaporation rates and the flying direction.4, the molecules condensate on the surface of condensationIf there is sufficient temperature difference (typically 70 ~ 100 ℃) between the hot side and cold side , and the form of condensation surface is smooth and reasonable, it is considered that the condensation steps can be completed in an instant, so it is very important to choose the form of the condenser.The conditions of molecular distillation1, the residual gas pressure must be very low, so that the length of mean free path of the residual gas is several times as the distance between the condenser’s surface and the distiller.2, under the saturation pressure, the length of mean free path of the vapor molecules must have the same magnitude with the distance between the condenser’s surface and the distiller.In this the ideal conditions, the evaporation is produced from the residual gas molecules without any obstacles. Without encountering any molecules, all the vapor molecules return to the liquid and reach on the surface of condenser. Evaporation rate achieve the maximum possible at the current temperature. Evaporation rate is proportional to the pressure, thus, the dis tillated liquid’s volume by molecular distillation is relatively small.The characteristics of molecular distillation1, the ordinary distillation may be separated at boiling point, and molecular distillation can be carried out at any temperature, as long as there is a temperature difference between two hot sides, the purpose of separation can be achieved.2, ordinary distillation evaporation and condensation is a reversible process, the equilibrium state of liquid and gas phase can be formed; in the process of the molecular distillation, the molecules escaping from the evaporation surface fly to the condensing surface directly, but there is not a collision with other molecules, in theory, there is not the possibility to return the evaporation surface, Therefore, molecular distillation process is not reversible.3, ordinary distillation has bubbling, boiling phenomena; there is no bubbling phenomenon because the liquid molecules on the surface of liquid evaporate freely.4 The separation factors which represent the separation capacity of ordinary distillation is relative to the ratio of the vapor pressure of the component , The separation factors which represent the separation capacity of molecular distillation is relative to the ratio of the vapor pressure and molecular weight of the component, them can be obtained from the relative speed of evaporation.The advantages of molecular distillation1 The temperature of molecular distillation is low. It is operated at the temperature much lower than the boiling point, as long as there is a temperature difference between two hot sides, the purpose of separation can be achieved, which is the essence of the distinction between conventional distillation and molecular distillation.2 Distillation has high vacuity .High vacuity can be obtained in the internal unit of molecular distillation, usually, molecular distillation can be operated at a very low pressure, so material is not easy to be oxidized and damaged.3 The membrane of distillation liquid is thin. The efficiency of heat transfer is high.4 Materials are heated in a short time. The distance between the surface of the liquid heated and condensing surface is less than the mean free path of light molecules, so the materials distillated are heated in a short time, residence time is from a few seconds to dozens of seconds, the chance of thermal decomposition of material should reduce.5 A higher degree of separation. The material that is not separated can be separated by molecular distillation.6 There is no the phenomena bubbling of boiling. Molecular distillation is a process of free evaporation on the surface of the liquid. Under the low pressure, there is no air dissolving in the liquid. So it is impossible to make all the liquid boil, and there is no bubbling phenomenon.7 Non-toxic, harmless and pollution-free, non-residual, the product of safe and pure can be obtained. the operation of molecular distillation is simple and the equipment is less.8 the equipment of molecular distillation is expensive, and it must ensure that the pressure of the system can achieve the high vacuity. A higher sealing material is required and the distance between evaporation surface and condensation surface is proper. The equipment is difficult to be processed and the cost is high.9 Energy-consuming of products is low. There is few loss of heat in the separation process of molecular distillation: the equipment of molecular distillation has special structure, the internal pressure is extremely low, the internal resistance is lower than the conventional distillation, and therefore power consumption can be reduced substantially.From the molecular distillation of the characteristics of the above, compared to conventi onal distillation technology, we can see that it has the following obvious advantages in the actual application of industrialization:1 molecular distillation provide the best separation method for materials of high boiling point, heat sensitive materials, materials that are easy to be oxidized, because It is operated at the temperature much lower than the boiling point and the retention time is short.2 the substances such as organic solvents, odor and so on can be removed effectively by molecular distillation. It is an effective method of desolution for the liquid using the solvent extraction.3 molecular distillation can make the goal product to be distilled off selectively and removes other impurities, it can separate 2 above materials through the multistage separations.4 the fractional process of molecular distillation is the physical process, thus may protect well the separated material not to polluted and violated.Molecular distillation equipmentA complete set of molecular distillation equipment include: molecular evaporator, degassing systems, feed systems, heating systems, cooling systems and vacuum control system. Molecular distillation unit is the core of the evaporator elements, of the types are mainly three kinds:(1) Falling film molecular distillation device: it is the early form of simple structure, but the liquid film is thickness, the efficiency is poor, countries of all over the world seldom used today. The device take up the following working way: the gravity make the material into the down liquid film. The materials are heated and the product of evaporation can be condensed on the surface of the across direction.(2) Wiped-Film molecular distillation deviceIn the end of 80's the installations and applied research of Wiped-Film molecular distillation s was carried out in our country. The forming liquid membrane is thin, the efficiency of separation is high, but the structure is more complex than falling-film. The device take up the following working way: the gravity make the material into the down liquid film, but in order to enable the thickness of the liquid film on the evaporation surface to be small and distributed evenly, a rotating scraper made of hard carbon or PTFE was set in the distiller. The scraper can not only make the down liquid be stirred fully, but also speed up the liquid surface layer to renew, thus the process of heat transfer and mass transfer was strengthened. Its advantages are: the thickness of liquid membrane is thin, and liquid flow along the evaporation surface; the remain time of distilled materials is short at operation temperature, the risk of thermal decomposition is small, the distillation can be operated continuously, the production capacity is large. The disadvantage is that: it is difficult to improve the liquid distribution device, it is difficult to ensure that all the liquid evaporation surface to be covered evenly; when liquid flows, there is frequent rolling phenomenon happening, foam and mist generated often spilled onto the condensation surface.. However, due to the structure of the device is relatively simple, relatively inexpensive, in the most cases the device is still used in the laboratories and the process of industrial production.(3) Centrifugal molecular distillation device: centrifugal film, thin film, evaporation efficiency, but t he structure is complex and is difficult to manufacture and operate, vacuum sealing is more difficult, the equipment is expensive. To enhance the efficiency of separation, multi-level series are often used to achieve multi-stage separation of the different substances. The materials are carried onto the centre of high-speed rotating turntable though the device and expend to form film on the rotation surface , at the same time they are heated and evaporate.Application of molecular distillation(A)the food industry1, the production of Monoglyceride Profits.2, the refinement of fish oil3, oil deacidification4, the refinement higher alcohol(B) in the Fine Chemical Industry1, aromatic oil purification2, the purification of polymer intermediates3, the extraction of lanolin(C) the pharmaceutical industryIn conclusion, as a special kind of new separation technology, molecular distillation technology mainly used in separation and purification of high boiling point,heat-sensitive materials. Practice has proved that this technology is not only a high technology, but also the range of applications is wide. It has a very broad prospect for industrial application of high-tech.。