海德堡印刷色彩管理大全

- 格式:pdf

- 大小:643.42 KB

- 文档页数:33

海德堡色彩管理Print Media AcademyAugust-2011 David.wei—海德堡第10届印艺学者论坛海德第届印艺学者论坛色彩管理的目标h i n e n A Gl b e r g e r D r u c k m a s c© H e i d e色彩管理的目标?——印刷能多快追数码打样? ——如何验证与修正?h i n e n A Gl b e r g e r D r u c k m a s c© H e i d e1屏幕色数码样和印刷品相差甚远今天色彩管理的窘境1.屏幕色、数码样和印刷品相差甚远2.分色和流程毫无关系3.中性灰永远不像4.校正方法不多5.打印的黑色不够黑6.数码样的标准及评价7.模拟印刷纸白(或者底灰)相差很远8h i n e n A G 8.打样机老是起扛9.制作ICC 的困惑10.数码打样纸的困惑l b e r g e r D r u c k m a s c 11.打样机——改装机(代用墨的使用)………© H e i d eISOcoated_V2_eci.iccGRACoL2006_Coated1v2.icc印前组合式错误印刷对印刷标准的认识错误PSO_Coated_NPscreen_ISO12647_eci.iccISOcoated_V2_300_eci.icch i n e n A Gl b e r g e r D r u c k m a s c© H e i d e不同的厂家对FOGRA27的定义——色域L=25 L=50 L=75h i n e n A G l b e r g e r D r u c k m a s c ——白色CoatedFOGRA27.ICC (Adobe 定义的,可在PhotoShop 查到)——红色ISOcoated.ICC (可在HDM 软件、FOGRA 网站上找到)© H e i d e (使用软件:Profilemaker5.0)不同的厂家对FOGRA39的定义——色域L=25 L=50 L=75h i n e n A G l b e r g e r D r u c k m a s c ——白色CoatedFOGRA39.ICC (Adobe 定义的,可在PhotoShop 查到)——红色ISOcoated_v2_eci.ICC (可在HDM 软件、FOGRA 网站上找到)© H e i d e (使用的软件:Profilemaker5.0)色彩管理从标准化开始heidelbergh i n e n A Gl b e r g e r D r u c k m a s c © H e i d e印刷技术标准h i n e n A G l b e r g e r D r u c k m a s c © H e i d eh i n e n A Gl b e r g e r D r u c k m a s c © H e i d e印刷技术标准h i n e n A Gl b e r g e r D r u c k m a s c © H e i d eh i n e n A Gl b e r g e r D r u c k m a s c © H e i d eh i n e n A Gl b e r g e r D r u c k m a s c © H e i d e1、2、3、h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e印刷色彩学理论1.颜色的定义与三要素:光源、物体、观察者22.颜色的三属性与颜色的描述形式 3.均匀色空间的理论(主要是关于色度学的基本理论)1、2、h i n e n A Gl b e r g e r D r u c k m a s c © H e i d eh i n e n A Gl b e r g e r D r u c k m a s c © H e i d eh i n e n A Gl b e r g e r D r u c k m a s c © H e i d eFOGRA39LISO12642-2数据组的特征——FOGRA39L ORIGINATOR "Fogra, "DESCRIPTOR "FOGRA39L"CREATED "December 2006"INSTRUMENTATION "D50, 2 degree, geometry 45/0, no polarisation filter, white backing, according to ISO 13655"PRINT CONDITIONS "Offset printing according to ISO 12647-2:2004/Amd 1OFCOM paper type 1or 2=PRINT_CONDITIONS Offset printing, according to ISO 126472:2004/Amd 1, OFCOM, paper type 1 or 2 = coated art, 115 g/m2, tone value increase curves A (CMY) and B (K)"NUMBER_OF_FIELDS 11h i n e n A G BEGIN_DATA_FORMATSAMPLE_ID CMYK_C CMYK_M CMYK_Y CMYK_K XYZ_X XYZ_Y XYZ_Z LAB_L LAB_A LAB_B l b e r g e r D r u c k m a s c END_DATA_FORMAT NUMBER_OF_SETS 1617BEGIN DATA © H e i d e BEGIN_DATAFOGRA27LECI2002数据组的特征——FOGRA27L ORIGINATOR "FOGRA, "DESCRIPTOR "FOGRA27"CREATED "September 2003"INSTRUMENTATION "GRETAGMACBETH SpectroChart and SpectroScan, D50, 2 degree, geometry 45/0, nopolarisation filter, white backing"PRINT_CONDITIONS "Offset printing, according to ISO/DIS 12647-2:2004, OFCOM, paper type 1 or 2 =coated art, 115 g/m2, screen ruling 60 cm-1, positive-acting plates, see readme"h i n e n A G NUMBER_OF_FIELDS 11BEGIN_DATA_FORMATSAMPLE ID CMYK C CMYK M CMYK Y CMYK K XYZ X XYZ Y XYZ Z LAB L LAB A LAB B l b e r g e r D r u c k m a s c SAMPLE_ID CMYK_C CMYK_M CMYK_Y CMYK_K XYZ_X XYZ_Y XYZ_Z LAB_L LAB_A LAB_B END_DATA_FORMAT NUMBER_OF_SETS 1485© H e i d e __BEGIN_DATAICC 特征1.ISOcoated_v2_eci.icc2.ISOcoated_v2_300_eci.icc i tO 523.ISOcoated.iccP 4052PrintOpen5.2是基于海德堡的PrintOpen4.0.5.2h i n e n A Gl b e r g e r D r u c k m a s c © H e i d eICC 特征4.PSO_Coated_NPscreenISO12647eci icc _ISO12647_eci.icc 是基于海德堡的ColorTool 3——调频网(FM)的标准h i n e n A Gl b e r g e r D r u c k m a s c © H e i d eISO12642-2FOGRA43LORIGINATOR "Fogra, "DESCRIPTOR "FOGRA43L"CREATED "June 2008"CREATED June 2008INSTRUMENTATION "D50, 2 degree, geometry 45/0, no polarisation filter, white backing, according to ISO 13655"PRINT_CONDITIONS "Offset printing, according to ISO 12647-2:2004/Amd1, OFCOM, paper type 1 or 2 = coatedart, 115 g/m2, non-periodic screening, tone value increase curves F (CMYK)"NUMBER_OF_FIELDS 11BEGIN DATA FORMAT h i n e n A G BEGIN_DATA_FORMATSAMPLE_ID CMYK_C CMYK_M CMYK_Y CMYK_K XYZ_X XYZ_Y XYZ_Z LAB_L LAB_A LAB_B END_DATA_FORMAT l b e r g e r D r u c k m a s c NUMBER_OF_SETS 1617BEGIN_DATA© H e i d e色域比较——红色为PSO_Coated_NPscreen _ISO12647_eci.icc——白色为ISOcoated_v2_eci.icc测试软件:Color ToolBox 2010h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e海德堡色彩管理h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e海德堡色彩管理——坚持标准化作业流程1.选择耗材2.确定生产条件3.优化印前流程4.优化印刷机状态5.印刷和测试样张的评估6h i n e n A G6.印刷网点补偿校准7.生成ICC 特性档案l b e r g e r D r u c k m a s c8.检查色彩管理流程© H e i d e (见海德堡小册“色彩管理”第8页)优化印前流程h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e印前色彩管理h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e多色设备的分色h i n e n A Gl b e r g e r D r u c k m a s c© H e i d e印刷放墨数据h i n e n A Gl b e r g e r D r u c k m a s c © H e i d eICC如何制作高品质的印刷1专业生成、专业生成ICC 软件2、仪器设备的准确度3、印刷的质量控制4、标准化实施和方法5、设备以及耗材的稳定性h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e实施色彩管理的过程1、校正印刷机h i n e n A Gl b e r g e r D r u c k m a s c © H e i d e实施色彩管理的过程2、设定墨键转角与开度——PCMEasyh i n e n A Gl b e r g e r D r u c k m a s c © H e i d e密度和网点扩大曲线的确定实施色彩管理的过程3、密度和网点扩大曲线的确定 线性版输出密度的确定测量出印刷网点面积扩大值修订印版的网点h i n e n A G重新出版 相同条件印刷 再修定放墨曲线l b e r g e r D r u c k m a s c © H e i d e实施色彩管理的方法实施色彩管理的方法:最主要方法的就是定密度、改网点1、视觉法——反差(对比度)以视觉判断CMYKRGB 为最高原则定义密度2、色度法——以色度符合ISO12647-2为最高原则定义密度3、灰平衡法△H*的评价方法G7的方法h i n e n A G 4、ICC 方法以上的方法除了方法外其改网点的依据都是遵循ISO126472l b e r g e r D r u c k m a s c G7和ICC 方法外,其改网点的依据都是遵循ISO12647-2的曲线© H e i d e让仪器成为质量控制的导航仪使用528、530 匹配功能,快速调用G7和ISO12647-2的参数S t E ISO1264722007标准数据P t 使用SpectroEye 的最佳匹配功能使用SpectroEye ISO12647-2:2007标准数据、Pantone 数据h i n e n A Gl b e r g e r D r u c k m a s c© H e i d e色彩管理不是终点,是起点END Thanksh i n e n A Gl b e r g e r D r u c k m a s c © H e i d e。

印刷知识:海德堡印刷机变色问题的几个简单处理方法我们在使用海德堡印刷机的时候,往往在使用一段时后可能会出现印变色的情况,对于这一情况,我们广大的海德堡印刷机使用者往往无从下手,而且要花费大量的时和金钱来维修这一情况,针对这一情况,我向大家介绍几个本人人为比较有效的方法,希望在大家使用的过程中能够起到作用。

1.首先我们应该检查我们印刷在版面上的设计是否合理,比如把墨量比较大的图案(或者是四色网的叠加)放在拖稍位置,对于这样的版面设计肯定是不利于我们印刷出高质量的印刷的,我们应该把他们放在叼口位置,这样有利于叼牙对纸张的控制,更容易印刷出不变色的印刷。

2.如果已经出现了印刷变色的情况,我们不要开始就下印刷机本身的问题这样的结论,我们应该先在印刷机的外围寻找原因,我们首先应该使用放大镜观察印刷版上的网点,检查它是否已经出现的网点的变形,如果发现在印刷版上已经出现了网点的变形,那么我们应该对片子进行检查,排除在出片的时候的问题。

3.在我们排除了片子问题之后,我们应该检查墨路系统是否出现问题,检查墨路系统我们可以用很简单的方法,首先我们使用洗车水(可加水)将墨路彻底清洗干净,停车后我们应该检查墨路中是否有白色结晶的颗粒物存在,如果我们发现有这样的物质存在,那么出现的变色情况有可能是结晶物质堆墨尔生的印刷局部变色,这种变色往往更体现出来的刷局部色彩偏色。

在洗车后没有发现这些结晶物质,我们重启动印刷机,打墨到每一根墨辊,打墨结束后我们合上靠版墨辊和靠版水辊,检查压力是否达到标准,如果没有,我建议将所有墨辊压力重调整,已达到较好的状态。

4.在墨路系统没有问题后,我们检查水路的情况,调整好靠版水辊,计量辊,水斗辊,及窜水辊之的压力,特别要调整好中辊的压力,在自己技术不够的条件下中水辊在印刷过程中最好不要使用。

5.如果水墨路都没有问题,我们应该检查橡皮的衬垫是否是标准,我们建议衬垫的厚度应该为35丝,橡皮布最好是牌的带铝条的而且橡皮布最好是的。

印刷流程中的色彩管理(一)印刷流程中的色彩管理(一)色彩管理在各位的生产流程中,可能每一天都会面临到,只是在之前的流程中如何来设定的问题,譬如工具的选用,以及色彩的选用等,而我们在这边提出来的重点是如何针对各位在整个工作流程中,轻易的做到色彩管理。

首先,我们先从印刷厂中怎么样的去做色彩管理的一个架构来看:我们这次实际的去做了一个实验,所使用的工具包括:●上海印刷厂的罗兰五色印刷机700+Pecom●爱克发的色彩管理系统ColorTunePro3.02●海得堡的色彩管理系统PrintOpen3.0●爱克发印前流程管理系统Apogee●台湾巴而可屏幕及色彩管理系统●爱克发印前校样设备Apogee Sherpa43●标准光源D65灯箱在这样的一个架构之下,我们就产生一个印刷的色彩管理流程。

(一)在整个色彩管理流程中最重要,也是色彩管理最后想达到的目标,就是最后要印刷的印刷品,所以我们针对这个部分,必须要先做Printer Profile(印机的色彩描述档),为什么要先做Printer Profile因为我们希望我们色彩仿真的对象是根据最终要去交货的印刷品,先做Printer Profile这样才会有一个依据,因此在整个色彩管理流程中,印机的色彩描述档,必须要先去做,做完之后才可以往前、往下去做,继续推演每一个流程你应该去取得的一个参数。

所以我们做的流程是利用IT8-7/3的一个电子稿直接送进底片输出机,晒成版或利用CTP直接制成印版,在印刷机上利用一个标准印刷条件,这个印刷条件是依据SID(满版印墨浓度)、及DG(网点扩大)来控制的,这两个参数一定要先设定在一般工厂生产的常用值,在这样的设定下去求取印刷机的色彩描述档,而在IT8-7/3的原稿中共有928个色块,利用色度计去量取,就可以得到印刷机的色彩描述档。

(二)另外,我们在仿真印刷机方面利用喷墨打样机直接做出印刷机的打样,在这一个部分我们在喷墨打样机的SID、DG部分必须要先做一个「线性的校正」,让喷墨打样机符合我们印刷机所能印刷出来的色域,而这个「线性校正」所根据的就是之前所说的印刷生产的常用值,否则喷墨打样的样张就可能是印刷机所无法印刷的颜色,经过这样的流程之后,我们就可以得到Proofer Profile(喷墨色彩描述档)(三)屏幕是大家在看档案的一个依据,我们可以利用一些工具来做屏幕的色彩描述文件,它的主要结构都是利用LED的感光,透过滤镜来接收不一样的色彩刺激值X、Y、Z,产生屏幕的色彩描述文件,记录屏幕的色彩记录能力。

xxxxxxxxxxxxxxx股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次/页数第 2 页共26页修订记录版次修订内容编制/日期审核/日期批准/日期A 初版发布B海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次/页数第 3 页共26页目录一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次/页数第 4 页共26页1、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2、适用范围本操作指导书适用于xxxxxxxxxxxxx股份有限公司海德堡四开五色平版印刷机,胶印设备。

3、应用的文件《海德堡四开五色平版印刷机使用说明书》4、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压:380V 额定电流:30A海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次/页数第 5 页共26页温度: 18ºC—25ºC; 相对温度:45%—65%5、胶印简单生产流程图6、技术参数6.1印刷材料:最大纸张尺寸:600*740mm (尺寸F)530*740mm(尺寸C) 最小纸张尺寸:210*350mm 最大纸张厚度:0.8mm 6.2油墨/上光:6.2.1 只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2 上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

6.3 自动清洗装置使用清洗液只允许使用具有下列特性的清洗液:闪点至少达到55℃。

海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次/页数第 6 页共26页苯含量要低于0.1%二甲苯和混合二甲苯的仿量小于1%芳香烃物质含量(>Cg)小于1%清洗剂中不得带有氯化烃,氯化氟代烃,共同点烯,h-已烷,二胺和酰胺。

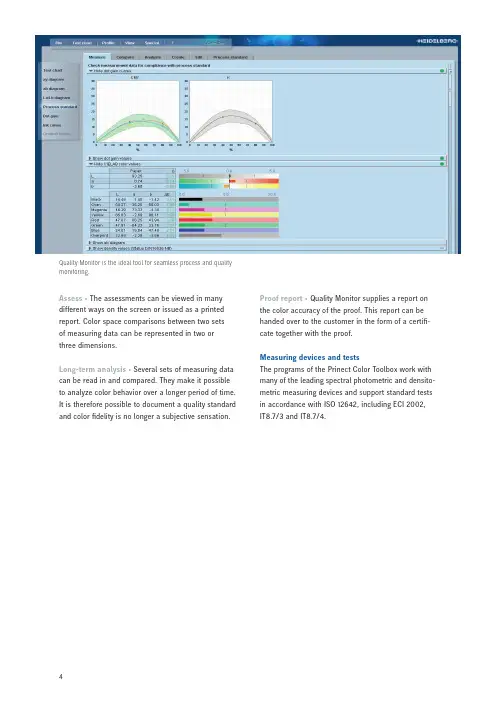

Assess • The assessments can be viewed in manyd ifferent ways on the screen or issued as a printedr eport. Color space comparisons between two sets of measuring data can be represented in two or three d imensions.Long-term analysis • Several sets of measuring data can be read in and compared. They make it possible to analyze color behavior over a longer period of time. It is therefore possible to document a quality standard and color fidelity is no longer a subjective sensation. Proof report • Quality Monitor supplies a report on the color accuracy of the proof. This report can be handed over to the customer in the form of a certifi-cate together with the proof.Measuring devices and testsThe programs of the Prinect Color Toolbox work with many of the leading spectral photometric and densito-metric measuring devices and support standard tests in accordance with ISO 12642, including ECI 2002, IT8.7/3 and IT8.7/4.Quality Monitor is the ideal tool for seamless process and quality monitoring.4elements, which are printed during normal production. Building on an ex-isting profile and the measuring data of the Mini Spots means that a p rofile adjustment can be calculated within a short space of time and is then al-ready available for the next set of plates.Any fluctuations related to the equipment can be recognized and smoothed out with a connectable profile smoothing. This makes Profile Tool the ideal tool for the creation of generic profiles to describe a printing standard.00.993.3615/01 e nHeidelberger Druckmaschinen AG Kurfuersten-Anlage 52–60 69115 Heidelberg GermanyPhone +49 6221 92-00 Fax +49 6221 92-6999 TrademarksHeidelberg, the Heidelberg logotype, Prinect and Mini Spots are registered trademarks of Heidelberger Druckmaschinen AG in the U.S. and other countries. PANTONE and Hexachrome are registered trademarks ofP antone Inc. All other trademarks are property of their respective owners. Subject to technical modifications and other changes.ICC output profiles for the proof • The creation of profiles for the proof is optimized in order to achieve the best possible color adjustment. The iterative proof correction makes it possible to achieve a level of accu-racy in the profile, which reduces the average colord eviation of the proof from the print to an absolute min-imum. An integrated color calculator converts spot colors to the CMYK values of the proofer. This means that the expanded color space of the proofer is fully utilized. The PANTONE® and HKS color tables are in-cluded in the software package.Color measurement and correction • The Profile Tool measures true spectral values in the color fields. All the desired values such as Lab, XYZ, CMYK or den-sity can easily be calculated from this. The program can therefore use values, which have been m easured once, in many ways. Optical brighteners in papers, which are interpreted by measuring devices as shades of blue and would therefore lead to errors in the pro-file calculation, are corrected by the Profile Tool on aspectral basis.Calibration and profiling with one proof run •N ormally a test sheet can be printed first to compile an ICC profile, if a process calibration has been carried out previously. The Profile Tool can also calculate good pro-files from the measuring data of an uncalibrated print taking account of the calibration data of C alibration Tool. This means it is no longer necessary to print and measure test sheets repeatedly, which is time-consum-ing. This saves not only time and materials. It also helps to cope with color management in the overall printing process rapidly and with certainty.Device Link Profile • In many cases it is necessary to align the print customer’s documents directly with one’s own production environment. Profile Tool has the functions necessary to do this. This also includes UCR/GCR functions in order to use less colored ink to achieve the same impression of color. This means that the gray balance can be stabilized and color fluctua-tions avoided. In addition, it is possible to limit the maximum inking of every object, whereby the color ad-justment on the printer can be managed more easily and quickly. Fine-tuning is generally carried out with device link profiles. The Profile Tool creates extremely sophisticated device link profiles for use in the Prinect workflow. There is no need to buy an expensive addi-tional solution for this purpose, as all the necessary functions are already integrated into the profile. P rocess conversions can therefore be carried out from one CMYK printing process to another with a high level of quality.Separation of up to seven colors • By using theo ptional multi color extension, it is possible to produce color separations for 5-, 6- and 7-color printing. The inks for this can be selected in a sequence, which makes sense in colorimetric terms. This means that frequently used color models such as Hexachrome® or HiFi Color are supported to the same extent asc ustomer-specific models.Profile Tool creates extremely sophisticated device linkp rofiles for use in the Prinect workflow.2Calibration ToolCentral management of all the calibration data • Calibration Tool makes it possible to create and cen-trally manage all the calibration data for the lineari-zation and process calibration of CtP platesetters and direct-imaging presses. The tool supports both thel inearization of platesetters and the calibration of the entire process section right up to printing.Thanks to Calibration Tool it is possible to set up as many spot colors in one data set for process calibra-tion as desired. This means that a data set can con-tain either all the process colors or be ap p lied indi-vidually for each separation.A central data pool • In a company with several plate-setters the curves for each output device can easily be arranged and managed. If several platesetters of the same type and using the same materials are de-ployed at the same time, Calibration Tool can be used to organize a central data pool. It is possible to feed the RIP imagesetter stations with the right curves for each job from there – creating ideal conditions for consistent quality at each station.Simple application of calibration curves • The print parameters such as type of paper, ink used, solid tint densities and printing press are stored with each cali-bration curve. Calling up the right curve is controlled by indicating these parameters. Calibration Tool offers only those curves, which are actually suited to the print parameters in the job. This not only makes o peration easier, but also helps to avoid errors.The actual dot gains are generally described by process standards. A range of standards is already provided with their dot gain curves. It is possible to define one’s own process parameters individually for corporate standards.The resulting process curves can be smoothed out in order to compensate for measuring errors.In addition, Calibration Tool offers numerous editing functions to compile new curves, which are superim-posed on an existing calibration. If one parameter changes, then a test sheet does not have to be printed and measured from scratch. All that needs to be done is to calculate the changes using the existing curve.A new, adjusted curve is then available for the next set of plates. Rapid calibration with Prinect Image Control • The interaction of Calibration Tool and Prinect I mage Control color measurement system provides superb rapid and precise calibration with Mini Spots. The mea s uring elements are assessed in one go and a fter a few seconds the measuring data are available for a calibration adjustment.RIP-independent installation • Calibration Tool does not have to be installed on the RIP station. It is also possible to set up a separate calibration station in which the curves are measured and compiled central-ly for the connected RIP imagesetter stations. By ad-ditionally installing Profile Tool, this station can beu pgraded to a central color management workstation within the company.Quality MonitorSeamless process and quality control • Print shops are increasingly applying for certification to a quality standard. This is associated with the requirement of being able to provide evidence of continuous compli-ance with the standard. This is where you need Quality Monitor: It is the ideal tool for seamless p rocess and quality control. It provides every print shop with de-tailed analysis results.Both printing companies, which already document the high standard through their certification, as well as companies, which are just starting out with standard-ized printing, can demonstrate the high quality of their work and present it clearly at any time with Quality Monitor. Detailed reports, even compiled over a longer period of time, therefore serve both as documents for control as well as evidence of reliable production at a consistently high level.All the decisive tasks of process supervision andm onitoring the proof and print can be carried out with Quality Monitor:Measure • Numerous keys, linearization strips and entire test sheets can be measured out with spectral photometers, densitometers or plate measuringd evices.Compare • Quality Monitor permits comprehensive comparisons between two sets of measuring data, e. g. the deviation between the proof and print or print standard or the deviation in a print run.3。

海德堡冬季大学Mar-07Guideline of Print Color Management 印刷色彩管理方案Karl Kowalczyk Vice President Print Media Center© Heidelberger Druckmaschinen AG • Winter University • Dec-06 • Karl Kowalczyk • Page 1海德堡冬季大学Mar-07Overview about all steps (一般步骤)1. Presentation of the Print Color Management Concept (色彩管理概念介绍) 2. Measurement of linear exposed plates (印版线性化) 3. Printing the test form on SM 74 / 102 press (印刷测试导表) 4. Evaluation of the printed OK-sheets (获取合格样张) 5. Process calibration in prepress (校正印前设备) 6. Optimization of the press (优化印刷设备) 7. Printing the calibrated test form on SM 74 / 102 (印刷经校正过的测试导表) 8. Measurement of the IT8 / PrintOpen Charts (测量IT8/PrintOpen 导表) 9. Creating an ICC profile of the press (生成印刷机的ICC曲线) 10. Proof output with the new ICC-profile (用新生成的ICC曲线输出数码样) 11. Printing the production job on SM 74 / 102 press (进行印刷生产)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 22 of 16海德堡冬季大学Mar-071. Presentation of the Print Color Management Concept(印刷色彩管理介绍)- Introduction (概念介绍) - Presenting the used testforms (测试导表介绍)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 33 of 16海德堡冬季大学Mar-072. Measurement of linear exposed plates(印版输出线性化)- Checking the plates of the uncalibrated “ColorCalibration” ..testform if they are linear (测量测试版是否是线性的) - The measured coverage on the plate should be the same as ..in the file (印版图案覆盖率应与文件一致)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 44 of 16海德堡冬季大学Mar-073. Printing the testform on SM74 / 102 press(印刷测试导表)- Make ready of the “ColorCalibration” testform on the press(上机准备“经校正过“的印版)- Printing the job with the desired inking standard.(按期望的墨量印刷测试活件)- Measuring the LAB values with Image Control(用图像控制仪测量印张的LAB值)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 55 of 16海德堡冬季大学Mar-074. Evaluation of the printed OK-sheets (获取合格的样张)- Measuring the actual dot gain of the press with ColorInterface, the new software module of Prinect Image Control(用图像控制仪测量样张的网点扩大率)- Saving the measured data to a file (把测量数据存贮成一个文件) - Making the file available for the RIP (把此文件转换为RIP能识别的格式)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 66 of 16海德堡冬季大学Mar-075. Process calibration in prepress (印前设备校正)- Creating a new transfer curve in the RIP for the calibrated plate ..exposure(在RIP里生成一条用于印版输出的曲线)- Exposing the "ColorCalibration" testform with new calibration(用所生成的曲线输出测试印版)100 90 80 70 60 Druck 50 40 30 20 10 0 0 10 20 30 40 50 60 70 80 90 100 Daten© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 77 of 16海德堡冬季大学Mar-076. Optimization of the press (印刷机优化)- Theoretical representation of the proceeding for the press ..optimization(将设备设定到最佳状态)- Structure and function of the "PressCalibration" test form(设定印刷机放墨曲线)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 88 of 16海德堡冬季大学Mar-077. Printing the calibrated test form on SM 74 / 102 press(印刷经校正过的测试导表) - Make ready of the calibrated “ColorCalibration” testform on ..the press (安装经校正过的测试版) - Printing the test form with the desired inking standard(按要求印到所需密度)- Measuring the dot gain with ColorInterface (测量网点扩大率) - Comparing the actual dot gain with the target dot gain(比较实际与期望网点扩大率)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 99 of 16海德堡冬季大学Mar-078. Measurement of the IT8 / PrintOpen Charts(测量IT8/PrintOpen 导表)- Measuring the IT8 / PrintOpen Charts with ColorInterface(用图像控制仪测量IT8导表)- Saving the LAB values to a file for the PrintOpen software PtintOpen(用软件能识别的格式将LAB值存成一个文件)One LAB value for each patch(每一色块对应一个LAB值)© Heidelberger Druckmaschinen AG • Karl Kowalczyk • Winter University • Dec-06 • Page 1010 of 16©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 119. Creating an ICC profile of the press-PrintOpen reads the file with the measured LAB values and ..creates an ICC-profile which describes the color space of the ..press(PrintOpen (解读文件里的LAB值并产生印刷机的色域)-Comparing the proofer profile with the press profile in the ..CIE-LAB color space (比较数码样与印刷样的色域)(生成印刷机的ICC 曲线)©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 1210. Proof output with the new ICC profile-Saving the ICC-profile of the press in the RIP of the proofer (将印刷机的ICC 存于打样机的RIP 里)-Printing a typical production job with the new ICC-profile(用新的ICC 生产一个印刷活件)(用新的ICC 曲线输出数码样)©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 1311. Printing the production job on SM 74 / 102 press-Printing the production job with the desired inking standard(用设定密度印刷产品)-Visual comparison with the proof(印刷品与数码样进行视觉比较)(正式生产)©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 14©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 15©Heidelberger Druckmaschinen AG •Karl Kowalczyk •Winter University •Dec-06 •Page 16Thank you for your attention.(谢谢!)Karl KowalczykHeidelberger Druckmaschinen AGPrint Media Center。

PRINTING FIELD 2020.05数字印刷是将数字图文信息直接转移至承印物上的复制过程。

整个过程接近于打印,故其色彩管理一般是按照打印机色彩管理流程进行的。

一、操作方法色彩管理系统的工作过程通过所谓的“3C”进行控制,即设备校正(Calibration)、特征化(Characterization)和色彩转换(Conversion),代表了色彩管理技术实施的三个重要环节。

本文按照这三个步骤进行数字印刷机的色彩管理操作实践。

其中用到的相关设备、测试工具软件和色表如下。

1.数字印刷机:海德堡Versafire EV;2.测试设备:EFI ES 2000,爱色丽i1 isis2 XL;3.测试色表:IT8.7/4Randomisis(A3).pdf、CI_GrayConM_i1_FOGRA51_v3_15mm.pdf;4.对比参考文件:Fogra51Random.txt;5.打印和测试软件:PrinectCockpit,Color Toolbox。

二、操作过程1.设备校正数字印刷机的校正(线性化)是保障数字印刷机处于稳定状态的重要操作。

操作方法是利用数字印刷机打印内置的测试文件,利用分光光度计测试文件中不同色块的密度值,跟目标值比较,然后进行自动补偿和修正。

数字印刷机的校正实质上是在其他参数确定的前提下,对某类纸张进行校正。

海德堡印通DF E流程中定义了多种纸张,常用的有光面纸、磨砂纸和普通纸(非涂布纸)三种。

首先,将需要做校准的纸张放到纸盘中,在Prinect Cockpit屏幕右上角选择打印管理器,在打印管理器界面选择校准标签。

在预定义的校准数据中选择接近要校准纸张的数据作为目标数据,用复制的方法建立一个新的校准数据。

在这里不能选择新建,否则就没有目标数据了。

另外不要复制结尾带有(日本纸)标记的预设数据,因为这些预设值仅针对日本纸设定。

接下来设定校准的名称,校数字印刷机色彩管理操作实践于士才则应循环上面的操作直至符合要求。

(完整版)海德堡印刷机操作手册xxxxxxxxxxxxxxx股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养1、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2、适用范围本操作指导书适用于xxxxxxxxxxxxx股份有限公司海德堡四开五色平版印刷机,胶印设备。

3、应用的文件《海德堡四开五色平版印刷机使用说明书》4、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压:380V 额定电流:30A频率:50HZ 气压:≥6kg/c㎡温度: 18oC—25oC; 相对温度:45%—65%、胶印简单生产流程图56.1印刷材料:最大纸张尺寸:600*740mm (尺寸F)530*740mm(尺寸C) 最小纸张尺寸:210*350mm 最大纸张厚度:0.8mm 6.2油墨/上光:6.2.1 只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2 上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

6.3 自动清洗装置使用清洗液只允许使用具有下列特性的清洗液:闪点至少达到55℃。

苯含量要低于0.1%二甲苯和混合二甲苯的仿量小于1%芳香烃物质含量(>Cg)小于1%清洗剂中不得带有氯化烃,氯化氟代烃,共同点烯,h-已烷,二胺和酰胺。

6.4 清洗剂和溶剂:要使用其闪点至少不55℃的清洗剂和溶剂。

6.5 噪声释放量:输纸机的噪声等线为84 dB(A)输纸机控制台处的噪声等级为:82dB(A)高纸堆收纸机上的噪声等级为:83 dB(A)6.6纸堆的最大重量:输纸机重量:1000kg收纸机重量:1000kg7、劳动安全要求应遵守公司内部的劳动安全条例。

13/06/2005Drupa Training Phase III, Shenzhen d i a C e n t r e S h e n z h e n W a l t e r W a n g印刷色彩与质量控制印刷质量控制的基本原理海德堡深圳印刷媒体技术中心徐斌13/06/2005diaCentreShenzh enWalterW ang胶印中的质量控制------为什么?当说明一个印刷任务时,下列内容可用数字表示:尺寸,以厘米和毫米或英寸表示页数印数价格期限,以天和小时计然而,长期以来却一直没有鉴定实际印刷质量的指标。

其他工业部门是遵循“满足所需准确度”的方针根据预定的基准数据组织生产,但即使在今天许多印刷厂仍然一直致力于“尽可能好地”印刷。

然而,由于没有客观的质量控制标准,结果往往变为“什么也不是”。

除了象环状白斑、起脏、糊版、划痕和套准等指标之外,印刷质量是根据网点和颜色复制的真实程度以及印刷过程中的稳定性来鉴定的。

客户不满意的最常见原因是原件和印刷图案色彩的差异以及印刷过程中色彩的变化。

Print B Print C13/06/2005diaCentreShenzh enWalterW ang目视鉴定色相所遇到的困难。

除了背景颜色会影响色彩鉴定之外,由于照明的不同以及每一印刷工人对色彩的感觉不同,因而只能作出主观的鉴定。

胶印中的质量控制------为什么?diaCentreShenzh enWalterW an gdiaCentreShenzh enWalterW an gdiaCentreShenzh enWalterW an g13/06/2005d i a C e n t r e S h e n z h e n W a l t e r W a ng 有各种工具可以帮助目视检查,例如:-标准化的5000K检查灯-印刷中的套准控制标记-显示网点变化的信号条-网点伸长、重影和油墨叠印度的控制区(控制条)。

xxxxxxxxxxxxxxx股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:目录一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养1、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2、适用范围本操作指导书适用于xxxxxxxxxxxxx股份有限公司海德堡四开五色平版印刷机,胶印设备。

3、应用的文件《海德堡四开五色平版印刷机使用说明书》4、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压:380V 额定电流:30A频率:50HZ 气压:≥6kg/c㎡温度: 18oC—25oC; 相对温度:45%—65%5、胶印简单生产流程图6、技术参数6.1印刷材料:最大纸张尺寸:600*740mm (尺寸F)530*740mm(尺寸C) 最小纸张尺寸:210*350mm 最大纸张厚度:0.8mm 6.2油墨/上光:6.2.1 只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2 上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

6.3 自动清洗装置使用清洗液只允许使用具有下列特性的清洗液:闪点至少达到55℃。

苯含量要低于0.1%二甲苯和混合二甲苯的仿量小于1%芳香烃物质含量(>Cg)小于1%清洗剂中不得带有氯化烃,氯化氟代烃,共同点烯,h-已烷,二胺和酰胺。

6.4 清洗剂和溶剂:要使用其闪点至少不55℃的清洗剂和溶剂。

6.5 噪声释放量:输纸机的噪声等线为84 dB(A)输纸机控制台处的噪声等级为:82dB(A)高纸堆收纸机上的噪声等级为:83 dB(A)6.6纸堆的最大重量:输纸机重量:1000kg收纸机重量:1000kg7、劳动安全要求应遵守公司内部的劳动安全条例。

注意:所有设备操作人员必须经过培训。

xxxxxxxxxxxxxxx股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:质量环境管理体系设备操作手册文件名称:海德堡四开五色平版印刷机操作手册文件编号文件版本修改状态生效日期页次 /页数第 2 页共26 页修订记录版次修订内容编制/日期审核/日期批准/日期A初版发布B质量环境管理体系设备操作手册文件名称:海德堡四开五色平版印刷机操作手册文件编号文件版本修改状态生效日期页次 /页数第 3 页共26 页目录一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养质量环境管理体系设备操作手册文件名称:海德堡四开五色平版印刷机操作手册文件编号文件版本修改状态生效日期页次 /页数第 4 页共26 页1 、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2 、适用范围本操作指导书适用于xxxxxxxxxxxxx股份有限公司海德堡四开五色平版印刷机,胶印设备。

3 、应用的文件《海德堡四开五色平版印刷机使用说明书》4 、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压: 380V 频率: 50HZ 额定电流: 30A气压:≥6kg/c㎡质量环境管理体系设备操作手册文件名称:文件编号海德堡四开五色平版印刷机操作手册文件版本修改状态生效日期页次 /页数第5页共26页温度 : 18 oC— 25oC;相对温度:45%—65%5 、胶印简单生产流程图胶印原材料大张检验丝印6 、技术参数6.1 印刷材料:最大纸张尺寸: 600*740mm(尺寸F)530*740mm(尺寸C)最小纸张尺寸: 210*350mm最大纸张厚度:0.8mm 6.2 油墨 / 上光:6.2.1 只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2 上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

xxxxxxxxxxxxxxx股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:目录一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养1、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2、适用范围本操作指导书适用于xxxxxxxxxxxxx股份有限公司海德堡四开五色平版印刷机,胶印设备。

3、应用的文件《海德堡四开五色平版印刷机使用说明书》4、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压:380V 额定电流:30A频率:50HZ 气压:≥6kg/c㎡温度: 18ºC—25ºC; 相对温度:45%—65%、胶印简单生产流程图56.1印刷材料:最大纸张尺寸:600*740mm (尺寸F)530*740mm(尺寸C) 最小纸张尺寸:210*350mm 最大纸张厚度:0.8mm 6.2油墨/上光:6.2.1 只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2 上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

6.3 自动清洗装置使用清洗液只允许使用具有下列特性的清洗液:闪点至少达到55℃。

苯含量要低于0.1%二甲苯和混合二甲苯的仿量小于1%芳香烃物质含量(>Cg)小于1%清洗剂中不得带有氯化烃,氯化氟代烃,共同点烯,h-已烷,二胺和酰胺。

6.4 清洗剂和溶剂:要使用其闪点至少不55℃的清洗剂和溶剂。

6.5 噪声释放量:输纸机的噪声等线为84 dB(A)输纸机控制台处的噪声等级为:82dB(A)高纸堆收纸机上的噪声等级为:83 dB(A)6.6纸堆的最大重量:输纸机重量:1000kg收纸机重量:1000kg7、劳动安全要求应遵守公司内部的劳动安全条例。

注意:所有设备操作人员必须经过培训。

(流程管理)海德堡 PCM 流程方案海德堡色彩管理客户前期准备、执行及保持维护色彩管理的终极目标就是让所有的技术人员更深入的了解印刷,了解影响色彩还原的因素和解决方法。

做到有能力提前预知,有能力提前预防。

为什么要做色彩管理1:在屏幕上看来漂亮的色彩,在印刷后却晦暗浑浊,黯然失色,与屏幕所见到的却是两回事。

2:一幅图用彩色打印机打印时颜色令人满意,而印刷时则颜色灰暗。

3:同样的数据在不同的设备上得不到同样的颜色。

4:不能确定客户的文件印刷出来是什么样子(不可预见)。

5:需要多次打样调色,才能追到客户的标准色样,浪费了成本,延误了交样时间,影响了客户的信任度。

色彩管理系统的目的,就是通过对所有设备的管理、补偿和控制这些设备间的差别,以得到精确的可预测的色彩。

一个色彩管理系统应该包括:1.一个色彩匹配处理程序。

即色彩管理模块。

2.一个与设备无关的色彩空间。

通常叫做参考色彩空间或特性文件连接空间,在转换过程中起着连接的作用。

3.设备特性文件。

设备特性化是用以界定输入设备可辨识的色域范围与输出设备可复制的色域范围的工作,并将不同设备之间 RGB 或 CMYK 的色彩与 CIE 所制定的设备色彩建立设备色彩与设备独立色彩间的色彩转换对应文件,该文件被称为设备特性文件。

满足三大特性:高度可预见性高度可还原性高度一致性核心工作:a.实现屏幕打样的印刷色彩模拟b.实现数码打样的高度色彩还原c.实现印刷机的可重复操作性。

稳定压倒一切!!!项目开始前明确目的:1.参照国标,确立公司的印刷标准;2.找准 CTP 制版的线性,确立出版的要求;3.确立印刷机的各类参数,以书面形式做记录;4.得到公司自己的标样,围绕此标样进行数码打样的线性校正与参数设置,并得到印刷机的ICC;5.正确设置工作流中的色彩参数匹配,尽可能实现“所见即所得”;6.C IP3 数据的建立生成与正确的调用;7.发掘可能存在的问题,找出解决方案。

什么是印刷色彩管理?•它一种方法校准整个从印前到印刷流程•目标是使流程标准化,允许以最小的损耗达到希望的印刷结果•包括培训操作人员印刷机状态标准化色彩管理的核心在于色彩校正技术维持色彩稳定的核心在于标准化作业的执行只有将材 料、印 刷 机、及 环 境 都做到标准化了,才可能谈得上印刷品质的稳定控制,因为这是保证产品质量的基础。

xxxxxxxxxxxxxxx 股份有限公司印刷车间海德堡四开五色平版印刷机操作指导书文件编号:文件版本:发放号码:受控状态:生效日期:编制:审核:批准:目录一、目的二、适用范围三、应作文件四、生产设备五、胶印简单流程图六、技术参数七、劳动安全及生产要求八、设备操作与保养1、目的本操作指导书为设备操作人员操作海德堡四开五色平版印刷机进行相关的质量检验提供工作指导。

2、适用范围本操作指导书适用于 xxxxxxxxxxxxx 股份有限公司海德堡四开五色平版印刷机,胶印设备。

3、应用的文件《海德堡四开五色平版印刷机使用说明书》4、生产设备德国海德堡机械有限公司所生产四开五色平版印刷机介质电压:380V 额定电流:30A频率:50HZ 气压:≥6kg/c㎡温度: 18ºC—25ºC; 相对温度:45%—65%5、胶印简单生产流程图6、技术参数6.1印刷材料:最大纸张尺寸:600*740mm (尺寸 F)530*740mm(尺寸 C) 最小纸张尺寸:210*350mm 最大纸张厚度:0.8mm 6.2油墨/上光:6.2.1只能够使用单张纸胶印机专用印刷油墨和上光材料。

6.2.2上光装置中只允许使用水基分散上光液,在使用紫外线上光液时,则需要使用专手型印刷机型。

6.3自动清洗装置使用清洗液只允许使用具有下列特性的清洗液:闪点至少达到55℃。

苯含量要低于 0.1%二甲苯和混合二甲苯的仿量小于 1%芳香烃物质含量(>Cg)小于 1%清洗剂中不得带有氯化烃,氯化氟代烃,共同点烯,h-已烷,二胺和酰胺。

6.4清洗剂和溶剂:要使用其闪点至少不55℃的清洗剂和溶剂。

6.5噪声释放量:输纸机的噪声等线为 84 dB(A)输纸机控制台处的噪声等级为:82dB(A)高纸堆收纸机上的噪声等级为:83 dB(A)6.6纸堆的最大重量:输纸机重量:1000kg收纸机重量:1000kg7、劳动安全要求应遵守公司内部的劳动安全条例。