连续管钻井水力参数计算软件工具全接

- 格式:xls

- 大小:70.50 KB

- 文档页数:9

钻井现场常用软件使用说明和总结★钻井现场常用软件使用说明和总结★最近和钻井院的老同学聚会时,我让他介绍工作经验他说“到了工作单位上才发现以前大学的时光白浪费了,特别是大四签工作以后拿半学期”他向我推荐重点学习一些钻井方面的应用软件。

即使看看介绍到了单位上你也会受益匪浅!至少你听过,知道它有什么功能!这就比别人强!为此我在网上总结了现在现场应用较多的钻井软件和大家分享!大家有什么不懂得和我联系!(就算是本人向即将工作的师兄师弟们送的小礼物,以后这用到了到这里来回贴阿,为了你的前途建议你花点时间全部看完!)1、Sysdrill钻井设计软件版本 2002平台 Windows简介Paradigm的钻井设计软件86. CEMPRO.v3.2.1版本 3.2.1平台 Windows简介一款优化钻井液浆替换法软件,主要用来固井作业时的流体力学分析。

2、CEMVIEW 2.0.0固井作业软件版本 2.0.0平台 Windows简介一款直观、功能强大的计算固井作业所需材料、使用量、成本的软件。

3、TADPRO 3.2.1版本 3.2.1平台 Windows简介计算钻井平台各种施工如扭距,拖拉,钻孔的参数,防止危险事故发生。

可视化的3D井孔,井钻。

可自动生成Word报告。

含有多种模型参数供调用。

4、PowerLog 2.61a版本 2.61a平台 Windows简介一套专业的油井勘探记录分析工具!对从发现到开发的数据进行详细的分析和证明,以达到准确。

5、Vcpk压井系统版本 1.0平台 Windows简介Vcpk系统是由西南石油学院钻井实验室开发设计制作的。

Vcpk 系统以一种全新的压井理论进行压井。

有效的控制了在生产实践中的不安全因互素出现,导致违规操作。

6.SlimHyd是一套钻井水力学软件各种类型井眼(包括小井眼)循环系统压力计算、钻头压降、井眼清洁状况、最低循环排量设计、喷嘴优化、测斜数据处理7.Wellead 井眼轨迹设计软件各种类型井眼轨迹设计、跟踪计算、误差分析、防碰扫描和显示8.Tadpro 摩阻和扭矩分析软件各种类型井眼钻压设计、钻柱强度校核、各种工况的管柱弯曲状态及动态模拟、各种工况的摩阻扭矩及动态模拟大钩载荷、钻机负荷预测9.SlimHyd 钻井水力学软件各种类型井眼(包括小井眼)循环系统压力计算、钻头压降、井眼清洁状况、最低循环排量设计、喷嘴优化、测斜数据处理10.Cempro 固井设计和监测软件各种类型井眼的固井排量设计、循环系统压力计算、流型分析、体积计算、U型管效应、测井井径处理、测斜数据处理、施工动态模拟11.CemView 固井作业工具包井眼和管柱建立向导、井眼和井内流体图形显示、体积计算、添加剂计算和管理、成本计算和水泥浆配方、报表标准化12.CasingDesign 套管设计和强度校核软件各种类型井眼的套管载荷计算、管材设计、强度校核(等安全系数法、双轴应力、三轴应力模型)13.CentraDesign 扶正器安装设计和套管居中度分析软件各种类型井眼扶正器安装位置设计和套管居中度分析14.CasingRun 下套管软件各种类型井眼套管起下钻(可考虑旋转)载荷分析、下钻的可行性分析、大位移井的漂浮下套管设计15.SurgeMod 起下钻和起下套管安全速度分析软件各种类型井眼的起下钻和起下套管柱时的井筒压力剖面、保证井眼完整性的最大允许速度设计16.Cleanup 完井液和洗井液顶替模拟软件各种类型井眼的完井液和洗井液排量设计和顶替过程动态模拟UnRiskIT 钻井风险经济评价各种类型井眼钻井风险分析、欠平衡钻井的经济可行性分析,使用蒙特卡罗模型17.Hubs 欠平衡钻井设计和监测软件各种类型流体钻井(包括气体钻井)的设计、分析、地层出水/油/气处理、相变、快捷排量设计、排量优化设计18.Drillworks 地层压力预测软件1、标准版本Standard:使用测井数据进行三个地层压力的预测,3D显示2、专业版本Pro:除测井资料外,还可以使用地震数据进行三个地层压力的预测;井壁稳定性分析3、专家版本Expert:通过盆地建模,可以进行各种地层(如碳酸岩)的地层压力预测19基于IADC的钻井报表管理系统IADC(International Association of Drilling Contractors)钻井工程报表是国际钻井承包商协会制定的钻井生产报表,IADC报表融入了先进的管理理念,现已被世界各大油公司广泛采用。

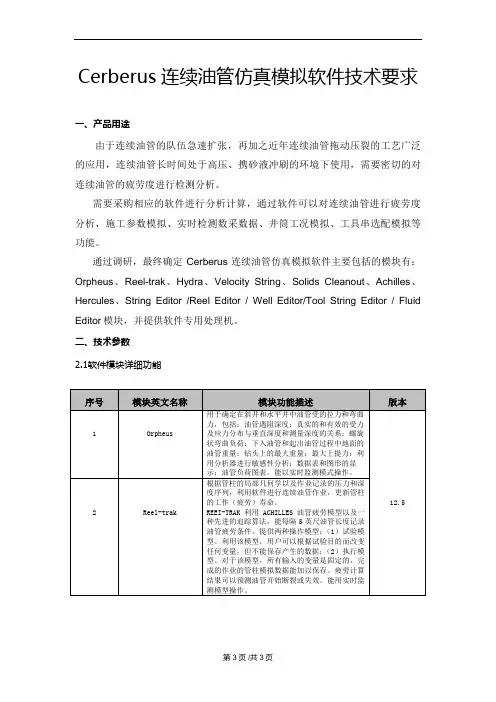

Cerberus连续油管仿真模拟软件技术要求

一、产品用途

由于连续油管的队伍急速扩张,再加之近年连续油管拖动压裂的工艺广泛的应用,连续油管长时间处于高压、携砂液冲刷的环境下使用,需要密切的对连续油管的疲劳度进行检测分析。

需要采购相应的软件进行分析计算,通过软件可以对连续油管进行疲劳度分析,施工参数模拟、实时检测数采数据、井筒工况模拟、工具串选配模拟等功能。

通过调研,最终确定Cerberus连续油管仿真模拟软件主要包括的模块有:Orpheus、Reel-trak、Hydra、Velocity String、Solids Cleanout、Achilles、Hercules、String Editor /Reel Editor / Well Editor/Tool String Editor / Fluid Editor模块,并提供软件专用处理机。

二、技术参数

2.1软件模块详细功能

2.2 软件载体处理机参数要求

(1)处理系统Windows10,64位系统,简体中文版;

(2)处理器:Inter i5-7200U或以上;

(3)内存4GB或以上;

(4)DirectX版本:DirectX12或以上。

(5)要求软件专机专用,使用硬件加密方式。

三、产品检验

依据有关标准,协议要求,合同及供方出具的相关技术文件对软件使用、各部性能进行检查验收。

生产过程中的组织、生产、检验由乙方负责。

四、产品质量保证及服务

1. 乙方提供软件培训;

2. 现场应用出现问题时,乙方服务人员及时向现场用户提供技术支持。

3. 每年密钥认证由乙方无偿提供。

井下作业公司压裂分公司

2018年9月17日。

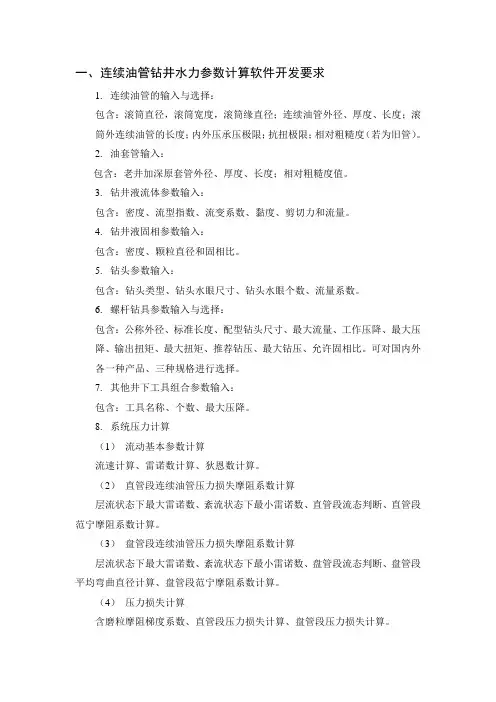

一、连续油管钻井水力参数计算软件开发要求1.连续油管的输入与选择:包含:滚筒直径,滚筒宽度,滚筒缘直径;连续油管外径、厚度、长度;滚筒外连续油管的长度;内外压承压极限;抗扭极限;相对粗糙度(若为旧管)。

2.油套管输入:包含:老井加深原套管外径、厚度、长度;相对粗糙度值。

3.钻井液流体参数输入:包含:密度、流型指数、流变系数、黏度、剪切力和流量。

4.钻井液固相参数输入:包含:密度、颗粒直径和固相比。

5.钻头参数输入:包含:钻头类型、钻头水眼尺寸、钻头水眼个数、流量系数。

6.螺杆钻具参数输入与选择:包含:公称外径、标准长度、配型钻头尺寸、最大流量、工作压降、最大压降、输出扭矩、最大扭矩、推荐钻压、最大钻压、允许固相比。

可对国内外各一种产品、三种规格进行选择。

7.其他井下工具组合参数输入:包含:工具名称、个数、最大压降。

8.系统压力计算(1)流动基本参数计算流速计算、雷诺数计算、狄恩数计算。

(2)直管段连续油管压力损失摩阻系数计算层流状态下最大雷诺数、紊流状态下最小雷诺数、直管段流态判断、直管段范宁摩阻系数计算。

(3)盘管段连续油管压力损失摩阻系数计算层流状态下最大雷诺数、紊流状态下最小雷诺数、盘管段流态判断、盘管段平均弯曲直径计算、盘管段范宁摩阻系数计算。

(4)压力损失计算含磨粒摩阻梯度系数、直管段压力损失计算、盘管段压力损失计算。

(5) 地面管汇压力损失计算 (6) 钻头喷嘴压力损失计算 (7) 环空压力损失计算 要考虑相对粗糙度的值。

(8) 泵压计算 9. 合适排量计算(1)根据环空返速得到的最低流量1 环空返速输入;最低流量1计算。

(2)连续管钻井水平井筒携岩最低流量2岩屑直径、密度、固相质量浓度和体积浓度输入;环空沉降末速计算;考虑絮凝干扰沉降末速计算;水平井筒携岩最低流量2。

(3)根据连续油管内压承载极限反算的最大允许流量1 (4)根据连续油管内压承载极限反算的最大允许流量2 (5)根据所选螺杆钻具得到的最大允许流量3 (6)连续油管钻井合适排量推荐二、相关计算模型推荐(一)压降计算CT 内流体的摩阻损失通常表示为压力降低的形式,即:22f L v P f dρ∆=中L 和d 分别是管长和管径,v 是管内的平均速度,f 是范宁Fanning 摩擦因子,它与流体的雷诺数、管壁的粗糙度等因素有关。

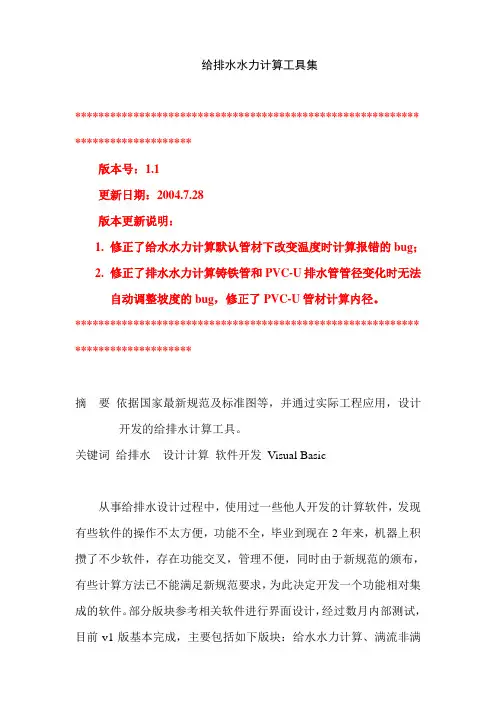

给排水水力计算工具集*********************************************************** ********************版本号:1.1更新日期:2004.7.28版本更新说明:1.修正了给水水力计算默认管材下改变温度时计算报错的bug;2.修正了排水水力计算铸铁管和PVC-U排水管管径变化时无法自动调整坡度的bug,修正了PVC-U管材计算内径。

*********************************************************** ********************摘要依据国家最新规范及标准图等,并通过实际工程应用,设计开发的给排水计算工具。

关键词给排水设计计算软件开发Visual Basic从事给排水设计过程中,使用过一些他人开发的计算软件,发现有些软件的操作不太方便,功能不全,毕业到现在2年来,机器上积攒了不少软件,存在功能交叉,管理不便,同时由于新规范的颁布,有些计算方法已不能满足新规范要求,为此决定开发一个功能相对集成的软件。

部分版块参考相关软件进行界面设计,经过数月内部测试,目前v1版基本完成,主要包括如下版块:给水水力计算、满流非满流水力计算、雨水水力计算、消火栓水力计算、灭火器配置计算、化粪池选型、钢制管件、防水套管、排水管件。

下面将介绍各版块的设计依据及设计思路。

1. 给水水力计算用于钢衬塑复合管、PP-R 冷、热水管、薄壁不锈钢管、衬树脂铸铁管、普通钢管、铸铁管、铜管的水力计算。

设计依据《建筑给排水设计规范》 GB50015-2003 《给水排水设计手册》第二版《2003全国民用建筑工程设计技术措施》给排水分册 沿程水头损失h i =k ·i ·L= k ·105C h -1.85d j -4.87q g 1.85·L, 流速v=2g 41q j d Sh i -沿程水头损失 i-单位长度水头损失d j-管道计算内径q g-给水设计流量C h-海澄-威廉系数L-管道长度v-流速k-温度修正系数,默认值为1.0当输入流量、管长后,选择管材、管径,软件自动确定海澄-威廉系数、计算内径等。

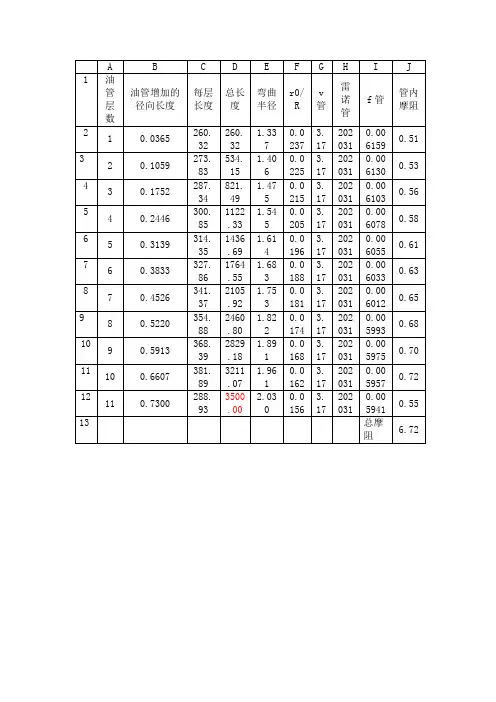

A B C D E F G H I J1 油管层数油管增加的径向长度每层长度总长度弯曲半径r0/Rv管雷诺管f管管内摩阻21 0.0365 260.32260.321.3370.02373.172020310.0061590.5132 0.1059 273.83534.151.4060.02253.172020310.0061300.5343 0.1752 287.34821.491.4750.02153.172020310.0061030.5654 0.2446 300.851122.331.5450.02053.172020310.0060780.5865 0.3139 314.351436.691.6140.01963.172020310.0060550.6176 0.3833 327.861764.551.6830.01883.172020310.0060330.6387 0.4526 341.372105.921.7530.01813.172020310.0060120.6598 0.5220 354.882460.801.8220.01743.172020310.0059930.68109 0.5913 368.392829.181.8910.01683.172020310.0059750.701110 0.6607 381.893211.071.9610.01623.172020310.0059570.721211 0.7300 288.933500.002.030.01563.172020310.0059410.5513 总摩阻6.72A B C D E F G H I J K L14 清水15 套管直径套管壁厚S环空v环空摩阻1摩阻2雷诺环空f环空0.005004直段盘管段15 0.1397 0.012100.00631.5892.041.45679510.004870.0061755.580.05.5817 0.1778 0.016260.01240.8070.320.23586810.005030.0061163.981.955.9318 0.006033 0.06.726.7219 Nreg环空水基泥浆Nreg管20 4.97 3.551580 0.010130.0063954444521 1.55 1.11769 0.020810.0076108.360.08.3622 0.007532 5.972.818.7823 0.007416 0.09.699.691K L M N O P Q R S T1 狄恩数DECT直径DCT厚度TCT内径d筒芯直径TD绝对粗糙度ks相对粗糙度KSNRe1 Q(L/min)2 31548 0.0730.00480.06342.60.0000472440.0007451741015096003 299654 直段长度盘管段长度密度Pn k a b △Pg5 第1种情况3500 清水1006 1 0.001 0.07860.25 0.0246 第2种情况2501000 水基泥浆1180 0.52564 0.8213 0.07300.28990.1047 全盘在滚筒上0 35002A B C D E F1 油管层数油管增加的径向长度每层长度总长度弯曲半径r0/R2 1 B2=$L2/2 C2=2*PI()*31*E2D2=C2E2=$O$2/2+$L$2/2F2=$N$2/2/E23 2 B3=B2+$L$2*0.95C3=2*PI()*31*E3D3=C3+D2E3=E2+$L$2*0.95F3=$N$2/2/E34 3 B4=B3+$L$2*0.95C4=2*PI()*31*E4D4=C4+D3E4=E3+$L$2*0.95F4=$N$2/2/E43G H I J1 v管雷诺管f管管内摩阻2 G2=($S$2/60000)/(PI()*$N$2^2/4)H2=$O$5*$N$2*$G2/$Q$5I2=$I$15+(0.0075*(F2)^0.5)J2=C2*$O$5*G2*G2*I2*2/$N$2/10000003 G3=($S$2/60000)/(PI()*$N$2^2/4)H3=$O$5*$N$2*$G3/$Q$5I3=$I$15+(0.0075*(F3)^0.5)J3=C3*$O$5*G3*G3*I3*2/$N$2/10000004G4=($S$2/60000)/(PI()*$N$2^2/4)H4=$O$5*$N$2*$G4/$Q$5I4=$I$15+(0.0075*(F4)^0.5)J4=C4*$O$5*G4*G4*I4*2/$N$2/1000000 45N1 CT内径d2 N2 =$L$2-2*$M$26Q R1 相对粗糙度KS NRe12 Q2=$P$2/$N$2 R2=59.7/(2*Q2)^(8/7)7R S T 4 a b △Pg5 R5=(LOG10(P5)+3.93)/50 S5=(1.75-LOG10(P5))/7T5=0.0003767*($O5/1000)^0.8*($Q5*1000)^0.2*($S$2/60)^1.86 R6=(LOG10(P6)+3.93)/50 S6=(1.75-LOG10(P6))/7T6=0.0003767*($O6/1000)^0.8*($Q6*1000)^0.2*($S$2/60)^1.88 K1 狄恩数DE2 K2=H2*($N$2/2/1.3)^0.53 K3=H3*($N$2/2/1.441)^0.5C D E15 S环空v环空摩阻116 C16=PI()*(($A16-2*$B16)^2-$L$2^2)/4 D16=36/3600/$C16E16=2*$H$16*$L$5*$O$5*$D16^2/($A16-2*$B16-$L$2)/100000017 C17=PI()*(($A17-2*$B17)^2-$L$2^2)/4 D17=36/3600/$C17E17=2*$H$17*$L$5*$O$5*$D17^2/($A17-2*$B17-$L$2)/10000009E20 E20=2*$H20*$L$5*$O$6*$D16^2/($A16-2*$B16-$L$2)/100000021 E21=2*$H21*$L$5*$O$6*$D17^2/($A17-2*$B17-$L$2)/100000010F15 摩阻216 F16 =2*$H$16*$L$6*$O$5*$D16^2/($A16-2*$B16-$L$2)/100000017 F17=2*$H$17*$L$6*$O$5*$D17^2/($A17-2*$B17-$L$2)/1000000181920 F20=2*$H20*$L$6*$O$6*$D16^2/($A16-2*$B16-$L$2)/100000021 F21=2*$H21*$L$6*$O$6*$D17^2/($A17-2*$B17-$L$2)/100000011G19 Nreg环空20 G20=($O$6*$D16^(2-$P$6)*($A16-2*$B16-$L$2)^$P$6/($Q$6*12^($P$6-1)))*(4*$P$6/(3*$P$6+1))^$P$621 G21=($O$6*$D17^(2-$P$6)*($A17-2*$B17-$L$2)^$P$6/($Q$6*12^($P$6-1)))*(4*$P$6/(3*$P$6+1))^$P$612G15 雷诺环空16 G16=$O$5*($A16-2*$B16-$L$2)*$D16/$Q$517 G17=$O$5*($A17-2*$B17-$L$2)*$D17/$Q$513H15 f环空16 H16=(1/(2*(1.8*LOG10($G16)-1.53)))^217 H17 =(1/(2*(1.8*LOG10($G17)-1.53)))^215H20 H20=16/G2021 H21=16/G2115I14 清水15 I15=(1/(2*((-2)*LOG10($Q$2/3.7065-(5.0452/H2)*LOG10($Q$2^1.1098/2.8257+(7.149/H2)^0.8961)))))^216I16 I16=$I$15+(0.0075*($N$2/2/1.3)^0.5)17 I17=$I$15+(0.0075*($N$2/2/1.441)^0.5)18 I18=$I$15+(0.0075*($N$2/2/1.683)^0.5)19 水基泥浆20 I20=$R$6/$J$20^$S$621 I21=1.06*$R$6*($N$2/2/1.3)^0.1/$J$20^(0.8*$S$6)22 I22=1.06*$R$6*($N$2/2/1.441)^0.1/$J$20^(0.8*$S$6)23 I23 =1.06*$R$6*($N$2/2/1.683)^0.1/$J$20^(0.8*$S$6)J15 直段16 J16=2*$I$15*$L5*$O$5*$G$2^2/$N$2/100000017 J17=2*$I$15*$L6*$O$5*$G$2^2/$N$2/100000018 J18=2*$I$15*$L7*$O$5*$G$2^2/$N$2/100000019 Nreg管20 J20=($O$6*$G$2^(2-$P$6)*$N$2^$P$6/($Q$6*8^($P$6-1)))*(4*$P$6/(3*$P$6+1))^$P$621 J21=2*$I$20*$L5*$O$6*$G$2^2/$N$2/100000022 J22=2*$I$20*$L6*$O$6*$G$2^2/$N$2/100000023 J23=2*$I$20*$L7*$O$6*$G$2^2/$N$2/100000018K L15 盘管段16 K16=2*$I16*$M5*$O$5*$G$2^2/$N$2/1000000 L16=J16+K1617 K17=2*$I17*$M6*$O$5*$G$2^2/$N$2/1000000 L17=J17+K1718 K18=2*$I18*$M7*$O$5*$G$2^2/$N$2/1000000 L18=J18+K18192021 K21=2*$I21*$M5*$O$6*$G$2^2/$N$2/1000000 L21=J21+K2122 K22=2*$I22*$M6*$O$6*$G$2^2/$N$2/1000000 L22=J22+K2223 K23=2*$I23*$M7*$O$6*$G$2^2/$N$2/1000000 L23=J23+K23()Re18/759.72Nε=1.10980.8961Re Re1 5.04527.1492lg[lg(())]3.7065 2.82572SLN N fεε=--+22fL vP fdρ∆=eRdNρνμ=214318nn nReg nnnd vNkρ--⎛⎫⎪+⎝⎭=0.10.81.06CL bRegrafN R⎛⎫= ⎪⎝⎭2CT 1431-12n n nRegn n n d d v N k ρ--⎛⎫ ⎪+⎝⎭=外套内)(0.100.81.06CLb Reg r a f N R ⎛⎫= ⎪⎝⎭11.8lg 1.532Re SLN f =-。

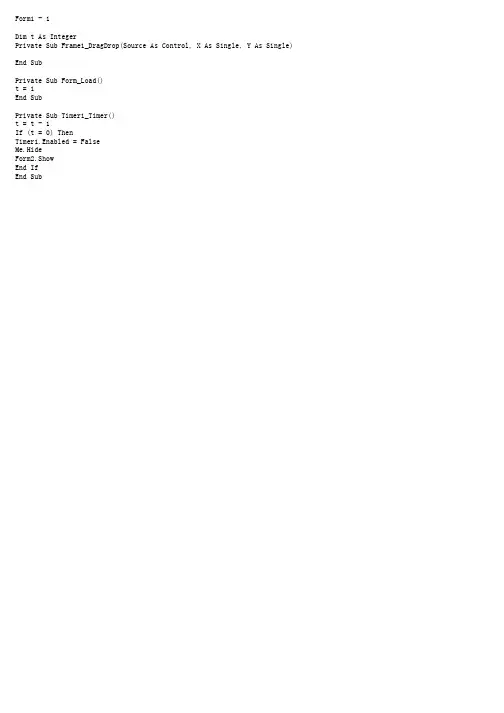

Dim t As IntegerPrivate Sub Frame1_DragDrop(Source As Control, X As Single, Y As Single) End SubPrivate Sub Form_Load()t = 1End SubPrivate Sub Timer1_Timer()t = t - 1If (t = 0) ThenTimer1.Enabled = FalseMe.HideForm2.ShowEnd IfEnd SubVERSION 5.00Begin VB.Form Form1Caption = "连续油管钻井水力参数计算软件"ClientHeight = 8160ClientLeft = 120ClientTop = 450ClientWidth = 15435FillColor = &H000080FF&LinkTopic = "Form1"LockControls = -1 'TrueScaleHeight = 8160ScaleWidth = 15435StartUpPosition = 3 '窗口缺省WindowState = 2 'MaximizedBegin VB.Timer Timer1Interval = 1000Left = 9600Top = 7560EndBegin bel Label2Caption = " 欢迎使用 CT钻井水力参 BeginProperty FontName = "宋体"Size = 21.75Charset = 134Weight = 700Underline = 0 'FalseItalic = 0 'FalseStrikethrough = 0 'FalseEndPropertyForeColor = &H8000000D&Height = 2535Left = 3480TabIndex = 1Top = 1680Width = 9015EndBegin bel Label1Caption = " 联系方式:948453545@"BeginProperty FontName = "宋体"Size = 15.75Charset = 134Weight = 400Underline = 0 'FalseItalic = 0 'FalseStrikethrough = 0 'FalseEndPropertyHeight = 975Left = 10920TabIndex = 0Top = 7200Width = 4455EndEnd联系欢迎使用CT 钻井水力参数计算软件Private Sub Command1_Click()Text1 = ""Text2 = ""End SubPrivate Sub Command2_Click()Dim i As IntegerIf Text1.Text <> "201003471" Or Text2.Text <> "660328" Then i = MsgBox("密码或帐号错误", 5 + vbExclamation, "警告")If i <> 6 ThenEndElseText2.Text = ""Text2.SetFocusEnd IfEnd IfForm3.ShowForm2.HideEnd SubPrivate Sub Form_Load()Text1.Text = ""Text1.MaxLength = 9Text2.Text = ""Text2.PasswordChar = 6Text2.PasswordChar = "*"End SubPrivate Sub Text1_LostFocus()If Not IsNumeric(Text1.Text) ThenMsgBox "帐号必须为数字", , "警告"Text1.Text = ""Text1.SetFocusEnd IfEnd SubVERSION 5.00Begin VB.Form Form2Caption = "Form2"ClientHeight = 7785ClientLeft = 120ClientTop = 450ClientWidth = 15150BeginProperty FontName = "宋体"Size = 21.75Charset = 134Weight = 400Underline = 0 'FalseItalic = 0 'FalseStrikethrough = 0 'FalseEndPropertyLinkTopic = "Form2"LockControls = -1 'TrueScaleHeight = 7785ScaleWidth = 15150StartUpPosition = 3 '窗口缺省WindowState = 2 'MaximizedBegin mandButton Command2Caption = "登陆(&L)"BeginProperty FontName = "宋体"Size = 18Charset = 134Weight = 400Underline = 0 'False Italic = 0 'False Strikethrough = 0 'False EndPropertyHeight = 735Left = 10560TabIndex = 5Top = 6780Width = 1935EndBegin mandButton Command1Caption = "重置"BeginProperty FontName = "宋体"Size = 18Charset = 134Weight = 400Underline = 0 'False Italic = 0 'False Strikethrough = 0 'False EndPropertyHeight = 735Left = 10560TabIndex = 4Top = 4620Width = 1935EndBegin VB.TextBox Text2BeginProperty FontName = "宋体"Size = 18Charset = 134Weight = 400Underline = 0 'False Italic = 0 'False Strikethrough = 0 'False EndPropertyHeight = 615Left = 7260TabIndex = 1Top = 6840Width = 1935EndBegin VB.TextBox Text1BeginProperty FontName = "宋体"Size = 18Charset = 134Weight = 400Underline = 0 'False Italic = 0 'False Strikethrough = 0 'False EndPropertyHeight = 615Left = 7260TabIndex = 0Top = 4680Width = 1935EndBegin bel Label2Caption = " 密码"Height = 615Left = 3960TabIndex = 3Top = 6840Width = 1935EndBegin bel Label1Caption = " 帐号"Height = 615Left = 3960TabIndex = 2Top = 4680Width = 1935EndEnd帐号密码Dim s As DoubleDim t As IntegerPrivate Sub List1_Click() End SubPrivate Sub Command1_Click() i = 0Text1 = ""Text2 = ""Text3 = ""Text4 = ""Text5 = ""Text6 = ""Text7 = ""Text8 = ""Text9 = ""Text10 = ""Text12 = ""Text13 = ""Text14 = ""Text15 = ""Text16 = ""Text17 = ""Text18 = ""Text20 = ""Text21 = ""Text22 = ""Text24 = ""Text25 = ""Text26 = ""Text27 = ""Text28 = ""Text29 = ""Text30 = ""Text31 = ""Text32 = ""Text33 = ""Text34 = ""Text35 = ""Combo1 = ""Combo2 = ""Combo3 = ""Combo4 = ""Combo5 = ""Combo6 = ""Combo7 = ""Combo8 = ""Form5.Text1 = ""Form5.Text2 = ""Form5.Text3 = ""Form6.Text1 = ""Form6.Text2 = ""Form6.Text3 = ""Form6.Text4 = ""Form6.Text5 = ""End SubPrivate Sub Command2_Click() a1 = Val(Text1.Text)a2 = Val(Text2.Text)a3 = Val(Text3.Text)a4 = Val(Combo1.Text)a5 = Val(Combo2.Text)a6 = Val(Text6.Text)a7 = Val(Text7.Text)a8 = Val(Text8.Text)a9 = Val(Text9.Text)a10 = Val(Text10.Text)a12 = Val(Text12.Text)a13 = Val(Text13.Text)a14 = Val(Text14.Text)a15 = Val(Text15.Text)a22 = Val(Text20.Text)a23 = Val(Text21.Text)a24 = Val(Text22.Text)a25 = Val(Combo3.Text)a26 = Val(Combo4.Text)a27 = Val(Text36.Text)a28 = Val(Text24.Text)a29 = Val(Combo5.Text)a30 = Val(Combo6.Text)a31 = Val(Text25.Text)a32 = Val(Text26.Text)a33 = Val(Text27.Text)a34 = Val(Text28.Text)a35 = Val(Text29.Text)a36 = Val(Text30.Text)a37 = Val(Text31.Text)a38 = Val(Text32.Text)a39 = Val(Text33.Text)a40 = Val(Combo7.Text)a41 = Val(Text34.Text)a43 = Combo8.TextIf (a12 - 2 * a13) > 0 Thenb1 = a18 / (1 / 4 * 3.1416 * (a4 - 2 * a5) ^ 2)End IfIf a4 <> 0 Thent = Fix(a2 / a4)End Ifs = 0n = 0Do While s < a6n = n + 1d(n) = a1 + (1.9 * n - 0.9) * a4e(n) = 3.1415 * t * (a1 + (1.9 * n - 0.9) * a4)s = s + e(n)Loopt = Fix((n + 1) / 2)b11 = d(t)If (i = 0) ThenMsgBox "请选择牛顿流或非牛顿流"End IfIf (i = 1) Thenb2 = a16 * (a4 - 2 * a5) * b1 / a17End IfIf (i = 2) Thenb2 = (a4 - 2 * a5) ^ a19 * b1 ^ (2 - a19) * a16 / a20 / 8 ^ (a19 - 1) * (4 * a19 / (3 * a19 + 1)) ^ a19End IfIf ((b2 < 3470 - 1370 * a19) And (i = 2)) Then '非牛顿流层流b6 = "层流"b10 = "层流"b7 = 16 / b2b12 = 5.22 * (a4 / b11) ^ 0.3 / b2 ^ 0.6End IfIf ((b2 > 4270 - 1370 * a19) And (i = 2)) Then '非牛顿流紊流b6 = "紊流"b10 = "紊流"b7 = (Log(a19) / Log(10) + 3.93) / 50 / b2 ^ ((1.75 - Log(a19) / Log(10)) / 7)b12 = 1.06 * (Log(a19) / Log(10) + 3.93) / 50 / b2 ^ (0.8 * (1.75 - Log(a19) / Log(10)) / 7) * (a4 / b11) ^ 0.1End IfIf ((b2 < 4270 - 1370 * a19 And b2 > 3470 - 1370 * a19) And (i = 2)) Then '非牛顿流过渡流b6 = "过渡流"b10 = "过渡流"b7 = 16 / (3470 - 1370 * a19) + (b2 - (3470 - 1370 * a19)) * (((Log(a19) / Log(10) + 3.93) / 50) / (4270 - 1370 * a19) - 1 6 / (3470 - 1370 * a19)) / (4270 - 3470)b12 = 5.22 * (a4 / b11) ^ 0.3 / (3470 - 1370 * a19) ^ 0.6 + (b2 - (3470 - 1370 * a19)) * (((1.06 * ((Log(a19) / Log(10) + 3.93) / 50) / (4270 - 1370 * a19) ^ 0.6 * (a4 / b11) ^ 0.1) - (5.22 * (a4 / b11) ^ 0.3) / (3470 - 1370 * a19) ^ 0.6)) / (4 270 - 3470)End IfIf i = 1 Then ' 牛顿流直管b3 = b2 * Sqr(a4 / b11)b4 = 300 / Sqr(a4 / b11)b5 = 2100 / Sqr(a4 / b11)r3 = 59.7 / (2 * a15) ^ (8 / 7)End IfIf (b3 > 30 And b3 < 300) And i = 1 Thenb7 = 16 / b2b6 = "层流"r6 = b7End IfIf ((b3 > 2100 And b3 < 14000) And (b2 > r3)) And i = 1 Thenr4 = -2 * Log(a10 / 3.7065 - 5.0452 / b2 * Log((a10) ^ 1.1098 / 2.8257 + (7.149 / b2) ^ 0.8961) / Log(10)) / Log(10) b7 = 1 / (4 * r4 ^ 2)b6 = "紊流混合区"End IfIf ((b3 > 2100 And b3 < 14000) And (b2 < r3)) And i = 1 Thenr2 = 1.81 * logb2 / Log(10) - 1.53b7 = 1 / (4 * r2 ^ 2)b6 = "紊流光滑区"End IfIf (b3 > 300 And b3 < 2100) And i = 1 Thenb6 = "过渡流"r1 = 1 / 4 * 1 / (1.8 * logb2 / Log(10) - 1.53) ^ 2b7 = (b2 - b4) / (b5 - b4) * (r1 - 16 / b4) + 16 / b4End IfIf i = 1 Thenr5 = 2100 * (1 + 12 * (a4 / b11) ^ 0.5) '牛顿流盘管b8 = 300 / Sqr(a4 / b11)b9 = r5 / Sqr(a4 / b11)End IfIf (b3 > 30 And b3 < 300) And i = 1 Thenb12 = b7 * (0.556 + 0.0969 * Sqr(b3))b10 = "层流"End IfIf (b3 > 300 And b3 < r5) And i = 1 Thenb10 = "过渡流"b12 = 1.8 / b2 ^ 0.5 * (a4 / b11) ^ 0.25End IfIf (b3 > r5 And b3 < 14000) And i = 1 Thenb10 = "紊流"b12 = b7 + 0.0075 * (a4 / b11) ^ 0.5End Ifr8 = 1 + (a22 / a16 - 1) * c4 '磨粒摩阻梯度系数MIf i = 1 Thenr9 = 1 + 2.5 * c4 + 10.05 * c4 ^ 2 + 0.00273 * Exp(1.66 * c4)End IfIf i = 2 Thenr9 = (1 - c4 / 0.63) ^ (-2.5 * a19)End IfIf b6 = "层流" Or b10 = "层流" Thenb13 = r9 ^ 0.6 * r8 ^ 0.4End IfIf b6 = "过渡流" Or b10 = "过渡流" Thenb13 = r9 ^ 0.5 * r8 ^ 0.5End IfIf b6 = "紊流混合区" Or b6 = "紊流光滑区" Or b10 = "紊流" Thenb13 = r9 ^ 0.2 * r8 ^ 0.8End Ifb14 = 2 * b7 * a7 * a16 * b1 ^ 2 / (a4 - 2 * a5) '压力损失b15 = 2 * b12 * (a6 - a7) * a16 * b1 ^ 2 / (a4 - 2 * a5)b28 = b14 + b15b16 = 3.767 * 10 ^ (-4) * a16 ^ 0.8 * b1 ^ 0.2 * a18 ^ 1.8b17 = 0.844 * a16 * a18 ^ 2 / (a19 ^ 2 * a17 ^ 2 * a26 ^ 4)b18 = 2 * b7 * a7 * a16 * ((a4 - 2 * a5) ^ 2 / ((a12 - 2 * a13) ^ 2 - a4 ^ 2) ^ 2) / (a12 - 2 * a13 - a4)b19 = b14 + b15 + b16 + b17 + b18 + a31b23 = c5 * 1 / 4 * 3.1416 * ((a12 - 2 * a13) ^ 2 - a4 ^ 2)r10 = (a17 ^ 2 / a16 / (a22 - a16)) ^ (1 / 3)If c1 <= 1.225 * r10 Thenb20 = 9.8 * (a22 - a16) * c1 ^ 2 / 18 / a17End IfIf c1 <= 20.4 * r10 And c1 >= 0.915 * r10 Thenb20 = 1.195 * c1 * ((a22 - a16) ^ 2 / a17 / a16) ^ (1 / 3)End Ifb21 = b20 / (2 / 3 * (1 - c4) ^ 2 * Exp(Abs(-2.5 * c4 / (1 - 39 / 64 * c4)))) If b20 > b21 Thenr11 = b20Elser11 = b21End IfIf Check1.Value = 1 Thenb22 = 2 * r11 * 1 / 4 * 3.1416 * ((a12 - 2 * a13) ^ 2 - a4 ^ 2)Elseb22 = 6 * r11 * 1 / 4 * 3.1416 * ((a12 - 2 * a13) ^ 2 - a4 ^ 2)End Ifb25 = a35If b23 > b22 Thenb26 = b23Elseb26 = b22End IfIf b24 > b25 Thenb27 = b24Elseb27 = b25End IfIf i = 1 Or i = 2 ThenMe.HideForm4.ShowEnd IfEnd SubPrivate Sub Command3_Click()Me.HideForm5.ShowEnd SubPrivate Sub Label11_Click()End SubPrivate Sub Label47_Click()End SubPrivate Sub Text23_Change()End SubPrivate Sub Text11_Change()End SubPrivate Sub Command4_Click()Me.HideForm6.ShowEnd SubPrivate Sub Command5_Click()If (Combo8.Text = "北石5LZ95*7.0") ThenText26 = "95"Text27 = "4.21"Text28 = "107.95"Text29 = "11.04"Text30 = "3.2"Text31 = "7.0"Text32 = "710"Text33 = "1240"Combo7 = "21"Text34 = "40"Text28 = "117.48"Text29 = "10"Text30 = "2.4"Text31 = "7.0"Text32 = "800"Text33 = "1780"Combo7 = " "Text34 = " "End IfIf (Combo8.Text = "克里斯坦Mach3") Then Text26 = "95"Text27 = "5.1"Text28 = " "Text29 = "107.95"Text30 = "9.15"Text31 = " "Text32 = " "Text33 = " "Combo7 = " "Text34 = " "End IfEnd SubVERSION 5.00Begin VB.Form Form3AutoRedraw = -1 'TrueCaption = "Form3"ClientHeight = 8985ClientLeft = 225ClientTop = 870ClientWidth = 15900LinkTopic = "Form3"ScaleHeight = 2.27911e8ScaleMode = 0 'UserScaleWidth = 1.42472e9StartUpPosition = 3 '窗口缺省WhatsThisButton = -1 'TrueWhatsThisHelp = -1 'TrueWindowState = 2 'MaximizedBegin mandButton Command4Caption = "非牛顿流"Height = 1935Left = 5880TabIndex = 83Top = 7440Width = 2415EndBegin mandButton Command3Caption = "牛顿流"Height = 1695Left = 5880TabIndex = 82Top = 4920Width = 2535EndBegin VB.Frame Frame1Caption = " 连续油管(CT)的输入" Height = 9735Left = 480TabIndex = 56Top = 240Width = 4215Begin VB.TextBox Text2Height = 495Left = 2520TabIndex = 66Top = 1263Width = 1575EndBegin VB.TextBox Text3Height = 495Left = 2520TabIndex = 65Top = 2166Width = 1575EndBegin VB.TextBox Text6Height = 495Left = 2520TabIndex = 64Top = 4485Width = 1575EndBegin VB.TextBox Text7Height = 495Left = 2520TabIndex = 63Top = 5388Width = 1575EndBegin VB.TextBox Text8Height = 495Left = 2520TabIndex = 62Top = 6291Top = 7194Width = 1575EndBegin VB.TextBox Text10Height = 495Left = 2520TabIndex = 60Top = 8097Width = 1575EndBegin boBox Combo1Height = 300Left = 2520TabIndex = 59Top = 3069Width = 1575EndBegin boBox Combo2Height = 300Left = 2520TabIndex = 58Top = 3777Width = 1575EndBegin VB.TextBox Text1Height = 495Left = 2520TabIndex = 57Top = 360Width = 1575EndBegin bel Label2Caption = "滚筒宽度(m)" Height = 495Left = 720TabIndex = 76Top = 1224Width = 1575EndBegin bel Label3Caption = "滚筒缘直径(m)" Height = 495Left = 720TabIndex = 75Top = 2088Width = 1575EndBegin bel Label4Caption = "CT外径"Height = 495Left = 720TabIndex = 74Top = 2952Width = 1575EndBegin bel Label5Caption = "CT厚度"Height = 495Left = 720TabIndex = 73Top = 3816Width = 1575EndBegin bel Label6Caption = "CT总长度(m)" Height = 495Left = 720TabIndex = 72Top = 4680Width = 1575Top = 5544Width = 1575EndBegin bel Label8Caption = "CT内压极限(Mpa)"Height = 495Left = 720TabIndex = 70Top = 6408Width = 1575EndBegin bel Label9Caption = "CT外压极限(Mpa)"Height = 495Left = 720TabIndex = 69Top = 7272Width = 1575EndBegin bel Label10Caption = "CT相对粗造度"Height = 495Left = 720TabIndex = 68Top = 8136Width = 1575EndBegin bel Label1AutoSize = -1 'TrueCaption = "滚筒直径(m)"Height = 495Left = 720TabIndex = 67Top = 360Width = 1575EndEndBegin VB.Frame Frame4Caption = " 钻井液固相参数输入 " Height = 3015Left = 10560TabIndex = 49Top = 240Width = 4215Begin VB.TextBox Text20Height = 375Left = 2160TabIndex = 52Top = 360Width = 1455EndBegin VB.TextBox Text21Height = 375Left = 2160TabIndex = 51Top = 1260Width = 1455EndBegin VB.TextBox Text22Height = 375Left = 2160TabIndex = 50Top = 2160Width = 1455EndBegin bel Label23Caption = "密度(kg/m^3)"Height = 375Left = 360TabIndex = 55Caption = "颗粒直径(m)"Height = 375Left = 360TabIndex = 54Top = 1260Width = 1455EndBegin bel Label25Caption = "固相比"Height = 375Left = 360TabIndex = 53Top = 2160Width = 1455EndEndBegin VB.Frame Frame5Caption = " 钻头参数输入" Height = 3135Left = 10560TabIndex = 44Top = 3660Width = 4215Begin boBox Combo3Height = 300Left = 2160TabIndex = 80Top = 480Width = 1575EndBegin VB.TextBox Text36Height = 375Left = 2160TabIndex = 77Top = 1790Width = 1575EndBegin boBox Combo4Height = 300Left = 2160TabIndex = 46Top = 1135Width = 1575EndBegin VB.TextBox Text24Height = 375Left = 2160TabIndex = 45Top = 2520Width = 1575EndBegin bel Label27Caption = "钻头类型"Height = 375Left = 240TabIndex = 81Top = 480Width = 1575EndBegin bel Label28Caption = "钻头水眼尺寸(m)"Height = 375Left = 240TabIndex = 79Top = 1160Width = 1575EndBegin bel Label30Caption = "流量系数"Height = 375Left = 240TabIndex = 78Caption = "Label26"Height = 375Left = 240TabIndex = 48Top = 360Width = 15EndBegin bel Label29Caption = "钻头水眼个数"Height = 375Left = 240TabIndex = 47Top = 1840Width = 1575EndEndBegin VB.Frame Frame7Caption = " 其他参数输入"Height = 2775Left = 10560TabIndex = 37Top = 7200Width = 4215Begin boBox Combo5Height = 300Left = 2160TabIndex = 40Top = 480Width = 1455EndBegin boBox Combo6Height = 300Left = 2160TabIndex = 39Top = 1200Width = 1455EndBegin VB.TextBox Text25Height = 300Left = 2160TabIndex = 38Top = 1920Width = 1455EndBegin bel Label31Caption = "工具名称"Height = 375Left = 240TabIndex = 43Top = 480Width = 1455EndBegin bel Label32Caption = "个数"Height = 375Left = 240TabIndex = 42Top = 1200Width = 1455EndBegin bel Label33Caption = "总压降(Mpa)"Height = 375Left = 240TabIndex = 41Top = 1920Width = 1455EndEndBegin VB.Frame Frame6Caption = " 螺杆钻具参数输入" Height = 9615Begin mandButton Command5 Caption = "确定选择" Height = 495Left = 2160TabIndex = 84Top = 960Width = 1455EndBegin VB.TextBox Text26Height = 375Left = 2160TabIndex = 25Top = 1680Width = 1455EndBegin VB.TextBox Text27Height = 375Left = 2160TabIndex = 24Top = 2400Width = 1455EndBegin VB.TextBox Text28Height = 375Left = 2040TabIndex = 23Top = 3120Width = 1455EndBegin VB.TextBox Text29Height = 375Left = 2040TabIndex = 22Top = 3960Width = 1455EndBegin VB.TextBox Text30Height = 375Left = 2040TabIndex = 21Top = 4680Width = 1455EndBegin VB.TextBox Text31Height = 375Left = 2040TabIndex = 20Top = 5400Width = 1455EndBegin VB.TextBox Text32Height = 375Left = 2040TabIndex = 19Top = 6240Width = 1455EndBegin VB.TextBox Text33Height = 375Left = 2040TabIndex = 18Top = 7200Width = 1455EndBegin boBox Combo7Height = 300Left = 2040TabIndex = 17Top = 7920Width = 1455EndBegin VB.TextBox Text34EndBegin boBox Combo8Height = 300Left = 2160TabIndex = 15Top = 360Width = 1575EndBegin bel Label34Caption = "公称外径(m)"Height = 375Left = 240TabIndex = 36Top = 1680Width = 1455EndBegin bel Label35Caption = "标准长度(m)"Height = 375Left = 120TabIndex = 35Top = 2400Width = 1455EndBegin bel Label36Caption = "钻头尺寸(m)"Height = 375Left = 240TabIndex = 34Top = 3120Width = 1575EndBegin bel Label37Caption = "最大流量(m^3/s)" Height = 375Left = 120TabIndex = 33Top = 3720Width = 1455EndBegin bel Label38Caption = "工作压降(Mpa)" Height = 375Left = 120TabIndex = 32Top = 4680Width = 1455EndBegin bel Label39Caption = "最大压降(Mpa)" Height = 375Left = 120TabIndex = 31Top = 5400Width = 1455EndBegin bel Label40Caption = "输出扭矩(KN.m)" Height = 375Left = 120TabIndex = 30Top = 6360Width = 1455EndBegin bel Label41Caption = "最大扭矩(KN.m)" Height = 375Left = 120TabIndex = 29Top = 7200Width = 1455TabIndex = 28Top = 7920Width = 1455EndBegin bel Label43Caption = "最大钻压(Mpa)"Height = 375Left = 240TabIndex = 27Top = 8760Width = 1455EndBegin bel Label45Caption = "螺杆钻具选择"Height = 255Left = 120TabIndex = 26Top = 480Width = 1575EndEndBegin VB.Frame Frame2Caption = " 油套管输入" Height = 4335Left = 5520TabIndex = 2Top = 240Width = 4215Begin VB.TextBox Text12Height = 375Left = 2640TabIndex = 7Top = 240Width = 1575EndBegin VB.TextBox Text13Height = 375Left = 2640TabIndex = 6Top = 1000Width = 1575EndBegin VB.TextBox Text14Height = 375Left = 2640TabIndex = 5Top = 1760Width = 1575EndBegin VB.TextBox Text15Height = 375Left = 2640TabIndex = 4Top = 2520Width = 1575EndBegin VB.CheckBox Check1Height = 375Left = 2640TabIndex = 3Top = 3240Width = 855EndBegin bel Label12Caption = "套管外径(m)"Height = 375Left = 240TabIndex = 13Top = 240Width = 1575EndTop = 990Width = 1575EndBegin bel Label14Caption = "套管相对粗造度"Height = 375Left = 240TabIndex = 11Top = 2490Width = 1575EndBegin bel Label15Height = 375Left = 240TabIndex = 10Top = 2760Width = 735EndBegin bel Label46Caption = "老井套管长度(m)" Height = 375Left = 240TabIndex = 9Top = 1740Width = 1575EndBegin bel Label16Caption = "是否为老井加深"Height = 375Left = 240TabIndex = 8Top = 3240Width = 1575EndEndBegin mandButton Command2Caption = "转到计算(&C)"CausesValidation= 0 'FalseHeight = 495Left = 17880TabIndex = 1Top = 9960Width = 1815EndBegin mandButton Command1Caption = "重新输入"Height = 495Left = 15480TabIndex = 0Top = 9960Width = 1815EndBegin VB.Line Line1X1 = 0X2 = 3.5842e5Y1 = 0Y2 = 0EndBegin VB.Menu 连续油管钻井水力参数计算Caption = "文件&F"WindowList = -1 'TrueBegin VB.Menu NewCaption = "新建"Shortcut = ^NEndBegin VB.Menu openCaption = "打开"Shortcut = ^OEndBegin VB.Menu saveasCaption = "另存为"Shortcut = ^SEndBegin VB.Menu printCaption = "打印"EndBegin VB.Menu exitCaption = "结束"Shortcut = ^EEndEndBegin VB.Menu inputCaption = "参数输入&L"Begin VB.Menu 油管Caption = "油管的输入" EndBegin VB.Menu 套管Caption = "套管的输入" EndBegin VB.Menu 钻井液流体Caption = "钻井液流体" EndBegin VB.Menu 钻井液固体Caption = "钻井液固体" EndBegin VB.Menu 钻头Caption = "钻头"EndBegin VB.Menu 螺杆Caption = "螺杆"EndBegin VB.Menu 其他Caption = "其他"EndEndBegin VB.Menu outputCaption = "结果输出&O"EndBegin VB.Menu helpCaption = "帮助&H"EndEnd是否为老井加深老井套管长度(m)套管相对粗造度套管厚度(m )套管外径(m )Private Sub Command1_Click()Me.HideForm3.ShowEnd SubPrivate Sub Command3_Click()c1 = Val(Text21.Text)c2 = Val(Text22.Text)c3 = Val(Text23.Text)c4 = Val(Text24.Text)c5 = Val(Combo1.Text)End SubPrivate Sub Form_Activate()Text1 = b1Text2 = b2Text3 = b3Text4 = b4Text5 = b5Text6 = b6Text7 = b7Text8 = b8Text9 = b9Text10 = b10Text11 = b11Text12 = b12Text13 = b13Text14 = b14Text15 = b15Text16 = b16Text17 = b17Text18 = b18Text19 = b19Text25 = b20Text26 = b21Text27 = b22Text20 = b23Text28 = b24Text30 = b25Text31 = b26Text29 = b27End SubPrivate Sub Frame11_DragDrop(Source As Control, X As Single, Y As Single) End SubVERSION 5.00Begin VB.Form Form4Caption = "系统压力计算"ClientHeight = 7875ClientLeft = 120ClientTop = 450ClientWidth = 15180LinkTopic = "Form4"ScaleHeight = 7875ScaleWidth = 15180StartUpPosition = 3 '窗口缺省WindowState = 2 'MaximizedBegin VB.Frame Frame10Caption = " CT钻井合适排量推荐" Height = 2895Left = 15960TabIndex = 74Top = 4920Width = 3735Begin VB.TextBox Text31Height = 615Left = 2160TabIndex = 79Text = "Text31"Top = 720Width = 975EndBegin VB.TextBox Text29Height = 735Left = 2160TabIndex = 78Text = "Text29"Top = 1680Width = 1095EndBegin bel Label34Caption = "最大流量"Height = 735Left = 360TabIndex = 77Top = 1920Width = 975EndBegin bel Label30Caption = "最小流量"Height = 615Left = 480TabIndex = 75Top = 720Width = 1095EndEndBegin mandButton Command3Caption = "确认计算"Height = 735Left = 17640TabIndex = 71Top = 9000Width = 1695EndBegin VB.Frame Frame1Caption = " 流动基本参数"Height = 2415Left = 720TabIndex = 52Top = 360Width = 3855Begin VB.TextBox Text3Height = 375Left = 1680Locked = -1 'TrueTabIndex = 55Top = 1680Width = 1095EndBegin VB.TextBox Text2Locked = -1 'TrueTabIndex = 54Top = 1020Width = 1095EndBegin VB.TextBox Text1Height = 375Left = 1680Locked = -1 'TrueTabIndex = 53Top = 360Width = 1095EndBegin bel Label11Caption = "狄恩数"Height = 375Left = 360TabIndex = 58Top = 1680Width = 1095EndBegin bel Label10Caption = "雷诺数"Height = 495Left = 360TabIndex = 57Top = 960Width = 855EndBegin bel Label9Caption = "流速(m/s)"Height = 375Left = 360TabIndex = 56Top = 360Width = 1095EndEndBegin VB.Frame Frame3Caption = " 盘管CT压力损失摩阻系数" Height = 3615Left = 10560TabIndex = 44Top = 240Width = 4215Begin VB.TextBox Text12Height = 375Left = 2400Locked = -1 'TrueTabIndex = 49Top = 3000Width = 1455EndBegin VB.TextBox Text11Height = 375Left = 2400Locked = -1 'TrueTabIndex = 48Top = 2340Width = 1455EndBegin VB.TextBox Text10Height = 375Left = 2400Locked = -1 'TrueTabIndex = 47Top = 1680Width = 1455EndBegin VB.TextBox Text9Height = 375Left = 2400Locked = -1 'TrueTabIndex = 46。

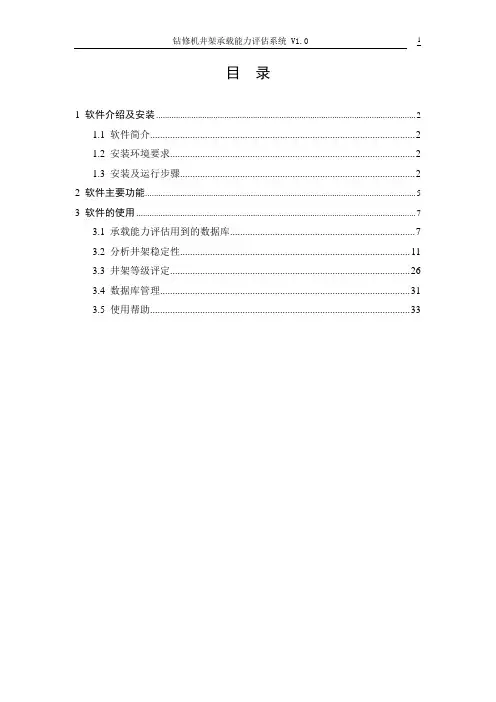

目录1 软件介绍及安装 (2)1.1 软件简介 (2)1.2 安装环境要求 (2)1.3 安装及运行步骤 (2)2 软件主要功能 (5)3 软件的使用 (7)3.1 承载能力评估用到的数据库 (7)3.2 分析井架稳定性 (11)3.3 井架等级评定 (25)3.4 数据库管理 (29)3.5 使用帮助 (31)钻修机井架承载能力评估系统使用说明1 软件介绍及安装1.1 软件简介本软件由长江大学机械工程学院开发,系统综合井架整体稳定性和局部稳定性的计算方法,以及井架等级的评定方法,通过对Excel、Access数据库及APDL 等数据的处理,从而快速、准确地对井架的承载能力做出客观的评价。

1.2 安装环境要求WINDOWS XP,WINDOWS 7等WINDOWS环境;如想使用完整功能,需安装Ansys(推荐使用10.0)环境,否则只能使用现场分析模块。

1.3 安装及运行步骤1、运行安装程序AssessDerricks.exe,如果已安装再次安装时提示如下;图1.1 再次安装提示信息2、在安装时,请关闭所有的应用程序,包括防护墙或允许软件的相关操作;3、接受安装协议后根据提示安装即可。

由于用于开发软件的计算机系统与用户系统存在一定的差异,在安装时可能出现系统文件替换,用户只需要确定即可;同时,由于意外会产生系统错误提示,用户忽略即可,并不影响程序的安装。

安装完后,在桌面及开始菜单中生成快速启动图标(如图1.2所示)。

图1.2 开始菜单处的快启动方式4、单击桌面快捷方法启动程序,首次安装时需要进行注册使用(可联系开发者获取)。

图1.3 用户注册使用5、注册成功后即可在启动界面选择模块。

图1.4 欢迎界面2 软件主要功能该软件主要有四大功能。

第一大功能是根据现场实测数据对井架进行稳定性分析。

工程技术人员可以通过应变仪测量井架每根杆的应变,在软件运行界面调用每根杆的基本参数和特征参数,然后计算每根杆的等效安全系数,得到最危险杆的等效安全系数,从而完成井架局部稳定性计算,工程技术人员也可以在软件运行界面对数据库中的数据进行维护,包括修改、删除等操作,以确保计算结果的准确性。

Cerberus连续油管仿真模拟软件技术要求

一、产品用途

由于连续油管的队伍急速扩张,再加之近年连续油管拖动压裂的工艺广泛的应用,连续油管长时间处于高压、携砂液冲刷的环境下使用,需要密切的对连续油管的疲劳度进行检测分析。

需要采购相应的软件进行分析计算,通过软件可以对连续油管进行疲劳度分析,施工参数模拟、实时检测数采数据、井筒工况模拟、工具串选配模拟等功能。

通过调研,最终确定Cerberus连续油管仿真模拟软件主要包括的模块有:Orpheus、Reel-trak、Hydra、Velocity String、Solids Cleanout、Achilles、Hercules、String Editor /Reel Editor / Well Editor/Tool String Editor / Fluid Editor模块,并提供软件专用处理机。

二、技术参数

2.1软件模块详细功能

2.2 软件载体处理机参数要求

(1)处理系统Windows10,64位系统,简体中文版;

(2)处理器:Inter i5-7200U或以上;

(3)内存4GB或以上;

(4)DirectX版本:DirectX12或以上。

(5)要求软件专机专用,使用硬件加密方式。

三、产品检验

依据有关标准,协议要求,合同及供方出具的相关技术文件对软件使用、各部性能进行检查验收。

生产过程中的组织、生产、检验由乙方负责。

四、产品质量保证及服务

1. 乙方提供软件培训;

2. 现场应用出现问题时,乙方服务人员及时向现场用户提供技术支持。

3. 每年密钥认证由乙方无偿提供。

井下作业公司压裂分公司

2018年9月17日。

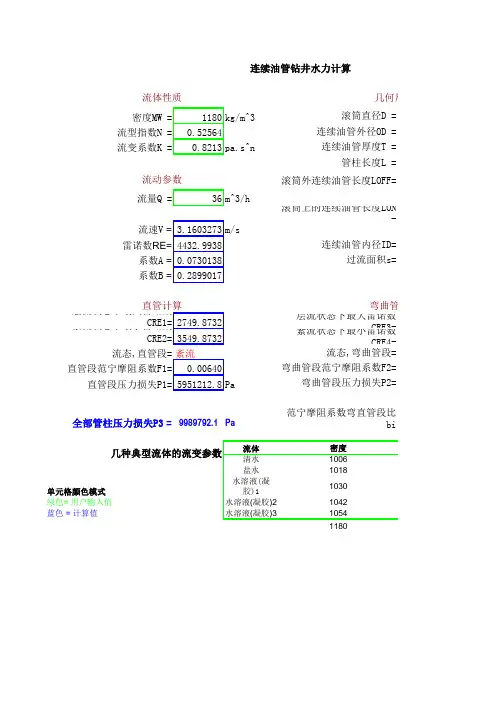

流体性质几何尺寸密度MW = 1180 kg/m^3 滚筒直径D = 2.54 m流型指数N = 0.52564连续油管外径OD =0.073025 m流变系数K = 0.8213 pa.s^n 连续油管厚度T =0.004776 m管柱长度L = 3500 m流动参数滚筒外连续油管长度LOFF= 2500 m流量Q = 36 m^3/h滚筒上的连续油管长度LON= 1000 m 流速V = 3.160327337 m/s雷诺数RE=4432.993792连续油管内径ID=0.063473 m系数A =0.073013768过流面积s=0.003164229 m^2系数B =0.289901656直管计算弯曲管计算层流状态下最大雷诺数CRE1= 2749.8732 层流状态下最大雷诺数CRE3=5576.74紊流状态下最小雷诺数CRE2= 3549.8732 紊流状态下最小雷诺数CRE4=6376.74流态,直管段= 紊流流态,弯曲管段= 层流直管段范宁摩阻系数F1= 0.00640 弯曲管段范宁摩阻系数F2=0.0077直管段压力损失P1= 5951212.806 Pa 弯曲管段压力损失P2=4038579.29 Pa全部管柱压力损失P3 =9989792.1 Pa 范宁摩阻系数弯直管段比bi 1.203几种典型流体的流变参数流体密度n K清水1006 1.000 0.0010盐水 1018 1.000 0.0010 单元格颜色模式 水溶液(凝胶)1 1030 0.669 0.0930 绿色= 用户输入值水溶液(凝胶)2 1042 0.605 0.5110 蓝色 = 计算值水溶液(凝胶)310540.507 2.188711800.525640.8213流体流动和压力损失计算表过渡流压力损失(Pa)流量 (m^3/h)层流 紊流临界值1 临界值2插值-f直管段26.040051 30.964283 3353665.832715951212.80631 2828674.110174695625.99035 6756555.5528弯管段 42.064289 46.068147 4038579.28537 2863224.58722 1455857.4360210825082.39628 21167776.7648弯管层流相关参数psi= 4.318574 雷诺数 4433狄恩数的幂phi=(0.055065)狄恩数700.76883直 863.150479 psi 弯 585.7464281 psi110.51324Re 210031phin phin D psi n D -⎛⎫⎛⎫= ⎪ ⎪+⎝⎭⎝⎭21513022Q/0.2271154.63(/0.0254)Reoff s l P D ρ=()22513022(Q/0.2271)154.63(/0.0254)off b s a l Re P D ρ⎛⎫⎪⎝⎭=2s135113022(Q /0.2271)154.63(/0.0254)Re off s l P D ρ=2s24513022(Q /0.2271)154.63(/0.0254)off b s a l Re P D ρ⎛⎫ ⎪⎝⎭=()()143321Re Re Re Re s s s s P P p P --=+-()21513022(Q/0.2271)154.63(/0.0254)Reon c psi Des l P D ρ=0.1120.822511.069189(Q/0.2271)154.63(/0.0254)on b c D al D ReP D ρ⎛⎫ ⎪⎝⎭=2c135133022(Q /0.2271)154.63(/0.0254)Re on c l P D ρ=()0.1212c20.84451(/0.2271)(/0.2271) 1.069189(Q /0.2271)154.63(/0.0254)on bc a D D l Re P D ρ=()()143321Re Re Re Re c c c c P P p P --=+-系号表示步骤1. LON=L-LOFF2, ID=OD-2*T3 S=ID^2*PI()/4 PI=3.1415926544 V=Q/3600/S5RE=(0.124*(Q/0.2271)^(2-N)*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N6 CRE1 =3470-1370*N7 CRE2 =4270-1370*N8 psi=47.969-153.8*N+166.22*N^2-60.132*N^39 phi=0.875*N-0.51510 CRE3 =(4*N/(3*N+1))^N*(2100*psi*(ID/D)^(0.5*phi))^(1/(1-phi))11 CRE4=CRE3+80012 A=(LOG(N)+3.93)/50 LOG(N)= LOG(N)/LOG(10)13 B=(1.75-LOG(N))/7 LOG(N)= LOG(N)/LOG(10)14 F1=A/RE^B15 F2=(1.069*A/RE^(0.8*B))*(ID/D)^0.116 bi=F2/F117 L10=(A/RE^B)*189*LOFF*MW*(Q/0.2271)^2/(154.63*(ID/0.0254)^5)18I10=((((0.124*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N)^(-1)*CRE1)^(1/(2-N))) *0.227119 M10=3022*LOFF*MW*(I10/0.2271)^2/(154.63*(ID/0.0254)^5*CRE1)20J10=((((0.124*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N)^(-1)*CRE2)^(1/(2-N)) )*0.227121 N10=(A/CRE2^B)*189*LOFF*MW*(J10/0.2271)^2/(154.63*(ID/0.0254)^5)22 O10=M10+(RE-CRE1)*(N10-M10)/(CRE2-CRE1)23 K10=3022*LOFF*MW*(Q/0.2271)^2/(154.63*(ID/0.0254)^5*RE)24K12=(0.124*(Q/0.2271)^(2-N)*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N25 K13 =K12*(ID/D)^0.526 K11=(psi*K13^phi)*3022*LON*MW*(Q/0.2271)^2/(154.63*(ID/0.0254)^5*RE)27L11=(ID/D)^0.1*1.069*A/RE^(0.8*B)*189*LON*MW*(Q/0.2271)^2/(154.63*(ID/0.0254)^5)28I11=((((0.124*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N)^(-1)*CRE3)^(1/(2-N))) *0.227129 M11=3022*LON*MW*(I11/0.2271)^2/(154.63*(ID/0.0254)^5*CRE3)30 J11=((((0.124*MW/(9.804^N*K*(ID/0.0254)^(4-3*N)))*(N/(1+3*N))^N)^(-1)*CRE4)^(1/(2-N)))*0. 227131N11=((ID/0.0254)*(D/0.0254))^0.1*(1.069*A/CRE4^(0.8*B))*189*LON*MW*(J11/0.2271)^2/(154.63*(ID/0.0254)^5)32 O11=M11+(RE-CRE1)*(N11-M11)/(CRE2-CRE1)33 P1=IF(RE<CRE1,K10,IF(RE>CRE2,L10,O10))IF RE<CRE1 THENP1=K10ELSEIF RE>CRE2 THENP1=L10ELSEP1=O10END IF34 P2 =IF(RE<CRE3,K11,IF(RE>CRE4,L11,O11))IF RE<CRE3 THENP1=K11ELSEIF RE>CRE4 THENP2=L11ELSEP2=O11END IF35 P3 =P1+P2。

AB C D E F G H I J K L M N O P Q R S T1 ρl (k g/m 3)ρs (k g/m 3)ds (m )液体 粘度μ (p a.s)D 套外 (m m ) t套(mm)D 油外 (m m )t 油 (m m ) S油 (m 2) S 油套 (m 2) 井筒深度(m)井筒 容积 (m 3) 环空 容积 (m 3)Q (L /m in )v 管 (m /s )v 环空(m/s )雷诺 管 雷诺 环空总平均 含砂率 (%)颗粒 范围 (m )21006 2300 0.000250.010 139.7 12.173 4.80.0032 0.00629 3511.049 22.22 600 3.168 1.589 202031 67951 5 0.0001121931006 2300 0.000250.010177.816.373 4.80.00320.012373511.04943.306600 3.1680.88202031 587020.00186833 41180 2300 0.000250.04550.101201012.2(2.65 3.32)0s sC C r r v v e--=R S T U V X Y 7环空沉降末速Vt(m /s) 颗粒群滑移速度Vr(m/s)考虑絮凝(球粒)干扰沉降速度Vts(m/s)非球形颗粒(0.8球粒度)干扰沉降速度Vts(m/s)干扰沉速/自由沉速竖直井筒正冲所需最低流量(L/s)水平井筒正冲所需最低流量(L/s)8 0.0354 0.0310 0.0517 0.0354 1.461 0.446 1.337 清水5-1/2"套管9 0.0354 0.0310 0.0517 0.0354 0.999 0.651 1.95310 0.0011 0.0009 0.0015 0.0011 0.876 2.628 清水7"套管1.280 3.840X Y130.013 0.040 泥浆5-1/2"套管140.019 0.058150.026 0.079 泥浆7"套管160.038 0.115I J1 S油(m2) S油套(m2)2=PI()*((G2-2*H2)/1000)^2/4 =PI()*(((E2-2*F2)/1000)^2-(G2/1000)^2)/43=PI()*((G3-2*H3)/1000)^2/4 =PI()*(((E3-2*F3)/1000)^2-(G3/1000)^2)/4L M1 井筒容积(m3) 环空容积(m3)2 =I2*K2 =J2*K23 =I3*K3 =J3*K3v管(m/s) v环空(m/s) 雷诺管雷诺环空=N2/1000/60/ I2 =N2/1000/60/J2=O2*$A$2*($G$2-2*$H$2)/1000/$D$2=P2*$A2*($E2-2*$F2-$G2)/1000/$D2=N3/1000/60/ I3 =N3/1000/60/J3=O3*$A$2*($G$2-2*$H$2)/1000/$D$2=P3*$A3*($E3-2*$F3-$G3)/1000/$D3颗粒范围(m)=1.225*(D2^2/(A2*(B2-A2)))^(1/3) =20.4*(D2^2/(A2*(B2-A2)))^(1/3) =1105*(D2^2/(A2*(B2-A2)))^(1/3)环空沉降末速Vt(m/s)颗粒群滑移速度Vr(m/s)考虑絮凝(球粒)干扰沉降速度Vts(m/s)非球形颗粒(0.8球粒度)干扰沉降速度Vts(m/s)干扰自由沉速=IF(C2<=$T$2,0.545*C2^2*(B2-A 2)/D2,IF(C2<=$T$3,1.195*C2*(( B2-A2)^2/(D2*A2))^(1/3),IF(C2 <$T$4,5.39*(C2*(B2-A2)/A2)^0. 5,5.39*(C2*(B2-A2)/A2)^0.5))) =R8*EXP(-(2.65*$S$2/100-3.32*K8^2.2))=1/((2/3)*(1-$S$2/100)^2*EXP(ABS((-2.5*$S$2/100)/(1-($S$2/100)*39/64))))*R8=1/((1-$S$2/100)^2*EXP(ABS((-2.5*0.8*$S$2/100)/(1-($S$2/100)*39/64))))*R8=T8/R8=IF(C3<=$T$2,0.545*C3^2*(B3-A 3)/D3,IF(C3<=$T$3,1.195*C3*(( B3-A3)^2/(D3*A3))^(1/3),IF(C3 <$T$4,5.39*(C3*(B3-A3)/A3)^0. 5,5.39*(C3*(B3-A3)/A3)^0.5))) =R9*EXP(-(2.65*$S$2/100-3.32*K9^2.2))=1/((2/3)*(1-$S$2/100)^2*EXP(ABS((-2.5*$S$2/100)/(1-($S$2/100)*39/64))))*R9=1/((1-$S$2/100)^2*EXP(ABS((-2.5*0.8*$S$2/100)/(1-($S$2/100)*39/64))))*R9=U8/R8=0.688*(B4-A4)*(C4^2)/D4 =R10*EXP(-(2.65*$S$2/100-3.32*K10^2.2))=1/((2/3)*(1-$S$2/100)^2*EXP(ABS((-2.5*$S$2/100)/(1-($S$2/100)*39/64))))*R1=1/((1-$S$2/100)^2*EXP(ABS((-2.5*0.8*$S$2/100)/(1-($S$2/100)*39/64))))*R10竖直井筒正冲所需最低流量(L/s) 水平井筒正冲所需最低流量(L/s)=2*$R$8*$J$2*1000 =6*$R$8*$J$2*1000 清水5-1/2"套管=2*$T$9*$J$2*1000 =6*$T$9*$J$2*1000=2*$R$8*$J$3*1000 =6*$R$8*$J$3*1000 清水7"套管=2*$T$9*$J$3*1000 =6*$T$9*$J$3*1000=2*$R$10*$J$2*1000 =6*$R$10*$J$2*1000 泥浆5-1/2"套管=2*$T$10*$J$2*1000 =6*$T$10*$J$2*1000=2*$R$10*$J$3*1000 =6*$R$10*$J$3*1000 泥浆7"套管=2*$T$10*$J$3*1000 =6*$T$10*$J$3*1000。

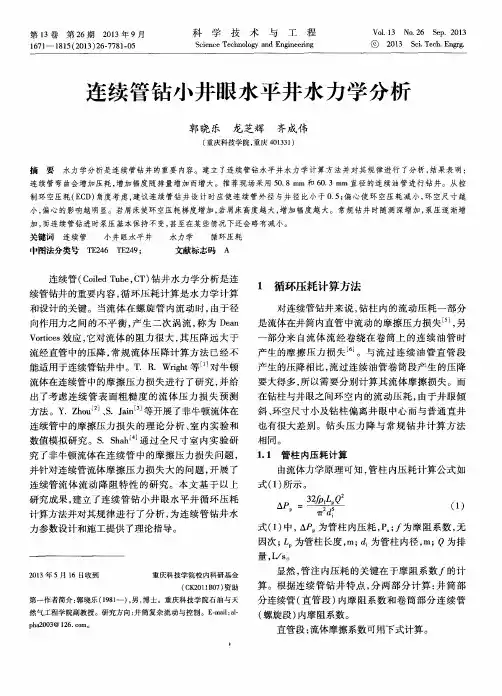

连续管钻井技术及其设备本文分析了连续管钻井技术、应用及其设备。

特别是重入钻井、新钻直井和欠平衡钻井中的应用。

连续管钻井装备组成、连续管主要装置,连续油管材料及其制造工艺。

标签:连续管;钻井技术;钻井装备;材料;制造工艺1 连续管钻井技术现状连续管钻井(Coiled Tubing Drilling,CTD)是一种采用连续管完成钻井的技术。

自20世纪90年代初获得成功。

近年来成为热门钻井新技术,广泛应用于海上和陆地油田,作业范围包括钻井、修井、完井、试采油等。

随着连续管材料和制造工艺的发展进步,特别是连续自动焊接,连续高频淬火工艺的进步,使得连续管成本大幅度降低、寿命进一步提高,现场大范围内广泛使用成为可能。

可靠性高的高强度大直径连续管产生、小直径容积式马达研制成功、先进的定向工具及测量系统和金刚石钻头的问世,有力地推动了连续管钻井技术发展与应用。

连续管钻井按钻井的类型分,有直井、定向井、水平井;按工艺方式分类,欠平衡压力钻井、平衡压力钻井和过平衡压力钻井三种。

单从技术难度来看,钻直井并不需要特殊的工艺设备。

经济可行性的连续管钻井,主要包括重入钻井、新钻直井和欠平衡钻井三大钻井。

1.1 连续管重入钻井连续管重入钻井有两种方式作业,直井加深作业和侧钻水平井及多分支井作业。

小直径连续管多进行过油管侧钻,因不需起下油管,可显著地降低钻井成本。

1.2 连续管新钻直井连续管新钻直井应用范围,一般指浅层油气藏和煤层气的开发。

用连续管作业特点是:钻井速度快,作业也机动灵活轻便、动迁性能特别好。

一般来讲,连续管新钻直井成本是常规钻井降低2/3左右,或许更低都有可能。

1.3 连续管欠平衡钻井连续管作业不需要接单根,是连续管作业的最大特点,且在防喷器组的协助下,井口压力控制可高达70 MPa,使井口欠平衡作业成为可能,能够实现真正意义上的欠平衡作业。

欠平衡连续管钻井的另一好处是,对压力递减储层、衰竭产层和酸性气体井非常有效。