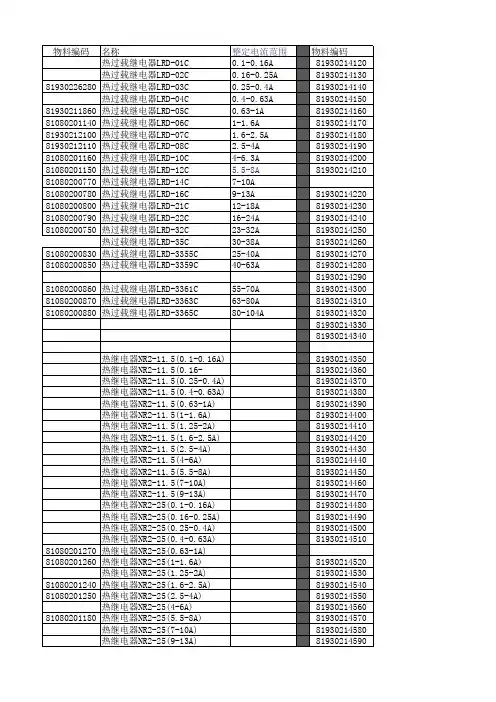

过载继电器[THR)

- 格式:doc

- 大小:11.50 KB

- 文档页数:1

热控专业常见的英语词汇热控专业常见的英语词汇学习任何语言都是需要花费很多努力,但不要放弃。

下面是热控专业常见的英语词汇,欢迎阅读。

A AshHandling System 除灰系统AH AirHeater 空气预热器AAh Analyzer,Alarm High 分析器,高值报警AIV AirIntake Valve 进气阀ALIGN Alignment 校正ALKF AirlockFeeder 锁气器AP AshSlurry Pump 灰浆泵ATM Atmosphere 大气AC AirConditioner 空气调节器AFT AtmosphereFlash Tank 大气扩容器AGC Automatic generation control 自动发电控制方式AC Alternating Current 交流电ALM Alarm 报警AMP Ampere 安培AX THR BRG AxisThrust Bearing 轴向推力,轴承ATMZ Atomizing 雾化AUTO Automation 自动AUX Auxiliary 辅助的BA BottomAsh 底灰BAH BottomAsh Hopper 底灰斗BF Boiler Follow mode锅炉跟随方式BLR Boiler 锅炉BSD BoilerShut Down 停炉BUSH Bushing 衬套BYPS Bypass 旁路BVD BoilerVents and Drains 锅炉疏水放气BFP BoilerFeedwater Pump 锅炉给水泵BFPT BoilerFeedwater Pump Turbine 锅炉给水泵汽机BFW BoilerFeedwater 锅炉给水BM BoilerMaster 锅炉主控BMCR BoilerMaximum Continuous Rating 锅炉最大连续出力BFBP BoilerFeed Booster Pump 锅炉给水增压泵BNR Burner 燃烧器BOP BalanceOf Plant 电厂辅机设备BPC BladePitch Control 叶片节距控制BT BoilerTube 炉管CH CrusherHouse 碎煤房COMB Combustion 燃烧COMP CompressedAir 压缩空气CONV Conveyer 输送机CPL ControlPanel Local 就地控制盘CPM ControlPanel Main 主控盘CRT CathodeRay Tube 阴极射线管CT CurrentTransformer 变流器CYCL Cyclone 旋风分离器CAS Casing 缸,壳CB CircuitBreaker 断路器CCS Cordinate control system 协调控制系统COMP Complete 完成CCCW ClosedCirculating Cooling Water 闭式循环冷却水CCW CycleCooling Water 循环水CCWHF ClosedCooling Water Heater 闭式冷却水冷却器CCWP ClosedCooling Water Pump 闭式冷却水泵CS ClosedCooling Water System 闭式冷却水系统CH CoalHandling 煤的装卸CHK VLV Check Valve 逆止阀CIRC Circulation 循环CLR Cooler 冷却器CLOW CoolingWater 冷却水CMPR Compressor 压缩机CNTL Control 控制CNTLE Controller 控制器COND Condensate 凝结水CONDTY Conductivity 导电率CP CondensatePump 凝结泵CIR Circuit 回路COUPI Coupling 联轴器CP CondensatePolisher 除盐装置CS ControlSwitch 控制开关CRSV ColdReheat Safety Valve 再热器冷段安全阀CV ControlValve 控制阀CWP CirculationWater Pump 循环水泵DMPR Damper 挡板DP DifferencePressure 差压DPIC DifferentialPressure Indicating Controller 压差指示控制器DPT DifferentialPressure Transmitter 压差变送器DRN Drain 疏水DV DrainValve 疏水阀DC DirectCurrent 直流电DSH Desuperheater 减温器DCA Drain Cooler Approach 疏水冷却器通道DEAER Deaerator 除氧器DEV Deviation 偏差DIFFRLY DifferentialRelay 差动继电器DISCH VLV DischargeValve 排放阀DIST Disturbance 故障,扰动DSCH Discharge 排出ECON Economizer 省煤器ESP ElectricalStatic Precipitator 静电除尘器ECC Eccentricity 偏心EFF Efficiency 效率EHC ElectricHydraulic Control 电液控制EO ElectricOperate 电气操作EQ Equipment 设备ER Error 误差ES ExtractionSystem 抽气系统ESC Escape 逃逸,超出ESS EngineeringSafety System 保安系统EU EngineeringUnit 工程单位EXH Exhaust 排汽EXT Extract 抽出FA FineAsh 细灰FDR Feeder 给料机FE FlowElement 流量元件FI FlowIndicator 流量指示件FDBK Feedback 反馈FITG Fitting 连接件FLW Flow 流量FO FailOpen 故障时自动打开FT FlowTotalizer 流量累加器FT Flowtransmitter 流量变送器FV FlowControl Valve 流量控制阀FY FlowRelay or Valve 流量传送器FA FailureAlarm 故障报警FD ForcedDraft 强制通风FDF ForcedDraft Fan 送风机FIC FlowIndicate Controller 流量指示控制器FLT FlashTank 扩容箱FLD Field 磁场FLG Flange 法兰FLM Flame 火焰FWH FeedWater Heater 给水加热器FO FuelOil 燃油FREQ Frequency 频率FURN Furnace 炉膛GLD Gland 密封GRDR Grinder 碎渣机GND Grounding 接地GC GeneratorCooling 发电机冷却GESE GlandSteam Condenser Exhauster 轴加风机GMT GeneratorMain Transformer 发电机变压器GRAD Grandient ['ɡreidint] 梯度GS GlandSteam 轴封蒸汽GSC GlandSteam Condenser 轴封加热器GV GovernorValve 高压调门HC HeatConservation 保温HS HandSwitch 手动开关HTR Heater 加热器HV HandControl Valve 手动控制器HY HandRelay or Transducer 手动继电器(转换器)H Hand 手动的HB HeatBalance 热平衡HD HeaterDrain 加热器疏水HDR Header 联箱HL HeatLoss 热损失HMDY Humidity 湿度HPH HighPressure Heater 高压加热器HPR Hooper 漏斗HPT HighPressure Turbine 高压汽机HR HotReheat 再热器热段HR HeatRate 热耗率HSV HotReheat Safety Valve 再热器热段安全阀HVAC HeatingVentilation & Air Conditioning 暖通HW Hotwell 热井HV HandControl Valve 手动控制器HVAC Heating-ventilation-air-conditioningHYD Hydraulic 液力的INTLK Interlock 联锁IC Instrumentand Control 仪表与控制(热工)ICV IntermediateControl Valve 中压控制阀ID InducedDraft 抽风,引风IDF InducedDraft Fan 引风机IGN Ignition 点火装置INLT Inlet 入口IPR InitialPressure 初压INST Instrument 仪表INVR Inverter 逆变器I/O Input/Output 输入/输出IP IntermediatePressure 中压ISV IntermediatePressure Turbine Steam Valve 中压缸进汽阀JP JetPump 喷射器LG LevelGauge 液位计LVL Level 水位,液位LA LevelAlarm 液位报警LIM(LMIR) Limiter 限制器LKG Leakage 泄漏LP LowPressure 低压L.P LowPoint 低位LPH LowPressure Heater 低压加热器LSH LocalSwitch Hand 就地开关LUB LubricatingOil 润滑油M Mechanical 机械M Motor 马达MAG Magnetic 磁性MOD Mode 方式M/A Manual/Automatic 手动/自动MAN Manual 手动MARG Margin 裕量MAX Maximum 最大的,最大值的MCR MaximumContinuous Rating 最大连续出力MCV MainControl Valve 主控制阀MD ModulationDamper 调节挡板MDBFP MotorDriven Boiler Feedwater Pump 电动给水泵MEAS Measure 测量MFT MasterFuel Trip 主燃料跳闸MIN Minimum 最小的MKUP (MU) Make-up 补充ML Mill 磨煤机MN Main 主要的M.O. ManualOperation 手操MPT MainPower Transformer 主变压器MS MainSteam 主蒸汽MSV MainSteam Valve 主汽阀NOZ Nozzle 喷嘴NPSH NetPump Suction Head 泵的.静吸压头OL Overload 过载OLR OverloadRelay 过载继电器OPER Operation 运行OSC Oscillograph 示波器OTLT Outlet 出口PA PrimaryAir 一次风PAF PrimaryAir Fan 一次风机PAH PressureAlarm High 高压报警PAL PressureAlarm Low 低压报PB PushButton 按钮PC PowerCentre 动力中心PC PressureController 压力控制器P.C. PressureControl 压力控制PCP Precipitator 除尘器PCV PressureControl Valve 压力控制阀PDI PressureDifferential Indication 差压指示PDT PressureDifferential Transmitter 差压变送器PED Pedestal 轴承座PERF CALC Performance Calculation 性能计算PF PowerFactor 功率因数PHTR Preheater 预热器PMP Pump 泵PNEU Pneumatic 气动的PR PressureRecorder 压力记录计PRG Purge 吹扫PRV PressureRelief Valve 泄压阀PRO Protection 保护PROGR Program 程序PT PressureTransmitter 压力变送器PULV Pulverizer 磨煤机PVSV PressureVacuum Safety Valve 压力真空安全阀PW PlantWater 厂用水PY PressureRelay 压力继电器QA Quality 质量,性能RB RunBack 快速降负荷RCV Recovering 回收RECIRC Recirculation 再循环RECT Rectifier 整流器RET Return 返回RH Reheater 再热器RO RestrictionOrifice 节流孔板ROT Rotor 转子RTU RemoteT elemetry Unit 遥测装置SA SecondaryAir 二次风SAT Saturate 饱和的SC SteamCoil Air Heater 暖风器SCAV Scavenge 吹扫SD Shut-offDamper 关断挡板SD Shut-Down 停机SEP Separator 分离器SG Switchgear 开关装置SH Superheater 过热器SLS Seals 密封SO ShutOff 关闭SPD Speed 转速SPRA Spray 喷水SPT Support 支持ST Start 启动,开始STD-BY StandBy 备用ST System 系统STM Steam 蒸汽STR Stator 定子STRNR Strainer 滤器SU StartUp 启动SV SolenoidValve 电磁阀SUCT Suction 吸入SW Switch 开关SW SteamWater 汽水SBLWR SootBlower 吹灰器TBFP TurbineDrive Boiler Feedwater Pump 汽动给水泵TCV TemperatureControl Valve 温度控制T.B. TransferDamper 转换挡板TE TemperatureElement 温度元件TG Turbine-generator 汽轮发电机Turbine-gear 汽机盘车THERM Thermal 热力的TMS TurbineMaster System 汽机主控系统TRANS Transfer 转换TRBL Trouble 故障TRKG Tracking 跟踪TT TemperatureTransmitter 温度变送器TTD TerminalTemperature Difference 温度端差TW Thermowell 热电偶套管UAM UnitAutomatic Master 机组自动系统VAC Vacuum 真空VAL Value 数值VB Vibration 振动VLV Valve 阀门WH Watthour 瓦小时WP WorkingPoint 工作点WW WaterWall 水冷壁WX WattTransducer 功率转换器COVER Crossover 切换管CV ControlValve 控制阀AVR automatic voltage regulator 自动电压调节器VCB vacuum circuit breaker 真空断路器。

ABB热继电器TA200DU175具有齐全的电流整定设置范围同时具备温度补偿、断相保护功能ABB热过载继电器主要用于保护电动机的过载或断相故障,与a-li ne全系列接触器配合,对额定工作电压至交流690v或直流800v的三相电动机进行过载或断相保护。

更多详情咨询0577-********ABB TA...DU系列热过载继电器具有整定电流设置等级,自由脱扣机构,环境温度补偿,缺相保护,复位测试功能。

适用于额定工作电压至AC690V或DC800V的电动机保护。

脱扣等级:10A;防护等级:符合EN50274标准,防止手部接触;符合欧洲及国际标准IEC、VDE、NFC、E

ABB热过载继电器主要结构及工作原理:

接触器为正装直动式双断点结构,罩盖与躯壳采用耐弧塑料制成,A9-A16采用自动灭弧,而A26-A110有U型的灭弧片置于躯壳中,形成封闭灭弧室灭弧好,飞弧距离为零。

触头采用抗熔焊及耐电磨损的银基合金材料制成,导电性能好,寿命长,对环境无污染。

铁芯采用E形结构,体积小。

线圈的接线方式有两种可供用户选择,一种两接线端在产品的同一端,另一种两接线端分别在产品的两端,接线灵活方便。

底座用玻璃纤维增强塑料制成,强度高,介电性能好。

安装方式可以螺钉安装,也可以用导轨安装,拆装方便迅速。

导电部件不外露,安全性能好。

正常工作条件和安装条件:

1、安装地点的海拔不超过2000M

2、周围空气温度不超过+40度,且其25H内的平均温度值不超过=35度,周围。

abb热过载继电器说明书

ABB热过载继电器是一种用于电气设备保护的重要组件。

它们

通常用于监测电动机的电流,以便在电流超出额定值时断开电路,

以防止电动机过载。

以下是关于ABB热过载继电器的说明书内容:

1. 产品介绍,说明书应该包括ABB热过载继电器的基本介绍,

包括产品型号、尺寸、额定电流范围、工作原理等内容。

它还应该

介绍产品的外观特征和安装方式。

2. 技术规格,说明书中应包括ABB热过载继电器的技术规格,

如额定电流、额定电压、动作特性、环境条件等。

这些规格对于用

户选择合适的继电器至关重要。

3. 安装和连接,说明书应该提供清晰的安装指导,包括继电器

的安装位置、连接方式、接线图等。

此外,还应包括安全注意事项

和安装过程中需要遵守的标准和规定。

4. 使用说明,说明书中应该包括ABB热过载继电器的使用说明,包括如何设置动作电流、如何进行故障诊断和维护等内容。

用户需

要清楚了解如何正确地使用和维护继电器。

5. 故障排除,说明书应该包括常见故障的排除方法和维修指导,以帮助用户在继电器出现故障时快速解决问题。

6. 安全注意事项,最后,说明书应该包括关于继电器安全使用

的注意事项,以及在维修和更换继电器时需要遵守的安全规定。

总的来说,ABB热过载继电器的说明书应该全面介绍产品的技

术参数、安装使用方法、维护保养和安全注意事项,以帮助用户正确、安全地使用这一重要的电气设备保护组件。

boiler house: 锅炉房coal conveyor 输煤装置coal bunker: 煤仓coal mill磨煤机steam boiler, water boiler tube 蒸汽锅炉,管式锅炉furnace(combustion chamber): 炉膛( 燃烧室)water tube: 水管ash pit 灰坑superheater: 过热器water preheater: 水预热器air preheater: 空气预热器gas duct(flue): 烟气管, 烟道dust collecting plant: 集尘室electrical precipitation plant: 电气除尘室induced draught fan: 引风机chimney: 烟囱deaerator: 除氧器feed water tank: 供水箱boiler feed pump: 给水泵switchgear: 开关设备cable tunnel: 电缆通道cable cellar: 电缆槽turbine room: 汽轮机室steam turbine with alternator: 蒸汽汽轮发电机组economizer: 省煤器steam drum: 汽包surface condenser: 表面凝汽low-pressure preheater: 低压预热器circulating water pipe(pump): 循环水管control room: 控制室electrostatic dust remover(precipitator): 静电除尘器pulverizer 磨煤机slag pump 灰渣泵thermal cycle: 热力循环(net)heat rate: (净)热耗率Assemblie: 集合,集结,组装comment 注释,评论module : 模块standby: 备用proximity 相近,接近,亲近detector: 探测器bracket: 支架interlocks 互锁,联锁axial: 轴向surge conditions: 喘振:accessory: 附件pulsation: 有节奏跳动,跳动fossil fired: 燃煤intent: 意图,目,意向intend: 意指,想要,打算consistent: 一致,调和practice: 惯例,实习,实践intrinsic: 固有,内在procurement 获得,获取fabrication: 制作,构成,伪造物vent: 通风孔,出烟孔,出口,放出,排出,noncondensible gas: 不凝结气体intermittent 间歇,断断续续blowdown : 排污tank: 桶,箱,罐diagram: 图表deaerator: 除氧器corrosion : 侵蚀,腐蚀状态concentration 集中,集合,浓缩,浓度recommend 推荐,介绍,托付,劝告abnormal and normal conditions: 变工况和额定工况warm up: 暖机acid wash: 酸洗scale: 范围,水垢,水锈,比例,刻度sludge :: 污泥,淤泥foreign matter: 不相关物质facilitate: 推动,促进,使简化multistage: 多级remote control: 遥控safety relief valve: 安全卸压阀gauge: 量规,量表,测量manhole: 人孔,检修孔equivalent: 等价物,相等forging:: 锻造seat: 部位,座socket welding: 管座焊接enthalpy: 焓estimate: 评价,评估,估价parameters 参数,参量nominal : 名义上,额定,标称MS — Main Steam : 主蒸汽Cycle:: 循环Intercept: 截止Fetting: 附件Gage:: 规,表,压力计Taps: 接头test wells: 测点插孔stress-relieved: 应力消除thermometer: 恒温计steam purge system: 蒸汽吹扫系统centrifugal type pumps: 离心式泵friction losses: 磨擦损失solenoid: 螺线管modulat: 调整,调节criteria: 标准wrenches: 扳手pipe taps: 管接头 .A List of Abbreviations and Symbols in English-ChineseA ::Ash Handling System: 除灰系统AH :Air Heater: 空气预热器AAh :Analyzer, Alarm High : 分析器,高值报警:: AIV :Air Intake Valve: 进气阀ALIGN Alignment: 校正ALKF :Airlock Feeder: 锁气器AP ::Ash Slurry Pump: 灰浆泵ATM :Atmosphere 大气AC ::Air Conditioner: 空气调节器AFT :Atmosphere Flash Tank: 大气扩容器AC :Alternating Current: 交流电ALM :Alarm:: 报警AMP :Ampere: 安培AX THR BRG :Axis Thrust Bearing: 轴向推力,轴承ATMZ :Atomizing: 雾化AUTO :Automation 自动AUX :Auxiliary: 辅助BA :Bottom Ash 底灰BAH ::Bottom Ash Hopper: 底灰斗BLR ::Boiler: 锅炉BSD ::Boiler Shut Down: 停炉BUSH :Bushing: 衬套BYPS :Bypass:: 旁路BVD ::Boiler Vents and Drains:: 锅炉疏水放气BFP :Boiler Feedwater Pump :: 锅炉给水泵BFPT:Boiler Feedwater Pump Turbine: 锅炉给水泵汽机BFW ::Boiler Feedwater: 锅炉给水BM :Boiler Master 锅炉主控BMCR:Boiler Maximum Continuous Rating: 锅炉最大连续出力BFBP:: Boiler Feed Booster Pump: 锅炉给水增压泵BNR :Burner: 燃烧器BOP :Balance Of Plant: 电厂辅机设备BPC :Blade Pitch Control: 叶片节距控制BT :Boiler Tube: 炉管CH: Crusher House: 碎煤房COMB ::Combustion 燃烧COMP ::Compressed Air: 压缩空气CONV ::Conveyer: 输送机CPL :Control Pannel Local: 就地控制盘CPM :Control Pannel Main: 主控盘CRT :Cathode Ray Tube: 阴极射线管:CT Current Transformer: 变流器CYCL :Cyclone: 旋风分离器CAS :Casing:: 缸、壳CB Circuit Breaker: 断路器COMP :Complete: 完成CCCW :Closed Circulating Cooling Water: 闭式循环冷却水CCW :Cycle Cooling Water: 循环水CCWHF ::Closed Cooling Water Heater 闭式冷却水冷却器CCWP :Closed Cooling WaterPump: 闭式冷却水泵CS :Closed Cooling Water System 闭式冷却水系统CH Coal Handling 煤装卸CHK VLV :Check Valve: 逆止阀CIRC: Circulation: 循环CLR Cooler: 冷却器CLOW :Cooling Water: 冷却水CMPR :Compressor: 压缩机CNTL :Control: 控制CNTLE :Controller:: 控制器COND :Condensate: 凝结水CONDTY :Conductivity: 导电率CP: Condensate Pump: 凝结泵CIR: Circuit: 回路COUPI :Coupling: 联轴器CP: Condensate Polisher: 除盐装置CS: Control Switch 控制开关CRSV :Cold Reheat Safety Valve: 再热器冷段安全阀CV: Control Valve : 控制阀CWP: Circulation Water Pump: 循环水泵DMPR: Damper : 挡板DP Difference Pressure: 差压DPIC: Differential Pressure Indicating Controller压差指示控制器DPT: Differential Pressure Transmitter 压差变送器DRN: Drain: 疏水DV Drain Valve:: 疏水阀DC Direct Current: 直流电DSH: Desuperheater: 减温器DCA: Drain Cooler Approach: 疏水冷却器通道DEAER Deaerator: 除氧器DEV: Deviation: 偏差DIFFRLY: Differential Relay: 差动继电器DISCH VLV :Discharge Valve 排放阀DIST: Disturbance:: 故障、扰动DSCH: Discharge: 排出ECON: Economizer:: 省煤器EP Electrical Static Precipitator: 静电除尘器ECC Eccentricity :: 偏心EFF Efficiency: 效率EHC Electric Hydraulic Control: 电液控制EO Electric Operate: 电气操作EQ Equipment: 设备ER Error: 误差ES :Extraction System 抽气系统ESC Escape: 逃逸、超出ESS Engineering Safety System: 保安系统EU Engineering Unit : 工程单位EXH Exhaust: 排汽EXT Extract: 抽出FA :Fine Ash: 细灰FDR Feeder: 给料机FE :Flow Element:: 流量元件FI :Flow Indicator:: 流量指示件FDBK: Feedback: 反馈FITG Fitting: 连接件FLW Flow 流量FO :Fail Open: 故障时自动打开FT: Flow Totalizer: 流量累加器FT :Flow transmitter: 流量变送器FV :Flow Control Valve 流量控制阀FY :Flow Relay or Valve 流量传送器FA: Failure Alarm: 故障报警FD :Forced Draft : 强制通风FDF Forced Draft Fan: 送风机FIC :Flow Indicate Controller: 流量指示控制器FLT :Flash Tank : 扩容箱FLD :Field 磁场FLG :Flange: 法兰FLM Flame: 火焰FWH Feed Water Heater 给水加热器FO :Fuel Oil: 燃油FREQ Frequency: 频率FURN Furnace: 炉膛GLD Gland: 密封GRDR Grinder: 碎渣机GND Grounding: 接地GC :Generator Cooling: 发电机冷却GESE Gland Steam Condenser Exhauster: 轴加风机GMT Generator Main Trandformer: 发电机变压器GRAD Grandient: 梯度GS :Gland Steam: 轴封蒸汽GSC :Gland Steam Condenser: 轴封加热器GV :Governor Valve: 高压调门H ::Heat Conservation 保温HS: Hand Switch:: 手动开关HTR Heater: 加热器HV: Hand Control Valve: 手动控制器HY: Hand Relay or Transducer 手动继电器(转换器)H :Hand: 手动HB :Heat Balance: 热平衡HD :Heater Drain:: 加热器疏水HDR :Header: 联箱HL ::Heat Loss: 热损失HMDY Humidity: 湿度HPH: High Pressure Heater: 高压加热器HPR :Hooper: 漏斗HPT :High Pressure Turbine: 高压汽机HR: Hot Reheat: 再热器热段HR: Heat Rate: 热耗率HSV: Hot Reheat Safety Valve: 再热器热段安全阀HVAC :Heating Ventilation & Air Conditioning:: 暖通HW :Hotwell: 热井HV ::Hand Control Valve: 手动控制器HYD :Hydraulic: 液力INTLK :Interlock : 联锁IC :Instrument and Control:: 仪表与控制(热工)ICV ::Inrtermediate Control Valve 中压控制阀ID :Induced Draft 抽风,引风IDF ::Induced Draft Fan: 引风机IGN ::Ignition: 点火装置INLT :Inlet: 入口IPR ::Initial Pressure: 初压INST :Instrument: 仪表INVR :Inverter: 逆变器I /O:: Input/Output 输入/ 输出IP :Intermediate Pressure: 中压ISV ::Intermediate Pressure Turbine Steam Valve: 中压缸进汽阀JP :Jet Pump: 喷射器LG :Level Gauge 液位计LVL ::Level: 水位,液位LA :Level Alarm: 液位报警LIM(LMIR): Limiter: 限制器LKG:: Leakage:: 泄漏LP :Low Pressure 低压L.P :Low Point : 低位LPH: Low Pressure Heater: 低压加热器LSH: Local Switch Hand: 就地开关LUB: Lubricating Oil: 润滑油M :Mechanical: 机械M :Motor: 马达MAG:: Magnetic: : 磁性MOD ::Mode: 方式:M/A :Manual/Automatic: 手动/ 自动MAN ::Manual :: 手动MARG: Margin:: 裕量MAX ::Maximum: 最大,最大值MCR ::Maximum Continuous Rating 最大连续出力MCV:: Main Control Valve: 主控制阀MD :Modulation Damper: 调节挡板MDBFP: Motor Driven Boiler Feedwater Pump: 电动给水泵MEAS ::Measure : 测量MFT: Master Fuel Trip: 主燃料跳闸MIN :Minimum: 最小MKUP (MU) Make-up: 补充ML :Mill: 磨煤机MN :Main: 主要M.O. :Manual Operation: 手操MPT :Main Power Transformer: 主变压器MS :Main Steam 主蒸汽MSV :Main Steam Valve: 主汽阀NOZ: Nozzle: 喷嘴NPSH :Net Pump Suction Head: 泵静吸压头OL: Overload: 过载OLR :Overload Relay: 过载继电器OPER :Operation: 运行OSC :Oscillograph: 示波器OTLT: Outlet: 出口PA: Primary Air: 一次风PAF :Primary Air Fan: 一次风机PAH :Pressure Alarm High: 高压报警PAL :Pressure Alarm Low: 低压报警PB: Push Button 按钮PC :Power Centre: 动力中心PC: Pressure Controller: 压力控制器P.C. :Pressure Control: 压力控制PCP :Precipitator 除尘器PCV :Pressure Control Valve:: 压力控制阀PDI :Pressure Differential Indication:差压指示PDT :Pressure Differential Trandsmitter: 差压变送器PED :Pdestal:: 轴承座PERF CALC Performance Calculation:: 性能计算PF: Power Factor 功率因数PHTR: Preheater: 预热器PMP :Pump: 泵PNEU :Pneumatic: 气动PR: Pressure Recorder: 压力记录计PRG :Purge: 吹扫PRV :Pressure Relief Valve: 泄压阀PRO :Protection: 保护PROGR:: Program: 程序PT: Pressure Transmitter: 压力变送器PULV: Pulverizer: 磨煤机PVSV :Pressure Vacuum Safety Valve 压力真空安全阀PW: Plant Water 厂用水PY: Pressure Relay: 压力继电器QA: Quality:: 质量,性能RB: Run Back: 快速降负荷RCV :Recovering: 回收RECIRC:: Recirculation 再循环RECT :Rectifier: 整流器RET :Return: 返回RH: Reheater: 再热器RO: Restriction Orifice: 节流孔板ROT :Rotor: 转子RTU :Remote Telemetry Unit:: 遥测装置SA :Secondary Air: 二次风SAT: Saturate: 饱和SC :Steam Coil Air Heater:: 暖风器SCAV :Scavenge: 吹扫SD: Shut-off Damper: 关断挡板:Shut-Down 停机SEP :Separator 分离器SG: Switchgear 开关装置SH: Superheater: 过热器SLS :Seals:: 密封SO: Shut Off: 关闭SPD :Speed: 转速SPRA: Spray: 喷水SPT :Support: 支持:ST: Start: 启动,开始STD-BY :Stand By: 备用ST: System:: 系统STM :Steam: 蒸汽STR: Stator:: 定子STRNR: Strainer: 滤器SU: Start Up: 启动SV: Solenoid Valve: 电磁阀SUCT: Suction: 吸入SW: Switch: 开关:Steam Water: 汽水SBLWR: Soot Blower 吹灰器TBFP Turbine Drive Boiler Feedwater Pump 汽泵TCV :Temperature Control Valve 温度控制T.B.: Transfer Damper: 转换挡板TE: Temperature Element: 温度元件TG: Turbine-generator: 汽轮发电机Turbine-gear: Turbine-gear: 汽机盘车THERM :Thermal 热力TMS: Turbine Master System: 汽机主控系统TRANS :Transfer: 转换TRBL: Trouble: 故障TRKG: Tracking: 跟踪TT: Temperature Transmitter: 温度变送器TTD: Terminal Temperature Difference: 温度端差TW: Thermowell: 热电偶套管UAM :Unit Automatic Master: 机组自动系统VAC: Vacuum: 真空VAL: Value: 数值VB: Vibration 振动VLV: Valve: 阀门WH: Watthour 瓦小时WP: Working Point: 工作点WW: Water Wall 水冷壁WX: Watt Transducer: 功率转换器COVER :Crossover 切换管CV: Control Valve: 控制阀英汉对照表A/H :AUTOMATION/HAND : 自动/ 手动;A/M :AUTOMATION/MANUAL: 自动/ 手动;ALARM 报警;AUX :AUXILIARY :: 辅助;BYPASS 旁路CLOSE 关(状态,常指阀门);CODE: 代码;编码COLD START — UP: 冷态启动COMPUTER : 计算机CURVE ,LINE: 曲线,线DATA: 数据;文件;资料DECREAS : 减少DESK: 台,桌DIGIT: 数字DISK: 磁盘DYNAMIC ;DYNAMICAL: 动态F :FLOW 流量;FAST: 快FIGURE: 图示HIGH: 高HOT START — UP: 热态启动I&C :INSTRUMENT AND CONTROL 仪表与控制INCREAS: 增加INDICATION ;DISPLAY : 指示;显示;INLET 入口;INPUT 输入;INTERMEDIATE 中KEYBOARD: 键盘KW :KILOWATT 千瓦L :LOAD 负荷,负载;LOC :LOCAL : 就地LOW: 低MCS :MANAGMENT COMMAND SYSTEM 管理命令系统MODE : 方式,模式MW :MEGAWATT 兆瓦NORMAL: 正常OFF : 关(状态);ON : 开(状态);OPEN: 开( 状态,常指阀门);OPERATE : 运行;操作;OUTLET 出口;OUTPUT 输出;P :PRESSURE: 压力;PANEL 盘PARAMETER : 参数PIPE ;TUBE: 管道,管子PLANT: 厂,站POWER: 功率,电源;PRINT: 打印R :RATE : 比率,速率;R :RESISTANCE: 电阻;REM :REMOTE : 摇控;RESET 复位ROOM : 室RPM:: 转/ 分;S :SPEED 速度;SELECT 选择SET POINT 设定点SHUTDOWN : 停机;SIDE (某)侧,边;SILENCER 消音器SLOW : 慢STAND BY: 备用;START : 启动;STARTUP : 起动;启动;STATIC 静态STATION 站STOP: 停止;SYMBOL 符号SYSTEM: 系统T :TEMPERATURE:: 温度;TEST: 试验;TRANSMITTIER;TRANSDUCER: 变送器;传感器TRIP 跳闸;TRIP ACKNOW: 跳闸确认UNAVAIL 不允许( 不能投用)UNIT : 单元、机组VALVE 阀门WARM START — UP: 温态启动ZOOM: 摄像机镜头锅炉部分ACTUAL MEGAWATT: 有功AIR DRAFT SEQUENCE: : 风机程序控制(顺控)AIR HEATER A MOTER: 空预器马达AAIR HEATER LOC/REM SELECT: 空预器就地/ 遥控选择AIR HEATER MOTOR LEAD: 空预器马达选择AIR HTR A SEC AIR OUT TEM 空预器A 二次风出口温度AIR PREHEATER: 空预器AIR SVCE SUPPLY: 服务空气ALARM LIMITS: :: 报警限制ALL AIR HTRS RUNNING 各空预器运行ALL PULV GRP SHUTDOWN 所有磨组停运ASH — HOPPER: : 灰斗ATTEMPERATOR: : 减温器AUX .ST: SPLY FOR ATOMIZ 辅助蒸汽供雾化蒸汽BOIL MILL A BNR MET TEMP 炉A 磨组喷燃器金属温度BOIL MILL A GR1 WDBOX PR 炉A 磨组第一组风箱压力BOILER AIR REQUIRED 锅炉风量需求(>30% )BOILER EFFLUENT STORAGE: POOL 锅炉废水池BOILER FOLLOW MODE: 炉跟随方式BOILER MASTER: 锅炉主控器BOILER TRIP RESET: : 锅炉跳闸复位BOILER: 锅炉BURNNER: : 燃烧器CHIMNEY ;STACK:: : 烟囱CLEAN: 清扫COAL BANKER: :: 煤仓COAL FEEDER : 给煤机COMBUSTION : 燃烧CONVEYOR: 皮带机COORDINATE MODE 协调方式CRUSHER: 破碎机DECR/INCR PRESS AT FIX LOAD:: 固定负荷方式增减压力DOWM COMER:: 下降管DRAIN & VENT: 疏水和排气ECONOMIZER : 省煤器EITHER FAN RUNNING : 任一风机运行EITHER ID FAN RUNNING 任一吸风机运行ELECTROSTATIC PRECIPITATOR : 静电除尘器FD FAN A FLOW:: A 送风机流量FD FAN/ID FAN A CONT DAMPER A 送/ 吸风机控制挡板FEED WATER FLOW: 给水流量FEEDER LOCAL SELECT: 给煤机就地控制选择FEEDER REMOTE SELECT: 给煤机遥控选择FLUE GAS: 烟气FORCED DRAFT FAN : 送风机FUEL GAS ID FAN A OUTLET PRESS A 吸风机出口压力FURNACE PRESS: 炉膛压力FURNACE: 炉膛GAS COAL: :: 烟煤HEADER : 联箱、母管IGNITOR: : 点火器,油枪INDUCED DRAFT FAN : 引风机INDUCED&FORCED DRAFTS: 吸送风机INITIATE: 启动、引燃、激发、触发ISOLATION: 隔离;绝缘LFO .DISCH .PRESS : 轻油出口压力LIGHT OIL SEL GRP 1: 第一组轻油枪选择LIGHT OIL: 轻油LUB OIL PUMP:: 润滑油泵MAIN STEAM STOP VLV: 主蒸汽截止阀MAIN STEAM TEMP/PRESSURE/FLOW 主汽温度/ 压力/ 流量MAINTAINED IGNITORS PULVERIZER A:磨煤机A油枪操作MANUAL LOAD SET/RATE:手动负荷设定/ 负荷率MANUAL MODE: 手动方式MANUAL THROTTEL PRESS SET POINT:手动节流压力设定值MILL A GROUP MASTER : A 磨组主控器MILL A LOAD: A 磨组负荷MILL A OUT TEMP CONT DAMPER : A 磨组出口温度控制挡板MIN MAX LOAD (LIMITS ): 最大最小负荷(限制)MMMC =MILLIMETER MERCURY ;MMH2O: 毫米汞柱;毫米水柱。

Company Info.PLCs Field I/O Software C-more & other HMI AC Drives AC Motors Power Transmiss.Steppers/Servos Motor Controls Proximity Sensors Photo Sensors Limit SwitchesEncoders Current Sensors Pressure Sensors Temp.Sensors Pushbuttons/Lights Process Relays/TimersComm.Terminal Blocks & Wiring PowerCircuit Protection Enclosures Tools AppendixPart IndexTK-E02-900TK-E6-6500TK-E2-800TK-E3-5000TK-E5-3600Fuji Duo Series Contactor and Overload Relay Selection T ablesSC-E ContactorTK-E Overload Relay+=Step 1. Select a SC-E contactor from Column A based on motor voltage,and horsepower.Step 2. Select a TK-E overload relay from Column B to work with the SC-Econtactor selected in Step 1. The motor full load current (FLA)should be within the adjustable current range of the overload relay.100-240V Single Phase Motor (1/3 to 25 hp)Step 1. Select a contactor from page 17–5based on motor voltage and horsepower. Step 2. Select an overload relay from page 17–21based on motor full load current.Motor voltage Motor full-load rated amperage (FLA)Check the data plate on the motor for the hp, volts and full-rated amps.ABThree Phase Motors - Refer to tables on following pageCompany Info.PLCs Field I/O Software C-more & other HMI AC Drives AC Motors Power Transmiss.Steppers/Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temp.Sensors Pushbuttons/Lights Process Relays/Timers Comm.Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Appendix Part IndexFuji Duo Series Overload Relay Selection T ablesFuji Duo Series TK-E Overload RelaysCompany Info.PLCs Field I/O Software C-more & other HMI AC Drives AC Motors Power Transmiss.Steppers/Servos Motor Controls Proximity Sensors Photo Sensors Limit SwitchesEncodersCurrent Sensors Pressure Sensors Temp.Sensors Pushbuttons/Lights ProcessRelays/TimersComm.Terminal Blocks & Wiring Power Circuit Protection Enclosures ToolsAppendix Part IndexFuji Duo Series TK-E Overload RelaysWiringBe sure to wire the relays correctly using the wiring diagrams on the supplied instal-lation sheets. Main terminals for models TK-E02-xxx to TK-E6-xxx are wired using solid wires or stranded wires. Stranded wires or flexible stranded wires can be connected by twisting them together and crimping a sleeve (ferrule) onto them before connecting.Tightening torqueIf wires are not tightened sufficiently, they may become hot or loosen and result in a fire, short-circuit, electric shock, or some other potentially dangerous situation. Be sure to tighten the wires to the torques specified in these tables.Fuji Duo Series TK-E Overload RelaysSZ-HCE56083SZ-HDE9054SZ-HCESZ-HDESZ-HEESZ-HCE Base UnitTK-E02-145 Thermal Overload RelayInstall thermal overload relay onto base unit as shown. Relay can now be installed onto DIN rail or panel.Company Info.PLCsField I/O SoftwareC-more & other HMIAC DrivesAC MotorsPower Transmiss.Steppers/ ServosMotor ControlsProximity SensorsPhoto SensorsLimit SwitchesEncodersCurrent SensorsPressure SensorsTemp. SensorsPushbuttons/ LightsProcessRelays/ TimersComm.Terminal Blocks & WiringPowerCircuit ProtectionEnclosuresToolsAppendixPart Index。

abb热过载继电器说明书

ABB热过载继电器是一种用于保护电动机免受过载和过热的

设备。

下面是ABB热过载继电器的说明书概述:

1. 产品概述:说明产品的用途和作用,主要用于监测和保护电动机免受过载和过热的影响。

2. 技术规格:包括产品的技术参数,例如额定电压、额定电流、额定频率等。

3. 安装指南:提供了关于如何正确安装ABB热过载继电器的

详细说明,包括安装位置、连接方法和接线图等。

4. 调试和设置:介绍了如何对ABB热过载继电器进行调试和

设置,包括参数设置和功能开关的操作方法。

5. 额定特性和保护功能:详细描述了ABB热过载继电器的额

定特性和保护功能,例如响应时间、过载保护等。

6. 维护和故障排除:提供了关于如何正确维护和故障排除

ABB热过载继电器的说明,包括常见问题及解决方法。

7. 附录:包含了额外的信息,例如产品的认证和标准遵守情况、安全警示等。

请注意,以上只是对ABB热过载继电器说明书的一般概述,

具体的说明书内容可能因不同产品型号和规格而有所不同。

建议查阅具体产品的说明书以获取更详细的信息。

热继电器型号热继电器的额定电流应大于电动机额定电流。

然后根据该额定电流来选择热继电器的型号。

热继电器的热元件的额定电流应略大于电动机额定电流。

当电动机启动电流为其额定电流的6倍及启动时间不超过5S时,热无件的整定电流调节到等于电动机的额定电流;当电动机的启动时间较长、拖动冲击性负载或不允许停车时,热元件整定电流调节到电动机额定电流的1。

1-1.15倍.型号机型额定TK-E02A-C热过载继电器0。

1-0.15ATK-E02B-C热过载继电器0。

13-0.2ATK—E02C—C热过载继电器0。

15—0。

24ATK—E02D—C热过载继电器0。

2—0.3ATK—E02E-C热过载继电器0。

24-0.36ATK-E02F-C热过载继电器0.3-0.45ATK-E02G—C热过载继电器0.36—0。

54ATK—E02H-C热过载继电器0。

48—0.72ATK-E02J—C热过载继电器0.64-0。

96ATK-E02K—C热过载继电器0。

8-1.2ATK-E02L—C热过载继电器0.95-1。

45ATK—E02M-C热过载继电器1.4-2.2ATK—E02N—C热过载继电器1.7-2.6ATK—E02P—C热过载继电器2.2—3。

4ATK—E02R—C热过载继电器2。

8-4.2ATK-E02S-C热过载继电器4-6ATK—E02T-C热过载继电器5-8ATK-E02U-C热过载继电器6-9ATK-E02V-C热过载继电器7-11ATK-E02W—C热过载继电器9—13ATK—E02X-C热过载继电器12—18ATK-E02Q—C热过载继电器16-22ATK-E02Y-C热过载继电器20-25ATK—E2S—C热过载继电器4-6ATK—E2U-C热过载继电器5-8ATK—E2V-C热过载继电器6-9ATK—E2W-C热过载继电器7-11ATK-E2X-C热过载继电器9-13ATK-E2B-C热过载继电器12-18ATK—E2E-C热过载继电器24-36ATK-E2I—C热过载继电器32—42ATK—E2H—C热过载继电器40-50ATK—E3V—C热过载继电器7-11ATK-E3W—C热过载继电器9-13ATK-E3X-C热过载继电器12—18ATK—E3B—C热过载继电器18-26ATK-E3E-C热过载继电器24-36ATK-E3F-C热过载继电器28—40ATK-E3G—C热过载继电器34-50ATK—E3J-C热过载继电器45-65ATK—E3O-C热过载继电器48-68A TK—E3R-C热过载继电器64-80ATK-E3M—C热过载继电器65-95ATK-E3I—C热过载继电器85-105A TK—E5B-C热过载继电器18-26ATK-E5E—C热过载继电器24-36ATK—E5F—C热过载继电器28-40ATK—E5G-C热过载继电器34—50ATK—E5J-C热过载继电器45-65ATK-E5M—C热过载继电器65-95A TK—E5I—C热过载继电器85-105ATK-E6J-C热过载继电器45-65ATK-E6L-C热过载继电器53—80ATK-E6M—C热过载继电器65-95ATK-E6N—C热过载继电器85—125ATK-E6P—C热过载继电器110-160ATK-E6HJ-C热过载继电器45-65ATK-E6HL—C热过载继电器53-80ATK-E6HM—C热过载继电器65-95ATK—E6HN-C热过载继电器85-125ATK-E6HP-C热过载继电器110-160A TK-N8M—C热过载继电器65-95ATK-N8N-C热过载继电器85—125ATK—N8P-C热过载继电器110—160A TK-N8R-C热过载继电器125—185ATK-N10N-C热过载继电器85-125ATK-N10P-C热过载继电器110—160ATK-N10R—C热过载继电器125—185ATK-N10S—C热过载继电器160—240ATK—N10HN-C热过载继电器85—125A TK-N10HP-C热过载继电器110—160ATK-N10HR-C热过载继电器125-185ATK-N10HS—C热过载继电器160-240A TK—N12P-C热过载继电器110—160ATK-N12R-C热过载继电器125—185A TK-N12S-C热过载继电器160-240A TK-N12T—C热过载继电器200-300A TK-N12U—C热过载继电器240-360ATK—N12V—C热过载继电器300-450ATK-N12HP—C热过载继电器110-160ATK—N12HR-C热过载继电器125—185ATK-N12HS-C热过载继电器160—240ATK-N12HT-C热过载继电器200-300ATK-N12HU-C热过载继电器240-360ATK-N12HV-C热过载继电器300—450ATK—EO2QM-C热过载继电器1。

火力发电站常用英语技术词汇boiler house: 锅炉房coal conveyor 输煤装置coal bunker: 煤仓coal mill磨煤机steam boiler, water boiler tube 蒸汽锅炉,管式锅炉furnace(combustion chamber): 炉膛( 燃烧室)water tube: 水管ash pit 灰坑superheater: 过热器water preheater: 水预热器air preheater: 空气预热器gas duct(flue): 烟气管, 烟道dust collecting plant: 集尘室induced draught fan: 引风机chimney: 烟囱deaerator: 除氧器feed water tank: 供水箱boiler feed pump: 给水泵switchgear: 开关设备cable tunnel: 电缆通道cable cellar: 电缆槽turbine room: 汽轮机室steam turbine with alternator: 蒸汽汽轮发电机组economizer: 省煤器steam drum: 汽包surface condenser: 表面凝汽low-pressure preheater: 低压预热器circulating water pipe(pump): 循环水管electrostatic dust remover(precipitator):静电除尘器pulverizer 磨煤机slag pump 灰渣泵thermal cycle: 热力循环(net)heat rate: (净)热耗率Assemblie: 集合,集结,组装comment 注释,评论module : 模块standby: 备用proximity 相近,接近,亲近detector: 探测器bracket: 支架interlocks 互锁,联锁axial: 轴向的surge conditions: 喘振:accessory: 附件pulsation: 有节奏的跳动,跳动fossil fired: 燃煤intent: 意图,目的,意向consistent: 一致的,调和的practice: 惯例,实习,实践intrinsic: 固有的,内在的procurement 获得,获取fabrication: 制作,构成,伪造物vent: 通风孔,出烟孔,出口,放出,排出,noncondensible gas: 不凝结气体intermittent 间歇的,断断续续的blowdown : 排污tank: 桶,箱,罐diagram: 图表deaerator: 除氧器corrosion : 侵蚀,腐蚀状态concentration 集中,集合,浓缩,浓度recommend 推荐,介绍,托付,劝告abnormal and normal conditions: 变工况和额定工况warm up: 暖机acid wash: 酸洗scale: 范围,水垢,水锈,比例,刻度sludge :: 污泥,淤泥foreign matter: 不相关的物质facilitate: 推动,促进,使简化multistage: 多级的remote control: 遥控safety relief valve: 安全卸压阀gauge: 量规,量表,测量manhole: 人孔,检修孔equivalent: 等价物,相等的forging:: 锻造seat: 部位,座socket welding: 管座焊接enthalpy: 焓estimate: 评价,评估,估价parameters 参数,参量nominal : 名义上的,额定的,标称的MS — Main Steam : 主蒸汽Cycle:: 循环Intercept: 截止Fetting: 附件Gage:: 规,表,压力计Taps: 接头test wells: 测点插孔stress-relieved: 应力消除thermometer: 恒温计steam purge system: 蒸汽吹扫系统centrifugal type pumps: 离心式泵friction losses: 磨擦损失solenoid: 螺线管modulat: 调整,调节criteria: 标准wrenches: 扳手pipe taps: 管接头.A List of Abbreviations and Symbols in English-ChineseA ::Ash Handling System: 除灰系统AH :Air Heater: 空气预热器AAh :Analyzer, Alarm High : 分析器,高值报警:: AIV :Air Intake Valve: 进气阀ALIGN Alignment: 校正ALKF :Airlock Feeder: 锁气器AP ::Ash Slurry Pump: 灰浆泵ATM :Atmosphere 大气AC ::Air Conditioner: 空气调节器AFT :Atmosphere Flash Tank: 大气扩容器AC :Alternating Current: 交流电ALM :Alarm:: 报警AMP :Ampere: 安培AX THR BRG :Axis Thrust Bearing: 轴向推力,轴承ATMZ :Atomizing: 雾化AUTO :Automation 自动AUX :Auxiliary: 辅助的BA :Bottom Ash 底灰BAH ::Bottom Ash Hopper: 底灰斗BLR ::Boiler: 锅炉BSD ::Boiler Shut Down: 停炉BUSH :Bushing: 衬套BYPS :Bypass:: 旁路BVD ::Boiler Vents and Drains:: 锅炉疏水放气BFP :Boiler Feedwater Pump ::锅炉给水泵BFPT:Boiler FeedwaterPump Turbine: 锅炉给水泵汽机BFW ::Boiler Feedwater: 锅炉给水BM :Boiler Master 锅炉主控BMCR:Boiler Maximum ContinuousRating: 锅炉最大连续出力BFBP::Boiler Feed Booster Pump: 锅炉给水增压泵BNR :Burner: 燃烧器BOP :Balance Of Plant: 电厂辅机设备BPC :Blade Pitch Control: 叶片节距控制BT :Boiler Tube: 炉管CH: Crusher House: 碎煤房COMB ::Combustion 燃烧COMP ::Compressed Air: 压缩空气CONV ::Conveyer: 输送机CPL :Control Pannel Local: 就地控制盘CPM :Control Pannel Main: 主控盘CRT :Cathode Ray Tube: 阴极射线管: CT Current Transformer: 变流器CYCL :Cyclone: 旋风分离器CAS :Casing:: 缸、壳CB Circuit Breaker: 断路器COMP :Complete: 完成CCCW :Closed Circulating Cooling Water: 闭式循环冷却水CCW :Cycle Cooling Water: 循环水CCWHF ::Closed Cooling Water Heater 闭式冷却水冷却器CCWP :Closed Cooling WaterPump: 闭式冷却水泵CS :Closed Cooling Water System 闭式冷却水系统CH Coal Handling 煤的装卸CHK VLV :Check Valve: 逆止阀CIRC: Circulation: 循环CLR Cooler: 冷却器CLOW :Cooling Water: 冷却水CMPR :Compressor: 压缩机CNTL :Control: 控制CNTLE :Controller:: 控制器COND :Condensate: 凝结水CONDTY :Conductivity: 导电率CP: Condensate Pump: 凝结泵CIR: Circuit: 回路COUPI :Coupling: 联轴器CP: Condensate Polisher: 除盐装置CS: Control Switch 控制开关CRSV :Cold Reheat Safety Valve: 再热器冷段安全阀CV: Control Valve : 控制阀CWP: Circulation Water Pump: 循环水泵DMPR: Damper : 挡板DP Difference Pressure: 差压DPIC: Differential Pressure IndicatingController压差指示控制器DPT:Differential Pressure Transmitter 压差变送器DRN: Drain: 疏水DV Drain Valve:: 疏水阀DC Direct Current: 直流电DSH: Desuperheater: 减温器DCA: Drain Cooler Approach: 疏水冷却器通道DEAER Deaerator: 除氧器DEV: Deviation: 偏差DIFFRLY: Differential Relay: 差动继电器DISCH VLV :Discharge Valve 排放阀DIST: Disturbance:: 故障、扰动DSCH: Discharge: 排出ECON: Economizer:: 省煤器EP Electrical Static Precipitator: 静电除尘器ECC Eccentricity :: 偏心EFF Efficiency: 效率EHC Electric Hydraulic Control: 电液控制EO Electric Operate: 电气操作EQ Equipment: 设备ER Error: 误差ES :Extraction System 抽气系统ESC Escape: 逃逸、超出ESS Engineering Safety System: 保安系统EU Engineering Unit : 工程单位EXH Exhaust: 排汽EXT Extract: 抽出FA :Fine Ash: 细灰FDR Feeder: 给料机FE :Flow Element:: 流量元件FI :Flow Indicator:: 流量指示件FDBK: Feedback: 反馈FITG Fitting: 连接件FLW Flow 流量FO :Fail Open: 故障时自动打开FT: Flow Totalizer: 流量累加器FT :Flow transmitter: 流量变送器FV :Flow Control Valve 流量控制阀FY :Flow Relay or Valve 流量传送器FA: Failure Alarm: 故障报警FD :Forced Draft : 强制通风FDF Forced Draft Fan: 送风机FIC :Flow Indicate Controller: 流量指示控制器FLT :Flash Tank : 扩容箱FLD :Field 磁场FLG :Flange: 法兰FLM Flame: 火焰FWH Feed Water Heater 给水加热器FO :Fuel Oil: 燃油FREQ Frequency: 频率FURN Furnace: 炉膛GLD Gland: 密封GRDR Grinder: 碎渣机GND Grounding: 接地GC :Generator Cooling: 发电机冷却GESE Gland Steam Condenser Exhauster: 轴加风机GMT Generator Main Trandformer: 发电机变压器GRAD Grandient: 梯度GS :Gland Steam: 轴封蒸汽GSC :Gland Steam Condenser: 轴封加热器GV :Governor Valve: 高压调门H ::Heat Conservation 保温HS: Hand Switch:: 手动开关HTR Heater: 加热器HV: Hand Control Valve: 手动控制器HY: Hand Relay or Transducer 手动继电器(转换器)H :Hand: 手动的HB :Heat Balance: 热平衡HD :Heater Drain:: 加热器疏水HDR :Header: 联箱HL ::Heat Loss: 热损失HMDY Humidity: 湿度HPH: High Pressure Heater: 高压加热器HPR :Hooper: 漏斗HPT :High Pressure Turbine: 高压汽机HR: Hot Reheat: 再热器热段HR: Heat Rate: 热耗率HSV: Hot Reheat Safety Valve: 再热器热段安全阀HVAC :Heating Ventilation& Air Conditioning:: 暖通HW :Hotwell: 热井HV ::Hand Control Valve: 手动控制器HYD :Hydraulic: 液力的INTLK :Interlock : 联锁IC :Instrument and Control:: 仪表与控制(热工)ICV ::Inrtermediate ControlValve 中压控制阀ID :Induced Draft 抽风,引风IDF ::Induced Draft Fan: 引风机IGN ::Ignition: 点火装置INLT :Inlet: 入口IPR ::Initial Pressure: 初压INST :Instrument: 仪表INVR :Inverter: 逆变器I /O:: Input/Output 输入/ 输出IP :Intermediate Pressure: 中压ISV ::Intermediate Pressure Turbine Steam Valve: 中压缸进汽阀JP :Jet Pump: 喷射器LG :Level Gauge 液位计LVL ::Level: 水位,液位LA :Level Alarm: 液位报警LIM(LMIR): Limiter: 限制器LKG:: Leakage:: 泄漏LP :Low Pressure 低压L.P :Low Point : 低位LPH: Low Pressure Heater: 低压加热器LSH: Local Switch Hand: 就地开关LUB: Lubricating Oil: 润滑油M :Mechanical: 机械M :Motor: 马达MAG:: Magnetic: : 磁性MOD ::Mode: 方式:M/A :Manual/Automatic: 手动/ 自动MAN ::Manual :: 手动MARG: Margin:: 裕量MAX ::Maximum: 最大的,最大值的MCR ::Maximum Continuous Rating 最大连续出力MCV:: Main Control Valve:主控制阀MD :Modulation Damper: 调节挡板MDBFP: Motor Driven Boiler FeedwaterPump: 电动给水泵MEAS ::Measure :测量MFT: Master Fuel Trip: 主燃料跳闸MIN :Minimum: 最小的MKUP (MU) Make-up: 补充ML :Mill: 磨煤机MN :Main: 主要的M.O. :Manual Operation: 手操MPT :Main Power Transformer: 主变压器MS :Main Steam 主蒸汽MSV :Main Steam Valve: 主汽阀NOZ: Nozzle: 喷嘴NPSH :Net Pump Suction Head: 泵的静吸压头OL: Overload: 过载OLR :Overload Relay: 过载继电器OPER :Operation: 运行OSC :Oscillograph: 示波器OTLT: Outlet: 出口PA: Primary Air: 一次风PAF :Primary Air Fan: 一次风机PAH :Pressure Alarm High: 高压报警PAL :Pressure Alarm Low: 低压报警PB: Push Button 按钮PC :Power Centre: 动力中心PC: Pressure Controller: 压力控制器P.C. :Pressure Control: 压力控制PCP :Precipitator 除尘器PCV :Pressure Control Valve:: 压力控制阀PDI :Pressure Differential Indication: 差压指示PDT :Pressure Differential Trandsmitter: 差压变送器PED :Pdestal:: 轴承座PERF CALC Performance Calculation::性能计算PF: Power Factor 功率因数PHTR: Preheater: 预热器PMP :Pump: 泵PNEU :Pneumatic: 气动的PR: Pressure Recorder: 压力记录计PRG :Purge: 吹扫PRV :Pressure Relief Valve: 泄压阀PRO :Protection: 保护PROGR:: Program: 程序PT: Pressure Transmitter: 压力变送器PULV: Pulverizer: 磨煤机PVSV :Pressure Vacuum Safety Valve 压力真空安全阀PW: Plant Water 厂用水PY: Pressure Relay: 压力继电器QA: Quality:: 质量,性能RB: Run Back: 快速降负荷RCV :Recovering: 回收RECIRC:: Recirculation 再循环RECT :Rectifier: 整流器RET :Return: 返回RH: Reheater: 再热器RO: Restriction Orifice: 节流孔板ROT :Rotor: 转子RTU :Remote Telemetry Unit:: 遥测装置SA :Secondary Air: 二次风SAT: Saturate: 饱和的SC :Steam Coil Air Heater:: 暖风器SCAV :Scavenge: 吹扫SD: Shut-off Damper: 关断挡板: Shut-Down 停机SEP :Separator 分离器SG: Switchgear 开关装置SH: Superheater: 过热器SLS :Seals:: 密封SO: Shut Off: 关闭SPD :Speed: 转速SPRA: Spray: 喷水SPT :Support: 支持:ST: Start: 启动,开始STD-BY :Stand By: 备用ST: System:: 系统STM :Steam: 蒸汽STR: Stator:: 定子STRNR: Strainer: 滤器SU: Start Up: 启动SV: Solenoid Valve: 电磁阀SUCT: Suction: 吸入SW: Switch: 开关:Steam Water: 汽水SBLWR: Soot Blower 吹灰器TBFP Turbine Drive Boiler FeedwaterPump 汽泵TCV :Temperature ControlValve 温度控制T.B.: Transfer Damper: 转换挡板TE: Temperature Element: 温度元件TG: Turbine-generator: 汽轮发电机Turbine-gear: Turbine-gear: 汽机盘车THERM :Thermal 热力的TMS: Turbine Master System: 汽机主控系统TRANS :Transfer: 转换TRBL: Trouble: 故障TRKG: Tracking: 跟踪TT: Temperature Transmitter: 温度变送器TTD: Terminal Temperature Difference:温度端差TW: Thermowell: 热电偶套管UAM :Unit Automatic Master: 机组自动系统VAC: Vacuum: 真空VAL: Value: 数值VB: Vibration 振动VLV: Valve: 阀门WH: Watthour 瓦小时WP: Working Point: 工作点WW: Water Wall 水冷壁WX: Watt Transducer: 功率转换器COVER :Crossover 切换管CV: Control Valve: 控制阀英汉对照表A/H :AUTOMATION/HAND : 自动/ 手动;A/M :AUTOMATION/MANUAL: 自动/ 手动;ALARM 报警;AUX :AUXILIARY :: 辅助; BYPASS 旁路CLOSE 关(状态,常指阀门);CODE: 代码;编码COLD START — UP: 冷态启动COMPUTER : 计算机CURVE ,LINE: 曲线,线DATA: 数据;文件;资料DECREAS : 减少DESK: 台,桌DIGIT: 数字DISK: 磁盘DYNAMIC ;DYNAMICAL: 动态F :FLOW 流量;FAST: 快FIGURE: 图示HIGH: 高HOT START — UP: 热态启动I&C :INSTRUMENT AND CONTROL仪表与控制INCREAS: 增加INDICATION ;DISPLAY : 指示;显示;INLET 入口;INPUT 输入;INTERMEDIATE 中KEYBOARD: 键盘KW :KILOWATT 千瓦L :LOAD 负荷,负载;LOC :LOCAL : 就地LOW: 低MCS :MANAGMENT COMMANDSYSTEM 管理命令系统MODE : 方式,模式MW :MEGAWATT 兆瓦NORMAL: 正常OFF : 关(状态);ON : 开(状态);OPEN: 开( 状态,常指阀门); OPERATE : 运行;操作; OUTLET 出口;OUTPUT 输出;P :PRESSURE: 压力;PANEL 盘PARAMETER : 参数PIPE ;TUBE: 管道,管子PLANT: 厂,站POWER: 功率,电源;PRINT: 打印R :RATE : 比率,速率;R :RESISTANCE: 电阻;REM :REMOTE : 摇控;RESET 复位ROOM : 室RPM:: 转/ 分;S :SPEED 速度;SELECT 选择SET POINT 设定点SHUTDOWN : 停机;SIDE (某)侧,边;SILENCER 消音器SLOW : 慢STAND BY: 备用;START : 启动;STARTUP : 起动;启动;STATIC 静态STATION 站STOP: 停止;SYMBOL 符号SYSTEM: 系统T :TEMPERATURE:: 温度;TEST: 试验;TRANSMITTIER;TRANSDUCER: 变送器;传感器TRIP 跳闸;TRIP ACKNOW: 跳闸确认UNAVAIL 不允许( 不能投用的)UNIT : 单元、机组VALVE 阀门WARM START — UP: 温态启动ZOOM: 摄像机镜头锅炉部分ACTUAL MEGAWATT: 有功AIR DRAFT SEQUENCE: : 风机程序控制(顺控)AIR HEATER A MOTER: 空预器马达AAIR HEATER LOC/REM SELECT: 空预器就地/ 遥控选择AIR HEATER MOTOR LEAD: 空预器马达选择AIR HTR A SEC AIR OUT TEM 空预器A 二次风出口温度AIR PREHEATER: 空预器AIR SVCE SUPPLY: 服务空气ALARM LIMITS: :: 报警限制ALL AIR HTRS RUNNING 各空预器运行ALL PULV GRP SHUTDOWN 所有磨组停运ASH — HOPPER: : 灰斗ATTEMPERATOR: : 减温器AUX .ST: SPLY FOR ATOMIZ 辅助蒸汽供雾化蒸汽BOIL MILL A BNR MET TEMP 炉 A磨组喷燃器金属温度BOIL MILL A GR1 WDBOX PR 炉 A磨组第一组风箱压力BOILER AIR REQUIRED 锅炉风量需求(>30% )BOILER EFFLUENT STORAGE: POOL锅炉废水池BOILER FOLLOW MODE: 炉跟随方式BOILER MASTER: 锅炉主控器BOILER TRIP RESET: : 锅炉跳闸复位BOILER: 锅炉BURNNER: : 燃烧器CHIMNEY ;STACK:: : 烟囱CLEAN: 清扫COAL BANKER: :: 煤仓COAL FEEDER : 给煤机COMBUSTION : 燃烧CONVEYOR: 皮带机COORDINATE MODE 协调方式CRUSHER: 破碎机DECR/INCR PRESS AT FIX LOAD:: 固定负荷方式增减压力DOWM COMER:: 下降管DRAIN & VENT: 疏水和排气ECONOMIZER : 省煤器EITHER FAN RUNNING : 任一风机运行EITHER ID FAN RUNNING 任一吸风机运行ELECTROSTATIC PRECIPITATOR : 静电除尘器FD FAN A FLOW:: A 送风机流量FD FAN/ID FAN A CONT DAMPER A送/ 吸风机控制挡板FEED WATER FLOW: 给水流量FEEDER LOCAL SELECT: 给煤机就地控制选择FEEDER REMOTE SELECT: 给煤机遥控选择FLUE GAS: 烟气FORCED DRAFT FAN : 送风机FUEL GAS ID FAN A OUTLET PRESS A吸风机出口压力FURNACE PRESS: 炉膛压力FURNACE: 炉膛GAS COAL: :: 烟煤HEADER : 联箱、母管IGNITOR: : 点火器,油枪INDUCED DRAFT FAN : 引风机INDUCED&FORCED DRAFTS: 吸送风机INITIATE: 启动、引燃、激发、触发ISOLATION: 隔离;绝缘LFO .DISCH .PRESS : 轻油出口压力LIGHT OIL SEL GRP 1: 第一组轻油枪选择LIGHT OIL: 轻油LUB OIL PUMP:: 润滑油泵MAIN STEAM STOP VLV: 主蒸汽截止阀MAIN STEAM TEMP/PRESSURE/FLOW 主汽温度/ 压力/ 流量MAINTAINED IGNITORS PULVERIZER A:磨煤机A油枪操作MANUAL LOAD SET/RATE:手动负荷设定/ 负荷率MANUAL MODE: 手动方式MANUAL THROTTEL PRESS SET POINT:手动节流压力设定值MILL A GROUP MASTER : A 磨组主控器MILL A LOAD: A 磨组负荷MILL A OUT TEMP CONT DAMPER : A 磨组出口温度控制挡板MIN MAX LOAD (LIMITS ): 最大最小负荷(限制)MMMC =MILLIMETERMERCURY ;MMH2O: 毫米汞柱;毫米水柱O 2 IN THE FUEL GAS 烟气含氧量OPEN/CLOSE SWING VLVS 摆阀开/ 关OPERATE MODE SELECT: 运行方式选择PENDANT: : 悬吊管PLATEN SPARY CONTROL VLVS SIDEA : 屏过减温水 A 侧控制阀PLATEN SUPERHEATER: 屏过PRESSURE DIFFERENCE: 压差PRI AIR DUCT PRESS 一次风管压力PRI AIR FAN A CONT DAMPER: A 侧一次风机控制挡板PRI AIR FAN A OUTLET PRESS A 一次风机出口压力PRI AIR FLOW MILL A CONTDAMPER 磨组一次风控制挡板PRI/SEC AIR FLOW MILL A A 磨组一次/ 二次风流量PRIMARY AIR FAN: 一次风机PRIMARY AIR SEQUENCE: 一次风控制PULVERIZER : 磨煤机PULVERIZER EMERGENCE TRIP 磨煤机紧急跳闸PULVERIZER INERT MODE SELECT: 磨煤机惰性方式选择PULVERIZER NORMAL MODE SELECT: 磨煤机正常方式选择PULVERIZER SELECTION A :: 磨煤机A 选择PULVERIZER: M/A: SELECT 磨煤机手/ 自动选择PURGE 吹扫RH ;REHEATER: 再热器SAFETY VALVE:: 安全阀SCANNER BLOWERS: 火检吹扫器SEAL AIR FAN PRESS: 密封风机压力SEAL AIR FAN:: : 密封风机SEC AIR DUCT PRESS: 二次风管压力SEC AIR FLOW MILL A CONTDAMPER A 磨组二次风流量控制挡板SEC SH OUT STEAM TEM 二级过热器出口蒸汽温度SEC SH SPARY CONT VLVS SIDE A二级过热器减温水 A 侧控制阀SECONDARY SH INLET TEMP 二级过热器进口温度SECONDARY: AIR 二次风SH ;SUPERHEATER: : 过热器SH STEAM ELECTR VLV: 过热器电磁阀SH STEAM TEMP SET POINT:: 过热温度设定点SH/RH SPARY W ATER STOP VLVS:: 过热器/ 再热器减温水截止阀SH/RH SPRAY CONTROL VLVSSELECT 过热器/ 再热器减温水控制阀选择SLIDING PRESS MODE: 滑压运行方式SOOT BLOWER: 吹灰器SPARK 火花,点火花SPEED CHANGE (NOT) PERMISSIVE:速度切换(不)允许SPRAY : 喷水STACKER RECLAIMER :: 堆取料机START IGNITOR GRP 1: 第一组油枪点火STEAM DRUM: : 汽包STEAM 蒸汽STONE COAL: 无烟煤STOP IGNITORS GRP 1: 第一组油枪停止STOP/START FEEDER 给煤机停止/ 启动STOP/START IGNITORS: 油枪停止/ 启动STOP/START MILL: 磨组停止/ 启动STOP/START PA FLOW: 一次风停止/ 启动STOP/START PULVERIZER 磨煤机停止/ 启动STOP/START SEQUENCEPULVERIZER A: 磨煤机 A 程序停止/ 启动THROTTLE PRESS:: 节流压力TRANSPORT AIR SEQUENCE 风量程序控制(顺控)TURB FIRST STAGE PRESS 汽机第一级( 调节级) 压力TURBINE FOLLOW MODE: 机跟随方式TURBINE MASTER: 汽机主控器TWIN FLOW AIR HTR A CONT VLV: :双流式空预器控制阀UNLOADER: :: 卸煤机WATER 水WATERWALL: : 水冷壁汽机部分:EMERG OIL PUMP: 事故油泵<P>CICR PMP DISCHARGE VLV: 循环泵出口阀1ST STAGE PRESS: 第一级压力ACTUAL MEGA WATT: : 实际负荷数AMS :ADMISSION: MODESELECTION 进汽方式选择AUX STEAM HEADER: : 辅汽联箱AUX STEAM TEMP CONTROL: 辅汽温度控制AUX STM HEADER PRESS CONTROLVLV 辅汽联箱压力控制阀BALANCE: : 平衡BEARING BRASS:: 轴瓦BEARING: : 轴承BLADE 叶片BOILER FOLLOW MODE: 锅炉跟随方式BOOSTER FEED PUMP: 前置给水泵CICR WTR PUMP: 循环泵CIRCULATING PUMP: : 循环泵CIRCULATING: 循环CLOSED COOLING WATER: 闭式冷却水CLOSED COOLING WTR PUMP: 闭式冷却水泵CMPTR: : 计数器CONDENSATE PUMP: 凝泵CONDENSER AIR SUCTION VLV: 凝汽器抽空气阀CONDENSER HOT WELL: : 热井CONDENSER LEVEL CONTROL VLV:凝汽器水位控制阀CONDENSER: 凝汽器CONDS EXTR PUMP DISCH : 凝结水抽吸泵出口CONDS STOR TANK LEVEL: 凝结水储水箱水位COOLER: : 冷却器COOLNG WTR PUMP: 水冷泵COORDINATE MODE: : 协调方式CV :CONTROL VALVE 高压调门CYLINDER 、CASING: 汽缸DEAERATOR LEVEL CONTROL VLV:除氧器水位控制阀DEAERATOR: : 除氧器DECR PRESS AT FIX LOAD: 在负荷不变下减压DEMI WATER: 除盐水DISPATCH PARTICIPATION 调度(参与)指令DURM PRESSURE:: 汽包压力EJECTOR: 喷射器,抽气器EMERGENCY GOVERNOR 危急保安器EXHAUST: 排汽EXPANSION: 膨胀EXTR ST TO HP HTR 抽汽至高加EXTRACTION STEAM 抽汽FILTER: : 滤网FLANGE 法兰FUNCTION GROUP: 功能组FW CONTROL V ALVE ' S BYPASS VLV: 给水控制阀的旁路阀FW FLOW 30% CONTROL VLV : 30% 给水控制阀FW FLOW MASTER CONTROL: 给水流量主控FW HP HTR DISCH TEMP: 给水高加出口温度FW PUMP RECIRCUL CONTROL VLV 给水泵循环控制阀FW VLV: 给水阀门GEARING: 盘车GOVERNOR: 调速器HP ATTEM PRESS CONTROL VLV: 高旁减温水压力控制阀HP ATTEMP BLOCK VLV: 高旁减温水闭锁阀HP BYPASS &HP ATTEMP VLVS:高压旁路及减温水阀HP BYPASS PRESS CONTROL VLV 高旁压力控制阀HP BYPASS PRESS SET POINT: 高旁压力设定值HP BYPASS TEMP CONTROL VALVE高旁温度控制阀HP&LP BYPASS COMMAND 高压及低压旁路指令HPH :HIGH PRESSURE HEATER : 高加HYDRAULIC OIL STATION PUMP: 液压油站泵INCR PRESS AT FIX LOAD: 在负荷不变下增压INT POS: 中间状态IV :INTERMEDIATE V ALVE 中压联合汽门JACKING OIL PUMP 顶轴油泵LP HTR STOP VLV 低加截止阀LP &HP BYPASS PRESS SIDE A 低压或高压旁路A侧压力LP &HP BYPASS TEMP SIDE A 低压或高压旁路A侧温度LPH :LOW PRESSURE HEATER: 低加LUBE OIL PUMP: 润滑油泵MAKE -UP W ATER: 补给水MANUAL LOAD RATE 手动负荷率MANUAL LOAD SET 手动负荷设定MANUAL Throttle Press Set Point手动节流压力设定值MEASURE SELECTION 测量选择站MOP :MAIN OIL PUMP: 主油泵MOTOR DRIVEN FEED WATER PUMP 电动给水泵MSV :MAIN STOP V ALVE: 主汽阀NOZZLE 喷嘴OIL PURIFIER: 净油器OIL STORAGE TANK : 储油箱OPERATE MANUAL MODE: 手动方式OPERATE MODE SELECT: 运行方式选择PILOT VALVE: 错油门PLATEN SH INLET TEMP SIDE A: A侧屏过入口温度PRIMARY SH STOP VALVE: 一级过热器截止阀PUMP A DISCH PRESS : A 泵出口压力RH SPRAY BLOCK VLVSTRIP INIT 再热器喷水闭锁阀跳闸启动RH SPRAY WTR STOP VLVS: 再热器喷水截止阀RH STEAM ATTEM FLOW: 再热喷水流量RH STEAM TEMP OUTLET: 再热器出口温度ROTOR 转子SEAL: 密封SHAFT 轴SILENCER: 消音器SLIDING PRESS MODE: 滑压方式SPEED INDICATOR OR SPEEDMETER: : 转速表STATOR 定子STEAM TURBINE : 汽轮机ST -UP BOIL FDW PUMP: 启动给水泵SUCTION PUMP: 抽吸泵SURGE APPROACH: 喘振SYNCHRONIZER: 同步器TFW PMP DISCHARGE VLV: 汽动泵出口阀TFW PUMP MAIN OIL PMP: 汽动给水泵的主油泵THROTTLE ORIFICE 节流孔板TURBINE DRIVEN FEED WATER PUMP: 汽动给水泵TURBINE FW PUMP AUX &VLV 小机给水泵辅汽及阀门TURBINE GENERATOR: 汽轮发电机组TURBINE INLET PRESS: 汽机入口压力TURBINE MASTER : 汽机主控器TURBING FOLLOW MODE: 汽机跟随方式VACCUM 真空VACUUM BROKEN VALVE: 真空破坏门VACUUM SEQ : 真空程控VIBRATION: 振动电液调节及控制部分1STAGE PRESSURE FEEDBACK: 第一级压力反馈ABNORMAL CONDITION: 异常状态ACCELERATION: 加速度ACTIVE POWER:: 有功功率ADMISSION MODE: 进汽方式ADS(ALARM DISPLAY SELECTPANELS) 报警显示选择屏AERIAL LINE: 架空线ALTERNATING CURRENT (AC): 交流AMPERE: 安培ANGLE OF LAG: 滞后角ANGLE OF LEAD: 超前角ANODE: 阳极ARC: 电弧ARMATURE 电枢AST :AUTO SHUT-DOWN TRIP: 自动停机遮断ASYNCHRONOUS MOTOR: 异步电动机AT SET SPEED: 在设定速度位置ATC :AUTO TURBINE CONTROL: 自动汽轮机控制AUTOFORMER: 自藕变AUTORECLOSING : 自动重合闸AUXI TRANSFORMER : 厂用变BACK UP TRANSFORMER 备用变BACK-UP OVERSPEED TRIP TEST 备用超速跳闸试验ELECTRICAL TRIP TEST 电气跳闸试验BACK-UP SPDSIG LOST: : 后备速度信号失去BARRING OIL PUMP 盘车油泵BASE LOAD: 基荷BATTERY : 电池BATTERY BACKED CLOCK 电池备用时钟BDV :BLOWDOWN VLV: 泄放阀BOOSTER PUMP: 前置泵BULB : : 灯泡BUS SECTION : 母线分段BUS: 母线BUSBAR FRAME: 母线架BUSCOUPLER: 母联BUSHING 套管CABLE 电缆CAPACITANCE: 电容CARRIER 载波CATHODE : 阴极CCR: 中控室CHARGING EQUIPMENT : 充电设备CHEST /ROTOR WARMING: 腔室/转子预暖CIU : 计算机接口单元CLOSE : 合闸CLOSED VALVES OVERSPEED TEST关闭阀超速CLOSED-LOOP : 闭环COIL:: 线圈COMBINED RECLOSING 综合重合闸COMBINED REHEAT V ALVES: 中压联合阀COMMON SERVICES LOGIC SUITE::公用系统逻辑柜COMMUNICATION: 通讯CONDUCTOR : 导体CONFIGURATION: 结构,布置,外形: CONTROL OIL: 控制油CORE: 铁芯CPU(CENTARL PROCESSING UNIT: 中心处理单元CRT: 显示屏CURRENT TRANSFORMER: 电流互感器CURRENT 电流CV:: 控制阀DAS: 数据采集系统DECREASING LOAD RATE: : 减负荷率DIESEL GENERATOR : 柴油发电机DIRECT CURRENT (DC) 直流DISCONNECTOR : 隔离开关DISTRIBUTED CONTROL SYSTEM:分散控制系统E.W.S.: 工程师工作站EHC STATUS: 电液调节系统状态EHC :ELECTRO-HYDRA CONTROLSYSTEM: 电液调节控制系统EHV MIMIC PANEL : 电气高压模拟屏ELECTRICAL MALFUNCTIONSYSTEM FAULT : 电气失灵系统故障EMERGENCY OIL PUMP: 事故油泵EMERGENCY SEAL OIL PUMP: 事故密封油泵ETS :EMERGENCY TRIP SYSTEM:危急跳闸系统EXCEPTION REPORT: 例外报告EXCITE 励磁EXCITOR 励磁机FA/PA POSITION : 全周/ 部分(进汽)位置FAST-ACTING SOLENOID: 快动电磁阀FIRST STAGE PRESS 调节级压力FIS :: 流量显示开关FREQUENCY: 频率FRF :FIRE RESISTANT FLUID:: 抗燃油FULL ARC : 全周进汽GAS : 瓦斯GEN. SHAFT SEAL&STATORWIND : 发电机密封及静子绕组GENERATOR : 发电机GROUNDING(EARTHING) 接地H2 TEMP CONT V : 氢气温度控制阀HARDW ARE 硬件HOLD: 保持HYDRAULIC FLUID PRESS: 抗燃油压力I.C.S: 数字控制站终端模件IN STANDBY: 在备用状态IND: :: 指示器INDUCTANCE: 电感INHIBITED: 停止进行、禁止INSULATOR 绝缘子INTERCEPT VALVE: 中间截流阀INTERCEPT VALVES: 中间截止阀INTERFACE 接口KILOW ATT 千瓦LC: 液位控制器LI: 液位显示LIGHT: 照明LINE 线路LK: 液位控制站LOAD DECREASING ;AT SETLOAD 负荷减;在设定负荷LOAD FLOW : 负荷潮流分布LOAD INCREASING: 负荷增LOAD LIMITING SET: 负荷极限设定LOAD MONITORING: 负荷监视LOAD SELECT: :: 负荷选择LOAD SET: 负荷设定LOAD: 负荷LOADING RATE LIMIT : 负荷(增、减)率限定LOCKED OUT: 闭锁LOSS : 损耗LOSS OF PWR:: 失去电源LVDT :线性位移差动变送器MAGNETIC FIELD: 磁场MAIN OIL PUMP: 主油泵MAIN SEAL OIL PMP : 主密封油泵MAIN STEAM PRESS 主蒸汽压力MAIN TRANSFORMER STEP-UPTRANSFORMER: 主变MANUAL: 手动MCC: 马达控制中心MEGAWATT: 兆瓦MFP : 多功能控制器MOTOR: 电动机MSPL :MAIN STEAM PRESSURE LIMITER : 主汽压力限制器MSV: 主蒸汽阀NEUTRAL POINT: 中性点OHM: 欧姆OIL GAUGE: 油位表OPC :OVERSPEED PROTECTION CONTROL: 超速保护控制OPEN-LOOP : 开环OPER AUTO: 操作员自动:: OPERATING MODE : 操作方式ORP :OIL RESET PISTON: 油复位活塞ORSV :OIL RESET SOLENOID VLV油复位电磁阀OTSV :OIL TRIP SOLENOID VLV: 油跳闸电磁阀OVER CURRENT: 过流OVER VOLTAGE : 过压OVERLOAD: 过载PART ARC : 部分进汽PC: 动力中心PDIS : 压差显示开关PEAK LOAD: 峰荷PERMANENT MAGNETICGENERATORDF 永磁发电机PG: 压力计PHASE ANGLE : 相角PHASE: 相PIC: 压力显示控制器PK: 压力控制站PLUG : 插头PLUG SOCKET: 插座POLE:: 电极POTENTIAL TRANSFORMER 电压互感器POWER 功率POWER FACTOR: 功率因数POWER LOAD UNBALANCE: 功载不平衡PP :: PREESSURE POINT 压力检测点PRI SPD SIG LOST 一次速度信号失去PS: 压力开关PT: 压力变送器REACTANCE: 电抗REACTIVE POWER: 无功功率RECLOSING : 重合闸REHEAT PRESS:: 再热汽压力REMOTE AUTO: 远方自动REMOTE OPERATION : 远操RESISTANCE: 电阻RSM :ROTOR STRESS MONITORING: 转子热应力监视: RSV: 再热汽截止阀SAFELY OIL : 安全油SCR CONTROLLER: 可控硅整流控制器SEAL OIL: 密封油SHUT-OFF VALVE:: 切断阀SIGNAL: 信号SLOW MEDIUM FAST: 慢、中、快SPEED INCREASING: 速度增SPEED MONITORING: 速度监视SPEED SET RPM : 转速设定转/ 分SPEED: 速度,转速START UP TRANSFORMER 启动变STATOR WIND COOLING WATERPUMP: 定子绕组冷却水泵STEAM SEAL BY-PASS UNLOAD VLV:蒸汽密封旁路泄放阀STEAM SEAL DIVERING VALV: 密封汽分流阀STEAM SEAL SYS:: 蒸汽密封系统SUCTION PMP A/M SEL: 抽吸泵手/自动选择SUCTION PUMP: 抽吸泵SUPERVISORS DESK: 值长台SWITCH 开关SWITCHGEAR : : 配电盘、开关装置TELEPHONE: 电话TEST SELECT: 试验选择(联锁)THERMO-COUPLE: : 热电偶THREE ELEMENTS LEVELCONTROLLER: 三冲量水位控制器THRUST BEARING WEAR DETECTORTEST 推力轴承磨擦检测试验TI : 温度显示器TIC :: 温度指示控制TIME DELAY: 时间延迟TP: 温度检测点TRANSFER AND FILTER PUMP: 输送和过滤油TRANSFORMER: 变压器TRANSMISSION: 传输TRIP 跳闸TS: 温度开关TSI: 汽机监视仪表TT:: 温度变送器TURB LUBE OIL TEMP CONTROL V : 汽机润滑油温度控制阀TURBIN DRAIN VALVES: 汽机疏水阀TURBINE LATCHED: 汽机挂闸TURN GEAR CONTROL SEQUENCE盘车控制程序TURN GEAR MOTOR: 盘车主电机TURN GEAR PIGGY: BACK MOTOR盘车啮合电机UNINTERRUPTED POWER SUPPLY:不间断电源UNIT CONTROL DESK: 机组控制台UNIT TRANSFORMER:: 单元变VACUUM TRIP: 真空跳闸VALVE POSITION: 阀位置VI : 阀位置指示VOLT(V): 伏特VOLTAGE 电压VT: 阀位置变送器VV :VENTILATING V ALVE : 通风阀WARMING RATE: 暖机速率WATT: 瓦特WINDING: 绕组。

过载继电器[THR)

普通电动机是以在电网电源下运行为前提而设计的,因此能够在电网电源驱动下进行长时间的连续运行。

但是,当将这样的普通电动机改为由变频器驱动并进行连续运转时,由于变频器输出中高次谐波的影响,即使电动机以低于额定转速的速度运行而且电流在额定电流以下,单由风扇进行冷却也难以满足照要。

尤其是当负载为但转矩负载时,即使电功机的转速在额定转速以下,电动机的电流也基本上等于额定电流,与电网电源驱动相比,电机的温升变大,甚至会出现烧损电机的可能n所以省电动机连续工作在低速区域时,以电动机额定电流为基准而选定的保护用过载继电器并不能为电机提供保护,这点在决定过载继电器时应该加以注意。

一般来说日前的新型变频器都具有电子热保护功能,并个需要专门设置外部过载继电器为电动机提供保护c但是,征下述情况下则应该设置过载继电器,以达到为电动机提供保护的口的。

(1)电动机容量在正常适用范围以外时。

由于变频器的电子热保护功能的设计和参数设走都是以jL常适用范闹内的电动机为对象的,当对象电动机的容量公正常适用范围以外(例如,电动机的容量小于正常适用的电机的容量)时.大法利用根据标难设定所得到的电子热保护功能对电动机进行保护。

因此,在这种情况下,为丁给电动机提供可靠的保护,应该另外设置过载继电器:但是,高压电机如果变频器的电子热保护设定值可以在所需范围内进行调节,则可以省略过载继电器。

(2)用一台变频器驱动多台电动机时。

虽然通过电子热保护可以对负载电机进行热保护,但是为了为电动机提供可靠保护,成为每台电动机设置过载继电器,如图5—5所尔。

此外.在上述情况下应同时使用变频器的“限制频率下限”的功能,以防止电动机以低于允许运行范围的频率运行。

电抗器的作用足抑制变频器输入输出电流中高汉LB汲瓜分常来的小良影响,而滤波器的作用则是抑制由变频器带来的无线电电波干扰,即电波噪声。

下面我们就分别介绍一下达两种周边设备的特性和使用.。