ASME CodeASME规范介绍

- 格式:pptx

- 大小:1.97 MB

- 文档页数:24

asme中的名词解释在工程和科技领域,准确解释和理解名词的含义是至关重要的,而ASME(美国机械工程师学会)成为了卓越工程领域的国际权威机构。

本文将通过对ASME中一些重要名词的解释,为读者提供更深入的了解。

1. ASME(美国机械工程师学会)ASME是一个非盈利的专业组织,于1880年成立,是一个拥有全球会员的国际性组织。

其宗旨是促进机械工程知识的应用和发展,为全球工程师和科技专家提供创新和交流的平台。

ASME推广工程标准的制定和使用,也为专业人士提供认证,并发表包括期刊、会议和规范等在内的专业出版物。

2. ASME规范(ASME Codes)ASME规范是ASME发表的一系列技术规范和标准,为机械工程领域的设计、制造、操作和维护提供了指导和要求。

其中最著名的是ASME锅炉及压力容器规范(ASME Boiler and Pressure Vessel Code)。

该规范是全球最广泛使用的压力容器设计和制造的指南,保证了这些设备的安全性和可靠性。

3. ASME认证(ASME Certification)ASME认证是指通过ASME认证程序,对符合ASME规范要求的压力容器、锅炉和其他机械设备进行认可。

获得ASME认证的企业可以在市场上展示其产品符合国际标准,提升信誉和市场竞争力。

同时,ASME认证也促进了全球压力容器和锅炉行业的技术合作和交流。

4. ASME标准(ASME Standards)ASME标准是ASME发表的技术规范和指南,具体规定了机械工程中各个领域的设计、制造和操作要求。

例如,ASME B31.1规范是针对工业管道系统的设计、建造和维护的标准;ASME Y14.5是用于制定工程图纸几何尺寸和公差的规范。

这些标准为工程师提供了通用的准则,确保产品的安全性和可靠性。

5. ASME会议(ASME Conferences)ASME会议是ASME组织的一个重要活动,为工程师、科学家和学者提供了交流和展示研究成果的平台。

De ar M ec ha ni ca l E ng in ee rin g St uden t:Th e ar tic le s in th is bo ok le t e xp lo re d iff er en t f ac et s of A SM E Co de s an d St an da rd s. W rit te n by e igh t A SM E ex pe rts , t he y w er e or igi na lly p ub lis he d in ASM E M ec ha ni ca l A dv an ta ge ,a pe rio di ca l f or to m or ro w’s en gin ee rs .AS M E Co de s an d St an da rd s pl ay a n im po rta nt ro le in e ns ur in g th e sa fe ty of th e pu bl ic an d in th e st an da rd iza tio n of th in gs a s co m m on a s nu ts an d bo lts . W e ha ve s el ec te d th e ar tic le s to d ra w yo ur a tte nt io n to s om e im po rta nt a sp ects o f y ou r p ro fe ss io na l l ife a s fu tu re m ec ha ni ca l e ng in ee rs .Fo r a n ov er vie w of A SM E Co de s an d St an da rd s, s ee th e “C od es a nd St anda rd s at a G la nc e” s ec tio n, w hi ch im m ed ia te ly fo llo ws th e ar tic le s.W e ho pe th at yo u fin d th is co lle ct io n in te re st in g an d in fo rm at ive , a nd th at it p ro vid es yo u wi th a n ew win do w in to th e fie ld o f A SM E Co de s an d St an da rd s. P le as e le t u s kn oww ha t y ou th in k at : cs @as m e.or g.Si nc er el y,Ta skG ro up o n AS M E Co de s an d St an da rd s fo r M ec ha ni ca l E ng in ee rin g Fa cu lty a nd S tu de nt sGe ra rd G . L ow en , C ha irSt ua rt Br ow nDo m en ic A. C an on icoRy an L . C ra neJo hn H . F er na nd esPh ilip M . G er ha rtHa lit M . K os arRi ch ar d M er zSa m Z am rikFo r m or e in fo rm at io n on A SM E Co de s an d St an da rd s, a sk yo ur fa cu lty advis er to s ho w yo u th e vid eo “In tro du ct io n to A SM E Co de s an d St an da rd s”an d its c om pa ni on b oo kle t.ASME’s Role in the Globalization ofCodes and Standardsby Don R. Frikken, P.E.Having one global standard becomes more and more important as companies merge across international boundaries, helped by regional trade agreements such as the North American Free Trade Agreement (NAFTA) and those estab-lished by the European Union (EU), which have facilitatedinternational mergers through the lowering of tariffs onimports.The companies involved in these consolidations, usedto selling to just one market, now find themselves sell-ing to global markets. The standards for products inthese markets are often different, which complicatesmanufacturing procedures. Local laws may require the use of a particular standard, yet these laws are viewed by the World Trade Organization (WTO) as technical barriers to trade, and WTO mem-ber countries are charged with reducing these and other barriers to free global trade.What is the best way for standards-developing organizations like ASME and for users of standards to find a solution? Possible approaches are to adopt the dominant standard, or to develop an umbrella standard that references other regional and national standards, or to develop a global consensus standard from scratch. ASME is involved in helping promote whichever approach best serves a specific industry and the users of the applicable ASME standards. ASME standards have changed over the last few years to include new con-struction materials, to address new topics, and to incorporate new calculation methods. As these changes continue to be introduced, globalization brings even more change, requiring greater flexibility and adaptation from industry.Elevators, Escalators, and Moving Walkwaysby Jim CoakerHow many times in the past week have you ridden in an elevator, on an esca-lator, or on a moving walk? These actions are so routine in everyday life that they happen automatically and are too numerous to recall.Behind each mechanism is a web of machinery, power sources, control sys-tems, and redundant safeguards in both design and operation that deliversafe vertical transportation without inci-dent. ASME International’s Safety Codesfor Elevators and Escalators, Inspectors’Manuals, Existing InstallationRequirements, Evacuation Guide, andElectrical Requirements are one of thelargest areas covered by the Society’s600 standards.Elevator ridership in the United States isconservatively estimated at more than200 billion passenger rides per year, a figure that makes it easy to appreciate the critical role that codes and stan-dards play in public safety. Dynamic change defines the world of technical applications and ASME’s standards are constantly updated to keep abreast of changes in technology.Starting with basic design principles relating to public safety, these codes and standards establish guidelines and requirements for equipment design, installation, operation, inspection, and maintenance. Even if the end result is invisible—a normal convenience in everyday life functioning without incident—the underlying complexities of the system present stimulation and challenge to the engineering mind. Some professionals spend their careers in this industry. The next time you ride an elevator or escalator, remember the engineers who have dedicated their careers to giving you a safe arrival!What are Performance Test Codes?by Philip M. Gerhart, Ph.D. and Sam J. Korellis, P.E.ASME Performance Test Codes (PTC) provide rules and procedures for planning, preparing, executing, and reporting performance tests. A performance test is an engineering evaluation; its results indicate how well the equipment performs its functions.Performance Test Codes originated as “Power Test Codes” and emphasized energy-conversion equipment. The first ASME Code was Rules for Conducting Boiler Tests, published in 1884. Today, nearly 50 PTCs are available; they cover individual components (steam generators, turbines, pumps, compressors), sys-tems (flue gas desulfurization, fuel cells), and complete plants (cogeneration plants). In addition to equipment codes, supplements on instruments and appa-ratus cover measurement systems (temperature, pressure, flow) and techniques (uncertainty analysis) common to several codes.For more than a century, ASME PTC tests have pro-vided results with the highest level of accuracy,based on current engineering knowledge and prac-tices, and taking into account the costs of the testsand the value of the information obtained. AllASME codes are developed using input from arange of parties, who may be interested in thecode and/or in the associated equipment orprocess. Codes have the force of a legal docu-ment when cited in contracts, as they frequently are, for determining the method by which equipment performs as guaranteed. PTCs are used by equipment owners, equipment suppliers, and test engineers. ASME PTCs protect users from poorly performing products and enable suppliers to compete fairly by offering reliable products. Purchase specifications are great-ly strengthened by citing the results of PTC tests. When buying new equipment, purchasers may specify that the equipment guarantee will be based on the results of a specific ASME PTC test. Design engineers consult PTC documentsto ensure that proper instrument connections will be available. Test engineers install the required instrumentation and use the code’s procedures and calcula-tion methods to conduct tests on the new equipment. Representatives of all par-ties to the test ensure that the test methods are in compliance with the code. Finally, the test results are compared to the performance criteria.Sometimes manufacturers and suppliers want to determine the exact perform-ance of their equipment to understand the design margins or the effects of man-ufacturing tolerances on performance. In this case, code tests are conducted outside of any performance guarantees.To ensure that ASME PTCs best serve global industries, additional products and services always are being evaluated. As the preeminent provider of standardized methods for performance testing; monitoring; and analysis of energy conversion and industrial processes, systems, and equipment, ASME continues to develop and add new codes.A Look at ASME’s Boiler and Pressure Vessel Code (BPVC)by Domenic Canonico, Ph.D.The ASME Boiler and Pressure Vessel Code (BPVC) is a standard that provides rulesfor the design, fabrication, and inspection of boilers andpressure vessels. A pressure component designedand fabricated in accordance with this standard willhave a long, useful service life, and one that ensuresthe protection of human life and property. Volunteers,who are nominated to its committees based on theirtechnical expertise and on their ability to contributeto the writing, revising, interpreting, and administeringof the document, write the BPVC.The idea for the BPVC arose in 1911 out of the need forpublic safety, following the invention of the steam engine inthe late 18th century. Throughout the 19th century there were thousands of boiler explosions in the United States and Europe, some of which resulted in many deaths.The first Boiler and Pressure Vessel Code (1914 edition) was published in 1915; it was one book, 114 pages long. Today there are 28 books, including twelve dedicated to the construction and inspection of nuclear power plant components and two Code Case books. (The 2001 edition of the Boiler and Pressure Vessel Code is more than 16,000 pages.) The 28 books are either standards that provide the rules for fabricating a component or they are support documents, such as Materials (Section II, Parts A through D), Nondestructive Examination (Section V), and Welding and Brazing Qualifications (Section IX). Code Cases provide rules that permit the use of materials and alternative methods of construction that are not covered by existing BPVC rules.The BPVC is the largest ASME standard, both in size and in the number of volunteers involved in its preparation. At any one time there are more than 800 volunteers serving on one or more committees. The fact that the BPVC is a committee organ-ized and administered by ASME may give the impression that the volunteers are all mechanical engineers. This is not the case; to write such a standard requires a breadth of knowledge that is not available in any one discipline. Volunteers on the committees have expertise in materials (metallurgical and materials engineering),structures (civil engineering), physics, chemistry (chemistry and chemical engi-neering), and other disciplines in addition to mechanical engineering.Various sections of the BPVC have been adopted into law in all the Canadian provinces and in 49 of the 50 United States. More than one-quarter of the compa-nies accredited by ASME Codes and Standards to manufacture pressure parts in accordance with various sections of the BPVC are located outside of North America.Internationally, the BPVC is recognized in more than 60 countries.The record of the BPVC is a testament to its success. The safety record of pressure-containing components manufactured in accordance with the rules of the BPVC is outstanding. The contributions made over the past 90 years by thousands of volun-teers, who have participated in the preparation of the BPVC, have made this possible.Ph ot o co ur te sy o f t he N oo te r C or po ra tio n,St . L ou is , M O.U.S. Government Use of ASME Codesand Standardsby Guy A. ArlottoYour organization wants to construct and operate a nuclear power plant; to supply the reactor steam supply system; to supply architect engineering services; or to supply components (e.g., pressure vessels, piping pumps, valves) for anuclear power plant. The U.S. NuclearRegulatory Commission (NRC), the federalagency responsible for issuing construc-tion permits and operating licenses fornuclear power plants, requires confor-mance with certain ASME codes andstandards in its regulations. Therefore,to obtain a construction permit or anoperating license, you must meet therequirements of these codes.In the 1980s the federal government’sOffice of Management and Budget (OMB)first issued OMB Circular A-119, whichrequired certain government agenciesto use applicable national consensusstandards wherever practical, in lieu ofdeveloping their own regulations to accomplish their missions. More recently, a public law (PL 104-113) mandates the use of national consensus standards, including ASME codes and standards, by federal agencies where applicable. (The Dept. of Defense, the U.S. Postal Service, and the U.S. Coast Guard routinely use them.)The U.S. Atomic Energy Commission (AEC), NRC’s predecessor, did not need the impetus of OMB A-119 or PL 104-113 to recognize the potential benefits of using ASME codes and standards to work more efficiently and to ensure public health and safety. A decade before OMB A-119 was first issued, the AEC had already endorsed certain ASME codes in its regulations. In fact, AEC involvement with the ASME codes and standards program dates from the mid-1960s, when AEC staff began working on appropriate ASME code committees. The use of nuclear power in the United States originated with the U.S. Navy program to develop it as the power source for submarines. The Navy took it further by applying it to surface ships and by demonstrating its potential for land-based electrical power generation at the nuclear power plant at Shipping Port, Pennsylvania.ASME recognized the need for enhanced codes and standards because the technology was new and had no tested codes and standards available, and because the consequences of component failures could have a serious impact on public safety. It created a committee to develop design and construction requirements to ensure the integrity, first of the reactor pressure vessel, and then of other important pressure-retaining components. This resulted in what is today called BPVC’s Section III. It covers an array of nuclear components, including pressure vessels, piping, pumps, valves, supports, core support structures, pressure relief, containment systems for spent fuel and high-level waste transport packaging, and concrete components.At the same time that Section III was being created by ASME in the late1960s and early 1970s, the AEC was receiving applications monthly from electric utilities in the United States for permits to construct nuclear power plants. It was at that time that the AEC committed resources to the ASME Codes and Standards program by supporting expert staff members to work on ASME committees developing nuclear codes. This gave the AEC the confi-dence to accept the finished code because its own staff had direct input in the development of the requirements, and it understood the contents of the code and the bases for the requirements. More important, the AEC decided to endorse portions of ASME codes in its regulations, thus making it a require-ment to satisfy the code as a condition for obtaining a construction permit. Federal (AEC/NRC) regulations require first that one obtain a construction permit allowing construction to begin. After construction is complete, the utility must apply for and receive an operating license before beginning operation. As nuclear power plants progressed from the construction phase to the oper-ating phase, ASME developed and published Section XI, Rules for Inservice Inspection of Nuclear Power Plant Components, to ensure that continued safe operation was maintained over the life of the plant. This also was endorsed in NRC regulations, making the periodic inspection and testing of components and meeting acceptance standards a requirement for maintaining a licenseto continue operation. This gives the NRC and the public a level of confidence that any degradation of the plant during the period of operation has not reduced safety below an acceptable level.The NRC’s use of ASME codes and standards benefits ASME, the NRC, and most important, the public. ASME’s codes and standards gain increased visi-bility and stature through government use, its volunteers see the fruits of their efforts, and public safety is maintained. The NRC benefits because by using ASME codes, it can be a more efficient government agency, both in its deci-sion-making and during various phases of the licensing process. The better the NRC functions, the better the health and safety of the public is protected.ASME Codes and Standards in Chinaby John FergusonFor several years The American Society of Mechanical Engineers has worked to advance the use of ASME codes and standards in China, most notably, standards for nuclear power plant equipment and for boilers and pressure vessels. Beginning in October 2000, several successful workshops were held in Beijing in cooperation with various Chinese organizations.ASME’s goals are to have China’s nuclearpower plants, facilities, and associatedequipment designed and constructed toASME codes, and to have existing facili-ties use ASME standards for operationand maintenance. Chinese engineersand regulatory personnel respect thetechnical content of these codes andstandards and, in the absence of havingtheir own technical standards, haveexpressed an interest in establishing ASME standards as the standard for their nuclear programs.In the last decade, ASME’s Boiler and Pressure Vessel Code (BPVC) has begun to get wider use in China, and the Chinese government accepts imported equipment constructed to its requirements. Greater use of the BPVC in the construction of fossil-fuel-fired power boilers and in the petroleum and chemical industries is being pursued.With the increased use of ASME codes and standards in China, U.S. manufac-turers and engineering service companies will have the opportunity to under-take jobs and participate in the current expansion and new construction taking place, particularly in the nuclear area. It also provides opportunities for the sale of U.S.-made components. By having common technical require-ments for equipment and services based on ASME codes and standards, barriers to trade are reduced and public safety is enhanced.A Global Highway for Mechanical Engineering Communications: ASME Y14.5, Dimensioningand Tolerancingby Lowell W. FosterASME Y14.5M-1994, Dimensioning and Tolerancing, which specifies engineering drawing requirements, originated in the 1950s. Over the years it has incorpo-rated technical innovations such as the new electronic compatible systems.Its original goal was to delineate and define mechanical part hardware and to create a common technical drawing language for standardized drawing prac-tices. It was also recognized that repre-senting a perfect part on the drawingmust include a permitted “tolerance”as a deviation from the perfect part(because perfection cannot be achievedin real production). This explains thedimensions and tolerances emphasisof Y14.5M. This standard is designatedas an “Internationally RecognizedStandard,” the standard of choicethroughout much of the world.ASME Y14.5M predominantly illustrates the Geometric Dimensioning and Tolerancing (GDT) language to capture the “function and relationships” of part features. This shows that the design requirements and dynamics of part fea-tures (e.g., holes, pins, slots, surfaces), as they relate in part function, fit, or assembly with mating parts, can be captured and specified with “geometric characteristics,” “datum references,” and the other tools of the system. For example, in a mating part situation where four pins on one part are to assem-ble with four mating part holes, would it not stand to reason that if a hole (any one of them and each individually) was produced away from its worst case low limit size as an individual feature (i.e., be larger within its size tolerance), that any permitted error (tolerance) of location of that hole could be increased an equal amount? In other words, size of features can have an effect on, com-pensate for, and assist in meeting the location tolerance. This is known as the “maximum material condition” principle and increases possible location toler-ances, brings down costs of production, and makes using functional gaging principles possible, which ensures assembly and other advantages. The prod-uct designer can select this option or decide on a more stringent method (called “regardless of feature size”) when this dynamic is prohibited. Othercontrols delineate part form, orientation, profile, and location of features rela-tive to design requirements. This is all done through the system’s symbolic language and the rules and guidelines provided in the standard. This useful, powerful, and widely recognized GDT language is now established as the best method for communicating design requirements. Through use of the GDT system, production, quality, inspection, tooling, programming, and all other supporting operations can meet the requirements using a greater range of methods.Cranes for Nuclear Facilitiesby James E. NelsonIt would be difficult to overstate the importance of using the safest crane design for handling heavy loads in nuclear facilities—it is critical. Dropping or losing control of a load—a dreaded scenario—could result in damage to safe-ty-critical equipment or spent fuel. It is unthinkable and it is impermissible.With this in mind, the ASME Committeeon Cranes for Nuclear Facilities (CNF) haswritten standards for overhead cranes,the equipment that handles the majorityof heavy loads.The Committee on Cranes was estab-lished in 1976, shortly after the U.S.Nuclear Regulatory Commission (NRC)first issued written guidelines for safety-critical or single-failure-proof (SFP) cranes.In 1980, the committee's scope wasbroadened from nuclear power plantsto nuclear (and other critical load han-dling) facilities. Its first standard, ASMENOG-1, Rules for Construction ofOverhead and Gantry Cranes, wasissued in 1983. The committee’s second standard, NUM-1, Rules for Construction of Cranes, Monorails, and Hoists, followed in 1996. Committee members represent a range of power plant and nuclear facility owners and operators, engineers, reg-ulatory personnel, constructors, equipment suppliers, and crane manufacturers.No other industry or government standards have addressed important issues for nuclear facility cranes such as quality assurance, dynamic seismic analy-sis, and SFP crane features. NOG-1 and NUM-1 cover all of these and more.In a Nuclear News magazine article,1NRC Commissioner Jeffrey Merrifield said, “I believe that the future of the nuclear industry does not hinge on cor-porate decisions about new plants, it hinges on the safety ofthe existing fleet of reactors,” and “Anyone who believes that safety and economic value are mutually exclusive goals is simply blind to the realities that history has unmistakably, and sometimes painfully, taught this industry.”Today, construction of new nuclear plants in the United States is being encour-aged and numerous operating plants are applying for operating life extensions.A heavy load drop would be disastrous for the industry, even without an offsite release of radioactive materials.The NRC defines a heavy load as anything weighing more than a nuclear fuel assembly (approximately one ton). A spent fuel cask can weigh 100 to 150 tons or more, and if dropped into the spent fuel pool, it could cause serious damage to the pool and/or the fuel, resulting in a radioactive release. Dropped elsewhere, it could damage safe shutdown equipment or rupture the cask itself. The empty hook block on such a crane can weigh four or five tons and can itself cause severe damage if it falls into the fuel pool or onto safety-related equipment.The NRC identified two primary causes of load drops as being severe types of overload: "two blocking" or "load hangup." Two blocking occurs when control malfunction or maintenance error permits unintentional overhoisting, resulting in solid contact between the hook block and the head block or its supporting structure. Immediate failure results with the wire rope and the dropping of the load or empty hook block.Load hangup is abrupt snagging of the moving load, resulting in similarly severe effects on the equipment. Other causes of dropped loads include "mis-reeving" of the hoist wire rope and failure of the hoisting machinery itself.The NRC guidelines for SFP cranes, as well as ASME NOG-1 "Type I" and NUM "Type I" SFP standards, specify cranes to be designed either to withstand all such incidents without damage or loss of load, or to make the likelihood of their occurrence extremely small. Type I NOG-1 and NUM-1 crane standards in particular incorporate design requirements specific to these concerns, and well beyond the requirements of other crane standards.The work of the CNF Committee of ASME and the application of its standards has never been more relevant. In the last few years there has been a tremen-dous increase in the handling of spent fuel casks to move fuel from plant fuel pools to independent spent fuel storage installations. Many operating plants have reached or are approaching the time when they must remove spent fuel from their pools in order to continue operation, but have delayed making heavy load handling (crane) decisions. Now the need is imminent. In the handling of spent fuel, both operating plants and decommissioning plants face many of the same issues.1 ”Safety: The foundation upon which economic value is built,” Nuclear News,August 2001.Codes and Standardsat a GlanceWhy are there codes and standards...?The Industrial Revolution profoundly changed the way people lived by introduc-ing machinery that transformed daily life. Farm implements no longer had to be made by hand—they could be manufactured. Affordable manufactured goods of all kinds would transform home life—textiles, dishware, reading material. A coal-burning furnace and boiler could heat the water in your home. Transportation began to move at unimagined speeds, far exceeding that of a horse. Slowly, handmade items were being replaced with manufactured items; human strength and horsepower were being replaced by machinery driven by steam power—steam engines, boilers....Because it’s a catastrophe when a screw doesn’t fit.The most serious problem facing 19th century engineers was exploding boil-ers. Heating water to produce steam and converting that steam into energy to power machinery revolutionized the production of goods. To build up pressure, steam must be contained in some type of vessel; but uncontrolled, pressur-ized steam can burst a vessel even if it’s made of steel. For want of reliably tested materials, secure fittings, and proper valves, boilers of every descrip-tion, on land and at sea, were exploding with terrifying regularity. (They would continue to do so into the 20th century.) Although engineers could take pride in America’s strides in technology, they could not ignore the 50,000 dead and 2 million injured annually by such accidents. Thus, mechanical engineers in the 1880s began seeking reliable methods for testing steam boilers.Lack of interchangeability was also becoming a problem. A consumer couldn’t buy a bolt in California and use it on a nut acquired in New Jersey because the threading didn’t match. Therefore, the farm implement, shotgun, or pipe was rendered useless, unreliable, or dangerous.When The American Society of Mechanical Engineers (ASME) was founded in 1880, discussion began immediately on establishing standards; it focused on shop drawing symbols, pulleys, line shafting, machine screws, key seats, and drawing boards. At its annual meeting in 1883, a committee on standards and gages was created and a paper was presented urging the adoption of a set of rules for conducting boiler tests that could be accepted as a standard code of practice by engineers. The paper emphasized the prevailing lack of uniformity in which “every engineer who performs a boiler test makes a rule for himself, which may be varied from time to time to suit the convenience or interests of the party for whom the test is made.”2。

国际检测标准ASMEASME国际检测标准。

ASME是美国机械工程师学会(American Society of Mechanical Engineers)的简称,它是一个国际性的标准化组织,致力于推动机械工程技术的发展和应用。

ASME制定了许多国际标准,其中包括了许多涉及检测的标准,这些标准的制定对于保障产品质量、促进国际贸易以及保护公众利益都起到了重要作用。

ASME的国际检测标准涵盖了许多领域,包括压力容器、锅炉、管道、阀门、风机、起重设备等。

这些标准在全球范围内被广泛应用,成为了许多国家和地区的法定检测依据。

在ASME的国际检测标准中,最为重要的要数ASME Boiler and Pressure Vessel Code(ASME锅炉和压力容器规范),这是ASME制定的最具影响力的标准之一。

该规范涵盖了锅炉、压力容器及其附件的设计、制造、检验、试验和安全运行等方面的要求,对于保障工业设备的安全运行起到了至关重要的作用。

除了ASME锅炉和压力容器规范外,ASME还制定了许多其他领域的国际检测标准,比如ASME B31系列标准涉及了管道系统的设计、施工、检测和运行等方面的要求;ASME PTC系列标准涉及了性能测试和计算方面的要求;ASME V&V 系列标准涉及了验证和验证方面的要求等等。

ASME的国际检测标准不仅在美国得到了广泛应用,在全球范围内也被广泛采纳和认可。

许多国家和地区都将ASME的标准作为自己的法定检测依据,这使得ASME的标准成为了国际贸易中的重要桥梁,也为各国的产品质量和安全提供了保障。

总的来说,ASME的国际检测标准在全球范围内发挥着重要作用,它不仅推动了机械工程技术的发展,也为国际贸易和公众利益提供了保障。

随着全球化进程的加速推进,ASME的国际检测标准将继续发挥着重要作用,推动着全球机械工程技术的发展和应用。

asme规范ASME(American Society of Mechanical Engineers)是美国机械工程师协会的简称,是一个国际性学术组织,致力于推动机械工程领域的标准化和规范化。

ASME规范是ASME发布的一系列标准和规范的总称,涵盖了机械工程领域的各个方面。

下面是关于ASME规范的1000字简介。

ASME规范从19世纪末开始发布,是世界上最早也是最重要的机械工程专业标准之一。

ASME规范包括了机械工程、航天工程、能源工程、核工程等众多领域的标准和规范。

这些规范主要涵盖了设计、制造、测试、安全等方面的要求,旨在确保机械设备的安全运行和性能质量。

ASME规范的编制过程非常严格和专业。

它由ASME成员组成的专业委员会负责起草和修订,经过多轮讨论和评审,最终由ASME发布。

ASME规范通常采用英制和国际单位两种计量单位,并提供了详细的计算公式和检验方法。

ASME规范的更新速度非常快,通常每隔几年就会进行修订,以适应科技和工程领域的新发展。

ASME规范在机械工程领域有着广泛的应用。

许多国家和地区都采用ASME规范作为机械工程设计和制造的标准。

在工程项目的投标、设备采购和工程监理等环节,ASME规范的符合性通常是评判和选择的重要依据。

同时,ASME规范也为工程师和设计师提供了一种通用的语言和技术标准,便于工程师之间的交流和合作。

ASME规范从整体上提高了机械工程领域的技术水平和工程质量。

它规定了机械设备的设计、制造和运行要求,确保了设备的安全性、可靠性和性能稳定性。

ASME规范还推动了机械工程领域的创新和发展,促进了新技术和新材料的应用。

通过ASME规范,机械工程师能够获得一种共同认可的标准和方法,提高了工程设计和制造的效率和质量。

总之,ASME规范是机械工程领域的重要参考标准,对于确保机械设备的安全和性能具有不可替代的作用。

它的不断更新和完善,为机械工程师提供了一种通用的技术语言和标准方法,促进了工程设计和制造的发展。

标准讲解-asmeASME标准是指美国机械工程师协会制定的一系列国际标准,涵盖了机械工程、石油和化工、航空航天、核能等多个领域。

ASME标准的制定旨在提高产品质量、保障安全、促进技术创新和国际贸易。

ASME标准不仅在美国得到广泛应用,也在全球范围内被广泛采纳和使用。

ASME标准的内容非常丰富,包括了设计、制造、测试、安全、材料、焊接、检验等方面的规定。

在机械工程领域,ASME标准被认为是行业内的权威,其标准的制定和修订都经过了严格的程序和流程,确保了标准的科学性和可靠性。

在ASME标准中,最为著名的要数ASME Boiler and Pressure Vessel Code (ASME锅炉和压力容器规范)了。

这一规范是ASME制定的最早的标准之一,也是应用最为广泛的标准之一。

ASME锅炉和压力容器规范涵盖了锅炉、压力容器、管道、阀门等设备的设计、制造和检验要求,被广泛应用于石油化工、电力、核能等行业。

ASME标准的制定过程非常严谨,通常包括以下几个步骤:首先,确定标准的需求和范围。

ASME标准的制定都是由专门的委员会负责的,他们会首先确定标准的需求和适用范围,明确标准所要涵盖的内容和适用的对象。

其次,收集和分析相关数据和信息。

ASME委员会会收集和分析相关的技术数据、市场需求、国际标准等信息,为标准的制定提供依据。

然后,制定标准草案。

在收集和分析了相关的信息之后,ASME委员会会制定初步的标准草案,明确标准的技术要求、测试方法、标志和标签等内容。

接下来,进行公开征求意见。

ASME委员会会将初步的标准草案公开征求行业内外的意见和建议,以便完善和修订标准。

最后,审定和发布标准。

经过多次的修改和完善,ASME委员会最终会审定并发布标准,确保标准的科学性和可行性。

总的来说,ASME标准是全球范围内最为权威和严谨的标准之一,其制定和修订过程严格规范,确保了标准的科学性和可靠性。

ASME标准的应用不仅可以提高产品质量、保障安全,也有助于促进国际贸易和技术交流。

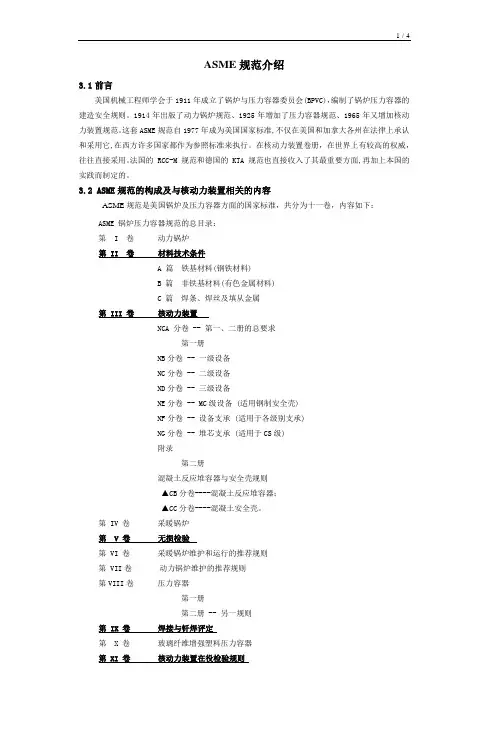

ASME规范介绍3.1前言••• 美国机械工程师学会于1911年成立了锅炉与压力容器委员会(BPVC),编制了锅炉压力容器的建造安全规则。

1914年出版了动力锅炉规范、1925年增加了压力容器规范、1965年又增加核动力装置规范。

这套ASME规范自1977年成为美国国家标准,不仅在美国和加拿大各州在法律上承认和采用它,在西方许多国家都作为参照标准来执行。

在核动力装置卷册,在世界上有较高的权威,往往直接采用。

法国的 RCC-M 规范和德国的 KTA 规范也直接收入了其最重要方面,再加上本国的实践而制定的。

3.2 ASME规范的构成及与核动力装置相关的内容ASME规范是美国锅炉及压力容器方面的国家标准,共分为十一卷,内容如下:•••••ASME 锅炉压力容器规范的总目录:第 I 卷动力锅炉第 II 卷材料技术条件A 篇铁基材料(钢铁材料)•••••••••• B 篇非铁基材料(有色金属材料)•• C 篇焊条、焊丝及填从金属• 第 III 卷核动力装置••••••• NCA 分卷 -- 第一、二册的总要求••• 第一册•••••••••• NB分卷 -- 一级设备•••••••••• NC分卷 -- 二级设备•••••••••• ND分卷 -- 三级设备•••••••••• NE分卷 -- MC级设备 (适用钢制安全壳) •••••••••• NF分卷 -- 设备支承 (适用于各级别支承)•••••••••• NG分卷 -- 堆芯支承 (适用于CS级) •••••••••• 附录•••••••••• 第二册•••••••••• 混凝土反应堆容器与安全壳规则▲CB分卷----混凝土反应堆容器;▲CC分卷----混凝土安全壳。

第 IV 卷采暖锅炉第 V 卷无损检验第 VI 卷采暖锅炉维护和运行的推荐规则第 VII卷动力锅炉维护的推荐规则第VIII卷压力容器•••••• 第一册•••••• 第二册 -- 另一规则第 IX 卷焊接与钎焊评定第 X 卷玻璃纤维增强塑料压力容器•• 第 XI 卷核动力装置在役检验规则其中第Ⅲ卷是关于核动力装置设备的规范,与第Ⅲ卷相关的其它部分有:第Ⅱ卷材料技术条件;第Ⅴ卷无损检验;第Ⅸ卷焊接及钎焊评定;第Ⅺ卷核动力装置设在役检验规程。

ASME规范鼎鼎大名,是目前世界上普遍遵循的规范之一。

可以毫不夸张地说,RCCM是其衍生产品,并对其进行了部分精简,有后来居上的感觉,但是美国人也很认真,不断地进行规范的升版,丝毫不敢懈怠,因为在这个全球化的时代,谁拥有了普适的标准的所有权,谁就有话语权,由此,便形成了生产力。

下面就ASME的结构和主要内容进行介绍,以方便学习工作中使用。

ASME简介1 概述••••••••••1.1 前言••••••••••1.2 ASME锅炉压力容器规范的构成及与核动力装置相关的内容••••••••••1.3 ASME-III 规范的性质••••••••••1.4 ASME核动力设备相关规范涉及范围••••••••••1.5 设备与部件分级••••••••••1.6 持证者遵守ASME规范的责任与义务和授权检验机构••••••••••1.7 ASME-III规范与设备规格书••••••••••1.8 RCC-M与ASME的同异2 第一册各分卷••••••••••2.1 概述••••••••••2.2 NX各分卷的结构及其与其它各卷的关系••••••••••••••••••••2.3 NX 各级设备的设计规定的特点••••••••••2.4 分析设计-- 一级设备与二、三级设备的根本差别之一•••••••• ••••••••••2.5 分析法设计的基本概念••••••••••2.6 NF设备支承结构3 材料••••••••••3.1 概述-材料相关的卷、册和章及其使用••••••••••3.2 材料的通则-- NX2000 材料章••••••••••3.3 不同级核材料要求的差异4 制造、安装、检验与试验••••••••••4.1 概述••••••••••4.2 焊接评定- IX 卷概要••••••••••4.3 无损检验方法- V 卷概要•••••••••• •5 动力管道••••••••••5.1 概述••••••••••5.2 管道支承件••••••••••5.3 管道的装配与安装6. 小结•••••••••• 概述( ASME-III NCA 分卷)••••••••••••••••••••1.0 前言••• 美国机械工程师学会(American Society of Mechanical Engineers 简称ASME)于1911•年成立了锅炉与压力容器委员会(BPVC)编制锅炉压力容器的建造安全规则(所谓建造是一个概括性的术语, 它包括设备在制造和安装中要求的材料、设计、制造、安装、检验、试验、检查和鉴定),规定了敁强制性的最低要求,以及维护和运行的建议。

asme规范ASME是美国机械工程师学会(The American Society of Mechanical Engineers)的简称,它是全球最大的专业技术学会之一。

ASME制定了许多国际公认的机械工程相关规范和标准,这些规范和标准广泛应用于工程设计、制造和安全等方面。

本文将详细介绍ASME规范的特点和应用。

ASME规范的特点之一是广泛适用性。

ASME规范涵盖了从设计到制造的各个环节,也涵盖了多个不同的行业和领域,如航空航天、核能、石油化工等。

这使得ASME规范成为了国际上最通用的机械工程标准之一,被许多国家和地区采用为本国的标准。

另一个ASME规范的特点是科学性和严谨性。

ASME的标准制定过程严格遵循科学原则和工程实践,通过试验和验证来确保标准的有效性和可行性。

ASME规范不仅仅是一些描述性的规定,更是一系列基于科学理论和实际经验的技术指导,能够帮助工程师更好地进行设计和制造。

ASME规范的应用范围广泛,其中一些常见的规范包括以下几个方面:1. ASME标准的设计规范:如ASME BPVC部分维修、改造和替换规范,规定了各类设备的设计要求,包括压力容器、锅炉、核反应堆压力壳体等。

这些规范能够确保设备在承受工作压力时的安全性和可靠性。

2. ASME标准的制造规范:如ASME PTC部分性能测试规范,规定了各类机械设备的制造要求和性能测试方法。

通过符合ASME规范,制造商可以提高产品的质量和可靠性,提高用户的满意度。

3. ASME标准的安全规范:如ASME B31.3工艺管道系统规范,规定了工艺管道系统的设计、施工和运营要求。

这些规范能够确保管道系统在工作过程中的安全性,预防事故和泄漏的发生。

ASME规范的应用不仅局限于美国本土,而是全球范围内的通用标准。

许多国家和地区的法规和标准都直接或间接地参考或采用了ASME规范。

即使在一些没有明确采用ASME规范的地区,ASME规范也被很多工程师和制造商作为一种参考标准来使用。

ASME和ASME锅炉和压力容器规范简介2006年9月中石协ASME规范产品协作网秘书长徐玉忠世界多极化、经济全球化和信息网络化的大潮正迅速改变着当今的世界。

经济全球化的趋势不仅是竞争,更呼唤加强国际合作,要求贸易和投资实现相对的、乃至最终的自由化。

而经济全球化的前提和结果必然是标准的全球化。

但是经济全球化不是一蹴而就的,当今经济全球化的第一步是经济的区域化,如北美自由贸易协定、欧盟、APEC、东盟自由贸易协定,以及10+1、10+3,最近,我国还加入了东南亚条约。

我国加入世界贸易组织(WTO)后,世界市场向中国开放,中国市场也向世界开放。

影响贸易的关税壁垒虽将逐步取消,但非关税壁垒,如技术壁垒、环保壁垒等依然存在,由于各国(或地区)间执行技术标准的不同,如我国的GB (国家标准)、ASME规范、欧共体的压力设备指令(PED)等,将成为影响国际间自由贸易的主要壁垒。

中国要真正成为一个制造大国,一个独立创新能力的制造强国,必须抓住这个机遇,并接受挑战。

今天向大家简单地介绍ASME和ASME规范。

一、美国机械工程师学会(ASME)ASME是美国机械工程师学会(The American society of Mechanical Engineers)的英文简称。

美国机械工程师学会(ASME)成立于1880年,现拥有125,500名个人会员(其中包含国外的会员)。

她是专业性的技术组织,主要从事于技术、教育和研究性活动。

在世界范围内组织众多的技术会议,每年提供数以百计的职业培训课程。

ASME还负责制订全球公认的工业及制造业的规范和标准,以确保公共安全。

所以她现在称ASME international。

总部设在纽约。

同时,ASME也是世界上最大的技术出版社之一。

组织机构:ASME新的组织机构有5个部门组成:即知识及团体(Knowledge and Community),规范和标准(Codes and Standards),中心(Centers),院所(Institute)和战略管理(Strategic Management)。

ASME标准与认证ASME Standards and Certificate一、ASME 简介美国机械工程师学会(ASME)成立于1880年,至今已有129年历史。

作为一个在提供技术信息、培训和教育一体化服务拥有丰富经验的非赢利性科技社团,ASME通过她的产品、服务和其他媒介,为社会及专业人士提供了一个共享多样资源的平台,以确保竞争力,健全各人职业发展规划,建立全球性的专家交流网络。

ASME同时是世界上最大的技术文献出版机构之一,其出版发行的约600项技术法规与标准被世界100多个国家和地区广泛采用。

其著名出版物包括ASME锅炉及压力容器标准;技术文件、学术报告、会议论文和ASME会刊《机械工程师》。

此外,ASME还提供大量的培训课程;实施认可认证项目;主办全球性技术会议等。

ASME还致力于为青年工程师开发适用于他们职业发展的有关标准和法规的培训项目,以此为未来工程技术科学的可持续发展作出贡献。

ASME拥有近13万名会员、5000 多家锅炉压力容器证书持证厂商、200多家核电证书持证厂商、30 多家授权检验认证机构以及2000 多位个人认证证书持有者。

ASME与中国的合作源远流长。

上世纪八十年代初,ASME即与中国机械工程学会、中国动力工程学会、中国核学会、中国电机工程学会等学术团体建立了合作关系,这些合作关系在过去的岁月中不断得到加强。

改革开放初期,ASME与原机械工业部、石油工业部、化学工业部、劳动部和国家科委等部门密切合作,为推动中美科技交流作出了有益的贡献。

目前,ASME与科学技术部、工业与信息化部、国家技术监督检验检疫总局、国家标准化管理委员会、国家外国专家局、中国科学院、中国工程院、中国科学技术协会、中国机械工业联合会等部门以及中石油、中石化、中核总、国核技、国机集团等中国大型骨干企业保持着互利互惠的合作关系。

ASME认证分类及证书数量如下(数据截止日期:2008.6.30):二、ASME标准体系介绍ASME 锅炉压力容器规范标准(ASME Codes and Standard)总共有12卷,分别是:I动力锅炉建造规则II材料III核设施部件建造规则IV采暖锅炉建造规则V无损检测VI采暖锅炉维护和运行推荐规则VII 动力锅炉维护推荐指南VIII压力容器建造规则IX焊接和钎接工艺,焊工、钎接工、焊接和钎接操作工评定标准(焊接和钎接评定标准)X纤维增强塑料压力容器建造规则XI核电站部件运行中检测标准XII 运输罐的建造和连续使用规则以上12卷ASME锅炉压力容器规范标准分为以下4大类:1)建造部分:共6卷,其中包括:第一卷:动力锅炉;第三卷:核设施部件建造规则;第四卷:采暖锅炉建造规则;第八卷:压力容器建造规则;第十卷:纤维增强塑料压力容器建造规则;第十二卷:运输罐的建造和连续使用规则。

asme压力容器标准ASME压力容器标准。

ASME(美国机械工程师协会)是全球最著名的标准化组织之一,其制定的压力容器标准被广泛应用于各种工业领域。

ASME压力容器标准的制定旨在确保压力容器的安全运行,保护人员和设备的安全。

本文将对ASME压力容器标准进行介绍和解读,以便读者更好地了解和应用这一标准。

ASME压力容器标准涵盖了许多方面,包括设计、制造、检验、安装和维护等。

其中,最为重要的是ASME Boiler and Pressure Vessel Code(ASME锅炉和压力容器规范),该规范被广泛应用于各种类型的压力容器,包括锅炉、储罐、换热器等。

ASME锅炉和压力容器规范主要包括以下几个部分,材料规范、设计规范、制造规范、检验规范、安装规范和维护规范。

在这些规范中,设计规范是最为重要的部分之一,它规定了压力容器的设计原则、计算方法和安全要求。

制造规范则规定了压力容器的制造工艺、工艺控制和质量要求。

检验规范则规定了压力容器的检验方法、检验程序和检验标准。

安装规范和维护规范则规定了压力容器的安装和维护要求。

在应用ASME压力容器标准时,需要严格遵守规范的要求,确保压力容器的设计、制造、检验、安装和维护符合标准要求。

首先,需要根据压力容器的使用条件和工艺要求选择合适的材料,并按照设计规范进行设计计算。

其次,需要严格按照制造规范进行制造,并对制造过程进行质量控制。

再次,需要按照检验规范进行检验,并对检验结果进行评定。

最后,需要按照安装规范进行安装,并按照维护规范进行维护。

总的来说,ASME压力容器标准是确保压力容器安全运行的重要保障,它规定了压力容器的设计、制造、检验、安装和维护的要求,对于确保压力容器的安全运行具有重要意义。

因此,我们在使用压力容器时,必须严格遵守ASME压力容器标准的要求,确保压力容器的安全运行,保护人员和设备的安全。

综上所述,ASME压力容器标准是确保压力容器安全运行的重要保障,它规定了压力容器的设计、制造、检验、安装和维护的要求,对于确保压力容器的安全运行具有重要意义。