英奇产品目录表

- 格式:xls

- 大小:293.50 KB

- 文档页数:2

More of what you need to work smarter,AccessoriesV i s u a l I n d e x59RG D-17T1RG D-17Partek Sleeve D-18ParKoil™ (PG) D-19GuardsO-Rings for CA, CE,CF MetricFlange “D” Rings Caterpillar ® Style FlangesT ube O-Ring Fittings and CompressorFittingsO-Rings for Compression Fittings (IT126)O-Rings for C9, OC, 1C Metric Swivels88HC-H Clamp D-2488DB Clamp D-24Hose Assembly D-26Workstations3/4 Reel Rack D-2772B-Cabinet D-28HR6 Hose Bin D-28Hose Adapters D437° Flare Metric Triple-Lok ®Sizes: 6 mm – 38 mmMaterials : Steel, Stainless Steel Pressures : Up to 7200 psi60° Cone BSPPK4Sizes : 1/8” – 2”Materials : Steel Pressures : Up to 5000 psi30° Flare Komatsu StyleSizes : M14 x 1.5 – M33 x 1.5Materials : Steel Pressures : Up to 4000 psiO-Ring Face-Seal Metric Seal-Lok™Sizes: 1/4” – 2”Materials: Steel, Stainless Steel Pressures: Up to 9200 psiJapanese Industrial Standard JISSizes : 1/4” – 1”Materials : Steel Pressures : Up to 5000 psiWhen ordering Parker Adapters, please state the Catalogued Number of each type of adapter desired. Be sure to double check tube and hose sizes of items required.To select proper seal materials for specific applications, refer to Media Compatibility Chart in Tube Fitting Catalog 4300, or contact your Parker Tube Fitting Distributor.If in doubt about which type or size of fitting to specify, consult your Parker Tube Fitting Distributor. In addition Parker Field Sales, Technical Services,the Tube Fitting Division and your local Parker Service Center will help you find answers to all your issues.Phone: (614) 279-7070Fax: (614) 279-7685Web: /tfdNote: Refer to Parker Catalog 4300 for more detailed application information.CALL TOLL-FREE 1-800-C PARKER (1-800-272-7537)Parker Information Center for catalogs, literature or additional information.O-Ring Face-Seal Seal-Lok™ Sizes: 6 mm – 38 mm Materials: Steel, Stainless Steel Pressures: Up to 9200 psi37° Flare FittingsTriple-Lok ®Sizes: 1/8” – 2”Materials: Steel, Stainless Steel, BrassPressures: Up to 9000 psiPipe Fittings and Port AdaptersSizes: 1/8” – 2”Materials : Steel, Stainless Steel, BrassPressures : Up to 7200 psiPipe SwivelsSizes : 1/8” – 2”Materials : Steel, Stainless Steel Pressures : Up to 5000 psiConversion AdaptersSizes: 1/4” – 1-1/2”Materials : Steel, Stainless Steel Pressures : Up to 7700 psiHydraulic Flange and Flange AdaptersSizes : 3/4” – 3”Materials : Steel, Stainless Steel Pressures : Up to 6000 psi15T3SAE (Code 61) Flange – Male SAE (JIC) 37˚ FlareCaution: Do not use the T3 flange to tube or swivel nut to tube adapter in hose assembly applications inwhich pressures exceed the SAE100R2 working pressure range.17T3SAE (Code 61) Flange – Male SAE (JIC) 37˚ Flare - 45˚ Elbow19T3SAE (Code 61) Flange – Male SAE (JIC) 37˚ Flare - 90˚ Elbow39T3Male - Female Swivel - SAE (JIC) 37˚ - 90˚ Elbow41T3Male - Female Swivel - SAE (JIC) 37˚ - 90˚ Elbow - Long4AH3SAE Code 61 Flange - Male SAE (JIC) 37˚ Flare - 5000 psi Caution: Do not use the T3 flange to tube or swivel nut to tube adapter in hose assembly applications in which pressures exceed the SAE100R2 working pressure range.4FH3SAE Code 61 Flange - Male SAE (JIC) 37˚ Flare - 5000 psi -45˚ Elbow4NH3SAE Code 61 Flange - Male SAE (JIC) 37˚ Flare - 5000 psi -90˚ Elbow6AH3SAE Code 62 Flange - Male SAE (JIC) 37˚ Flare6FH3SAE Code 62 Flange - Male SAE (JIC) 37˚ Flare - 45˚ Elbow4AJMCode 61 Flange - Male Seal-Lok4FJMCode 61 Flange - Male Seal-Lok - 45˚ Elbow4NJMCode 61 Flange - Male Seal-Lok - 90˚ Elbow6NH3SAE Code 62 Flange - Male SAE (JIC) 37˚ Flare - 90˚ Elbow6NJMCode 62 Flange - Male Seal-Lok - 90˚ Elbow6FJMCode 62 Flange - Male Seal-Lok - 45˚ Elbow6AJMCode 62 Flange - Male Seal-LokNote:*5000 psi with 4A, 4F and 4N Fittings and 50H Flange Halves.There are two non-interchangeable SAE split flanges: a: S tandard or Code 61 is for 3,000psi to 5,000psi maximum, depending on size.b.H igh Pressure or Code 62 is for 6,000psi maximum, r egardless of size. The flange head is “V” notched for identification.Consult these tables to determine flange halves and flange kits specifications.High Pressure (Code 62)Standard Pressure (Code 61)Note: For use with 4A, 4F and 4N Flanges.50H5000 psi Flange Half (Code 61)Note: For use with 4A, 4F and 4N Flanges.Note: High pressure applications also require the use of Code 61 Flange End hose fittings.51HSAE Flange Half (Code 61)5050HK5000 psi Flange Kit (Code 61)5151HKSAE Flange Kit (Code 61)HFHSAE Flange Half (Code 62) HFHFHKSAE Flange Kit (Code 62) 8FHFlange Half (8000 psi)8FHFHKFlange Kit (8000 psi)DIN and ISO Metric PortsDIN (German) and ISO (International Organization for Standardization) flange heads are the same as SAE flange heads. By comparison, the ports have the same configura-tion except that the DIN and ISO Type I ports accept metric bolts. This requires specialflange halves in most sizes.Note: High pressure applications also require the use of Code 62 Flange End hose fittings.M1HDIN (ISO) Flange HalfM1M1HKDIN (ISO) Flange Kit (Code 61)M2M2HKDIN (ISO) Flange Kit (Code 62)M2HDIN (ISO) Flange Half (Code 62)711509O-Rings - SAE Thread (Compound N552-90)*711510O-Rings - Code 61 and Code 62 Flanges (Compound N552-90)**Note: F or use with petroleum base fluids, other compounds available for Phosphate Ester fluids.Please contact The Parker Hannifin Seal Group/O-Ring Division (1-800-C-PARKER) for additional information.C9RG O-Rings for CA, CE, CF MetricC9RG O-Rings for C9, OC, 1C Metric SwivelsD9DTBonded Seal for BSPP Port Fittings*Note: D 9DT must be ordered from the Tube FittingsDivision. Please contact TFD for additional size and product information.XARGFlange “D” Rings Caterpillar ®Style FlangesJ0RGO-Rings - Seal-Lok ®Note: O -Rings for use in Seal-Lok ® connections are illustrated in actual size. Part numbers for O-Ringsused in Seal-Lok ® and in SAE port connections are also listed in the table. O-Rings are supplied in Nitrile NBR compound, 90 durometer hardness.SAE 711509-4-8Seal-Lok J0RG-8-8Photo shows an actual comparison between an SAE port O-Ring (top) and a Seal-Lok ® O-Ring (bottom). They differ in both diameter and cross section.8ARGFlange “D” Rings for 76 Series Style FlangeT1RGO-Rings for Compression Fittings (1T126)Charge Ports CapsR134aR12CORGCaptive O-Ring Assembly ToolsParker’s new CORG Assembly Tools are designed to facilitate the installation of the O-Ring into the half-dovetail groove of the O-Ring face seal fitting.Note: C ORG Assembly T ools must be ordered from the T ube Fittings Division (614) 279-7070.Note: O -Rings listed are for use with petroleum base fluids. Other compounds are available for Phosphate Ester fluids by special order. For Viton ® or otherO-Ring compounds, consult Parker Hannifin, Seal/O-Rings Products Division (1-800-C-PARKER.)Bench TypeHand Type59RGO-Rings for Tube O-Ring Fittingsand Compressor FittingsNote:T he above O-Rings (RG) have HNBR compound number N1195-70 (green).Accessory Selection Guide – Partek Sleeve (AS-B, AS-Y or PS)Note: T he inside flat “A” dimension correspondswith the inside diameter “B” dimension. For example, AS-Y -13 flat surface “A” is 1.34 in. This offers a .86 in. inside diam-eter “B”. Hose with a smaller O.D. can be specified for this size sleeve. Parker 201-5 hose has a .58 in. O.D. and can easily be inserted in the Partek AS-Y -13Sleeve.Note: 1. T he dimensions shown are related to the hose outside diameter and may not fit over the fitting. For over the fitting applications, a larger sizesleeve may be required.2. Cut lengths are available. Contact your local distributor for prices ().Partek SleevePartek “PS” SleeveParker’s Partek Nylon Protective Sleeving gives you tough hose abrasion protection two ways. First, per the ISO 6945 specification, Partek has a unique tubular weave nylon construction, Partek “AS” is strong enough to withstand greater than 200,000 abrasion cycles without wearing through the fabric at any loca-tion. Partek “PS” can withstand greater than 50,000 abrasion cycles. In addition, this weave also gives an exceptionally smooth interior wall, allowing rubber hose to move freely inside the sleeve. This provides easy installation and prevents any internal abrasion problems. Partek sleeving is available in either black or yellow and in sizes to fit most hydraulic hose. Partek, the quick and easy solution to hose protection in high-abrasion areas.Temperature Range: -67°F to +248°F (-53°C to +120°C)Accessory Selection Guide – PolyGuard (HG)• S hield hose from abrasion and cuts • Minimize kinking• Cannot rust or corrode • R esist water, oil, gasoline, hydraulic fluid, and most solvents • I deal for bundling plastic tubing or hose lines • E asy to install without removing hose lines; no clamps neededPolyGuardHeavy-duty polyethylene provides protection in rugged operating conditions.Great for b undling high-pressure hose lines.Cut edges can be smoothed by applying heat.CAUTION: This material will support combustion.Color: BlackTemperature Range:0˚F to +200˚F (-17˚C to +93˚C)Parkoil ™Lower-cost protection for applications that call for a tighter bend radius and are less demanding.Cut edges can be smoothed by applying heat.CAUTION: This material will support combustion.Color: BlackTemperature Range:0˚F to +200˚F (-17˚C to +93˚C)Accessory Selection Guide – ParKoil ™ (PG)Accessory Selection Guide – Spring Guard and Armor GuardNote:Spring Guard and Armor Guard are packaged in 10 ft. pieces.Parker Spring Guard and Armor Guard are two products that prolong the life of hose lines that are exposed to rugged operating conditions. They distribute bending radii to avoid kinking in hose lines and protect hose from abrasion and deep cuts. Guards areconstructed of steel wire and plated to resist rust.Spring Guard (SG)Armor Guard (AG)Accessory Selection Guide – Firesleeve (FS-F)Parker Firesleeve is a flame resistant sheath that protects the hose from extreme temperature conditions. Firesleeve easily slides over hoses and readily expands over fitting. It can be assembled with Parker FSC or properly sized wormgear clamp.Construction: Braided fiberglass sleeve and an orange,bonded and seamless silicone rubber cover.Specifications: Conforms to SAE Aerospace Standard 1072A Type 2A.Temperature Range:-54˚C to +260˚C (-65˚F to +500˚F).Note: T he Firesleeve inside dimension (I.D.)must exceed the outside diameter (O.D.) of the hose and offer an allowance for easy hose insertion. For example, 201-16 has a 1.23 in. O.D. FS-S-24, with an I.D. of 1.46 in., is the suggested Firesleeve. Note: P arker FSC Clamp fits all hoses up to2 in. O.D. Note: P arker HC Clamps (wormgear) are listedon page D-24.Note: See Page D-22 for Firesleeve assembly instructions.Firesleeve (FS-F)FSC ClampPart Number: FSC(One size fits all hoses up to 2 inch O.D.)Accessory Selection Guide – Firesleeve (cont.)1. A ssemble one end fitting on hose. Cut firesleeve to same length as hose. Cover approximately 1” of each end of fire-sleeve with FSS sealant and allow to dry.2. P ush firesleeve back from cut end of hose and assemble the second end fitting. Then pull firesleeve completely over both sockets.3. I nsert tail of FSC clamp into FST clamping tool.4. P osition clamp around middle of socket and tighten with tool. Bend end of band back over buckle. Repeat on other end.Repair any scuffs or abrasions in firesleeve with FSS sealant.FSC ClampUsed to attach firesleeve around socket on hose sizes with a 2” maximum O.D.FST Clamp ToolPart Number: FST -711617 Used to secure FSC clamp.FSS Firesleeve SealantKeeps end of firesleeve from fraying - for neater, longer lasting installation.FiresleeveAssembly InstructionsAccessory Selection Guide – CL ClampVinyl coated steel clamps provide hose support where long lengths are used. Provides neater installation of hose lines, minimizes hose chafing and prevents damage to hose.Material: CR Steel with Zinc PlatingCoating: Black Vinyl Plastisol - 0,8 mm (0.03 inch) thick.Temperature Range:-40°C to +107°C (-40°F to +225°F).Accessory Selection Guide – HC, 88HC-H and 88DB ClampThe Parker HC Clamp is a stainless steel worm gear clamp designed for low presure industrial hose applications.Material: Stainless steelSpecifications: SAE J1508, Type F and Type HD88HC-HSeries Hose Clamp(High Torque Wormgear)88DBSeries Heavy Duty Hose Clamp(Double Bolt Hose Clamp)HC Hose Clamp TableNote: See 88 Series Assembly Instructions for proper 88HC-H clamp attachment.Accessory Selection Guide – Protection Shields (HP , HT, and HP-B)Prevent hose abrasion while extending your hose life. Parker Hose Protection Shields extend hose life by protecting the hose from abrasion that occurs when hose rubs against other hose, metal or concrete. Parker hose shields are resistant to oil, lubricants, gasoline, most solvents and can withstand ambient temperatures from -40° to +300° F . Easily installed and secured by cable ties without disconnect-ing any hose lines. Use with hose from 1/4” to 2” I.D.♦ Eliminate hose abrasion on concrete, metal or any rough surface. ♦ Guard against hose deterioration on mobile hydraulic equipment. ♦Let Parker fill all your hydraulic and pneumatic hose product needs.Hose Protector Shields are a fast and extremely cost effective way to isolate fluid lines from direct contact with other lines, components or structural members. They’re available in 4-inch, 6-inch and 8-inch lengths and the width can be trimmed to satisfy a variety of situations. These flexible protectors simply clamp around the hose and are securely held in place by nylon cable ties which are included. The cable ties are recessed in molded grooves to protect them from abrasion. You don’t need to disconnect a line to install a Parker Hose Protector Shield the way you do with a continuous tubular sleeve. Just wait until the installation is up and running to see exactly where contact needs to be prevented.Parker Hose Protector Shields are available in bulk quantities and in convenient assortments in 4”, 6” and 8” sizes. Cable ties are included with all protectors and are also available in bulk.Hose ShieldsTie Wraps HP-B-13X18-KIT2 ea. HP-13 RFL HT -12-KIT 30 ea. HT -12 Tie Wraps 2 ea. HP-15 RFL HT -16-KIT 30 ea. HT -16 Tie Wraps4 ea. HP-18 RFLHT -22-KIT15 ea. HT -22 Tie Wraps20 Hose Protectors and 60 Tie Wraps for each size are in point of purchase display box.HP-B-13-RFL 10 ea. HP-B-13 Hose Protectors (4”). 30 ea. HT -12 Tie Wraps in a sealed plastic bag.HP-B-15-RFL10 ea. HP-B-15 Hose Protectors (6”). 30 ea. HT -16 Tie Wraps in a sealed plastic bag.HP-B-18-RFL5 ea. HP-B-18 Hose Protectors (8”). 15 ea. HT -22 Tie Wraps in a sealed plastic bag.Contact your authorized Parker Hose Products Distributor for pricing and delivery information.Note: Parker Hose Protector Shield products are intended to prevent damage. They are not suitable as patches or repairs for lines which are already damaged or worn beyond safe use standards.Counter DisplayThe complete on-site complete hose assembly workstation design (above) includes:• TH7-5-C—6’ table with 1 hose reel and 1 bottom shelf • TH7-6—16 hose reel system, with rotating base • T H7-7—15” wide table set up for Parker 239 or 339 Cut-Off Saw Specifications: HoseFab Table (heavy duty)• Laminated wood table top • 1-1/2” square tubing structure • Gussetted corner braces • 6-leg design• All legs have adjustable feet • Hose reel/shelf combinations• 40B-Cabinet or 72B-Cabinet for fitting storage • Optional: Hose trough for measurement of hose • Calibrated to line up to Saw Table • Adjustable stop for standard length cuts• Built-in tape measureSpecifications: Rotary Reel Rack (TH7-6)• 16 Hose reel capacity • Compact design• Rotates for 1 man use• Center post bolts to floor in 4 places • Optional: Overhead craneSpecifications: Saw Table (TH7-7)• Calibrated to line up to Hose trough • Adjustable feet• Mounts to 6-foot benchSpecifications: 3 or 4 Reel Rack • Free standing 3 reel rack (TH7-8)• Bolts to floor• Optional: 4th reel capacity with wall mounts (TH7-8-F)• (2) 40B-Cabinet 40 openings - 4·1/2” x 4·1/2” x 12” in size • TH7-6-C—Optional overhead crane • T H7-5-HT—Optional 6’ measured hose trough with ad -justable hose stopPictured left is a complete on-site hose assembly workstation, the Parker Kart:The Parker Kart, TH7-4, is a portable all-in-one unit designed to hold a Minikrimp, Karrykrimp, Karrykrimp 2, or Parkrimp 1; a 332T -115V Cut-off Saw; 4 reels of hose; and has a 40 bin cabinet with 3 drawers for tools. The TH7-4 can be customized to fit your specific hose assembly needs. Contact Parker HPD or your Parker Hose distributor for details.Note: Part number TH7-4 does not include hose, fittings or equipment.Note: Part number and specifications of components for both workstations are listed on the following pages.HPD Hose Assembly WorkstationsHose Products Division has set up an agreement to allow Hose Products customers to purchase directly from our vendor, Safety Step.Safety Step’s contact information is:Safety Step Annette Cox 888-448-4237*********************See Safety Step contact information at the top of this pageSaw TableFeaturesThe Saw Table, specially designed for Parker 239 or 339 Hose Cut-Off Saw, attaches directly to the HoseFab Table.Part Number DescriptionTH7-715” wide table set up for Parker 239 or 339 Cut-Off Saw Table measurements:H eight - 18” Width - 28”Length - 14”3/4 Reel RackFeaturesCompact in its design, the standard version will hold 3 reels of hose. Optional 4th reel capacity designed with wall anchor mounts.P art Number DescriptionTH7-8 Upright 3 hose reel rackTH7-8-FO ptional extension with wall anchor for 4th reel Rack measurements:Height - 59” (82·1/2” with 4th reel option) Width - 27·3/4”Length - 27·1/2”HoseFab TableFeaturesHeavy duty constructed table for mounting Minikrimp, Karrykrimp, Karrykrimp 2, or Parkrimp 1. HoseFab Table is available in 3 versions to meet your require-ments. Options include two 40B-Cabinets or 72B-Cabinets for fitting storage.Part Number Description TH7-5-R 6’ table with 2 hose reels TH7-5-S 6’ table with 2 bottom shelves TH7-5-C 6’ table with 1 hose reel and 1 bottom shelf TH7-5-HT O ptional 6’ measured hose trough with adjustable hose stop 40B-Cabinet 40 openings - 4·1/2” x 4·1/2” x 12” in size 72B-Cabinet 72 openings - 4·1/2” x 4·1/2” x 12” in size Table measurements: Height - 31-3/4” Width - 29”Length - 72”Rotary Reel RackFeatures16 Hose reel capacity that fits in a compact area. Supplied with heavy duty casters which allow for ease of turning, even when fully loaded. Optional overhead crane available.Part Number DescriptionTH7-6 16 hose reel system, with rotating base TH7-6-C Optional overhead craneRack measurements:Height - 104” (120” with optional overhead crane) Width - 67”Length - 67”See Safety Step contact information on page D-26See Safety Step contact information on page D-26See Safety Step contact information on page D-26See Safety Step contact information on page D-26Parker Kart Part No. TH7-4Parker Kart organizes and stores all your necessary Parker hoses, fittings, power and hand tools - everything you need to make fast hose assemblies on site. As a valued addition to any facility, Parker Kart will save on downtime and labor costs, as well as eliminate errors in cutting and fitting attachment. With Parker Kart, you’ll always have the materials you need, right when and where you need them.• Easy one-man movement• Eight-inch urethane casters with brakes• Forklift carry tubes• Electric receptable with cord• Fitting bins and drawers• Large tool drawer• Four hose reel holders• Choice of Parker crimping equipment• Optional accessories availableParker Kart can be customized to fit specific hose assem-bly needs. Parker Kart does not include hose, fittings orequipment.Fitting Stock Bins72B-Cabinet36” wide, 43” high, 12” deep, with 72 openings each 4-1/2”x 4-1/2” x 12”, heavy duty steel, all welded construction.Product bin labels are available.Hose Stock BinsHR6-Hose-BinRugged metal cabinet for stocking coils of Parker hose 36”wide, 28” high, 20” deep, with upright separators to provide6 compartments varying in width from 4” to 8”.Provides suitable base on which to place the fittings stockbin (top measures 36” x 20”, bottom of fittings bin measures36” x 12”.)Yellow with black “Parker Hose” lettering.See Safety Step contact information on page D-26。

电磁阀VUVG/阀岛VTUGSubject to change –2017.062→Internet:/catalogue/...电磁阀VUVG主要特性创新通用可靠易安装•可设置为内先导或外先导,用于板式阀阀组•通过电接口插件可方便地更换连接技术•最大压力10bar •结构特点:–活塞滑阀,带密封圈(VUVG-LK,VUVG-BK)–活塞滑阀,带密封阀芯(VUVG-L,VUVG-B)•多种阀功能•可选快插接头•管式阀•板管式阀可用作气路板集成安装•M5和M7管式阀可组合在一块气路板上•气路板带多个压力分区•IP40,IP65•坚固耐用的金属元件–阀–气路板•快速排除故障,得益于360°LED 显示•可快捷地更换阀片,维护便利•可选手控装置:按钮式,封盖式,按钮式/锁定式或锁定式(不带附件)•牢固地安装到墙面或H 型导轨•随带螺丝和密封件,安装方便•通过电接口插件可方便地更换连接技术•标签支架,用于阀的标签阀岛配置器CAD 相关数据→阀岛配置器帮助您选择正确的阀岛VTUG ,订购正确的产品更方便。

阀岛VTUG 通过订货代码订购。

所有阀岛供货时已装配完毕并单独做过测试。

最大限度减少了装配和安装时间。

订货系统,用于阀岛VTUG →Internet:vtug-V-新产品VUVG-LK,VUVG-BK2017.06–Subject to change 3Internet:/catalogue/...电磁阀VUVG主要特性–气动元件单个阀和阀岛管式阀用作单个阀管式阀VUVG-LK/VUVG-L管式阀可无需气动耦合就可使用。

所有气接口位于阀上,可配备接头/气管。

电接口有多种不同的电接口插件可选。

如果使用过了特殊密封套件,管式阀VUVG 还可作为半管式阀安装在气路板(气动耦合)上。

板管式阀可用作气路板集成安装半管式阀VUVG-S阀岛VTUG 由半管式阀VUVG-S 组成对于半管式阀,进气口(1,3和5)通过气动耦合(如,气路板)与阀连接。

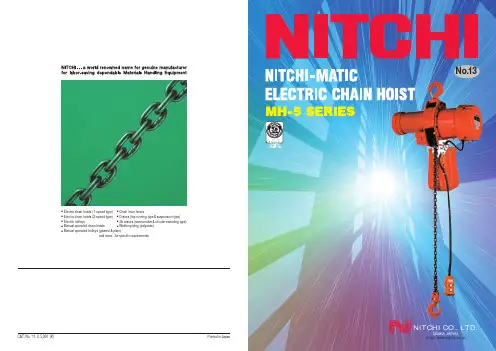

No.13http://www.nitchi.co.jp/ISO 9001ISO 14001JQA-2734JQA-EM1902NITCHI CO., LTD.OSAKA. JAPAN,The NITCHI-MATIC Model MH-5 Series is a line of premium quality electric chain The This system responds instantly and supplies dependable positive braking power. An extremely long service life has been achieved with the use of non-asbestos brake linings.The NITCHI casehardened load chains are made from special alloy steel, and aregiven super-tough carbonized hardsurfaces that resist erosion several times longer than conventional through hardened load chains. The soft core section gives the load chain the elasticity which is essential for material lifting equipment. Every link of load chain is tested, and a record of each chain production lot is kept on record at our factory.Ultra-Tough Load Chainsload chain with the load sheave.Possibilities OVER-HOISTING &hoists that are designed especially to fulfill the severe requirements of industry. A multitude of special heavy duty features are employed into the NITCHI-MATIC MH-5 Series for extra efficiency, dependability, durability and safety.special heavy duty high performance motors of Model MH-5 (1-Speed) have 30 minutes ratings and Class B insulation for severe use in heavy duty applications.HEAVY DUTY MOTORpowerful brake achieved with ELECTROMAGNETIC BRAKEThe main frame consists of two ruggedsteel side plates that will provide maximum protection against dynamic loads. Castingsthat are able to crack or break have notbeen employed in the main frame.STEEL CONSTRUCTIONBoth the top and bottom hooks on all capacities swivel to all directions and are made of drop-forged steel that is heat-treated for greater strength. Everybottom hookis equipped with a thrustbearing for smooth rotation and has a safety latch as a standard equipment.FORGED STEEL HOOKSThe load sheave is made of alloy steel that is expertly machined and heat-treated for long wearing, smooth engagement with the load chain. The load chain guide directs the load chain smoothly into the NITCHI-MATIC for positive engagement WEAR-RESISTANTLOAD SHEAVE & CHAIN GUIDEof damage to theNITCHI-MATIC caused by over-hoisting and over-lowering are eliminated with the limit switch.OVER-LOWERING PROTECTIONSPECIAL VARIATIONSFriction type over load protectionExtra powerful electro-magnetic brake 0.5 ton & 1 ton:2 ton:3 ton:5 & 7.5 ton:10 ton:15 ton & Larger:30.1 meters 20.1 meters 10.1 meters 10.1 meters 8.6 meters Same for standard lifts and high lift type The following are only a few of the special variations of MH-5 Series electric chain hoists that are available atmoderate extra charges. Please contact your nearest NITCHI dealer or distributor without hesitation for further information on special variations:The CE Version is a special variation made to suit the European market, which fulfills the requirements of the EN regulations. The CE Version has a friction type over load protection, an emergency stop control, and other modifications as standard equipment, which are in accordance with the EN regulations. The use of an extra powerful electro-magnetic brake makes it possible to remove the mechanical brake, and replace it with a friction type over load protection device. The trolleys for the CE Version are applicable to a wide variety of beam widths ranging up to extra wide, and are equipped with anti-drop plates.MH-5 CE VersionThe power source voltage setting of a dual-voltage MH-5 electric chain hoist can be easily changed to low voltage (a voltage in the area of 200-volt) or to high voltage (a voltage in the area of 400-volt) by simply rearranging some of the wiring connections within the electric chain hoist. A 220/380-volt version and a 220/440-volt version are available. Please consult your nearest NITCHI dealer or distributor for information on other dual-voltages that are available.Dual-voltage MH-5These are electric chain hoists with chain bucket assemblies for long lengths of load chain. The connecting methods of high lift type MH-5 electric chain hoists with trolleys are different from the standardconnecting method used on non-long lift type MH-5 electric chain hoists with trolleys. Also, the chain bucket assemblies of hook suspended typelong lift type MH-5 electric chain hoists require support chains to be connected to the structure supporting the electric chain hoists. The MH-5 electric chain hoists are classified to be “long lift type” electric chain hoists when the load-lifting heights of the right table are exceeded.High Lift Type MH-5MH-5 Electric chain hoists with long duty time ratings or MH-5 electric chain hoists for continuous operations are also available.MH-5 WITH LONG DUTY TIME RATINGThe traversing speed of the motorized trolleys can be reduced to 1/2, 1/4 or 1/8 of the standard traversing speed.MOTORIZED TROLLEYS WITH SLOW TRAVERSING SPEED A separate catalog for the following special applications is available on request:1. Low head room electric chain hoist (0.5 ton to 5 ton)2. 2-Point lifting electric chain hoist (0.5 ton to 3 ton)3. Load rotator electric chain hoist (1 ton to 3 ton)4. Diagonal pulling electric chain hoist (0.5 ton to 3 ton)5. Load chain climbing electric chain hoist (1 ton and 2 ton)6. Base mounted electric chain hoist (0.5 ton and 1 ton)SPECIAL APPLICATIONSCase hardened NN Chain The very reliable mechanical brake works in cooperation with the electromagnetic brake and holds suspended loads at anypoint.MECHANICAL BRAKEThe first stage helical gearing provides a dependable and longer quieter life by reducing gear tooth impact and vibration to a minimum. The reduction gears are exclusively designed for extra durability and are made of special alloy steel that is expertly machined for positive engagement and precisely heat - treated for maximum strength.FIRST STAGE HELICAL GEARINGThis relay prevents damage to the hoist caused by misconnections (negative phase connections) of the power source wires.ANTIPHASE PROTECTION RELAYSAs in all types high quality machinery the NITCHI-MATIC Series uses the oil bath lubrication system. The continuous bath of oil lubricates the reduction gear system and also acts as a coolant for the mechanical brake.OIL BATH LUBRICATION The strong light-weight push-button switchof NITCH-MATIC is rainproof and responds immediately at a touch of the button.PUSH-BUTTON SWITCH Durability is one of the main features we are able to boast about. The NITCHI-MATIC MH-5 Series is designed and made to the Grade M4 and M5 durability standards of the Japanese Industrial Standard. (In accordance with (JIS) B8815-1994)INCREASED DURABILITYNITCHI-MATIC is a series of electric chain hoists with standard capacities rangingfrom 0.5 ton to 50 ton that are available in a wide variety of variations for handling nearly all material handling requirements. The industrial type 3-phase power source version can be used independently as a suspended type electric chain hoist or as an electric chain hoist directly coupled to a manual operated trolley or a motorizedtrolley. The lifting speed of the NITCHI-MATIC can be selected between single-speedand 2-speed whichever most adequately fulfills your requirements for increasing productivity. Also, a single phase power source version is available for light materials handling operations and home use where 3-phase power sources are not readily available.A high duty rating is essential for fulfilling the severe work cycles that are required for production in industry. The 40% ED rating of Model MH-5 (1-Speed) is sufficient for almost all heavy duty industrial applications.HIGH DUTY RATINGTwo completely independent brakes not only reduce the possibility of brake failure,but also increase the braking surface and contribute to the dissipation of heat generated by repeated braking.DUAL BRAKING SYSTEM The ingeniously designed compact construction of NITCHI-MATIC makes it extremely compact and permits the highest possible lift where the last inch of lift must be obtained.SHORT HEADROOM The low 24-volt control protects the operator from harmful electrical shocks.24-VOLT CONTROL The robust pressed steel design simplifies the maintenance and the replacement of components.EASY SERVICINGEach NITCHI-MATIC hoist is supplied with a comprehensive handbook that provides sufficient instructions and information on installation, operation and EFUL MANUAL OPTIONAL EQUIPMENT This is a special device for additional safety to operators, hoist and load. When a load that is greater than the setting of the overload protection is applied, the hoist will stop automatically and prevent the load from being hoisted.OVERLOAD PROTECTIONThis is a series of Nitchi case hardened chains with a special non-electrolytic nickelplating that is fused into the material of the chains. This special plating does not effect the original features of the chains and will not peel off like conventional surface plated chains. The NN case hardened chains have outstanding characteristics in resisting rust and corrosion caused by rain, seawater, steam and chemicals.NN CASE HARDENED CHAINWIDE SELECTION StandardCase hardened ChainMHC-5 0.5-1 ton Diagrammatic onlyNITCHI-MATIC ELECTRIC CHAIN HOIST WITH SINGLE-PHASE MOTORSMODEL MHC-5Item No.A BDEFPQ S(m)Rated Load(ton)MC5005MC50100.513053052852851521521061062025220220Major Dimensions (approx.) (mm)6903.6The specially developed high performance capacitor-start induction motors of Model MHC-5 single-phase hoist are extremely long wearing and will enable reliable handing of heavy loads on household power sources.When used together with a Nitchi trolley, it will be possible to use Model MHC-5 on a large variety of applications for the efficient and safe transportation of loads.The design, materials and specifications are subject to change for improvements without notice.N.B. The dimensions P and Q marked *above vary according to different lifts.Item No.Rated Load (ton)Lift (m)Test Load (ton)Minimum Headroom (Max.)G (mm)Net Weight(approx.)( kgHoisting Speed(m/min)Hoist Motor 1-phase Load Chain 50Hz 60Hz Rating (min)Dia (mm)Nos.of falls GradeMC5005MC50100.51 5.42.76.43.20.6215%ED257.1115505600.6251.255858M5M4Output (kW)4.0STANDARD SPECIFICATIONS : MHC-5 Electric Chain Hoist (Single-voltage)QEABGSEMT-MH-5 7.5 tonDiagrammatic onlyMH-5 60ton (Special version)EABEMT-MH-5 40ton (Special version)EMT-MH-5 10ton & 15tonDurability is one of the main features we are able to boast about. The NITCHI-MATIC MH-5 Series is designed and made to the Grade M4 and M5 durability standards of the Japanese Industrial Standard. (In accordance with (JIS) B8815-1994)INCREASED DURABILITYNITCHI-MATIC is a series of electric chain hoists with standard capacities rangingfrom 0.5 ton to 50 ton that are available in a wide variety of variations for handling nearly all material handling requirements. The industrial type 3-phase power source version can be used independently as a suspended type electric chain hoist or as an electric chain hoist directly coupled to a manual operated trolley or a motorizedtrolley. The lifting speed of the NITCHI-MATIC can be selected between single-speedand 2-speed whichever most adequately fulfills your requirements for increasingproductivity. Also, a single phase power source version is available for light materials handling operations and home use where 3-phase power sources are not readily available.A high duty rating is essential for fulfilling the severe work cycles that are required for production in industry. The 40% ED rating of Model MH-5 (1-Speed) is sufficient for almost all heavy duty industrial applications.HIGH DUTY RATINGTwo completely independent brakes not only reduce the possibility of brake failure,but also increase the braking surface and contribute to the dissipation of heat generated by repeated braking.DUAL BRAKING SYSTEM The ingeniously designed compact construction of NITCHI-MATIC makes it extremely compact and permits the highest possible lift where the last inch of lift must be obtained.SHORT HEADROOMThe low 24-volt control protects the operator from harmful electrical shocks.24-VOLT CONTROLThe robust pressed steel design simplifies the maintenance and the replacement of components.EASY SERVICINGEach NITCHI-MATIC hoist is supplied with a comprehensive handbook that provides sufficient instructions and information on installation, operation and EFUL MANUAL OPTIONAL EQUIPMENTThis is a special device for additional safety to operators, hoist and load. When a load that is greater than the setting of the overload protection is applied, the hoist will stop automatically and prevent the load from being hoisted.OVERLOAD PROTECTIONThis is a series of Nitchi case hardened chains with a special non-electrolytic nickelplating that is fused into the material of the chains. This special plating does not effect the original features of the chains and will not peel off like conventional surface plated chains. The NN case hardened chains have outstanding characteristics in resisting rust and corrosion caused by rain, seawater, steam and chemicals.NN CASE HARDENED CHAINWIDE SELECTION StandardCase hardened ChainMHC-5 0.5-1 ton Diagrammatic onlyNITCHI-MATIC ELECTRIC CHAIN HOIST WITH SINGLE-PHASE MOTORSMODEL MHC-5Item No.A BDEFPQ S(m)Rated Load(ton)MC5005MC50100.513053052852851521521061062025220220Major Dimensions (approx.) (mm)6903.6The specially developed high performance capacitor-start induction motors of Model MHC-5 single-phase hoist are extremely long wearing and will enable reliable handing of heavy loads on household power sources.When used together with a Nitchi trolley, it will be possible to use Model MHC-5 on a large variety of applications for the efficient and safe transportation of loads.The design, materials and specifications are subject to change for improvements without notice.N.B. The dimensions P and Q marked *above vary according to different lifts.Item No.Rated Load (ton)Lift (m)Test Load (ton)Minimum Headroom (Max.)G (mm)Net Weight(approx.)( kgHoisting Speed(m/min)Hoist Motor 1-phase Load Chain 50Hz 60Hz Rating (min)Dia (mm)Nos.of falls GradeMC5005MC50100.51 5.42.76.43.20.6215%ED257.1115505600.6251.255858M5M4Output (kW)4.0STANDARD SPECIFICATIONS : MHC-5 Electric Chain Hoist (Single-voltage)The This achieved with the use of non-asbestos brake linings.The NITCHI casehardened load chains are made from special alloy steel, and aregiven super-tough carbonized hardsurfaces that resist erosion several times longer than conventional through hardened load chains. The soft core section gives the load chain the elasticity which is essential for material lifting equipment. Every link of load chain is tested, and a record of each chain production lot is kept on record at our factory.Ultra-Tough Load Chainsload chain with the load sheave.Possibilities OVER-HOISTING &The NITCHI-MATIC Model MH-5 Series is a line of premium quality electric chain hoists that are designed especially to fulfill the severe requirements of industry. A multitude of special heavy duty features are employed into the NITCHI-MATIC MH-5 Series for extra efficiency, dependability, durability and safety.special heavy duty high performance motors of Model MH-5 (1-Speed) have 30 minutes ratings and Class B insulation for severe use in heavy duty applications.HEAVY DUTY MOTORpowerful brake system responds instantly and supplies dependable positive braking power. An extremely long service life has been achieved with ELECTROMAGNETIC BRAKEThe main frame consists of two ruggedsteel side plates that will provide maximum protection against dynamic loads. Castingsthat are able to crack or break have notbeen employed in the main frame.STEEL CONSTRUCTIONBoth the top and bottom hooks on all capacities swivel to all directions and are made of drop-forged steel that is heat-treated for greater strength. Everybottom hookis equipped with a thrustbearing for smooth rotation and has a safety latch as a standard equipment.FORGED STEEL HOOKSThe load sheave is made of alloy steel that is expertly machined and heat-treated for long wearing, smooth engagement with the load chain. The load chain guide directs the load chain smoothly into the NITCHI-MATIC for positive engagement WEAR-RESISTANTLOAD SHEAVE & CHAIN GUIDEof damage to the NITCHI-MATIC caused by over-hoisting and over-lowering are eliminated with the limit switch.OVER-LOWERING PROTECTIONSPECIAL VARIATIONSFriction type over load protectionExtra powerful electro-magnetic brake 0.5 ton & 1 ton:2 ton:3 ton:5 & 7.5 ton:10 ton:15 ton & Larger:30.1 meters 20.1 meters 10.1 meters 10.1 meters 8.6 meters Same for standard lifts and high lift type The following are only a few of the special variations of MH-5 Series electric chain hoists that are available atmoderate extra charges. Please contact your nearest NITCHI dealer or distributor without hesitation for further information on special variations:The CE Version is a special variation made to suit the European market, which fulfills the requirements of the EN regulations. The CE Version has a friction type over load protection, an emergency stop control, and other modifications as standard equipment, which are in accordance with the EN regulations. The use of an extra powerful electro-magnetic brake makes it possible to remove the mechanical brake, and replace it with a friction type over load protection device. The trolleys for the CE Version are applicable to a wide variety of beam widths ranging up to extra wide, and are equipped with anti-drop plates.MH-5 CE VersionThe power source voltage setting of a dual-voltage MH-5 electric chain hoist can be easily changed to low voltage (a voltage in the area of 200-volt) or to high voltage (a voltage in the area of 400-volt) by simply rearranging some of the wiring connections within the electric chain hoist. A 220/380-volt version and a 220/440-volt version are available.Please consult your nearest NITCHI dealer or distributor for information on other dual-voltages that are available.Dual-voltage MH-5These are electric chain hoists with chain bucket assemblies for long lengths of load chain. The connecting methods of high lift type MH-5 electric chain hoists with trolleys are different from the standardconnecting method used on non-long lift type MH-5 electric chain hoistswith trolleys. Also, the chain bucket assemblies of hook suspended typelong lift type MH-5 electric chain hoists require support chains to be connected to the structure supporting the electric chain hoists. The MH-5 electric chain hoists are classified to be “long lift type” electric chain hoists when the load-lifting heights of the right table are exceeded.High Lift Type MH-5MH-5 Electric chain hoists with long duty time ratings or MH-5 electric chain hoists for continuous operations are also available.MH-5 WITH LONG DUTY TIME RATINGThe traversing speed of the motorized trolleys can be reduced to 1/2, 1/4 or 1/8 of the standard traversing speed.MOTORIZED TROLLEYS WITH SLOW TRAVERSING SPEED A separate catalog for the following special applications is available on request:1. Low head room electric chain hoist (0.5 ton to 5 ton)2. 2-Point lifting electric chain hoist (0.5 ton to 3 ton)3. Load rotator electric chain hoist (1 ton to 3 ton)4. Diagonal pulling electric chain hoist (0.5 ton to 3 ton)5. Load chain climbing electric chain hoist (1 ton and 2 ton)6. Base mounted electric chain hoist (0.5 ton and 1 ton)SPECIAL APPLICATIONS。

!T echnology | Technical Service | Practice Services© 2021 Henry Schein, Inc. No copying without permission. Not responsible for typographical errors. To guarantee special pricing/offers, where applicable, please include the three-digit promo code when ordering. Henry Schein Dental reserves the right to discontinue this promotion at any time [including, without limitation, if supply or demand for the promotional products is affected due to extraordinary events]. Note: Participating in a promotional discount program (e.g., points, discount redemptions or other special awards) is only permissible in accordance with discount program rules. By participation in such program, you agree that, to your knowledge, your practice complies with the program requirements. For HS promotions: This promotion offers a bundled discount. The cost of any “buy/get” (or “no charge”) items is a discount applied to your other purchases on the same invoice. The reportable value (unit price) of the “no charge” item will be identified on the invoice. To calculate the applicable discount on the other items on the same invoice, divide the total value (unit price(s)) of any no-charge item(s) by the total value (extension price(s)) of all other items purchased on the same invoice, and apply the resulting percentage equally to each item to determine net prices. For manufacturer promotions: The prices stated in the invoice or statement may reflect a discount or be subject to a rebate. You must fully and accurately report this stated discount price, or if applicable, any net pricing, after giving effect to any rebates, to Medicare, Medicaid, Tricare and any other federal or state program upon request by any such program. Accordingly, you should retain these records. It is your responsibility to review any agreements or other documents applicable to these prices to determine if they are subject to a rebate. 21DS7958Keep your staff and patients safe with in-office COVID results in 10–20 minutes.Choose from 4 COVID testing platforms*:• Cue Health molecular• BD Veritor antigen• Abbott BinaxNOW antigen• Premier Biotech antibodyHenry Schein Dental has developed acomprehensive program to guide you throughsetting up and conducting testing in your practice.• Laboratory Licensure• Setting Up Testing Environment• Ordering Supplies• Administering Tests• Reporting Results• Reimbursement and/or Billing the Patient************************.For technical questions, feel free to contact******************************Bring Diagnostic Testing to Your Office Starting with COVID Testing!Announcing Henry Schein’s Dental Diagnostic Testing Program*These tests have not been cleared or approved by FDA, but they have been authorized by FDA under Emergency Use Authorizations for use in Authorized Laboratories (e.g., point-of-care settings with CLIA Certificates of Waiver). The Cue Health molecular test is authorized only for the detection of nucleic acid from SARS-CoV-2, not for any other viruses or pathogens; the BD Veritor antigen test and the Access Bio antigen test are authorized only for the detection of proteins from SARS-CoV-2, not for any other viruses or pathogens; the Premier Biotech antibody test has been authorized only for detecting the presence of IgM and IgG antibodies to SARS-CoV-2, not for any other viruses or pathogens. The emergency use of all of these tests is only authorized for the duration of the declaration that circumstances exist justifying the authorization of emergency use of in vitro diagnostics for detection and/or diagnosis of COVID-19 under Section 564(b)(1) of the Federal Food, Drug and Cosmetic Act, 21 U.S.C. § 360bbb3(b)(1), unless the declaration is terminated or authorization is revoked sooner.。

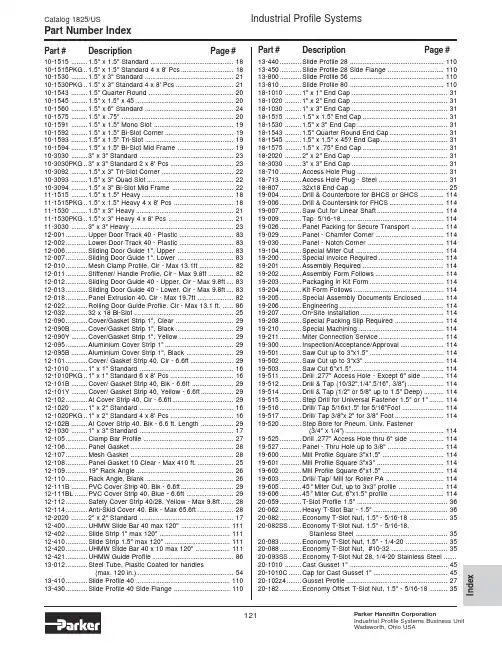

121Parker Hannifin CorporationIndustrial Profile Systems Business UnitWadsworth, Ohio USA10-1515.........1.5" x 1.5" Standard ..............................................1810-1515PKG..1.5" x 1.5" Standard 4 x 8' Pcs.............................1810-1530.........1.5" x 3" Standard .................................................2110-1530PKG..1.5" x 3" Standard 4 x 8' Pcs ................................2110-1543.........1.5" Quarter Round ...............................................2010-1545.........1.5" x 1.5" x 45......................................................2010-1560.........1.5" x 6" Standard .................................................2410-1575.........1.5" x .75"..............................................................2010-1591.........1.5" x 1.5" Mono Slot ............................................1910-1592.........1.5" x 1.5" Bi-Slot Corner......................................1910-1593.........1.5" x 1.5" Tri-Slot .................................................1910-1594.........1.5" x 1.5" Bi-Slot Mid Frame ...............................1910-3030.........3" x 3" Standard ....................................................2310-3030PKG..3" x 3" Standard 2 x 8' Pcs ...................................2310-3092.........1.5" x 3" Tri-Slot Corner ........................................2210-3093.........1.5" x 3" Quad Slot................................................2210-3094.........1.5" x 3" Bi-Slot Mid Frame ..................................2211-1515.........1.5" x 1.5" Heavy...................................................1811-1515PKG..1.5" x 1.5" Heavy 4 x 8' Pcs .................................1811-1530.........1.5" x 3" Heavy......................................................2111-1530PKG..1.5" x 3" Heavy 4 x 8' Pcs ....................................2111-3030.........3" x 3" Heavy .........................................................2312-001............Upper Door Track 40 - Plastic ..............................8312-002............Lower Door Track 40 - Plastic ..............................8312-006............Sliding Door Guide 1", Upper ...............................8312-007............Sliding Door Guide 1", Lower ...............................8312-010............Mesh Clamp Profile, Clr - Max 13.1ft ...................8212-011............Stiffener/ Handle Profile, Clr - Max 9.8ft ..............8212-012............Sliding Door Guide 40 - Upper, Clr - Max 9.8ft....8312-013............Sliding Door Guide 40 - Lower, Clr - Max 9.8ft....8312-018............Panel Extrusion 40, Clr - Max 19.7ft ....................8212-022............Rolling Door Guide Profile, Clr - Max 13.1 ft.......8612-032............32 x 18 Bi-Slot .......................................................2512-090............Cover/Gasket Strip 1", Clear ................................2912-090B .........Cover/Gasket Strip 1", Black ................................2912-090Y .........Cover/Gasket Strip 1", Yellow ..............................2912-095............Aluminium Cover Strip 1"......................................2912-095B .........Aluminium Cover Strip 1", Black ..........................2912-101............Cover/ Gasket Strip 40, Clr - 6.6ft........................2912-1010.........1" x 1" Standard ....................................................1612-1010PKG..1" x 1" Standard 6 x 8' Pcs ...................................1612-101B .........Cover/ Gasket Strip 40, Blk - 6.6ft .......................2912-101Y .........Cover/ Gasket Strip 40, Yellow - 6.6ft..................2912-102............Al Cover Strip 40, Clr - 6.6ft..................................2912-1020.........1" x 2" Standard ....................................................1612-1020PKG..1" x 2" Standard 4 x 8' Pcs ...................................1612-102B .........Al Cover Strip 40, Blk - 6.6 ft. Length ..................2912-1030.........1" x 3" Standard ....................................................1712-105............Clamp Bar Profile ..................................................2712-106............Panel Gasket .........................................................2812-107............Mesh Gasket .........................................................2812-108............Panel Gasket 10 Clear - Max 410 ft.....................2512-109............19" Rack Angle......................................................2612-110............Rack Angle, Blank .................................................2612-111B .........PVC Cover Strip 40, Blk - 6.6ft.............................2912-111BL .......PVC Cover Strip 40, Blue - 6.6ft ..........................2912-112............Safety Cover Strip 40/28, Yellow - Max 9.8ft.......2812-114............Anti-Skid Cover 40, Blk - Max 65.6ft....................2812-2020.........2" x 2" Standard ....................................................1712-400............UHMW Slide Bar 40 max 120"...........................11112-402............Slide Strip 1" max 120".......................................11112-410............Slide Strip 1.5" max 120"....................................11112-420............UHMW Slide Bar 40 x 10 max 120"...................11112-421............UHMW Guide Profile .............................................8613-012............Steel Tube, Plastic Coated for handles(max. 120 in.).....................................................5413-410............Slide Profile 40....................................................11013-430............Slide Profile 40 Side Flange . (110)13-440............Slide Profile 28....................................................11013-450............Slide Profile 28 Side Flange ...............................11013-800............Slide Profile 56....................................................11013-810............Slide Profile 80....................................................11018-1010.........1" x 1" End Cap .....................................................3118-1020.........1" x 2" End Cap .....................................................3118-1030.........1" x 3" End Cap .....................................................3118-1515.........1.5" x 1.5" End Cap...............................................3118-1530.........1.5" x 3" End Cap..................................................3118-1543.........1.5" Quarter Round End Cap................................3118-1545.........1.5" x 1.5" x 45? End Cap.....................................3118-1575.........1.5" x .75" End Cap...............................................3118-2020.........2" x 2" End Cap .....................................................3118-3030.........3" x 3" End Cap .....................................................3118-710............Access Hole Plug ..................................................3118-713............Access Hole Plug - Steel ......................................3118-807............32x18 End Cap......................................................2519-004............Drill & Counterbore for BHCS or SHCS .............11419-006............Drill & Countersink for FHCS ..............................11419-007............Saw Cut for Linear Shaft.....................................11419-009............Tap 5/16-18........................................................11419-026............Panel Packing for Secure Transport ..................11419-029............Panel - Chamfer Corner ......................................11419-030............Panel - Notch Corner ..........................................11419-104............Special Miter Cut .................................................11419-200............Special Invoice Required ....................................11419-201............Assembly Required .............................................11419-202............Assembly Form Follows......................................11419-203............Packaging in Kit Form.........................................11419-204............Kit Form Follows..................................................11419-205............Special Assembly Documents Enclosed............11419-206............Engineering..........................................................11419-207............On-Site Installation..............................................11419-208............Special Packing Slip Required ...........................11419-210............Special Machining ...............................................11419-211............Miter Connection Service....................................11419-300............Inspection/Acceptance/Approval ........................11419-501............Saw Cut up to 3"x1.5".........................................11419-502............Saw Cut up to 3"x3"............................................11419-503............Saw Cut 6"x1.5"...................................................11419-511............Drill .277" Access Hole - Except 6" side ............11419-512............Drill & Tap (10/32",1/4",5/16", 3/8")....................11419-514............Drill & Tap (1/2" or 5/8" up to 1.5" Deep)...........11419-515............Step Drill for Universal Fastener 1.5" or 1"........11419-516............Drill/ Tap 5/16x1.5" for 5/16"Foot .......................11419-517............Drill/ Tap 3/8"x 2" for 3/8" Foot...........................11419-520............Step Bore for Pneum. Univ. Fastener(3/4" x 1/4")......................................................11419-525............Drill .277" Access Hole thru 6" side ...................11419-527............Panel - Thru Hole up to 3/8"l Profile Square 3"x1.5"l Profile Square 3"x3"l Profile Square 6"x1.5"..................................11419-603............Drill/ Tap/ Mill for Roller PA ................................11419-605............45° Miter Cut, up to 3x3" profile .........................11419-606............45° Miter Cut, 6"x1.5" profile ..............................11420-059............T-Slot Profile 1.5"..................................................3620-062............Heavy T-Slot Bar - 1.5".........................................3620-082............Economy T-Slot Nut, 1.5" - 5/16-18.....................3520-082SS.......Economy T-Slot Nut, 1.5" - 5/16-18,Stainless Steel ...................................................3520-083............Economy T-Slot Nut, 1.5" - 1/4-20.......................3520-088............Economy T-Slot Nut, #10-32...............................3520-093SS.......Economy T-Slot Nut 28, 1/4-20 Stainless Steel .......20-1010.........Cast Gusset 1"......................................................4520-1010C.......Cap for Cast Gusset 1".........................................4520-102z4........Gusset Profile ........................................................2720-182............Economy Offset T-Slot Nut, 1.5" - 5/16-18. (35)122Parker Hannifin CorporationIndustrial Profile Systems Business Unit Wadsworth, Ohio USA20-193............Economy Offset T-Slot Nut 1.5" - 1/4-20.............3520-200............Retainer for Wire mesh 1"Single ..........................8120-201............Retainer for Wire mesh 1" Double........................8120-202............Retainer for Wire mesh 1.5" Single ......................8120-203............Retainer for Wire mesh 1.5" Double.....................8120-300............Joining Plate, 1.5" x 3"..........................................4820-301............Joining Plate, 1.5" x 6"..........................................4820-302............Joining Plate, 3" x 3".............................................4820-303............Joining Plate, 3" x 6".............................................4820-304............Joining Plate, Corner 4.5" x 4.5"..........................4920-305............Joining Plate, T , 4.5" x 4.5".................................4920-306............Joining Plate, Corner 6" x 6"................................4920-307............Joining Plate, T , 6" x 6".......................................4920-310............Joining Plate, 1" x 2".............................................5020-311............Joining Plate, 1" x 4".............................................5020-312............Joining Plate, 2" x 2".............................................5020-313............Joining Plate, 2" x 4".............................................5020-314............Joining Plate, Corner 3" x 3".................................5120-315............Joining Plate, T , 3" x 3".......................................5120-330............Connection Element, 90 1.5" x 1.5" x 1.5"...........4220-335............Connection Element, 90 1" x 1" x 1"....................4320-336............Connection Element, 90 1" x 1" x 2"....................4320-337............Connection Element, 90 1.5" x 1.5" x 3"..............4220-338............Connection Element, 90 1.5" x 3" x 3".................4220-4040.........1 x 1 Single Gusset (die cast)..............................4520-440............Gusset Bracket, 3" x 3" x 1.5"..............................4420-441............Gusset Bracket, 3" x 3" x 3".................................4420-442............Gusset Bracket, 3" x 3" x 1".................................4420-500............Corner Element 1, 1.5"..........................................4620-501............Corner Element 1, 3".............................................4620-502............Corner Element 2, 1.5"..........................................4620-503............Corner Element 2, 3".............................................4620-504............Corner Element 3, 1.5"..........................................4620-505............Corner Element 3, 3".............................................4620-506............Machined Gusset 1" x 1"......................................4720-507............Machined Gusset 1" x 2"......................................4720-508............Machined Gusset 1.5" x 1.5"................................4720-509............Machined Gusset 1.5" x 3"...................................4720-8040.........2 x 2 Single Gusset (die cast)..............................4521-020............Rubber Insert 80....................................................9221-021............Clamping Shoe 80.................................................9221-032............Floor Fastening Set...............................................9221-057z4........L-Bracket Profile....................................................2721-060............L Base Floor Anchor 1.5"......................................9321-061............L Base Floor Anchor 1".........................................9321-073............UHMW Guide Insert Set - 1/4-20..........................8621-075............Roller Insert Set.....................................................8621-1020-04....Base Plate, 1" x 2", 1/4-20..................................10121-1020-05....Base Plate, 1" x 2", 5/16-18................................10121-1030-04....Base Plate, 1" x 3", 1/4-20..................................10121-1030-05....Base Plate, 1" x 3", 5/16-18................................10121-1530-06....Base Plate, 1.5" x 3", 3/8-16..............................10121-1530-08....Base Plate, 1.5" x 3", 1/2-13..............................10121-1530-10....Base Plate, 1.5" x 3", 5/8-11..............................10121-2020-05....Base Plate, 2" x 2", 5/16-18................................10121-2020-06....Base Plate, 2" x 2", 3/8-16..................................10121-2020-08....Base Plate, 2" x 2", 1/2-13..................................10121-250............Flange Foot 1.5" x 1.5".........................................9521-252............Flange Foot 1" x 1"................................................9521-255............Flange Foot 1.5" x 3.0".........................................9521-256............Flange Foot 3.0" x 3.0".........................................9521-300............Caster Swivel 2" - Hollow King Pin.......................9621-301............Caster Swivel 2", Locking - Hollow King Pin........9621-302............Caster Rigid 3" - Top Plate ...................................9721-303............Caster Swivel 3" - Top Plate.................................9721-3030-06....Base Plate, 3" x 3", 3/8-16..................................10121-3030-08....Base Plate, 3" x 3", 1/2-13..................................10121-3030-10....Base Plate, 3" x 3", 5/8-11. (101)21-304............Caster Swivel 3", Locking - Top Plate..................9721-305............Caster Swivel 3" - 7/16 Grip Ring.........................9621-306............Caster Swivel 3", Locking - 7/16 Grip Ring..........9621-309............Caster Swivel 3" - Hollow King Pin.......................9621-310............Caster Swivel 3", Locking - Hollow King Pin........9621-311............Caster Rigid 5" - Top Plate ...................................9721-312............Caster Swivel 5" - Top Plate.................................9721-313............Caster Swivel 5", Locking - Top Plate..................9721-316............Caster Swivel 5" - Plate 550lbs ..........................10021-317............Caster Swivel 5", Locking - Plate 550lbs ...........10021-318............Caster Swivel 5" - Plate 900lbs ..........................10021-319............Caster Swivel 5", Locking - Plate 900lbs ...........10021-320............Standard Duty 1-5/8" - 7/16 Grip Ring .................9621-323............Leveling Caster 1"- Threaded Stud M12..............9921-324............Leveling Caster 1" - Plate Mount.........................9921-325............Floor Lock - Plate Mount.....................................10021-327............Leveling Caster 1.5"- Threaded Stud M12...........9921-328............Leveling Caster 1.5"- Plate Mount.......................9921-330............Socket for 1.5" x 3" Heavy....................................9621-331............Socket for 1.5" x 3" Standard ...............................9621-332............Corner Bracket for Standard Duty Casters ..........9621-333............Straight Bracket for Standard Duty Casters ........9621-336............Caster Swivel 3" - 1/2" Stem ................................9721-337............Caster Swivel 3" - Locking - 1/2" Stem ................9721-338............Caster Swivel 5" - 1/2" Stem ................................9721-339............Caster Swivel 5"- Locking - 1/2" Stem .................9721-340............Furniture 2" - 5/16 Grip Ring.................................9821-341............Furniture 2" - 5/16 Grip Ring-Locking ..................9821-342............Institutional Twin Wheel ........................................9821-343............Institutional Twin Wheel Locking ..........................9821-344............Dual Wheel 3" - 1/2" Stem ....................................9821-401............Knuckle Foot 1.5", 5/16-18 x 2"............................9021-402............Knuckle Foot 1.5", 5/16-18 x 3"............................9021-403............Knuckle Foot 1.5", 3/8-16 x 3"..............................9021-404............Knuckle Foot 3", 1/2-13 x 4".................................9021-405............Knuckle Foot 3", 1/2-13 x 6".................................9021-406............Knuckle Foot 3", 5/8-11 x 4".................................9021-407............Knuckle Foot 3", 5/8-11 x 6".................................9021-409............Corner Mounting Plate ..........................................9221-410............Knuckle Foot 1" Delrin, 1/4-20 x 2"......................8921-411............Knuckle Foot 1" Delrin, 3/8-16 x 3"......................8921-412............Knuckle Foot 1" Steel, 1/4-20 X 2".......................8921-413............Knuckle Foot 1" Steel, 3/8-16 X 3".......................8921-414............Knuckle Foot 1" Steel, 1/2-13 x 3".......................8921-415............L-Base Leveling Foot 1.5".....................................9321-416............L-Base Leveling Foot 1"........................................9321-420............Leveling Foot 3, Bolt Down, 1/2-13......................9121-421............Leveling Foot 3, Bolt Down, 5/8-11......................9121-422............Anti-Vibration Leveler 1/2-13, Light......................9121-423............Anti-Vibration Leveler 1/2-13, Medium.................9121-424............Anti-Vibration Leveler 1/2-13, Heavy ...................9121-440............Floor Mounting Bracket 1.5".................................9421-441............Floor Mounting Bracket 3"....................................9421-442............Floor Mounting Bracket 1"....................................9421-443............Floor Mounting Bracket 2"....................................9421-500............Adapter Plate 1.5".................................................9921-501............Adapter Plate 1.0".................................................9921-502............Adapter Plate 1.5".................................................9921-504............Base Plate for heavy Casters.............................10022-111............Economy Mesh Clamp 1.5"..................................8122-115............Multiblock 1.5" - 1/4-20.........................................8022-116............Multiblock 1" - 1/4-20............................................8022-153............Corner Bracket 1.5"...............................................4122-154............Connector Cap 1.5" Radius ..................................4122-155............Connector Cap 45 Degree ....................................4122-202............Cable Tie Holder....................................................8722-204............T-Clip 5/32-1/4 w/Fast Kit .....................................8722-206............T-Clip 1/4-5/16 w/Fast Kit . (87)123Parker Hannifin CorporationIndustrial Profile Systems Business UnitWadsworth, Ohio USA22-209z1........T-Clip 5/16-3/8 w/Fast Kit .....................................8722-211z1........T-Clip 3/8-1/2 w/Fast Kit .......................................8722-213z1........T-Clip 1/2-5/8 w/Fast Kit .......................................8722-216z1........T-Clip 5/8-3/4 w/Fast Kit .......................................8722-219z1........T-Clip 3/4-7/8 w/Fast Kit .......................................8722-223z1........T-Clip 7/8-1 w/Fast Kit ..........................................8722-230............Cable Hose Holder w/ English Fast Kit ................8723-030............Light Duty Aluminium Handle ...............................5323-031............Handle PA 132......................................................5423-032Z1.......Handle PA 179......................................................5423-033............Handle PA 93.5.....................................................5423-038............L-Handle Locking...................................................5523-038z1........Backing Plate.........................................................5723-039............L-Handle Non-locking............................................5523-046............Magnetic Catch......................................................6023-051............Strike Plate for Magnetic Catch............................6023-058............Mini-Key Safety Switch - Straight Key .................7023-059............Mini-Key Safety Switch - Angle Key.....................7023-060............Safety Switch 1 (1 NC + 1 NO).............................7223-061............Safety Switch 1 (2 NC)..........................................7223-062............Safety Switch 2 (1 NC + 1 NO).............................7323-063............Safety Switch 2 (2 NC + 2 NO).............................7323-064............Safety Switch 3 (2 NC) - To Lock.........................7423-066............Safety Switch 3 (2 NC) - To Unlock .....................7423-070............Open Angled Handle .............................................5323-071............Closed Angled Handle ..........................................5323-072............Tube Handle Ends.................................................5423-073............Tube Handle Center Supports ..............................5423-102............Mini-Key Mounting Bracket...................................7023-104............Safety Switch Mounting Bracket 1.......................7223-108............Mini Key Mounting Bracket - Top .........................7123-109............Mini Key Mounting Bracket - Sliding ....................7123-110............Safety Switch Mounting Bracket 3.......................7423-119............Mounting Bracket for Magnetic Catch..................6023-120............Ball Catch Bracket Style 1....................................5823-121............Ball Catch ..............................................................5823-122............Magnetic Catch Bracket........................................6023-124............Door Stop 1"..........................................................6323-125............Door Stop 1.5" - Straight.......................................6323-126............Door Stop 1.5" - Angle ..........................................6323-127............Ball Catch Bracket Style 2....................................5823-128............Ball Plunger, 3/8" Dia x .786"...............................5923-129............Ball Plunger, 1/2" x 1.10"......................................5923-130............Rachet Lock (for panel sliding doors)..................6323-133............Quarter Turn Latch T-Handle Non-Locking..........5523-134............Quarter Turn Latch Wing Knob Locking...............5523-135............Quarter Turn Latch - Square Insert ......................5523-137............Ball Catch Bracket 1"............................................5923-140z1........Spare Key for 23-134/23-144...............................5723-140z2........Square Key for 23-135/23-145.............................5723-140z4........Cam 45-2 Offset ....................................................5723-140z5........Cam 35-10 Offset ..................................................5723-140z7........Keeper Bracket......................................................5723-140z8........Cam 45-8...............................................................5723-142z1........Hooked Cam..........................................................5723-143............Quarter Turn Latch T-Handle Non-Locking Panel 5623-144............Quarter Turn Latch Wing Knob Locking Panel ....5623-145............Quarter Turn Latch - Square Insert Panel ...........5623-155............Slam Latch - Keyed...............................................6223-156............Slam Latch - Non Locking.....................................6223-158............Velcro Plate ...........................................................6323-159............Internal Handle for Quarter Turn Handles............5623-160............Deadbolt Latch ......................................................6223-210............Grabber Door Catch ..............................................6123-211............Grabber Door Catch w/Micro-Switch..................6123-212............Grabber Door Catch Bracket 90 degree ..............6123-213............Grabber Door Catch Bracket Flat.........................6123-220............Adjustable Hinge 1................................................6823-222............Adjustable Hinge 2................................................6823-224............Positioning Hinge 85°............................................6823-226............Positioning Hinge 120°..........................................6823-228............Positioning Hinge 155°..........................................6823-250............Hinge 1" - Steel .....................................................6623-250L .........Hinge 1" - Steel Left ..............................................6623-250R.........Hinge 1" - Steel Right............................................6623-251............Hinge 1"/1.5" - Steel..............................................6623-251L .........Hinge 1"/1.5" - Steel Left ......................................6623-251R.........Hinge 1"/1.5" - Steel Right ....................................6623-252............Hinge 1.5" - Steel ..................................................6623-252L .........Hinge 1.5" - Steel Left ...........................................6623-252R.........Hinge 1.5" - Steel Right ........................................6623-260............Pivot Joint 1", Blk ..................................................6923-261............Pivot Joint 1", Blk - Locking..................................6923-262............Pivot Joint 1.5", Blk ...............................................6923-263............Pivot Joint 1.5", Blk - Locking...............................6923-550............Plastic Hinge 1".....................................................6723-550L .........Plastic Hinge 1" - Left ...........................................6723-550R.........Plastic Hinge 1" - Right .........................................6723-551............Plastic Hinge 1.5"..................................................6723-551L .........Plastic Hinge 1.5" - Left ........................................6723-551R.........Plastic Hinge 1.5" - Right......................................6723-552............Plastic Hinge 1/1.5"...............................................6723-552L .........Plastic Hinge 1/1.5" - Left .....................................6723-552R.........Plastic Hinge 1/1.5" - Right...................................6723-620............Aluminum Hinge 1.5" - Right Long .......................6423-621............Aluminum Hinge 1.5" - Left Long..........................6423-622............Aluminum Hinge 1.5" - Right Short ......................6423-623............Aluminum Hinge 1.5" - Left Short .........................6423-624............Aluminum Hinge 1.5" - Receiver ..........................6423-625............Aluminum Hinge 1.5" - Double Pin .......................6423-626............Aluminum Lift off Hinge 1.5" - Heavy Duty ..........6523-626L .........Aluminum Lift off Hinge 1.5" - Left .......................6523-626R.........Aluminum Lift off Hinge 1.5" - Right .....................6523-630............Aluminum Hinge 1" - Right Long ..........................6423-631............Aluminum Hinge 1" - Left Long.............................6423-632............Aluminum Hinge 1" - Right Short..........................6423-633............Aluminum Hinge 1" - Left Short ............................6423-634............Aluminum Hinge 1" - Receiver..............................6423-635............Aluminum Hinge 1" - Double Pin ..........................6423-636............Aluminum Lift off Hinge 1" - Heavy Duty..............6523-636L .........Aluminum Lift off Hinge 1" - Left...........................6523-636R.........Aluminum Lift off Hinge 1" - Right ........................6523-640............Aluminum Lift off Hinge 1"/1.5" - Heavy Duty......6523-640L .........Aluminum Lift off Hinge 1"/1.5" - Left ...................6523-640R.........Aluminum Lift off Hinge 1"/1.5" - pression Springfor Economy T-Nuts, 1/pression Springfor Economy T-Nuts, 5/16-18...........................3525-001............T-Slot Nut 40 Steel 1/4-20....................................3425-002............T-Slot Nut, 1.5" - 5/16-18......................................3425-002SS.......T-Slot Nut, 1.5" - 5/16-18, Stainless Steel...........3425-003............Standard Fastener 5/16-18...................................3225-003SS.......Standard Fastener 5/16-18, Stainless Steel........3225-004............Universal Fastener 5/16-18..................................3325-005............Drop In T-Nut 10-32...................................................25-006............Drop in T-Nut 1/4-20", Rubber post...........................25-007............Drop in T-Nut 5/16-18", Rubber post.........................25-008............Drop-in T-Nut, 1/4-20, 28/56......................................25-009............T-Slot Nut, 1.5" *- #10-32......................................3425-014............Single Ear Standard Fastener 1.5" - 5/16-18.......3225-015............Profile to Wall Universal Fastener 5/16-18..........3325-016............Butt Fastener Assembly 5/16-18..........................3325-017............Butt Fastener Assembly 1/4-20............................3325-022............Standard Fastener, 1/4-20....................................3225-022z1........Standard Fastener, 1/4-20 - Clip .. (32)。