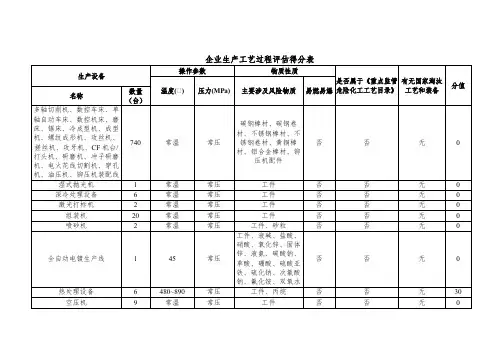

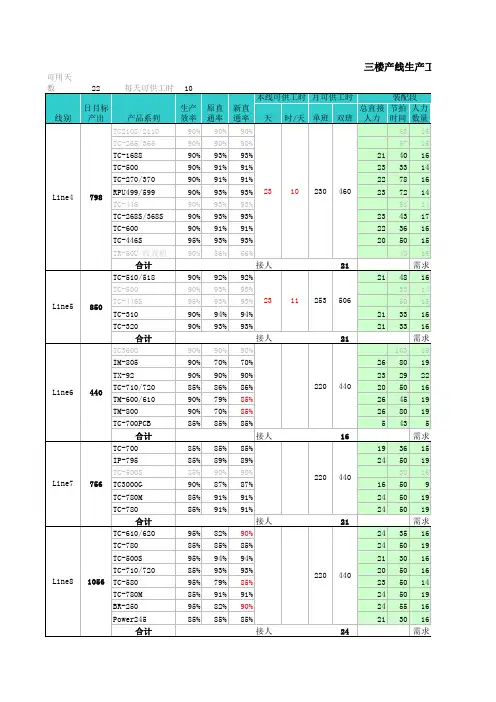

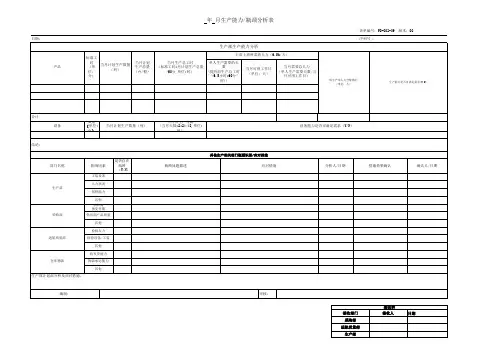

瓶颈工序产能评估表

- 格式:doc

- 大小:35.50 KB

- 文档页数:1

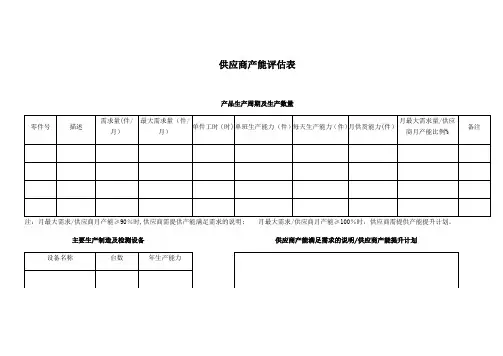

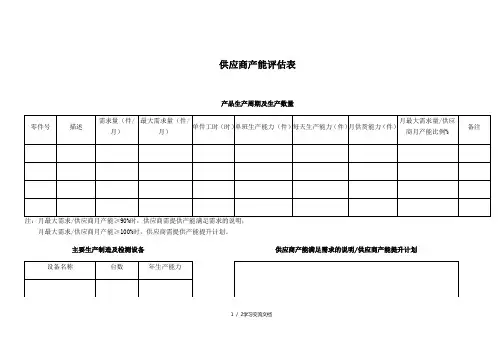

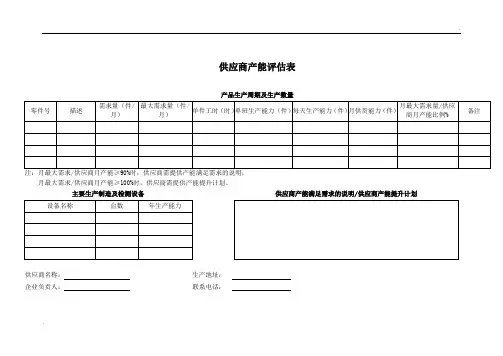

Part(s) Number: input the Customer's part number (not the supplier's internal part number). When the sheet applies to multiple parts, specify number of all the parts.零件号:输入SGM 零件号(非供应商的内部零件号)。

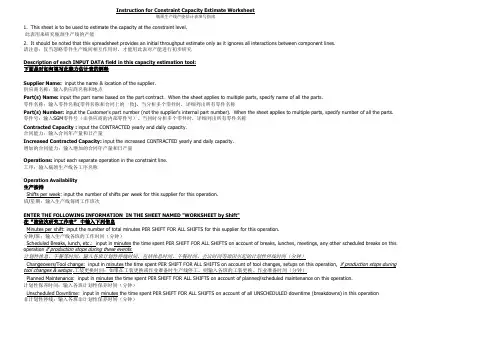

当同时分析多个零件时,详细列出所有零件名称Instruction for Constraint Capacity Estimate Worksheet瓶颈生产线产能估计表填写指南 Scheduled Breaks, lunch, etc.: input in minutes the time spent PER SHIFT FOR ALL SHIFTS on account of breaks, lunches, meetings, any other scheduled breaks on this operation if production stops during these events.计划性休息,午餐等时间:输入各班计划性停线时间,包括休息时间、午餐时间、会议时间等原因引起的计划性停线时间(分钟) Changeovers/Tool change: input in minutes the time spent PER SHIFT FOR ALL SHIFTS on account of tool changes, setups on this operation, if production stops during tool changes & setups .工装更换时间:如果在工装更换或作业准备时生产线停工,则输入各班的工装更换、作业准备时间(分钟) Unscheduled Downtime: input in minutes the time spent PER SHIFT FOR ALL SHIFTS on account of all UNSCHEDULED downtime (breakdowns) in this operation 非计划性停线:输入各班非计划性保养时间(分钟)1. This sheet is to be used to estimate the capacity at the constraint level.此表用来研究瓶颈生产线的产能2. It should be noted that this spreadsheet provides an initial throughput estimate only as it ignores all interactions between component lines.请注意:仅当忽略零件生产线间相互作用时,才能用此表对产能进行初步研究Part(s) Name: input the part name based on the part contract. When the sheet applies to multiple parts, specify name of all the parts.零件名称:输入零件名称(零件名称和合同上的一致)。