施耐德工厂自动化助力客户实现生产能力提高25%的自动化工厂

- 格式:docx

- 大小:14.88 KB

- 文档页数:2

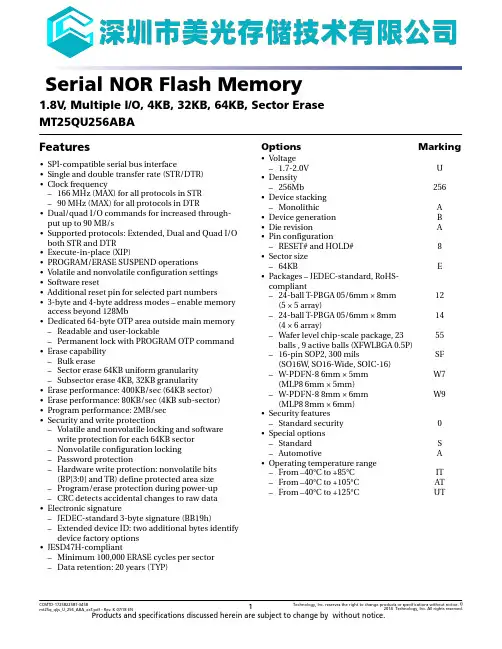

Serial NOR Flash Memory 1.8V , Multiple I/O, 4KB, 32KB, 64KB, Sector Erase MT25QU256ABAFeatures•SPI-compatible serial bus interface•Single and double transfer rate (STR/DTR)•Clock frequency –166 MHz (MAX) for all protocols in STR–90 MHz (MAX) for all protocols in DTR•Dual/quad I/O commands for increased through-put up to 90 MB/s•Supported protocols: Extended, Dual and Quad I/Oboth STR and DTR•Execute-in-place (XIP)•PROGRAM/ERASE SUSPEND operations•Volatile and nonvolatile configuration settings•Software reset•Additional reset pin for selected part numbers•3-byte and 4-byte address modes – enable memoryaccess beyond 128Mb•Dedicated 64-byte OTP area outside main memory–Readable and user-lockable–Permanent lock with PROGRAM OTP command•Erase capability–Bulk erase–Sector erase 64KB uniform granularity–Subsector erase 4KB, 32KB granularity•Erase performance: 400KB/sec (64KB sector)•Erase performance: 80KB/sec (4KB sub-sector)•Program performance: 2MB/sec•Security and write protection–Volatile and nonvolatile locking and softwarewrite protection for each 64KB sector–Nonvolatile configuration locking–Password protection–Hardware write protection: nonvolatile bits(BP[3:0] and TB) define protected area size–Program/erase protection during power-up–CRC detects accidental changes to raw data•Electronic signature–JEDEC-standard 3-byte signature (BB19h)–Extended device ID: two additional bytes identifydevice factory options•JESD47H-compliant–Minimum 100,000 ERASE cycles per sector–Data retention: 20 years (TYP)Options Marking •Voltage – 1.7-2.0V U •Density –256Mb 256•Device stacking –Monolithic A •Device generation B •Die revision A •Pin configuration –RESET# and HOLD#8•Sector size –64KB E •Packages – JEDEC-standard, RoHS-compliant –24-ball T-PBGA 05/6mm × 8mm (5 × 5 array)12–24-ball T-PBGA 05/6mm × 8mm (4 × 6 array)14–Wafer level chip-scale package, 23balls , 9 active balls (XFWLBGA 0.5P)55–16-pin SOP2, 300 mils (SO16W, SO16-Wide, SOIC-16)SF –W-PDFN-8 6mm × 5mm (MLP8 6mm × 5mm)W7–W-PDFN-8 8mm × 6mm (MLP8 8mm × 6mm)W9•Security features –Standard security 0•Special options –Standard S –Automotive A •Operating temperature range –From –40°C to +85°C IT –From –40°C to +105°C AT –From –40°C to +125°C UTCCMTD-1725822587-3458mt25q_qljs_U_256_ABA_xxT.pdf - Rev. K 07/18 EN 1 Technology, Inc. reserves the right to change products or specifications without notice. © 2014 Technology, Inc. All rights reserved.Products and specifications discussed herein are subject to change by without notice.Device DescriptionThe MT25Q is a high-performance multiple input/output serial Flash memory device. It features a high-speed SPI-compatible bus interface, execute-in-place (XIP) functionali-ty, advanced write protection mechanisms, and extended address access. Innovative,high-performance, dual and quad input/output commands enable double or quadru-ple the transfer bandwidth for READ and PROGRAM operations.Figure 2: Block DiagramNote: 1.Each page of memory can be individually programmed, but the device is not page-eras-able.256Mb, 1.8V Multiple I/O Serial Flash Memory Device DescriptionCCMTD-1725822587-3458mt25q_qljs_U_256_ABA_xxT.pdf - Rev. K 07/18 EN 9 Technology, Inc. reserves the right to change products or specifications without notice. © 2014 Technology, Inc. All rights reserved.Package Dimensions – Package Code: 12Figure 9: 24-Ball T -PBGA (5 x 5 ball grid array) – 6mm x 8mmNotes: 1.All dimensions are in millimeters.2.See Part Number Ordering Information for complete package names and details.256Mb, 1.8V Multiple I/O Serial Flash Memory Package Dimensions – Package Code: 12CCMTD-1725822587-3458mt25q_qljs_U_256_ABA_xxT.pdf - Rev. K 07/18 EN 18 Technology, Inc. reserves the right to change products or specifications without notice. © 2014 Technology, Inc. All rights reserved.Serial Flash Discovery Parameter DataThe serial Flash discovery parameter (SFDP) provides a standard, consistent method to describe serial Flash device functions and features using internal parameter tables. The parameter tables can be interrogated by host system software, enabling adjustments to accommodate divergent features from multiple vendors. The SFDP standard defines a common parameter table that describes important device characteristics and serial ac-cess methods used to read the parameter table data.Micron's SFDP table information aligns with JEDEC-standard JESD216 for serial Flash discoverable parameters. The latest JEDEC standard includes revision 1.6. Beginning week 42 (2014), Micron's MT25Q production parts will include SFDP data that aligns with revision 1.6.Refer to JEDEC-standard JESD216B for a complete overview of the SFDP table defini-tion.Data in the SFDP tables is read by the READ SERIAL FLASH DISCOVERY PARAMETER operation.See TN-25-06: Serial Flash Discovery Parameters for MT25Q Family for serial Flash discovery parameter data.256Mb, 1.8V Multiple I/O Serial Flash Memory Serial Flash Discovery Parameter DataCCMTD-1725822587-3458mt25q_qljs_U_256_ABA_xxT.pdf - Rev. K 07/18 EN 40 Technology, Inc. reserves the right to change products or specifications without notice. © 2014 Technology, Inc. All rights reserved.。

GW7F-252型隔离开关安装使用说明书编号:0TK.466.5011泰开集团山东泰开隔离开关有限公司二○○六年十二月1 概述1.1 产品用途GW7F-252型隔离开关是三相交流50Hz的户外高压隔离电器,供高压线路在无载荷情况下进行换接,以及对被检修的高压母线、断路器等高压电气设备与带电的高压线路进行电气隔离之用。

1.2 符合标准GB 1985-2004 《交流高压隔离开关和接地开关》GB/T 11022-1999 《高压开关设备和控制设备标准的共用技术要求》1.3 产品特点GW7F-252型隔离开关为三柱式水平双断口翻转式隔离开关,可在一侧或两侧附装JW7-252Ⅱ两步动作式接地开关,该产品结构新颖设计合理,性能优良,运行可靠,它具有以下特点:a.导电管翻转特性:GW7F-252系列隔离开关主闸刀导电管采用水平运动和绕自身轴线旋转的复合运动,大大降低了动静触头分、合过程中所需要的操作力矩。

b.辅助触指结构:GW7F-252系列隔离开关增加了动、静辅助触指,可以有效的开断容性电流、感性电流和开合母线转换电流。

c.取消铜铝双金属板过渡的做法,将两种材质的电接触面镀银或镀锡,减少电连接中间环节,从而减小了接触电阻,有效地杜绝了长期运行中电接触表面发热烧蚀现象。

d.改进镀银工艺,保证镀银层硬度大于HV120,大大增加了镀层的附着力,可靠保证了镀银层长期工作不脱落。

e.采用全密封轴承座,轴承表面涂满足量耐高温和低温性能优良的宽温润滑脂,低温不固化,高温不流失,确保长期运行中转动灵活可靠。

f.主闸刀设有高低调节装置,该装置结构简单,调整方便,可快速调整主导电的高度和倾斜度,便于现场安装调试。

g.接地闸刀为两步动作式结构,采用动触棒插入梅花形静触指啮合方式,接触点多,通流能力强,动作可靠,合闸冲击小。

h.对所有标准件和有尺寸配合的钢制件采用真空渗锌处理,对铸铁铸钢件采用热喷锌处理,对尺寸要求不严的零部件采用热镀锌处理。

F-7 SMAZEUser ManualEnglish© 2014 Antari Lighting and Effects Ltd.User Manual - EnglishPlease read the following safety information carefully before operating themachine. This information includes important safeguards about installation,usage, and maintenance. Pay attention to all warning labels and instructions inthis manual and printed on the machine.If you have questions about how to operate the machine safely, please contact your local Antari dealer for help.․Keep this device dry.․Always connect to a grounded circuit to avoid risk of electrocution.․Before connecting machine to power, always check voltage indicate on machine match to your local AC voltage. Do not use the machine if AC power voltage doesnot match.․Disconnect the machine from AC power before servicing and when not in use.․This product is for indoor use only! Do not expose to rain or moisture. If fluid is spilled, disconnect AC power and clean with a damp cloth. If fluid is spilled ontoelectronic parts, immediately unplug the machine and contact your local Antaridealer for advice.․No user serviceable and modifiable parts inside. Never try to repair this product, an unauthorized technician may cause damage or malfunction to the machine.․For adult use only. Never leave the machine running unattended.․Installed the machine in a well-ventilated area. Provide at least 50 cm space around the machine.․Never add flammable liquid of any kind to the machine.․Make sure there are no flammable materials close to the machine while operating.․Only use Antari fluid. Other fluid may lead to heater clog and malfunction.․If the machine fails to work, unplug the machine and stop operation immediately.Contact your local Antari dealer for advise.․Before transporting the machine, make sure the fluid tank is completely drained.․Fog fluid may present health risks if swallowed. Do not drink fog fluid. Store it securely. In case of eye contact or if fluid is swallowed, immediately look formedical advice.Immediately upon receiving the machine, carefully unpack the carton, check the content to ensure that all parts are present and have been received in good condition. If any parts appear damaged or mishandled from shipping, notify the shipper immediately and retrain the packing material for inspection.What is included: 1 x F-7 SMAZE Machine2 x Power Cord (One for Fog Machine, the other for Fan)2 x Fluid Tank1 x User Manual710 mm412 mm710 mmStep 1: Place the machine on a flat surface and in a suitable large area with at least 50 cm open space around the machine.Step 2: Fill the fluid tank with Antari approved fluid.Step 3: Connect the machine to suitable rated power supply.To determine the power requirement for the machine refer to the label on the machine.Always connect the machine to a protected circuit and ensure it is properly grounded to avoid risk of electrocution.Step 4: Turn on the machine and allow it to heat up. Heat up takes approximatly 6 mintues. Once the machine has reached operating temperature, the display will show Ready to Fog. Now the machine is ready for operation.Step 5: To start making fog, press the VOLUME button on the control panel.Tank Capacity :5 litersBlue LCD screen, Timermode, Volume modeNeutrik PowerCon XLR 5-Pin DMX ConnectorXLR 3-Pin DMX Connector Control Options :DMX 、W-DMXStep 6: To turn off the machine, hold the STOP button for 3 seconds; the machine will automatically run a self-cleaning process and shut down after the self-cleaning process is done.Control Panel OperationSelect Fog or Faze ModeOperation ModeXXXXSet interval time at Timer mode from 1 to 300 secondsSet duration time at Timer mode from 1 to 120 secondsSet output volume at Timer mode from 20 to 100 %Set output volume at Volume mode from 20 to 100 % or continuous outputSet fan speed from 20 to 100% or to turn off FanSet DMX/W-DMX address from 1 to 510Turn On/Off W-DMX functionUnlink from a W-DMX transmitterTurn On/Off Air Pump SensorTurn On/Off run last setting functionTimer IntervalXXX Sec Timer DurationXXX SecTimer OutputXXX %Volume OutputXXX %Fan SpeedXXX %DMX-512Address: XXXRun Last SettingXXAir Pump SensorXXW-DMX PowerXXW-DMX ResetXXDMX Connector Pin AssignmentThe machine provides a 3- or 5-pin XLR connector for DMX connection. The diagram below indicates pin assignment information.DMX OperationMaking the DMX Connection– Connect the machine to a DMX controller or to one of the machines in the DMX chain. The machine uses a 3-pin or 5-pin XLR connector for DMX connection, the connector is located on the front of the machine.Address Setup – Use control menu to set DMX address. The machine occupies 3 control channels. The starting address is defined as the first channel from which the machine will respond to the controller. Always double check to make sure there are no overlapping channles in order to control the machine correctly.DMX Channel Function․Do not allow the machine and fluid to become contaminated.․Regularly fill distilled water to fluid tank and run the machine to clean the system.After cleaning, refill Antari fog fluids into fluid tank and make sure machine canproduce fog properly.․It is recommended to run the machine on a monthly basis in order to achieve best performance and output condition.․Excessive dust, liquid and dirt built up will degrade performance and cause overheating.Input voltage 110-120V 60Hz or 220-240V 50HzPower Consumption Heater: 1500 WFan: 72W at 120V 60Hz74W at 230V 50HzWarm-up time 6 minutes (approx.)Fluid tank capacity 5 LiterMaximum Fluid consumption Fog Mode: 140 ml per minuteFaze Mode: 28ml per minuteRecommended Fluid Antari FLG water-based fog fluid for the best effect Control options LCD Menu, DMX 512, Wireless DMXAdjustable output volume and fan speedDMX channels 3 channelsPower connection Neutrik PowerCONDMX data connection 3-pin and 5-pin XLRDimension L 710 x W 412 x H 710 mmDry weight 52.5kgC08F00700。

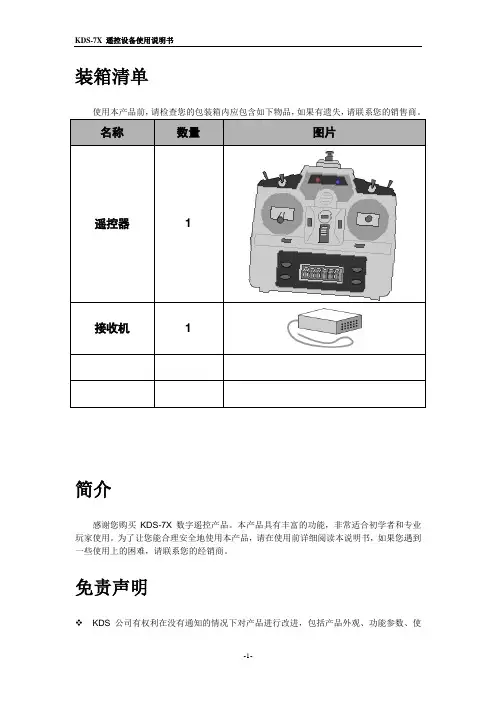

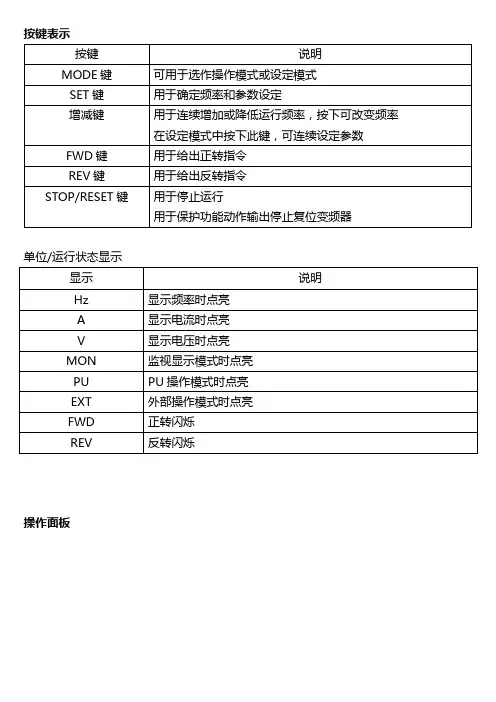

按键表示单位/运行状态显示操作面板1 按MODE键改变监视状态单次按MODE键,将一次切换到监视模式、频率设定模式、参数设定模式、运行模式、帮助模式。

2 显示监视器显示运转中的指令1)EXT指示灯亮表示外部操作2)PU指示灯亮表示PU操作3)EXT和PU灯同时亮表示PU和外部操作组合方式注:1)按SET键超过1.5秒能把电流监视模式改为上电监视模式2)在报警监视模式按SET键超过1.5秒能显示最近4次的错误指示进入参数设定模式1、更改参数P77(参数写入禁止选择)为2。

2、更改参数P79(操作模式选择):按现场实际控制方式选择。

(一般设定为3--外部和PU组合方式设定)。

3、设定参数P1(上限频率,一般为50hz)、参数P7(加速时间)、参数P8(减速时间)、参数P9(电子过电流保护—1.1倍电机额定电流)。

升降段注意多段速频率设定,根据端子接线情况设定是使用高P4、中P5、低P6哪两个参数设定。

4、在参数写入时应按住SET键1.5秒写入设定值并更新。

5、如在设定时依旧有问题可查找说明书的出错对策。

参数拷贝和复制出错(报警)定义操作面板显示 E.OC1名称加速时过电流断路内容加速运行中,当变频器输出电流超过额定电流的200%时,保护回路动作,停止变频器输出仅给R1,S1端子供电,输入启动信号时,也为此显示检查要点是否急加速运转输出是否短路主回路电源(R,S,T)是否供电处理延长加速时间自适应调整:pr71=3,pr80=7.5,pr81=4,然后设定pr96=1,按fwd键,屏幕显示1,2,3,自适应设定完成。

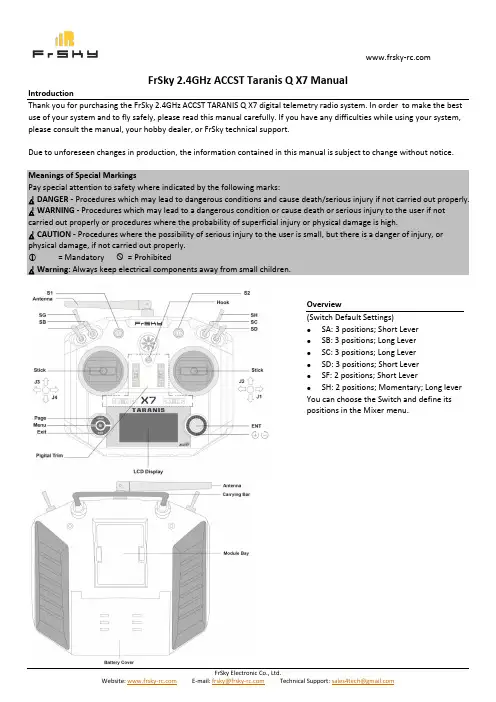

FrSky 2.4GHz ACCST Taranis Q X7 ManualIntroductionThank you for purchasing the FrSky 2.4GHz ACCST TARANIS Q X7 digital telemetry radio system. In order to make the best use of your system and to fly safely, please read this manual carefully. If you have any difficulties while using your system, please consult the manual, your hobby dealer, or FrSky technical support.Due to unforeseen changes in production, the information contained in this manual is subject to change without notice.Meanings of Special MarkingsPay special attention to safety where indicated by the following marks:△!DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out properly. △!WARNING - Procedures which may lead to a dangerous condition or cause death or serious injury to the user if not carried out properly or procedures where the probability of superficial injury or physical damage is high.△!CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of injury, or physical damage, if not carried out properly. = Mandatory = Prohibited△!Warning: Always keep electrical components away from small children.Overview(Switch Default Settings) ● SA: 3 positions; Short Lever ● SB: 3 positions; Long Lever ● SC: 3 positions; Long Lever ● SD: 3 positions; Short Lever ● SF: 2 positions; Short Lever ● SH: 2 positions; Momentary; Long lever You can choose the Switch and define its positions in the Mixer menu.SpecificationsModel Name: Taranis Q X7Operating Voltage Range: 6~15V (2S, 3S Lipos are acceptable)Operating Current: 210mA maximum (both RF module and backlit are on)Operating Temperature: -10~45℃Backlight LCD Screen: 128*64 outdoor readable LCDModel Memories: 60 (extendable by SD card)Compatibility: FrSky X series, D series and V8-II series receivers (plus other receivers if an external module is used) Features● Quad Ball Bearing Gimbals● Receiver Match● Audio Speech Outputs (values, alarms, settings, etc.)● Antenna Status Detection and Adjustment● Real-time Flight Data Logging ● Receiver Signal Strength Indicator (RSSI) Alerts ● Super Low Latency● Smart Port Supported● Vibration Alerts△! Cautions on handling antenna✠Do not touch the antenna during operation. Doing so could interfere with transmission, causing a crash.✠Do not carry the transmitter by the antenna. The antenna wire could break and prevent transmission.✠Do not pull the antenna forcefully. The antenna wire could break and prevent transmission.Rotating AntennaThe antenna can be rotated 180 degrees and angled 90degrees. Forcing the antenna further than this can causedamage to the antenna. The antenna is not removable.Angle adjustment of the antennaThe antenna rotation and angle can be adjusted. Theantenna features week radio signal in the forward directionand strong radio signal in the sideways directions. Adjust theantenna angle to match your flying style.△! Notes and Warnings for Battery (Not provided)Model Setup for Taranis Q X7 Internal RF ModuleThe internal RF module of FrSky Taranis Q X7 is newly developed by FrSky under the name of XJT.Enter the MODEL SETUP menu (for details, refer to the Guide included on the SD card, or download it from FrSky website).Step 1: Set the Mode for Taranis Q X7 Internal RFRefer to the table below and set the Taranis Q X7 to the mode corresponding to your receiver (D8, D16 or LR12 ).Mode of Taranis Q X7 Compatible ReceiversNumber of Output servoChannels D8 V8-II series in D mode (V8FR-II, V8R7-II, V8R4-II, VD5M, etc.) D series (D8R-II plus, D8R-XP, D6FR, D4R-II, etc.)8D16 X series (X8R, etc.) Up to 16 LR12 L series (L9R, etc.) 12Note: older V8 receivers are not supported by the internal module but can be used with an external DJT module in V8 mode.Step 2: Set the Channel RangeThe internal RF module of Taranis Q X7 supports up to 16 output servo channels. The channel range is configurable, and needs double check before use.Step 3: Set the Receiver NumberWhen you create a new model, the system will assign you a receiver number automatically, but this can be easily changed. The range of the receiver number is 00-63, with the default number being 01 (use 00 is not recommended). Once the receiver is set to the desired number and is bound to the Taranis Q X7, the bind procedure will not need to be repeated✠ Please connect a battery in the battery compartment before use. ✠ The voltage range should be DC 6-15V. ✠ Be careful not to drop the battery.✠ Don't pull the battery wires as this could produce, short-circuits and cause the battery to explode.✠ Do not remove the battery from the TARANIS Q X7 transmitter while the voltage warning is blinking as this could cause iinternal settings and memories to be destroyed.✠ Do not use the transmitter if a “Backup Error” warning occurs. Battery Connector Polarity Ensure that the battery connector polarity is correct when connecting batteries into the battery compartment, otherwise the Taranis Q X7 might not be powered on.unless the receiver number is changed, In this case, either set the receiver number to the previous one, repeat the bind procedure.Step 4: BindBind refers to Taranis Q X7 binding mode. M ove the cursor to “Bind”, press ENTER button, the cursor will flash and the speaker will beep to remind you that the RF module has entered the bind mode. Then put your receiver into binding mode and finish the bind procedure (refer to the receiver’s manual for details).Press Enter or EXIT to exit.Step 5: Set Failsafe modeThere are 4 failsafe modes: No Pulse, Hold, Custom, Receiver (this mode only used above opentx-v2.0.0 firmware).● No Pulse: on loss of signal the receiver produces no pulses on any channel. To use this type, select it in the menu and wait 9 seconds for the failsafe to take effect.● Hold: the receiver continues to output the last positions before signal was lost. To use this type, select it in the menu and wait 9 seconds for the failsafe to take effect.● Custom: pre-set to required positions on lost signal. Move the cursor to “Set” and press ENTER, you will see FAILSAFE SETTING screen below. Move the cursor to the channel you want to set failsafe on, and press ENTER. When moving the corresponding sticks or switches, you will see the channel bar moving. Move the channel bar to the place you want for failsafe and long press ENTER to finish the setting. Wait 9 seconds before the failsafe takes effect.●Receiver: set the failsafe on the receiver(see receiver instructions) in D16 or LR12 mode, select it in the menu and wait 9 seconds for the failsafe to take effect.Notice:The above instructions do not apply to D-series receivers, which require the internal RF module of Taranis Q X7 to be in D8 mode. For these receivers, failsafe must be set on the receiver side (see receiver instructions)●SBUS port always outputs, No Pulse could not perform properly on it. Set “Hold” or “Custom” for SBUS port.Step 6: RangeRange refers to Taranis Q X7 range check mode. A pre-flight range check should be done before each flying session. Move the cursor to “Range” and press ENTER. In range check mode, t he effective distance will be decreased to 1/30. Press Enter or EXIT to exit.Model Setup for Taranis Q X7 External RF ModuleThe external RF module can be powered on or off by software. The setup process is the same as that for the internal RF . If you use other brand RF module than FrSky, please choose PPM mode.CEThe product may be used freely in these countries: Germany, UK, Italy, Spain, Belgium, Netherlands, Portugal, Greece, Ireland, Denmark, Luxembourg, Austria, Finland, Sweden, Norway and Iceland.France: the law permits the emission band 2400 to 2483.5 MHz with the limitation of transmission power of 100 mW (reduced to 10 mW between 2454 and 2483.5 MHz for outdoor flying).FCC Statement§ 15.19 Labelling requirements.This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.§ 15.21 Information to user.Any Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.§ 15.105 Information to the user.Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuantto part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmfulinterference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radiocommunications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:-Reorient or relocate the receiving antenna.-Increase the separation between the equipment and receiver.-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. -Consult the dealer or an experienced radio/TV technician for help.* RF warning for Portable device:The device has been evaluated to meet general RF exposure requirement. The device can be used in portable exposure condition without restriction.FLYING SAFETY△! Warning: To ensure the safety of yourself and others, please observe the following precautions. Have regular maintenance performed . Although your TARANIS Q X7 protects the model memories with non-volatile EEPROM memory (which does not require periodic replacement) and of a battery, it still should have regular check-ups for wear and tear. We recommend sending your system to your FrSky Service Center annually during your non-flying-season for a complete check-up and service. Always pay partic ular attention to the flying field’s rules , as well as the presence and location of spectators, the wind direction, and any obstacles on the field. Be very careful flying in areas near power lines, tall buildings, or communication facilities as there may be radio interference in their vicinity.At the flying field To prevent possible damage to your radio gear, turn the power switches on and off in the proper sequence: If you do not turn on your system on and off in this order, you may damage your servos or control surfaces, flood your engine, or in the case of electric-powered or gasoline-powered models, the engine may unexpectedly turn on and cause a severe injury. Make sure your transmitter can’t tip it over. If it is knocked over, the throttle stick may be accidentally moved, causing the engine to speed up. Also, damage to your transmitter may occur. In order to maintain complete control of your aircraft it is important that it remains visible at all times. Flyingbehind large objects such as buildings, grain bins, etc. must be avoided. Doing so may interrupt the radio frequency link to the model, resulting in loss of control. ✠ Do not grasp the transmitter's antenna during flight. Doing so may degrade the quality of the radio frequency transmission and could result in loss of control. ✠ As with all radio frequency transmissions, the strongest area of signal transmission is from the sides of the transmitter's antenna. As such, the antenna should not be pointed directly at the model. If your flying style creates this situation, easily move the antenna to correct this situation Before taxiing, be sure to extend the transmitter antenna to its full length.A collapsed antenna will reduce your flying range and cause a loss of control. It is a good idea to avoid pointing the transmitter antenna directly at the model, since the signal is weakest in that direction.1. Pull throttle stick to idle position, or otherwise disarm your motor/engine.2. Turn on the transmitter power and allow your transmitter to reach its home screen.3. Confirm the proper model memory has been selected.4. Turn on your receiver power.5. Test all controls. If a servo operates abnormally, don’t attempt to fly until you determine the cause of theproblem. (For PCM systems only: Test to ensure that the Failsafe settings are correct by waiting at least 2 minutes after adjusting then, turning the transmitter off and confirming the proper surface/throttle movements. Turn the transmitter back on.) 6. Start your engine. 7. Complete a full range check. 8. After flying, bring the throttle stick to idle position, engage any kill switches or otherwise disarm your motor/engine. 9. Turn off receiver power.Don’t fly in the rain! Water or moisture may enter the transmitter through the antenna or stick openings and cause erratic operation or loss of control. If you must fly in wet weather during a contest, be sure to cover your transmitter with a plastic bag or waterproof barrier. Never fly if lightning is expected.Secure Digital (SD) Memory Card Handling InstructionsThe MicroSD card (TF Card) (not provided with Taranis Q X7) can store various files, such as model data, music, sound files, pictures and text. The card is locked when it is pushed in all the way in. To remove the card, push in on the card again, it will pop out allowing you to remove it .If model data generated by a transmitter with a new software version is copied to an one with older software, the transmitter may not operate correctly. Before copying the model data, update the destination transmitter to the new software version.Do not expose the MicroSD card to dirt, moisture, water or fluids of any kind. ✠ Never remove the MicroSD card or turn off power while entering data.✠ Never store the MicroSD card where it may be subject to strong static electricity or magnetic fields. ✠ Do not expose the MicroSD card to direct sunlight, excessive humidity or corrosive environments. ✠Be certain to insert the MicroSD card in the correct direction.Read data from a PCMusic and image files edited by a PC can be transferred onto the MicroSD card and used on your TARANIS Q X7 transmitter. Equipment for reading and writing MicroSD cards is available at most electronics stores.Stored dataThe life of the MicroSD card is limited due to the use of Flash memory. If you have a problem saving or reading data such as picture data after a long period of use you may need to purchase a new MicroSD card. ∙ We are not responsible for, and cannot compensate for any failure to the data stored in the memory card for any reason. Be sure to keep a backup of your models and data in your MicroSD card. ∙ TARANIS Q X7 transmitters and MicroSD cards use non-volatile memory devices so that the data stored is retained, even without a backup battery. Nevertheless, it is good practice to back up the data in the transmitter to the MicroSD card. The clock for the transmitter does depends on the lithium battery, which may need to be replaced occasionally.UpdatesFrSky is continuously adding features and improvements to our radio systems. Updating (via the MicroSD card in Taranis Q X7) is easy and free. To get the most from your new transmitter, please check the download section of the FrSky website , for the latest update firmware and how-to guide.﹡The currently pre-installed firmware of FrSky Taranis Q X7 is modified from OpenTX firmware, improved and well tested by FrSky and the developing union.﹡More information about OpenTX can be found on: .△! Warning Be sure to turn off the power of the transmitter before inserting or removing a MicroSD card. ✠ As the MicroSD card is a precision device, do not use excessive force when inserting.。

关于峰的文案1.峰是一种极具力量和美感的自然现象,它象征着壮丽和雄伟。

2.峰常常吸引着探险家和攀登者,因为它们代表着极限挑战和胜利的喜悦。

3.无论是在静谧的寂静山谷中,还是在狂风暴雨中,峰都屹立不倒,展现出坚韧和顽强。

4.峰是大自然的杰作,是地球的脊梁,它们承载着天空的荣光和云雾的飘渺。

5.登上峰顶,俯瞰群山,人们往往会感到一种莫名的震撼和欣慰。

6.峰的轮廓线条清晰,光影交错之间,如梦似幻。

7.在古代文学作品中,峰常被描述为神灵居所,具有神秘和仙境的意味。

8.登峰造极,是人类追求卓越和超越的象征,也是一种成就感的体现。

9.峰峦叠嶂,山水相连,表现出大自然的恢弘和壮美。

10.峰不仅仅是一种地理现象,也是一种精神象征,代表了力量、毅力和胜利。

11.峰峦起伏,一波接一波,勾画出丰富多彩的山水画卷。

12.每一座峰都有其独特的魅力和故事,值得我们去探寻和欣赏。

13.攀登峰顶,需要克服重重困难和挑战,是一种身心的洗礼和锻炼。

14.峰的高耸挺拔,给人一种高远和激励的感受,让人们产生向上的力量和梦想。

15.峰峦绵延,让人感受到时间的流逝和岁月的变迁,是历史的见证者。

16.峰有时被赋予诸多文化和宗教的象征意义,是人们心灵的寄托和信仰。

17.峰与水、云、树相互辉映,形成一幅壮丽的自然景观,令人叹为观止。

18.峰的存在让人感受到生命的奇迹和生存的意义,是自然界的神奇之一。

19.从峰的角度去看世界,或许会让人得到一种全然不同的视觉和心灵体验。

20.峰之美,峰之神秘,峰之力量,一直是人类心中永远的话题和探索。

21.峰是一个充满活力和热情的人,总是能够激励身边的人。

22.他的工作态度一丝不苟,总是追求完美。

23.在团队合作中,峰总是能够很好地协调各方利益。

24.他善于挖掘团队成员的潜力,让每个人都能发挥出最好的水平。

25.峰在工作中总是能够站在客户的角度思考问题,为客户着想。

26.他对待工作充满热情,总是能够以最佳状态去完成任务。

常见胡蜂大全学名:Vespamanderinia别名:金环胡蜂;地王蜂(广西)、地龙蜂、红头蜂(云南贵州)、大土蜂(台语);台湾大虎头蜂;中华大虎头蜂;黑腰蜂(云南贵州)。

分布:主要分布於中海拔1,000-2,000公尺山区,高、低海拔零星分布。

体长:雌蜂5.0厘米,雄蜂3.9厘米,工蜂4.0厘米。

特征:体表绒毛较少;头部浅黄褐色;每一腹节后缘都有黄色环纹,末端数节呈黄色。

是世界上体型最大的虎头蜂。

3-4月间筑造於土穴中、树洞中或石穴中,蜂巢有外壳学名:Vexpaducalis(Vespatropica)别名:双金环虎头蜂;黑尾胡蜂。

分布:主要分布于低、中海拔500-1,500公尺地区,高海拔零星分布。

体长:雌蜂3.6-3.8厘米,雄蜂3.0-3.2厘米少数2.6-3.0厘米,工蜂3.6-3.8厘米、少数3.2-3.8厘米。

特征:腹部每一、二腹节为暗黄色、并有一黑色环带,第二腹节支环带分成三段,第三腹节以后为黑色。

因此也称黑尾虎头蜂,体型第二大的虎头蜂。

4-5月间筑巢於现成的土穴、石穴或树洞中黄腰虎头蜂。

分布:主要分布于海拔1,000公尺以下地区。

体长:雌蜂3-4.2厘米,雄蜂2.5-2.9厘米,工蜂2.5-3.5厘米。

特征:腹部第二节为金黄色,后半部其余各节为黑色。

学名:Vespaaffinis(V.formossana)别名:小黄腰胡蜂黄腰仔、三节仔(台语);台湾虎头蜂。

分布:主要分布于海拔1,000公尺以下地区,也是都市或市郊最常见的种类。

体长:雌蜂2.8-3.4厘米,雄蜂2.5-2.9厘米,工蜂2.2-2.8厘米。

特征:腹部第一、二节为金黄色,后半部其余各节为黑色。

极易辨认。

3-4月间筑巢多半在较低矮的树枝上、地表的草丛上、屋檐下、窗台外,少数蜂巢在较高的树上或低矮的树丛中,蜂巢略成圆球形黑盾胡蜂,别名:洋鬼子,黄胡蜂体长:雌蜂2.8-3.4厘米,雄蜂2.5-2.9厘米,工蜂2.2-2.8厘米。

峰字怎么读和解释

峰,读音[fēng]

部首: 山

部外笔画: 7

总笔画: 10

五笔86: mtdh

五笔98: mtdh

仓颉: uhej

笔顺编号: 2523541112

四角号码: 27754

郑码: llrc

Unicode: CJK 统一汉字 U+5CF0

汉字首尾分解: 山夆

汉字部件分解: 山夂丰

笔顺编号: 2523541112

笔顺读写: 竖折竖撇折捺横横横竖

峰字的基本解释:

高而尖的山头:山~。

~巅。

~峦。

高~。

险~。

形状像山峰的东西:驼~。

浪~。

最高处:登~造极。

~年(自然界中某种活动达到高峰的年度)。

〈名〉

(形声。

从山,峯( fēng)声。

本义:山顶)

同本义 [peak]

峯,山耑也。

——《说文新附》

夹岸高山…争高直指,千百成峰。

——吴均《与朱元思书》

又如:山峰(山的突出的尖顶);高峰;孤峰;峰岫,峰朵,峰头;峰腹(山峰中部)

最高点;顶点[summit;peak]。

如:洪峰;眉峰;登峰造极;主峰(山脉的最高峰)

拔地而起的高山[mount]。

如:峰脚(山麓);峰岚(山中云雾);峰岭(山岭)

突起 [hump]。

如:驼峰;峰牛(封牛)。

峰字的组词和造句

峰字的组词:

众峰、骊峰、才峰、昆峰、尖峰、三峰、龟峰、鳌峰、峰顶、霁峰、绝峰、云峰、闾峰、山峰、珠峰、峰年、尼峰、峰头、悬峰、洪峰、灵峰、鹫峰、雪峰、炉峰、眉峰、霭峰、岚峰、上峰、峰岚、峰峦、肩峰、险峰、危峰、乔峰、词峰、峰胁、峰岭、琼峰、主峰、连峰、缑峰、峰值、波峰、烟峰、衡峰、冰峰、势峰、眉峰、霜峰、五峰、层峰、攒峰、巅峰、驼峰、峰林、鹈峰、顶峰、极峰、峰颖、峰巅、乳峰、玉霄峰、紫驼峰、回乐峰、香炉峰、飞来峰、单峰驼、雪峰山脉、独峰牛、日观峰、雁回峰、白鹤峰、十二峰、冯雪峰、五老峰、双峰驼、雷峰夕照、五峰先生、鹰窠峰、雷峰塔、邱岳峰、仙峰寺、圣母峰、回雁峰、白鹤峰、独秀峰、十二晚峰、十二巫峰、乔戈里峰、冈仁波齐峰、干城章嘉峰

峰字的造句:

1 . 到顶峰有一小时的攀登路程。

2. 珠穆朗玛峰顶高耸入云。

3. 攀登科学高峰,无坦途可走。

4. 岩峰在平面图上的呈叶瓣状。

5. 前头对岸上有座圆顶的高峰。

6. 他们的顶峰就是智慧。

7. 他是第一个登上这座山峰的人。

8. 当选总统是他一生事业的顶峰。

9. 几率线则会缩成一条狭窄的峰。

10. 从这里可以看到那座山的山峰。

峰字的组词和造句峰字的组词:众峰、骊峰、才峰、昆峰、尖峰、三峰、龟峰、鳌峰、峰顶、霁峰、绝峰、云峰、闾峰、山峰、珠峰、峰年、尼峰、峰头、悬峰、洪峰、灵峰、鹫峰、雪峰、炉峰、眉峰、霭峰、岚峰、上峰、峰岚、峰峦、肩峰、险峰、危峰、乔峰、词推荐度:点击下载文档文档为doc格式。

施耐德电气汽车行业解决方案亮相中国国际汽车制造技术与装备及材料展览会

助力客户实现生产能力提高25%的自动化工厂

全球能效管理专家施耐德电气工业事业部日前携汽车行业解决方案亮相上海国际汽车

制造技术与装备及材料展览会,并联合公司其它事业部集中展示施耐德电气基于EcoStruxureTM能效管理平台的综合解决方案,其中包含过程控制及机器自动化整体解决方PlantStruxure,配电系统及智能能效整体解决方案PowerStruxure,楼宇自动化整体解决

方案BuildingStruxure及数据中心整体解决方案InfraStruxure,完美诠释了施耐德电气

一站式解决方案带给客户“高效安全的生产和透明精益的信息化管理完美融合”的价值主张。

施耐德电气中国区副总裁,工业事业部负责人修德华表示:“施耐德电气EcoStruxureTM能效管理平台所提供的综合解决方案,可以广泛应用各个行业及领域。

在汽车行业,施耐德电气解决方案能够帮助行业内客户实现一个生产能力提高25%的透明而高效、精益又安全的自动化工厂,能够为快速成长中的中国汽车整车及零部件厂商提供越来越多的优质产品,方案及服务,以应对汽车产业飞速发展所带来的挑战。

”

在展会上,施耐德电气通过PlantStruxure 协同自动化控制系统的方案演示墙及行业

解决方案架构图示及说明展板,全面而生动直观地展示了施耐德电气为汽车整车生产厂,动力总成工厂及零部件生产厂提供的从工厂级,到控制级及现场设备级的全厂自动化解决方案,以及所有相关产品及架构。

另外,施耐德电气还展示了为行业客户提供交钥匙项目集成服务的能力,包括ANDON电子看板系统 , EMS能源管理系统和MES 制造执行系统等项目服务方案及成功案例等。

施耐德电气与汽车行业生产自动化的渊源可以追溯至1968年,施耐德电气旗下Modicon 公司的前身Bedford Associates 为美国通用汽车公司设计开发出世界第一台商用可编程逻辑控制器(PLC)以取代之前繁杂的继电器硬接线控制系统。

此后, PLC的应用迅速从汽车行业扩散至几乎所有工业控制领域,并在能源、基础设施及楼宇等行业也获得了广泛应用,开创了工业自动化的全新时代。

同样,在配电电气领域,原施耐德电气旗下另一公司Square D也以其卓越的产品品质获得北美三大汽车公司的高度认可,其产品在北美汽车行业被广泛应用。

这样,施耐德电气以其旗下两大优秀公司的产品和服务为北美汽车行业做出了不可磨灭的贡献。

与此同时,在汽车工业高度繁荣发达的欧洲,原施耐德电气旗下公司Telemecanique和Merlin Gerin 也分别以其世界领先的工控自动化产品,配电电气产品和服务为汽车行业装备其配电及自动化控制系统,并结合其对汽车制造工艺的深刻理解和先进的电气自动化产品及方案,帮助欧洲各大汽车公司建立起其配电及电气自动化标准。

进入新时期,施耐德电气继续保持着在配电及工控领域的全球领先地位,并先后并购了世界领先的楼宇自动化和数据中心解决方案的专业公司,成功完成了“一个施耐德电气”的品牌融合。

自此,施耐德电气整合了各领域内全球领先的优质资源,可以为相关行业客户提供集配电系统,生产自动化,楼宇及数据中心等综合解决方案,汽车行业作为工业化大生产的代表行业,其装备高度集中,且对可靠性,生产连续性和效率,安全性及系统开放性等均有很高要求,且随着行业的发展,对管理信息化的需求与日俱增,对生产环境的控制也逐渐提高,对节能环保的新要求也提上议事日程,这就使得该行业需要一家能够提供综合解决方案的供应商,为客户提供可靠安全的配电系统,高效先进的自动化控制系统,专业高效的楼控系统以及可靠且配置优化的数据中心平台。

施耐德电气基于EcoStruxure 的全新平台以

及多年服务于汽车行业的丰富经验,可以为客户提供覆盖以上所有需求的一站式服务,帮助客户实现高效安全的生产和透明精益的管理,助力客户全面提升其生产及经营管理水平。

未来,施耐德电气将在继续保有与国际品牌汽车厂商密切合作的基础上,大力支持自主品牌厂商提升生产自动化水平,机器及人身安全水平,以及管理信息化水平,同时帮助客户提升配电系统的可靠性。

并以完善的产品线,整体解决方案及丰富的行业应用经验为所有在中国的汽车制造商及零部件制造商一站式提供先进高效的生产过程及机器自动化解决方案,可靠的配电系统及智能能源管理系统,厂房环境及楼宇自动化控制系统,以及数据中心整体解决方案等,帮助客户实现高效安全的生产和透明精益的信息化管理。

中国国际汽车制造技术与装备及材料展览会于8月11至-14日在上海召开,该活动是

由是由中国汽车工程学会主办,创办于2004年,旨在致力于打造中国汽车工业装备一站式服务的展会发展平台,也是一次全面展示汽车制造生产技术领域创新产品及先进理念的盛会。