德国化学成分牌号与DIN系统的数字材料号对照表

- 格式:docx

- 大小:17.94 KB

- 文档页数:4

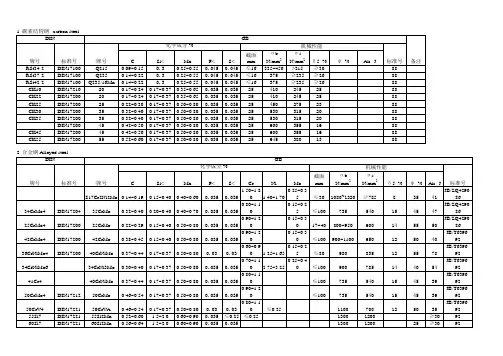

耐热铸钢和热强铸钢标准对照表:

标准内容:

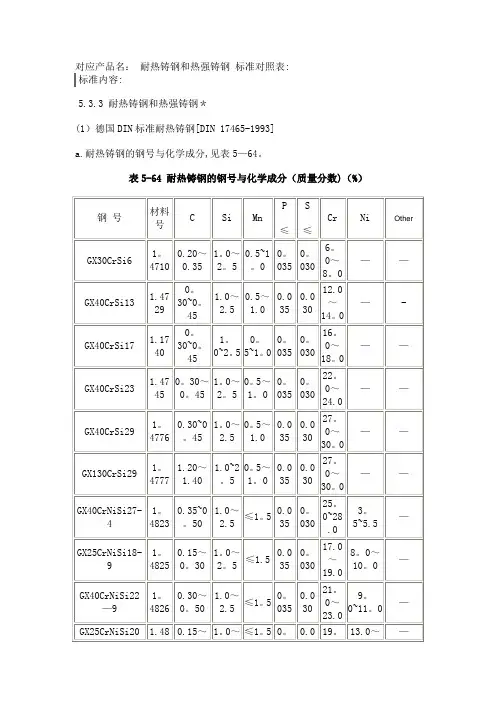

5.3.3 耐热铸钢和热强铸钢*

(1)德国DIN标准耐热铸钢[DIN 17465-1993]

a.耐热铸钢的钢号与化学成分,见表5—64。

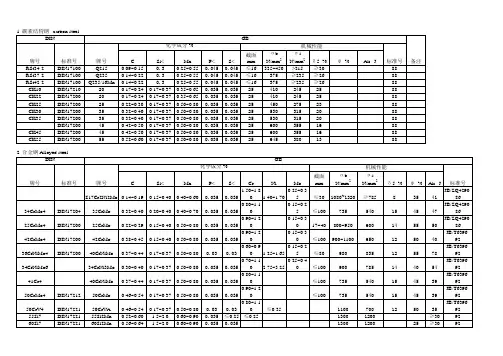

表5-64 耐热铸钢的钢号与化学成分(质量分数)(%)

b。

耐热铸钢的室温力学性能,见表5-56.

表5—56 耐热铸钢的室温力学性能

c。

耐热铸钢的高温力学性能,见表5—66。

表5-66 耐热铸钢的高温力学性能

(2)德国DIN标准铁素体热强铸钢[DIN 17245—1987]

a。

铁素体热强铸钢的钢号与化学成分,见表5—67.

表5-67 铁素体热强铸钢的钢号与化学成分(质量分数)(%)

b.铁素体热强铸钢的力学性能,见表5-68。

表5-68 铁素体热强铸钢的力学性能。

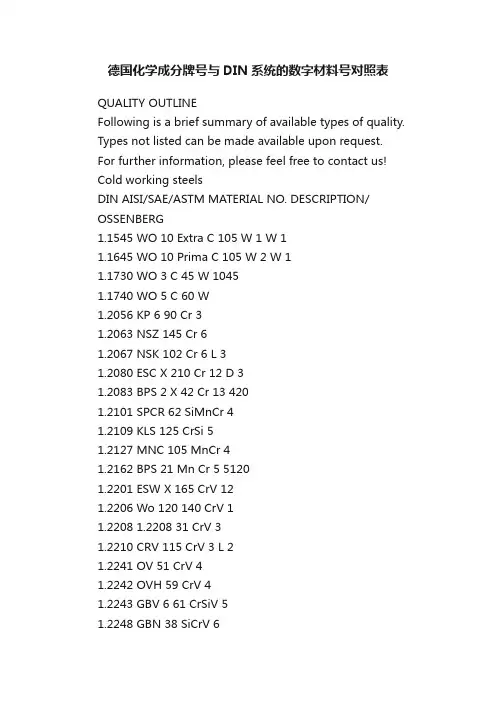

德国化学成分牌号与DIN系统的数字材料号对照表QUALITY OUTLINEFollowing is a brief summary of available types of quality. Types not listed can be made available upon request. For further information, please feel free to contact us! Cold working steelsDIN AISI/SAE/ASTM MATERIAL NO. DESCRIPTION/ OSSENBERG1.1545 WO 10 Extra C 105 W 1 W 11.1645 WO 10 Prima C 105 W 2 W 11.1730 WO 3 C 45 W 10451.1740 WO 5 C 60 W1.2056 KP 6 90 Cr 31.2063 NSZ 145 Cr 61.2067 NSK 102 Cr 6 L 31.2080 ESC X 210 Cr 12 D 31.2083 BPS 2 X 42 Cr 13 4201.2101 SPCR 62 SiMnCr 41.2109 KLS 125 CrSi 51.2127 MNC 105 MnCr 41.2162 BPS 21 Mn Cr 5 51201.2201 ESW X 165 CrV 121.2206 Wo 120 140 CrV 11.2208 1.2208 31 CrV 31.2210 CRV 115 CrV 3 L 21.2241 OV 51 CrV 41.2242 OVH 59 CrV 41.2243 GBV 6 61 CrSiV 51.2248 GBN 38 SiCrV 61.2304 1.2304 85 CrMo 71.2319 BSC X 64 CrMo 141.2341 BPS 7 X 6 CrMo 41.2353 1.2353 27 CrMoV 6 121.2357 1.2357 50 CrMoV 13 14 S 7 1.2358 1.2358 60 CrMoV 18 51.2363 EPS 52 X 100 CrMoV 51 A 2 1.2369 EPS 69 81 MoCrV 42 16 M 50 1.2376 BSC 2 X 96 CrMoV 121.2378 ESV 2 X220 CrVMo1221.2379 ESMo 2 X155 CrVMo121 D 2 1.2378.10 ESV 2 Sonder1.2410 WO 410 74 CrW 11.2419 UVW 105 WCr 61.2436 ESS X 210 CrW 12 D 61.2442 1.2442 115 W 81.2453 SS 511 X 130 W 51.2510 1.2510 100 MnCrW 4 0 1 1.2516 CW 11 120 WV 4 F 11.2519 1.2519 110 WCrV 51.2542 EPM 45 WCrV 7 S 11.2550 EKL 60 WCrV 7 S 11.2562 ERW 3 142 WV 131.2601 ESMo X 165 CrMoV12 D 2 1.2631 BSC 3 X 50 CrMoW9111.2710 1.2710 45 NiCr 61.2718 ELB 1 55 NiCr 10 6 F 51.2721 ELB 50 NiCr 131.2735 NE 35 15 NiCr 141.2764 ECNK X 19 NiCrMo 4 P 211.2766 ELB 3 35 NiCrMo 161.2767 ELB Spezial X 45 NiCrMo 4 6 F 7 1.2823 SP 70 Si 71.2826 SP 2 60 MnSiCr 4 S 41.2833 KP 100 V 1 W 2101.2835 KP Extra 95 V 41.2838 V 35 145 V 331.2842 UVW 2 90 MnCrV 8 0 21.2880 ESS Spezial X 165 CrCoMo12 1.2884 ESS 1 X 210 CrCoW 121.2900 EKL Spezial1.2901 ESSW1.2902 VSC1.2929 Pr?gnant1.2937 KRO 11.2939 He 1Hot working steels1.2323 WPS 2 48 CrMoV 671.2343 EPS 51 X 38 CrMoV 51 H 111.2344 EPS 51 V X 40 CrMoV 51 H 13 1.2345 1.2345 X 50 CrMoV 511.2360 1.2360 X 48 CrMoV 811 Chipper 1.2362 EPS 62 X 63 CrMoV 511.2365 EPS 33 X 32 CrMoV 33 H 101.2367 EPS 53 X 38 CrMoV 53 H 10 + Cr 1.2360.11 1.2360 Sonder1.2362.11 1.2362 Sonder1.2390 1.2390 X 82 CrVMo 8321.2547 EPS 25 45 WCrV 771.2564 EPS 35 X 30 WCrV 411.2567 EPS 45 X 30 WCrV 17-21.2581 EPS X 30 WCrV 93 H 211.2581.01 EPS Sonder1.2603 WPMV 45 CrMoW 581.2606 EPSW 51 X 37 CrMoW 51 H 121.2622 EPD X60 WcrMoV 941.2662 EPSK 2 X 30 WcrCoV 931.2678 1.2678 X45 CoCrWV555 H 191.2709 1.2709 X3NiCoMoTi18951.2713 WPS 55 NiCrMoV 6 L 61.2714 WPS 1 56 NiCrMoV 7 L 61.2726 1.2726 26 NiCrMoV 51.2740 WPS 3 28 NiCrMoV 101.2743 WPS 1 Ni 3 60 NiCrMoV 1241.2744 1.2744 57 NiCrMoV 771.2746 1.2746 45 NiCrMoV 166 6 F 7 + V + Mo 1.2747 1.2747 28 NiMo 171.2782 1.2782 X 16CrNiSi 2520 3141.2786 1.2786 X 13NiCrSi 3616 303301.2885 1.2885 X32CrMoCoV333 H 10 A1.2886 1.2886 X15CrCoMoV101051.2888 1.2888 X20CoCrWMo1091.2889 EPS 71 X45CoCrMoV553 H 19 A1.2906 EPDMo1.2930 1.29301.2932 1.29321.2935 1.29351.2960 1.29601.2965 1.29651.2968 VSW1.2974 1.29741.2978 1.2978High-speed working steels1.3202 K 5 S 12-1-4-5 T 151.3207 K 10 Spezial S 10-4-3-10 T 421.3211 K 3 S 12-1-2-31.3243 DMo 5 Co S 6-5-2-5 M 351.3245 1.3245 S 6-5-2-5 S M 35 + S 1.3246 1.3246 S 7-4-2-5 M 411.3247 1.3247 S 2-10-1-8 M 421.3249 1.3249 S 2-9-2-8 M 331.3255 K 5 W S 18-1-2-5 T 41.3257 K 15 S 18-1-2-151.3265 K 10 S 18-1-2-10 T 51.3302 EH 0000 S 12-1-41.3316 EH 00 S 9-1-21.3318 EH 000 S 12-1-21.3333 EHV S 3-3-21.3342 DMo 5 C SC 6-5-2 M 31.3343 DMo 5 S 6-5-2 M 21.3344 DMo 5 V S 6-5-3 M 3 Class 2 1.3346 BMo 9 S 2-9-1 M 11.3348 1.3348 S 2-9-2 M 71.3355 EH 0018 S 18-0-1 T 11.3357 EH 0018 Mo S 18-1-11.3990 K 18 S 18-12-18Stainless and acid-resistant steels1.4000 1.4000 X 6 Cr 13 410 S1.4001 RF 1 X 7 Cr 14 410 S1.4016 RFS 1 X 6 Cr 17 4301.4021 RF 3 X 20 Cr 13 4201.4024 RF 2 X 15 Cr 13 4031.4034 RF 4 X 46 Cr 13 4201.4057 RFS 4 X 17 CrNi 162 4311.4104 RFS 3 X 14 CrMoS17 430 F 1.4109 1.4109 X 70 CrMo 15 440 A 1.4110 1.4110 X 55 CrMo 141.4111 RFSH 1 X 110 CrMoV151.4112 RFSH 2 X 90 CrMoV18 440 B 1.4116 RFSH 5 X 50 CrMoV151.4120 RF 5 X 20 CrMo 131.4122 RFSH 4 X 39 CrMo 171 431 1.4125 RFSH 6 X 105 CrMo 17 440 C 1.4136 1.4136 X 70 CrMo 2921.4138 1.4138 X 120 CrMo2921.4301 SB 2 X 5 CrNi1810 3041.4305 1.4305 X 10 CrNiS189 303 1.4401 SB 5 X5CrNiMo17122 316 1.4460 SB 9 X4CrNiMoN2752 329 1.4510 RFS 2 X 3 CrTi 17 430 Ti1.4512 1.4512 X 2 CrTi 12 4091.4528 RFSH 7 X105CrCoMo1821.4535 RFSH 3 X90CrCoMoV171.4541 SB 3 X6 CrNiTi 1810 3211.4542 RFS 5 X 5CrNiCuNb164 630 1.4550 SB 4 X6CrNiNb 1810 3471.4571 SB 6 X6CrNiMoTi17122 316 Ti1.4580 SB 7 X6CrNiMoNb17122 316 CBHeat-resistant steels1.3912 Ni 36 Ni 361.3917 Ni 42 Ni 421.4713 Hi 1 X 10 CrAl 71.4721 1.4721 X 215 Cr 121.4724 Hi 2 X 10 CrAl 131.4742 Hi 3 X 10 CrAl 18 4301.4762 Hi 4 X 10 CrAl 24 4461.4821 Hi 10 X 20CrNiSi 254 3271.4828 Hi 21 X 15CrNiSi 2012 3091.4841 Hi 22 X 15 CrNiSi 2520 3101.4842 1.4842 X 12 CrNi2520 310 S1.4845 1.4845 X 12 CrNi 2521 XM 121.4864 Hi 23 X 12 NiCrSi3616 303301.4873 1.4873 X45CrNiW 1891.4878 Hi 20 X 12 CrNiTi189 3211.4885 Hi 24 X12CrNiMoNb20151.4923 1.4923 X22CrMoV 1211.4939 1.4939 X12CrNiMo 12 A 565 (XM32) Constructional and heat-treated steels1.5122 1.5122 37 Mn Si 51.5662 1.5662 X 8 Ni 9 A 333 Grade 8 1.5860 ECN 45 14 NiCr 181.5864 NV 45 35 NiCr 181.6545 1.6545 30 NiCrMo 221.6742 1.6742 20 NiCrMo1461.6926 1.6926 38NiCrMoV73 43371.6958 1.6958 26NiCrMo1461.7006 1.7006 46 Cr 21.7325 1.7325 25 MoCr 41.7335 1.7335 13 Cr Mo 44 A 336 F 12 1.7362 1.7362 12 CrMo 195 A 182-78 F 5 1.7709 1.7709 21 CrMoV 571.7711 1.7711 40 CrMoV 471.7733 1.7733 24 CrMoV551.8161 1.8161 58 CrV 4。

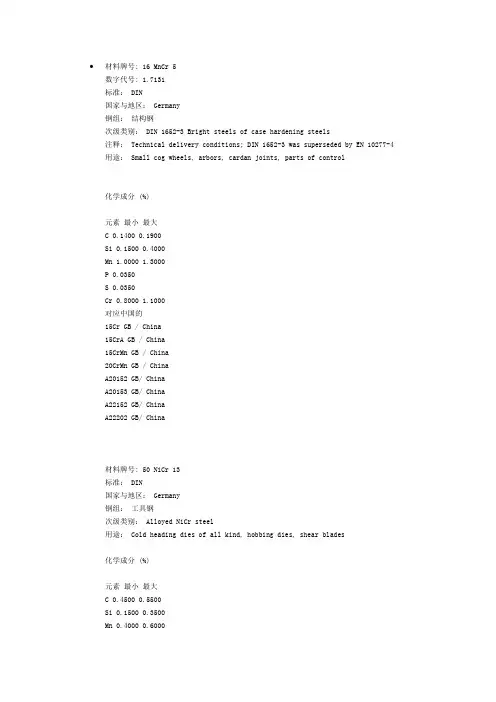

材料牌号: 16 MnCr 5数字代号: 1.7131标准: DIN国家与地区: Germany钢组:结构钢次级类别: DIN 1652-3 Bright steels of case hardening steels注释: Technical delivery conditions; DIN 1652-3 was superseded by EN 10277-4 用途: Small cog wheels, arbors, cardan joints, parts of control化学成分 (%)元素最小最大C 0.1400 0.1900Si 0.1500 0.4000Mn 1.0000 1.3000P 0.0350S 0.0350Cr 0.8000 1.1000对应中国的15Cr GB / China15CrA GB / China15CrMn GB / China20CrMn GB / ChinaA20152 GB/ ChinaA20153 GB/ ChinaA22152 GB/ ChinaA22202 GB/ China材料牌号: 50 NiCr 13标准: DIN国家与地区: Germany钢组:工具钢次级类别: Alloyed NiCr steel用途: Cold heading dies of all kind, hobbing dies, shear blades化学成分 (%)元素最小最大C 0.4500 0.5500Si 0.1500 0.3500Mn 0.4000 0.6000P 0.0350S 0.0350Cr 0.9000 1.2000Ni 3.0000 3.5000∙添加评论∙ydmouldsteel | 2010-03-19 09:20:07∙有0人认为这个回答不错 | 有0人认为这个回答没有帮助∙16MnCr5是从德国引进的钢种,相当于我国15CrMn钢,有较好的淬透性和切削性,对较大截面零件,热处理后能得到较高表面硬度和耐磨性,低温冲击韧度也较高。

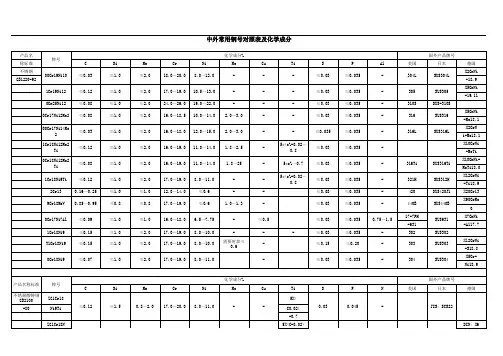

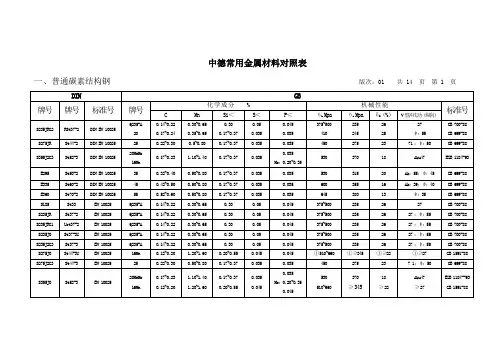

中德常用金属材料对照表

一、普通碳素结构钢版次:01 共 14 页第 1 页

一、碳素结构钢版次:01 共 14 页第 2 页

注:

(a)V:调质处理;

(b)①为调质处理时参数。

一、碳素结构钢版次:01 共 14 页第 3 页

注:

N:正火。

二、合金结构钢版次:01 共 14 页第 4 页

①截面≤100时,调质;②截面≤ 120时,调质;③截面 15时,调质;④截面25时,调质;⑤截面30时,调质。

三、灰口铸铁:球墨铸铁Grey cast iron;nodular cast irou版次:01 共 14 页第 5页

四、铸钢 Casting steel版次:01 共 14 页第 6 页

四、铸钢 Casting steel版次:01 共 14 页第 7 页

注:①正火+回火;②调质。

六、弹簧钢Spring steel 版次:01 共14 页第9 页

七、无缝钢管用碳素钢 Carbon steel for seamless steel tube版次:01 共 14 页第 10 页

八、有色金属材料 non-ferrous metal maerial 版次:01 共 14 页第11 页

八、有色金属材料 non-ferrous metal maerial版次:01 共 14 页第13 页

注:S—砂型铸造;J—金属型铸造;Li—离心铸造;La—连续铸造

九、轴承钢 Bearing Steel 版次:01 共 14 页第 14 页。

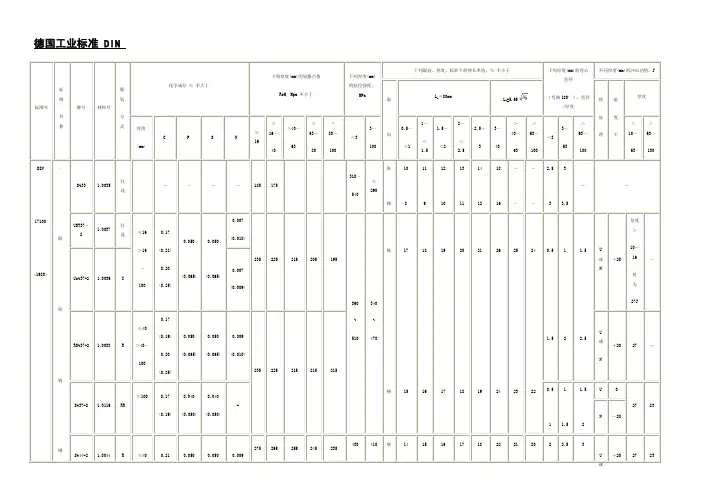

德国工业标准 DIN标准号标准名称牌号材料号脱氧方式化学成分%不大于下列厚度(mm)的屈服点值ReH, Mpa 不小于下列厚度(mm)的抗拉强度,MPa下列取向、厚度、标距下的伸长率值,%不小于下列厚度(mm)的弯心直径(弯曲180°),直径/厚度不同厚度(mm)的冲击功值,J取向L0=80mmL0=5.65热处理温度℃厚度厚度(mm)C P S N≤16>16~40>40~63>63~80>80~100<33~1000.5~<11~<1.51.5~<22~<2.52.5~33~40>40~63>63~100<33~63>63~100>10~63>63~100DIN 17100 (1980)一般结构St33 1.0035任选----185175310~540≥290纵横1081191210131114121816----2.5333.5--UST37-21.0037任选≤16>16~1000.17(0.21)0.20(0.25)0.050(0.065)0.050(0.065)0.007(0.010)235225215205195360~510340~470纵横171518161917201821192624252324220.51.5121.52.5U或N+20厚度>10~16时为27J-Ust37-2 1.0036U0.007(0.009)RSt37-2 1.0038R≤40>40~1000.17(0.19)0.20(0.25)0.050(0.065)0.050(0.065)0.009(0.010)235225215215215U或N+2027-St37-2 1.0116RR≤1000.17(0.19)0.040(0.050)0.040(0.050)-0.5111.51.52U02723N-20 St44-2 1.0044R≤400.21 0.050 0.050 0.009275265255245235430 410 纵14 15 16 17 18 22 21 20 2 2.5 3 U或+202723备注:1.钢牌号后的数字表示质量等级,相对等级2而言,等级3的钢必须满足脆性断裂不敏感性的较高要求,它表现在冲击韧性试验温度上。

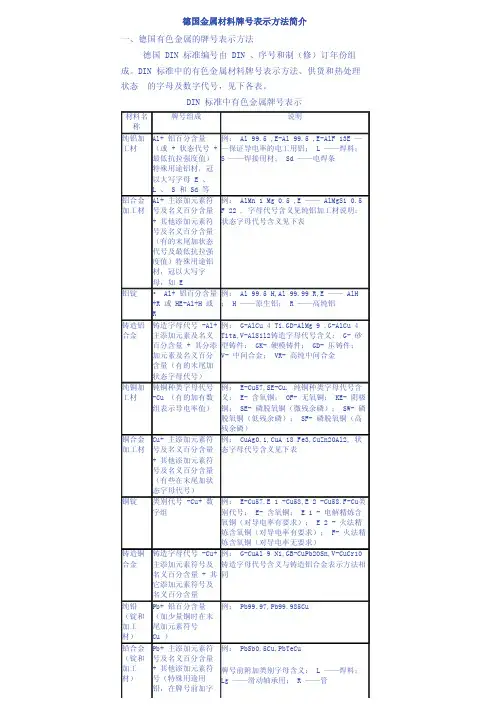

德国金属材料牌号表示方法简介--2二、德国黑色金属的牌号表示方法1.德国(DIN)钢铁牌事情表示方法简介1.1 德国钢铁牌号表示方法概述第二次世界大战后,一道柏林墙,将德国分为东德和西德两个国家标准代号分别为TG L 和DI N 。

由于TG L 标准中钢铁牌号的表示方法和DI N 标准中钢铁牌号表示方法相同,故统一后的德国仍以DI N 为德国工业标准的代号。

D I N (D EU TS CHE I nd us tr ia N or m )是德国工业标准的代号。

D I N 17006 系统标准独有铸钢和铸铁牌号表示方法。

近年德国对非合金钢牌号的表示方法采用欧洲标准。

其牌号S××× ,S 表示钢,×××表增屈服点最低值(Mp a ),有时加后缀符号用来表示质量等级或供货状态。

根据钢材直径或厚度不同,允许对同一牌号用钢的碳含量进行调整。

另一种是DI N 17007 系统标准。

它是用7 位数字组合成材料号,一般情况下用 5 位数字表示,与牌号可以并用符号(代号)为W-Nr 。

如42Cr Mo4 为牌号, 1.7725 为材料号1.2 DI N17006 系统钢铁牌号表示方法1.2.1各种符号和数字的含义(1)各种会号的含义,各种符号的含义见表1-24。

表1-24各种符号及含义表中一个符号有两种含义时,应视符号在牌号中的位置确定其含义。

(2)合金钢中合金元素含量的表求方法用合金元素平均含量乘以表1-25中的系数表示金元素含量值。

表1-25合金元素的系数合金元素含量≤5% 时,用上表系数相乘,合金元素含量>5%时,不再乘以系数,而是如数直接标出。

2.按强度等级表示钢铁牌号示例说明该牌号表示方法仅适用于非合金刚。

S235J R系D I N-EN标准中牌号,相当于旧牌号St37-2。

235 表示抗拉强度(MP a )最低值,新旧牌号对照见表1-26表1-26 新旧牌号对照示例3. 按化学成分表示钢的牌号示例说明该牌号表示方法适用于非合金钢、低合金钢和高合金钢。

德国牌号对应中国牌号的材料对照表1.紧固件对照件序号中国德国1 GB65-85 ISO12072 GB5782-86 ISO4014GB5783-863 GB5782-86 ISO4017GB5783-864 GB6170-86 ISO40325 GB2510-81 ISO43796 GB827-86 ISO87467 GB879-86 ISO87528 GB91-86 DIN949 GB95-85 DIN12510 JB/ZQ4349-86 DIN42211 GB853-88 DIN43412 GB894.1-86 DIN47113 GB893.1-86 DIN47214 JB/ZQ4446-86 DIN90615 JB/ZQ4444-86 DIN90816 GB70-85 DIN91217 GB78-85 DIN91418 GB5782-86 DIN93119 GB6184-86 DIN98020 GB812-88 DIN98121 GB11263-89 DIN102522 GB707-85 DIN102623 GB9787-88 DIN102824 GB9788-88 DIN102925 GB2510-81 DIN185026 GB8163-87 DIN244827 GB4141.29-84 DIN633628 GB1096-79 DIN688529 GB2673-86 DIN799130 GB93-87 DIN7980JB/ZQ4340-97 SN77831 JB/ZQ4454-86 DIN760332 GB7277-87 DIN3121133 GB10603-89 DIN8210134 GB704-88 EN1002935 GB119-86 SN53037 膨胀螺栓SN84538 GB858-88 DIN540639 GB70-85 ISO476240 GB71-85 ISO743441 GB91-86 ISO123442 GB825-88 DIN58043 JB/ZQ4444-86 SN8692.材料对照件(1)有色铸件序号中国材料德国材料1 ZCuSn10Pb11 GZ-CuPb10Sn2 ZCuAL10Fe3 G-Cu AL10NiZQAL9-4-4-23 CuZn8或ZQAL9-4 GZ-Cu Sn12Ni4 ZCuSn10Pb1 GC-Cu Sn12ZQSn10-55 ZQSn6-6-3 GZ-Cu Sn7ZnPbZQSn10-56 ZQSn10-5 HCuSn86.13/8-27ZHAL63-6-3-2 G-Cu Zn35AL1G-Cu Zn34AL2GZ-Cu Zn35AL1GZ-Cu Zn34AL28 紫铜垫Nebar9 L4 ALMg3F2310 H62或H63 MS6311 耐油橡胶NP81512 MC尼龙PA6(2)不锈钢序号中国材料德国材料1 1Cr18Ni9Ti X10CrNiTi1892 0Cr19Ni9 X5CrNi1893 2Cr13 X20Cr135 0Cr17Ni7AL X7NiAL177(3)铸铁序号中国材料德国材料1 HT100 GG-102 HT150 GG-153 HT200 GG-204 HT250 GG-255 HT300 GG-306 HT350 GG-35(4)球铁序号中国材料德国材料1 QT100-18 GGG-402 QT450-10 GGG-453 QT500-7 GGG-504 QT600-3 GGG-605 QT700-7 GGG-706 QT800-2 GGG-80(5)合金结构钢序号中国材料德国材料1 35SiMn 30Mo5V2 42CrMo 42CrMo4V42MnMoV3 50CrMo 50CrMo4V4 34CrNiMo 34CrNiMo6V37SiMn2MoV5 34CrNi3Mo 30CrNiMo8V30CrMn2MoB6 34CrNi3Mo30CrMoV9V25Cr2MoV32CrMnMo7 20CrMnTi 16MnCr58 20CrMnTi 15CrNi69 35SiMn 30Mn5V10 40CrNi 40CrNi611 40CrNiMoA 36NiCrMo412 20CrMo5 20CrMnMo13 20CrMnTi 20MnCr514 65Mn FSt55Si7(6)碳素结构钢序号中国材料德国材料1 Q215 RSt34-22 Q215 USt34-23 Q235或20 RSt37-24 Q235 USt37-25 25或20 St44-26 16M St52-27 35 St50-2 E295 E293 St50 St50-2SH8 45 St60-2 E3359 55 St70-2 E36010 20 St33或St3511 20 St35.8或St35.4NBK或St3512 45 St50KG E33513 45 St45K C45K14 20 C22N(正火)15 35 C35N(正火)16 45 C45N(正火)17 55 C60N(正火)18 45 C45V(调质)19 42CrMo C45V(调质)20 Q235 S235JRG221 16Mn或35 S335J2G2或S335J2G322 65Mn PStS5Si723 20 E295GC24 Q235 St3725 35 St50或St50-2SH26 42CrMo CK45V27 16Mn St52-3(7)弹簧钢序号中国材料德国材料1 65 CK672 85 CK853 55Si2Mn 55Si74 60Si2Mn 66Si75 50CrVA 50CrV46 65Mn FSt55Si7(8)合金工具钢序号中国材料德国材料1 9SiCr 90CrSi52 Cr2 100Cr63 4CrW2Si 35WCrV74 6CrW2Si 60WCrV75 4Cr5MoSiV1 X40CrMoV516 3Cr2W8V X30WCrV937(9)铸钢序号中国材料德国材料1 ZG200-400 GS-252 ZG230-450 GS-38.33 ZG230-450 GS-454 ZG270-500 GS-52.35 ZG310-570 GS-60.3或GS-606 ZG20SiMn GS-C25N(正火)7 ZG20SiMn GS-20Mn5V(调质)8 ZG35SiMn GS-35Mn5V(调质)9 ZG35CrMo GS-25CrMo4V(调质)10 ZG35CrMo GS-42CrMo4V(调质)1.4301——0Cr18Ni91.5415——1Cr18Ni91.0038——Q2351.4401——0Cr17Ni12Mo21.4571——0Cr18Ni12Mo2TiAMPCO18——ZQAL9—41. 8715___60Si2MnHGW2082——PFCC1E295GC+C——35。

∙ 本标准已被德国采用为DIN EN 10025取代了DIN 17100-(10)拉伸性能符号为:Re——屈服强度(点2. 表中钢的类别符号含义为:BS=基本钢(Base Steel);QS=质量钢(Quality Steel)。

3. 计算重量用密度7.85kg/dm 3。

∙ 本标准尚有多项可由供需双方商定的条款,例如碳当量FF=完全镇静钢,它含有足以将游离氮全部固定的固氮元素(例如含0.020%Al)。

牌号材料号脱氧标准号标准方法名称4. 诸钢级的J2G3及K2G3牌号产品的供货状态应为正火状态或正火轧制状态,其余由制造厂选择(对钢板产品)。

5. 碳当量计算公式为:。

Rm 下列厚度170~340440镇静≤0.08DD12DD13≥25≥28≥23380≥312. 成品分析允许偏C +0.02%化 学 成 分 (熔炼分析) %下列厚度(mm)的不大于MPaCMnp S 其他 1.5~<21. 除非订货时有规定,生产厂可选用脱氧剂如Ti,B等。

2~8L 0=80mm t:1.5~<2由生产厂选择≤0.12≤0.60≤0.045≤0.045S +0.005%170~360冷成型用热连轧低碳薄钢板及钢带DD11 1.0321.0335EN 10111-19981.0398镇静≤0.10≤0.45≤0.035≤0.035≤0.40≤0.030≤0.030170~330420170~340170~Mn +0.05%P +0.005%170~310170~170~400DD14 1.0389镇静≤0.08≤0.35≤0.025≤0.025不小于(厚度≥3~>2.53~>40>63>10~150mm)≤100~340~63~100290~101418--51081216--34017212625244701519242322-20-20410~14182221205601216201918-20-20490~14182221206301216201918-20-20-20-20470~12162019186101014181716590~812161514710610141312670~48111098303710981718151614172760~51014151517161197131210861413119715--宽度≥600mm的钢板、带也可用横向试样。