《英文专利文献翻译》PPT课件

- 格式:ppt

- 大小:3.65 MB

- 文档页数:40

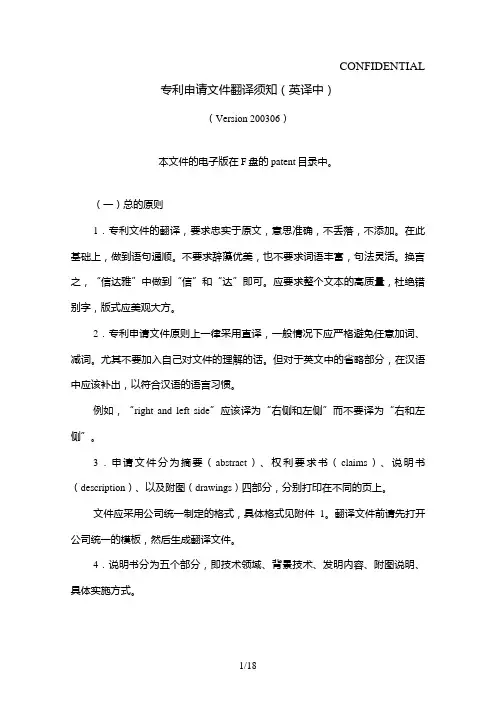

CONFIDENTIAL专利申请文件翻译须知(英译中)(Version 200306)本文件的电子版在F盘的patent目录中。

(一)总的原则1.专利文件的翻译,要求忠实于原文,意思准确,不丢落,不添加。

在此基础上,做到语句通顺。

不要求辞藻优美,也不要求词语丰富,句法灵活。

换言之,“信达雅”中做到“信”和“达”即可。

应要求整个文本的高质量,杜绝错别字,版式应美观大方。

2.专利申请文件原则上一律采用直译,一般情况下应严格避免任意加词、减词。

尤其不要加入自己对文件的理解的话。

但对于英文中的省略部分,在汉语中应该补出,以符合汉语的语言习惯。

例如,“right and left side”应该译为“右侧和左侧”而不要译为“右和左侧”。

3.申请文件分为摘要(abstract)、权利要求书(claims)、说明书(description)、以及附图(drawings)四部分,分别打印在不同的页上。

文件应采用公司统一制定的格式,具体格式见附件1。

翻译文件前请先打开公司统一的模板,然后生成翻译文件。

4.说明书分为五个部分,即技术领域、背景技术、发明内容、附图说明、具体实施方式。

5.根据专利文件的特点,翻译的次序应该如下,先是背景技术,然后是具体实施方式,然后是技术领域,然后是权利要求部分,再然后是发明内容、摘要和附图说明。

发明内容、摘要和附图说明的内容常常是与其他部分重复的,请采用先拷贝,然后再核对的方式,这样效率高,而且错误少。

6.翻译说明书的时候,一定要对照附图。

这样对于理解发明是非常有帮助的。

抛开附图,只看说明书就进行翻译是要绝对避免的。

7.由于专利文件常常涉及多学科的知识,本所同仁在碰到不熟悉的问题时,要虚心向他人请教,在别人请教问题时,应该耐心作答。

8.在工作中碰到不熟悉的单词、句法及其它问题要勤查字典。

电子字典不可过分依赖,尤其是金山词霸只可以参考使用,因为其中的错误实在太多,而且翻译不准确的地方也比比皆是。

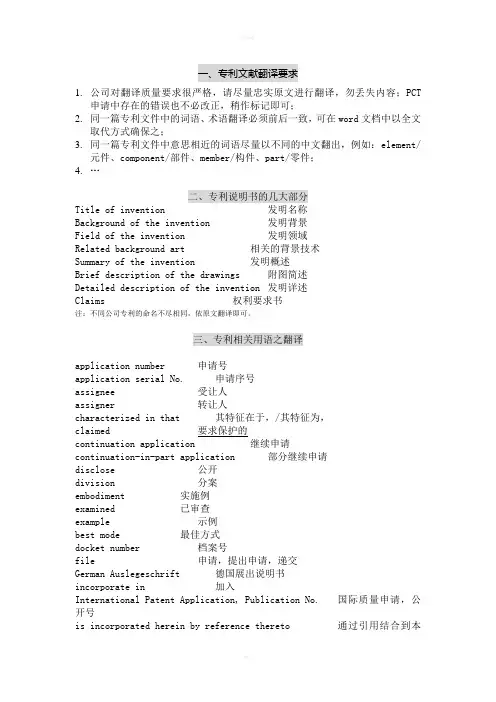

一、专利文献翻译要求1.公司对翻译质量要求很严格,请尽量忠实原文进行翻译,勿丢失内容;PCT申请中存在的错误也不必改正,稍作标记即可;2.同一篇专利文件中的词语、术语翻译必须前后一致,可在word文档中以全文取代方式确保之;3.同一篇专利文件中意思相近的词语尽量以不同的中文翻出,例如:element/元件、component/部件、member/构件、part/零件;4.…二、专利说明书的几大部分Title of invention 发明名称Background of the invention 发明背景Field of the invention 发明领域Related background art 相关的背景技术Summary of the invention 发明概述Brief description of the drawings 附图简述Detailed description of the invention 发明详述Claims 权利要求书注:不同公司专利的命名不尽相同,依原文翻译即可。

三、专利相关用语之翻译application number 申请号application serial No. 申请序号assignee 受让人assigner 转让人characterized in that 其特征在于,/其特征为,claimed 要求保护的continuation application 继续申请continuation-in-part application 部分继续申请disclose 公开division 分案embodiment 实施例examined 已审查example 示例best mode 最佳方式docket number 档案号file 申请,提出申请,递交German Auslegeschrift 德国展出说明书incorporate in 加入International Patent Application, Publication No. 国际质量申请,公开号is incorporated herein by reference thereto 通过引用结合到本文中issue 颁发/公告Laidopen (日本专利)公开more particularly, 尤其/更详细地讲,more specifically, 更准确地说,更具体地讲parent application 原申请PCT Publication PCT说明书preamble 前序部分preferably...more preferably...most preferably 优选...更优选...最优选preferable 这个词不要翻成最好,因为优选还有一个递进的问题:优选,更优选,还更优选,特别优选,最优选,optional 任选的optionally 任选,意思是可以选择这样做也可以选择不这样做;preferred embodiment (example) 优选实施实施例prior art 现有技术provisional disclosure 临时说明书Publication (日本专利)公告published application 公开申请said 所述known as 公知的selected from the group of consisting of 选自...specificaly, (插入语)具体地说,state of the art 现有技术水平subject 题述sub-license 分许可证the art 本领域the persons skilled in the art 本领域技术人员trade name 厂商名称unexamined 未审查Utility Model 实用新型wherein 其中a aspect of the present invention 本发明的一个方面a further aspect of the present invention 本发明的另一个方面it is understood 应当理解的是thus obtained 这样得到的in cases that 在…的情况下for the purpose of the present invention 就本发明的目的而言as described in 如…中所述as disclosed in 如…中所公开filed December 23,2002 2002年12月23日提交can be selected from the group consisting of 可选自the term “”as used herein 本文所用的术语“”refers to 是指comprised of 由….组成International Publication WO 国际专利说明书WOJAPENESE LAID-OPEN PATENT PUBLICATION 日本公开特许公报title to patent 专利所有权under 35USC§119(e)根据美国法典第35条119 (e)款。

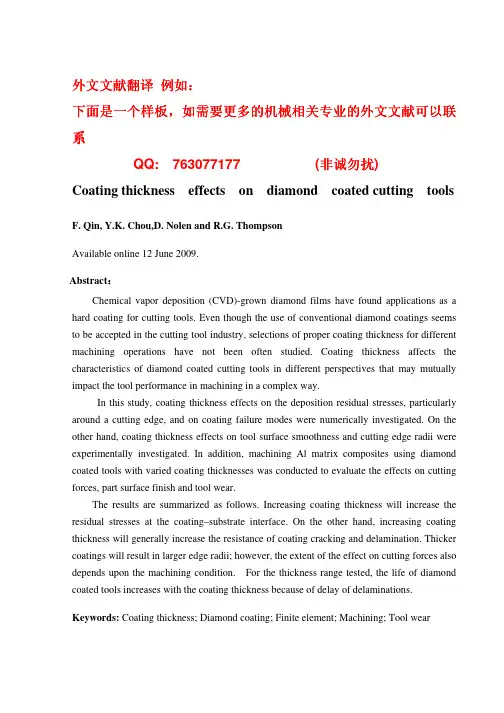

外文文献翻译 例如例如::下面是一个样板下面是一个样板,,如需要更多的机械相关专业的外文文献可以联系QQ: 763077177 (非诚勿扰) Coating thickness effects on diamond coated cutting tools F. Qin, Y.K. Chou,D. Nolen and R.G. ThompsonAvailable online 12 June 2009. Abstract :Chemical vapor deposition (CVD)-grown diamond films have found applications as a hard coating for cutting tools. Even though the use of conventional diamond coatings seems to be accepted in the cutting tool industry, selections of proper coating thickness for different machining operations have not been often studied. Coating thickness affects the characteristics of diamond coated cutting tools in different perspectives that may mutually impact the tool performance in machining in a complex way.In this study, coating thickness effects on the deposition residual stresses, particularly around a cutting edge, and on coating failure modes were numerically investigated. On the other hand, coating thickness effects on tool surface smoothness and cutting edge radii were experimentally investigated. In addition, machining Al matrix composites using diamond coated tools with varied coating thicknesses was conducted to evaluate the effects on cutting forces, part surface finish and tool wear.The results are summarized as follows. Increasing coating thickness will increase the residual stresses at the coating–substrate interface. On the other hand, increasing coating thickness will generally increase the resistance of coating cracking and delamination. Thicker coatings will result in larger edge radii; however, the extent of the effect on cutting forces also depends upon the machining condition. For the thickness range tested, the life of diamond coated tools increases with the coating thickness because of delay of delaminations. Keywords: Coating thickness; Diamond coating; Finite element; Machining; Tool wear1. IntroductionDiamond coatings produced by chemical vapor deposition (CVD) technologies have been increasingly explored for cutting tool applications. Diamond coated tools have great potential in various machining applications and an advantage in fabrications of cutting tools with complex geometry such as drills. Increased usages of lightweight high-strength components have also resulted in significant interests in diamond coating tools. Hot-filament CVD is one of common processes of diamond coatings and diamond films as thick as 50 µm have been deposited on various materials including cobalt-cemented tungsten carbide (WC-Co) . There have also been different CVD technologies, e.g., microwave plasma assisted CVD , developed to enhance the deposition process as well as the film quality too. However, despite the superior tribological and mechanical properties, the practical applications of diamond coated tools are still limited.Coating thickness is one of the most important attributes to the coating system performance. Coating thickness effects on tribological performance have been widely studied. In general, thicker coatings exhibited better scratch/wear resistance performance than thinner ones due to their better load-carrying capacity. However, there are also reports that claim otherwise and . For example, Dorner et al. discovered, that the thickness of diamond-like-coating (DLC), in a range of 0.7–3.5 µm, does not influence the wear resistance of the DLC–Ti6Al4V . For cutting tool applications, however, coating thickness may have a more complicated role since its effects may be augmented around the cutting edge. Coating thickness effects on diamond coated tools are not frequently reported. Kanda et al. conducted cutting tests using diamond-coated tooling . The author claimed that the increased film thickness is generally favorable to tool life. However, thicker films will result in the decrease in the transverse rupture strength that greatly impacts the performance in high speed or interrupted machining. In addition, higher cutting forces were observed for the tools with increased diamond coating thickness due to the increased cutting edge radius. Quadrini et al. studied diamond coated small mills for dental applications . The authors tested different coating thickness and noted that thick coatings induce high cutting forces due to increased coating surface roughness and enlarged edge rounding. Such effects may contribute to the tool failure in milling ceramic materials. The authors further indicated tools with thin coatings results in optimal cutting of polymer matrix composite . Further, Torres et al. studied diamondcoated micro-endmills with two levels of coating thickness . The authors also indicated that the thinner coating can further reduce cutting forces which are attributed to the decrease in the frictional force and adhesion.Coating thickness effects of different coating-material tools have also been studied. For single layer systems, an optimal coating thickness may exist for machining performance. For example, Tuffy et al. reported that an optimal coating thickness of TiN by PVD technology exists for specific machining conditions . Based on testing results, for a range from 1.75 to 7.5 µm TiN coating, thickness of 3.5 µm exhibit the best turning performance. In a separate study, Malik et al. also suggested that there is an optimal thickness of TiN coating on HSS cutting tools when machining free cutting steels . However, for multilayer coating systems, no such an optimum coating thickness exists for machining performance .The objective of this study was to experimentally investigate coating thickness effects of diamond coated tools on machining performance — tool wear and cutting forces. Diamond coated tools were fabricated, by microwave plasma assisted CVD, with different coating thicknesses. The diamond coated tools were examined in morphology and edge radii by white-light interferometry. The diamond coated tools were then evaluated by machining aluminum matrix composite in dry. In addition, deposition thermal residual stresses and critical load for coating failures that affect the performance of diamond coated tools were analytically examined.2. Experimental investigationThe substrates used for diamond coating experiments, square-shaped inserts (SPG422), were fine-grain WC with 6 wt.% cobalt. The edge radius and surface textures of cutting inserts prior to coating was measured by a white-light interferometer, NT1100 from Veeco Metrology.Prior to the deposition, chemical etching treatment was conducted on inserts to remove the surface cobalt and roughen substrate surface. Moreover, all tool inserts were ultrasonically vibrated in diamond/water slurry to increase the nucleation density. For the coating process, diamond films were deposited using a high-power microwave plasma-assisted CVD process.A gas mixture of methane in hydrogen, 750–1000 sccm with 4.4–7.3% of methane/hydrogen ratio, was used as the feedstock gas. Nitrogen gas, 2.75–5.5 sccm, was inserted to obtain nanostructures by preventing columnar growth. The pressure was about 30–55 Torr and the substrate temperature was about 685–830 °C. A forward power of 4.5–5.0 kW with a low deposition rate obtained a thin coating; a greater forward power of 8.0–8.5 kW with a highdeposition rate obtained thick coatings, two thicknesses by varying deposition time. The coated inserts were further inspected by the interferometer.A computer numerical control lathe, Hardinge Cobra 42, was used to perform machining experiments, outer diameter turning, to evaluate the tool wear of diamond coated tools. With the tool holder used, the diamond coated cutting inserts formed a 0° rake angle, 11° relief angle, and 75° lead angle. The workpieces were round bars made of A359/SiC-20p composite. The machining conditions used were 4 m/s cutting speed, 0.15 mm/rev feed, 1 mm depth of cut and no coolant was applied. The selection of machining parameters was based upon previous experiences. For each coating thickness, two tests were repeated. During machining testing, the cutting inserts were periodically inspected by optical microscopy to measure the flank wear-land size. Worn tools after testing were also examined by scanning electron microscopy (SEM). In addition, cutting forces were monitored during machining using a Kistler dynamometer.5. ConclusionsIn this study, the coating thickness effects on diamond coated cutting tools were studied from different perspectives. Deposition residual stresses in the tool due to thermal mismatch were investigated by FE simulations and coating thickness effects on the interface stresses were quantified. In addition, indentation simulations of a diamond coated WC substrate with the interface modeled by the cohesive zone were applied to analyze the coating system failures. Moreover, diamond coated tools with different thicknesses were fabricated and experimentally investigated on surface morphology, edge rounding, as well as tool wear and cutting forces in machining. The major results are summarized as follows.(1) Increase of coating thickness significantly increases the interface residual stresses, though little change in bulk surface stresses.(2) For thick coatings, the critical load for coating failure decreases with increasing coating thickness. However, such a trend is opposite for thin coatings, for which radial cracking is the coating failure mode. Moreover, thicker coatings have greater delamination resistance.(3) In addition, increasing the coating thickness will increase the edge radius. However, for the coating thickness range studied, 4–29 µm, and with the large feed used, cutting forces were affected only marginally.(4) Despite of greater interface residual stresses, increasing the diamond coating thickness, for the range studied, seem to increase tool life by delay of coating delaminations.AcknowledgementsThis research is supported by National Science Foundation, Grant No.: CMMI 0728228. P. Lu provided assistance in some analyses.金刚石涂层刀具的涂层厚度的影响作者:F. Qin, Y.K. Chou,D. Nolen and R.G. Thompson发表日期:2009摘要:化学气相沉积法(CVD),金刚石薄膜的发现,作为涂层刀具的应用。

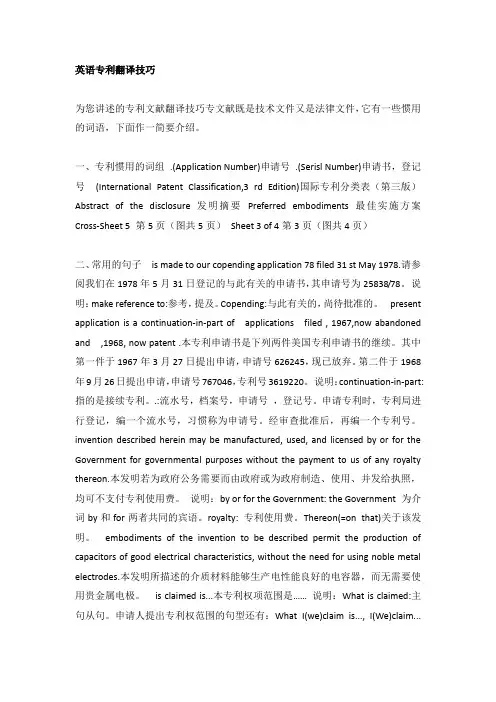

英语专利翻译技巧为您讲述的专利文献翻译技巧专文献既是技术文件又是法律文件,它有一些惯用的词语,下面作一简要介绍。

一、专利惯用的词组.(Application Number)申请号.(Serisl Number)申请书,登记号(International Patent Classification,3 rd Edition)国际专利分类表(第三版)Abstract of the disclosure发明摘要Preferred embodiments最佳实施方案Cross-Sheet 5 第5页(图共5页)Sheet 3 of 4第3页(图共4页)二、常用的句子is made to our copending application 78 filed 31 st May 1978.请参阅我们在1978年5月31日登记的与此有关的申请书,其申请号为25838/78。

说明:make reference to:参考,提及。

Copending:与此有关的,尚待批准的。

present application is a continuation-in-part of applications filed , 1967,now abandoned and ,1968, now patent .本专利申请书是下列两件美国专利申请书的继续。

其中第一件于1967年3月27日提出申请,申请号626245,现已放弃。

第二件于1968年9月26日提出申请,申请号767046,专利号3619220。

说明:continuation-in-part:指的是接续专利。

.:流水号,档案号,申请号,登记号。

申请专利时,专利局进行登记,编一个流水号,习惯称为申请号。

经审查批准后,再编一个专利号。

invention described herein may be manufactured, used, and licensed by or for the Government for governmental purposes without the payment to us of any royalty thereon.本发明若为政府公务需要而由政府或为政府制造、使用、并发给执照,均可不支付专利使用费。

如何做好英文专利翻译Ⅰ.总则1. 专利说明书的中译,应特别注重"信"与"达"两大要求,即译文必须与原文内容完全相符,不得有任何出入或节略。

但中文必须通顺易读,使任何人不必参阅原文,即能了解中文内容。

2. 一件专利申请会包含「说明书摘要」、「摘要附图」、「权利要求书」、「说明书」及「说明书附图」,除摘要附图不需编页码外,其它个部分均需独立编页,亦即每一部份均需从「1」开始编页码(见附件一)。

3. PCT案件之摘要附图为首页之附图,CN案件本所则会另有指示,「摘要附图」不需加上页码,同时必须将「图X」之字样去除。

4. 在「说明书附图」中,请勿以「1/4」之页码编排而应在下方加阿拉伯数字自然排序,就如同「说明书」页码一样,但是附图中之「图1」,「图2」...则仍须保留。

5. 专利申请中的说明书应依以下各部分编译并写明各部分的标题(发明名称除外),每一部份之标题均需完全与下列标题完全相同:3.1 发明名称(Title)3.2 技术领域(Technical Field):要求保护的技术方案所属的技术领域;3.3 背景技术(Background Art):对要求保护的技术方案的理解、检索、审查有用的背景技术;3.4 发明内容(Contents of the invention):要求保护的技术方案所要解决的技术问题以及解决该技术问题所用的技术方案,及对照现有技术所得的有益效果;3.5 附图说明(Description of figures):各幅附图的简略说明;3.6 具体实施方式(Mode of Carrying out the Invention):要求保护的技术方案的优选方式得详细说明,其中可能包含实施例或对照附图的说明。

6. 书写规则:4.1 规格:用纸规格为297毫米×210毫米(A4);4.2 页边:译文的顶部(有标题的,从标题上沿至页边)应当留有25毫米空白;左侧应当留有25毫米空白;右侧应当留有15毫米空白,底部从页码下沿至页边应当留有15毫米空白;4.3 字体:应当使用宋体、仿宋体或者楷体,不应当使用草体及其它字体;4.4 字高:应当在3.5毫米至4.5毫米之间;行距应当在2.5毫米至3.5毫米之间。

一、专利惯用的词组Appl.No.(Application Number)申请号Ser.No.(Serisl Number)申请书,登记号Int.Cl.3 (International Patent Classification,3 rd Edition)国际专利分类表(第三版)Abstract of the disclosure 发明摘要Preferred embodiments 最佳实施方案Cross-Sheet 5 第5 页(图共5 页)Sheet 3 of 4 第3 页(图共4 页)二、常用的句子1.Reference is made to our copending application No.25838/78 filed 31 st May 1978.请参阅我们在1978 年5月31 日登记的与此有关的申请书,其申请号为25838/78。

说明:make reference to:参考,提及。

Copendi ng:与此有关的,尚待批准的。

2.The present application is a continuation-in-part ofU.S.patent applications Ser.No.626245, filed Mar.27, 1967,now abandoned and Ser.No.767046,filed Sept.26,1968, now patent No.3619220.本专利申请书是下列两件美国专利申请书的继续。

其中第一件于1967 年3 月27 日提出申请,申请号626245,现已放弃。

第二件于1968 年9 月26 日提出申请,申请号7 67046,专利号3619220。

说明:continuation-in-part:指的是接续专利。

Ser.No.:流水号,档案号,申请号,登记号。

申请专利时,专利局进行登记,编一个流水号,习惯称为申请号。

经审查批准后,再编一个专利号。

如何做好英文专利翻译Ⅰ.总则1. 专利说明书的中译,应特别注重"信"与"达"两大要求,即译文必须与原文内容完全相符,不得有任何出入或节略。

但中文必须通顺易读,使任何人不必参阅原文,即能了解中文内容。

2. 一件专利申请会包含「说明书摘要」、「摘要附图」、「权利要求书」、「说明书」及「说明书附图」,除摘要附图不需编页码外,其它个部分均需独立编页,亦即每一部份均需从「1」开始编页码(见附件一)。

3. PCT案件之摘要附图为首页之附图,CN案件本所则会另有指示,「摘要附图」不需加上页码,同时必须将「图X」之字样去除。

4. 在「说明书附图」中,请勿以「1/4」之页码编排而应在下方加阿拉伯数字自然排序,就如同「说明书」页码一样,但是附图中之「图1」,「图2」...则仍须保留。

5. 专利申请中的说明书应依以下各部分编译并写明各部分的标题(发明名称除外),每一部份之标题均需完全与下列标题完全相同:3.1 发明名称(Title)3.2 技术领域(Technical Field):要求保护的技术方案所属的技术领域;3.3 背景技术(Background Art):对要求保护的技术方案的理解、检索、审查有用的背景技术;3.4 发明内容(Contents of the invention):要求保护的技术方案所要解决的技术问题以及解决该技术问题所用的技术方案,及对照现有技术所得的有益效果;3.5 附图说明(Description of figures):各幅附图的简略说明;3.6 具体实施方式(Mode of Carrying out the Invention):要求保护的技术方案的优选方式得详细说明,其中可能包含实施例或对照附图的说明。

6. 书写规则:4.1 规格:用纸规格为297毫米×210毫米(A4);4.2 页边:译文的顶部(有标题的,从标题上沿至页边)应当留有25毫米空白;左侧应当留有25毫米空白;右侧应当留有15毫米空白,底部从页码下沿至页边应当留有15毫米空白;4.3 字体:应当使用宋体、仿宋体或者楷体,不应当使用草体及其它字体;4.4 字高:应当在3.5毫米至4.5毫米之间;行距应当在2.5毫米至3.5毫米之间。

Patent law of the People's Republic of ChinaAdopted at the 4th Session of the Standing Committee of the Sixth National People's Congress on March 12, 1984.Amended by the Decision Regarding the Revision of the Patent Law of the People's Republic of China, adopted at the 27th Session of the Standing Committee of the Seventh National People's Congress on September4 ,1992.Amended for the second time by the Decision Regarding the Revision of the Patent Law of the People's Republic of China, adopted at the 17th Session of the Standing Committee of the Ninth National People's Congress on August 25,2000Content TablesChapter 1: General ProvisionsChapter 2: Requirements for Grant of PatentChapter 3: Application for PatentChapter 4: Examination and Approval of Application for PatentChapter 5: Duration, Cessation and Invalidation of Patent RightChapter 6: Compulsory License for Exploitation of PatentChapter 7: Protection of Patent RightChapter 8: Supplementary ProvisionsChapter 1: General ProvisionsArticle 1. This Law is enacted to protect patent rights for inventions-creations, to encourageinventions-creations, to foster the spreading and application of Inventions-creations, and to promote the development of science and technology, for meeting the needs of the construction of socialist modernization.Article 2 . In this Law, "inventions-creations" mean inventions, utility models and designs.Article 3. The Patent Administrative Organ under the State Council is responsible for the patent work nationwide, receives and examines patent applications and grants patent rights for inventions-creations that conform with the provisions of this Law.The authorities for patent work under he people's governments of provinces autonomous regions and municipalities directly under the Central Government are responsible for the patent administration work of their own administrative areas.Article 4 . Where an invention-creation for which a patent is applied relates to the security or other vital interests of the State and is required to be kept secret, the application shall be treated in accordance with the relevant prescriptions of the State.Article 5 . No patent right shall be granted for any invention-creation that is contrary to the laws of the State or social morality or that is detrimental to public interest.Article 6 . An invention-creation, made by a person in execution of the tasks of the entity to which he belongs, or made by him by mainly using the material and technical means of the entity is a service invention. For a service invention-creation, the right to apply for a patent belongs to the entity. After the application is approved, the entity shall be the patentee. For a non-service invention-creation, the right to apply for a patent belongs to the inventor or creator. After the application is approved, the inventor or creator shall be the patentee. For an invention-creation, made by a person by using the material and technical means of the entity to which he belongs, and where the entity and the inventor or creator has entered into an agreement under which there is provision on who has right to apply for a patent and to whom the patent right belongs, the provisions of the agreement shall prevail.Article 7. No entity or individual shall prevent the inventor or creator from filing an application for a patent for a non-service invention-creation.Article 8. For an invention-creation jointly made by two or more entities or individuals, or made by an entity or individual in execution of a commission for another entity or individual, the right to apply for a patent belongs, unless otherwise agreed upon, to the entity or individual which made, or to the entities or individual which jointly made, the invention-creation. After the application is approved, the entity or individual that applied for it shall be the patentee.Article 9 . Where two or more applicants file applications for patent for the identical invention- creation, the patent right shall be granted to the applicant whose application was filed first.Article 10 . The right to apply for a patent and the patent right may be assigned. Any assignment, by a Chinese entity or individual, of the right to apply for a patent, or of the patent right, to a foreigner must be approved by the competent department concerned of the State Council.Where the right to apply for a patent or the patent right is assigned, the parties must conclude a written contract and should register it with the patent administrative organ under the State Council. The patent administrative organ shall announce the registration .The assignment will come into force upon the date of registration.Article 11 . After the grant of the patent right for an invention or utility model, except as otherwise provided for in the law, no entity or individual may, without the authorization of the patentee, exploit the patent, that is, make, use, offer to sell, sell or import the patented product; or use the patented process or use, offer to sell, sell or import the product directly obtained by the patented process, for production or business purposes. After the grant of the patent right for a design, no entity or individual may, without the authorization of the patentee, exploit the design, that is, make, sell or import the product incorporating its or his patented design, for production or business purposes.Article 12 . Any entity or individual exploiting the patent of another must, except as provided for in Article 14 of this Law, conclude with the patentee a written license contract for exploitation and pay the patentee a fee for the exploitation of the patent. The licensee has no right to authorize any entity or individual, other than that referred to in the contract for exploitation, to exploit the patent.Article 13 . After the publication of the application for a patent for invention, the applicant may require the entity or individual exploiting the invention to pay an appropriate fee.Article 14 . For any patent for invention belonging to state-owned enterprises or entities, which is of great significance to national or public interests, the competent departments concerned of the State Council as well as the people's governments of provinces, autonomous regions or municipalities directly under the Central Government have the power to decide, after approved by the State Council, the said patented invention be spread and exploited within the prescribed scope and to allow designated entities to exploit it . The entities that exploit it shall, according to the prescriptions of the State , pay exploitation fees to the patentee.Any patent for inventionbelonging to a Chinese entity under collective ownership or an individual, which is of great significance to national or public interests and is in need of spreading and exploitation, may be treated alike by making reference to the provisions of the preceding paragraph.Article 15. The patentee has the right to affix a patent marking and to indicate the number of the patent on the patented product or on the packing of that product.Article 16 . The entity that is granted the patent right shall award to the inventor or creator of a service invention-creation a reward and, upon the exploitation of the patented invention-creation, shall award to the inventor or creator an appropriate remuneration based on the extent of exploitation and application and the economic benefits yielded.Article 17 . The inventor or creator has the right to be named as such in the patent document.Article 18 . Where any foreigner, foreign enterprise or other foreign organization having no habitual residence or business office in China files an application for a patent in China, the application shall be treated under this Law in accordance with any agreement concluded between the country to which the applicant belongs and China, or in accordance with any international treaty to which both countries are party, or on the basis of the principle of reciprocity.Article 19 . Where any foreigner, foreign enterprise or other foreign organization having no habitual residence or business office in China applies for a patent, or has other patent matters to attend to, in China, he or it shall appoint a patent agency designated by the patent administrative organ under the State Council to act as his or its agent. Where any Chinese entity or individual applies for a patent or has other patent matters to attend to in the country, it or he may appoint a patent agency to act as its or his agent. The patent agencies should abide by the laws and administrative regulations and should deal with patent applications and other patent matters according to the commissions of the clients. Except for those applications that have been p ublished or announced, the agencies should bear the responsibility for keeping confidential the content of its clients' inventions-creations. The administrative regulations for administering the patent agencies shall be formulated by the State Council.Article 20 . Where any Chinese entity or individual intends to file an application in a foreign country for a patent for its or his domestic invention-creation, it or he shall file first an application for patent with the patentadministrative organ under the State Council and, shall appoint a patent agency designated by the said organ to act as its or his agent, and shall abide by the prescriptions of Article 4 in this law. Any Chinese entity of individual may, according to the international treaties concerned to which China is a party, file an international application for patent for its or his invention-creation. The applicant for the international application should abide by the provisions of the preceding paragraph . The patent administrative organ under the State Council shall handle the international application for patent in line with the international treaty to which China is a party, this law and the administrative regulations concerned made by the State Council.Article 21 . The patent administrative organ under the State Council and the patent reexamination board subordinated to it shall handle patent applications and requests concerned according to law and in the spirit of objectiveness, justice, precision and punctuality. Until the publication or announcement of the application for a patent, staff members of the patent administrative organ and other personnel involved have the duty to keep its content confidential.Chapter 2: Requirements for Grant of PatentArticle 22 . Any invention or utility model for which patent right may be granted must possess novelty, inventiveness and practical applicability. Novelty means that, before the date of filing, no identical invention or utility model has been publicly disclosed in publications in the country or abroad or has been publicly used or made known to the public by any other means in the country, nor has any other person filed previously with the patent administrative organ under the State Council an application which described the identical invention or utility model and was published after the said date of filing. Inventiveness means that, as compared with the technology existing before the date of filing the invention has prominent substantive features and represents a notable progress and that the utility model has substantive features and represents progress. Practical applicability means that the invention or utility model can be made or used and can produce effective results.Article 23 . Any design for which patent right may be granted must not be identical with or similar to any design which, before the date of filing, has been publicly disclosed in publications in the country or abroad or has been publicly used in the country, and must not collide with any legal prior rights obtained by any other person.Article 24. An invention-creation for which a patent is applied for does not lose its novelty where, within six months before the date of filing, one of the following events occurred:Chapter 3: Application for PatentArticle 26 . Where an application for a patent for invention or utility model is filed, a request, a description and its abstract, and claims shall be submitted. The request shall state the title of the invention or utility model, the name of the inventor or creator, the name and the address of the applicant and other related matters. The description shall set forth the invention or utility model in a manner sufficiently clear and complete so as to enable a person skilled in the relevant field of technology to carry it out; where necessary, drawings are required. The abstract shall state briefly the main technical points of the invention or utility model. The claims shall be supported by the description and shall state the extent of the patent protection asked for.Article 27 . Where an application for a patent for design is filed, a request, drawings or photographs of the design shall be submitted, and the product incorporating the design and the class to which that product belongs shall be indicated.Article 28 . The date on which the patent administrative organ under the State Council receives the application shall be the date of filing. If the application is sent by mail, the date of mailing indicated by the postmark shall be the date of filing.Article 29 . Where, within twelve months from the date on which any applicant first filed in a foreign country an application for a patent for invention or utility model, or within six months from the date on which any applicant first filed in a foreign country an application for a patent for design, he or it files in China an application for a patent for the same subject matter, he or it may, in accordance with any agreement concluded between the said foreign country and China, or in accordance with any international treaty to which both countries are party, or on the basis of the principle of mutual recognition of the right of priority, enjoy a right of priority.Where, within twelve months from the date on which any applicant first filed in China an application for a patent for invention or utility model, he or it files with the patent administrative organ under the State Council an application for a patent for the same subject matter, he or it may enjoy a right of priority.Article 30 . Any applicant who claims the right of priority shall make a written declaration when the application is filed, and submit, within three months, a copy of the patent application document which was firstfiled; if the applicant fails to make the written declaration or to meet the time limit for submitt ing the patent application document, the claim to the right of priority shall be deemed not to have been made.Article 31 . An application for a patent for invention or utility model shall be limited to one invention or utility model. Two or more inventions or utility models belonging to a single general inventive concept may be filed as one application. An application for a patent for design shall be limited to one design incorporated in one product. Two or more designs which are incorporated in products belonging to the same class and are sold or used in sets may be filed as one application.Article 32 . An applicant may withdraw his or its application for a patent at any time before the patent right is granted.Article 33 . An applicant may amend his or its application for a patent, but the amendment to the application for a patent for invention or utility model may not go beyond the scope of the disclosure contained in the initial description and claims, and the amendment to the application for a patent for design may not go beyond the scope of the disclosure as shown in the initial drawings or photographs.(1) where it was first exhibited at an international exhibition sponsored or recognized by the Chinese Government;(2) where it was first made public at a prescribed academic or technological meeting;(3) where it was disclosed by any person without the consent of the applicant.Article 25 . For any of the following, no patent right shall be granted:(1) scientific discoveries;(2) rules and methods for mental activities;(3) methods for the diagnosis or for the treatment of diseases;(4) animal and plant varieties;(5) substances obtained by means of nuclear transformation.For processes used in producing products referred to in items (4) of the preceding paragraph, patent right may be granted in accordance with the Provisions of this Law.Chapter 4: Examination and Approval of Application for PatentArticle 34 . Where, after receiving an application for a patent for invention, the patent administrative organ under the State Council, upon preliminary examination, finds the application to be in conformity with the requirements of this Law, it shall publish the application promptly after the expiration of eighteen months from the date of filing. Upon the request of the applicant, the patent administrative organ under the State Council publishes the application earlier.Article 35 . Upon the request of the applicant for a patent for invention, made at any time within three years from the date of filing, the patent administrative organ under the State Council will proceed to examine the application as to its substance. If, without any justified reason, the applicant fails to meet the time limit for requesting examination as to substance, the application shall be deemed to have been withdrawn. The patent administrative organ under the State Council may, on its own initiative, proceed to examine any application for a patent for invention as to its substance when it deems it necessary.Article 36 . When the applicant for a patent for invention requests examination as to substance, he or it shall furnish pre-filing date reference materials concerning the invention. For an application for a patent for invention that has been already filed in a foreign country, the patent administrative organ under the State Council may ask the applicant to furnish within a prescribed time limit documents concerning any search made for the purpose of examining that application or concerning the results of any examination made in that country. If, without any justified reason, the said documents are not furnished within the prescribed time limit, the application shall be deemed to have been withdrawn.Article 37. Where the patent administrative organ under the State Council, after it has made the examination as to substance of the application for a patent for invention, finds that the application is not in conformity with the provisions of this Law, it shall notify the applicant and request him or it to submit, within a specified time limit,his or its observations or to amend the application. If, without any justified reason, the time limit for making response is not met, the application shall be deemed to have been withdrawn.Article 38 . Where, after the applicant has made the observations or amendments, the patent administrative organ under the State Council finds that the application for a patent for invention is still not in conformity with the provisions of this Law, the application shall be rejected.Article 39 . Where it is found after examination as to substance that there is no cause for rejection of the application for a patent for invention, the patent administrative organ under the State Council shall make a decision to grant the patent right for invention, issue the certificate of patent for invention, and register and announce it. The patent right for invention shall come into force upon the date of the announcement.Article 40 . Where it is found after preliminary examination that there is no cause for rejection of the application for a patent for utility model or design, the patent administrative organ under the State Council shall make a decision to grant the patent right for utility model or the patent right for design, issue the relevant patent certificate, and register and announce it. The patent right for utility model or design shall come into effect upon the date of the announcement.Article 41 . The patent administrative organ under the State Council shall set up a Patent Reexamination Board. Where an applicant is not satisfied with the decision of the patent administrative organ under the State Council rejecting his application for patent, such applicant may, within three months from the date of receipt of the notification, request the Patent Reexamination Board to make a reexamination. The Patent Reexamination Board shall, after reexamination, make a decision and notify the applicant for patent. Where the applicant for patent who made the request for reexamination is not satisfied with the decision of the Patent Reexamination Board, he or it may, within three months from the date of receipt of the notification, institute legal proceedings in the people's court.Chapter 5: Duration, Cessation and Invalidation of Patent RightArticle 42. The duration of patent right for inventions shall be twenty years, the duration of patent right for utility models and patent right for designs shall be ten years, counted from the date of filing.Article 43 . The patentee shall pay an annual fee beginning with the year in which the patent right was granted.Article 44. In any of the following cases, the patent right shall cease before the exp iration of its duration:(1) where an annual fee is not paid as prescribed;(2) where the patentee abandons his or its patent right by a written declaration.Any cessation of the patent right shall be registered and announced by the patent administrative organ under the State Council.Article 45 . Where, starting from the date of the announcement of the grant of the patent right by the patent administrative organ under the State Council, any entity or individual considers that the grant of the said patent right is not in conformity with the relevant provisions of this Law, it or he may request the Patent Reexamination Board to declare the patent right invalid.Article 46. The Patent Reexamination Board shall examine the request for invalidation of the patent right, make a decision and notify the person who made the request and the patentee. The decision declaring the patent right invalid shall be registered and announced by the patent administrative organ under the State Council. Where any party is not satisfied with the decision of the Patent Reexamination Board declaring the patent right invalid or upholding the patent right, such party may, within three months from receipt of the notification of the decision, institute legal proceedings in the people's court. The people's court shall notify the opponent party of the party which has requested for the invalidation procedure to be represented the proceedings as the third party.Article 47 . Any patent right which has been declared invalid shall be deemed to be non-existent from the beginning. The decision of invalidation shall have no retroactive effect on any judgment or order on patent infringement which has been pronounced and enforced by the people's court, on any decision concerning the handling of patent infringement which has been implemented or enforced, and on any contract of patent license and of assignment of patent right which have been performed, prior to the decision of invalidation; however, the damages caused to other persons in bad faith on the part of the patentee shall be compensated. If, pursuant to the provisions of the preceding paragraph, no repayment, by the patentee or the assignor of the patent right to thelicensee or the assignee of the patent right, of the fee for the exploitation of the patent or the price for the assignment of the patent right is obviously contrary to the principle of equity, the patentee or the assignor of the patent right shall repay the whole or part of the fee for the exploitation of the patent or the price for the assignment of the patent right to the licensee or the assignee of the patent right.Chapter 6: Compulsory License for Exploitation of Patent Article 48 . Where any entity which is qualified to exploit the invention or utility model has made requests for authorization from the patentee of an invention or utility model to exploit its or his patent on reasonable terms and such efforts have not been successful within a reasonable period of time, the patent administrative organ under the State Council may, upon the application of that entity, grant a compulsory license to exploit the patent for invention or utility model.Article 49 . Where a national emergency or any extraordinary state of affairs occurs, or where the public interest so requires, the patent administrative organ under the State Council may grant a compulsory license to exploit the patent for invention or utility model.Article 50 . Where the invention or utility model for which the patent right was granted is of important technical advance of considerable economic significance compared with another invention or utility model for which a patent right has been granted earlier and the exploitation of the later invention or utility model depends on the exploitation of the earlier invention or utility model, the patent administrative organ under the State Council may, upon the request of the later patentee, grant a compulsory license to exploit the earlier invention or utility model.Where, according to the preceding paragraph, a compulsory license is granted, the patent administrative organ under the State Council may, upon the request of the earlier patentee, also grant a compulsory license to exploit the later invention or utility model.Article 51 . The entity or individual requesting, in accordance with the provisions of this Law, a compulsory license for exploitation shall furnish proof that it or he has not been able to conclude with the patentee a license contract for exploitation on reasonable terms.Article 52 . The decision made by the patent administrative organ under the State Council granting a compulsory license for exploitation shall be notified to the patent concerned as soon as reasonably practicable and shall be registered and announced. The decision of the patent administrative organ under the State Council granting a compulsory license for exploitation shall limit the scope and duration of the exploitation on the basis of the reasons justifying the grant. If and when the circumstances which led to such compulsory license cease to exist and are unlikely to recur, the patent administrative organ under the State Council may, upon the request of the patentee, terminate the compulsory license after examination.Article 53 . Any entity or individual that is granted a compulsory license for exploitation shall not have an exclusive right to exploit and shall not have the right to authorize exploitation by any others.Article 54 . The entity or individual that is granted a compulsory license for exploitation shall pay to the patentee a reasonable exploitation fee, the amount of which shall be fixed by both parties in consultations. Where the parties fail to reach an agreement, the patent administrative organ under the State Council shall adjudicate.Article 55 . Where the patentee is not satisfied with the decision of the patent administrative organ under the State Council granting a compulsory license for exploitation, or where the patentee or the entity or individual that is granted the compulsory license is not satisfied with the adjudication made by the patent administrative organ under the State Council regarding the exploitation fee payable for exploitation, he or it may, within three months from the receipt of the notification, institute legal proceedings in the people's court.Chapter 7: Protection of Patent RightArticle 56 . The extent of protection of the patent right for invention or utility model shall be determined by the terms of the claims'. The description and the appended drawings may be used to interpret the claims. The extent of protection of the patent right for design shall be determined by the product incorporating the patented design as shown in the drawings or photographs.Article 57 . Where anyone exploits a patent without the authorization of the patentee, he or it constitutes an infringement to the patent right of the patentee. For the disputes resulted from the infringement, the parties concerned may settle it by themselves through consultation. Where the parties are not willing to settle the disputes through consultation or where the consultation fails to reach an agreement, the patentee or any interested party。

abandonment of a patent 放弃专利权abandonment of a patent application 放弃专利申请abridgment 文摘abstract 文摘(摘要)abuse of patent 滥用专利权action for infringement of patent 专利侵权诉讼action of a patent 专利诉讼address for service 文件送达地址affidavit 誓书amendment 修改annual fee 年费annuity 年费anticipation 占先appeal 上诉appellation of origin 原产地名称applicant for patent 专利申请人application date 申请日期application documents 申请案文件application fee 申请费application for patent 专利申请(案)application laying open for public inspection 公开供公众审查的申请application number 申请号application papers 申请案文件arbitration 仲裁art 技术article of manufacture 制品assignee 受让人assignment 转让assignor 转让人author of the invention 发明人author's certificate 发明人证书basic patent 基本专利Berne Convention 伯尔尼公约Berne Union 伯尔尼联盟best mode 最佳方式bibliographic data 著录资料BIRPI 保护知识产权联合国国际局board of appeals 申诉委员会breach of confidence 泄密Budapest Treaty on the International Recognition of the Deposit of Microorganisms for the Purposes of Patent Procedure 国际承认用于专利程序的微生物保存布达佩斯条约burden of proof 举证责任case law 判例法caveat 预告certificate of addition 增补证书certificate of correction 更正证明书certificate of patent 专利证书certified copy 经认证的副本Chemical Abstracts 化学文摘citation 引证claim 权项classifier 分类员co-applicants 共同申请人co-inventors 共同发明人color coding 色码制commissioner 专利局长Community Patent Convention 共同体专利公约complete application 完整的申请案complete description 完整的叙述complete specification 完整的说明书comptroller 专利局长compulsory license 强制许可证conception 概念conception date 概念日期confidential application 机密申请confidential information 保密情报conflict award 冲突裁定conflict procedure 冲突程序conflicting applications 冲突申请案continuation application 继续申请continuation-in-part application 部分继续申请案contractual license 契约性许可证contributory infringement 简介侵犯convention application 公约申请convention country 公约国convention date 公约日期Convention Establishing the World Intellectual Property Organization 建立世界知识产权组织公约convention period 公约期限convention priority 公约优先权copyright 版权correction slip 勘误表counter pleadings 反诉状counterclaim 反诉country code 国家代号cross license 交叉许可证data 资料data exchange agreement 资料交换协议data of application 申请日期date of grant 授予日期date of issue 颁发日期date of patent 专利日期date of publication 公布日期dedication to the public 捐献于公众defendant 被告人defenses 辩护defensive publication 防卫性公告deferred examination 延迟审查dependent claim 从属权项dependent patent 从属专利Derwent Publications Ltd. 德温特出版有限公司design patent 外观设计专利development 发展disclaimer 放弃权项disclosure 公开division 分案divisional application 分案申请domination patent 支配专利drawing 附图duration of patent 专利有效期economic patent 经济专利effective filing date 实际申请日期employee’s invention雇员发明EPO 欧洲专利局European Patent Office 欧洲专利局ESARIPO 英语非洲工业产权组织European Patent Convention 欧洲专利公约evidence 证据examination 审查examination countries 审查制国家examination for novelty 新颖性审查examiner 审查员examiner’s report审查员报告exclusive license 独占性许可证exclusive right 专有权experimental use 实验性使用expired patent 期满专利exploitation of a patent 实施专利exposition priority 展览优先权expropriation 征用extension of term of a patent 延长专利期限fee 费用FICPI 国际工业产权律师联合会file copy 存档原件filing date 申请日期filing fee 申请费filing of an application 提出申请final action 终局决定书first-to-file principle 先申请原则first-to-invention principle 先发明原则force majeure 不可抗力foreign patent application 外国专利申请formal examination 形式审查gazette 公报Geneva Treaty on the International Recording of Scientific Discoveries 关于科学发现国际注册日内瓦条约grace period 宽限期grant of a patent 授予专利权holder of a patent 专利持有人ICIREPAT 专利局间情报检索国际合作巴黎联盟委员会Paris Union Committee for International Cooperation in Information Retrieval among Patent Offices 专利局间情报检索国际合作巴黎联盟委员会IFIA 国际发明人协会联合会prescription 时效prevention of unfair competition principal patent 主专利prior art 先有技术prior use 先用priority 优先权priority claim 优先权声明priority declaration 优先权声明process patent 方法专利processing of an application 申请案的处理product patent 产品专利provisional specification 临时说明书publication 公布reclassification 再分类reexamination 复审refusal 驳回register of patents 专利登记册registered patent 登记专利registered trade mark 注册商标registration 登记registration countries 登记制国家reissue patent 再颁发专利rejection 驳回remedy 补救renewal fee 续展费request 请求书restoration of a lapsed patent 恢复已终止的专利restricted conditions 限制条款review 复审revival of an abandoned application 恢复已放弃的申请revocation of a patent 撤销专利royalties 提成费Science Abstracts 科学文摘scientific discovery 科学发现scope of protection 保护范围seal 盖章search 检索secret patent 机密专利service invention 职务发明service mark 服务标记signature 签署simple license 普通许可证single applicant 单独申请人sliding scale of royalties 滑动提成费sole license 排他性许可证specification 说明书state of the art 先有技术水平statement of claim 诉讼陈述statement of defense 辩护陈述substance patent 物质专利substantive examination 实质性审查succession 继承sufficiency of description 充分描述technical assistance 技术协助technical data 技术资料technology transfer 技术转移temporary protection 临时保护term of a patent 专利有效期The Hague Agreement Concerning the International Deposit of Industrial Designs 工业品外观设计国际保存海牙协定title of invention 发明名称title to patent 专利所有权trade mark 商标Trademark Registration Treaty 商标注册条约trade name 厂商名称trial 审判unfair competition 不正当竞争unity of invention 发明单一性Universal Copyright Convention 世界版权公约unpatentable subject matter 不能取得专利的主题use patent 用途专利utility certificate 实用证书utility model 实用新型Vienna Agreement Establishing an International Classification of the Figurative Elements of Marks 建立商标图形要素国际分类维也纳协定Vienna Agreement for the Protection of Type Faces and their International Deposit 印刷字体保护及其国际保存维也纳协定WIPO 世界知识产权组织withdrawal of an application 撤回申请witness 证人working of a patent 实施专利World Intellectual Property Organization 世界知识产权组这WPI 世界专利索引World Patent Index 世界专利索引专利翻译知识★★xilidge(金币+2,VIP+0):感谢分享:)Ⅰ.总则1. 专利说明书的中译,应特别注重"信"与"达"两大要求,即译文必须与原文内容完全相符,不得有任何出入或节略。