AWS D1.1焊接工艺规程中英文对照模板

- 格式:docx

- 大小:10.86 KB

- 文档页数:1

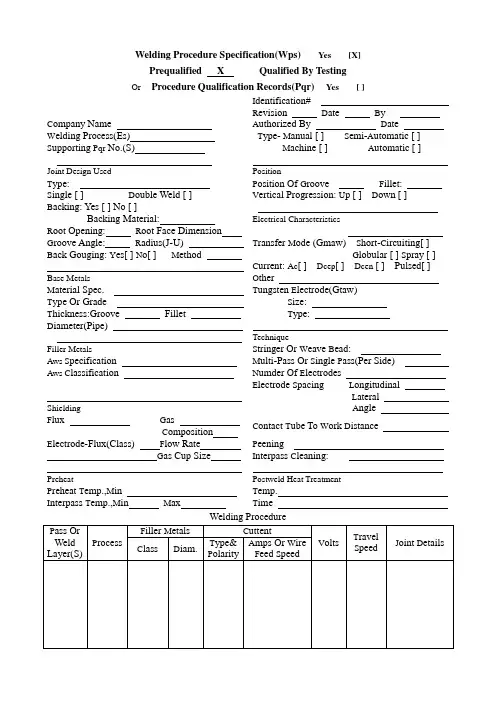

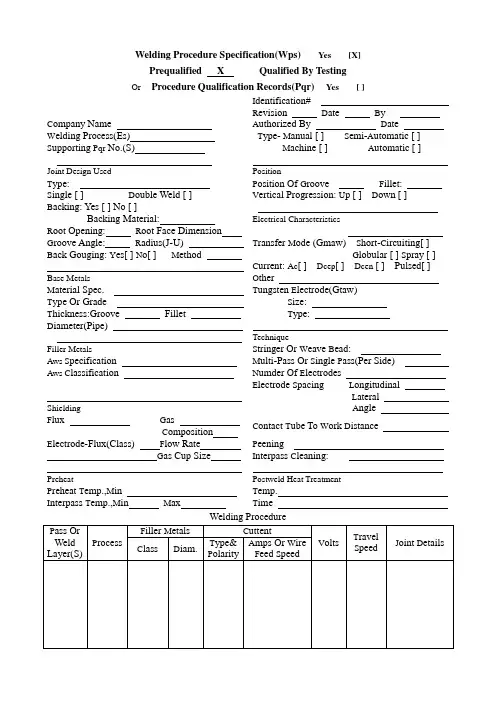

W elding Procedure Specification(Wps) Y es [X]Prequalified X Qualified By TestingOr Procedure Qualification Records(Pqr)Y es [ ]I dentification#R evision D ate B yC ompany Name A uthorized ByD ateW elding Process(Es) T ype- M anual [ ] S emi-A utomatic [ ]S upporting Pqr No.(S) M achine [ ] A utomatic [ ] Joint Design Used PositionT ype: P osition Of G roove F illet:S ingle [ ] D ouble Weld [ ] V ertical Progression: U p [ ] D own [ ]B acking: Y es [ ] No [ ]Backing Material: Electrical CharacteristicsR oot Opening: R oot Face DimensionG roove Angle: R adius(J-U) T ransfer M ode (Gmaw) S hort-C ircuiting[ ]B ack Gouging: Y es[ ] N o[ ] M ethod G lobular [ ] S pray [ ]C urrent: Ac[ ] Dcep[ ] Dcen [ ] Pulsed[ ] Base Metals O therM aterial Spec. T ungsten E lectrode(Gtaw)T ype Or Grade S ize:T hickness:Groove Fillet T ype:D iameter(Pipe)TechniqueFiller Metals S tringer Or W eave B ead:A ws S pecification M ulti-Pass Or S ingle P ass(Per Side)A ws C lassification N umder Of E lectrodesE lectrode S pacing L ongitudinalL ateralShielding A ngleF luxG asC ontact T ube To W orkD istanceC ompositionE lectrode-Flux(Class)F low Rate P eeningG as Cup Size I nterpass C leaning:Preheat Postweld Heat TreatmentP reheat T emp.,M in T emp.I nterpass T emp.,M in M ax T imeWelding ProcedureProcedure Qualification Record (PQR)#Test ResultsGUIDED BEND TESTVISUAL INSPECTIONAppearance Radiographic-Ultrasonic ExaminationUndercut RT report no: ResultPiping Porosity UT report no: ResultConvexity (FILLET WELD TEST RESULTS)Test Date Minimum Size Multiple Pass Maximum Size Single Pass Witnesses By Macroetch Macroetch1. 3. 1. 3.2. 2.All-weld-metal tension testOther tests Tensile strength ,psiYield point/strength,psiElongation in 2 in,%Laboratory test no.Welder’s name Clock no. stamp no.Test’s conducted by LaboratoryTest numberPerWe,the undersigned,certify that the statements in this record are correct and that the test welds were prepared,welded,and tested in accordance with the requirements of section 4 of AMSI/A WS D1.1,( 86 ) structural welding code-steel. Y earSignedByTitleDate。

AWS D1.1/D1.1M:2002Structural Welding Code — SteelAWS D1.1/D1.1M:2002 An American National StandardStructural Welding Code — SteelCOPYRIGHT 2003; American Welding Society, Inc. 00:02:09 MDT Questions or comments about this message: please call the DocumentDocument provided by IHS Licensee=Aramco HQ/9980755100, User=, 04/24/20031Policy Management Group at 1-800-451-1584.AWS D1.1/D1.1M:2002Structural Welding Code — SteelAWS D1.1/D1.1M:2002 An American National Standard Approved by American National Standards Institute August 31, 2001Structural Welding Code — Steel18th Edition Supersedes AWS D1.1:2002Prepared by AWS D1 Committee on Structural WeldingUnder the Direction of AWS Technical Activities CommitteeApproved by AWS Board of DirectorsAbstractThis code covers the welding requirements for any type of welded structure made from the commonly used carbon and low-alloy constructional steels. Sections 1 through 8 constitute a body of rules for the regulation of welding in steel construction. There are twelve mandatory and fifteen nonmandatory annexes in this code. A Commentary of the code is included with the document.550 N.W. LeJeune Road, Miami, Florida 33126COPYRIGHT 2003; American Welding Society, Inc. 00:02:09 MDT Questions or comments about this message: please call the DocumentDocument provided by IHS Licensee=Aramco HQ/9980755100, User=, 04/24/20032Policy Management Group at 1-800-451-1584.AWS D1.1/D1.1M:2002Structural Welding Code — Steel1 General Requirements 通用原则1.1 Scope 适用范围This code contains the requirements for fabricating and erecting welded steel structures. When this code is stipulated in contract documents, conformance with all provisions of the code shall be required, except for those provisions that the Engineer (see 1.4.1) or contract documents specifically modifies or exempts. 本规范包括制作和安装焊接钢结构的要求。

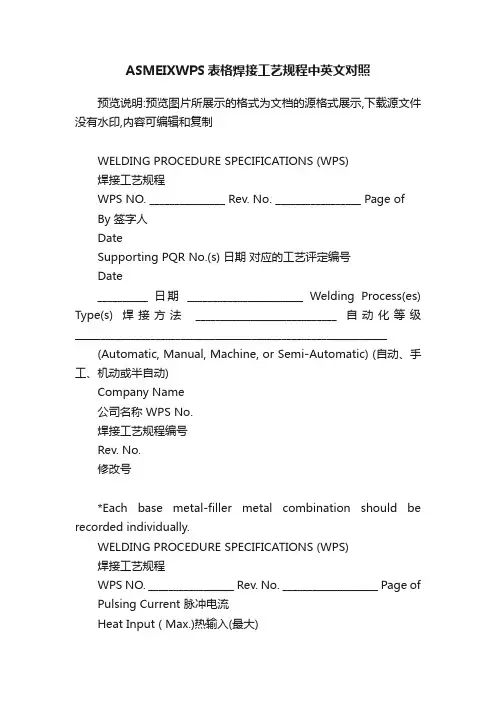

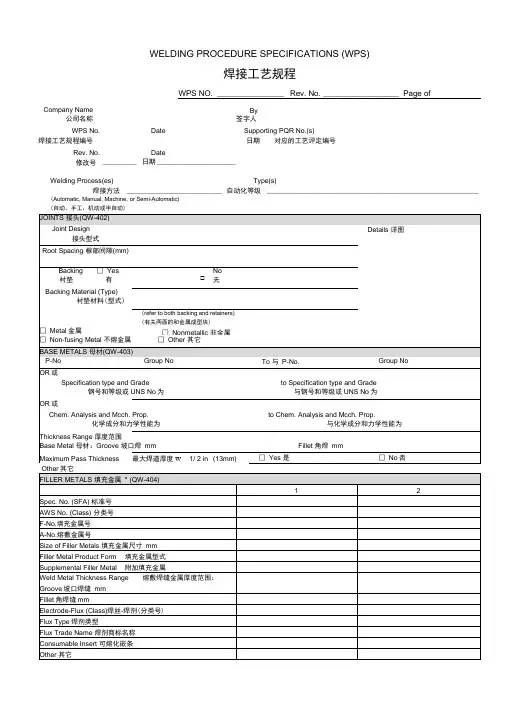

ASMEIXWPS表格焊接工艺规程中英文对照预览说明:预览图片所展示的格式为文档的源格式展示,下载源文件没有水印,内容可编辑和复制WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _______________ Rev. No. _________________ Page ofBy 签字人DateSupporting PQR No.(s) 日期对应的工艺评定编号Date__________ 日期_______________________ Welding Process(es) Type(s) 焊接方法____________________________ 自动化等级______________________________________________________________ (Automatic, Manual, Machine, or Semi-Automatic) (自动、手工、机动或半自动)Company Name公司名称 WPS No.焊接工艺规程编号Rev. No.修改号*Each base metal-filler metal combination should be recorded individually.WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _________________ Rev. No. ___________________ Page of Pulsing Current 脉冲电流Heat Input ( Max.)热输入(最大)Tungsten Electrode Size and Type ( Pure Tungsten,2Thoriated etc.)钨极尺寸和型号(纯钨,2%钍钨极等) Mode of Metal Transfer for GTAW (FCAW) ( Spray Arc, Short Circuiting Arc, et 熔滴过渡型式(射流或短路)Electrode Wire Feed Speed Rang 送丝速度范围____________________________________________________________________ __________________Other 其它TECHNIQUE 焊接技术(QW-410)Stri ng or Weave Bead 直进焊或摆动焊____________________________________________________________________ __________________ Orifice or Gas Cup Size 嘴孔或喷嘴尺寸 mm Initial and Interpass Cleaning打底焊道和中间焊道的清理方法(Brushing, Grinding, etc.)( 刷理或打磨等等) ______________________Method of Back Gouging背面清根方法Oscillati on 横摆方法____________________________________________________________________ ____________________________________ Con tact Tube to Work Dista nee 导电嘴至工件距离____________________________________________________________________ ________ Multiple or Single Pass 多道焊或单道焊 (Per Side)( 每侧) _________________________________________________________________ Multiple or Single Electrodes 多丝焊或单丝焊Travel Speed 焊接速度(Range)(范围) ____________________________________________________________________ _____________Peening 锤击Use of thermal processes 使用热工艺____________________________________________________________________ ___________________ Other 其它对于每一母材-填充金属的组合均需分别填表Date 日期。

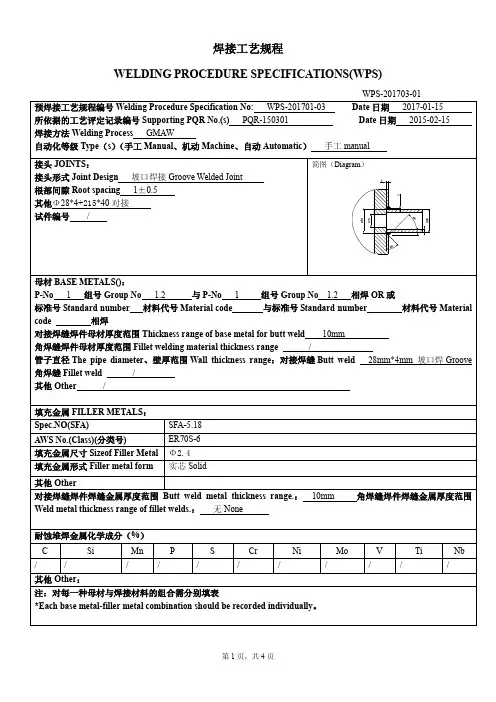

美标A W S D1.1焊接工艺评定中英文(总5页)-CAL-FENGHAI.-(YICAI)-Company One1-CAL-本页仅作为文档封面,使用请直接删除WELDING PROCEDURE SPECIFICATION(WPS)YES [√] PREQUALIFIED: QUALIFIED BY TESTING:Or PROCEDURE QUALIFICATION (or PQR) YES [ ]CODE: AWS D 1.1WELDING PROCEDURE SPECIFICATION(WPS)YES [ ] PREQUALIFIED: QUALIFIED BY TESTING:Or PROCEDURE QUALIFICATION (or PQR) YES [√]CODE: AWS D 1.1PQR No.: YH-PQR-201506-2 Rev.: 0 page 2 of 2Test ResultsAppearance ACC RT report NO.: 31B15RT14-3-11 result: ACCUndercut None UT report NO.: N/A result: N/APiping porosity None (FILLET WELD TEST RESULTS)Convexity 2mm Minimum size multiple pass Maxmum size single passTest date Macroetch MacroetchWitnessed by 1. N/A 2. N/AOther: 3. N/A 4. N/A5. N/A6. N/AAll-weld metal tension testTensile strength:N/AYield point/strength:N/AElongation in 2 in,%:N/ALaboratory Test NO.Welder’s Name: Wang jianming Stamp NO.: Tests conducted by:Laboratory Test NO.: 2015GT-W0502We,the undersigned,certify that the statement in this record are correct and that the test welds were prepared,welded,and tested in accordance with the requirements of section 4 of ANSI/SWSD1.1/D1.1M Structural Welding Code-Steel.Tangshan Yonghe Metallurgical Equipment Manufacturing Co., LTD Procedure Qualification WeldingRecordPQR NO. YHPQR201506-2Page 1/1DateCoupon No.:YH201501SB Site Welding Training center Welding process:GMAW Position of groove :1G Welder’s Name:Wang jianming WPS NO.:YH201506-02 Stamp No.:ITP NO.:Base metal Steel Spec. Size Heat No. MaterialcertificateOther Q235-B δ14 157-06745 2015050020801 N/AFiller metal AWS NO. Size (mm) Lot No. MaterialcertificateDrying DepositedMetalthickness(mm) ER70S-6φ1.2 769212 N/A 14Welding Equipment Type:YD-350-KR Welding Equipment NO.:TSM16514-01 Ambient Temp:28℃Ambient Humidity:39﹪Preheat Temp.: N/APWHT Temp.and Purity: N/AArc Shielding Gas and purity:CO2 99.5% Tungsten Electrode Type and size: N/A Gas Nozzle Size:Cleaning:GrindingLayers /PassFiller metal TypeandPolarityAmps.(A)Voltage(V)TravelSpeed(cm/min)Gas FlowRate(L/min)Inter-passTemp.(℃) AWSNO.Size(mm)face back1/1 ER70S-6 φ1.2 DCEN 120~14020~2213.912.5 12.5 N/A2/1 ER70S-6 φ1.2 DCEN 120~13020~2212.7512.5 12.5 N/A3/1 ER70S-6 φ1.2 DCEN 130~14020~2211.312.5 12.5 N/A4/1 ER70S-6 φ1.2 DCEN 130~14020~2211.312.5 12.5 N/ARecord by:Date :Witness:Date:。

W elding Procedure Specification(Wps) Y es [X]Prequalified X Qualified By TestingOr Procedure Qualification Records(Pqr)Y es [ ]I dentification#R evision D ate B yC ompany Name A uthorized ByD ateW elding Process(Es) T ype- M anual [ ] S emi-A utomatic [ ]S upporting Pqr No.(S) M achine [ ] A utomatic [ ] Joint Design Used PositionT ype: P osition Of G roove F illet:S ingle [ ] D ouble Weld [ ] V ertical Progression: U p [ ] D own [ ]B acking: Y es [ ] No [ ]Backing Material: Electrical CharacteristicsR oot Opening: R oot Face DimensionG roove Angle: R adius(J-U) T ransfer M ode (Gmaw) S hort-C ircuiting[ ]B ack Gouging: Y es[ ] N o[ ] M ethod G lobular [ ] S pray [ ]C urrent: Ac[ ] Dcep[ ] Dcen [ ] Pulsed[ ] Base Metals O therM aterial Spec. T ungsten E lectrode(Gtaw)T ype Or Grade S ize:T hickness:Groove Fillet T ype:D iameter(Pipe)TechniqueFiller Metals S tringer Or W eave B ead:A ws S pecification M ulti-Pass Or S ingle P ass(Per Side)A ws C lassification N umder Of E lectrodesE lectrode S pacing L ongitudinalL ateralShielding A ngleF luxG asC ontact T ube To W orkD istanceC ompositionE lectrode-Flux(Class)F low Rate P eeningG as Cup Size I nterpass C leaning:Preheat Postweld Heat TreatmentP reheat T emp.,M in T emp.I nterpass T emp.,M in M ax T imeWelding ProcedureProcedure Qualification Record (PQR)#Test ResultsGUIDED BEND TESTVISUAL INSPECTIONAppearance Radiographic-Ultrasonic ExaminationUndercut RT report no: ResultPiping Porosity UT report no: ResultConvexity (FILLET WELD TEST RESULTS)Test Date Minimum Size Multiple Pass Maximum Size Single Pass Witnesses By Macroetch Macroetch1. 3. 1. 3.2. 2.All-weld-metal tension testOther tests Tensile strength ,psiYield point/strength,psiElongation in 2 in,%Laboratory test no.Welder’s name Clock no. stamp no.Test’s conducted by LaboratoryTest numberPerWe,the undersigned,certify that the statements in this record are correct and that the test welds were prepared,welded,and tested in accordance with the requirements of section 4 of AMSI/A WS D1.1,( 86 ) structural welding code-steel. Y earSignedByTitleDate。

WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _______________ Rev. No. _________________ Page ofBy 签字人DateSupporting PQR No.(s) 日期 对应的工艺评定编号Date__________ 日期 _______________________ Welding Process(es) Type(s) 焊接方法 ____________________________ 自动化等级 ______________________________________________________________(Automatic, Manual, Machine, or Semi-Automatic) (自动、手工、机动或半自动)Company Name公司名称 WPS No.焊接工艺规程编号Rev. No.修改号*Each base metal-filler metal combination should be recorded individually.WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _________________ Rev. No. ___________________ Page ofPulsing Current 脉冲电流Heat Input ( Max.)热输入(最大)Tungsten Electrode Size and Type ( Pure Tungsten,2Thoriated etc.)钨极尺寸和型号(纯钨,2%钍钨极等) Mode of Metal Transfer for GTAW (FCAW) ( Spray Arc, Short Circuiting Arc, et 熔滴过渡型式(射流或短路)Electrode Wire Feed Speed Rang 送丝速度范围 ______________________________________________________________________________________Other 其它TECHNIQUE 焊接技术(QW-410)Stri ng or Weave Bead 直进焊或摆动焊 ______________________________________________________________________________________ Orifice or Gas Cup Size 嘴孔或喷嘴尺寸 mmInitial and Interpass Cleaning打底焊道和中间焊道的清理方法(Brushing, Grinding, etc.)( 刷理或打磨等等) ______________________Method of Back Gouging背面清根方法Oscillati on 横摆方法 ________________________________________________________________________________________________________ Con tact Tube to Work Dista nee 导电嘴至工件距离 ____________________________________________________________________________ Multiple or Single Pass 多道焊或单道焊 (Per Side)( 每侧) _________________________________________________________________ Multiple or Single Electrodes 多丝焊或单丝焊Travel Speed 焊接速度(Range)(范围) _________________________________________________________________________________Peening 锤击Use of thermal processes 使用热工艺 _______________________________________________________________________________________ Other 其它对于每一母材-填充金属的组合均需分别填表Date 日期。

WPS-按ASME标准填写的中英对照的焊接工艺评定指导书1000字WPS Welding Procedure Specification,即焊接工艺规范。

按ASME标准填写的WPS需要包括以下内容:1.焊接参数:包括电流、电压、焊接速度、焊接位置等焊接过程中必要的参数。

Welding Parameters: including necessary parameters such as current, voltage, welding speed, and welding position.2.准备工作:包括焊接材料和设备的准备工作,以及焊前检查和清洁工作。

Preparation: including preparation of welding materials and equipment, as well as pre-weld inspection and cleaning.3.焊接过程:包括焊接顺序、焊接方法、填充物类型、预热和热处理等细节。

Welding Process: including welding sequence, welding method, filler type, preheating and post-weld heat treatment, and other details.4.质量控制:包括焊接检测、检验和记录,以确保焊接过程及焊缝质量符合要求。

Quality Control: including welding testing, inspection and records to ensure that the welding process and weld quality meet requirements.WPS填写时需要注意以下几点:1. 按ASME标准填写,需要详细描述焊接工艺流程及其参数,确保符合标准和要求。

2. 语言简洁明了,避免使用模糊或不明确的术语和表述。

- 57 -Location : Examiner or test body :工艺编号:pWPS-XXXX-0601 工艺评定编号:Welding procedure reference No.: WPAR No. :制造商: 焊工姓名:Manufacturer : Welder ,s name :焊接方法: 焊接位置:Welding process : Welding positions :接头类型: 坡口制备和清理方法:Joint type : Method of preparation and cleaning :母材牌号及证书: 母材厚度/规格(mm ): Parent material specification : Material thickness/outside diameter (mm ):焊材类别和牌号: 焊材特殊烘干规定:Filler metal classification and trade name :Special baking or drying :焊接准备情况(简图)*: 钨极种类/直径(mm ):Details of backing : Details of back gouging :预热温度: 层间温度:Preheat temperature : Interpass temperature :焊后热处理: 加热和冷却速度*:Post-weld heat treatment : Heating and cooling rates*:其它说明*Other information*焊丝干伸长度: 摆动(焊道最大宽度)(mm ):Contact tube-to-workpiece distance : Weaving(maximum width of run) (mm):脉冲焊接情况: 等离子焊接情况:Pulse welding details : Plasma welding details :制造商: 评定或检验机构:Manufacturer : Examiner or test body : (姓名、日期、签字 Name, date and signature) (姓名、日期、签字 Name, date and signature) *如果需要(If required ) 注:XXXX 指企业英文缩写,最多不超过4位数。

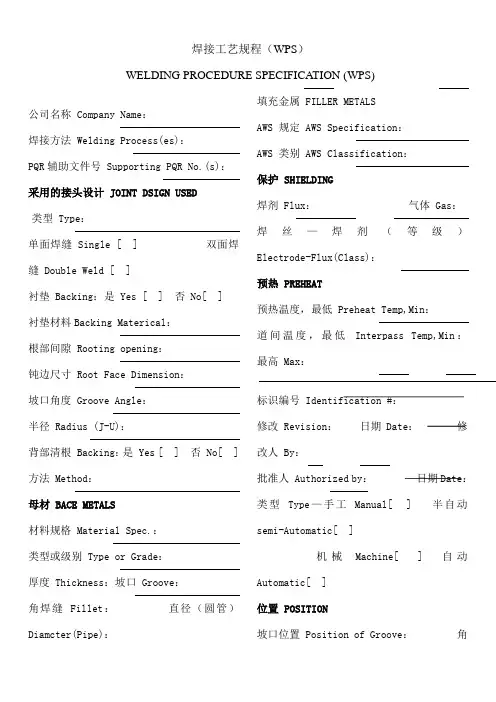

焊接工艺规程(WPS)WELDING PROCEDURE SPECIFICATION (WPS)公司名称 Company Name:焊接方法 Welding Process(es):PQR辅助文件号 Supporting PQR No.(s):采用的接头设计 JOINT DSIGN USED类型 Type:单面焊缝 Single [ ] 双面焊缝 Double Weld [ ]衬垫 Backing:是 Yes [ ] 否 No[ ] 衬垫材料Backing Materical:根部间隙 Rooting opening:钝边尺寸 Root Face Dimension:坡口角度 Groove Angle:半径 Radius (J-U):背部清根 Backing:是 Yes [ ] 否 No[ ]方法 Method:母材 BACE METALS材料规格 Material Spec.:类型或级别 Type or Grade:厚度 Thickness:坡口 Groove:角焊缝 Fillet:直径(圆管)Diamcter(Pipe):填充金属 FILLER METALSAWS 规定 AWS Specification:AWS 类别 AWS Classification:保护 SHIELDING焊剂 Flux:气体 Gas:焊丝—焊剂(等级)Electrode-Flux(Class):预热 PREHEAT预热温度,最低 Preheat Temp,Min:道间温度,最低Interpass Temp,Min:最高 Max:标识编号 Identification #:修改 Revision:日期Date:修改人 By:批准人 Authorized by:日期Date:类型Type—手工Manual[ ] 半自动semi-Automatic[ ]机械Machine[ ] 自动Automatic[ ]位置 POSITION坡口位置 Position of Groove:角焊缝 Fillet:立焊方向Vertical Progression:上行Up[ ] 下行 Down[ ]电特性 ELECTRICAL CHARACTERISTICS过渡形式(GMAW) Transfer Mode(GMAW) 短路 Short-Circuting:[ ] 熔滴Globular:[ ]喷射 Spray:[ ]电流 Current:交流 AC:[ ] 直流反接 GCEP:[ ]脉冲 Pulsed:[ ] 直流正接 DCEN:[ ]钨极(GTAW) Tungsten Electrode尺寸 Size:类型 Type:技术 TECHNIQUE直线或横向摆动喊道Stringer or Weave Bead:多道或单道(每边) Multi-pass or Single Pass(per side):焊丝数 Numbei of Electrodes:焊丝间隔Electrode Spacing 纵向Longitudinal:横向Lateral:角度 Angle:导电咀到工件距离 Contact Tube to Work Distance:锤击 Peening:道间清理 Interpass Cleaning:焊后热处理 POSTWELD HEAT TREATMENT温度 Temp.:时间 Time :。

Welding Procedure Specification(Wps) Yes [X]Prequalified X Qualified By TestingOr Procedure Qualification Records(Pqr)Yes [ ]I dentification#R evision D ate B yC ompany Name A uthorized ByD ateW elding Process(Es) T ype- M anual [ ] S emi-A utomatic [ ] S upporting Pqr No.(S) M achine [ ] A utomatic [ ]Joint Design Used PositionT ype: P osition Of G roove F illet: S ingle [ ] D ouble Weld [ ]V ertical Progression: U p [ ] D own [ ]B acking: Yes [ ] No [ ]Backing Material: Electrical CharacteristicsR oot Opening: R oot Face DimensionG roove Angle: R adius(J-U) T ransfer M ode (Gmaw) S hort-C ircuiting[ ]B ack Gouging: Y es[ ] N o[ ] M ethod G lobular [ ] S pray [ ]C urrent: Ac[ ] Dcep[ ] Dcen[ ]Pulsed[ ]Base Metals O therM aterial Spec. T ungsten E lectrode(Gtaw)T ype Or Grade S ize:T hickness:Groove Fillet T ype:D iameter(Pipe)TechniqueFiller Metals S tringer Or W eave B ead: Aws S pecification M ulti-Pass Or S ingle P ass(Per Side) Aws C lassification N umder Of E lectrodesE lectrode S pacing L ongitudinalL ateral Shielding A ngleF luxG asC ontact T ube To W orkD istanceC ompositionE lectrode-Flux(Class)F low Rate P eeningG as Cup Size I nterpass C leaning:Preheat Postweld Heat TreatmentP reheat T emp.,M in T emp.I nterpass T emp.,M in M ax T imeWelding ProcedureProcedure Qualification Record (PQR)#Test ResultsTENSILE TESTGUIDED BEND TESTVISUAL INSPECTIONAppearance Radiographic-Ultrasonic ExaminationUndercut RT report no: Result Piping Porosity UT report no: Result Convexity (FILLET WELD TEST RESULTS)Test Date Minimum Size Multiple Pass Maximum Size Single PassWitnesses By Macroetch Macroetch1. 3. 1. 3.2. 2.All-weld-metal tension testOther tests Tensile strength ,psiYield point/strength,psiElongation in 2 in,%Laboratory test no.Welder’s name Clock no. stamp no.Test’s conducted by LaboratoryTest numberPerWe,the undersigned,certify that the statements in this record are correct and that the test weldswere prepared,welded,and tested in accordance with the requirements of section 4 of AMSI/AWSD1.1,( 86 ) structural welding code-steel. YearSignedByTitleDate如有侵权请联系告知删除,感谢你们的配合!。

A W S D焊接工艺规程中英文对照集团文件版本号:(M928-T898-M248-WU2669-I2896-DQ586-M1988)焊接工艺规程(WPS)WELDING PROCEDURE SPECIFICATION (WPS)公司名称 Company Name:焊接方法 Welding Process(es):PQR辅助文件号 Supporting PQR No.(s):采用的接头设计 JOINT DSIGN USED类型 Type:单面焊缝 Single [ ] 双面焊缝 Double Weld [ ]衬垫 Backing:是 Yes [ ] 否 No[ ] 衬垫材料Backing Materical:根部间隙 Rooting opening:钝边尺寸 Root Face Dimension:坡口角度 Groove Angle:半径 Radius (J-U):背部清根 Backing:是 Yes [ ] 否No[ ]方法 Method:母材 BACE METALS材料规格 Material Spec.:类型或级别 Type or Grade:厚度 Thickness:坡口 Groove:角焊缝 Fillet:直径(圆管)Diamcter(Pipe):填充金属 FILLER METALSAWS 规定 AWS Specification:AWS 类别 AWS Classification:保护 SHIELDING焊剂 Flux:气体 Gas:焊丝—焊剂(等级) Electrode-Flux(Class):预热 PREHEAT预热温度,最低 Preheat Temp,Min:道间温度,最低 Interpass Temp,Min:最高 Max:标识编号 Identification #:修改 Revision:日期Date:修改人 By:批准人 Authorized by:日期Date:类型 Type—手工 Manual[ ] 半自动semi-Automatic[ ]机械 Machine[ ] 自动Automatic[ ]位置 POSITION坡口位置 Position of Groove:角焊缝 Fillet:立焊方向 Vertical Progression:上行Up[ ] 下行 Down[ ]电特性 ELECTRICAL CHARACTERISTICS过渡形式(GMAW) Transfer Mode(GMAW) 短路 Short-Circuting:[ ] 熔滴 Globular:[ ]喷射 Spray:[ ]电流 Current:交流 AC:[ ] 直流反接 GCEP:[ ]脉冲 Pulsed:[ ] 直流正接 DCEN:[ ]钨极(GTAW) Tungsten Electrode尺寸 Size:类型 Type:技术 TECHNIQUE 直线或横向摆动喊道 Stringer or Weave Bead:多道或单道(每边) Multi-pass or Single Pass(per side):焊丝数 Numbei of Electrodes:焊丝间隔 Electrode Spacing 纵向Longitudinal:横向Lateral:角度Angle:导电咀到工件距离 Contact Tube to Work Distance:锤击 Peening:道间清理 Interpass Cleaning:焊后热处理 POSTWELD HEAT TREATMENT温度 Temp.:时间 Time :。

焊接工艺规程(WPS)WELDING PROCEDURE SPECIFICATION (WPS)

公司名称Company Name:

焊接方法Welding Process(es):

PQR辅助文件号Supporting PQR No.(s):

采用的接头设计JOINT DSIGN USED

类型Type:

单面焊缝Single [ ] 双面焊缝Double Weld [ ] 衬垫Backing:是Yes [ ] 否No[ ]

衬垫材料Backing Materical:

根部间隙Rooting opening:

钝边尺寸Root Face Dimension:

坡口角度Groove Angle:

半径Radius (J-U):

背部清根Backing:是Yes [ ] 否No[ ]

方法Method:

母材BACE METALS

材料规格Material Spec.:

类型或级别Type or Grade:

厚度Thickness:坡口Groove:

角焊缝Fillet:直径(圆管)Diamcter(Pipe):

填充金属FILLER METALS

AWS 规定AWS Specification:

AWS 类别AWS Classification:

保护SHIELDING

焊剂Flux:气体Gas:

焊丝—焊剂(等级)Electrode-Flux(Class):

预热PREHEAT

预热温度,最低Preheat Temp,Min:

道间温度,最低Interpass Temp,Min:最高Max:标识编号Identification #:修改Revision:日期Date:修改人By:

批准人Authorized by:日期Date:

类型Type—手工Manual[ ] 半自动semi-Automatic[ ] 机械Machine[ ] 自动Automatic[ ]

位置POSITION

坡口位置Position of Groove:角焊缝Fillet:

立焊方向Vertical Progression:上行Up[ ] 下行Down[ ] 电特性ELECTRICAL CHARACTERISTICS

过渡形式(GMAW)Transfer Mode(GMAW)

短路Short-Circuting:[ ] 熔滴Globular:[ ]

喷射Spray:[ ]

电流Current:交流AC:[ ] 直流反接GCEP:[ ]

脉冲Pulsed:[ ] 直流正接DCEN:[ ] 钨极(GTAW)Tungsten Electrode

尺寸Size:类型Type:

技术TECHNIQUE

直线或横向摆动喊道Stringer or Weave Bead:

多道或单道(每边)Multi-pass or Single Pass(per side):

焊丝数Numbei of Electrodes:

焊丝间隔Electrode Spacing 纵向Longitudinal:

横向Lateral:

角度Angle:

导电咀到工件距离Contact Tube to Work Distance:

锤击Peening:

道间清理Interpass Cleaning:

焊后热处理POSTWELD HEAT TREATMENT

温度Temp.:

时间Time :。