JSJ#.12055零部件技术规格书18秒延时冲洗电磁阀A版.doc

- 格式:doc

- 大小:105.00 KB

- 文档页数:5

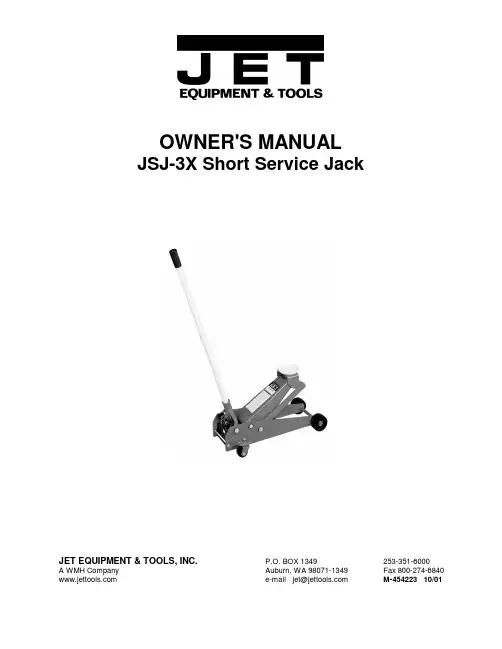

OWNER'S MANUALJSJ-3X Short Service JackJET EQUIPMENT&TOOLS,INC.P.O.BOX1349253-351-6000A WMH Company Auburn,WA98071-1349Fax800-274-6840 e-mail****************M-45422310/01Important Information1-YEAR JET offers a one-year limited LIMITED WARRANTY warranty on this productReplacement parts for this tool are available directly form JET Equipment&Tools.To place an order,call1-800-274-6848.Please have the following information ready:1.Visa,MasterCard,or Discover Card number2.Expiration date3.Part number listed within this manual4.Shipping address other than a Post Office box.JET Equipment&Tools makes every effort to assure that parts meet high quality and durability standards and warrants to the original retail consumer/purchaser of our parts that each such part(s)to be free from defects in materials and workmanship for a period of thirty(30)days from the date of purchase.Please retain your dated sales receipt as proof of purchase to validate the warranty period.JET makes every effort to assure that its products meet high quality and durability standards and warrants to the original retail consumer/purchaser of our products that each product be free from defects in materials and workmanship as follows:1YEAR LIMITED WARRANTY ON THIS JET PRODUCT.Warranty does not apply to defects due directly or indirectly to misuse,abuse,negligence or accidents,repairs or alterations outside our facilities or to a lack of maintenance.JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL.EXCEPT AS STATED HEREIN,ANY IMPLIED WARRANTIES OR MECHANTABILITY AND FITNESS ARE EXCLUDED.SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.JET SHALL IN NO EVENT BE LIABLE FOR DEATH,INJURIES TO PERSONS OR PROPERY OR FOR INCIDENTAL,CONTINGENT,SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.To take advantage of this warranty,the product or part must be returned for examination, postage prepaid,to an authorized service station designated by our Auburn office.Proof of purchase date and an explanation of the complaint must accompany the merchandise.If our inspection discloses a defect,JET will either repair or replace the product or refund the purchase price,if we cannot readily and quickly provide a repair or replacement,if you are willing to accept such refund.JET will return repaired product or replacement at JET’s expense,but if it is determined there is no defect,or that the defect resulted from causes not within the scope of JET’s warranty,then the user must bear the cost of storing and returning the product.This warranty gives you specific legal rights,and you have other rights,which vary,from state to state.JET Equipment&Tools•P.O.Box1349,Auburn,WA98071-1349•(253)351-6000WARNING1.This is a lifting device only.Do not move or dolly the vehicle while on the jack.The load shall besupported immediately by other appropriate means.2.Do not overload.Overloading can cause damage to or failure of the jack.3.Lift only on areas of the vehicle specified by the vehicle manufacturer.4.This jack is designed for use on hard,level surfaces capable of sustaining the e on otherthan hard,level surfaces can result in jack instability and possible loss of load.5.Do not get under vehicle while jack is being used as the only support.6.If jack needs service,contact your local JET distributor for the location of the closest JET ServiceStation.e only factory replacement parts when replacement of parts is necessary.8.Failure to comply with all of these warnings may result in loss of load,damage to jack,and/or failureresulting in personal injury or property damage.Specifications:JSJ-3XStock Number (454223)Rated Capacity.................................................................................................................................3Ton Minimum Height...............................................................................................................................5-1/2”Maximum Height..................................................................................................................................21”Saddle..............................................................................................................................................5-1/8”Overall Length......................................................................................................................................26”Overall Width.......................................................................................................................................13”Handle Length................................................................................................................................373/4”Net Weight(approx.)........................................................................................................................86lb. Shipping Weight(approx.)................................................................................................................90lb. AssemblyNote:For parts identification,refer to parts list.1.Insert upper handle(34,page5)into lower handle(32,page5)and fasten with hex cap bolt(31,page5).2.Remove handle bolt(25,page5).3.Insert handle assembly into handle socket(27,page5).Make sure handle assembly engages gearshaft(29,page5)by turning handle back and forth and observing movement of handle socket gear (14,page7).4.Install handle bolt(25,page5)to secure handle assembly.LubricationNote:Before initial operation,lubricate the jack.1.Handle-use#2tube grease on release valve gears below handle and lightly grease handle at pointwhere it fits into socket.2.Lifting Arm-inject#2tube grease into grease fitting.3.Plunger-use#2tube grease to lubricate pump plunger.4.Lubricate pivoting and moving parts with a30W oil.Lubrication PointsOperating InstructionsImportant:Sometimes during shipment and handling,air gets into the hydraulic system,causing poor lifting performance.Before initial operation,purge any air from the system by fully opening release(turn handle counter-clockwise).Then,while holding the saddle down,pump handle rapidly several times.Raising the Jack1.Turn handle clockwise,until resistance is felt,to close release valve.Do not over tighten.2.Place jack directly under object to be lifted.Make sure saddle takes up weight firmly,and centrally.Check positioning under slight load to confirm jack or load will not slip.3.Raise jack by pumping handle until desired height is reached.After lifting,secure load byappropriate means.Do not use jack as the only means of support.Lowering the Jack1.Slowly turn handle counter-clockwise.Speed of descent is controlled by how much the release valveis turned.Always store jack in the fully lowered position.TroubleshootingIf jack fails to raise to its limit,remove oil fill plug(7,page7).Fill with just enough quality hydraulic jack fluid so that the jack raises to its limit.Index PartNo.No.Description Size Qty.1..........JSJ3S-01.........................Retainer Ring*. (2)2..........JSJ3S-02.........................Washer (2)3..........JSJ3S-03.........................Front Wheel* (2)4..........JSJ3S-04.........................Side Plate Assembly. (1)5..........JSJ3S-05.........................Lock Washer (2)6..........JSJ3S-06.........................Nut................................................................M16. (2)7..........JSJ3S-07.........................Caster Assembly*(inclds:#7-10).. (2)8..................................................Ball Ring. (2)9..................................................Ball Bearing (38)10................................................Ball Cover. (2)11........JSJ3S-11.........................Lock Washer (4)12........JSJ3S-12.........................Socket Head Cap Screw................................M12x25. (2)13........JSJ3S-13.........................Arm Shaft.. (1)14........JSJ3S-14.........................Retainer Ring.. (2)15........JSJ3S-15.........................Nut................................................................M10. (3)16........JSJ3S-16.........................Lock Washer (3)17........JSJ3S-17.........................Shaft (1)18........JSJ3S-18.........................Nut................................................................M12. (2)19........JSJ3S-19.........................Bolt (2)20........JSJ3S-20.........................Lock Washer (2)21........JSJ3S-21.........................Pin. (1)22........JSJ3S-22.........................Washer (1)23........JSJ3S-23.........................Gear. (1)24........JSJ3S-24.........................Pump Pin.. (1)25........JSJ3S-25.........................Bolt (1)26........JSJ3S-26.........................Torsion Spring* (1)27........JSJ3S-27.........................Handle Socket. (1)28........JSJ3S-28.........................Washer (1)29........JSJ3S-29.........................Gear Shaft. (1)30........JSJ3X-30.........................Power Unit Assembly (1)31........JSJ3S-31.........................Bolt*..............................................................M6x35 (1)32........JSJ3S-32.........................Lower Handle*. (1)33........JSJ3S-33.........................Handle Grip*. (1)34........JSJ3S-34.........................Upper Handle*. (1)35........JSJ3S-35.........................Bolt (2)36........JSJ3S-36.........................Lifting Arm Assembly (1)37........JSJ3S-37.........................Saddle*.. (1)38........JSJ3S-38.........................Retainer Ring.. (2)39........JSJ3S-39.........................Grease Fitting.. (1)40........JSJ3S-40.........................Cross Head.. (1)41........JSJ3S-41.........................Pin. (1)42........JSJ3S-42.........................Return Spring*. (1)*Indicates normal stocked part.Other parts may be purchased on a special order basis only.Contact JET Equipment&Tools(1-800-274-6848)for details.Index PartNo.No.Description Size Qty.2..........JSJ3X-P02.......................O-Ring**......................................................30x3.55. (1)3..........JSJ3X-P03.......................Tank Nut (1)4..........JSJ3X-P04.......................O-Ring**.. (2)5..........JSJ3X-P05.......................Cylinder.. (1)6..........JSJ3X-P06.......................Oil Tank. (1)7..........JSJ3X-P07.......................Oil Fill Plug**. (1)8..........JSJ3X-P08.......................U-Cup** (1)9..........JSJ3X-P09.......................O-Ring**......................................................33x3.55. (1)11........JSJ3X-P11.......................Gear Retaining Nut........................................M8 (1)12........JSJ3X-P12.......................O-Ring**......................................................16x2.4 (1)13........JSJ3X-P13.JSJ3S-P15....Release Valve Assembly*. (1)14........JSJ3X-P14.......................Valve Stem.. (1)15........JSJ3X-P15.......................Guide Plate.. (1)16........JSJ3X-P16.......................Ball................................................................6 (1)17........JSJ3X-P17.......................Seal Washer**.. (1)18........JSJ3X-P18.......................Screw.. (1)19........JSJ3X-P19.......................Adjustment Screw.. (1)20........JSJ3X-P20.......................Seal Washer**.. (1)21........JSJ3X-P21.......................Wiper**. (1)22........JSJ3X-P22.......................Back Up Ring**.. (1)23........JSJ3X-P23.......................O-ring**.......................................................16x2.4 (1)24........JSJ3X-P24.......................Base. (1)25........JSJ3X-P25.......................Piston Pump. (1)26........JSJ3X-P26.......................Ball................................................................4 (1)27........JSJ3X-P27.......................Ball................................................................6 (1)28........JSJ3X-P28.......................Screw.. (1)29........JSJ3X-P29.......................Ball................................................................4 (1)30........JSJ3X-P30.......................Adapter.. (1)31........JSJ3X-P31.......................Spring.. (1)32........JSJ3X-P32.......................Ram. (1)33........JSJ3X-P33.......................O-ring**.......................................................14x2.4 (1)34........JSJ3X-P34.......................Washer (1)35........JSJ3X-P35.......................Back Up Ring.. (1)36........JSJ3X-P36.......................Spring.. (1)37........JSJ3X-P37.......................Ram. (1)38........JSJ3X-P38.......................Back Up Ring**. (1)39........JSJ3X-P39.......................O-ring**.......................................................50x2.4 (1)40........JSJ3X-P40.......................Cylinder Gasket** (1)41........JSJ3X-P41.......................Spring.. (1)42........JSJ3X-P42.......................O-ring**.......................................................6x3.. (3)43........JSJ3X-P43.......................Ball................................................................6 (1)44........JSJ3X-P44.......................Spring.. (1)45........JSJ3X-P45.......................Back Up Ring**. (2)46........JSJ3X-P46.......................Screw.. (1)47........JSJ3X-P47.......................Ball................................................................6 (1)48........JSJ3X-P48.......................Screw.. (1)49........JSJ3X-P49.......................Ball................................................................3 (1)50........JSJ3X-P50.......................Pin. (1)............JSJ3S-SK........................Seal Kit*(inclds parts marked with an“**”)......................................... ............JSJ3X-30.........................Power Unit Assembly(inclds:index numbers2-50)............................. *Indicates normal stocked part.Other parts may be purchased on a special order basis only.Contact JET Equipment&Tools(1-800-274-6848)fordetails.TGJET EQUIPMENT&TOOLS,INC.2415West Valley Highway N Fax:800-274-6840 A WMH Company P.O.Box1349Phone:253-351-6000 Auburn,WA98071-1349e-mail:****************。

Operating Instructions and Parts ManualLong Chassis Service JacksModels JSJ-3T/JSJ-5T/JSJ-10TWMH TOOL GROUP2420 Vantage DriveElgin, Illinois 60123 Part No. M-454430 Ph.: 800-274-6848 Revision A8/05 Copyright © WMH Tool GroupThis manual has been prepared for the owner and operators of a JET Model JSJ Service Jack. Its purpose, aside from machine operation, is to promote safety using accepted operating and maintenance procedures. To obtain maximum life and efficiency from your jack and to aid in using it safely, please read this manual thoroughly and follow the instructions carefully.Warranty and ServiceWMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service Center located throughout the United States can provide quick service or information.In most cases, a WMH Tool Group Service Center can assist in authorizing repair work, obtaining parts, or perform routine or major maintenance repair on your JET product.For the name of an Authorized Service Center in your area, please call 1-800-274-6848, or visit our web site at More InformationRemember, WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with your local WMH Tool Group distributor, or visit our web site at WMH Tool Group WarrantyWMH Tool Group makes every effort to assure that its products meet high quality and durability standards and warrants to the original retail consumer/purchaser of our products that each product be free from defects in materials and workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, repair or alterations outside our facilities, or to a lack of maintenance.WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.To take advantage of this warranty, the product or part must be returned for examination, postage prepaid, to an Authorized Service Center designated by our office. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the product at our discretion, or refund the purchase price if we cannot readily and quickly provide a repair or replacement. We will return the repaired product or replacement at WMH Tool Group’s expense, but if it is determined there is no defect, or that the defect resulted from causes not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and returning the product. This warranty gives you specific legal rights; you may also have other rights, which vary from state to state.WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to effect at any time, without prior notice, alterations to parts, fittings and accessory equipment, which they may deem necessary for any reason whatsoever.Table of ContentsWarranty and Service (2)Table of Contents (3)Warning (3)Introduction (4)Description (4)Specifications (4)Unpacking (5)Assembly (5)Before Operation (5)Operation (5)Maintenance (5)Replacement Parts (6)JSJ-3T, JSJ-5T, JSJ-10T Service Jacks (7)Parts List: JSJ-3T Service Jack (8)Parts List: JSJ-5T Service Jack (10)Parts List: JSJ-10T Service Jack (12)1. Read and understand the entire owner’s manual before attempting assembly or operation.2. This jack is designed for lifting vehicles only.3. The vehicle owner’s manual should be consulted prior to lifting the vehicle. Lift only on areas of thevehicle specified by the vehicle manufacturer.4. The jack must be on level and solid ground with wheels of vehicle facing straight ahead.5. Do not overload the jack. Overloading can cause damage to or failure of the jack.6. No one should remain in a vehicle that is being lifted.7. When lifting the vehicle, be sure to place the axle on the center of the jack saddle.8. After lifting the vehicle, place safety stands under the axles.9. Never get under a vehicle that is supported only by a jack.10. Never move the jack while is it supporting the vehicle.11. When lowering the vehicle, make sure nobody is around or under the lifted vehicle. Lower slowly.12. Safety valve is factory adjusted and no further adjustment is required.13. While not in use, always keep the handle straight up and locked so that it won’t fall.14. Read and understand the warnings posted on the jack and in this manual. Failure to comply with all ofthese warnings may result in loss of load, damage to jack and/or personal injury or property damage.15. Replace the warning labels if they become obscured or removed.16. Use only factory replacement parts when part replacement is necessary.- - SAVE THESE INSTRUCTIONS - -IntroductionThis manual is provided by WMH Tool Group covering the safe operation and maintenance procedures for a JET Model JSJ Service Jack. This manual contains instructions on assembly, safety precautions, general operating procedures, maintenance instructions and parts breakdown. This jack has been designed and constructed to provide years of trouble free operation if used in accordance with instructions set forth in this manual. If there are any questions or comments, please contact either your local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site: .DescriptionThe Model JSJ Service Jack is for heavy-duty automotive and truck repair and maintenance. It’s equipped with strong steel side plates, an extra wide swivel saddle, foot pump and locking T-bar handle. Hydraulic cylinder parts have been high-pressure tested at the factory, and parts at maximum stress points have been heat-treated. Also features a safety overload bypass system.SpecificationsModel Number.....................................JSJ-3T................................JSJ-5T.................................JSJ-10T Stock Number......................................454430...............................454450. (454410)Capacity (ton)...............................................3.........................................5 (10)Minimum Height (in.)..................................5.1....................................5.91.......................................6.30 Maximum Height (in.)..............................23.62..................................22.05.....................................22.05 Overall Length (in.)..................................51.6.................................55-1/2....................................60-7/8 Overall Width (in.)....................................12.8...............................14-5/16....................................19-1/2 Handle Length (in.).................................45.28..................................45.28.....................................45.28 Net Weight (lbs.).......................................155.....................................210. (320)The above specifications were current at the time this manual was published, but because of our policy of continuous improvement, WMH Tool Group reserves the right to change specifications at any time and without prior notice, without incurring obligations.UnpackingOpen shipping container and check for shippingdamage. Report any damage immediately toyour distributor and shipping agent. Do not discard any shipping material until the ServiceJack is assembled and running properly.AssemblyThe numbers in parentheses refer to the itemnumbers on the parts breakdown, page 7.1. Insert the handle (38) as far as it will go intothe handle socket (26).2. Tighten the hex cap screw (30) securely.When transporting the jack, the handle can beremoved and carried separately.Before OperationBefore operating the jack, any air in thehydraulic system must be removed. Proceed asfollows:1. Open the release valve by turning therelease valve knob (39) counter-clockwise.Pump the foot pedal (27) about six fullstrokes to let the air out of the hydraulicsystem.2. Close the release valve by turning therelease valve knob (39) clockwise as far asit will go.3. Pump the foot pedal (27) to raise the jack asfar up as it will go. Lower the jack byopening the release valve (39).NOTE: If the jack does not immediately respondto the pump action, repeat steps 1 through 3.OperationDo not use a saddle extenderwith this jack. Failure to comply may causedamage to property and/or serious injury.1. To raise the vehicle, make sure the releasevalve knob (39) is closed – turn it clockwiseuntil resistance is felt; do not overtighten.2. Carefully position the jack under the vehicle with the saddle under the point of contact.3. Pull the lock lever (31) up and push it over to the left until it slides into the upper slot.4. Pump the handle (38), or use the foot pedal (27) to raise the vehicle.5. To lower the vehicle, slowly and carefully rotate the release valve knob (39) counterclockwise. Speed of descent iscontrolled by how much the knob is rotated. Make sure all tools and personnel are clear before lowering the load. Lower slowly. Maintenance Lubricate the pin and other moving elements on the Lifting Arm with #2 tube grease. Lubricate the pin and other moving parts of the Handle Assembly. Tighten any loose screws. Insert grease into the grease fitting on the Front Wheels. With saddle completely lowered and handle in its lowest position, remove oil plug and check oil level. If low, fill with hydraulic jack oil until oil is level with the inner cylinder as seen from the opening of the filler hole. NOTE: Completely drain and re-fill the oil tank at least once a year. With saddle completely lowered and handle in lowest position, remove the oil plug. Lay the jack on its side and drain fluid into an appropriate container. Re-fill with good quality hydraulic jack oil and replace oil plug. Never use brake fluid or any other highly viscous or volatile oil. Always store jack in the fully lowered position with handle upright.TroubleshootingNumbers in parentheses refer to the item numbers on the parts breakdown, page 7. Trouble Probable CauseRemedy Release valve not properly closed.Tighten release valve knob (39). No oil in system.Fill to prescribed level. Jack is overloaded.Remedy overload condition. Use jack with proper capacity for the load. Release Valve (52-54) or Safety Valve(55-60) malfunctioning. Valve Ball notproperly seated.Clean valves to remove dirt or foreign matter and replace oil. Jack will not lift.Seal/gasket worn out or defective.Replace seal/gasket. Jack will only lift partway. Oil level low or too high. Fill to proper level, or remove excess oil.Release Valve (52-54) or Safety Valve (55-60) malfunctioning. Valve Ball not properly seated. Inspect valves; clean and adjust seatsurface.Jack will lift load, but will not hold. Seal/gasket worn out or defective. Replace seal/gasket.Release valve (52-54) not opening. Clean and adjust Release Valve.Reservoir is overfilled. Drain oil to proper level.Jack will not lower after unloading. Linkages binding. Clean and lubricate moving parts.Pump gasket (50) defective or Valves malfunctioning. Replace gasket and/or clean valves.Oil level low, or dirty oil. Fill or replace oil.Poor lift performance. Air trapped in system. Bleed air from system.Pump plunger (49) bent or marred. Replace pump plunger.Jack Spring damaged. Replace spring.Jack will not lower completely. Link section warped or deformed due topossible over-loading.Replace warped parts.Replacement PartsReplacement parts are listed on the following pages. To order parts or reach our service department, call 1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model Number and Serial Number of your machine available when you call will allow us to serve you quickly and accurately.JSJ-3T, JSJ-5T, JSJ-10T Service JacksParts List: JSJ-3T Service JackIndex No. Part No. Description Size Qty1...............JSJ3M-18................Frame and Lift Arm Assembly (1)2...............JSJ3T-2..................Front Wheel (2)3...............JSJ3M-16................Flat Washer.................................................Ø 22.5 x 2mm. (2)4...............JSJ3M-15................Snap Ring....................................................Ø 15mm. (2)5...............JSJ3T-5..................Grease Fitting (4)6...............JSJ3T-6..................Saddle.. (1)7...............JSJ3M-12................Link Rod.. (2)8...............JSJ3M-11................Link Rod Bolt. (2)9...............JSJ3M-8..................Lock Washer................................................M16. (2)10.............JSJ3M-9..................Hex Nut.......................................................M16. (2)11.............JSJ3M-21................Spring (1)12.............TS-2210161............Hex Cap Screw............................................M10 x 16mm (1)13.............TS-1491031............Hex Cap Screw............................................M10 x 25mm (2)14.............TS-2361101............Lock Washer................................................M10. (2)15.............JSJ3T-15................Shaft.. (1)16.............JSJ3M-07................Rear Wheel Assembly.. (2)17.............JSJ3M-02................Hex Nut.......................................................M12 x 1.25mm (4)18.............JSJ3M-32................Snap Ring....................................................Ø 18mm. (2)19.............JSJ3M-33................Shaft.. (1)20.............TS-1550061............Flat Washer.................................................M8 (1)21.............JSJ3T-21................Pin...............................................................Ø 3 x 18mm. (2)22.............JSJ3M-36................Link (2)23.............JSJ3T-23................Snap Ring....................................................Ø 12mm. (2)24.............JSJ3T-24................Pedal Pin. (1)25.............JSJ3M-26................Spring (1)26.............JSJ3T-26................Handle Socket.. (1)27.............JSJ3M-29................Pedal. (1)28.............JSJ3M-40................Lock Nut......................................................M10. (1)29.............JSJ3M-41................Flat Washer.................................................M10. (2)30.............JSJ3M-42................Hex Bolt.......................................................M10 x 35mm (1)31.............JSJ3T-31................Control Rod (1)32.............JSJ3T-32................Handle Sleeve.. (2)33.............JSJ3T-33................Fixing Ring. (1)34.............JSJ3T-34................Spring (1)35.............JSJ3M-53................Flat Washer.................................................Ø 10mm. (1)36.............JSJ3T-36................Rod Joint. (1)37.............JSJ3T-137...............Cotter Pin....................................................Ø 4 x 20mm. (1)38.............JSJ3T-38................Handle.. (1)39.............JSJ3T-39................Knob.. (1)40.............JSJ3T-40................Lock Pin......................................................Ø 4 x 40mm. (1)41.............JSJ3M-28................Universal Joint Assembly. (1)42.............JSJ3T-42................Pin...............................................................Ø 3 x 20mm. (1)43.............JSJ3M-43................Spring (1)44.............JSJ3T-44................Lock Pin......................................................Ø 3 x 18mm. (1)45.............JSJ3T-45................Release Rod.. (1)46.............JSJ3T-46................Lock Pin......................................................Ø 4 x 20mm. (2)47.............JSJ3T-47................Cover. (1).................JSJ3T-200...............Hydraulic Cylinder Assembly (includes index # 48 thru 76)48.............JSJ3T-48................Pump Plunger Pin (1)49.............JSJ3T-49................Pump Plunger (1)50.............JSJ3T-50................Nylon Gasket *.............................................Ø 14mm. (2)51.............JSJ3T-51................O-Ring *......................................................Ø 14 x 2.65mm.. (2)52.............JSJ3T-52................Release Pin (1)53.............JSJ3T-53................Seal *. (1)54.............SB-6MM..................Steel Ball.....................................................Ø 6mm (2)55.............SB-4MM..................Steel Ball.....................................................Ø 4mm (1)56.............JSJ3T-56................Safety Valve Ball Seat.. (1)57.............JSJ3T-57................Safety Valve Spring (1)58.............JSJ3T-58................Safety Valve Adjusting Screw (1)59.............JSJ3T-59................Seal *. (1)60.............JSJ3T-60................Safety Valve Screw. (1)61.............JSJ3T-61................Spring (1)62.............SB-9MM..................Steel Ball.....................................................Ø 9mm (1)63.............JSJ3T-63................Spring (1)64.............JSJ3T-64................Copper Washer (1)65.............TS-1506011............Socket Head Cap Screw..............................M12 x 20mm (1)66.............JSJ3T-66................Oil Filler Plug. (1)67.............JSJ3T-67................Oil Tank Assembly.. (1)68.............JSJ3T-68................Snap Ring....................................................Ø 36mm. (1)69.............JSJ3T-69................O-Ring Retainer (1)70.............JSJ3T-70................O-Ring *......................................................Ø 36 x 4.6mm. (1)71.............JSJ3T-71................Seal Washer * (1)72.............JSJ3T-72................Piston Ring. (1)73.............JSJ3T-73................Ram.. (1)74.............JSJ3T-74................Bushing (2)75.............JSJ3T-75................O-Ring *......................................................Ø 43 x 3.55mm.. (1)76.............JSJ3T-76................Snap Ring (1).................JSJ3T-RK...............Repair Kit for JSJ-3T............................................................................... NOTE: Items marked with an asterisk (*) are included in the Repair Kit.Parts List: JSJ-5T Service JackIndex No. Part No. Description Size Qty1...............JSJ5M-18................Frame and Lift Arm Assembly (1)2...............JSJ5T-2..................Front Wheel (2)3...............JSJ5M-16................Flat Washer.................................................Ø 22.5 x 2mm. (2)4...............JSJ5M-15................Snap Ring....................................................Ø 19mm. (4)5...............JSJ3T-5..................Grease Fitting (3)6...............JSJ5T-6..................Saddle.. (1)7...............JSJ5M-12................Link Rod.. (2)8...............JSJ5M-11................Link Rod Bolt. (2)9...............JSJ5M-8..................Lock Washer................................................M20. (2)10.............JSJ5M-9..................Hex Nut.......................................................M20. (2)11.............JSJ5M-21................Spring (1)12.............TS-2210161............Hex Cap Screw............................................M10 x 16mm (1)13.............TS-1491031............Hex Cap Screw............................................M10 x 25mm (2)14.............TS-2361101............Lock Washer................................................M10. (2)15.............JSJ5T-15................Shaft.. (1)16.............JSJ5T-16................Rear Wheel Assembly.. (2)17.............JSJ3M-02................Hex Nut.......................................................M12 x 1.25mm (4)18.............JSJ3M-32................Snap Ring....................................................Ø 18mm. (2)19.............JSJ5M-33................Shaft.. (1)20.............TS-1550061............Flat Washer.................................................M8 (1)21.............JSJ3T-21................Pin...............................................................Ø 3 x 18mm. (2)22.............JSJ5M-36................Link (2)23.............JSJ3T-23................Snap Ring....................................................Ø 12mm. (2)24.............JSJ3T-24................Pedal Pin. (1)25.............JSJ3M-26................Spring (1)26.............JSJ3T-26................Handle Socket.. (1)27.............JSJ3M-29................Pedal. (1)28.............JSJ3M-40................Lock Nut......................................................M10. (1)29.............JSJ3M-41................Flat Washer.................................................M10. (2)30.............JSJ3M-42................Hex Cap Screw............................................M10 x 35mm (1)31.............JSJ3T-31................Control Rod (1)32.............JSJ3T-32................Handle Sleeve.. (2)33.............JSJ3T-33................Fixing Ring. (1)34.............JSJ3T-34................Spring (1)35.............JSJ3M-53................Flat Washer.................................................Ø 10mm. (1)36.............JSJ3T-36................Rod Joint. (1)37.............JSJ3T-137...............Cotter Pin....................................................Ø 4 x 20mm. (1)38.............JSJ3T-38................Handle.. (1)39.............JSJ3T-39................Knob.. (1)40.............JSJ3T-40................Lock Pin......................................................Ø 4 x 40mm. (1)41.............JSJ10M-28..............Universal Joint Assembly. (1)42.............JSJ3T-42................Pin...............................................................Ø 3 x 20mm. (1)43.............JSJ3M-43................Spring (1)44.............JSJ3T-44................Lock Pin......................................................Ø 3 x 18mm. (1)45.............JSJ3T-45................Release Rod.. (1)46.............JSJ3T-46................Lock Pin......................................................Ø 4 x 20mm. (2)47.............JSJ5T-47................Cover. (1).................JSJ5T-200...............Hydraulic Cylinder Assembly (includes index #48 thru 76)48.............JSJ3T-48................Pump Plunger Pin (1)49.............JSJ3T-49................Pump Plunger (1)50.............JSJ3T-50................Nylon Gasket *.............................................Ø 14mm. (2)51.............JSJ3T-51................O-Ring *......................................................Ø 14 x 2.65mm.. (2)52.............JSJ3T-52................Release Pin (1)53.............JSJ3T-53................Seal *. (1)54.............SB-6MM..................Steel Ball.....................................................Ø 6mm (2)55.............SB-4MM..................Steel Ball.....................................................Ø 4mm (1)56.............JSJ3T-56................Safety Valve Ball Seat.. (1)57.............JSJ3T-57................Safety Valve Spring (1)58.............JSJ3T-58................Safety Valve Adjusting Screw (1)59.............JSJ3T-59................Seal *. (1)60.............JSJ3T-60................Safety Valve Screw. (1)61.............JSJ3T-61................Spring (1)62.............SB-9MM..................Steel Ball.....................................................Ø 9mm (1)63.............JSJ3T-63................Spring (1)64.............JSJ3T-64................Copper Washer (1)65.............TS-1506011............Socket Head Cap Screw..............................M12 x 20mm (1)66.............JSJ3T-66................Oil Filler Plug. (1)67.............JSJ5T-67................Oil Tank Assembly.. (1)68.............JSJ5T-68................Snap Ring....................................................Ø 40mm. (1)69.............JSJ5T-69................O-Ring Retainer (1)70.............JSJ5T-70................O-Ring *......................................................Ø 46.2 x 5.7mm. (1)71.............JSJ5T-71................Seal Washer * (1)72.............JSJ5T-72................Piston Ring. (1)73.............JSJ5T-73................Ram.. (1)74.............JSJ5T-74................Bushing (2)75.............JSJ5T-75................O-Ring *......................................................Ø 51.5 x 4.6mm. (1)76.............JSJ5T-76................Snap Ring (1).................JSJ5T-RK...............Repair Kit for JSJ-5T............................................................................... NOTE: Items marked with an asterisk (*) are included in the Repair Kit.Parts List: JSJ-10T Service JackIndex No. Part No. Description Size Qty1...............JSJ10M-18..............Frame and Lift Arm Assembly (1)2...............JSJ10T-2................Front Wheel (2)3...............JSJ10M-16..............Flat Washer.................................................Ø 22.5 x 2mm. (2)4...............JSJ10M-15..............Snap Ring....................................................Ø 19mm. (4)5...............JSJ3T-5..................Grease Fitting (3)6...............JSJ10T-6................Saddle.. (1)7...............JSJ10M-12..............Link Rod.. (2)8...............JSJ10M-11..............Link Rod Bolt. (2)9...............JSJ5M-8..................Lock Washer................................................M20. (2)10.............JSJ5M-9..................Hex Nut.......................................................M20. (2)11.............JSJ10M-21..............Spring (1)12.............TS-2210161............Hex Cap Screw............................................M10 x 16mm (1)13.............TS-1491031............Hex Cap Screw............................................M10 x 25mm (2)14.............TS-2361101............Lock Washer................................................M10. (2)15.............JSJ10T-15...............Shaft.. (1)16.............JSJ10T-16...............Rear Wheel Assembly.. (2)17.............TS-154010..............Hex Nut.......................................................M16. (2)17A...........TS-2361161............Lock Washer (not shown)............................M16. (2)18.............JSJ3M-32................Snap Ring....................................................Ø 18mm. (2)19.............JSJ10M-33..............Shaft.. (1)20.............TS-1550061............Flat Washer.................................................M8 (1)21.............JSJ3T-21................Pin...............................................................Ø 3 x 18mm. (2)22.............JSJ10M-36..............Link (2)23.............JSJ3T-23................Snap Ring....................................................Ø 12mm. (2)24.............JSJ3T-24................Pedal Pin. (1)25.............JSJ10M-26..............Spring (1)26.............JSJ3T-26................Handle Socket.. (1)27.............JSJ3M-29................Pedal. (1)28.............JSJ3M-40................Lock Nut......................................................M10. (1)29.............JSJ3M-41................Flat Washer.................................................M10. (2)30.............JSJ3M-42................Hex Cap Screw............................................M10 x 35mm (1)31.............JSJ3T-31................Control Rod (1)32.............JSJ3T-32................Handle Sleeve.. (2)33.............JSJ3T-33................Fixing Ring. (1)34.............JSJ3T-34................Spring (1)35.............JSJ3M-53................Flat Washer.................................................Ø 10mm. (1)36.............JSJ3T-36................Rod Joint. (1)37.............JSJ3T-137...............Cotter Pin....................................................Ø 4 x 20mm. (1)38.............JSJ3T-38................Handle.. (1)39.............JSJ3T-39................Knob.. (1)40.............JSJ3T-40................Lock Pin......................................................Ø 4 x 40mm. (1)41.............JSJ10M-28..............Universal Joint Assembly. (1)42.............JSJ3T-42................Pin...............................................................Ø 3 x 20mm. (1)43.............JSJ3M-43................Spring (1)44.............JSJ3T-44................Lock Pin......................................................Ø 3 x 18mm. (1)45.............JSJ3T-45................Release Rod.. (1)46.............JSJ3T-46................Lock Pin......................................................Ø 4 x 20mm. (2)47.............JSJ10T-47...............Cover. (1).................JSJ10T-200.............Hydraulic Cylinder Assembly (includes index # 48 thru 76)48.............JSJ10T-48...............Pump Plunger Pin (1)49.............JSJ10T-49...............Pump Plunger (1)50.............JSJ10T-50...............Nylon Gasket *.............................................Ø 15mm. (2)51.............JSJ10T-51...............O-Ring *......................................................Ø 15 x 2.65mm.. (2)52.............JSJ3T-52................Release Pin (1)53.............JSJ3T-53................Seal *. (1)54.............SB-6MM..................Steel Ball.....................................................Ø 6mm (2)55.............SB-4MM..................Steel Ball.....................................................Ø 4mm (1)。

SomachineA刷新程序说明1、Somachine对文件是以工程以及工程存档来管理的。

●工程文件(.project):具有图标,可以双击直接用Somachine打开,属于可执行文件,具有友好性的特点。

但是因其首次在陌生的PC平台中使用时会导致库文件的丢失而报错,造成无法编译等错误,使其可移植性不够好。

●工程存档文件(.projectarchive):其与工程文件(.project)是两个不同的概念。

工程存档文件可以解压出工程文件,甚至包括该程序所需硬件的库,可移植性好。

●首次分发文件时,将以工程存档文件(.projectarchive)下发。

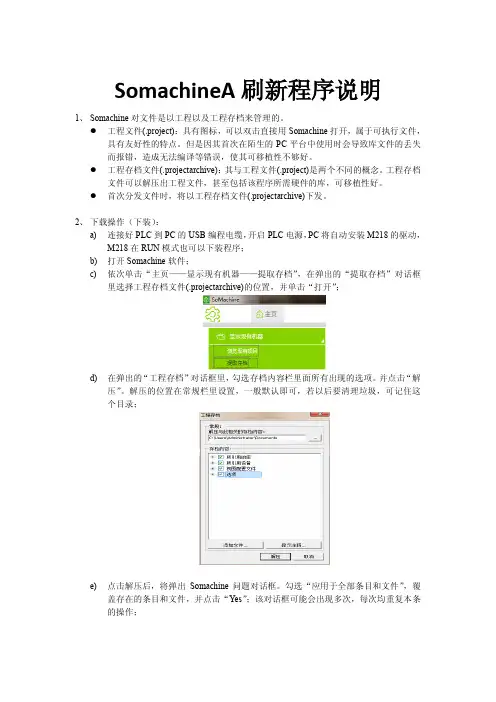

2、下载操作(下装):a)连接好PLC到PC的USB编程电缆,开启PLC电源,PC将自动安装M218的驱动,M218在RUN模式也可以下装程序;b)打开Somachine软件;c)依次单击“主页——显示现有机器——提取存档”,在弹出的“提取存档”对话框里选择工程存档文件(.projectarchive)的位置,并单击“打开”;d)在弹出的“工程存档”对话框里,勾选存档内容栏里面所有出现的选项。

并点击“解压”。

解压的位置在常规栏里设置,一般默认即可,若以后要清理垃圾,可记住这个目录;e)点击解压后,将弹出Somachine问题对话框。

勾选“应用于全部条目和文件”,覆盖存在的条目和文件,并点击“Yes”;该对话框可能会出现多次,每次均重复本条的操作;f)上述的操作后,将选项卡从“属性”切换到“程序”;g)点击出现的工具栏里的“在线——登录到‘Application[MyController:PLC]’”;h)如果弹出如下对话框,请点击确定;i)然后在“MyController——通讯设置”的选项卡中,点击“添加网关…”,将弹出网关对话窗,直接“确定”。

j)点击“扫描网络”按钮,并等待该按钮变成可操作状态。

然后点击,等待前面出现展开符号,然后点击展开所有项目,选中展开的最底层的(M218)SN ******[****.****],变深色,如下图所示:k)点击“设置使用路径”,在弹出的“警告”窗口后,按组合键“AL T+F”,即可,如下图;不相同,将弹出如下窗口,请选择“登录并下装”,确定即可;下装之前,该平台将自动对程序进行编译并生成代码。

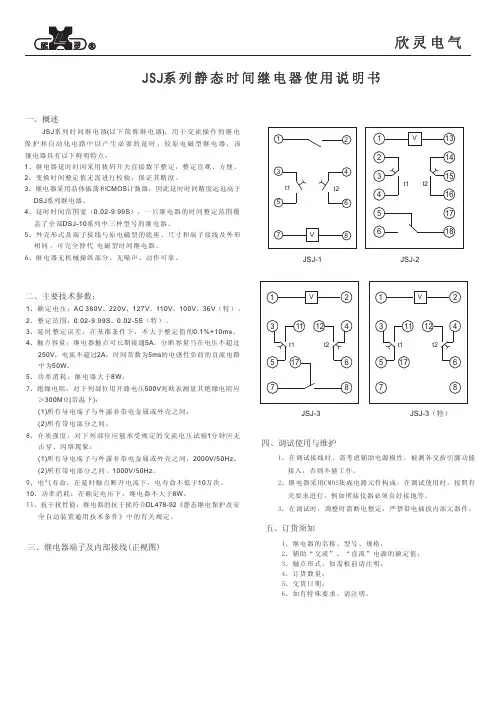

一、概述JSJ 系列静态时间继电器使用说明书三、继电器端子及内部接线(正视图)二、主要技术参数:JSJ 系列时间继电器(以下简称继电器),用于交流操作的继电保护和自动化电路中以产生必要的延时。

较原电磁型继电器,该 继电器具有以下鲜明特点:1、继电器延时时间采用拔码开关直接数字整定,整定直观、方便。

2、变换时间整定值无需进行校验,保证其精度。

3、继电器采用晶体振荡和CMOS 计数器,因此延时时间精度远远高于 DSJ 系列继电器。

4、延时时间范围宽(0.02-9.99S ),一只继电器的时间整定范围覆5、外壳形式及端子接线与原电磁型的底座、尺寸和端子接线及外形 相同 ,可完全替代 电磁型时间继电器。

6、继电器无机械操纵部分、无噪声、动作可靠。

3、延时整定误差:在基准条件下,不大于整定值的0.1%+10ms 。

4、触点容量:继电器触点可长期接通5A ,分断容量当在电压不超过 250V ,电流不超过2A ,时间常数为5ms 的电感性负荷的直流电路 中为50W 。

7、绝缘电阻:对下列部位用开路电压500V 兆欧表测量其绝缘电阻应 ≥300M Ω(常温下):(1)所有导电端子与外露非带电金属或外壳之间; (2)所有带电部分之间;8、介质强度:对下列部位应能承受规定的交流电压试验1分钟应无 击穿、闪络现象:(1)所有导电端子与外露非带电金属或外壳之间,2000V/50Hz 。

(2)所有带电部分之间,1000V/50Hz 。

9、电气寿命:在延时触点断开电流下,电寿命不低于10万次。

10、功率消耗:在额定电压下,继电器不大于8W 。

11、抗干扰性能:继电器的抗干扰符合DL478-92《静态继电保护及安 全自动装置通用技术条件》中的有关规定。

1、额定电压:AC 380V 、220V 、127V 、110V 、100V 、36V (特)。

2、整定范围:0.02-9.99S 、0.02-5S (特)。

盖了全部DSJ-10系列中三种型号的继电器。

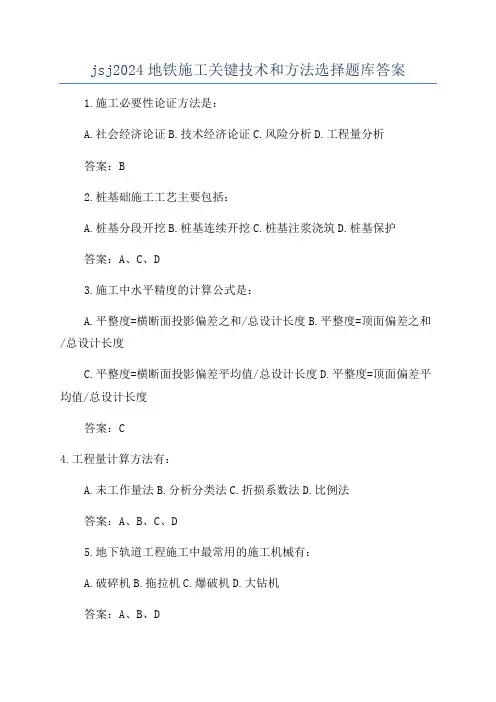

jsj2024地铁施工关键技术和方法选择题库答案

1.施工必要性论证方法是:

A.社会经济论证

B.技术经济论证

C.风险分析

D.工程量分析

答案:B

2.桩基础施工工艺主要包括:

A.桩基分段开挖

B.桩基连续开挖

C.桩基注浆浇筑

D.桩基保护

答案:A、C、D

3.施工中水平精度的计算公式是:

A.平整度=横断面投影偏差之和/总设计长度

B.平整度=顶面偏差之和/总设计长度

C.平整度=横断面投影偏差平均值/总设计长度

D.平整度=顶面偏差平均值/总设计长度

答案:C

4.工程量计算方法有:

A.未工作量法

B.分析分类法

C.折损系数法

D.比例法

答案:A、B、C、D

5.地下轨道工程施工中最常用的施工机械有:

A.破碎机

B.拖拉机

C.爆破机

D.大钻机

答案:A、B、D

6.地铁轨道的硬度检测方法主要有:

A.钻孔法

B.压入法

C.厚度检测法

D.动摩擦指数法

答案:A、B、D

7.地铁线路布置中选择枢纽站的基本原则是:

A.满足经济效益

B.提高利用率

C.节约施工成本

D.减少运行时间

答案:A、B、D

8.地铁施工关键技术中的安全技术应用包括:

A.运行安全技术

B.电气安全技术

C.原材料安全技术

D.水土保持技术答案:A、B、C。

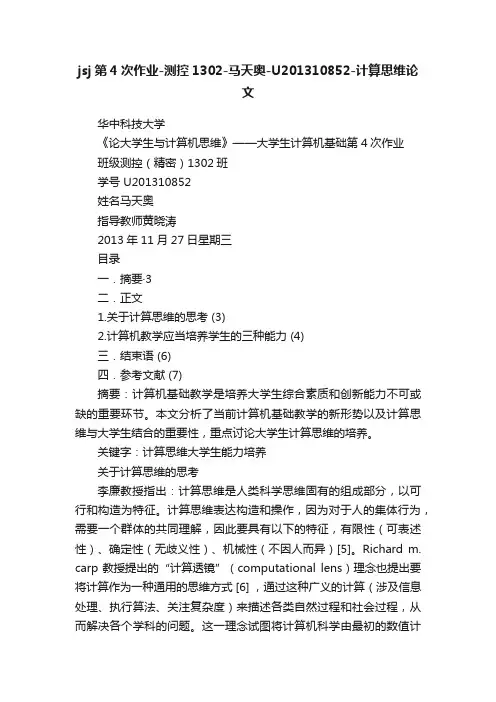

jsj第4次作业-测控1302-马天奥-U201310852-计算思维论文华中科技大学《论大学生与计算机思维》——大学生计算机基础第4次作业班级测控(精密)1302班学号 U201310852姓名马天奥指导教师黄晓涛2013年11月27日星期三目录一.摘要·3二.正文1.关于计算思维的思考 (3)2.计算机教学应当培养学生的三种能力 (4)三.结束语 (6)四.参考文献 (7)摘要:计算机基础教学是培养大学生综合素质和创新能力不可或缺的重要环节。

本文分析了当前计算机基础教学的新形势以及计算思维与大学生结合的重要性,重点讨论大学生计算思维的培养。

关键字:计算思维大学生能力培养关于计算思维的思考李廉教授指出:计算思维是人类科学思维固有的组成部分,以可行和构造为特征。

计算思维表达构造和操作,因为对于人的集体行为,需要一个群体的共同理解,因此要具有以下的特征,有限性(可表述性)、确定性(无歧义性)、机械性(不因人而异)[5]。

Richard m. carp教授提出的“计算透镜”(computational lens)理念也提出要将计算作为一种通用的思维方式 [6] ,通过这种广义的计算(涉及信息处理、执行算法、关注复杂度)来描述各类自然过程和社会过程,从而解决各个学科的问题。

这一理念试图将计算机科学由最初的数值计算工具、仿真与可视化技术以及后来基于网络、面向多学科的e-science平台,变成普遍适用于自然和社会领域的通用思维模式。

计算科学是一门正在兴起的综合性学科,它依赖于先进的计算机及计算技术对理论科学、大型实验、观测数据、应用科学、国防以及社会科学进行模型化、模拟与仿真、计算等。

特别是对极复杂系统进行模型与程序化,然后利用计算机给出严格理论及实验无法达到的过程数据或者直接模拟出整个复杂过程的演变或者预测过程的发展趋势。

对基础科学、应用科学、国防科学、社会科学以及工程技术等的发展有着不可估量的科学作用与经济效益。

JSJ-GL型爬架控制系统使⽤说明书JSJ-GL型爬架控制系统使⽤⼿册JSJ-GL型爬架控制系统使⽤说明书⼀、系统概述JSJ-GL型爬架控制系统综合运⽤单⽚机和测⼒传感器测控技术,通过单⽚微型计算机对被提升脚⼿架的载荷进⾏综合分析并作出相应处理,实现了对脚⼿架的升降的全过程的实时监测和⾃动控制,使整个爬架的升降⾃如、快速、准确、安全,从⽽有效地保证了施⼯的优质进⾏。

JSJ-GL型爬架控制系统使⽤以总控和多台以单⽚微型计算机为核⼼的分控以及测⼒传感器组成的测量系统。

通过单⽚微型计算机对系统中各分控的载荷进⾏实时检测、实时报警、实时排障和实时控制,有效地保证了脚⼿架施⼯的快速、安全和准确。

系统特点:本系统采⽤两种控制⽅式:⼿动控制和遥控器控制,实现现场操作的简易化。

控制系统的控制线路采⽤并⾏的⽅式连接,解决了过去因分控线路出现故障⽽使整个控制信号⽆法传递给总控的状况。

同时各分控全部有单独控制动作,当分控的单⽚微型计算机检测到当前机位异常时,会⾃动发出相应的动作,并将信号传递给总控。

简单易懂易操作,操作者不需要懂得计算机知识,只要懂得⼀定的升降架的基本原理,就能很轻松地掌握该系统的操作。

本系统设计安全控制机位数为35台,如需增加机位,可根据⽤户要求定做。

⼆、爬架控制系统的原理、组成2.1基本原理本套系统采样的主要数据是机位的载荷数据,通过单⽚微型计算机实现各种状态的动作切换,控制的主要对象是三相交流电机。

2.2 系统组成(注:n表⽰吊点数⽬,最多可控制50台分控)总控:1台对总控和分控发布升、降、停等命令。

分控:n台采集的每个机位的实时载荷数据,进⾏综合分析,以判别各种故障,及时作出相应的⾃动化操作,如预警和停机。

测⼒传感器:n套带5芯屏蔽电缆、5芯航空插座,它是机位吊点载荷的直接承受者,通过对载荷的实时测量并产⽣相应的模拟信号,供分控单⽚微型计算机采集。

控制电缆:采⽤总线的控制模式,将各分控连接在⼀起,控制电缆1条。

専門用語1.あいこんアイコン(icon)2.あくせすアクセス(access)3.あどれすアドレス(address)4.あっぷアップ(up)5.あせんぶらアセンブラ(assembler):汇编程序,程序集6.あぷりけーしょん・アプリケーション(application)7.いめーじイメージ(image)8.いんたーねっとインターネット(Internet)9.いんたーふぇーすインタフェース(Interface)10.えらーエラー(error)11.えりあエリア(Area)12.おぶじぇくとオブジェクト(object)13.おぷしょんオプション(option)14.かたろぐカタログ(Catalog)15.キー(key)16.きーぼーどキーボード(Keyboard)17.くりあクリア(clear)18.くらいあんとクライアント(client)19.くりっくクリック(Click)20.ぐるーぷグループ(Group)21.ケースcase22.コアcore(核核心)23.コーディングcoding(编码)24.コストcost(成本费用)コストダウンcost Down()25.コピーcopy(复制复印)26.コマンドcommand(命令指令)27.コメントcomment(评论注释说明)28.コミュニケーションcommunication(沟通交流通信传达)29.コントロールcontrol30.コンピュータcomputer31.コードcode(代码)32.サーバーServer(服务)サービスservice 33.サイズsize(型号)34.サブシステムsubsystem(子系统)35.サポートsupport(支持)36.システムsystem36.シリーズseries(系列)37.スキルskill(技能技巧)38.スケジュールschedule(日程表进度日程)39.ステップstep(步骤阶段台阶)40.スピードspeed(速度)41.スライドショーslideshow(幻灯片)42.スペースspace(空格)43.スクリーンscreen(屏幕)44.セットset(设置)45.セキュリティsecurity(保护安全)46.ソースコードsource code(源代码)47.ソフトウェアsoftware(软件)48.ソリューシォンsolution(解决方案)49.タスクtask(工作任务)50.ダウンロードdownload(下载)51.タイプtype(种类类型)52.チェック(check)检查确认53。

1.一个完整的JSJ系统包括__. A)主机.键盘.显示器 B)JSJ及其外部设备 C)系统软件与应用软件 D)JSJ的硬件系统和软件系统解答:一个完整的JSJ系统是由硬件系统和软件系统组成的.JSJ 的硬件是一个物质基础,而JSJ软件是使硬件功能得以充分发挥的不可缺少的一部分.因此,对于一个完整的JSJ系统,这两者缺一不可. 答D.2.MJSJ的运算器.控制器及内存储器的总称是__.A)CPU B)ALU C)MPU D)主机解答:CPU是中央处理器简称,包括MPU和ALU;MPU 是微处理器简称;ALU是算术逻辑单元简称;CPU和内存储器总称主机,它是微型机核心部分. 答D.3."长城386微机"中的"386"指的是__.A)CPU的型号 B)CPU的速度 C)内存的容量D)运算器的速度解答:CPU的品质直接决定了微机的档次,在奔腾出现之前,微机名称中直接使用微机中的CPU型号,386机表示了它们使用的CPU芯片为80386. 答A.4.在MJSJ中,微处理器的主要功能是进行__.A)算术逻辑运算及全机的控制 B)逻辑运算C)算术逻辑运算 D)算术运算解答:微处理器是JSJ一切活动的核心,它的主要功能是实现算术逻辑运算及全机的控制. 答A.5.反映JSJ存储容量的基本单位是__. A)二进制位 B)字节 C)字 D)双字解答:存储容量大小是JSJ的基本技术指标之一.通常不是以二进制位.字或双字来表示,因为这些表示不规范,一般约定以字节作为反映存储容量大小的基本单位. 答B6.在微机中,应用最普遍的字符编码是__.A)ASCII码 B)BCD码 C)汉字编码 D)补码解答:字符编码是指对英文字母.符号和数字的编码,应用最广泛的是美国国家信息交换标准字符码,简称为ASCII码.BCD码是二—十进制编码.汉字编码是对汉字不同表示方法的各种汉字编码的总称.补码是带符号数的机器数的编码. 答A.7.DRAM存储器的中文含义是__. A)静态随机存储器 B)动态只读存储器 C)静态只读存储器 D)动态随机存储器解答:动态随机存储器的原文是(Dynamic Random AccessMemory:DRAM).随机存储器有静态随机存储器和动态随机存储器之分.半导体动态随机存储器DRAM的存储速度快,存储容量大,价格比静态随机存储器便宜.通常所指的64MB或128MB内存,多为动态随机存储器DRAM. 答D.8.MJSJ的发展是以__的发展为表征的.A)微处理器 B)软件 C)主机 D)控制器解答:微处理器是JSJ一切活动的核心,因此MJSJ 的发展是以微处理器的发展为表征的. 答A.9.世界上公认的第一台电子JSJ诞生在__.A)1945年 B)1946年 C)1948年 D)1952年解答:世界上公认的第一台电子JSJENIAC(埃尼阿克)于1946年在美国诞生. 答B.10.个人JSJ(PersonalComputer)属于__. A)小巨型机 B)中型机 C)小型机 D)微机解答:我国JSJ界根据JSJ的性能指标,如机器规模的大小.运算速度的高低.主存储器容量的大小.指令系统性能的强弱以及机器价格等,将JSJ分为巨型机.大型机.中型机.小型机.微型机和单片机6大类.目前,国外还有一种比较流行的看法,根据JSJ的性能指标及厂家生产的JSJ的主要面向应用对象,把JSJ 分为巨型机.小巨型机.大型机.小型机.工作站和个人JSJ又称MJSJ(MicroComputer)6大类. 答D.11.通常,在微机中所指的80486是__.A)微机名称 B)微处理器型号 C)产品型号D)主频解答:CPU的品质直接决定了微机的档次,在奔腾出现之前,微机名称中直接使用微机中的CPU型号,486机表示了它们使用的CPU芯片为80486.主频与所用微处理器档次有关,如同样是80486芯片,其主频可能为60MHz,也可能为100MHz.目前占主流的微处理器产品是Intel公司的PentiumIII和PentiunIV微处理器芯片. 答D.12.一个字节的二进制位数是__. A)2 B)4 C)8D)16 解答:一个字节定义为8位2'S. 答C.13.在微机中,bit的中文含义是__.A)二进制位 B)字节 C)字 D)双字解答:在微机中,信息的最小单位为二进制位,用bit来表示;8位二进制构成一个字节,用Byte来表示;一个或一个以上字节可组成一个二进制表示的字,字长可以是8位.16位.32位或64位;两个字长的字,称为双字. 答A.14.JSJ内部使用的数是__.A)二进制数 B)8'S C)10'S D)16'S解答:在JSJ内部,电路中常用的器件具有两种不同的稳定状态:高电平和低电平.这两种状态之间能相互转换.因此,在JSJ内部,一切信息的存放.处理和传送都采用二进制数的形式. 答A.15.在微机中,存储容量为5MB,指的是__.A)5×lO00×1000个字节 B)5×1000×1024个字节C)5×1024×1000个字节 D)5×1024×1024个字节解答:因为JSJ内部的计数基本单位是2,2的10次幂是1024.所以1024个字节为1K字节,写做1KB.1024×1024个字节为1M字节,记做1MB.答D.16.400个24×24点阵汉字的字形库存储容量是__.A)28800个字节 B)0.23604M个二进制位C)0.8K个字节 D)288个二进制位解答:24×24点阵的一个汉字字模共有24行;每行有24列,占24个二进制位,即3个字节.因此,24×24点阵的一个汉字字模占24×3=72个字节,400个汉字共占72×400=28800个字节. 答A.17.在下列设备中,属于输出设备的是__. A)硬盘B)键盘 C)鼠标 D)打印机解答:硬盘是一种存储介质,连同驱动器和适配卡共同组成外存储器;键盘与鼠标均属于输入设备3打印机将JSJ中的文件输出至纸上供用户阅读,是输出设备. 答D.18.在MJSJ中,下列设备属于输入设备的是—.A)打印机 B)显示器 C)键盘 D)硬盘解答:打印机和显示器均属于输出设备,只有键盘属于常用的输入设备,硬盘为存储器的存储介质. 答C.19.鼠标是微机的一种__. A)输出设备 B)输入设备 C)存储设备 D)运算设备解答:鼠标是一种比传统键盘的光标移动键更加方便.更加准确快捷的输入设备.鼠标的优越性已被越来越多的人所认识. 答B.20.断电会使原存信息丢失的存储器是__.A)半导体RAlkI B)硬盘 C)ROM D)软盘解答:硬盘存储器.软盘存储器和ROM存储器都属非易失性存储器,其中所存信息不会因断电而丢失;只有半导体RAM存储器,断电后原存信息会丢失. 答A.21.在下列存储器中,访问速度最快的是__.A)硬盘存储器 B)软盘存储器C)磁带存储器 D)半导体RAM(内存储器)解答:内存储器的优点在于访问速度快,但是价格较贵,存储容量比外存储器小.外存储器单位存储容量的价格便宜,存储容量大,但是存取速度较慢.通常的外存储器包括硬盘存储器.软盘存储器和磁带存储器.半导体RAM通常作为内存储器使用.答D.22.MJSJ硬件系统主包存储器.输入设备.输出设备和__. A)中央处理器 B)运算器 C)控制器 D)主机解答:一个完整的JSJ硬件系统包括运算器.控制器.存储器.输入设备和输出设备,运算器和控制器合称中央处理器或微处理器,中央处理器与内存储器合在一起称为主机. 答A.23.硬盘连同驱动器是一种__. A)内存储器 B)外存储器 C)只读存储器 D)半导体存储器解答:内存储器访问速度快,但是价格较责,存储容量比外存储器小.外存储器单位存储容量的价格便宜,存储容量大,但是存取速度较慢.硬盘连同驱动器是磁性随机存储器,由于它的价格便宜,存储容量大,存取速度较慢,所以通常作为外存储器使用. 答B.24.把微机中的信息传送到软盘上,称为__. A)拷贝B)写盘 C)读盘 D)输出解答:拷贝是指将信息按照原样复制;将信息传送到屏幕等输出设备上,称为输出;读盘是指将磁盘上的信息传送到另一个地方;写盘是指把信息传送到磁盘上. 答B.25.JSJ的内存储器比外存储器__. A)速度快B)存储量大 C)便宜 D)以上说法都不对解答:内存储器访问速度快,但是价格较贵,存储容量比外存储器小. 答A.26.下列可选项,都是硬件的是__.A)Windows.ROM和CPU B)WPS.RAM和显示器C)ROM.RAM和Pascal D)硬盘.光盘和软盘解答:A.B.C各项中,A中的Windows.B中的WPS.C中的Pascal不是硬件;只有D中的各项均为JSJ的存储设备,属于硬件. 答D.27.具有多媒体功能的微机系统,常用CD-ROM作为外存储器,它是__. A)只读软盘存储器 B)只读光盘存储器 C)可读写的光盘存储器 D)可读写的硬盘存储器解答:CD-ROM的英语原文是:Compact Disc-Read OnlyMemory.中文译为名只读光盘存储器.具有多媒体功能的微机系统,除了配备软盘存储器和硬盘存储器之外,还配备有只读光盘存储器CD-ROM. 答B.28.3.5英寸软盘的移动滑块从写保护窗口上移开,此时__. A)写保护 B)读保护 C)读写保护 D)驱动器定位解答:3.5英寸软盘的移动滑块从写保护窗口上移开时,起写保护作用,此时只能够读盘,不能写盘. 答A.29.目前,微机上常用3.5英寸的双面高密度软盘的存储容量为__. A)360KB B)720KB C)1.2MBD)1.44MB 解答:5.25英寸双面低密度软盘的容量为360KB;高密度则为1.2MB.3.5英寸双面低密度软盘的容量为720KB;高密则为1.44MB. 答D.30.十进制数14对应的2'S是__.A)1111 B)1110 C)1100 D)1010解答:十进制整数N转换为2'的方法是:将N不断的除以二,直到商为0,将每一步的余数从右向左排列,即可得到对应的2'S(即除以2反序取余).14mod2=0, 14div2=7;7mod2=1,7div 2=3;3mod2=1,3div2=1;1mod2 =1,1div2=0,此时运算停止,相应的结果时1110. 答B.31.与二进制小数0.1等值的十六进制小数为__.A)0.1 B)0.2 C)0.4 D)0.8 解答:此题属于综合题.首先,把二进制小数0.1转化成十进制小数:(0.1)2=l×2-1=(0.5)10;然后把十进制小数0.5转化成十六进制小数:0.5×16=8,而整数部分为0,所以(0.1)2=(0.5)10=(0.8)16 答D.32.二进制数1011十1001=__.A)10l00 B)1010l C)11010 D)10010解答: 因为:0+0=0;0+1=13 1+0=1;1+1=10.所以,l011+1001= 10100. 答A.33.(1110)2×(1011)2=—.A)11010010 B)10111011C)10110110 D)10011010解答:因为:0*0=0;0*1=1;1*0=0;1*1=1. 答D.34.逻辑运算1001 U 1011=__.A)1001 B)1011 C)1101 D)1100解答:因为:0V0=0;0V1=1;1V0=1;1V1=1. 所以, 答B.35.十六进制数(AB)16变换为等值的8'S是__A)253 B)35l C)243 D)101 解答:解题思路:先把十六进制数化成二进制数,再把二进制数化成八进制数. (AB)16=(10101011)2=(253)8 答A36.十六进制数(AB)16变换为等值的2'S是__.A)10101011 B)11011011 C)11000111 D)10101011解答:(A)16=(10)10=(1010)2;(B)16=(1011)2 答A37.十六进制数(AB)16变换为等值的10'S是__A)17 B)161 C)21 D)171 解答:(A)16=10;(B)16=11:(AB)16=10*l6+11=17l 答D.38.十进制数21变换为等值的八进制数是__.A)(21)8 B)(23)8 C)(25)8 D)(27)8解答:21=2*8+5 答C.39.十进制数123变换为等值的二进制数是__.A)110101 B)110110 C)111011 D)110011解答:2 | 123 (1)2 | 61 (1)2 | 30 02 | 15 (1)2 | 7 (1)2 | 3............ 1 答C40.微机唯一能够直接识别和处理的语言是__.A)甚高级语言 B)高级语言 C)汇编语言 D)机器语言解答:JSJ语言分为机器语言.汇编语言.高级语言和甚高级语言4代.甚高级语言是第四代语言,这是一种面向问题的语言,数据库语言属于这种语言.高级语言是面向过程的语言,属于第三代语言,包括Pascal.C.BASIC语言等.汇编语言是一种用字母和符号表示的面向机器的语言,是第二代语言.机器语言是以二进制代码表示的面向机器的语言,是第一代语言,也是微机唯一能够直接识别和处理的语言. 答D.41.在微机中,外存储器通常使用软磁盘作为存储介质.软磁盘中存储的信息,在断电后__.A)不会丢失 B)完全丢失 C)少量丢失 D)大部分丢失解答:软盘是靠磁化磁盘中某个区域来保存信息的,一旦存入信息,不会自行丢失,即使断1110111000001110-----10011010电,也不会丢失,可永久保存信息. 答A.42.半导体只读存储器(ROM)与半导体随机存取存储器(RAM)的主要区别在于__.A)在掉电后,ROM中存储的信息不会丢失,RAM信息会丢失 B)掉电后,ROM信息会丢失,RAM则不会C)ROM是内存储器,RAM是外存储器 D)RAM是内存储器,ROM是外存储器解答:ROM可以永久保存信息,即使掉电,其中存放的信息也不会丢失;而在掉电的情况下,RAM中存储的信息便会丢失.通常半导体ROM和RAM是作为内存器使用. 答A.43.JSJ软件系统应包括__.A)管理软件和连接程序 B)数据库软件和编译软件C)程序和数据 D)系统软件和应用软件解答:通常,我们可把JSJ软件系统分为系统软件和应用软件两大类.系统软件包括操作系统.语言处理程序和各种工具软件;应用软件包括应用软件包和面向问题的应用程序.本题的编译软件.连接程序和管理软件属于系统软件范畴;数据库软件包括数据库管理系统和数据库应用系统,前者属于系统软件,后者属于应用软件.程序和数据可以属于系统软件,也可以属于应用软件. 答D.44.在微机中的“DOS”,从软件归类来看,应属于__.A)应用软件 B)编辑系统 C)工具软件 D)系统软件解答:软件分为系统软件和应用软件两大部分.本题中的工具软件和编辑软件应属于系统软件.“DOS”是磁盘操作系统的简称,用来管理微机的硬件和软件资源,属于系统软件. 答D.45.BASIC语言解释程序属于__.A)应用软件 B)系统软件 C)编译程序的一种 D)汇编程序的一种解答:编译程序将源程序翻译成目标程序,然后JSJ才能执行,每种高级语言应配有相应的编译程序.用汇编语言编写的源程序要经过汇编程序汇编成用机器语言表示的目标程序之后,JSJ才能执行.BASIC语言解释程序是将用BASIC 语言编写的源程序逐条解释并执行,不产生目标程序.以上3种程序均属于系统软件范畴. 答B.46.操作系统是__.A)软件与硬件的接口 B)主机与外设的接口C)JSJ与用户的接口 D)高级语言与机器语言的接口解答:软件与硬件的接口应该是机器语言;主机与外设之间的接口是I/0接口芯片;操作系统是用户与JSJ之间的接口;高级语言与机器语言之间的接口应该是编译(或解释)程序. 答C.47.操作系统的主要功能是__.A)控制和管理JSJ系统软硬件资源 B)对汇编语言.高级语言和甚高级语言程序进行翻译 C)管理用各种语言编写的源程序 D)管理数据库文件解答:操作系统是用户与JSJ之间的接口,用户通过操作系统来控制和管理JSJ系统的软硬件资源.对汇编语言.高级语言和甚高级语言程序进行翻译的程序称为语言处理程序;管理数据库文件使用的是数据库管理系统. 答A.48.微机的诊断程序属于__.A)管理软件 B)系统软件 C)编辑软件 D)应用软件解答:微机的诊断程序的作用是对微机的系统功能进行测试,查找系统的错误,如果发现错误,则进行相应的改正.因此微机的诊断程序是用户管理系统的工具,属于系统软件. 答B.49.在下列软件中,不属于系统软件的是__.A)操作系统 B)诊断程序 C)编译程序 D)用PASCAL编写的程序解答:操作系统.诊断程序.编译程序均属于系统软件范畴,用PASCAL编写的程序不属于系统软件. 答D.50.某公司的财务管理软件属于__.A)工具软件 B)系统软件 C)编辑软件 D)应用软件解答:微机软件系统包括系统软件和应用软件两大部分.系统软件主要用于控制和管理JSJ的硬件和软件资源.应用软件是面向某些特定应用问题而开发的软件.财务管理软件是面向财务系统应用而开发的软件,属于应用软件范畴. 答D.51.JSJ软件应包括__. A)系统软件与应用软件B)管理软件和应用软件 C)通用软件和专用软件D)实用软件和编辑软件解答:实用软件不是专业名词,系统软件和应用软件均具有实用性;编辑软件属于系统软件范畴;通用软件与专用软件是从软件的通用性来衡量的;管理软件一般指应用软件.从软件的分类角度出发,JSJ软件应当归结为系统软件和应用软件两大类. 答A. 52.Windows95操作系统属于__.A)单用户单任务操作系统 B)单用户多任务操作系统 C)多用户单任务操作系统 D)多用户多任务操作系统解答:在操作系统分类中,有上述4种操作系统.其中,Windows95操作系统属于单用户多任务操作系统. 答B.53.在Windows 95中,其“桌面”指的是__.A)整个屏幕 B)某一个窗口 C)全部窗口的集会D)当前打开的窗口解答:Windows95操作系统努力将复杂的JSJ操作变得简单,贴近用户的日常逻辑.在Windows95操作系统中,某系统启动成功后,整个屏幕称之为“桌面”. 答A.54.在Windows中,将某个应用程序窗口最小化之后,该应用程序__. A)仍在后台运行 B)暂时停止运行 C)完全停止运行 D)出错解答:在Windows中,一个窗口最小化后,只是暂时停止运行,窗口恢复大小后该程序又被激活,可以重新接受用户的输入和操作. 答B.55.在Windows95的“开始”菜单中,包括了Windows95系统提供的__.A)部分功能 B)初始功能 C)主要功能 D)全部功能解答:在Windows 95的“开始”菜单中,包括了Windows95系统提供的全部功能,如可执行程序,文件管理,系统设置等等. 答D.56.在Windows95桌面上,任务栏处于屏幕底部,其上有个“开始”按钮,单击该按钮则__. A)关闭任务栏 B)打开任务栏 C)打开“开始”菜单 D)关闭“开始”菜单解答:在Widows95桌面上,任务栏处于屏幕底部,其上有一个“开始”按钮.单击该按钮,系统将打开“开始”菜单,在Windows95的“开始”菜单中,包括了Windows95系统提供的全部功能,如可执行程序.文件管理.系统设置等等. 答C.57.在Windows中,如果窗口表示一个应用程序,则打开该窗口的含义是__. A)显示该应用程序的内容 B)运行该应用程序 C)结束该应用程序的运行 D)显示并运行该应用程序解答:在Windows环境中,如果某窗口表示一个程序,则打开该窗口就意味着运行该应用程序. 答B.58.在Windows95桌面左上角有一个“我的电脑”图标,双击该图标可以__. A)启动我的电脑B)关闭我的电脑 C)关闭Winows95系统 D)浏览本JSJ上的资源解答:“我的电脑”图标中包含了驱动器中的文件和文件夹或JSJ中已安装的打印机驱动程序等.双击“我的电脑”图标,可以打开该图标的窗口浏览本JSJ上的资源. 答D.59.在Windows95桌面左上角有一个“回收站”图标,“回收站”的作用是__.A)回收并删除应用程序B)回收编制好的应用程序 C)回收将要删除的用户程序 D)回收用户删除的文件或文件夹解答:在Windows95桌面左上角有一个“回收站”图标.它的作用是回收用户将要删除的文件或文件夹.当用户“删除文件或文件夹”时,系统将文件暂时放在回收站中,当确认这些被删除的文件或文件夹已确无用处时,才清空回收站或某些文档,从而彻底删除文件. 答D.60.在Windows95桌面上有一个任务栏,通常在任务上有一个“En”图标__. A)它没有任务作用B)它是任务栏的标识 C)它是某一窗口的提示符D)它是输入法图标,说明当前输入方式为英文解答:在Windows95桌面上有一个任务栏,任务栏上包括“开始”图标和其他正在执行的程序的图标,一般在右下角还有其他图标,如喇叭图标.输入法图标和时间图标等其中图标“En”是输入法图标,它说明当前系统输入方式为英文.单击该图标产生一个输入法选择菜单.再单击某项,可从中选择所选输入方法,也可以通过快捷键进行切换. 答D.61.通常把JSJ网络定义为__.A)以共享资源为目标的JSJ系统,称为JSJ网络B)能按网络协议实现通信的JSJ系统,称为JSJ网络 C)把分布在不同地点的多台JSJ互联起来构成的JSJ系统,称为JSJ网络 D)把分布在不同地点的多台JSJ在物理上实现互联,按照网络协议实现相互间的通信,以共享硬件.软件和数据资源为目标的JSJ系统,称为JSJ网络.解答:选项A描述了JSJ网络的目标;选项B描述了JSJ网络实现的技术保障;选项C描述了JSJ网络的物理表现.而JSJ网络应该是上述三者的集合.答D.62.当前,在JSJ应用方面已进入以__为特征的时代.A)并行处理技术 B)分布式系统C)MJSJ D)JSJ网络解答:JSJ网络是现代JSJ发展的最新趋势. 答D.63.JSJ网络的应用越来越普遍,它的最大好处在于__. A)节省人力 B)存储容量扩大C)可实现资源共享 D)使信息存取速度提高解答:JSJ网络已得到非常广泛的应用.这主要是因为它可以实现资源共享.资源共享包括硬件资源共享.软件资源共享和数据资源共享. 答C.64.JSJ网络的资源共享功能包括__.A)硬件资源和软件资源共享 B)软件资源和数据资源共享 C)设备资源和非设备资源共享D)硬件资源.软件资源和数据资源共享解答:JSJ网络最主要的功能是资源共享.资源共享包括硬件资源.软件资源和数据资源共享. 答D.65.JSJ网络按其所涉及范围的大小和JSJ之间互联距离的不同,其类型可分为__.A)局域网.广域网和万维网 B)局域网.广域网和国际互联网 C)局域网.城域网和广域网 D)广域网.因特网和万维网解答:按照通信距离分类,可以将网络分为:局域网.城域网和广域网.如果网络的服务区域在一个局部范围(一般几十千米之内),则称为局域网.在一个局域网中,可以有一台或多台主JSJ以及多个工作站,各JSJ系统.工作站之间可通过局域网进行各类数据的通信.所涉及的范围一般限制在一个城市之内,JSJ之间互联距离一般在几十公里之内,称为城域网.服务地区不局限于某一个地区,而是相当广阔的地区(例如各省市之间,全国甚至全球范围)的网络称为广域网.因特网和万维网均属于广域网范畴. 答C.66.在JSJ网络中,LAN网指的是__.A)局域网 B)广域网 C)城域网 D)以太网解答:JSJ网络可分为局域网.城域网和广域网.以太网是当前应用较广泛的一种网络的名称.LAN是局域网的英文绍写(LocalArea Network). 答A.67.局域网的拓扑结构主要包括__.A)总线结构.环型结构和星型结构B)环网结构.单环结构和双环结构C)单环结构.双环结构和星型结构D)网状结构.单总线结构和环型结构解答:拓扑是一种研究与大小.形状无关的线和面构成图形的特性的方法.网络拓扑则是指各种网络构成图形的基本性质的研究.局域网常用的拓扑结构有总线型.环型和星型3种形式. 答A.68.在JSJ网络中使用MODEM时,它的功能是__.A)实现数字信号的编码 B)把模拟信号转换为数字信号 C)把数字信号转换为模拟信号 D)实现模拟信号与数字信号之间的相互转换解答:在远距离传送时,为防止信号畸变,一般采用频带传输,即将数字信号变换成便于在通信线路中传输的交流信号进行传输.此时在发送端由直流变成交流称为调制,在接收端由交流变成直流称为解调,兼有这两种功能的装置称为调制解调器(MODEM). 答D.69.互联设备中Hub称为__. A)网卡 B)网桥 C)服务器 D)集线器解答:Novell网采用集线器将一个高带宽通路分支为若干个低带宽通路,这里的集线器就是通常所说的Hub. 答D.70.Internet网是目前世界上第一大互联网,它起源于美国,其雏形是__. A)NCFC网 B)CERNET网C)GBNET网 D)ARPANET网B)解答:1980年美国国防部高等研究计划局研制的名为“ARPANET”的JSJ网络,后来发展称为如今的Internet网.其余三个选项:NCFC网是中国国家JSJ网络设施(也称为中关村网),CERNET网是中国教育和科研网,GBNET网是金桥网. 答D.71.对于网间连接器,下列叙述中不正确的是__.A)中继器能够延长网络线路长度和改变网络的拓扑结构 B)网桥用于连接两个不同类型的局域网(网络操作系统必须相同) C)网关用于连接两个不同类型的局域网(网络操作系统可以不同)C)D)网间连接器不能将局域网和广域网连接起来解答:网间连接器可以将两个局域网连接起来,形成更大规模.更高性能的网络.常见的网间连接器及其功能如下:中继器用于延长规定的网络线路长度和改变网络拓扑结构;网桥用于连接两个同类型的局域网;网关用于连接两个不同类型的局域网或者一个局域网和另一个广域网.分析四个选项,只有D的表述是不正确的. 答D.72.网络互联实现在更大的范围内传输数据和共享资源,要解决两个问题:一是网络之间要有通信链路,二是提供__. A)协议转换功能 B)数据库管理功能 C)安全保密功能 D)信息传输功能解答:网络互联指的是将几个网络连接起来建立更大的网络.这个连接需要两个条件:通信链路用来进行网络之间的信息传输;协议转换功能用于在维持各网络结构不变的基础上实现不同网络的一致性.答A. 73.因特网是__. A)局域网的简称 B)城域网的简称 C)广域网的简称 D)国际互联网(Intenet)的简称解答:因特网属于广域网的范畴,它是国际互联网(Intenet)的简称. 答D.74.WWW网是__. A)局域网的简称 B)城域网的简称 C)广域网的简称 D)万维网的简称解答:WWW(World WideWeb)网属于广域网范畴,是万维网的简称.答D.75.在JSJ网络中,数据资源共享指的是__.A)各种文件数据的共享 B)各种应用程序数据的共享 C)各种数据文件和数据库的共享D)各种表格文件和数据库文件的共享解答:在JSJ网络中,数据资源共享指的是各种数据文件和数据库的共享. 答C.76.在JSJ领域中,媒体系指__. A)各神数据的载体B)打印信息的载体 C)各种信息和数据的编码D)表示和传播信息的载体解答:在JSJ领域中,媒体系指表示和传播信息(文本.图形.图像和声音等)的载体.当这种载体可表示和传播两种或两种以上的信息时,称之为多媒体. 答D.77.多媒体技术是__. A)一种图像和图形处理技术 B)文本和图形处理技术 C)超文本处理技术D)JSJ技术.电视技术和通信技术相结合的综合技术解答:多媒体技术是指利用JSJ技术把文字.声音.图形和图像等多种媒体综合一体化,使它们建立起逻辑联系,并能进行加工处理的技术.这里所说的“加工处理”主要是指对这些媒体的录入.对信息进行压缩和解压缩.存储.显示.传输等.答D 78.JSJ病毒具有隐蔽性.潜伏性.传播性.激发性和__. A)入侵性 B)可扩散性 C)恶作剧性D)破坏性和危害性解答:JSJ病毒具有隐蔽性.潜伏性.传播性.激发性.破坏性和危害性.恶作剧性是一种破坏性较小的病毒类型;入侵性和可扩散性实际上属于传播性.破坏性和危害性才是病毒最主要的特性. 答D.填空题1.JSJ的主机是由__和__组成.解答:JSJ的硬件系统由中央处理器.存储器.输入设备和输出设备等部分组成.中央处理器和内存储器合起来称为主机2.CPU是由__和__组成的. 解答:CPU又称中央处理器,它主要由运算器和控制器组成.运算器的主要功能是负责算术运算和逻辑运算;控制器的主要功能是控制JSJ各部件协同动作.3.目前,我国JSJ界把JSJ分为巨型机.大型机.中型机;小型机.单片机和__等6类. 解答:巨.大.中.小.微.单片是JSJ早期发展分类的规律.答微型机.4.从发展趋势来看,未来的JSJ将是__技术.__技术.__技术和电子仿生技术相结合的产物.解答:JSJ技术发展迅速,从发展趋势来看,未来的JSJ将是电子技术.光学技术.超导技术和电子仿生技术互相结合的产物.5.衡量MJSJ性能的5项主要技术指标是__.存储容量.存取周期.__.__.解答:字长标志着处理信息的精度,字长越长,精度越高.存储容量主要是指内存容量,以字节为单位来计算.存取周期是存储器进行一次完整的读/写操作所允许的最短时间间隔.存取周期越短,则存取速度越快.主频是JSJ的时钟频率;主频越高,运算速度越块4运算速度用每秒所能执行的指令条数来表示,单位是百万次/移,甩MIPS表示. 答字长.主频和运算速度.6.JSJ应用领域包括__.__.__.__和__.解答:JSJ应用范围广泛.不胜枚举.概括起来可分为5个方面:科学计算.数据处理和信息管理.自动控制.辅助设计制造和测试.系统仿真.7.总线是连接JSJ各部件的一簇公共信号线,由__.__和控制总线组成.解答:总线是一簇用来进行信息传递的公共信号线,它由地址总线.数据总线和控制总线组成.总线结构是微机使用极为广泛的系统结构,它确定了各部件构成系统时的连接方式. 8.微处理器按其字长可分为__位.__位.__位和64位微处理器.解答:微处理器的种类繁多,按它的字长可以分为8位.16位.32位和64位微处理器.9.第四代电子JSJ采用的逻辑元件为__.解答:第四代电子JSJ采用的逻辑元件为大规模和超大规模集成电路. 10.汉字国标码GB2312-80,从实质上来说,它是一种__码.解答:汉字国标码GB2312-80为信息交换用汉字编码字符集——基本集.从实质上来说它是一种交换码.11.根据工作方式的不同,可将存储器分为__和__两种.解答:存储器分类方法很多,根据工作方式不同,可分为随机存储器(RAM)和只读存储器(ROM);据所用材料不同,分为磁存储器.半导体存储器和光存储器等;据设在主机内外分内存和外存.12.显示器是微机系统的__设备.解答:微机系统由硬件系统和软件系统组成,硬件系统包括微处理器.存储器.输入设备和输出设备,显示器属于微机系统的输出设备.13.鼠标是一种比传统键盘的光标移动更加方便.更加准确的__设备. 解答:微机系统由硬件系统和软件系统组成,硬件系统包括微处理器.存储器.输入设备和输出设备,鼠标属微机系统的输入设备.14.在微机中,常用的软盘存储器,按其记录密度的大小,可分为__和__两种.解答:软盘存储器由于价格便宜.可以任意扩充.易于备份,所以应用十分广泛.软盘按其单面涂有磁性材料,还是双面均涂有磁性材料,可分单面软盘和双面软盘两种;按记录密度大小,又分低密度和高密度两种;按存储容量大小,可分360KB.720KB.1.2MB和1.44MB等;按直径大小可分3.5英寸和5.25英寸两种.15.在启动DOS时,显示或修改系统时间的正确输入格式是__. 解答:显示或修改系统时间格式中的时.分.秒,其分隔符是“:”. 答TIME时:分:秒.16.热启动应同时按下的组合键是__. 解答:[Ctrl十Alt十Del]三个键需同时按下才起作用.17.[Enter]键的功能是___. 解答:目前,微机上使用最多的键盘是101标准键盘.这种键盘上的键可分为:打字键.功能键和控制键三类.[Enter]键为控制键,其功能是回车.18.JSJ软件系统包括系统软件和应用软件.操作系统是一种__. 解答:答系统软件.19.系统软件包括__.__和__三类. 解答:系统软件用来管理.控制和维护JSJ各种资源,并使其充分发挥作用,提高工效,方便用户的各种程序的集合.系统软件是构成微机系统必备的软件,在购置微机系统时,可根据用户的需求进行配备.答操作系统.语言处理程序和工具软件.20.操作系统包括处理机管理.存储器管理.__.__和作业管理五大类管理功能. 解答:操作系统用来直接控制和管理微机系统硬件资源和软件资源,是用户充分而有效地利用这些资源管理程序的集合.答设备管理.文件管理.21.已知英文字母符号A的ASCII码为65,英文字母符号F的ASCII码为__;已知数字符号9的ASCII码为57,数字符号5的ASCII码为__.解答:英文字母的ASCII码是以字母顺序为序的,因此,只要知道了一个字母的ASCII码,就可以推算出其他字母的ASCII码.对于数字符号也是如此.根据这个规律,很容易推算出字母F的ASCII码为65十5=70,数字符号5的ASCII码为57-5=52.22.假定今天是2000年8月15日,则按美国的日期格式输入为__.解答:美国的标准日期格式为:mm—dd—yy,mm表示月份,dd表示日期,yy表示年份.答08/15/2000或8/15/2000或08-15-2000或8-15-2000. 23.JSJ网络发展经历了远程终端联机阶段.JSJ网络阶段.__阶段和信息高速公路阶段解答:JSJ网络的发展大体上经历了4个阶段即远程终端联机~.JSJ网络~.网络互联~和信息高速公路~.24.按病毒设计者的意图和破坏性大小,可将JSJ病毒分为__和__. 解答:按病毒设计者的意图和破坏性大小,可将JSJ病毒分为良性病毒和恶性病毒.良性病毒是破坏性较小的JSJ病毒,只是降低系统运行速度,干扰用户操作b恶性病毒具有明显破坏目标,其破坏和危害性都很大,可以删除有用的文件,甚至格式化硬盘.25.按JSJ病毒入侵系统的途径可将JSJ病毒分为__.__.__和__.解答:源码病毒是在源程序被编译之前,就插入到用高级语言编写的源程序当中,其破坏性和危害性都很大.入侵病毒是把病毒程序的一部分插入到主程序中.一旦入侵,难以清除.操作系统病毒是把病毒程序逻辑加入或替代部分操作系统进行工作的病毒.这种病毒攻击力强.常见.破坏性和危害性最大.外壳病毒是把病毒程序置放在主程序周围,一般不修改源程序.它大多是感染DOS下的可执行程序,易编制,也易于检测和消除.答源码病毒.入侵病毒.操作系统病毒和外壳病毒.1.世界上第一台具有存储程序功能的JSJ是由匈牙利籍著名数学家冯·诺伊曼主持设计的,其工作原理是存储程序和程序控制,奠定了现代计算的理论基础. 2.JSJ由运算器.控制器.存储器.输入设备和输出设备五大部分组成,其中运算器和控制器合称为中央处理器,也叫CPU. 3.自1946年世界上第一台JSJ诞生来,电子JSJ发展经历了四个阶段,各阶段的JSJ所采用的电子元器件分别是电子管.晶体管.集成电路和大规模和超大规模集成电路.4.衡量微机性能的技术指标有速度.兼容性.可靠性和可维护性等,其中速度用CPU的主频和运算速度两项指标来评价.主频的单位为MHZ,运算速度单位是秒。

JSJ-GL型爬架控制系统使用手册JSJ-GL型爬架控制系统使用说明书一、系统概述JSJ-GL型爬架控制系统综合运用单片机和测力传感器测控技术,通过单片微型计算机对被提升脚手架的载荷进行综合分析并作出相应处理,实现了对脚手架的升降的全过程的实时监测和自动控制,使整个爬架的升降自如、快速、准确、安全,从而有效地保证了施工的优质进行。

JSJ-GL型爬架控制系统使用以总控和多台以单片微型计算机为核心的分控以及测力传感器组成的测量系统。

通过单片微型计算机对系统中各分控的载荷进行实时检测、实时报警、实时排障和实时控制,有效地保证了脚手架施工的快速、安全和准确。

系统特点:本系统采用两种控制方式:手动控制和遥控器控制,实现现场操作的简易化。

控制系统的控制线路采用并行的方式连接,解决了过去因分控线路出现故障而使整个控制信号无法传递给总控的状况。

同时各分控全部有单独控制动作,当分控的单片微型计算机检测到当前机位异常时,会自动发出相应的动作,并将信号传递给总控。

简单易懂易操作,操作者不需要懂得计算机知识,只要懂得一定的升降架的基本原理,就能很轻松地掌握该系统的操作。

本系统设计安全控制机位数为35台,如需增加机位,可根据用户要求定做。

二、爬架控制系统的原理、组成2.1基本原理本套系统采样的主要数据是机位的载荷数据,通过单片微型计算机实现各种状态的动作切换,控制的主要对象是三相交流电机。

2.2 系统组成(注:n表示吊点数目,最多可控制50台分控)总控:1台对总控和分控发布升、降、停等命令。

分控:n台采集的每个机位的实时载荷数据,进行综合分析,以判别各种故障,及时作出相应的自动化操作,如预警和停机。

测力传感器:n套带5芯屏蔽电缆、5芯航空插座,它是机位吊点载荷的直接承受者,通过对载荷的实时测量并产生相应的模拟信号,供分控单片微型计算机采集。

控制电缆:采用总线的控制模式,将各分控连接在一起,控制电缆1条。

三、分控分控面板如下:分控箱下端的控制面板分布了四个航空插头,分别为传感器、控制进、控制出和提升电机。

双轴加湿搅拌机使用说明书1、概述该系列调湿灰、渣双轴加湿搅拌机主要适用于火力发电厂灰、渣库(或灰、渣斗)卸灰渣系统或干灰、渣湿式输送系统。

作为灰、渣加湿的搅拌设备,可快速将干灰、渣制成含水率15-25%左右的松散、潮湿、不飞扬的灰、渣,装车、装船或皮带输送。

2、结构及工作原理双轴加湿搅拌机主要由搅拌机壳体、叶片轴2组、驱动装置、加水系统、电气控制系统(无特殊约定用户自理)等组成。

干灰(渣)进入搅拌机后,加水系统开始喷雾加湿,在双轴叶片组的搅拌下,干灰(渣)被制成含水率15-25%左右的湿灰(渣),达到松散、潮湿、不飞扬的程度。

同时,在叶片的旋转推动下,湿灰(渣)向排料口移动并排出。

a)型号说明JSJ —□干灰渣出力(t/h)双轴加湿搅拌机b)产品特点a.喷雾装置设计、安装合理,使灰水混合达到最佳效果;b.喷雾装置可将干灰下落时的飞灰封闭在机体内,不致向外飞扬;c.轴及传动结构密封结构设计合理,检修方便;d.使用高耐磨材料铸成的搅拌叶片,延长了机器的使用寿命;e.叶片、轴承、齿轮便于更换;f.本产品分为两种传动方式,一种为联轴器直联传动,另一种为驱动装置在机体侧面链传动,可视不同的场地布置情况由用户选择。

c)主要技术性能参数及外形尺寸主要技术性能参数表a.安装时,要求机体与地面保持水平,不允许倾斜布置,其出料口向上倾斜误差不得超过10mm。

b.两传动链轮要保持同一直线,其偏差不得大于0.2mm。

c.搅拌机底座为框架结构,安装时应与基础(钢梁或预埋件)各部垫平,并在进料口垂直中心线位置处与基础焊牢,其余部位自由膨胀。

d.减速机底座外侧槽钢与基础梁或预埋件焊牢。

e.落料方管安装完毕,根据用户选用汽车的高度,如果落料管距车较高,用户可自行在落料口下方增加其长度(可用橡胶或化纤织物),使落料口距车近些,防止(水蒸气携带的)灰飞扬,但不得防耐通行。

e)系统配置与运行程序i.按系统流程,灰(渣)库(或斗)下部需配手动插板阀、气动阀(必须严密)、电动给料机(渣用流量调节阀)。

JSJ 聚合物防水砂浆胶乳 产品简介 聚合物防水砂浆胶乳(JSJ )是采用进口高分子乳液和助剂加工制成的防水乳液。

掺入水泥砂浆中组成聚合物水泥砂浆,抹压成坚韧密实的防水层。

适用范围:本产品适用于屋面、厕浴间、地下室、水池及外墙面的防水、防潮、抗渗。

产品优点:1、具有较高的抗压强度(24MPa )、抗折强度(8Mpa ),抗裂性好;2、具有较高的抗渗性能,抗渗标号达1.5MPa ;3、具有较高粘接强度,可达到1.2MPa 以上;4、具有与水泥砂浆相同的耐久性和耐腐蚀能力;5、可在潮湿基面施工,干燥基面应洒水湿润(无明水);6、工艺简单,施工方便。

施工方法:1、基层应平整、干净、湿润、无明水,无油渍;2、基层处理剂,按水泥:胶:水=1:0.15:适量水,搅拌均匀后涂刷于基层;3、按水泥(1.0):砂(1.5 ~ 2.5):胶(0.1~0.25):水(0.15~0.25)配比,称量正确、搅拌均匀;4、按设计要求摊铺聚合物水泥砂浆,用抹子抹压平整光滑。

当厚度>10㎜时,宜分层施工;5、砂浆表面需二次压光,施工温度宜为10~35℃。

当气温低于5℃时,应采取措施,不宜在太阳直射高温下施工。

施工一天后保湿润养护3~5天,未硬化前不得浇水养护。

6、水泥选用普通硅酸盐水泥和52.5号或42.5号硅酸盐水泥,砂为干净中砂,含泥量≤3%,云母含量≤1%。

包装存放:1、产品包装:以塑料桶包装,50kg/桶。

2、产品存放:0℃以上阴凉处,保质期为6个月。

检验依据:JC/T984-2005《聚合物水泥防水砂浆》Ⅱ类技术指标要求。

试验配比为水泥:标准砂:防水胶:水为1:2:0.2:0.25,其中水泥为P ·O42.5,砂为GB178标准砂。

JSJ 胶乳掺量参考:金标 Kingbird。