牛仔布生产流程 ppt课件

- 格式:ppt

- 大小:7.89 MB

- 文档页数:11

牛仔布工艺流程

《牛仔布工艺流程》

牛仔布是一种经典的纺织品,因其耐穿耐磨的特性和时尚的外观而备受青睐。

而要制作出优质的牛仔布,就需要经过一系列精心的工艺流程。

首先,制作牛仔布的原料是棉花。

种植、采摘和加工棉花是牛仔布的第一步工艺流程。

优质的棉花决定了后续牛仔布的品质。

然后,将经过加工的棉花进行纺纱、织造。

在纺纱过程中,将棉花经过清理、精梳后,形成精细的纱线。

织造是将纱线经过织布机的编织,形成牛仔布的纹理和图案。

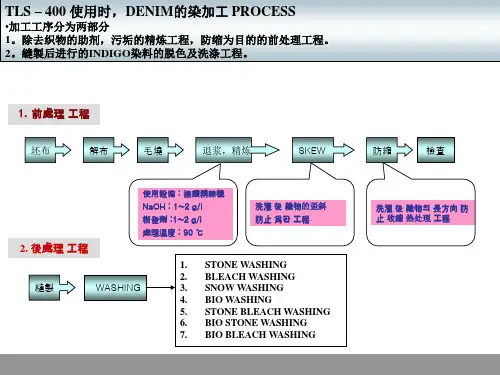

接下来,将经过织造的布料进行浸染和印花。

浸染是将布料浸入染液中,使其吸收颜色;印花则是通过印花机将图案印刷在布料上,使其更加丰富多彩。

最后,牛仔布还需要进行整理和后整理工艺。

整理是对布料进行定型、捻斜、卷曲等处理,使其更加平整、光亮;后整理则是增加牛仔布的柔软度和舒适性,通常包括磨砂、漂白等步骤。

通过以上一系列的工艺流程,最终制成了一张张高品质的牛仔布。

这些牛仔布可能会被用于制作牛仔裤、夹克、帽子等产品,成为人们生活中不可或缺的一部分。

牛仔布生产流程1. 原材料准备纱线选择:牛仔布的原料主要是棉纤维,通常使用纯棉纱线,且纱线的粗细和强度会根据牛仔布的用途有所不同。

常见的为16支到40支的棉纱。

染料选择:牛仔布的经典颜色为蓝色,通常采用靛蓝染料(Indigo)来染色。

靛蓝染料一般通过还原染色法获得,也可以使用其他类型的染料来满足不同需求。

2. 纺纱开松和梳理:棉花经过开松机去除杂质,再通过梳理机梳理成纤维网状,以便进一步纺织。

纺纱:将纤维通过纺纱机加工成纱线。

纱线的粗细、强度和纺织质量都会影响牛仔布的最终质量。

3. 织布织机准备:使用织布机进行织造,传统的牛仔布通常采用斜纹织法。

通过将不同颜色的经纱(纵向纱线)和纬纱(横向纱线)交织,形成独特的斜纹结构。

经纬纱配比:通常,牛仔布的经纱采用较细的蓝色染纱,而纬纱则使用较粗的未染色或白色的棉纱,这样的搭配使得布料的外观有了经典的蓝色外层和白色内层。

4. 染色靛蓝染色:牛仔布最具标志性的蓝色来源于靛蓝染料。

通常采用还原染色法,将靛蓝染料还原成可溶解的状态,经过多次浸染使纱线呈现浓郁的蓝色。

染色过程一般在染缸中进行。

染色方式:牛仔布的染色一般为“渐变染色”,即每一根经纱在染色过程中并非完全均匀,而是染料浸泡反应的时间和浓度不同,形成了独特的色彩效果。

5. 织布后的整理处理水洗:牛仔布织造完成后,进行水洗工艺。

水洗可以去除布面上的多余染料,形成更柔软的手感,并且可以避免成品在穿着过程中掉色。

常见的水洗方法有石磨水洗、硅胶水洗等。

磨毛:为了给牛仔布增加磨损效果,特别是做出经典的褪色效果,牛仔布还需要通过机械磨毛来模拟经过多次穿着后的效果。

6. 后整理柔软处理:对于一些牛仔布,可能会进行柔软处理,使得布料更加舒适,提升穿着体验。

常用的柔软剂可以使布料更加柔滑。

定型处理:为了增强牛仔布的平整性和牢固性,通常会使用定型设备对布料进行定型处理,确保其尺寸的稳定。

染色及印花(可选):某些牛仔布可能会进行进一步的染色处理或者印花设计,比如渐变色、图案或图形的印刷等。

牛仔面料的生产工艺流程英文回答:Denim Fabric Production Process.Denim fabric, also known as denim, is a sturdy cotton twill fabric widely used in jeans, jackets, and other clothing items. The production process of denim fabric involves several stages, each contributing to thedistinctive characteristics of the fabric.1. Spinning the Yarn:The first step is to spin the yarn used in denim fabric. Cotton fibers are twisted together to create strong and durable threads. The warp yarns, which run vertically inthe fabric, are typically finer than the weft yarns, which run horizontally.2. Dyeing the Warp Yarns:To achieve the characteristic blue color of denim, the warp yarns are dyed using indigo dye. The dyeing process occurs in multiple stages to ensure the deepest and most consistent shade of blue. The indigo dye penetrates the fibers, resulting in a color that remains vibrant even after repeated washing.3. Weaving the Fabric:The dyed warp yarns are then woven together with the undyed weft yarns using a twill weave. This weaving technique creates the iconic diagonal pattern that is synonymous with denim fabric. The tightness of the weave influences the fabric's weight and durability.4. Desizing and Scouring:After weaving, the fabric undergoes desizing and scouring processes to remove any impurities or excess starch. This step prepares the fabric for further processing.5. Mercerizing (Optional):Mercerizing is an optional step that enhances thefabric's luster, strength, and dye receptivity. The fabric is treated with a strong alkali solution, which causes the fibers to swell and become smoother.6. Dyeing the Fabric (Optional):If desired, the fabric can be further dyed to achieve various colors beyond the classic indigo blue. Acid dyes or reactive dyes are commonly used for this purpose.7. Finishing:The final stage involves finishing processes that improve the fabric's appearance and performance. This may include sanforizing, which pre-shrinks the fabric to minimize shrinkage after washing, and various washing and drying techniques to create different textures and effects.中文回答:牛仔面料的生产工艺流程。

牛仔色织生产工艺流程英文回答:Indigo Denim Woven Fabric Production Process.1. Spinning.The production of denim fabric begins with spinning, where cotton fibers are twisted together to create yarn. The yarn used for denim is typically a ring-spun yarn, which is strong and durable.2. Dyeing.The yarn is then dyed with indigo dye, which gives denim its characteristic blue color. The dyeing process can be done in several ways, but the most common method is vat dyeing, in which the yarn is submerged in a vat of indigo dye.3. Weaving.The dyed yarn is then woven together to create the denim fabric. Denim is typically woven in a twill weave, which gives it its distinctive diagonal pattern.4. Finishing.After weaving, the denim fabric is finished to give it its desired appearance and properties. The finishing process can include desizing, scouring, bleaching, and dyeing.5. Garment Construction.The finished denim fabric is then used to create garments, such as jeans, jackets, and skirts.中文回答:牛仔色织生产工艺流程。

牛仔生产工艺流程1.打样,让设计师设计好款式,有纸师打出纸样,按纸样的大小打出样版裤。

样版裤一般都是27码。

至于,实际购买中的其他尺码,都是后面按实际需求裁剪的。

这里出来的是原始纸样,打样师都要根据纸样来裁剪样裤。

纸样出来后,就是按纸样上的大小,用这机器裁剪布块。

2.栽床,做裤子都是用布在这里批量裁成裤子的样式,才进入车间制作的。

3.打五线,就是将裤子缝起来。

不然,穿出去就是挂布条了。

4.落袋条,是做袋子的一个工序。

5.做工艺,是给裤子车上装饰的东西。

就是一般大家看到的牛仔裤上闪闪的东西,一般这活都是给厂里心灵手巧的姑娘做的。

6.开袋,也是做裤子裤袋的一个工艺。

7.埋小浪,是做裤档的一个工序。

这道工序要是漏了,牛仔裤穿起来就会很受的哦。

8.拉裤头,就是裤头里的工序。

9.打枣,一般都是打在裤耳的步骤。

说白了,就是平时大家穿皮带是要穿过去的那几个洞。

10.装后袋,就是车上裤子的后袋。

你摸摸屁股,有摸到2个口袋了吗?对,就是那2个口袋。

这叫牛仔裤的后袋11.拉前袋口,车前袋口。

一样的,往前摸。

摸到裤子前面的2个口袋了吗?对,你们很聪明,就是那2个。

12.打钉机,专门用来打裤子装饰的金属钉子。

看看你的牛仔裤上,是不是有很多一颗颗的小圆钉。

这机器就是干这个的13.剪线,是裤子洗水回来后的工序,就是把裤子上的线头剪掉,修理,平时买裤子质量好不好,看裤子的线头处理也是一个重要环节。

裤子做到这里,已经快完工了。

这个工序开始,就是一些修修整整的事了。

14.烧线头,就是把剪了的线头,再烧一下,使线头处理得更好。

一些很难剪干净的线头,最后,就是用烧线头把它们都处理掉。

让裤子看起来,细节更美观。

15.打包装。

牛仔面料的生产工艺流程英文回答:Denim Fabrication Process.The production of denim fabric involves several intricate stages, each contributing to its unique characteristics and durability. Here's a detailed overview of the denim fabrication process:1. Cotton Cultivation and Harvesting:Denim is primarily made from cotton fibers. The production process begins with cultivating cotton plants, which are harvested when the bolls are ripe and bursting with fluffy cotton.2. Ginning and Spinning:After harvesting, the cotton bolls are processed in agin to remove seeds and impurities, leaving behind rawcotton fibers. These fibers are then spun into yarn, which forms the foundation of denim fabric.3. Weaving:The yarn is woven together on looms using a specifictwill pattern. The warp threads (running lengthwise) andweft threads (running crosswise) interlace to create the characteristic diagonal lines known as denim's "herringbone" pattern.4. Indigo Dyeing:The most distinctive feature of denim is its indigo dye. The yarn is dipped into large indigo vats multiple times to achieve the desired depth of blue color. The dyeing process is carefully controlled to ensure even distribution andcolor consistency.5. Finishing:After dyeing, the denim fabric undergoes various finishing processes to enhance its properties and appearance. These may include sanforizing (pre-shrinking)to minimize shrinkage, stonewashing to create a softer feel, and distressing to achieve a vintage or worn-in look.6. Inspection and Packaging:The finished denim fabric is thoroughly inspected to ensure quality and compliance with specifications. It is then rolled into bolts and packaged for distribution to garment manufacturers.中文回答:牛仔面料生产工艺流程。