60335-2-79高压清洗机

- 格式:doc

- 大小:32.00 KB

- 文档页数:6

D ra f tf or vo t eFINAL DRAFT EUROPEAN STANDARD EN 60335-2-79 NORME EUROPÉENNE FprACEUROPÄISCHE NORMDecember 2008CENELECEuropean Committee for Electrotechnical Standardization Comité Européen de Normalisation Electrotechnique Europäisches Komitee für Elektrotechnische NormungCentral Secretariat: rue de Stassart 35, B - 1050 Brussels© 2008 CENELEC - All rights of exploitation in any form and by any means reserved worldwide for CENELEC members.Project: 22138 Ref. No. EN 60335-2-79:2004/FprAC:2008 EICS 97.080English versionHousehold and similar electrical appliances -Safety -Part 2-79: Particular requirements for high pressure cleanersand steam cleanersAppareils électrodomestiqueset analogues - Sécurité -Partie 2-79: Règles particulières pour les appareils de nettoyage à haute pression et les appareils de nettoyage à vapeur Sicherheit elektrischer Geräte für den Hausgebrauch und ähnliche Zwecke - Teil 2-79: Besondere Anforderungen für Hochdruckreiniger und DampfreinigerThis draft amendment FprAC, if approved, will modify the European Standard EN 60335-2-79:2004; it is submitted to CENELEC members for Unique Acceptance Procedure. Deadline for CENELEC: 2009-05-08.It has been drawn up by CLC/TC 61.If this draft becomes an amendment, CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this amendment the status of a national standard without any alteration.This draft amendment was established by CENELEC in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CENELEC member into its own language and notified to the Central Secretariat has the same status as the official versions.CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Cyprus, the Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and shall not be referred to as a European Standard.D ra f tf or vo t eEN 60335-2-79:2004/FprAC:2008 – 2 –ForewordIn the light of the necessity to adapt EN 60335-2-79 with regard to the requirements of the Machinery Directive 2006/42/EC, the present draft was prepared by CENELEC TC61/WG6/J in co-operation with the MD Consultant, taking also into account the results of CENELEC TC61/WG6 work on EN 60335-1. The approach to amend EN 60335-2-79:2004 aiming toward listing the standard under the MD was discussed and approved during the Kista meeting of CENELEC TC61 in June 2008 (see CLC/TC 61/SEC/1649), when it was decided to submit a draft for an amendment to the Unique Acceptance Procedure.In this document, the text of the draft amendment FprAC is written in blue. The National Committees are invited to vote on this blue text only.If voted positively, the present document as a whole will be approved as a new edition of EN 60335-2-79 with the common modifications identified by a vertical line in the left margin.The following dates are proposed:–latest date by which the existence of the amendment has to be announced at national level(doa)dor + 3 months –latest date by which the amendment has to be implemented at national level by publication of an identical national standard or by endorsement(dop)2009-12-29 (same as dow)–latest date by which the national standards conflicting with the EN have to be withdrawn(dow)2009-12-29 ** A dow of 2009-12-29 is proposed so as this European Standard applies at the same time as the time of application of the new Machinery Directive. There are no special national conditions causing a deviation from this amendment.There are no national deviations from this amendment.WG6/J Convenor’s note:Several meetings between the MD Consultant and CENELEC TC 61/WG6/J between March 2008 and November 2008 resolved all concerns of the MD Consultant and should lead to a positive assessment against the Machinery 2006/42/EC during the UAP.____________D ra f tf or vo t e– 3 – EN 60335-2-79:2004/FprAC:2008Text of FprAC to EN 60335-2-79:2004The text of draft amendment FprAC is the blue text in this file. After the vote, this text will be approved and published as a new edition of EN 60335-2-79 (IEC 60335-2-79:2002 + A1:2004 + A2:2007, modified).1 ScopeThis clause of Part 1 is replaced by the following.This European Standard deals with the safety of high pressure cleaners without traction drive, intended for household and commercial indoor or outdoor use, having a rated pressure not less than 2,5 MPa and not exceeding 35 MPa.It also applies to steam cleaners and those parts of hot water high pressure cleaners incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa·l. The following power systems of the drive for the high pressure pump are covered: –mains powered motors up to a rated voltage of 250 V for single-phase machines and 480 V for other machines,– battery powered motors, – internal combustion engines, –hydraulic or pneumatic motors.This part 2 applies in conjunction with EN 60335-1:2002 and its amendments, which is referred to in this text as “Part 1”. This part 2 supplements or modifies the corresponding clauses of Part 1 as indicated in the text. This standard does not apply to – high pressure water jet machines as covered by EN 1829-1;– steam cleaners intended for domestic use as covered by IEC 60335-2-54; – machines designed to be part of a production process;– machines designed for use in vehicles or on board of ships or aircraft;– machines designed for use in corrosive or explosive environments (dust, vapour or gas); – cleaners designed for medical application;– hand-held motor-operated electric tools as covered by IEC 60745 (series); – transportable motor-operated electric tools as covered by IEC 61029 (series); –machines for application of coating;NOTE Z101 EN 1953 gives requirements for atomising and spraying equipment for coating materials. EN 12621 gives requirements for machinery for the supply and circulation of coating and/or auxiliary materials under pressure– agricultural sprayers; NOTE Z102 EN 907 gives requirements for sprayers and liquid fertilizer distributors for agricultural and forestrypurposes–non-liquid, solid abrasive cleaners.NOTE Z103 Attention is drawn to the fact that in many countries additional requirements on the safe use of the equipment covered may be specified by the national health authorities, the national authorities responsible for the protection of labour, the national water supply authorities and similar authorities.D ra f tf or vo t eEN 60335-2-79:2004/FprAC:2008 – 4 –2 Normative referencesThis clause of Part 1 is applicable except as follows. Addition:IEC 60335-2-54, Household and similar electrical appliances – Safety – Part 2-54: Particular requirements for surface cleaning appliances for household use employing liquids or steamIEC 60364-1, Electrical installations of buildings – Part 1: Fundamental principles, assessment of general characteristics, definitionsIEC 60745 series, Hand-held motor-operated electric tools - SafetyIEC 61029 series, Safety of transportable motor-operated electric toolsIEC 61558-2-3, Safety of power transformers, power supply units and similar – Part 2-3: Particular requirements for ignition transformers for gas and oil burnersIEC 61770, Electric appliances connected to the water mains - Avoidance of backsiphonage and failure of hose setsISO 3743-1, Acoustics - Determination of sound power levels and sound energy levels of noise sources using sound pressure - Engineering method for small, movable sources in reverberant fields - Part 1: Comparison method for hard-walled test roomsISO 3744, Acoustics - Determination of sound power levels and sound energy levels of noise sources using sound pressure - Engineering method for an essentially free field over a reflecting planeISO 4871, Acoustics - Declaration and verification of noise emission values of machinery and equipmentISO 5349-1, Mechanical vibration – Measurement and evaluation of human exposure to hand-transmitted vibration - Part 1: General requirementsISO 12100-2, Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principlesEN 1829-1, High pressure water jet machines — Safety requirements — Part 1: Machines *)3 DefinitionsThis clause of Part 1 is applicable except as follows.3.1.9 Replacement: normal operationconditions under which the machine is operated in normal use.———————*) At draft stage.D ra f tf or vo t e– 5 – EN 60335-2-79:2004/FprAC:2008It denotes the operation at rated flow and rated pressure with the appropriate nozzle and hose line fitted, all strainers and filters in a clean operating condition and the unloader valve set to the rated pressure . The water heater , if fitted, is operated at maximum power. Electric motor driven machines are supplied at rated voltage .Power outlets for accessories are loaded with a resistive load in accordance with the marking. The burner is operated at rated power. Machines designed for operation at more than one rated power setting are additionally tested at the most disadvantageous power.On machines designed for use with a flue pipe, a section of flue pipe is attached to the machine. Flue gas determinations are taken in this flue pipe.The draught is adjusted as recommended in the instructions3.101unloader valvepressure operated device which, when the pump pressure exceeds a preset value, releases the pressure and leads the excess fluid into the inlet system. In addition it bypasses the total pump flow at reduced pressure when its outlet flow is cut off3.102safety valvepressure operated device which, when the pump or steam cleaner pressure exceeds a preset value, releases the pressure and which may return the excess fluid or steam either to the inlet system or into the atmosphere3.103rated pressuremaximum working pressure at the pressure generator during normal operation3.104allowable pressuremaximum pressure up to which a machine and/or parts of the machine may be subjected without impairing its safety3.105rated flowmaximum flow at rated pressure at the nozzle during normal operation3.106water heaterdevice for heating the cleaning agent by means of electricity, gas, liquid fuel or heat exchange 3.107cleaning agentwater with or without the addition of gaseous, soluble or miscible detergent or solid abrasive 3.108pressure switchdevice which, in response to varying fluid pressure, provides a controlling function at a pre-set value 3.109flow switchdevice which, in response to a varying rate of fluid flow, provides a controlling function at a pre-set valueD ra f tf or vo t eEN 60335-2-79:2004/FprAC:2008 – 6 –3.110flame safety controlcontrol device that responds directly to flame properties sensing the presence of flame and, in event of ignition failure or unintentional flame extinguishment, causes safety shut downNOTE Flame safety controls are also known as flame failure devices.3.111trigger gunhand-held spraying device where the flow of the cleaning agent is regulated by an integrated manually operated control device3.112continuous ignitionignition of an oil or gas fired burner that is continuously maintained throughout the time the burner is operational , whether the burner is firing or not3.113rated temperaturemaximum temperature of the cleaning agent during normal operation 3.114pencil jet nozzlenozzle that gives a concentrated, parallel water jetNOTEPencil jet nozzles are also known as needle jet nozzles, solid jet nozzles or 0 degree jet nozzles3.115water jetterpipe-cleaning device, connected to and controlled by a trigger gun, consisting of a high-pressure hose and a cleaning head with nozzles3.116motorized cleaning headhand-held or hand-guided cleaning device connected to the machine, with an integrated electrical motorNOTEThe permanently attached main cleaning head is not regarded as a motorized cleaning head3.117low pressure accessorydevice, connected to and controlled by a trigger gun , with large nozzle openings generating a pressure below rated pressureNOTE Typical examples of low pressure accessories are washing brushes, foam nozzles, washing sponges.3.118hand-guided machinemachine that needs to be moved on the floor 3.Z101maximum flow ratehighest possible flow at the nozzleNOTE Typically, the maximum flow rate occurs at working pressures lower than rated pressure and with a nozzle designed for spraying of cleaning agents .3.Z102 hose lineassembly of high pressure hoses mounted with appropriate fittingsD ra f tf or vo t e– 7 – EN 60335-2-79:2004/FprAC:20083.Z103 guardpart of the machine specifically designed to provide protection by means of a physical barrier 3.Z104 operatorperson installing, operating, adjusting, maintaining, cleaning or moving the machine3.Z105test solutiona solution which consists of 20 g of NaCl and 1 ml of a solution of 28 % by mass of dodecyl sodium sulphate in each 8 l of waterNOTE The chemical designation of dodecyl sodium sulphate is C 12H 25NaSO 4.3.Z106 riskprobability of being exposed to an injury or damage to health3.Z107commercial useintended use of machines covered by this standard in a professional wayFor the purpose of this standard commercial use may be read as not intended for domestic use4 General requirementThis clause of Part 1 is applicable except as follows.Replace the first paragraph by the following:Machines shall be constructed so that they function safely so as to cause no danger to persons or surroundings during normal use, even in the event of carelessness, and during installation, adjusting, maintenance, cleaning, repairing or transportation. Addition:For the purpose of this standard, the term ‘appliance’ as used in Part 1 is to be read as ‘machine’.5 General conditions for the testsThis clause of Part 1 is applicable except as follows.Addition :5.Z101 The test solution is stored in a cool atmosphere and used within seven days after its preparation.5.Z102 Protective devices and safety valves shall remain fully functional but not trip under normal operation .D ra f tf or vo t eEN 60335-2-79:2004/FprAC:2008 – 8 –6 ClassificationThis clause of Part 1 is applicable except as follows. 6.1 Replacement:Machines shall be one of the following classes with respect to the protection against contact with live parts :– class I, – class II, or –class III .However, hand-held appliances and hand-held parts of steam cleaners and high pressure cleaners shall be class II or class III.Compliance is checked by inspection and by the relevant tests. 6.2 Replacement:The machines shall have a degree of protection against harmful ingress of water according to Table 101:Table 101 – Degree of protection against harmful ingress of waterProtection class (electric shock)Protection degree(IEC 60529)Steam cleanersfor indoor use onlyI – IIIPX4III IPX3for outdoor useI-II-III IPX5 Hand-held partsII IPX7 III IPX3 High pressure cleanersHand-held appliancesII-III IPX7Other types of machines I-II-IIIIPX5Hand-held partsII-III IPX7However, fixed appliances that are specified for installation in a separate room, where they will not be subject to spillage or splashing of water, shall be at least IPX0. Compliance is checked by inspection and by the relevant tests.7 Marking and instructionsThis clause of Part 1 is applicable except as follows. 7.1 Replace the 4thdashed item as follows:–the business name and full address of the manufacturer and, if applicable, his authorised representative;D ra f tf or vo t e– 9 – EN 60335-2-79:2004/FprAC:2008Addition :Machines shall be marked in addition with the following: – serial number, if any; – designation of the machine; – designation of series or type;– the year of construction, that is the year in which the manufacturing process is completed; – rated pressure in Pascal; – allowable pressure in Pascal; – rated flow in litre per minute;–maximum flow rate in litre per minute, if necessary. The number of flow rate markings is limited to two;– maximum rated temperature where this is above 50 ºC; –maximum power of the water heater in kW, if applicable (for electric heaters the input power, for gas-fired or oil-fired heaters the output power).Machines equipped with wheels shall be marked with the mass of the most usual configuration in kg.A yellow label with black lines showing the substance of the warning symbols in accordance with Figure 101 shall be permanently fixed to the machine.Machines shall be marked in addition with the following, if applicable: – When the surface of a flue or duct for exhaust gases from the heater exceeds a temperature rise of 60 K, a warning notice shall be fitted near to the hot surface statingWARNINGHot. Do not touch.This wording may be replaced by symbol IEC 60417-5041. The height of the lettering shall be not less than 4 mm.– Steam cleaners shall be marked with symbol IEC 60417-5597.– Machines not intended to be connected to the potable water mains shall be marked with the symbol according to Figure 104, coloured as shown or in monochrome colour.–Machines that are designed to be used indoors and are powered by internal combustion engines, except LPG-powered engines, shall be marked with the symbol according to Figure 105.Compliance is checked by inspection.7.1.Z101 All high pressure hoses shall be marked with the following:– allowable pressure in Pascal or bar; – maximum temperature in degrees Celsius;–business name of the manufacturer of the hose and the date of production. These data may be coded.Compliance is checked by inspection.D ra f tf or vo t eEN 60335-2-79:2004/FprAC:2008 – 10 –7.1.Z102 All high pressure accessories (e.g. trigger gun , spray lance) shall be marked with the following: – allowable pressure in Pascal or bar; –maximum temperature in degrees Celsius.Compliance is checked by inspection.7.1.Z103 Motorized cleaning heads shall be marked with their model or type reference. Compliance is checked by inspection.7.1.Z104 Power outlets for accessories shall be marked with the maximum load in watts on the power outlet or close to it.Compliance is checked by inspection. 7.6 Addition :[symbol IEC 60417-5597]steam7.12 Addition:The front cover of the instructions shall include the substance of the following warning:WARNING Read the instructions before using the machine.This wording may be replaced by symbols 0434 and either 1641 or 0790 of ISO 7000.The words “Original instructions” shall appear on the language version(s) verified by the manufacturer.The instructions shall contain at least the following: – the business name and full address of the manufacturer and, if applicable, his authorised representative;– designation of series or type of the machine as marked on the machine itself, except for the serial number;– the general description of the machine;– the intended use of the machine and the auxiliary equipment as covered by the scope of this standard;–the meaning of the symbols used on the machine and in the instructions;– drawings, diagrams, descriptions and explanations necessary for the safe use, maintenance and repair of the machine and for checking its correct functioning;– technical data including the markings on the machine and the maximum inlet water pressure in Pascal;– information regarding putting into service, safe operation, handling, transportation, andstorage of the machine taking into account its weight;–instructions to enable adjustment and maintenance to be carried out safely, including the protective measures that should be taken during these operations;D ra f t f o r v o t e – the conditions in which the machine meets the requirement of stability during use,transportation, assembly, dismantling when out of service, testing or foreseeable breakdowns;– the operating method to be followed in the event of accident (e.g. contact with detergents:rinse with an abundance of clean water) or breakdown to prevent unsafe situations.The instructions shall indicate the type and frequency of inspections and maintenance required for safe operation including the preventive maintenance measures. They shall, if applicable, give the specifications of the spare parts if they affect the health and safety of the operator .In addition, the instructions shall give the following information, if applicable:– information about appropriate Personnel Protection Equipment (PPE) for high pressurecleaners in operation e. g. safety boots, safety gloves, safety helmets with visors, hearing protection etc. which shall be worn while operating the equipment;– instructions for water jetters shall be given, such as “Insert hose to red mark before turningon the machine”;–adequate information about the connection with the water mains, including the maximum inlet pressure, if not given on the rating plate; –adequate information about the nozzles to be used, the danger of the kickback force and the sudden torque on the spray assembly when opening the trigger gun ; – the kickback forces if they exceed 20 N;– the functioning of the safety devices, e.g. safety valves, flow switches, pressureswitches ;–for battery operated machines, the precautions to be taken for safe charging; –information regarding safe disposal of batteries;– for mains operated machines the substance of the following:The electric supply connection shall be made by a qualified electrician and comply with IEC 60364-1. It is recommended that the electric supply to this machine should include either a residual current device that will interrupt the supply if the leakage current to earth exceeds 30 mA for 30 ms or a device that will prove the earth circuit.– For oil fired machines without a flame safety control , the substance of the following:This machine must be attended during operation. – For fixed appliances intended to be used in a dry independent room, and for steamcleaners intended for indoor use only, the substance of the following:Do not splash or wash down.For machines intended to be connected to the potable water mains, the instructions shall give the following information, if applicable:–adequate information for the correct connection to the potable water mains; –necessary length and quality of the water supply hose; – necessary measures for conversion of the connection from supply from the potable watermains to supply from other water sources. For machines not intended to be connected to the potable water mains, the instructions shall give the following information, if applicable: –adequate information for the correct connection to the water supply; –adequate information about suction operation; –necessary length and quality of the water supply hose; – necessary measures for conversion of the connection from supply from other water sourcesto supply from the potable water mains.D ra f t f o r v o t e 7.12.Z101 The instructions shall include information on airborne noise emission as indicated in ZAA.2.7.7.12.Z102 The instructions shall give the following information:– the vibration total value to which the hand-arm system is subjected, measured in accordancewith ISO 5349-1 for arm vibrations, the machine being supplied at rated voltage or at the maximum rated voltage for machines with a range of voltages, if it exceeds 2,5 m/s². Where this value does not exceed 2,5 m/s², this shall be mentioned;–the uncertainty surrounding this value. These values shall be either those actually measured for the machine in question or those established on the basis of measurements taken for a technically comparable machine which is representative of the machine being produced.Regarding operating conditions during measurement and the methods used for measurement, the reference of the harmonised standard applied (EN 60335-2-79) must be specified7.12.Z103 The instructions shall include warnings concerning ways in which the machine shall not be used that experience has shown might occur. At least, it shall include the substance of the following warnings, if applicable.– WARNING This machine has been designed for use with the cleaning agent supplied orrecommended by the manufacturer. The use of other cleaning agents orchemicals may adversely affect the safety of the machine.– WARNING High pressure jets can be dangerous if subject to misuse. The jet must not be directed at persons, live electrical equipment or the machine itself. –WARNING Do not use the machine within range of persons unless they wear protective clothing. –WARNING Do not direct the jet against yourself or others in order to clean clothes or foot-wear. –WARNING Risk of Explosion – Do not spray flammable liquids. –WARNING High pressure cleaners shall not be used by children or untrained personnel. – WARNING High pressure hoses, fittings and couplings are important for the safety of themachine. Use only hoses, fittings and couplings recommended by themanufacturer.– WARNING To ensure machine safety, use only original spare parts from the manufactureror approved by the manufacturer.–WARNING Water that has flown through backflow preventers is considered to be non-potable. – A warning that the machine shall be disconnected from its power source during cleaning or maintenance and when replacing parts or converting the machine to another function: •for mains operated machines by removing the plug from the socket-outlet; •for battery operated machines by safely disconnecting at least the non-earthed pole of the battery or by an equivalent method (disconnecting device); • for internal combustion engine powered machines by removing the ignition key and by disconnecting the battery.– WARNING Do not use the machine if a supply cord or important parts of the machine aredamaged, e.g. safety devices, high pressure hoses, trigger gun.D r a f t f o r v o t e – WARNING If an extension cord is used, the plug and socket must be of watertightconstruction.– WARNING Inadequate extension cords can be dangerous.– WARNING Do not use combustion engine powered machines indoors unless adequateventilation is assessed by national labour authorities.– WARNING Ensure that any exhaust emissions are not in the vicinity of air intakes.– WARNING For gas or oil-heated machines it is important to provide adequate ventilationand make sure that the flue gases are properly discharged.Instructions for machines where gas or liquid fuel are used shall also include the specification of the correct fuel and the substance of the following:– WARNING Incorrect fuels shall not be used as they may prove hazardous.Instructions for machines having a current-carrying hose for dry suction, operating at other than safety extra-low voltage , shall also include the substance of the following: – WARNING This hose contains electrical connections: do not use it to collect water and donot immerse in water for cleaning.8 Protection against access to live partsThis clause of Part 1 is applicable except as follows.8.1 Addition:Water and water-borne cleaning agents are considered conductive.[addition to 8.1.4 deleted]9 Starting of motor-operated appliancesThis clause of Part 1 is not applicable except as follows.It shall only be possible to start the machine by intended actuation of a control device provided for the purpose. The same requirement applies when restarting the machine after a stoppage, whatever the cause.Compliance is checked by inspection and by test.10 Power input and currentThis clause of Part 1 is applicable except as follows. [addition to 10.1 deleted]。

7.标志7.1 增加:当非工作热表面的温升超过表Z101规定值但未超过规定值的两倍时,需有以下警告语或符号:CAUTION: Hot surface or此警告语或符号应贴于最高温度的表面且正常操作过程中能清晰可见。

此符号至少要8mm高度7.10 增加:为控制器具开关运行功能的装置(如果有的话),应可从其形状、尺寸、表面手感或状态位置等方式跟其它的手动装置区别开来。

以触觉、视觉、听见的方式反馈产品的运行状态。

注:蒸汽释放的声音可当作是听见信息。

7.12增加:说明书中应包括以下内容的说明:此器具不适宜给8岁或以下儿童或身体感官、心智有缺陷、缺乏经验和知识的人使用,除非有专门负责安全的人监护指导.应当照看儿童防止他们把电器当作玩具玩耍.清洁和用户保养不得由无监管的儿童进行。

说明书还应包括以下内容:—当电烫斗带电工作时,请使用者不要离开;—当往水箱注水的时候,务必将插头从插座上拔下(针对蒸汽电烫斗和带有喷水功能的电烫斗);—当在使用时,务必不能打开注水口,说明书中一定要说明安全注水的方法(压力蒸汽咖啡机);—电烫斗应放于其专用的基座上使用(针对无绳电烫斗);—不要连续使用电烫斗(针对旅行电烫斗);—电烫斗必须在平稳的表面上使用;—当电烫斗放置在其基座上时,应确保电烫斗已放置平稳;—如果电烫斗已被跌落请不要使用它,并确认其是否有跌破、是否有泄漏等损坏现象;—当电烫斗通电时或冷却时,请保证电烫斗及其软线无法被低于8岁的小孩触及到;—当电烫斗有此符号时,应在说明书上有“在正常使用时可能变热”的警告语;7.12.Z101:在7.12中器具的安全运行特殊的警告说明应调整到一起并位于说明书的前面;其大写字母的字体高度至少要4mm;的大写字母的高度至少为4.0mm;11发热11.8 器具按照正常运行的方式运行,其外表面最大温升不得超过以下规定值:表Z101-可触及表面的温升限值11.Z101温升测量应按照制造商的使用说明在正常操作的状态下测量;底部或工作表面的温升不被测量。

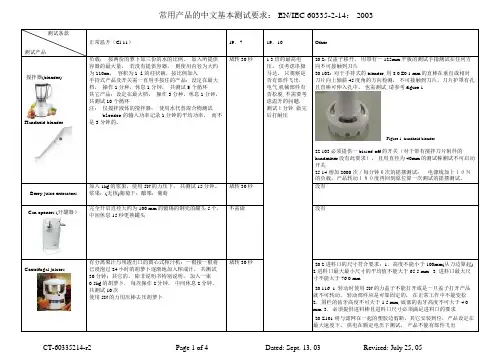

常用产品的中文基本测试要求: EN/IEC 60335-2-14: 2003 测试条款测试产品正常温升(Cl.11)19.7 19.10 Other搅拌器(blender) Handheld blender 负载:按两份的萝卜加三份的水的比例,加入所提供容器的最大量,若没有提供容器,则使用内径为大约为110mm,容积为1 l的柱状碗,按比例加入手持式产品及开关需一直用手按住的产品:设定在最大档,操作1分种,休息1分钟,共测试5个循环其它产品:设定在最大档,操作3分种,休息1分钟,共测试10个循环注:仅搅拌液体的搅拌器:使用水代替混合物测试blender的输入功率记录1分钟的平均功率,而不是3分钟的。

堵转30秒 1.3倍的最高电压,仅考虑串极马达,只观察是否有部件飞出,电气,机械部件有否松脱, 不需要考虑温升的问题,测试1分钟. 做完后打耐压.20.2: 仅盖子移开,用带有一125mm 平板的测试手指测试在任何方向不可接触到刀片20.102: 对于手持式的blender, 用8.0 ±0.1 mm的直棒在垂直或相对刀片向上倾斜45度角的方向检测,不可接触到刀片,刀片护罩有孔且直棒可伸入孔中,也需测试, 请参考figure 1Figure 1, handheld blender22.103必须提供一biased-off的开关(对于带有搅拌刀片附件的handmixer没有此要求),且用直径为40mm的测试棒测试不可启动开关25.14 增加2000 次/每分钟6次的摇摆测试:电源线加上10N的负载,产品转动180度再回到原位算一次测试的摇摆测试。

Berry-juice extractors 加入1kg的浆果,使用5N的力压下,共测试15分钟。

浆果:(无核)葡萄干;醋栗;葡萄堵转30秒没有Can openers (开罐器)完全开启直径大约为100 mm的镀锡的钢壳的罐头5个,中间休息15秒更换罐头不需做没有Centrifugal juicers 有分离果汁与残渣出口的离心式榨汁机:一根接一根将已浸泡过24小时的胡萝卜逐渐地加入榨成汁,共测试30分钟;其它的,除非说明书特别说明,加入一束0.5kg的胡萝卜,每次操作2分钟,中间休息2分钟,共测试10次使用5N的力用压棒去压胡萝卜堵转30秒20.2进料口的尺寸符合要求:1.高度不能小于100mm(从刀边算起)2.进料口最大最小尺寸的平均值不能大于65.5 mm3. 进料口最大尺寸不能大于76.0 mm20.116 1. 转动时使用5N的力盖子不能打开或是一旦盖子打开产品就不可转动,转动部件应是可靠固定的,在正常工作中不能变松2.围栏的齿牙高度不可大于1.5 mm, 底部的齿牙高度不可大于4.0mm 3.必须提供进料棒且进料口尺寸必须满足进料口的要求20.Z101 将与滤网在一起的塑胶边剪断,其它安装到位,产品设定在最大速度下,供电在额定电压下测试,产品不能有部件飞出Citrus-fruit squeezers 使用50N的力去压半个橙子使产生果汁;在15秒内压两个半个的橙子,中间休息15秒,共测试10次不需做 1.3倍的最高电压,仅考虑串极马达,只观察是否有部件飞出,电气,机械部件有否松脱, 不需要考虑温升的问题,测试1分钟.做完后打耐压.没有Coffee mills/coffee grinder not exceeding 500g hopper capacity 产品有分离的收集咖啡粉的容器的咖啡碾磨器操作至容器完全满,再休息1分钟,再测试一个循环,共测试两个循环其它的咖啡碾磨器操作至咖啡完全被磨细或30秒取最长时间,休息1分钟,共测试3个循环堵转5分钟(取决于19.102)1.3倍的最高电压,仅考虑串极马达,只观察是否有部件飞出,电气,机械部件有否松脱, 不需要考虑温升的问题, 仅测试30秒. 做完后打耐压.用手按住开关工作的产品不用做此测试: 19.101: 产品供电在额定电压下,在所要求的测试时间及休息时间操作5次,所测试的绕组的温升不能超过table 8.测试时间:有定时器的,定时器的最长时间其它:-工作时间比收集容器装料或倒空料斗所需时间长30秒,取最短的时间-其它:1min休息时间:-10秒对于有收集容器的产品-60秒对于其它产品19.102: Coffee mills: 三个产品测试,产品中加入40g的咖啡豆,再加入两颗可通过8mm但不小于7mm的筛子的花岗片,产品工作在额定电压下,若产品堵转,则再做19.7的测试Coffee grinder: 同coffee mills, 只是使用两颗可通过4mm但不小于3mm的筛子的花岗片测试Cream whippers Egg beaters 产品的有效长度的80%插入有水的碗中,设定在最大设置,测试10分钟不需做 1.3倍的最高电压,仅考虑串极马达,只观察是否有部件飞出,电气,机械部件有否松脱, 不需要考虑温升的问题,测试1分钟. 做完后打耐压.20.101 不能有刀边可接触,否则需使用保护装置保护,若转速大于1500 转每分钟,则不能在产品转动时可将转动部件退出Food mixerFood mixer with kneader 在所提供的容器中加入35%最大容积的面粉,确认所加面粉的重量,再按100g 面中加入72g水的比例加入所要求的水,操作10分钟,若为手持式的产品则操作时走8字形,每分钟10-15次,测试5分钟;若为使用biased-off switch的产品,测试5分钟。

C3系列-自动吸嘴清洗机用户手册◎2018版◎伟凯美(香港)有限公司目录1.前言 (2)2注意事项 (3)3技术参数和规格尺寸................................................4-6 4操作说明 (8)5保养维护操作.........................................................9-12 6保修记录 (13)7保修卡 (14)前言首先,我们诚挚地感谢选AC24P-5自动吸嘴清洗机!您将可利用这款产品实现方便快捷的操作,提高生产效率、减低生产成本帮助你更好维护好吸嘴。

使用这台机器前,请您详细地阅读这份使用手册,并将它妥善保存。

自动吸嘴清洗机第三代C3系列AC24P-52.注意事项(1).使用注意事项1).使用之前确认吸嘴是否在清洗范围之内。

2).只能使用我们推荐的清洗液(工业纯净水)。

3).使用之前确认吸嘴与托盘是否相符。

5).禁止在含有腐蚀气体、化学药品等等的环境下使用清洗机。

6).禁止在户外和有阳光直射的地方使用清洗机。

7).设备总电源关闭后,等待2分钟后方可再启动电源。

关闭总电源后又瞬间开启,则有可能会出现24V电源开关自动开启保护的措施,使设备无法正常工作的风险。

若出现此类情况请断开清洗机总电源,等待半个小时后再接通电源(在此过程中设备电源处于自动放电状态)。

8).每次清洗完毕使用气枪吹干工作室里的殘留水滴。

9)清洗过程严禁打开注水开关。

(2).吸嘴放置之注意事项1).每次放置吸嘴完毕后要确认吸嘴是否完全放到位及吸嘴是否与置具贴合。

2).放置吸嘴盘到工作区域的托盘上时要注意不要碰撞到气缸喷头。

3).吸嘴放置到位后盖上盖板,放置清洗过程中出现松动导致吸嘴损坏等现象(3).清洗液注入之注意事项1).确定清洗机在停止工作状态或关闭清洗机的气源开关。

2).打开注水盖子时,应注意灰尘或带有杂质的物体进入储液罐。

集亿思智慧科技(南京)有限公司啄木鸟GP3000产品手册2022.07 Rev.1啄木鸟GP3000超精过滤系统GP3525产品手册集亿思智慧科技(南京)有限公司啄木鸟GP3000产品手册2022.07 Rev.1目录1. 基本说明& 安全注意GP3525通常配备一个整体式HPU,并通过肾回路与系统的油箱连接。

循环抽油通常是从油箱的低位抽出,然后返回到同一油箱的油面或顶部。

GP3525可有效去除污染物(如固体/软颗粒)、自由水、乳化水和漆膜。

这些污染物被保留在GPO3525滤芯内。

本手册提供正确安装及操作指导。

集亿思智慧科技(南京)有限公司(下称“集亿思”)不对该设备的正确安装是否符合国家、地方或其他任何规范承担任何责任。

如果在安装过程中忽视规范/标准,将存在人身伤害和/或设备损坏的危险。

在使用GP3525之前,确保所有必要的安全隔离就位,包括电气和液压隔离,并完全减压。

不遵守这一预防措施可能会导致严重的人身伤害或生命危险!只有合格的电气/机械人员,在充分熟悉并了解本设备相关操作及涉及的危险后,才可以安装、调试、操作或维修本设备。

在继续之前,请阅读并理解本手册和其他适用手册的全部内容。

不遵守这一预防措施可能会导致严重的人身伤害或生命危险!1.1 安装前电力驱动的GP35251.2 调试前在调试之前,检查设备是否有故障,或由于运输造成的损坏。

将系统流体注入GP3525装置的油泵内,以提高吸收率。

将配件、软管/油管连接到吸入和排出端口上。

检查所有连接是否正确组装和拧紧。

检查吸入和排出球阀是否处于开启状态。

此外,GP3525外壳上的球阀和塞孔以及泵的压力侧都被关闭。

回程上没有安装球阀。

确保电源线、插头等没有损坏,不会造成电击的危险。

如果您的GP3525系列机组由三相电源供电,在启动时检查电机旋转方向。

面对风扇盖时,电机风扇应顺时针旋转。

每次设备移动到新位置时都要检查。

单相电压设备无须检查。

电气连接工作只能由具备有相关资质的专业人员进行。

UL 1776ISBN 1-55989-934-4高压清洗机美国UL安全检测实验室公司(Underwriters Laboratories Inc.)(UL)伊利诺伊州60062-2096诺斯布罗克市普芬斯腾路333号UL安全标准用于高压清洗机,UL 1776第二版,日期1995年12月27日修订:本标准含有直至1997年6月19日(包括1997年6月19日)作出的修改。

凡改动之处,均在受到影响的项目后面以一个提示标明。

提示的前面和后面都有一个星号。

日期为1997年6月19日的修订稿包括本标准的打印标题页(第1页)。

这份在UL的Northbrook Office的标准的主体是一份正式文件,是关系到一项UL服务,以及一种产品和该产品或服务是否符合要求的正式文件。

或者解答有关于本标准的准确性的问题。

UL的“安全标准”的版权属于UL。

“标准”的复印件也好,“磁盘上的标准”也好以及销售用磁盘上的“标准”文件也好都不得以任何方式予以改动。

与这些标准有关的所有UL的标准和所有版权、所有权,以及权利应始终是UL的独家财产。

版权所有。

未经UL的事先允许,本出版物的任何部分不得被复制、储存在可以取用的系统中,或用任何方式,不论是电子的、机械复印的,记录的方式,或其它手段进行传输。

“UL安全标准”的修订本经常会发布。

“UL安全标准”只有在包含最新的修订本的情况下,这个安全标准才是现行的。

UL“按原样”提供本“标准”,不作出任何种类的、明确的或隐含的保证,包括但不限于为了任何目的的适销性或合适性的保证。

不论在什么情况下,UL都不对由于使用本标准或不能使用本标准而造成的任何特殊的、偶发的、间接发生的、间接的或类似的损失,包括利润的损失、节蓄的损失、数据损失,或任何其它损失负责,即使UL或授权的UL代表已被通知了这种损失的可能性。

不论在什么情况下,UL对任何损失的责任都不超过为这份标准支付的价格,不论如何索赔。

UL将设法回答有关WordPerfect、Envoy,以及Standards-on-Diskette的需要得到支持的请求。

EN60335-2-79(翻译稿)国际标准 IEC(国际电工技术委员会)60335-2-79 1995年修正12000年7月家用和类似电气设备的安全�C 部分2-79:工业和商业用高压清洗器和蒸汽清洗器的特别要求 cIEC2000 �C 版权所有○国际电工委员会瑞士日内瓦凡伦贝路3号传真:+41 22 919 0300e-mail: inmail@iec.ch IEC网址:http://www.iec.ch 国际电工委员会价格代码 B 关于价格,请见现在样本cIEC2000(E) 60335-2-79 修正1 ○本修正是由国际电工技术委员会61的子委员会“工业用电气马达操纵的清洗设备”准备的。

内容是:家用和类似的电气设备的安全本修正的内容是根据下列文件: FDIS61J/112/FDIS用于本修正批准的关于选举(投票)的全部资料可在上述关于选举(投票)的报告中找到。

本修正两种文字对照的版本可在以后颁发。

2 定义在P11上加下列定义: 2.115 水喷洗装置高压管清洗装置在高压软管端部有一个喷嘴。

P177.12.1 增加在P19上在子条末了插入下列新内容水喷洗装置使用说明(如果适用)应予以提供,和“在运转装置前,将软管插到红色记号处”。

cIEC2000(E) 60335-2-79 修正1 ○P19插入下列内容8.1.4 上一节后加:电化学酸性或碱性的24个电池的电池隔离系统,包括凝胶电池应被看作是III类,条件是: - 每个电池充电时的最大电压不超过2.7V; - 无接电件(见27条)- 导电件不能落下,因此,桥接另一侧的电极带电部分(见22条) P3722.103 由下列新内容替换本子条的内容:装置或触发枪应备有一个使喷嘴停止液体流动的装置。

关于手持式清洗装置,蒸汽清洗机和触发枪,当本装置的工作电源不是由使用者操作时,它应在无液(水)压的情况下自动操作。

手提式清洗装置、蒸汽清洗机和触发枪的工作电源都有一个装置,该装置在不工作时,可以锁紧上述装置。

中车洛阳机车有限公司生物循环零部件清洗机、微水高压除漆机采购项目技术参数一、招标依据中车洛阳机车有限公司2017年3月份投资计划。

二、招标项目简介2.1 生物循环零部件清洗机用于机车零部件除油污清洗。

高效而环保,同生物循环零部件清洗剂配套使用。

2.2 微水高压除漆机主要用于机车检修过程中,中小型部件的焊缝探伤前的局部除漆作业。

2.3 本次招标共两个标段:一标段:2台生物循环零部件清洗机;二标段:1台微水高压除漆机。

投标人应就一个标段进行完整投标,不得将一个标段拆开投标,否则将不被接受。

符合资格要求的投标人可对两个标段投标,并同时中两个标段。

本项目的两个标段均不接受联合体投标。

2.4 本项目的两个标段的标的物必须是国内外知名品牌,若是国外进口产品,其中国总经销授权的代理服务商,在投标报名资格预审和开标时对投标人资格正式审核时,投标人必须提供全面授权书和设备的海关报关证明;对国内厂家,只接受设计生产制造商报名,不接受代理经营商。

三、一标段招标项目技术要求(生物循环零部件清洗机)(一)设备用途生物循环零部件清洗机用于机车零部件除油污清洗。

高效而环保,同生物循环零部件清洗剂配套使用。

(二)技术要求2.1基本要求:2.1.1本设备必须是全新设备(包括所有零部件、元器件和附件),能高效,安全,保质完成工作。

2.1.2本设备运行噪音符合国家相关环保标准(设备工作噪音小于75dB)。

2.1.3本设备应选用优质材料制造,所选用的机械、电器电子组件是优质的、先进的、可靠的系列产品。

2.1.4所有电机、泵和控制元件均选用国内外知名专业厂家产品。

2.1.5设备应有可靠的安全保护,保险措施,以防止误操作或意外事故致使机器受损或造成人身伤亡。

2.1.6本设备的各零件、仪器、仪表之计量单位全部采用国际单位制(IS)标准,所有零部件和仪表的设计制造应符合ISO和IES标准。

2.1.7本设备必须技术先进,结构设计合理、操作简便、安全可靠、便于维护且具有良好的维修性。

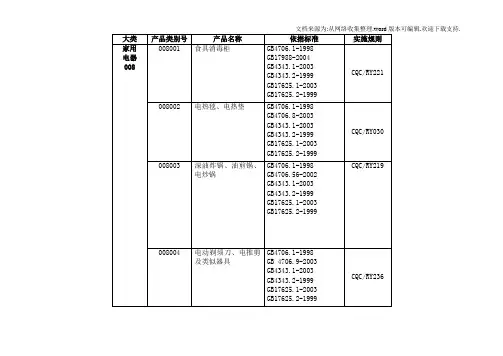

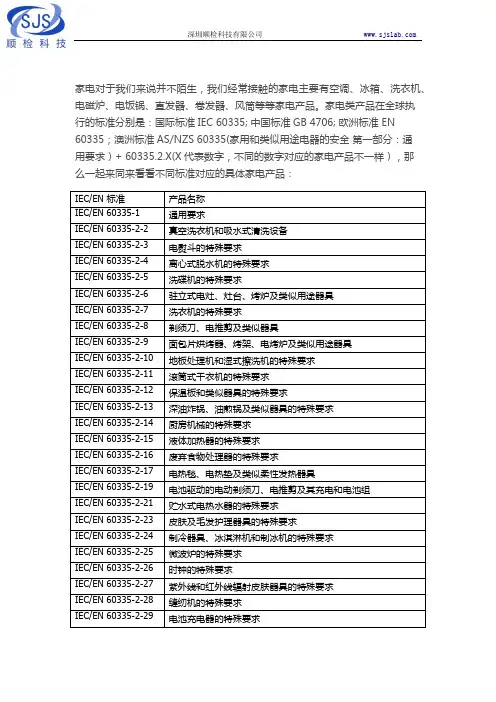

家电对于我们来说并不陌生,我们经常接触的家电主要有空调、冰箱、洗衣机、电磁炉、电饭锅、直发器、卷发器、风筒等等家电产品。

家电类产品在全球执

行的标准分别是:国际标准 IEC 60335; 中国标准GB 4706; 欧洲标准 EN 60335;澳洲标准AS/NZS 60335(家用和类似用途电器的安全第一部分:通

用要求)+ 60335.2.X(X代表数字,不同的数字对应的家电产品不一样),那

么一起来同来看看不同标准对应的具体家电产品:

所有的产品都是参照IEC/EN 60335-1 通用标准的测试要求,但是不同类型的产品又在IEC/EN 60335-1 的基础上加了属于自己产品内专属的测试要求。

专利名称:洗地机及其净水箱

专利类型:发明专利

发明人:王胜,王国强,曾国辉,杨蛟龙,陈俊祺,王庆鹏申请号:CN202111554551.9

申请日:20211217

公开号:CN114052574A

公开日:

20220218

专利内容由知识产权出版社提供

摘要:本发明涉及一种洗地机及其净水箱,净水箱包括箱体,其上开设有进水口;盖体,沿第一方向可拆卸地装配于箱体;以及弹性件,配接于盖体上,并被构造能够相对盖体运动至打开与关闭进水口;其中,当弹性件关闭进水口时,弹性件同时密封并封堵于进水口内。

本发明提供的洗地机及其净水箱装配简单。

申请人:珠海格力电器股份有限公司

地址:519000 广东省珠海市香洲区前山金鸡西路

国籍:CN

代理机构:广州华进联合专利商标代理有限公司

代理人:王秀君

更多信息请下载全文后查看。

FS 15/35冷水高压清洗机使用说明书一FUSSEN系列高压清洗机1. 您所购买的高压冷水清洗机是由具有领先技术水平的制造商设计的。

2. 为了要确保产品的使用寿命和较高的耐久性, 我们建议您在操作设备之前仔细阅读这本操作手册。

3. 本操作手册提供给:操作者、维护技术人员和修理技术人员。

4. 随着我司不断对产品研发, 本使用指南内容与资料日后如有所更新将不另行通知。

二高压冷水清洗机1. FUSSEN 系列高压冷水清洗机,可使您在更短的时间内达到最佳清洗效果。

2. FUSSEN提供了您高效率主机及配件来满足您对繁重及严峻考验的清洗工作要求。

主机的构造,设计与其经过喷塑处理的钢框架使您的高压清洗机在运输和使用中受到最佳保护,以上的结合帮助您解决高压清洗工作中的一切问题。

高压冷水清洗机系列是根据清洗工作繁重及环境考验程度而设计的。

所有的泵和所有与水接触的部件均由抗腐蚀的材料组成,陶瓷活塞,长寿命的密封和不锈钢阀,它们一起确保了水枪的长寿命和耐久性。

三技术参数类型参数型号FS 15/35最大压力(巴/兆帕/PSI)0-350/0-35/0-5075最大流量(升/小时)900驱动(伏特/相/赫兹)400/3/50功率(千瓦)11最大进水温度(摄氏度)60最小进水流量(升/分钟)32转速(转/分钟)1450重量(公斤)180尺寸(长宽高毫米)1150×800×800四高压冷水清洗机的用途能够除去清洗车辆、机械、船舶、建筑物上附着的任何类型的污垢:1. 水泥/混凝土2. 表面附着物/表面处理3. 去除油漆和锈4. 去除凝结的污垢5. 使用选用配件能进行更多的处理工作:5.1喷砂5.2下水道的清洁五安全预防1. 为防止意外事件发生而且确保操作人、旁观者以及周围机械安全,应在附近放置一些警示牌或采取安全防范措施。

把机器视为一个高速切削的工具。

2. 请不要让孩子、行为障碍人士或没有阅读安全操作手册的人操作机器。

马桶起身助力器60335标准

马桶起身助力器是一种用于帮助行动不便的人士起身的辅助设备。

60335标准是指IEC 60335标准,是国际电工委员会(IEC)发

布的家用和类似用途的电器安全标准。

这个标准主要关注电器的安

全性能,包括电器的结构、绝缘、接地、电气连接、绝缘材料等方

面的要求。

对于马桶起身助力器这样的电器产品,符合60335标准

意味着产品在设计和制造过程中需要满足标准中规定的安全要求,

以确保产品在正常使用时不会对用户造成电气、机械或其他方面的

危险。

从安全性能角度来看,符合60335标准的马桶起身助力器应该

具备良好的绝缘性能,电气连接应稳固可靠,材料应符合标准要求,以防止发生火灾、电击或其他安全事故。

此外,产品在使用过程中

应符合人体工程学原理,确保用户在使用时的舒适度和安全性。

除了安全性能,60335标准也可能涉及产品的环保要求、能效

要求等方面的内容。

因此,符合60335标准的马桶起身助力器在设

计和制造过程中需要考虑到这些方面的要求,以满足国际上对于电

器产品的安全、环保和能效等方面的规定。

总的来说,符合60335标准的马桶起身助力器意味着产品在安全性能、环保性能和能效方面都得到了国际公认的认可,对用户而言可以更加放心地使用这样的产品。

家用和类似电动工具的安全要求

PART 2-79

高压清洗机的特定要求

目录

简介(略)

1.适用范围

2.参考标准

3.定义

4.一般要求

5.测试的一般条件

6.分类

7.标识和说明

8.防止与带电零件的接触

9.启动和操作

10.输出功率和电流

11.温升

12.略

13.操作温度时的泄露电流和耐电压强度14.瞬时的超压

15.防潮性

16.泄露电流和耐电压强度

17.变压器的过载保护和相关电路18.耐久性

19.不正常操作

20.稳定性和机械危险

21.机械强度

22.结构

23.内部布线

24.组件

25.电源连接和外部电线

26.外部导线的接线端子

27.接地

28.螺丝和连接件

29.爬电距离和电气间隙

30.高温防火

31.防锈

32.放射性

附录

文献

图101 警告标志

图102冲击测试

图103 扶手的反作用力

高压清洗机的特定要求

1.适用范围

第一部分的本章由以下更替:

本标准针对压强为2.5mPa-25mPa,功率≤10KW的高压清洗

机,单相工具额定电压≤250V,其它工具480V。

本标准也适用于压强<2.5mPa的工业和商业用途的蒸气清洗机。

本标准涉及到的常见危险除以下外:

----儿童和非专业人员在无人监管的情况下使用

----儿童用工具来玩耍

2.参考标准(略)

3.定义

第一部分的本章除以下外适用:

3.1.9正常操作:工具在供额定电压,厂商对喷嘴和水管规定的额定流量和额定压强

下操作,无负载值由额定压强设置。

(工具若装有热水器,应在最大功率下操作。

)3.101 无负载值:当泵浦压强超过预定值,多出的流量返回进水系统时,操作的压强值。

补充,当出水被切断时,在降低的压强,迂回至总泵浦流量。

3.102 安全值:当泵浦压强超过预定值,多出的流量返回进水系统时,操作的压强值。

3.103 额定压强:生产商为高压清洗机设定的最大压强值。

3.104 允许的额定压强:在高压清洗机不受冲击的前提下,生产商对其规定的压强限值。

3.105 额定流量:生产商对高压清洗机喷嘴规定的在额定压强下的流量。

3.106 热水器:电动或引擎的水加热器。

3.107 不适用。

3.108 压强开关:针对变化的流量压强,在预定值提供的控制功能。

3.109 流量开关:针对额定的和变化的流量,在预定值提供的控制功能。

3.110 初始开关:当出现点火失败或无意思熄火时的一个安全切断设备。

3.111 扳机枪(控制枪):在操作位置不持扳机,关闭水外留的装置。

3.112 不间断点火:通过一个能源,点火器一直点火,在一个特定的时间判断点火器是

否点火。

3.113 额定温度:生产商规定的最大温度。

3.114 喷嘴:略。

3.115 喷水管:略。

4. 一般要求

第一部分的本章适用。

5. 测试的一般条件

除以下外,第一部分的本章适用。

5.1补充:

工具在额定功率下操作,工具有不止一个额定功率的,取其最不利功率条件下测试。

6.分类

除以下外,第一部分的本章适用。

6.1更换为:

工具应分I,II,III类且有相关触电保护,对于手持式工具,高压清洗机应为II类或III类。

通过目视和相关测试来检验是否符合要求。

6.2更换为:

工具应有足够的防水程度,如表101:

对于固定式工具,其安装一般不会漏水,其防水程度应为IP X 0.

通过目视和相关测试进行检验。

7.标识和说明

除以下外,第一部分的本章仍适用。

7.1补充:

----外箱上应标明额定压强(实际未标注)

----外箱上应标明允许的压强(实际未标注)

----应标明每分钟的最大额定流量(实际未标注)

----最大额定温度应高于50℃(实际未标注)

----编号(实际未标注)

----生产年份(如2004年应标04)(实际未标注)

----若说明书上未标最大进水量,应在外箱上标明(实际未标注)

----热水器的最大功率KW (实际未标注)

注101 电热水器的输入功率是特定的。

图101黄底黑线的警告粘标应永久性标在工具上。

(实际未标注)

所有的水管应标明允许的压强mPa,最大温度℃,及生产商名称,生产日期。

(实际未标注)

扳机和喷水管应标明允许的压强mPa,最大温度℃,及生产商名称。

(实际未标注)

当热水器的排气表面温度超过60K,应在热表面标明警告注意。

(此处不要)

警告:请勿触摸。

字母的高度应不低于4 mm.

7.12 补充:

说明书的封面应包括以下:

警告:使用前请阅读说明书。

警告应用ISO 7000的代号0434和1641代替,在此情况下,应提供此代号的解释说明。

若工具上标有IEC 60417-1中NO.5041,则应提供此代号的解释说明。

说明书应包括以下:

电源线应满足IEC 60364-1的要求。

----警告:本工具的清洗功能由生产商设定。

----警告:未穿保护服,请勿使用工具。

----警告:喷嘴危险,请勿将此对向人。

----工具维修时,请切断电源线

----高压清洗机不可给儿童,未受过训练的人员使用

----为确保工具安全,仅限使用生产商提供的原装零件

----警告:工具的高压管,配件,连接件的安全性十分重要,仅限使用生产商提供的原装零件。

----若工具的电源线,或其它重要部件受损,禁止使用工具,如,安全设备,高压管,扳机

----若使用电源延长线,插头和插座应不漏水。

----警告:长度不适当的电源延长线十分危险的。

----若有使用气体或液体的燃料,则警告应包括以下:

警告:不可使用错误的燃料,避免危险。

----应对喷嘴有足够的说明,当使用控制枪时,避免出现反踢危险,喷射组件出现转动。

----若反踢力超过20N,应在说明书上标注。

----安全设备的功性能,例如,安全值,流量开关,压强开关。

----用户的使用说明

----对出现故障的说明

----当提供远信号时,必须对电源线的安装要求有所说明

----若在粘标上未对最大进水压强进行说明,应在说明书中标注

说明书中对水管的说明应例如“在打开工具前,将水管插入红色标记。

”

8.防止与带电部件的接触

除以下外第一部分的本章适用。

8.1补充:注101:水和无水的高压清洗机都认为是导电的。

8.1.4 补充:酸碱电化学物的18-24节电池,包括胶电池的,应被认为是III类工具。

----充电器上每节电池的最大电压应不超过2.7V.

----无接地部件。

----导电部件不能落下,造成带电部件相反极。

9.启动

第一部分的本章不适用。

10.输入功率和电流

除以下外第一部分的本章适用。

10.101 正常操作时,压强偏差应不超过额定压强的 10%,且应不超过允许的压强。

注:应根据生产商要求调整点火器功性能。