关键词(塑胶模具)

- 格式:xls

- 大小:23.00 KB

- 文档页数:6

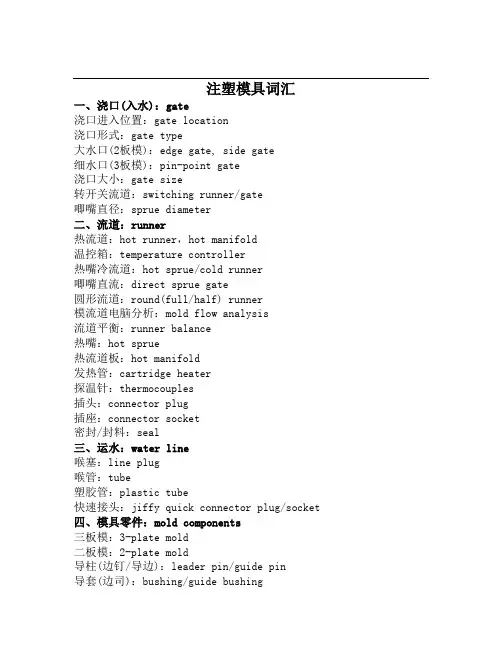

注塑模具词汇一、浇口(入水):gate浇口进入位置:gate location浇口形式:gate type大水口(2板模):edge gate, side gate细水口(3板模):pin-point gate浇口大小:gate size转开关流道:switching runner/gate唧嘴直径:sprue diameter二、流道:runner热流道:hot runner,hot manifold温控箱:temperature controller热嘴冷流道:hot sprue/cold runner唧嘴直流:direct sprue gate圆形流道:round(full/half) runner模流道电脑分析:mold flow analysis流道平衡:runner balance热嘴:hot sprue热流道板:hot manifold发热管:cartridge heater探温针:thermocouples插头:connector plug插座:connector socket密封/封料:seal三、运水:water line喉塞:line plug喉管:tube塑胶管:plastic tube快速接头:jiffy quick connector plug/socket 四、模具零件:mold components三板模:3-plate mold二板模:2-plate mold导柱(边钉/导边):leader pin/guide pin导套(边司):bushing/guide bushing顶针板:ejector retainer plate托板:support plate螺丝:screw管销(管钉):dowel pin开模槽:ply bar slot内模管位锁:core/cavity inter-lock顶针:ejector pin司筒:ejector sleeve司筒针:ejector sleeve pin推板:stripper plate缩呵:movable core,return core,core puller 扣机(尼龙拉勾):nylon latch lock斜顶:lifter模胚(架):mold base上内模:cavity insert下内模:core insert行位(滑块):slide镶件:insert压座(斜鸡):wedge,heeled block耐磨板/油板:wedge wear plate压条:guide way plate模顶(撑头):support pillar唧嘴:sprue bushing挡板:stop plate定位圈:locating ring锁扣:latch扣鸡:parting lock set推杆:push bar栓打螺丝:S.H.S.S.(socket head shoulder screw) 杯头螺丝:S.H.C.S.(socket head cap screw)活动臂:lever arm分流锥:sprue separator垃圾钉:stop pin水隔片:buffle弹弓柱:spring rod弹弓:die spring中托司:ejector guide bush中托导套(边):ejector guide pin镶针:insert pin波子弹弓:ball catch喉塞:pipe plug锁模块:lock plate行位斜导柱:angle pin斜顶杆:angle ejector rod复位键/提前回杆:early return bar气阀:valves五、术语:terms承压平面平衡:parting surface support balance模排气:parting line venting回针碰料位:return pin and cavity interference模闭合总厚度:mold base shut height顶针碰运水:water line interferes with ejector pin料位出上(下)模:part from cavity (core) side模胚原身出料位:cavity direct cut on A-plate,core direct cut on B-plate.不准用镶件: do not use (core/cavity) insert用铍铜做镶件: use beryllium copper insert初步(正式)模图设计:preliminary (final) mold design反呵:reverse core弹弓压缩量:spring compressed length强度不够:insufficient rigidity均匀冷却:even cooling扣前模:sticking热膨胀:thermo expansion公差:tolerance铜电极(铜公):copper electrode石墨电极:graphite electrode夹线:weld line翘曲:warpage缺胶:short shot困气:air trap毛刺:flash,burr~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ 模具述语一、入水:gate进入位:gate location水口形式:gate type大水口:edge gate细水口: pin-point gate水口大小:gate size转水口:switching runner/gate唧嘴口径:sprue diameter二、流道: runner热流道:hot runner,hot manifold热嘴冷流道: hot sprue/cold runner唧嘴直流: direct sprue gate圆形流道:round(full/half runner流道电脑分析:mold flow analysis流道平衡:runner balance热嘴:hot sprue热流道板:hot manifold发热管:cartridge heater探针: thermocouples插头:connector plug插座: connector socket密封/封料: seal三、运水:water line喉塞:line lpug喉管:tube塑胶管:plastic tube快速接头:jiffy quick connector plug/socker四、模具零件:mold components三板模:3-plate mold二板模:2-plate mold边钉/导边:leader pin/guide pin边司/导套:bushing/guide bushing中托司:shoulder guide bushing中托边L:guide pin顶针板:ejector retainner plate托板:support plate螺丝: screw管钉:dowel pin开模槽:ply bar scot内模管位:core/cavity inter-lock顶针:ejector pin司筒:ejector sleeve司筒针:ejector pin推板:stripper plate缩呵:movable core,return core core puller 扣机(尼龙拉勾):nylon latch lock斜顶:lifter模胚(架): mold base上内模:cavity insert下内模:core insert行位(滑块): slide镶件:insert压座/斜鸡:wedge耐磨板/油板:wedge wear plate压条:plate撑头: support pillar唧嘴: sprue bushing挡板:stop plate定位圈:locating ring锁扣:latch扣鸡:parting lock set推杆:push bar栓打螺丝:S.H.S.B顶板:eracuretun活动臂:lever arm分流锥:spure sperader水口司:bush垃圾钉:stop pin隔片:buffle弹弓柱:spring rod弹弓:die spring中托司:ejector guide bush中托边:ejector guide pin镶针:pin销子:dowel pin波子弹弓:ball catch喉塞: pipe plug锁模块:lock plate斜顶:angle from pin斜顶杆:angle ejector rod尼龙拉勾:parting locks活动臂:lever arm复位键、提前回杆:early return bar气阀:valves斜导边:angle pin术语:terms承压平面平衡:parting surface support balance模排气:parting line venting回针碰料位:return pin and cavity interference模总高超出啤机规格:mold base shut hight顶针碰运水:water line interferes withejector pin料位出上/下模:part from cavith (core) side模胚原身出料位:cavity direct cut on A-plate,core direct cut on B-plate.不准用镶件: Do not use (core/cavity) insert用铍铜做镶件: use beryllium copper insert初步(正式)模图设计:preliinary (final) mold design反呵:reverse core弹弓压缩量:spring compressed length稳定性好:good stability,stable强度不够:insufficient rigidity均匀冷却:even cooling扣模:sticking热膨胀:thero expansion公差:tolorance铜公(电极):copper electrode~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ Surface Appearance 外观Glossiness/gloss finish 光洁度Matt finish/matt surface 毛面Glass fiber rich surface/glass emergence on the surface 玻纤外露Blooming/surface blooming 表面析出White patches on surface 表面白斑Silver marks/silver streak 银纹Splay mark 水纹Flow mark 流纹Weld line 溶结纹Brittle/brittleness 脆Bubbles/trapped gas 气泡Void 孔Burn marks 烧伤FR failed 阻燃不合格Flame rating V-2 阻燃V-2Poor dispersion 分散不好FR/PTFE …agglomerates etc 阻燃剂/PTFE…结块Pellet porous 粒子不密/蜜蜂窝Low impact/tensile etc 物理性能低High flow/filler content etc 流动性/填充…过高Longs/fines/doubles 长粒/碎屑/连粒Poor cut 粒形不好Bristle/voids 表面有小气泡/孔Glass bundles 玻纤结团Product was rejected due to 产品不能接受因为…High moisture level 高水分Warpage/warped 翘曲Shrinkage/shrink 收缩Sink marks 缩影Short shot/short molding 打不满Distortion 变形Over dimension 尺寸过大Under dimension 尺寸过小Flashing 飞边Discoloration 变色Off color 颜色差异Flow rate 流动率Viscous 粘High flow 高流动Low flow 低流动Sticky 粘Mold release 脱模Antioxidant 抗氧剂Flame retardant agent 阻燃剂Heat stabilizer 热稳定剂Chopped glass fiber 短切玻纤Roving glass fiber 粗纱/长玻纤Glass beads 玻璃微珠Milled fiber 碾磨纤Molybdenum disulfide/moly/MoS2 二硫化钼Colorant 着色剂Pigment 颜料Dye 染料Accepted product specification 接受产品规格Approved our product 认可我们的产品Re-set spec 重新定标准Add in extra …添加多一点…Reduced … content 减少…含量Dropped/reduced … by x%减少…含量…%Confirmed color standard 确认颜色标准Approved color standard 认可颜色标准Re-confirmed color standard 重新确认颜色标准Qualified our product 认可我们的产品Undergoing heat aging test 在做热老化实验Product is under testing 产品在测试当中Received first order 接了第一个定单Expected to finish by …预计在…完成Expected order is xMT 预计定单量…吨Estimated annual/monthly consumption 预计年/月用量兰亭序永和九年,岁在癸丑,暮春之初,会于会稽山阴之兰亭,修禊事也。

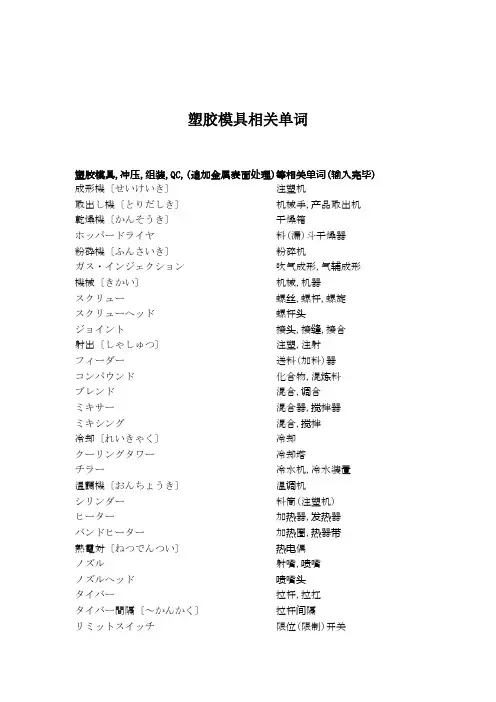

塑胶模具相关单词塑胶模具,冲压,组装,QC,(追加金属表面处理)等相关单词(输入完毕)成形機〔せいけいき〕注塑机取出し機〔とりだしき〕机械手,产品取出机乾燥機〔かんそうき〕干燥箱ホッパードライヤ料(漏)斗干燥器粉砕機〔ふんさいき〕粉碎机ガス・インジェクション吹气成形,气辅成形機械〔きかい〕机械,机器スクリュー螺丝,螺杆,螺旋スクリューヘッド螺杆头ジョイント接头,接缝,接合射出〔しゃしゅつ〕注塑,注射フィーダー送料(加料)器コンパウンド化合物,混炼料ブレンド混合,调合ミキサー混合器,搅拌器ミキシング混合,搅拌冷却〔れいきゃく〕冷却クーリングタワー冷却塔チラー冷水机,冷水装置温調機〔おんちょうき〕温调机シリンダー料筒(注塑机)ヒーター加热器,发热器バンドヒーター加热圈,热器带熱電対〔ねつでんつい〕热电偶ノズル射嘴,喷嘴ノズルヘッド喷嘴头タイバー拉杆,拉扛タイバー間隔〔~かんかく〕拉杆间隔リミットスイッチ限位(限制)开关操作スイッチ〔そうさ~〕操作开关操作ガイド操作指南制御盤〔せいぎょばん〕操纵盘,操纵器全自動〔ぜんじどう〕全自动半自動〔はん~〕半自动手動〔しゅどう〕手动ハンドル手柄,把手,操纵押出し機〔おしだしき〕挤塑机,押出机押出し挤塑ブロー成形機吹塑机ブロー成形吹塑シャープ高感度,锐利ソフト低感度パージモード清料方式オープン开放スタンダード标准プログラム制御程序操纵プロセス工艺,工序,过程インジェクトバイザー注塑工艺程序操纵装置インジェクトロール注塑程序操纵装置結晶性高分子〔けっしょうせいこうぶんし〕结晶性聚合物ポリマー聚合物成形条件〔~じょうけん〕注塑条件成形サイクル注塑周期周密成形〔せいみつ~〕周密成形条件出し设定注塑条件金型取付〔かながたとりつけ〕安装模具,上模型卸〔かたおろし〕落模,下模圧力〔あつりょく〕压力低圧〔ていあつ〕低压低圧型締め〔~かたじめ〕低压锁模保圧時間〔ほあつじかん〕保压时刻背圧〔はいあつ〕背压,返压型締力〔かたじめりょく〕合模力,锁模力型締圧力〔~あつりょく〕锁模压力型締ストローク合模行程型締装置〔~そうち〕锁模装置型開き〔かたびらき〕开模型閉じ合模スピード速度射出スピード射出速度射出量注塑量計量〔けいりょう〕计量計量ストローク计量行程リブ骨位,筋位,加强筋インサート嵌入,嵌件肉厚〔にくあつ〕胶厚,壁厚可塑化〔かそか〕塑化熱分解〔ねつぶんかい〕热分解収縮〔しゅうしゅく〕收缩樹脂〔じゅし〕树脂原料〔げんりょう〕原料,材料プラスチック塑料,塑胶制品ラバー橡胶マスターバッチ色母,注胶料パウダー色粉,粉末ドライカラー色粉,干色粉ペレット粒,塑胶粒ガラス繊維〔~せんい〕玻璃纤维ホース管,软管アニール退火,热处理オーバーパッキング过充填型傷〔かたきず〕模伤,模痕ショック冲击,打击ダメージ损坏,损害引け〔ひけ〕缩水,收缩ショートショット充填不足,欠料バリ毛边,披峰糸バリ〔いと~〕胶丝コールドスラグ冷料,早凝料コールドスラグウエル冷料井凍結〔とうけつ〕冷凝油圧〔ゆあつ〕液压,油压油圧押出〔~おしだし〕液压顶出,油压脱模油圧ポンプ液压泵油圧モータ液压马达エアコンプレッサー空气压缩机,空压机油漏れ〔あぶらもれ〕漏油オイルタンク油箱,油槽ピストン活塞エアシリンダー气缸アラーム报警安全ドア〔安全~〕安全门专门停止〔ひじょうていし〕紧急停止色変え〔いろかえ〕换色パージ材〔~ざい〕清机胶料,过料樹脂温度〔じゅしおんど〕胶料温度型温〔かたおん〕模温ヒートアップ升温,升热空打ち〔からうち〕空打,空射胶試作〔しさく〕试模離型〔りけい〕脱模離型剤〔りけいざい〕脱模剂防錆剤〔ぼうせいざい〕防锈剂抜けない〔ぬけない〕粘模,无法脱模ショット注,射,啤,冲击ゲート浇口センターゲート中心浇口スプルーランナー注口,流道料クリアランス间隔,余隔スプルー主流道,注(塑)口エアベント散气孔,通风口ガス抜き排气,散气金型〔かながた〕模具マシニングセンター加工中心万能フライス盤铣床,锣床旋盤〔せんばん〕车床平面研削盤〔へいめんけんさくばん〕平面磨床ボール盤鑽床放電〔ほうでん〕火花机加工ワイヤーカット线切割窒化鋼〔ちっかこう〕氮化钢窒素ガス〔ちっそ~〕氮气窒化処理〔ちっかしょり〕氮化处理チタン钛熱処理热处理焼入れ〔やきいれ〕淬火焼戻し〔やきもどし〕回火アニーリング退火白化〔はっか〕白化,顶白シルバー银白,银痕フローマーク流纹焼け〔やけ〕烧黑,烧焦異物〔いぶつ〕异物,黑点取られ〔とられ〕粘模エェルド溶接线,结合线フラッシュ料花,焊瘤,毛口,溢料油汚れ〔あぶらよごれ〕油污,油渍打痕〔だこん〕打痕,击伤割れ〔われ〕/ヒビ裂,开裂ジェッテング气纹,喷射変形〔へんけい〕变形反り〔そり〕翘曲,外倾,弯曲曲がり〔まがり〕弯曲捩れ〔ねじれ〕扭曲色斑〔いろむら〕颜色不平均偏肉〔へんにく〕壁厚不平均気泡〔きほう〕气泡,空泛,间隙縞〔しま〕条纹染み〔しみ〕污垢,污点剥がれ〔はがれ〕脱落,剥落捲れ〔めくれ〕翻卷浮き〔うき〕浮起ネジバカ螺丝滑牙員数不足〔いんずうふそく〕员数不足,欠品振れ〔ふれ〕跳动度,偏心収縮膨張〔~ぼうちょう〕收缩膨胀勘合不良〔かんごうふりょう〕嵌合不良,装配不良応力〔おうりょく〕应力内部応力〔ないぶ~〕内应力段取り〔だんどり〕安排,预备ショットカウンタ生产数计数器リセットする重新计数サポートプレート托板サポートピラ撑头プーラーロック拉塞プーラーボルト拉杆取付板〔とりつけいた〕工字板,水口板ボトムプレート底板リターン回针,回流ガイドピン导柱ガイドブッシュ导套,导管,导销衬套ダイ模具,动模,移动模板,板牙ダイプレート模板,载模板,印模モジュール模块,模件,模数パーツ零件,模具零件吊ボルト〔つり~〕吊环螺栓クーレン起重机,吊车,天车フック勾,吊勾プリハード鋼预加硬钢硬度〔こうど〕硬度柔らかい〔やわらかい〕软,软的電極〔でんきょく〕铜公,焊条,电极入れ子〔いれこ〕镶件スライド行位,滑块勾配〔こうばい〕斜度テーパー斜度,錐度,錐形的抜き勾配脱模斜度ガイドピン导向柱スリーブピン丝筒针角ピン〔かく~〕方顶针傾斜突出し〔けいしゃつきだし〕斜顶针キャビティ模腔,前模,上模コア模心,后模,下模取数〔とりすう〕取数,模腔数ロケットリング定位环〔圈〕OリングO环,胶圈〔模具水管处〕肉付け〔にくづけ〕加胶肉盛り〔にくもり〕加胶肉盗み〔にくぬすみ〕减胶型改造〔かたかいぞう〕改模〔因设变修理〕型修正〔かたしゅうせい〕模具修理ストッパー挡块,浇口塞棒活门ストリッパー推板,脱模板,剥皮器敷板〔しきいた〕垫板モールドベース模胚型構造〔かたこうぞう〕模具构造,模具结构インプット输入3D図3D图,三维图2D図2D图,平面图正面図〔しょうめんず〕正面图平面図〔へいめんず〕平面图断面図〔だんめんず〕剖面图キャドデータCAD数据二次元データ〔にじげん~〕平面图数据ソフトウェア软件,程序系统金型図面模具图部品図面〔ぶひんずめん〕零件图略図〔りゃくず〕草图図面を書く画图図面訂正〔~ていせい〕图订寸法記入〔すんぽうきにゅう〕记入尺寸抜き方向〔ぬきほうこう〕出模方向抜き勾配〔ぬきこうばい〕出模斜度ピッチ间距,齿距角度〔かくど〕角度投影面積〔とうえいめんせき〕投影面积テーパー錐度,斜度アンダーカット倒扣,下切,凹槽ワイヤー钢丝,散热片,网膜鑢〔やすり〕锉刀油砥石〔あぶらといし〕油石サンドペーパー砂纸メッシュ筛号,网状物刻印〔こくいん〕刻印シボ蚀纹放電目〔ほうでんめ〕火花纹ダイャカット钻石纹ローレット滚花纹,刻痕ブラスト喷沙,喷砂器ホットランナー热流道修理〔しゅうり〕修理溶接〔ようせつ〕溶接,烧焊溶接機〔~き〕焊机,电焊机溶接棒〔~ぼう〕焊条,电焊条アルゴンアーク溶接氩弧焊トーチバーナ喷燃烧器,火焰燃烧器ゲートブッシュ浇口衬套設計〔せっけい〕设计設計図〔~ず) 设计图設計変更〔~へんこう〕设计变更,设变設計者〔~しゃ〕设计者,设计人员ダイレクトゲート直截了当浇口,直截了当门マルチゲート复式浇口ファンゲート扇形浇口フィルムゲート扇形浇口,片门ジャンプゲート搭接浇口ゲートバランス浇口平稳デザイナー设计者,设计人员金型設計模具设计金型製作仕様書模具制作式样书仕様规格水管〔すいかん〕水管,运水湯溜り〔ゆたまり〕散水,浇口杯冷却回路〔れいきゃくかいろ〕冷却回路,运水モデリング模型制造モックアップ模型,原尺寸模型,样机手作りサンプル〔てづくり~〕手板,手工样品モジュール模数,模量,模件ギア齿轮,连锁装置,传动装置はすば歯車〔~はぐるま〕螺旋齿轮ソリッド整体的,固体変換〔へんかん〕变换,转换フロッピー磁盘,软盘バージョン种类,形式,版本読み込み〔よみこみ〕读取読み出し〔よみだし〕读出データの読取〔~よみとり〕读数圧縮〔あっしゅく〕压缩。

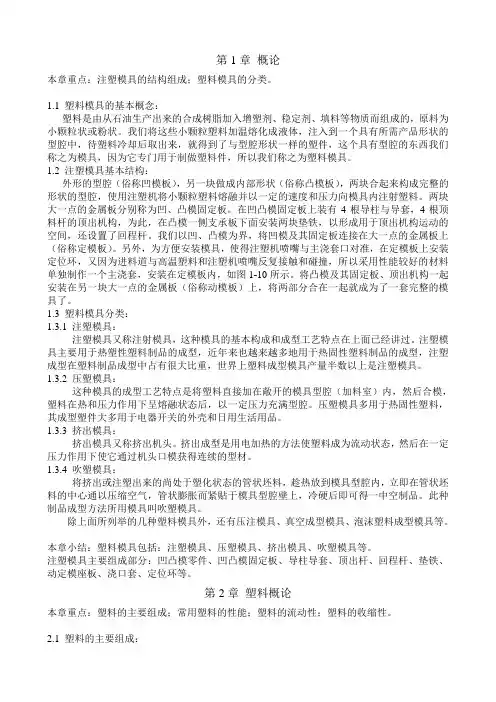

第1章概论本章重点:注塑模具的结构组成;塑料模具的分类。

1.1 塑料模具的基本概念:塑料是由从石油生产出来的合成树脂加入增塑剂、稳定剂、填料等物质而组成的,原料为小颗粒状或粉状。

我们将这些小颗粒塑料加温熔化成液体,注入到一个具有所需产品形状的型腔中,待塑料冷却后取出来,就得到了与型腔形状一样的塑件,这个具有型腔的东西我们称之为模具,因为它专门用于制做塑料件,所以我们称之为塑料模具。

1.2 注塑模具基本结构:外形的型腔(俗称凹模板),另一块做成内部形状(俗称凸模板),两块合起来构成完整的形状的型腔,使用注塑机将小颗粒塑料熔融并以一定的速度和压力向模具内注射塑料。

两块大一点的金属板分别称为凹、凸模固定板。

在凹凸模固定板上装有4根导柱与导套,4根顶料杆的顶出机构,为此,在凸模一侧支承板下面安装两块垫铁,以形成用于顶出机构运动的空间,还设置了回程杆。

我们以凹、凸模为界,将凹模及其固定板连接在大一点的金属板上(俗称定模板)。

另外,为方便安装模具,使得注塑机喷嘴与主浇套口对准,在定模板上安装定位环,又因为进料道与高温塑料和注塑机喷嘴反复接触和碰撞,所以采用性能较好的材料单独制作一个主浇套,安装在定模板内,如图1-10所示。

将凸模及其固定板、顶出机构一起安装在另一块大一点的金属板(俗称动模板)上,将两部分合在一起就成为了一套完整的模具了。

1.3 塑料模具分类:1.3.1 注塑模具:注塑模具又称注射模具,这种模具的基本构成和成型工艺特点在上面已经讲过。

注塑模具主要用于热塑性塑料制品的成型,近年来也越来越多地用于热固性塑料制品的成型,注塑成型在塑料制品成型中占有很大比重,世界上塑料成型模具产量半数以上是注塑模具。

1.3.2 压塑模具:这种模具的成型工艺特点是将塑料直接加在敞开的模具型腔(加料室)内,然后合模,塑料在热和压力作用下呈熔融状态后,以一定压力充满型腔。

压塑模具多用于热固性塑料,其成型塑件大多用于电器开关的外壳和日用生活用品。

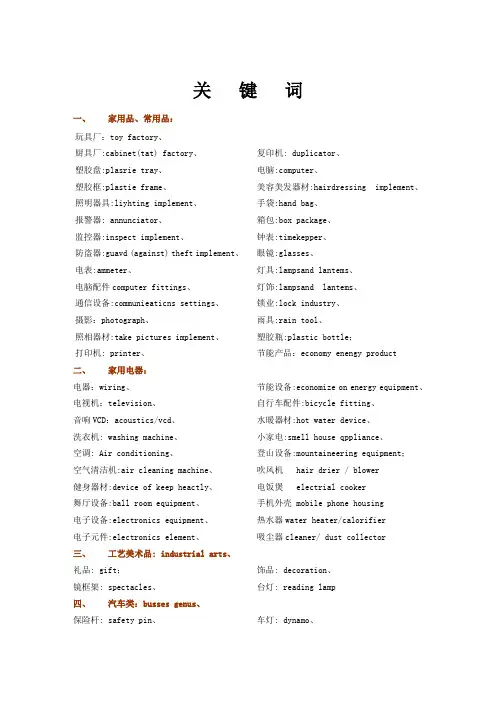

关键词一、家用品、常用品:玩具厂:toy factory、厨具厂:cabinet(tat) factory、塑胶盘:plasrie tray、塑胶框:plastie frame、照明器具:liyhting implement、报警器: annunciator、监控器:inspect implement、防盗器:guavd (against) theft implement、电表:ammeter、电脑配件computer fittings、通信设备:communieaticns settings、摄影:photograph、照相器材:take pictures implement、打印机: printer、复印机: duplicator、电脑:computer、美容美发器材:hairdressing implement、手袋:hand bag、箱包:box package、钟表:timekepper、眼镜:glasses、灯具:lampsand lantems、灯饰:lampsand lantems、锁业:lock industry、雨具:rain tool、塑胶瓶:plastic bottle;节能产品:economy enengy product二、家用电器:电器:wiring、电视机:television、音响VCD:acoustics/vcd、洗衣机: washing machine、空调: Air conditioning、空气清洁机:air cleaning machine、健身器材:device of keep heactly、舞厅设备:ball room equipment、电子设备:electronics equipment、电子元件:electronics element、节能设备:economize on energy equipment、自行车配件:bicycle fitting、水暖器材:hot water device、小家电:smell house qppliance、登山设备:mountaineering equipment;吹风机 hair drier / blower电饭煲 electrial cooker手机外壳 mobile phone housing热水器water heater/calorifier吸尘器cleaner/ dust collector三、工艺美术品: industrial arts、礼品: gift;镜框架: spectacles、饰品: decoration、台灯: reading lamp四、汽车类:busses genus、保险杆: safety pin、车灯: dynamo、拉手:hold hands、窗:windows、风扇: fan、仪表: meter、仪表板:meter plate、摩托车配件: motorcycle fittings;五、机械制造及设备:保护罩盖、cover机床平柄:machine tod、齿轮: gear、不受力防锈件等;六、仪器仪表及度量衡器:仪器:apparatus、仪表: instrument、衡量器、Measurment 马达:motor、光子产品、Photonic products自动化控制仪;Automation control instrument七、浴室设备: bathroom、小百货: bibelot,八、游艇:yacht、登山:mountaineering、Grille, Bumper, H/L door, Valance Panel, Side bumper, Side cornerAmplifiers , speakers , audio and video, lamb , stereo enclosures , plastic display Plastic enclousure toolingExtraction fan car audiolamp regulator flange。

Washing machines manufacturers, Washing machines Exporters, Washing machines Dealers, Washing machines Suppliers, Washing machines Wholesalers, Washing machines Distributors, Gas Industries, Gas Appliances Manufacturing Companies, Geysers manufacturers, Geysers Exporters, room Air Coolers manufacturers, Gas Appliances, Air Coolers, Fans, Padestals, Wall Fans, Ceiling, Electric Items, Electrical, Plastic Furniture, Tables, Suppliers, Distributors, Plastic Products, Occasional Tables, Upholstered Furniture, Bercoat Chairs, Cosmos Chairs, Moulded Furniture, Plastic Tables, Plastic Steel Furniture, Public Sofas Sets, Computer Chairs, Revolving Chairs, Study Chairs, School Furniture, Baby Furniture, Executive Chairs, Benches, Manufacturers, Plastic industry, Steel & plastic Furniture, Office Furniture, Hospital Furniture, College Furniture, Flower pots, Institutional Furniture, Furniture Exporters, Office Chair, Furniture manufacturers, Restaurant Furniture, Furniture Companies, Steel Plastic tables, Plastic Stools, Waiting Room Furniture, Chairs, Stools, Full Plastic, Semi Plastic, Public Sofas, Sets, Schools Furniture, Household Items, Products, Snack Tables, Desks, Garden Furniture, Fans Manufacturers, Electric Fans, Electric Fans Manufacturers, Fans Exporters, Home Appliances, Fans Dealers, Fans Mfrs, Fans Distributors, Fans Suppliers, Fans Wholesalers, Fans Industry, Electrical Industry, Fan Makers, Pakistan Electric Fans Manufacturers Association, Affiliated With Gujranwala Chamber Of Commerce, Member Chamber Of Commerce & Industry Gujranwala, Ceiling Fans, Pedestals, Table Cum Pedestals, TCP Fans, Table Fans, Exhausts, Exhaust Fans, Louvre Fans, Circumatic Fans, Wall Bracket Fans, Exporters, Wholesalers, Dealers, Ceiling Fans Manufacturers, Electric Fans Industry, Electric Fans Company, Traders, Electrical Fans, Electrical Company, Fan Manufacturing Company, Fans Company, Fans Spare Parts, Fans Spare Parts Manufacturers, Electrical Products, Fans Designers, Fans Manufacturers & Suppliers, Digital Fans, Remote Control Fans, Exhaust Fans Manufacturers, Pakistan Electric Fans Manufacturers, Automatic Fans, Electric Fans Products, Fans Factory, Fans Sellers, Electric Fans Exporters, Pedestal Fans, Table Cum Pedestal Fans, Pedestal Fans Manufacturers, Bracket Fans Manufacturers, Circumatic Fans Manufacturers, Ceiling Fans Exporters, electric Washing machines in Gujranwala, Washing machines in Pakistan, Gas appliances Manufacturers, twin tub washing machines manufacturers, Steel Plastic Furniture, Washing Machines, Dryers, Geyser, Room Cooler, Electric Fan, Motor Cycle, Air Cooler, Engineering Company, Fan Industry, Furniture, Geysers, Home Furniture, Plastic Chairs, Plastic Furniture Exporters, Spin Dryers, Steel and Plastic Furniture, Washing Machine, MotorcycleBrand Keywords:tv manufacturermp3 supplierinjection sellerdental moldrefrigerator manufacturermicrophone producerbulb manufacturerled moldring manufacturertoothbrush manufacturerIndonesia household applianceengland toyAfrica bottleKorea combdesk lampchairdryer supplierprinterwashing machine importercamera importerplastic manufacturermask manufacturermedical instrument manufacturerdrinking bottlebowl manufacturerplate manufacturerfork manufactrerknife manufactrerplastic box manufacturerteapot manufacturerPorcelain manufacturerPan manufacturerbuy computercup italyjuicing machinebutton exporterpen+USATV+AFRICA exportmouse usa exportfan manufacturerSculpture manufacturerclock manufacturercake box manufacturerCup manufacturermilk suppliercosmetics manufacturerbattery manufacturermirror manufacturerfeeding bottlekitchen knife makebicycle manufactruerwash basin manufacturer toothpaste manufacturermotor manufacturerjewel casecar manufacturermagnifying glass manufacturerdashboardshock absorberauto tire manufacturersback lampcoolerelectro-drive fangearwheel manufacturerglow indicator manufacturer lamp carrier manufacturer magneto manufacturerselectric shaver manufacturer tape recorder manufacturerair conditioning manufacturer electronic oven manufacturer electric foot warmer manufacturer electric cooker manufacturerelectric iron manufacturerdishwasher emailFireplace manufacturermassager manufacturerElevator manufacturerFire extinguisherfire hydrantfire-fighting apparatusTypewriter manufacturerSprinklerFax machineink box manufacturerplasticinjectionmouldplastic mouldinjection mouldcleanerautomotivetoolingplatsic bottleTea filter cupplastic bagsPlastic mouldingplastic fridge magnetplastic Photo Frameplastic mobile phone holderplastic u disk shellplastic charmremote control manufacturerbottle capFirst aid boxautmotive partsConnectorcommunication junction boxMedical productsautomotive equipment casebaffle box bracketDoorbell门铃mainframe-box(机箱)mobile manufacturerpower manufacturerconnector manufacturerSocket manufacturer(插座制造商)Thermometer manufacturer(温度计制造商)lighting(灯具)two way radioalarm clock manufacturerWashing machineRefrigerator manufacturerTV manufacturerpipe manufacturer shopping basket switch manufacturer。

塑胶模具的科学注塑方法研究及应用摘要:传统的注塑试模过程,往往只是获取注塑机床及辅助设备上显示的表面上的成型参数,这些参数不能够反应注塑过程的真实情况,导致所得参数的可复制性差,不能有效指导批量生产。

本文从塑胶材料的角度出发,基于材料本身的流动行为,研究制定了一套科学的注塑方法,获取塑胶材料在干燥、熔胶、注塑填充、补缩、保压、冷却等过程中实际的温度、压力、速度、时间、位置等参数数据;这些参数不受试模机床差异、辅助设备差异以及它们本身精度的影响,能有效指导批量生产。

本文为注塑试模调试人员及生产调机人员提供了一套标准的、科学的试模流程和方法,并附以案例说明。

关键词:科学注塑、试模、塑胶、模具、成型参数Research and Application of Scientific Injection Molding Method for Plastic MouldZhengZichengGree Electric Appliances,Inc.ofZhuhaiZhuhai,Guangdong519000Abstract: In the traditional injection molding trial process, the molding parameters on the surface displayed on the injection molding machine and auxiliary equipment are often obtained, but these parameters cannot reflect the real situation of the injection molding process. As a result, the reproducibility of the obtained parameters is poor and the batch production can not be effectively guided. Based on the flow behavior of plastic materials, a set of scientific injection molding methods is developed in this paper. Obtain actual temperature, pressure, speed, time, position and other parameter data of plastic materials during drying, glue melting, injection filling, feeding, pressure maintaining, cooling and other processes; theseparameters are not affected by the difference of testing machine tool, auxiliary equipment and their own accuracy, and can effectively guide batch production. This paper provides a set of standard and scientific test process and method for injection mould commissioning personneland batch production adjustment personnel, and a case is attached.Key words: scientific injection molding, trial molding, plastic, mold, molding parameters1、前言:塑胶模具的试模是指在模具零部件完成加工制作、模具组装完毕后,在批量生产之前通过注塑机进行注塑试生产并得到注塑件样品,然后通过对样品的检测、装配、实验测试情况,以及试生产过程中对模具各方面的符合性排查评估,来确定该模具是否符合设计要求、满足批量生产要求的过程。

塑胶模具的知识及技术详细说明:塑胶模具的基本知识及技术应用1、引言我们日常生产、生活中所使用到的各种工具和产品,大到机床的底座、机身外壳,小到一个胚头螺丝、纽扣以及各种家用电器的外壳,无不与模具有着密切的关系。

模具的形状决定着这些产品的外形,模具的加工质量与精度也就决定着这些产品的质量。

因为各种产品的材质、外观、规格及用途的不同,模具分为了铸造模、锻造模、压铸模、冲压模等非塑胶模具,以及塑胶模具。

近年来,随着塑料工业的飞速发展和通用与工程塑料在强度和精度等方面的不断提高,塑料制品的应用范围也在不断扩大,如:家用电器、仪器仪表,建筑器材,汽车工业、日用五金等众多领域,塑料制品所占的比例正迅猛增加。

一个设计合理的塑料件往往能代替多个传统金属件。

工业产品和日用产品塑料化的趋势不断上升。

2、模具的一般定义:在工业生产中,用各种压力机和装在压力机上的专用工具,通过压力把金属或非金属材料制出所需形状的零件或制品,这种专用工具统称为模具。

3、注塑过程说明:模具是一种生产塑料制品的工具。

它由几组零件部分构成,这个组合内有成型模腔。

注塑时,模具装夹在注塑机上,熔融塑料被注入成型模腔内,并在腔内冷却定型,然后上下模分开,经由顶出系统将制品从模腔顶出离开模具,最后模具再闭合进行下一次注塑,整个注塑过程是循环进行的。

4、模具的一般分类:可分为塑胶模具及非塑胶模具:(1)非塑胶模具有:铸造模、锻造模、冲压模、压铸模等。

A.铸造模——水龙头、生铁平台B.锻造模——汽车身C.冲压模——计算机面板D.压铸模——超合金,汽缸体(2)塑胶模具根据生产工艺和生产产品的不同又分为:A.注射成型模——电视机外壳、键盘按钮(应用最普遍)B.吹气模——饮料瓶C.压缩成型模——电木开关、科学瓷碗碟D.转移成型模——集成电路制品E.挤压成型模——胶水管、塑胶袋F.热成型模——透明成型包装外壳G.旋转成型模——软胶洋娃娃玩具◆注射成型是塑料加工中最普遍采用的方法。

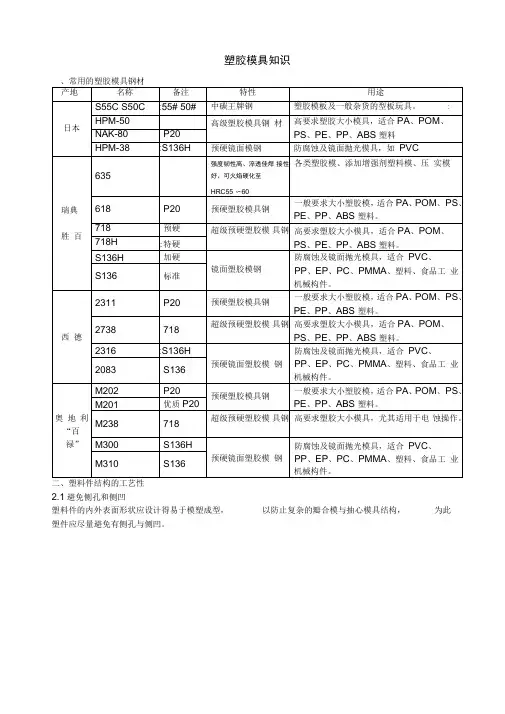

塑胶模具知识二、塑料件结构的工艺性2.1避免侧孔和侧凹塑料件的内外表面形状应设计得易于模塑成型,以防止复杂的瓣合模与抽心模具结构,为此塑件应尽量避免有侧孔与侧凹。

表4-1带有侧孔侧凹塑料件设计示例原塑料件结构必须采用侧面抽芯机构,改进后可避免侧面抽芯。

左图抽芯i左图出模困难,模具必须 采用特姝的脱模结构才能 脱模。

改进后模具简化, 易脱模。

尤图需采用拼合凹模,不但模具复 杂,而且塑件表面容易有熔接线。

攻进后模貝简化,觀件萸观。

左图犁件成型后无法或极 难脱模。

改进后大人简化 了脱模。

左图侧壁有孔,成型时需 要侧面抽芯,改进后,不 但避免了侧面抽芯,还因 增加了脱模斜度易于脱模。

当塑件内瞳包儿个小侧面 凸起时,可采用S 〈1MM 的 圆形凸起而进行强行脱模。

这种方法不适用于热固性或热脆性塑料。

对于外表面有凸卩啲手轮或手柄等塑件,应使凸凹纹的条纹与脱模方向一数, 以便与模具制造和脱模。

左图分型面的E边不易清除,改进后分型面处形状为一恻形飞边,容易清除。

3.2脱模斜度为了便于塑件从模腔中脱出来或从塑件中抽出型芯,塑件设计时须考虑其内外壁应有足量的脱模斜度,最小脱模斜度与塑料性能、收缩率大小、塑件几何形状等有关。

材质脆、硬的脱模斜度要求大,一般情况下光滑表面的脱模斜度应大于0.5度,细皮纹表面大于1度,粗皮纹表面大于1.5度。

,深腔结构产品设计时外表面斜度要求小于内表面斜度,但在具体选择脱模斜度时还应注意以下几点:1)制件精度要求越高,脱模斜度应越小.2)尺寸大的制件,应采用较小的脱模斜度.3)制件的形状复杂不易脱模的,应选用较大的斜度.4)制件收缩率大,斜度也应加大.5)增强塑料宜选大斜度,含有自润滑剂的塑料可用小斜度.6)制件壁厚大,斜度也应加大.7)斜度的方向•内孔以小端为准,满足图样尺寸要求,斜度向扩大方向取得;外形则以大端为准,满足图样要求,斜度向偏小方向取得•一般情况下,脱模斜度a可不受制件公差带的限制,高精度塑料制件脱模斜度则应当在公差带内.♦具备以下条件的型心,可采用较小的脱模斜度:1)推出时制件刚度足够.2)制件与模具钢材表面的摩擦系数较低.3)型心的表面粗糙度值小,抛光方向又与制件的脱模方向一致.4)制件收缩量小,滑动摩擦力小.在不影响尺寸精度的情况下,塑件的内外表面都应有斜度,特别是深形的容器类制件,塑件内侧的斜度可以比外侧的斜度大1度,以保证注塑时模具型芯不偏位,得到均匀的产品壁厚,并保证产品开口部位的材料密度强度。

塑料模具基本结构简介一. 概述塑料模就是利用其特定形状去成型具有一定形状和尺寸的塑料制品的工具.2.模具分类:模具加工的一般流程以上所有模具,在其相应的生产领域中,都有其举足轻重的作用.因为我们个人的精力所限和社会分工的结果,使我们无法逐一去了解和精通每一种类型的模具奥秘,结合塑料中心实际,我们所看到和接触最多的模具便是塑料模,而几乎100%的塑料模具是热塑性塑料注射模.所以下面的内容我们将重点禅述此类模具细节.细分下去,热塑性塑料模具又可分为以下机几种:标准模具(两板模.三板模.拼合型腔模具,推板脱模模具).迭层模具.热流道模具.冷流道模具和特殊设计模具.二. 塑料及塑料制品塑料模具是用来生产塑料制品的工具,所以我们在设计制造模具之前.必须对各种常用塑料的特性有充分了解和掌握.才能精确控制模具尺寸与塑料件尺寸及成型条件之间的内在关系.才能设计出优秀的模具,常用热塑性塑料之特性如下:三. 典型塑料模胚结构图模具的几个常用名词:1.溶注口或水口(sprue)塑料由此进入模腔内,亦称主流道.溶注口瀙套连接喷嘴与模具,已形成标准件.有些母模板较薄的模具,不须瀙套,直接在模具上钻出溶注口.2.冷料穴(cold-slug well)喷嘴最前端的熔融塑料温度较低,形成冷料渣.在进料口的末端公模仁上开设洞穴,以防止冷料渣进入模腔,造成堵塞流道.减缓料流速度,产品上形成冷料痕结合线.为了开模时从瀙套内拉出冷凝料,一般在冷料穴末端设置拉料杆(顶针上).3. 分流道(runer)分流道是主流道的连接部分,是塑料流入模腔的通道,它可在压力损失最小的条件下,将主流道内的塑料以较快的速度送到浇口处,其主要类型有:圆形.半圆形.矩形.梯形. 要求分流道的表面积或侧面积与其截面积的比值为最小.4.栅门(gates)亦称浇口,是分流道和型腔之间连接部分,也是浇注系统的最后部分.其作用是使流道内熔融塑料以较快速度进入模腔.型腔充满后浇口能很快冷却封闭,防止型腔内未冷却料回流.其类型.位置.形状.多种多样.主要有:盘形.扇形.环形.点状.侧进胶.直接进胶.潜伏进胶.5.排气槽(vent)当模具完全闭合时,模腔与浇道内充满空气.注射时必须将空气排出模具以外,否则将产生烧焦,填充不满,毛边,气泡,银线等不良.排气槽的形式,大小.深度因材料和模具结构不同而异(如上表),其方法主要有:分模面排气法,顶针排气法,镶件排气法,水路排气法,真空排气法.6.顶出系统(Ejection device)是将产品从模具上脱出之装置,亦称脱模机构.是模具的重要组成部分,其形式和推出方式因产品形状,结构和塑料特性有关,其零件有顶针,推板,顶出块,斜梢,司筒,油缸或气缸,齿轮等,它与模仁之间是间隙配合,表面积尽可能大,设在不影响外观和功能处,注意脱模平衡.7.模穴模仁(Mold cavity)模穴是在模板上挖框,,以便埋入模仁,主要是节省材料和加工方便方面考虑.有些分模面断差大的模具母模侧,会不挖模穴直接在模板上加工产品部分.模仁主要指模具的产品部分,其精度,材质要求比模胚部分要高,其形状,形式对不同的模具有不同的要求,为整套模具最重要部分.8.模具钢(Mold Steel)一套模具外观看似乎都是一样的钢铁,其实它的各部位因要求不同必须使用不同之材质,模具钢之选择对模具寿命,加工性,精度等影响很大.模具钢材料因模具之构造塑料产品要求不同而异.选材要求主要如下:1.采购容易2.机械加工性优良3.耐磨,耐腐蚀,耐热性好4.组织细密一致,无针孔等内部缺陷5.适合热处理变形小6.经济,降低成本又能满足使用要求9.温控系统(temperature control)一般模具,通常以常温的水来冷却,其温度控制藉水的流量调节,流动性好的低融点材料大都以此方法成形。

1.Tools,Tool ConstructionInjection Moulding ToolsPlastic Tool ConstructionPrecision ToolsDrawing ToolsIndustrial Tools2.Die-CastDie-Cast Articles of ThermoplasticsDie-Cast PartsDie-Cast MouldsPressure CastingsInjection Moulds for PlasticsDie-Cast ArticlesPress and Die Casting Moulds,Pressure Cast Parts of Aluminium AlloysPrecision Pressure Cast PartsDie-Cast Parts of TPEPressure Casting Moulds,Pressure Casting Moulds for Plastics3.Mould ConstructionInjection Moulds for PlasticsMoulds for the Plastics Processing IndustryMoulds for Thermoplastic Precision Parts4.Plastic Treatment and Processing,Plastics Engineering ,Technical Injection-Moulded Articles of Thermo-Plastics Injection-Moulded Plastic PartsPlastic PartsPlastic ProductsPlastic IndustryShaped Plastic ArticlesTechnical Shaped Parts of PlasticsShaped Parts of PlasticsMotor Car Accessories of PlasticsPlastic Parts according to Sample or Drawing, Injection-Moulded PlasticsSemi-Finished Plastic Products,Plastics and Semi-Finished Plastic Products, ThermoplasticsPressed and Injection-Moulded Plastic PartsMetal Design,Mechanical Engineering,CAD-CAM Services,Technical Shaped Parts of Plastics , Aluminium Component Manufacturer. Aluminium Die CastingAluminium Die CastingsAluminium DiecastingsAluminium Gravity Die Casting Aluminium Gravity Die Castings Automotive Plastic ComponentsCNC Machined Diecastings Component DesignDesign Plastic ComponentsDie CastingDie Casting ManufacturersDiecastingDiecasting ServicesGravity Die CastingsGravity DiecastingHigh Pressure Die CastingsInjection MouldedInjection Moulded Components Injection MouldersInjection MouldingInjection MouldingsMachine Tool Manufacturing Services Machined Die CastingsManufacturer Plastic Components Manufacturing ServicesMoulded PlasticsMouldingsNon Ferrous Aluminium Die Castings Non Ferrous High Pressure Die Casting Non Ferrous High Pressure Die Castings Non Ferrous Zinc Die Castings Nonferrous Die CastingNonferrous High Pressure Die Casting Nonferrous High Pressure Die Castings Outsourcing SolutionsPlasic KnobsPlastic Component DesignPlastic ComponentsPlastic HandlesPlastic InjectionPlastic Injection Mould Tool DesignPlastic Injection Mould Tool ManufacturePlastic Injection Mould ToolmakersPlastic Injection Mould ToolsPlastic Injection MoulderPlastic Injection MoulderingPlastic Injection MouldersPlastic Injection MouldingPlastic Injection Moulding Plastic Injection Moulders Plastic Injection Moulding ProductsPlastic Injection Moulding ServicesPlastic Injection MouldingsPlastic ManufacturerPlastic Moulded ComponentsPlastic Moulded PartsPlastic Moulded Product DesignPlastic Moulded ProductsPlastic MouldersPlastic MouldingPlastic Moulding ManufacturePlastic Moulding SupplierPlastic MouldingsPlastic Mouldings SupplierPlastic OvermouldingPlastic PartsPlastic Product DesignPlasticsPlastics Injection Mould ToolsPlastics Injection MouldingPlastics Injection Moulding ServicesPrecision Component ManufacturerPrecision Injection MouldersPrecision Plastic Injection MouldersPrecision Plastic Injection MouldingPrecision Plastic MouldersPressure Die CastingPressure Die Casting ServicesPressure DiecastingSub-Contract Injection MouldingTechnical Injection MouldingsThermoplastic Injection MouldingsThermosetTrade Plastic Injection MouldingsTurnkey Solutions Plastic Injection Mouldings Zinc Die CastingZinc Die CastingsZinc DiecastingsZinc Gravity Die CastingZinc Gravity Die Castings3D Cad3D CAD Design3D CAD Drawings3D CAD Modelling3D DesignABS Injection MouldingsAcetal Injection MouldingsComponent DesignComputer Aided DesignComputer Aided Design For Manufacture Computer Aided Design ServiceCustom Plastic Injection MouldingsDesignDesign & ManufactureDesign And ManufactureDesign Services Injection Moulding Engineering Polymer Injection Mouldings Glass Filled Plastic Injection Mouldings HIPS Injection MouldingInjection MouldingInjection Moulding Design Services Injection Moulding ModelsInjection Moulding ServicesInjection Moulding Sub-ContractInjection Moulding ThermoplasticInjection MouldingsInjection Mouldings GeneralInjection Mouldings NylonsInjection Mouldings PlasticPlastic Injection Mould Tool DesignPlastic Injection Mould Tool Manufacture Plastic Injection Mould ToolsPlastic Injection MouldingPlastic Injection Moulding AssemblyPlastic Injection Moulding ServicesPlastic Injection Moulding Sub-Contract Plastic Injection MouldingsPlastic Moulded AssembliesPlastic Moulded ComponentsPlastic Moulded PartsPlastic Moulded Product DesignPlastic Moulded ProductsPlastic MouldingPlastic Moulding AssemblyPlastic Moulding ManufacturePlastic Moulding ServicesPlastic Moulding SupplierPlastic MouldingsPlastic Mouldings Post-OperativePlastic Mouldings SupplierPlastic Product AssemblyPlastic Product DesignPlastic ProductsPlastics Injection Mould ToolsPlastics Injection MouldingPlastics Injection Moulding ServicesPlastics MouldersPolycarbonate Injection MouldingsPolypropylene Injection MouldingsPolystyrene Injection MouldingsPrototype Injection MouldingsSub-Contract Injection MouldingThermoplastic Eleastomer (TPE) Injection Mouldings Thermoplastic Injection MouldingThermoplastic Injection MouldingsTrade Plastic Injection MouldingsMould ToolsPlastic Injection Mould ToolsPrecision MoulderISO Approved Plastic Injection MoulderPlastic InjectionPlastic Injection Mould ToolsPlastic Injection MouldersPlastic Injection MouldingInjection Mould Tool MakingInjection Mould ToolmakingInjection Mould ToolsMould ToolsMoulding And MouldPlastic Injection Mould ToolsCNC MachiningJigs And FixturesPlastic Mould Toolmakers Precision EngineeringPressure Die CastingSpecial Purpose Machinery ToolmakingTool MakerTool MakersTool MakingToolmakerToolmakersInjection MouldersPlastic Injection Moulding Plastics Injection Moulding Injection Mould Tool Making Injection Mould Toolmaking Precision EngineeringPrecision EngineersToolmakerAutomotive ToolMould DesignProduct DesignComponent Development Moldflow AnalysisOver Moulding2 Shot MouldProduction MouldingMould and DieMulti Cavity MouldMulti Shot MouldMoulds with Hot Runner Systems Large Size CapabilityTool Trials。

1.1.模具行业搜

索email可能涉及到

的常见关键词

injection mold engineering television set

metal mold metal product dust collector

plastic mold pump vacuum cleaner

mold design pipe OA equipment

mold maker electric products printer

bathroom mold electric equipment copy machine

case mold tooling, hardware FAX machine

funnel mold electrical household computer

shelf mold air-condition automobile accessory, plastic product refrigerator automotive parts, plastic industry icebox communication

equipment,

industrial products washing machine telephone,

mobile phones.

1.2.模具行业搜

索email可能涉及到

的其他关键词

air-condition greece multi-media

allumen hardware multimedia

artwork Hawaii muotti

auto hdd norway

autocar health notbook

automaker hitech notebook

Automative hub noulding

automobile Ibi Oklahoma automotive icebox optic

bathroom import outillage

battery industrial packaging

belt industrical palstic

blow Industries part

blowing industry patch

bobbin iniezione phone

box Injecao pigtail

breaker instrument pill

britain insulating pipe

bucket ipod plasic

cable ireland plasitc

calculator israel plastemner camcorder jars plastic

camcorders Jewelry plastica

camera kunda plastice

cameras laptop plastiche

canada laptops plasticl

cap LCD plasticmold car led plastics case lighting Plastikfabrik cctv machine plastique children machinery plastis commodity machinist plastverktyg communication mahinery plug Computer maker plumbing computerl making poly computers manufactory Portugal Connecticut manufacture precicion connector manufacturer precise connectors Manufacturing precision connnectors market printer construction maschinenbau producing cover massager product craft mechanical production cup medcine products Delaware media produit digital Medical proe distributors metal promo druckguss miller promotion dvd milling promotional DVR mini prototype electric mobile Prototypen electrical moblie pump Electronics mold purchase embroidery molder purchasing Engineering molding pvc equipment moldmaker pvcbox fabricate moldmaking realisation fabrication Molds realizzazione facility motor refrigerator factory motorcar relay

Fiber mould resin

Fiscal moulder riflescope fitness moulding rubber fitting mouldMadison sartorius formenbau mouldmaking scanner formtechnik moule sewing formteile moules shelf

funnel mound shipping furniture mouse

gear mp3

gift mp4

gifts multi

glass gps

shower

silica

silicaKodiak

skin

socket

spectrum Spritzgiessteile spritzgiesswerkzeug spuitgiet

spuitqiet spuitqieten stampaggio

stampi

stamping stationery

stockist

supplier

supply

surrogate

switche

switchette switching szerszamipar telecommunication telephone

telephones television telmould telplastic termoformatura termoplast termoplastiche termoplastycznych thermoforming Thermoplaste thermoplastique toilet

tolling

tool

tooling toolingmaker toolmake toolmaker toolmaking

tools toolsAnnapolis tooth

toothbrush

Tour

tourism

toy

toys

travel

tray

trays

treadmill

vacuum

valve

verktyg

wallet

washing

watches

web

welding

wireness wisconsin。