abb流量计说明书.pdf

- 格式:pdf

- 大小:2.03 MB

- 文档页数:9

ABB质量流量计中文说明书发布时间:10-04-08 来源:点击量:33792 字段选择:大中小操作手册D184B111U02科里奥利质量流量计标准软件D699G001U01 A.3x零件号.D184B111U02发行日期:11/04版本:01制造商:ABB Automatio n Products GmbHDran sfelder Str. 237079 Götti nge n, Germa ny 电话:+49 (0) 55 19 05- 0传真:+49 (0) 55 19 05- 777© Copyright 2004 by ABB Automation Products GmbHWe reserve the right to tech ni cal ame ndme nts. 本文档有版权保护.本文档中的信息仅用于帮助用户对设备进行安全有效的操作.没有版权所有者的书面批准不得全部或部分复制其内容.2 FCM2000 D184B111U021基本安全信息和使用方法1基本安全信息和使用方法1.1基本安全信息1.1.1仪表安全标准􀁺本仪表符合压力设备规范以及最新技术的安全要求。

本仪表已根据安全要求通过工厂测试,并根据正确的订单发货。

为使仪表在操作过程中仍符合安全指标,必须遵守本操作手册中列出的要求。

􀁺;请注意关于防暴设计的仪表启动的特别信息,在本手册第七章。

􀁺仪表符合EN61326/NAMUR NE21的电磁兼容(EMC 要求及低电压指示。

􀁺对于尺寸直到DN100( 4”)的科里奥利质量流量计有防水外壳可选项,流量计传感器的最大工作压力为PS= 40bar (外壳的爆炸压力为PS>60bar)。

在压力设备指示的可用范围内本保护设计不会失效。

􀁺当供电中断发生时,仪表参数存储在一个括最新的累积值)中。

—A B B M E A S U R E M E N T&A N A L Y T I C S|SP A R E P A R T S LI S T CoriolisMaster FCB400, FCH400Coriolis mass flowmeterMeasurement made easyAdditional Information Additional documentation on CoriolisMaster FCB400, FCH400 is available for download free of charge at /flow.Alternatively simply scan this code:2 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | SPL/FCB400/FCH400-EN REV. CTable of contents1 Safety instructions for repair work (3)2 Name plate specifications for spare parts orders 4Name plate of sensor in integral mount design (example)43 Spare parts list (5)Coriolis mass flowmeter FCB430, FCB450, FCH430,FCH450 in remote mount design (5)Transmitter FCT430, FCT450 (5)Sensor FCB430, FCB450, FCH430, FCH450 (10)Coriolis mass flowmeter FCB430, FCB450, FCH430,FCH450 in integral mount design (12)4 Upgrade Kits (15)Conversion kit FCB3XX to FCB430, FCB450, FCH430,FCH450 (15)5 Activation codes (15)1Safety instructions for repair workABB flowmeters are designed to be easy to repair thanks to uniform replacement parts and simple replacement of predefined parts.However, if repair work is not carried out in accordance with the guidelines, this may result in malfunctioning of the device, causing serious injury to persons, and harm to the environment. This is especially true for safety-critical devices and those certified for use in explosion hazard environments. Certifications will also lapse if the repairs were not carried out with the proper tool or by persons without adequate training. We therefore recommend all repair work on flowmeters be carried out by ABB service technicians.As the manufacturer of the device, ABB cannot guarantee the necessary quality of the repair procedures if the work and/or parts exchange was not carried out by ABB.The plant operator is responsible for all repairs carried out by the customer, plant operator, or third party. In this case, ABB will reject all responsibility for any improper device functionality, in particular all safety-related functions. ABB does not assume any liability for the deterioration or loss of device performance, malfunctions, or damage arising from the above repair work or replacement. All liability for defects shall lapse when the replacement or repair work is not carried out by ABB.If you are unsure about the repair process even if some or all replacement parts are available, please get in touch with ABB Service before beginning work.Respect national and internal laws when carrying out repairs. In particular laws relating to certified flowmeters used in explosion hazard environments. Repair work which is carried out without following the legal requirements can result in the revocation of your operating permit.For more information, go to/service/repairs or contact your local ABB Customer Service Center.2Name plate specifications for spare parts ordersThe flowmeter version can be identified by referring to the name plate that is attached to the housing.Name plate of sensor in integral mount design (example)When placing spare parts orders, always remember to state the serial number as shown on the name plate.1 Serial numberFigure 1: Name plate of sensor in integral mount design (example)NotePrices available upon request!3 Spare parts listCoriolis mass flowmeter FCB430, FCB450, FCH430, FCH450 in remote mount designTransmitter FCT430, FCT450Figure 2:Upper part with electronicsNumber DesignationVariantOrdering numberRecommended spare part1+2+8+k T3 housing including motherboard and EMCboard aluminum zone 2 / DIV 2 M20 U high Without explosion protection, ATEX / IECExZone 23KQZ 407115U0100T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U highWithout explosion protection, ATEX / IECExZone 2, cFMus Class 1 Div. 23KQZ 407115U0500T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U lowWithout explosion protection, ATEX / IECExZone 2, cFMus Class 1 Div. 23KQZ 407115U0700T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 M20 U lowWithout explosion protection, ATEX / IECExZone 23KQZ 407115U0300... 3 Spare parts listNumber Designation Variant Orderingnumber Recommendedspare part1+2+8+k T3 housing including motherboard and EMCboard aluminum zone 2 / DIV 2 M20 U high Without explosionprotection, ATEX / IECExZone 23KQZ407133U1100 Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U high Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 23KQZ407133U1500 Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U low Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 23KQZ407133U1300 Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 M20 U low Without explosionprotection, ATEX / IECExZone 23KQZ407133U1700 Modbus and DP1 T3 housing aluminum M20 Zone2 / DIV 2pa. without gland Without explosionprotection, ATEX / IECExZone 23KQZ407020U0100T3 housing aluminum NPT Zone 2 / DIV 2 pa. without plug Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 23KQZ407020U0300T3 housing aluminum M20 Zone 2 / DIV 2 pa. without gland Without explosionprotection, ATEX / IECExZone 23KQZ407020U0100 Modbus and DPT3 housing aluminum NPT Zone 2 / DIV 2 pa. without plug Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 23KQZ407020U0300 Modbus and DPO-ring housing 41.00 x 1.78 NBR – D101A040U01 X2 Motherboard complete U high – D800D520U19X Motherboard complete U low – D800D520U20XFuse 5 x 20 mm 1.25 A 1500 A @ 250 V AC – 3KQR000757U0100 X Only 1:1 replacementin case of EXFuse 5 x 20 mm 0.8 A 1500 A @ 250 V AC – 3KQR000757U0200 X Only 1:1 replacementin case of EXk T3 spacing bolts HML type c – 3KQZ407017U01004 HMI Type C pre assy. no data logger – 3KQZ407125U0100 XNumber Designation Variant Orderingnumber Recommendedspare part3 DP Plug-in card – 3KQZ400027U0100 Only 1:1 replacementin case of EX Modbus plug-in card – 3KQZ400028U0100 Only 1:1 replacementin case of EXPlug-in card current output 4 to 20 mA passive (red) – 3KQZ400029U0100 Only 1:1 replacementin case of EXPlug-in card digital output passive (green) – 3KQZ400030U0100 Only 1:1 replacementin case of EX Plug-in card 24 V DC power supply (blue) – 3KQZ400031U0100 Only 1:1 replacementin case of EX Plug-in card passive digital input (yellow) – 3KQZ400032U0100 Only 1:1 replacementin case of EX EMC protection sheet T3 – 3KXF003070U0100 Only 1:1 replacementin case of EX5 Cover with glass pre-mounted Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 2D612A197U01Cover with glass pre-mounted, Ex, ATEX / IECEx Zone 1,cFMus Class 1 Div. 1D612A197U027 Cover, VST rear, type 3, STDAluminum, INT Without explosionprotection, ATEX / IECExZone 2, cFMus Class 1Div. 2D612A226U01Cover, VST rear, type 3, EX Aluminum ATEX / IECEx Zone 1,cFMus Class 1 Div. 1D612A226U026 O-ring cover 118 x 3.70, NBR – D101A034U05 X 8 T3 EMC board complete ZN2 /DIV 2/ DIV1 D800D520U21 X4WCTW EMC Board complete ZN1 POT ZN1 D800D520U22 XT3 EMC board complete ZN2 /DIV 2/ DIV1 D800D520U23 X4WCTW EMC Board complete ZN1 POT ZN1 D800D520U24 X 9 T3 plastic cap network connection – 3KQZ407005U0100j Screw for network connection cap M 4 x 6DIN7985 – D004G106AU20... 3 Spare parts list... Coriolis mass flowmeter FCB430, FCB450, FCH430, FCH450 in remote mount designFigure 3:Wall mountNumber DesignationVariantOrdering numberRecommended spare part1T3 wall mount, base aluminum ZN1 M20 pre assy W ithout explosionprotection, ATEX / IECEx Zone 23KQZ 407114U0100T3 wall mount, base aluminum DIV 1 NPT pre assyWithout explosion protection, ATEX / IECEx Zone 2cFMus Class 1 Div. 23KQZ 407114U03002T2 cover wall mount aluminum Zone 1, 2 / DIV 1, 2 pre assyWithout explosion protection, ATEX / IECEx Zone 2ATEX / IECEx Zone 1, cFMus Class 1 Div. 2, cFMus Class 1 Div. 13KQZ207035U01003 O-ring cover wall mount 118 x 3.70 NBR – D101A034U054 O-Ring 41 x 1.78 NBR – D101A040U01 5Terminal block 4-pole–3KQR002621U0100Number Designation Variant Ordering number Recommended sparepart6 Raised-head screw for terminal block ISO7985M3 x 20 A2-70– 3KQP000063U0100 Accessory bag for cable clamps – 3KXF002015U0100T3 connection cable wall mount for housing Without explosionprotection, ATEX / IECExZone 2cFMus Class 1 Div. 23KQZ407087U0100Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 5 m 3KQZ407123U0500Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 10 m 3KQZ407123U1000Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 15 m 3KQZ407123U1500Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 20 m 3KQZ407123U2000Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 25 m 3KQZ407123U2500Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 30 m 3KQZ407123U3000Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 35 m 3KQZ407123U3500Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 40 m 3KQZ407123U4000Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 50 m 3KQZ407123U5000Signal cable wall mounting for connection box 4WCTW 4 x 0.75 mm 80 m 3KQZ407123U8000... 3 Spare parts list... Coriolis mass flowmeter FCB430, FCB450, FCH430, FCH450 in remote mount designSensor FCB430, FCB450, FCH430, FCH450Figure 4:Terminal boxNumber DesignationVariantOrdering numberRecommended spare part1Connection box aluminum M20 GP/ZN2/DV2/ZN1 PreA 1EntryWithout explosion protection, ATEX / IECEx Zone 2, ATEX / IECEx Zone 1, cFMus Class 1 Div. 23KXF002568U0100With Div. 1 not replaceableConnection box aluminum NPT GP/ZN2/DV2/ZN1 PreA 1EntryWithout explosion protection, ATEX / IECEx Zone 2, ATEX / IECEx Zone 1, cFMus Class 1 Div. 23KXF002568U0200With Div. 1 not replaceableTerminal box stainless steel M20 GP/ZN2/DV2/ZN1 PreA 1EntryWithout explosion protection, ATEX / IECEx Zone 2, ATEX / IECEx Zone 1, cFMus Class 1 Div. 23KXF002567U0100With Div. 1 not replaceableTerminal box NPTGP/ZN2/DV2/ZN1 PreA 1EntryWithout explosion protection, ATEX / IECEx Zone 2, ATEX / IECEx Zone 1, cFMus Class 1 Div. 23KXF002567U0200With Div. 1 not replaceableNumber DesignationVariantOrdering numberRecommended spare part2Slide-In Remote GP/ZN/DV2/DV1 U low CorIFWithout explosion protection, ATEX / IECEx Zone 2, cFMus version Class 1 Div. 23KXF002566U0100 XSlide-In Remote ZN1 U low Cor_IFATEX / IECEx, (Zone 1 / 21), cFMus version Class 1 Div. 13KXF002566U0200X3Memory module assembled- 3KXF002906U0100 Memory module assembled programmed-3KXF002906U0100AX4Cover, VST rear, TYPE3, standard, aluminum, INT W ithout explosionprotection, ATEX / IECEx Zone 2, ATEX / IECExZone 1, cFMus Class 1 Div. 2D612A226U01Cover, VST rear, TYPE3, EX, aluminum cFMus Class 1 Div. 1 D612A226U02Cover VST, rear stainless steelWithout explosion protection, ATEX / IECExZone 2, ATEX / IECEx Zone 1, cFMus Class 1 Div. 2, cFMus Class 1 Div. 13KQZ 407109U0100Rounded head screw ISO7380 M5 x 16 A2 - 3KQP000043U0100 O-Ring 4.76 x 1.78 NBR-D101A034U075Raised-head screw with cross slot M4 x 12 D7985 stainless- D396A014U02 Spacing bolts for Ex M4 x 8 SW7ATEX / IECEx, (Zone 1 / 21)3KXF002616U01007 Washer A 4.3 DIN 125 without bevel stainless- D085A021AU206Spring washer B 4.0 DIN 127 SS- D085C020BU20... 3 Spare parts listCoriolis mass flowmeter FCB430, FCB450, FCH430, FCH450 in integral mount designFigure 5:FCB4x0, FCH4x0 with integral mount designNumberDesignationVariantOrdering numberRecommended spare part1+2+j +m T3 housing including motherboard and EMCboard aluminum zone 2 / DIV 2 M20 U high Without explosion protection, ATEX / IECEx Zone 23KQZ 07115U0100T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 M20 U low Without explosion protection, ATEX / IECEx Zone 23KQZ407115U0300T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U high Without explosion protection, ATEX / IECEx Zone 2 cFMus Class 1 Div. 23KQZ407115U0500T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U low Without explosion protection, ATEX / IECEx Zone 2 cFMus Class 1 Div. 23KQZ407115U0700T3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 M20 U high Without explosion protection, ATEX / IECEx Zone 23KQZ407133U1100Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 M20 U low Without explosion protection, ATEX / IECEx Zone 23KQZ407133U1500Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U high Without explosion protection, ATEX / IECEx Zone 23KQZ407133U1300Modbus and DPT3 housing including motherboard and EMC board aluminum zone 2 / DIV 2 NPT U lowWithout explosion protection, ATEX / IECEx Zone 23KQZ407133U1700Modbus and DPNumber Designation Variant Ordering number Recommended sparepart1 T3 base aluminum M20 Zone2 / DIV 2 pa.without gland Without explosion protection,ATEX / IECEx Zone 23KQZ407020U0100T3 base aluminum NPT Zone 2 / DIV 2 pa. without plug Without explosion protection,ATEX / IECEx Zone 2, cFMusClass 1 Div. 23KQZ407020U0300O-ring housing 41.00 x 1.78 NBR D101A040U01 X2 Motherboard complete U high – D800D520U19X Motherboard complete U low – D800D520U20XFuse 5 x 20 mm 1.25 A 1500 A @ 250 V AC 3KQR000757U0100 X Only 1:1 replacementin case of EXFuse 5 x 20 mm 0.8 A 1500 A @ 250 V AC 3KQR000757U0200 X Only 1:1 replacementin case of EXm T3 spacing bolts HML type c – 3KQZ407017U01003 Front end board Cor_IF pre assy – 3KXF002564U0100 X4 DP Plug-in card – 3KQZ400027U0100 Only 1:1 replacementin case of EX Modbus plug-in card – 3KQZ400028U0100 Only 1:1 replacementin case of EXPlug-in card current output 4 to 20 mA passive (red) – 3KQZ400029U0100 Only 1:1 replacementin case of EXPlug-in card digital output passive (green) – 3KQZ400030U0100 Only 1:1 replacementin case of EX Plug-in card 24 V DC power supply (blue) – 3KQZ400031U0100 Only 1:1 replacementin case of EX Plug-in card passive digital input (yellow) – 3KQZ400032U0100 Only 1:1 replacementin case of EX EMC protection sheet T3 3KXF003070U0100 Only 1:1 replacementin case of EX5 Memory module assembled – 3KXF002906U0100Memory module assembled programmed 3KXF002906U0100A X6 HMI Type C pre assy. no data logger – 3KQZ407125U0100 X... 3 Spare parts list... Coriolis mass flowmeter FCB430, FCB450, FCH430, FCH450 in integral mount designNumber Designation Variant Ordering number Recommended sparepart7 Cover with glass pre-mounted Without explosion protection,ATEX / IECEx Zone 2, ATEX /IECEx Zone 1, cFMus Class 1 Div. 2D612A197U01Cover with glass pre-mounted, Ex ATEX / IECEx Zone 1, cFMusClass 1 Div. 1D612A197U029 Cover, VST rear, TYPE 3, Standard,Aluminum INT Blind Without explosion protection,ATEX / IECEx Zone 2, ATEX /IECEx Zone 1, cFMus Class 1 Div. 2D612A226U01Cover, VST rear, TYPE3, EX, aluminum ATEX / IECEx Zone 1, cFMusClass 1 Div. 1D612A226U028 O-ring cover 118 x 3.70, NBR – D101A034U05 X j T3 EMC board complete ZN2 /DIV 2/ DIV1 D800D520U21 X 4WCTW EMC Board complete ZN1 POT ZN1 D800D520U22 XT3 EMC board complete ZN2 /DIV 2/ DIV1 D800D520U23 X4WCTW EMC Board complete ZN1 POT ZN1 D800D520U24 X k T3 plastic cap network connection – 3KQZ407005U0100l Screw for network connection cap M 4 x 6DIN7985 – D004G106AU20Accessory bag for cable clamps 3KXF002015U01004Upgrade KitsConversion kit FCB3XX to FCB430, FCB450, FCH430, FCH450Number Designation Variant Orderingnumber Recommendedspare part Conversion kit FCB3xx > FCB4xx U high remotemount design M20 without explosion protectionD800D520U03Conversion kit FCB3xx > FCB4xx U low remote mount designM20 without explosion protection D800D520U04Conversion kit FCB3xx > FCB4xx U high remotemount designNPT without explosion protectionD800D520U05Conversion kit FCB3xx > FCB4xx U low remotemount designNPT without explosion protectionD800D520U06Conversion kit FCB3xx > FCB4xx U high integralmount design M20 without explosion protectionD800D520U07Conversion kit FCB3xx > FCB4xx U low integralmount design M20 without explosion protectionD800D520U08Conversion kit FCB3xx > FCB4xx U high integralmount design NPT without explosion protectionD800D520U09Conversion kit FCB3xx > FCB4xx U low integralmount design NPT without explosion protectionD800D520U10NoteUpgrades shall be at the user's own risk!The upgrade can be performed by request on site or by the Göttingen service center.5Activation codesNumber Designation Variant Orderingnumber Recommendedspare part DensiMass measurement activation code – 3KXS360060L0001FillMass filling application activation code – 3KXS360060L0002VeriMass diagnosis measurement activationcode– 3KXS360060L0003TrademarksModbus is a registered trademark of the Modbus Organization— ABB Automation GmbH - Service Instruments - Schillerstraße 72 D-32425 Minden DeutschlandFax: +49 571 830-1744Mail: **************************.com/flowIhre lokale ABB-Niederlassung finden Sie unter: /contactsS P L /F C B 400/F C H 400-E N R e v . C 05.2018—We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbidden without prior written consent of ABB. Copyright© 2018 ABB All rights reserved 3KXF411013R4701。

TABLE OF CONTENTS Introduction (4)Specifications (6)Installation (7)Operational Start-Up (9)Troubleshooting (11)Flow Monitor Information (12)Repair Kit Information (13)Statement of Warranty (15)INTRODUCTIONFluid entering the meter passes through the inlet flow straightener which reduces its turbulent flow pattern and improves the fluid’s velocity profile. Fluid then passes through the turbine blades causing it to rotate at a speed proportional to the fluid velocity. As each blade passes through the magnetic field, created at the base of the pickoff transducer, AC voltage (pulse) is generated in the pick-up coil (see Figure 1). These impulses produce an output frequency proportional to the volumetric flow through the meter. The output frequency is used to represent flow rate and/or totalization of fluid passing through the turbine flow meter.FIGURE 1Schematic illustration of electric signalgenerated by rotor movementTURBINE METERThe FTB-1400 Series Turbine Flow Meter is designed to withstand the rigorous demands of the most remote flow measurement applications. The FTB-1400 Series Flow Meter maintains measurement accuracy and mechanical integrity in the corrosive and abrasive fluids commonly found in oil field waterflood project pipelines, in-situ mining operations, offshore facilities and plant locations. Simple to install and service, it can operate in any orientation (horizontal to vertical) as long as the“flow direction” arrow is aligned in the same direction as the actual line flow. For optimum performance, the flow meter should be installed with a minimum of 10 diameters upstream pipe length and 5 diameters downstream pipe length.FIGURE 2Typical cross-section of FTB-1411 throughFTB-1441 turbine flow meterSPECIFICATIONSMATERIALS of CONSTRUCTION: Body : 316 Stainless SteelRotor : CD4MCU Stainless SteelRotor Support and Bearings : 316 Stainless SteelRotor Shaft : Tungsten CarbideOPERATING LIMITATIONS:Temperature: -150 °F to +350 °F (-101 °C to +177 °C) The metershould not be subjected to temperatures above +350° F(177° C), or below -150° F (-101° C) or the freezingpoint of the metered liquid. High temperatures willdamage the magnetic pick-up, while lower temperatureswill limit the rotation of the rotor.Pressure : Maximum pressure ratings as follows:5,000 psi ─ all NPT meters up to 2"2,000 psi ─ 3" male NPT1,500 psi ─ 4" male NPT1,000 psi ─ 6" male NPT800 psi ─ all grooved end metersNote: Consult factory for pressure ratings for flanged meters. Accuracy:± 1.0% of reading Repeatability: ± 0.1%Calibration: Water (NIST Traceable Calibration) Corrosion: All FTB-1400 series turbine meters are constructed ofstainless steel and tungsten carbide. The operator mustensure that the operating fluid is compatible with thesematerials. Incompatible fluids can cause deterioration ofinternal components and cause a reduction in meteraccuracy.Pulsation andVibration: Severe pulsation and mechanical vibration will affectaccuracy and shorten the life of the meterFiltration: If small particles are present in the fluid, it is recommendedthat a strainer be installed upstream of the meter (see Table 1 WARNING: Pressure in excess of allowable rating may cause the housing to burst and cause serious personal injury.FLOW MONITOR:For a complete flow monitor package, Omega offers the FTB-1400 Series Flow Monitors (see Appendix B on page 12 for flow monitor information). These digital signal processing displays utilize the low-level frequency input from the FTB-1400 Series Turbine Meters to calculate flow rate and total. When ordered with an Omega FTB-1400 Series Turbine Meter, the included factory calibration will provide dependable and accurate flow information.REPAIR KIT:The FTB-1400 Series Turbine Meter Repair Kit is designed for easy field service of a damaged flow meter, rather than replacing the entire flow meter (see Appendix B on page 12 for repair kit information).Repair parts are constructed of stainless steel alloy and tungsten carbide and are factory calibrated to ensure accuracy throughout the entire flow range. Each kit is complete and includes the calibrated K-factor which is used to recalibrate the flow monitor or other electronics to provide accurate output data.INSTALLATION INSTRUCTIONSPrior to installation, the flow meter should be checked internally for foreign material and to ensure the turbine rotor spins freely. Fluid lines should also be checked and cleared of all debris.The flow meter must be installed with the flow arrow, etched on the exterior of the meter body, pointing in the direction of fluid flow. Though the meter is designed to function in any position it is recommended, where possible, to install horizontally with the magnetic pick-up facing upward.The liquid being measured should be free of any large particles that may obstruct rotation of the rotor. If particles are present, a mesh strainer should be installed upstream before operation of the flow meter. (See Table 1 on page 8.)TABLE 1 Strainer Mesh Installation DetailsThe preferred plumbing setup is one containing a by-pass line (Figure 3 on page 10) that allows meter inspection and repair without interrupting flow. If a by-pass line is not utilized, it is important that all control valves be located downstream of the flow meter (Figure 4 on page 10).This is true with any restriction in the flow line that may cause the liquid to flash. If necessary, air eliminators should be installed to ensure that the meter is not incorrectly measuring entrained air or gas.PARTNUMBER STRAINER MESH CLEARANCE FILTER SIZE FTB-1411, FTB-142160 × 60 .0092 260 Micron FTB-1412, FTB-142260 × 60 .0092 260 Micron FTB-1413, FTB-142360 × 60 .0092 260 Micron FTB-142460 × 60 .0092 260 Micron FTB-1425 60 × 60 .0092 260 MicronFTB-1431 20 × 20 .0340 .86mm FTB-1441 20 × 20 .0340 .86mmCAUTION: Damage can be caused by striking an empty meter with a high velocity flow stream.It is recommended that a minimum length, equal to ten (10) pipe diameters of straight pipe, be installed on the upstream side and five (5) diameters on the downstream side of the flow meter. Otherwise, meter accuracy may be affected. Piping should be the same size as the meter bore or threaded port size.Do not locate the flow meter or connection cable close to electric motors, transformers, sparking devices, high voltage lines, or place connecting cable in conduit with wires furnishing power for such devices. These devices can induce false signals in the flow meter coil or cable, causing the meter to read inaccurately.If problems arise with the flow meter and monitor, consult Appendix A (Troubleshooting Guide) on page 11. If further problems arise, consult the factory.If the internal components of the turbine flow meter are damaged beyond repair, turbine meter repair kits are available. Information pertaining to the turbine meter repair kits is referenced in Appendix B on page 12.OPERATIONAL START-UPThe following steps should be followed when installing and starting the meter.WARNING: Make sure that fluid flow has been shut off and pressure in the line released before attempting to install the meter in an existing system.1. After meter installation, close the isolation valves and open theby-pass valve. Flow liquid through the by-pass valve for sufficient time to eliminate any air or gas in the flow line.CAUTION: High velocity air or gas may damage the internal components of the meter.2. Open upstream isolating valve slowly to eliminate hydraulic shockwhile charging the meter with the liquid. Open the valve to full3. Open downstream isolating valve to permit meter to operate.4. Close the by-pass valve to a full closed position.5. Adjust the downstream valve to provide the required flow ratethrough the meter. Note: The downstream valve may be used as a control valve.FIGURE 3Meter installation utilizing a by-pass line(Shown with an FTB-1400 Series Flow Monitor)FIGURE 4Meter installation without utilizing a by-pass lineAPPENDIX ATROUBLESHOOTING GUIDE Trouble Possible Cause RemedyMeter indicates higher than actual flow rate -Cavitation-Debris on rotor support-Build up of foreign materialon meter bore-Gas in liquid-Increase back pressure-Clean meter-Clean meter-Install gas eliminatorahead of meterMeter indicates lower than actual flow rate -Debris on rotor-Worn bearing-Viscosity higher than calibrated-Clean meter and add filter-Clean meter and add filter-Recalibrate monitorErratic system indication, meter alone works well (remote monitor application only) Ground loop in shielding Ground shield one placeonly. Look for internalelectronic instrumentground. Reroute cablesaway from electrical noiseIndicator shows flow when shut off Mechanical vibration causesrotor to oscillate without turningIsolate meterNo flow indication. Full or partial open position Fluid shock, full flow into drymeter or impact caused bearingseparation or broken rotor shaftRebuild meter with repairkit and recalibrate monitor.Move to location wheremeter is full on start-up oradd downstream flowcontrol valveErratic indication at low flow, good indication at high flow Rotor has foreign materialwrapped around itClean meter and add filterNo flow indication Faulty pick-up Replace pick-upSystem works perfect, except indicates lower flow over entire range By-pass flow, leak Repair or replace by-passvalves, or faulty solenoidvalvesMeter indicating highflow, upstream pipingat meter smaller thanmeter boreFluid jet impingement on rotor Change pipingOpposite effects of above Viscosity lower than calibrated Change temperature,change fluid or recalibratemeter11APPENDIX BFTB-1400 SERIES FLOW MONITOR Simplified Version• Displays rate and/or total• Large 8 digit by 3/4” display• Front panel programming• NEMA 4X enclosure• Five selectable units of measure• Programs in seven simple stepsPart Number InformationFTB 1400 X DMounting StyleM = Meter MountR =Remote MountS =Swivel Mount Advanced Version• Displays rate and/or total• Large 8 digit by 3/4” display• Front panel programming• NEMA 4X enclosure• Thirteen selectable units of measure• Selection of time intervals for rate measurement• Ten point linearization• Provides additional programming optionsPart Number InformationFTB 1400 X D AMounting StyleM = Meter MountR =Remote MountS =Swivel Mount1213FTB-1400 REPAIR KITFigure 5Typical turbine meter component directoryFlow Meter SizeRepair Kit FitsMeter Part NumberRepair KitPart Number3/8" FTB-1411,FTB-1421 FTB-1400A-RK 1/2" FTB-1412, FTB-1422 FTB-1400B-RK 3/4" FTB-1413, FTB-1423 FTB-1400C-RK 7/8" FTB-1424 FTB-1400D-RK 1" FTB-1425 FTB-1400E-RK 1-1/2" FTB-1431 FTB-1400F-RK 2" LowFTB-1441 FTB-1400F-RK Standard Magnetic Pick-upAll Meter SizesFTB-1400-MPNOTES 141516。

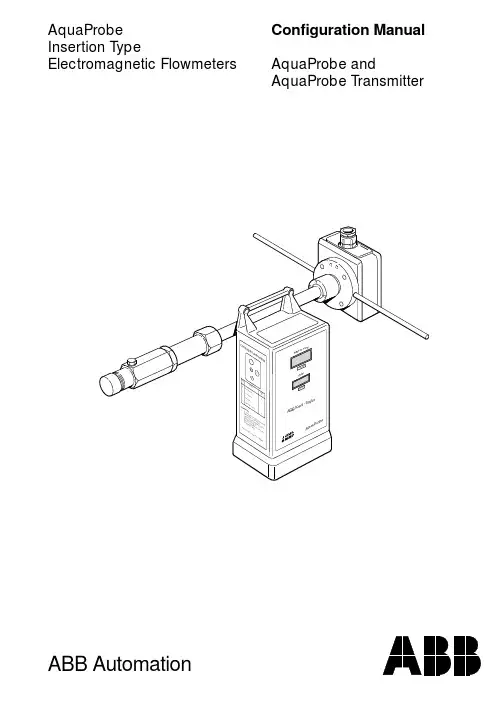

AquaProbeInsertion Type Electromagnetic Flowmeters Configuration Manual AquaProbe andAquaProbe TransmitterABB AutomationABB INSTRUMENTATIONAlthough Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage,it must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution rmation in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of Technical Communications Department, ABB Instrumentation.The CompanyABB Instrumentation is an established world force in the design and manufacture of instrumentation for industrial process control, flow measurement, gas and liquid analysis and environmental applications.As a part of ABB, a world leader in process automation technology, we offer customers application expertise, service and support worldwide.We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled service and support.The quality, accuracy and performance of the Company’s products result from over 100 years experience, combined with a continuous program of innovative design and development to incorporate the latest technology.The NAMAS Calibration Laboratory No. 0255 is just one of the ten flow calibration plants operated by the Company, and is indicative of ABB Instrumentation’s dedication to quality and accuracy.BS EN ISO 9001St Neots, U.K. – Cert. No. Q5907Stonehouse, U.K. – Cert. No. FM 21106Stonehouse, U.K. – Cert. No. 0255EN 29001 (ISO 9001)Lenno, Italy – Cert. No. 9/90A Use of InstructionsHealth and SafetyTo ensure that our products are safe and without risk to health, the following points must be noted:1.The relevant sections of these instructions must be read carefully before proceeding.2.Warning labels on containers and packages must be observed.3.Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information given.4.Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure and/or temperature.5.Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be used.6.When disposing of chemicals ensure that no two chemicals are mixed.Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be obtained from the Company address on the back cover, together with servicing and spares information.CONTENTS Page1OPERATION1.1Intermittent Mode (2)1.2Continuous Mode (2)1.2.1Display (Continuous Mode Only) (2)1.3Totaliser (2)1.3.1Totaliser Reset (2)2PROGRAMMING2.1Programming the AquaProbe Transmitter (3)2.1.1Accessing and Using theMain Menu (3)2.2Vary Parameter Command (4)2.2.1Parameter Values (4)2.2.2Negative Parameter Values (4)2.2.3Changing Parameter Values (4)2.2.4Parameters (6)APPENDICESA1Psion Organiser Series 2 (7)A1.1Keyboard Designations (7)A2Psion Organiser Series 3 (7)A2.1Keyboard Designations (7)A3Husky Hunter Portable Computer (8)A3.1Keyboard Designations (8)A4Microscribe Series 300 (8)121.3TotaliserThe AquaProbe Transmitter is fitted with an 8 digit totaliser module. The totaliser is configured to count pulses in the forward direction only at a x1F rate, or at this rate divided by 10, 100 or 1000.Example – if x1F is in litres then the internal totaliser can be made to display cubic metres by selecting '÷ 1000' – see Fig.2.2 on page 5.1.3.1Totaliser ResetThe totaliser is reset by:a)Connecting Pin J of the output cable connector ('RESET' –white wire in cable MVBX 99147) to GND (Pins G, S or V).For full connection details see Section 4 in the AquaProbe Installation Manual.b)Applying the wand to the 'RESET' pad with Pins J and T ofthe output cable connector linked together (i.e. yellow and white wires of cable MVBX 99147) or by serial data lead assemblies MVBX 99117 or 99119.The totaliser is equipped with an overflow indicator. A small dot appears in the top left hand corner of the display when there is overflow from '99999999' to '00000000'.1OPERATIONThe AquaProbe Transmitter can be used in either a continuous or intermittent mode.1.1Intermittent ModeThe AquaProbe Transmitter measures the average flow rate over a period of approximately 5 seconds, at a regular user defined Intermittent Interval of 1 to 255 minutes. Between readings the transmitter is in a 'sleep' state resulting in minimal current usage. Battery life is proportional to the intermittent interval and can allow unattended operation from a small battery pack for in excess of one year. At the end of each measurement period the measurement is transmitted to any data terminal or data loggers connected to the AquaProbe Transmitter. The pulse output, reduced in frequency if required, is fed to an internal totaliser module.1.2Continuous ModeIf the wand is held over the 'ACTIVATE' pad for longer than 3seconds the AquaProbe Transmitter measures and displays flow continuously. Serial data is transmitted at approximately 1.2 second intervals and the frequency output is updated continuously. Once initiated continuous mode is maintained for a user defined Continuous Time of 2 to 255 minutes.Connection of 'A+' to ground or +12V (see AquaProbe Installation Manual) forces the AquaProbe Transmitter into continuous mode.1.2.1Display (Continuous Mode Only)The 4-digit liquid crystal display (l.c.d.) has automatic decimal point selection. The maximum number of figures displayed after the decimal point is automatically selected to give a resolution approximately equivalent to 0.001 m/s. Flow rate is indicated in chosen units (e.g. litres per second) to a maximum of ±9999 units.The display indicates the following overrange conditions:a)If the measuring range of the transmitter is exceeded(approximately 15 m/s), all displayed digits flash.b)If the flow rate exceeds the capacity of the display, a valueof ±9999 is shown continuously.32PROGRAMMING…Vary ParametersFlow Abort Save oror or or Testor 2.1.1Accessing and Using the Main MenuOn the data terminal, type a ‘V ’ and press enter and refer to Section 2.2 for full programming details.The Vary Parameter command allows changes to be made to the AquaProbe Transmitter internal data. To alter parameters 4 to 9 first enter the input security code for security level 1. To alter parameters 4 to 9 and 10 to 12 first enter the input security code for security level 2.On the data terminal, type an ‘F ’ and press enter. The AquaProbe returns to flow measurement, in continuous mode, using the parameter data entered in Vary Parameters until interrupted by a serial link.On the data terminal, type an ‘A ’ and press enter. The AquaProbe Transmitter returns to normal operation ignoring any alterations made to its parameters.On the data terminal, type an ‘S ’ and press enter. All data entered in Vary Parameters is saved and the AquaProbe Transmitter returns to normal operation. This is the only command which changes the AquaProbe Transmitter internal data.On the data terminal, type a ‘T ’ and press enter. The AquaProbe enters continuous mode until interrupted by a serial link. All flow settings and sensor calibration data are ignored and the display shows m/s only. This mode can be used in conjuction with the ABB Kent-Taylor VMD simulator to confirm correct operation.2.1Programming the AquaProbe TransmitterProgramming the AquaProbe transmitter allows various operating parameters to be changed. A security system consisting of two security codes is incorporated to restrict access to some parameters. If using a Psion Organiser, Husky Hunter Portable Computer or Microscribe Series 300 refer to APPENDICES for connection and/or keyboard operations.Table 2.1 Security Access to Parameters in the Vary Parameter MenuSecurity Level12Security Code to EnterSETUP TESTCALAccessible Parameters Parameters 1 to 8Factory set parameters 10, 11 and 12If required, remove page below above line to prevent unauthorised access to calibration details4…2PROGRAMMING2.2Vary Parameter Command 2.2.1Parameter ValuesParameter values are displayed as either floating point in the range ±1E –38 to ±1E+38, or integer in the range –128 to +255.Parameter values can be entered in either format but if an integer value is required then only the integer part of the entry is accepted.2.2.2Negative Parameter Valuesc)If a negative value is entered into parameter 7 (PU), thedisplayed flowrate is not affected but the forward/reverse pulse outputs are interchanged.2.2.3Changing Parameter Values – Fig. 2.1 and 2.2To change parameters 4 to 12 it is necessary to enter a security code – see Section 2.1.1 on previous page.Parameters 13 to 15 are not adjustable. Press 'Escape' to return to the main menu at any time.2PROGRAMMING…5c)Pulse Units – PU is the factor applied to the volume unitsto give the OUTPUT PULSE in the required units. It is the ratio between the volume flow rate units and the required pulse output units.Example 2– for a flow rate in m3 and a pulse output per m3the value of PU is 1.Example 3– for a flow rate in litres and a pulse output per m3 PU is 0.001.PU=Volume UnitsPulse Units1 litre1m31 litre1000 litres===0.001d)Time Mode – TM is the factor applied to the output pulseunits to give the INTERNAL TOTALISER in the required units. It is the ratio between the required totaliser units and the pulse output units and its value is expressed as a power of 10.Example 4– for a flow rate in m3 and a totaliser in m3 the value of TM should be 1. Since 1 is 100, TM = 0.Example 5– for a flow rate in litres and a pulse output in m3 the value of TM should be 1000. Since 1000 is 103, TM = 3.T M=Totaliser UnitsPulse Output Units1m31 litre1000 litres1 litre==Since 1000 = 103, TM = 32.2.4ParametersWhen programming the AquaProbe the following parametersare required:VU–Volume Units, e.g. litres, m3, gallons etc.TU–Time Units, e.g. per second, per minute etc.PU–Pulse Units (the value of pulse output),e.g. 1 pulse per m3.TM–Totaliser Mode (the value of internal totalisercount), e.g. 1 count per m3.a)Volume Units – VU is the parameter which defines theunits of measurement. It is calculated as the volume of a 1metre length of the pipeline in the required units. Table 2.2gives the values of VU for NOMINAL pipe sizes and isintended as a guide only. Calculate the actual value of VUfor a given pipe size using the formula:VU= x KWhere:D=internal diameter of pipeK=number of units in 1 m3,K=1000 if volume units are litresK=220.1 if units are Imperial GallonsK=264.17 if units are U.S. Gallonsn= a constant depending on the units of D,n=4,000,000 if D is in mmn=4 if D is in metresn=6200 if D is in inchesb)Time Units – TU is set to:1 for seconds60 for minutes3600 for hours86,400 for days.Example 1– for an 800mm pipeline and flow units of m3/hour,VU = 0.5026 and TU = 3600.…2PROGRAMMINGe z i Sep i Pl an imoN UVf oeu l aVmm)00,00,4=n(sehcn I)02,6=n(se r t i L)00,1=K()1=K(msno l l aG.pmI)1.022=K(sno l l aGSU)71.462=K(278.70514.134130.0799.6592.85248.99580.941940.0918.01569.21 0318.118386.07770.0065.514966.81 0457.51066.5217521.09376.72142.33 0596.918343.6913691.04152.346498.15 0626.320537.2827282.08932.266776.47 0805.13046.25625.06596.0115618.231 0173.930573.5874587.08719.2710374.72 02142.74049.031,1931.15959.842517.892 04121.550533.935,13935.15349.8334676.64 06199.26065.010,2610.24146.2449690.135 0247.8705.141,35141.31176.1965198.9283Table 2.2 Standard VU Parameter Values67A2Psion Organiser Series 3If using the Psion Organiser Series 3 the following must be carried out:a)Connect the Psion Organiser Communications LinkAdapter to the AquaProbe Transmitter using the Serial Interface Lead MVBX 99119.b)Refer to the Psion Series 3, 3 Link (RS232) handbook andinstall the Comms Application for use with the AquaProbe Transmitter. Access the 'Port' option on the 'Special' menu and set the following values.A1Psion Organiser Series 2If using a Psion Organiser Series 2 it is recommended that the mains adapter is used to power the organiser. The following must be carried out:a)Connect the Psion Organiser Communications LinkAdapter to the AquaProbe Transmitter using the Serial Interface Lead MVBX 99119.b)Access the Comms 'SETUP' mode and set the followingvalues.APPENDICESTransmission ParametersRate-4800Prtcl-none Pty-none CTS-n DTR-n Echo-n T/O-no Null-0 Press ENTER if acceptableReceiving ParametersRate-4800Prtcl-none Pty-none RTS-off DSR-n DCD-n T/O-no Serig-000 Press ENTER if acceptableMicroscribe 320 V 2.11 STATUSBaud Protocol TX Mode AutoLF Disp Audio4800Xon/off CHAR OFF40OFF Parity L.Echo EOF EOL Mode Sleep RESET OFF OFF CR NORM OFF BATTERY LEVEL100%XXXXXA3Husky Hunter Portable ComputerIf using a Husky Hunter Portable Computer the following must be carried out:a)Connect the Husky Hunter Portable Computer to theAquaProbe Transmitter using the Serial Data Lead MVBX 99117.b)Refer to the Husky Hunter Portable Computer handbookand enter the values shown below.A4Microscribe Series 300If using a Microscribe Series 300 the following must be carried out:a)Connect the Microscribe Series 300 to the AquaProbeTransmitter using the Serial Data Lead MVBX 99117.b)Refer to the Microscribe Series 300 handbook and enterthe values shown below.A3.1Keyboard Designations – Fig. A3.1…APPENDICES8PRODUCTS & CUSTOMER SUPPORTA Comprehensive Instrumentation RangeAnalytical Instrumentation•TransmittersOn-line pH, conductivity, and dissolved oxygen transmitters and associated sensing systems.•SensorspH, redox, selective ion, conductivity and dissolved oxygen.•Laboratory InstrumentationpH and dissolved oxygen meters and associated sensors.•Water AnalyzersFor water quality monitoring in environmental, power generation and general industrial applications including: pH, conductivity, ammonia, nitrate, phosphate, silica, sodium, chloride, fluoride, dissolved oxygen and hydrazine.•Gas AnalyzersZirconia, katharometers, hydrogen purity and purge-gas monitors, thermal conductivity.Controllers & Recorders•ControllersDigital display, electronic, pneumatic. Discrete single-loop and multi-loop controllers which can be linked to a common display station, process computer or personal computer.•RecordersCircular and strip-chart types (single and multi-point) for temperature, pressure, flow and many other process measurements.Electronic Transmitters•Smart & Analog TransmittersFor draft, differential, gauge and absolute pressure measurement. Also, liquid level and temperature.•I to P Converters and Field IndicatorsFlow Metering•Magnetic FlowmetersElectromagnetic, insertion type probes and watermeters.•Turbine Flowmeters•Wedge Flow Elements•Mass Flow MetersTransmitters, sensors, controllers and batch/display units.Level Control•Submersible, Capacitance & Conductivity.Pneumatic Instrumentation•Transmitters•Indicating Controllers•Recording Controllers Customer SupportABB Instrumentation provides a comprehensive after sales service via a Worldwide Service Organization. Contact one of the following offices for details on your nearest Service and Repair Centre.United KingdomABB Instrumentation LimitedTel: +44 (0)1480 475321Fax: +44 (0)1480 470787United States of AmericaABB Automation Inc.InstrumentationTel: +1 215-674-6000Fax: +1 215-674-7183ItalyABB Kent-Taylor SpATel: +39 (0) 344 58111Fax: +39 (0) 344 58278Client WarrantyPrior to installation, the equipment referred to in this manual must be stored in a clean, dry environment, in accordance with the Company's published specification. Periodic checks must be made on the equipment's condition.In the event of a failure under warranty, the following documentation must be provided as substantiation:1.A listing evidencing process operation and alarm logs at timeof failure.2.Copies of operating and maintenance records relating to thealleged faulty unit.The Company’s policy is one of contin u o u s prod u ct improvement and the right is reserved to modify the information contained herein without notice.© ABB 2000Printed in UK (10.00)ABB Instrumentation Ltd St. NeotsCambs.England, PE19 8EUTel: +44 (0) 1480 475321 Fax: +44 (0) 1480 217948ABB Instrumentation LtdAnalytical & Flow GroupStonehouse, Glos.England, GL10 3TATel: +44 (0) 1453 826661Fax: +44 (0) 1453 827856ABB Automation Inc.Instrumentation Division125 E. County Line RoadWarminster, PA 18974 USATel: +1 215-674-6000Fax: +1 215-674-7183IM/AP/AP–CMIssueAABB Instrumentation SpA22016 LennoComoItalyTel: +39 (0) 344 58111Fax: +39 (0) 344 58278。

A ct i v eC l a s s i c L i mi t e dR e pl a c e me n t e l e c t r o ni c s Re tr o f i r e l e c t r on i c sR ep l a c e m e n t f l o w m e t e r O b s o l e t e —A B B M E A SU R EM ENT & A N A LY TI C S | PRO DUC T G U I DEFlowmeter retrofit servicesEMF, Coriolis and Vortex upgradesCost-effective upgrades thatimprove performance and reliability Measurement made easyProduct lifecycle and retrofits explainedAfter years of solid performance from yourflowmeter there comes a time when you need to consider its future.ABB uses a lifecycle model to manage products from cradle to cradle. Products no longer in production move into the classic phase and availability of spare parts and services is guaranteed. Products move into the limited phase and spare parts and services may not all be available.Retrofit electronics upgrades are a cost-effective way of extending product life and accessing modern technology without replacing the complete flow meter system.Service offeringFor general purpose applications, ABB offers a range of retrofit DIY kits allowing you to upgrade your key flow meters.Electromagnetic flow• COPA-XE (FXE4000) to ProcessMaster (FET300)• MAG-XE (FXE4000) to ProcessMaster (FET300) • COPA-XM (FXM2000) to ProcessMaster (FET500• MAG-XM (FXM2000) to ProcessMaster (FET500) Coriolis• CoriolisMaster (FCB300) to CoriolisMaster (FCB400) • CoriolisMaster (FCH300) to CoriolisMaster (FCH400)Swirl• TRIOWIRL (FS4000) to SwirlMaster (FSS430 / 450) Vortex• TRIOWIRL (FV4000) to VortexMaster (FSV430 / 450)ABB can also perform upgrades, refurbishments and calibration services in certified workshops. Alternatively arrange for a field technician to perform the upgrade on-site.—Lifecycle management to ensure process continuityFlow servicesBenefits of ABB retrofitsMaximize capital investments Extend product life time.Service availabilityKeep your flowmeter modern and guarantee access to all spare parts and services.Warranty extensionWork performed by ABB provides 6 months warranty for complete system and 12 months for kit of parts.Modernize processesAccess state of art technology.Figure 1 EMF Before and after upgradeP G /S R R 250–E N R e v . B 01.2018—We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction,disclosure to third parties or utilization of its contents – in whole or in parts – isforbidden without prior written consent of ABB. ©ABB 2018All rights reserved—To find your local ABB contact, visit:/contactsFor more information visit:/measurement3KXS240011R2401—Scalable and flexible management of product and resources。

ABB流量计操作说明XE电磁流量计设置步骤:(1)通电后,按”#”,进入总菜单,按”▼”或”▲”翻页翻到” prog.protectionon”按住”▲”3秒钟进入,然后按”▼”或”▲”选择,”off”,再按住”▲”3秒确认.(2)按”▼”或”▲”翻到”cede number ****”, 按住”▲”3秒,输入:4000,再翻到”prog prot code 0”,输入4000.(3)按”▼”或”▲”翻到”submenu primary”,按住”▲”3秒进入,确认管径,CZ、CS的值,如管径不对应传感器,按“#”返回上一层菜单后,按”▼”或”▲”翻到重新出现“submenu primary”,进入后出现“metersize ***mm **in”按住”▲”3秒进入,在右下角出现“***mm**in_”,再按”▼”或”▲”修改为相应的口径。

然后按“▲”3秒确认。

(4)修改口径后,再按”▼”或”▲”翻到“store data in extomal EEPROM”按住”▲”3秒进入,出现“YES?”就再按住”▲”3秒进行确认保存。

(5)修改单位、量程,翻页翻到”submenu unit”,按住”▲”3秒进入,选择所需单位,按“#”返回上一层菜单,然后翻到“RANGE **** m3/h”,按”▼”或”▲”选择所需的量程,然后按”▲”3秒确认。

按“#”返回上一层菜单,再按”▼”或”▲”翻到“store data in extomal EEPROM”按住”▲”3秒进入,出现“YES?”就再按住”▲”3秒进行确认保存。

(6)按”▼”或”▲”翻页到”submenu detectore pipe”,空管检测,按住”▲”3秒进入,出现“detextore pipe on/off”将其改为“ON”,然后按”▼”翻到“Adiust Detertorepipe”空管检测调整。

按住”▲”3秒进入, 然后按”▼”或”▲”修改其数值“Adiust2000:,改为2000左右,然后按”▲”3秒确认。

—A B B M E A SU R EM ENT & A N A LY TI C S | PRO DUC T G U I DEProcessMaster electromagnetic flowmeterThe perfect fit for the oil and gas industryABB has responded to the oil andgas industry’s need for a rugged,reliable electromagnetic flowmeterMeasurement made easyExpertise in measurement technologyABB’s high pressure electromagnetic flowmeters are reliable, accurate and easily maintained. Customers worldwide have benefited from our application-oriented know-how and comprehensive service.To learn more about our extensive portfolio, visit /measurement.Designed specifically for oil and gas We have added a two-tier, high-pressure version to our comprehensive range of electro-magnetic ProcessMaster flowmeters. It is available with either weld neck or slip-on flanges with RTJ and raised face connections.There are differences between X-Ray and dye penetrant test. For weld neck design we offer both dye penetrant and X-Ray tests; for slip-on design we offer only dye penetrant test.A Slip-on flangeB Fillet weld (outside)C Fillet weld (inside)D Pipe Applications• Slurries such as drilling mud• Mixtures of fluids such as oil/water plus sand or produced water plus sand• Injection fluids including sand and chemical additives for lubrication and corrision prevention • Sludge or sludge-like wastewater from produced water treatment• Operating conditions such as high pressure or entrained gas in the fluid• Harsh environmental conditions such as heat, moisture or vibration and explosive or corrosiveatmospheresA Weld neck flangeB Butt weldC Pipe—ProcessMaster flowmeters – perfect for the oil and gas industryP G /F L O W /011–E N R e v . A 03.2020—We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction,disclosure to third parties or utilization of its contents – in whole or in parts – isforbidden without prior written consent of ABB. ©ABB 2018All rights reserved—ABB LimitedMeasurement & Analytics Oldends Lane, Stonehouse Gloucestershire, GL10 3TA, UK Tel: +44 (0)1453 826 661Email:**********************.com/flowRobust design for long lifeThe ProcessMaster flow sensor is designed for reliability in the demanding operating conditions found in oil and gas industry applications.• Long lasting sensor lining materials withstand abrasion and corrosion, resulting in longer sensor service life and minimal maintenance requirements• No additional pressure drop caused by protrusions into the pipe• Optional self-cleaning measuring electrodes prevent issues caused by build-up of deposits• Double sealed measuring electrodes minimize the risk of leakage and enhance reliability• Optional all-316 stainless steel construction for corrosive offshore atmosphere• Optional fully-welded sensor made from 316 material• Protection of internal sensor components against moisture and vibration with potted Ex sensorRange of certificates and test reports• 3.1 material certificates and/or PMI certificates • Certificates for non-destructive testing, X-Ray and/or dye penetration test• Welder qualifications and procedures •Hydrostic pressure testingFEP630 hIgh pressure magnetic flowmeter SpecificationAccuracyStandard: 0.4 % of rate Enhanced: 0.2 % of rate Nominal size range DN 25 to 400 (1 to 18 in)Nominal pressure ASME CL 600 to 2500Lining Hard rubber, ETFEElectrodesStainless steel, Hastelloy C Process connection Steel, stainless steel IP ratingIP67, IP68Fluid temperature –25 to 130 °C (–13 to 266 °F)Power supply 100 to 230 V AC, 24 V AC/DC I/OsCurrent, pulse status output Communication *HART protocol, PROFIBUS PA, FOUNDATION Fieldbus Sensor housing materialStainless steel 316Transmitter housing materialStainless steel Wetted parts material Option for NACE Ex approvals ATEX/IEC Zone 1.2, FM/cFM Cl1 Div.1, Cl1 Div.2Marine approval DNV VerificationScanMaster* AcknowledgementsHART is a registered trademark of FieldComm Group, Austin, Texas, USA.PROFIBUS is a registered trademark of PROFIBUS andPROFINET International (PI).FEP610 hIgh pressure magnetic flowmeter。

—ABB ME A SUREMENT & ANALY TICS | DATA SHEET Wellhead control applicationFlow computers & remote controllers2W E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN—OverviewMany of ABB Totalflow’s wellhead control applications can be used individually or together, to provide many forms of wellhead automation. With these applications, you are able to implement such things as:• Timer based and process based intermitting• Production control with overrides• Adaptive plunger lift control• Nominations control• Emergency shutdown control• Reservoir / well test control• Injection well control• Simple math/logic with user operators• Complex math/logic using IEC61131Many of ABB Totalflow’s wellhead control schemes are implemented in two standard applications:• Valve control• Plunger liftAfter many years and thousands of wells, these applications have proven to provide a robust and mature base from which solutions can be implemented, often without change.ABB Totalflow continues to adapt these applications and, if needed, can also adapt them to meet your requirements. Other types of custom math and control logic can be accommodated using:• User operators• IEC61131 control language —Valve controlThis application fundamentally provides automatic feedback control of Differential Pressure (DP), Static Pressure (SP), or Flow Rate for the purpose of positioning a control valve to maintain a desired value.Additionally, other parameters (such as differential pressure and static pressure) can be monitored for override conditions. If override conditions are met the controller will maintain the override value until the override condition clears, after which the controller will revert to the primary control scheme. This feature can be used, for example, to control a well’s production rate, as well as to help maintain pressure entering the gathering system. It can also automatically shut-in a well when a compressor goes down and then bring the well back on when the compressor starts back up.Through configuration options it is also possible to intermit a well based either on simple timers or based on more dynamic measurements of differential and static pressure.It is also possible to halt the control algorithm and manually step the valve in either direction. The valve can be moved in small increments or can be instructed to ramp the valve to it’s full open or full closed position.W E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN3—Controller algorithmThe control algorithm is best described as a ‘Single Speed Floating Algorithm’. This algorithm provides integral action based on:• The process variable’s difference from set point (error).• The process variable’s range of control (span).• The total possible valve travel time or (gain).• The controller output is computed and applied anytime the (error) term is outside a user defined dead band.—Controller outputDigital valve actuatorA digital actuator, such as a stepper motor or an E/P actuator is interfaced to the XSeries/X core Valve Controller using two digital outputs and two digital inputs. The outputs are used to control the polarity and duration of the control signal. The inputs are used to detect valve stops. In this scheme, the computed outputs from the Controller are (1) duration and (2) direction. Voltage is applied to the valve actuator for the computed duration in either the open or close direction. This output results in valve movement. The output voltage duration and direction, and the resulting valve movement are such that the Process Variable is maintained at a pre-determined user defined value (Set point).Analog valve actuatorAn analog actuator, such as an I/P actuator is interfaced to the XSeries/X core Valve Controller using a 4-20 ma analog output. In this case, the analog output is used to control the percent open or close position of the valve.—Summary of featuresThe following are features provided with ABB Totalflow’s standard Valve Control Application:• Single Speed Floating Algorithm providing integral action feedback control of flow rate, differential or static pressure.• Continuous monitoring of override conditions for secondary control needs.• Manual control of valve.• Use of either two digital outputs or an analog output to interface to control valve actuator.• Appropriate valves and communication options can be powered from the same battery packs used for the XSeries/X core device.• Control of wellhead pressure using downstream static pressure by estimating pressure drop using Weymouth equation.• Intermitting logic based on either timers or dynamic inputs, such as differential pressure and static pressure.• All control features can be accessed either locally with PCCU32 or remotely with WinCCU, ABB’s SCADAvantage or TDS32 (non-ABB SCADA systems).• Valve Control is an option on all XSeries/X core productsby simply adding the appropriate TFIO module or I/O daughter card.4W E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN—Nomination applicationThe nomination application is used to deliver a specified amount of volume over a specified period of time. For example, if a delivery point is contracted to deliver an exact volume of gas over a month’s period of time, then nominations is used to ensure these targets are met.The nomination application is implemented in the XSeries/X core device. Once properly configured the application operates unattended, making sure your requirements are being met.The nomination application is implemented as a supervisory application, atop the valve control application. As such, the nomination application continuously feeds new flow rate set points to the valve control application in order to meet the nominated volume over the specified period of time.All the while, the valve control application is honoring overrides making sure to maintain the process variable at set point. Even if valve control needs to shut in a well, due to a down compressor, the system will attempt to make up the nominated volume automatically, when the compressor comes back on line.As shown here, there are three standard nomination periods.• Previous Period: Settings and results of the most recently completed nomination period.• Current Period: Settings and status of the currently active nomination period.• Next Period: Settings for the upcoming nomination period. All control features can be accessed either locally with PCCU32 or remotely with WinCCU, ABB’s SCADAvantageor TDS32 (other SCADA systems).—Plunger lift applicationPlunger lift is often used on wells exhibiting production drop-off from fluid build-up and has been shown to increase gas production and extend well life. In one sense, plunger lift logic is merely another form of intermittent logic. However, superior plunger logic has several common traits.• Monitors dynamic parameters (pressures, differential pressures, flow rates and plunger arrival time) in order to predict the optimum conditions for continuing to flow or continuing to shut-in the well.• Supports adaptive algorithms to dynamically tune the control system to each unique well, with minimal oversight and unattended operation.• Maintains data logger for engineering and operations analysis.• Can be configured and tuned either on-site using local user interfaces or off-site, using remote communications.• Is implemented in a software environment that can be readily adapted to new control algorithms as state-of-the art evolves.Plunger applications, as implemented in ABB Totalflow’s XSeries/X core products, have proven to exemplify all of these features. When integrated into ABB’s various host and SCADA systems, the user is provided a complete, turnkey solution empowering the user to monitor, control and optimize the whole reservoir.The plunger application software is implemented in theIEC61131 control language. This software environment allows for rapid and accurate modification of the control algorithm, if the need should arise.Plunger logic is an option on all XSeries/X core products by simply adding the appropriate TFIO module or I/O daughter card and downloading the appropriate plunger application.W E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN5—Plunger optionsThe fundamental goal of plunger lift logic is to determine the optimum conditions for continuing to flow the well or continuing to shut-in the well by deciding when to transition from flowing to shut-in and vice versa.As depicted here, several options are available for deciding when to make these state transitions. Some of these options, and their associated step change criteria, can be automatically adapted by the plunger application in order to achieve the theoretical optimum arrival time of the plunger. Open Conditions (with optional tuning)• Timer expires¹• (Tubing-Line) > Limit• (Tubing-Casing) > LimitClose Conditions (with optional tuning)• Timer expires¹• Low DP timer expires• Low flow rate timer expires• (Tubing-Line) < Limit• (Tubing-Casing) < Limit• (Casing < Limit)The plunger application also supports many details beyond the scope of this overview; among which is the support for a blow valve feature that also has selectable options. Please contact Totalflow for a more detailed description of the plunger applications.¹Timers are implemented as fixed duration switches between open and close conditions, acting as override operations, and are not included in any tuning logic.6W E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN—Plunger and valve controlThe flow line control valve can be a simple open/close valve or it can be a modulating control valve. When using a simple open/close valve a standard TFIO DI/DO module is used forinterfacing to the valve.PCCU32 Tabular User Interface ScreenWhen using a modulating control valve a standard TFIO VCIO module is used for interfacing to the control valve. In this case, both the Plunger Application and the Valve Control application are integrated so that the Valve Control application provides automatic control of flow rate, differential pressure or static pressure when the well is flowing.When used in this way, the standard Valve Control andNominations features are also made available. Taken together with the Plunger Application this can provide a rich set of wellhead control schemes; all with simple, straightforward options to any XSeries/X coredevice.GUI from Plunger Application Plug-InSales Service SoftwareW E LLH E A D CO NTRO L A PPLI C ATI O N FLOW CO M P U TER S & RT US | DS/2101129-EN7—Plunger user interface optionsProperly configured, ABB Totalflow’s standard PCCU32 and Array WinCCU products support tabular user interfaces to theplunger application, as depicted here.An optional WinCCU plug-in is available that provides a moregraphical user interface, as depicted here. This application canbe used remotely via communications or locally at the site.In addition to these options, ABB’s SCADAvantage, a state-of-the-art, multi-protocol SCADA system can also be interfacedto these and other XSeries/X core applications. Plunger LiftPlug-In also supports reporting as depicted here.Additionally, using Totalflow’s DDE/OPC driver (TDS32)Report from Plunger Application Plug-Inor Totalflow’s Communications Library, other SCADA systemscan be interfaced to these and other XSeries/X coreapplications.—We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbidden without prior written consent of ABB.© Copyright 2018 ABB.All rights reserved.D S /2101129-E N R e v . A G 09.2018—ABB Inc.Measurement & AnalyticsQuotes:************************.com Orders:**********************.com Training:*************************.com Support:***********************.com +1 800 442 3097 (opt. 2)Main Office7051 Industrial Boulevard Bartlesville, OK 74006Ph: +1 918 338 4888/upstreamCalifornia Office 4300 Stine Road Suite 405-407Bakersfield, CA 93313 Ph: +1 661 833 2030 Kansas Office2705 Centennial Boulevard Liberal, KS 67901Ph: +1 620 626 4350Texas Office – Odessa 8007 East Business 20Odessa, TX 79765 Ph: +1 432 272 1173Texas Office – Houston 3700 West Sam Houston Parkway South, Suite 600 Houston, TX 77042Ph: +1 713 587 8000Texas Office – Pleasanton 150 Eagle Ford Road Pleasanton, TX 78064Ph: +1 830 569 8062。

ABB电磁流量计部分操作说明本说明针对FXE4000-DE47F类型的ABB电磁流量计测量过程中出现较大波动时修改励磁频率来稳定流量显示、出现较小波动或干扰时进行滤波及小信号切除的操作进行说明。

该电磁流量计为四线制接线,由DCS柜中的24VDC空开来提供电源,4~20mA电流信号接入DCS的FTA模拟输入无源端子。

电磁流量计表头(转换器键盘和显示器)说明::显示器为液晶屏显示,屏幕显示为双行的文本显示格式;在电源开启时,转换器的型号在第一行显示,软件版本在第二行显示;正常测量过程中,在第一行显示目前的流向(→F正向或←R反向)以及瞬时流量值(百分数或直接读取工程单位),在第二行显示目前的流向(→F正向或←R反向)以及累计流量。

转换器键盘,分按键和磁感键两种按键功能描述:C/CE 用于在操作模式与菜单之间切换STE P↓是两个箭头键中的一个,用于向前滚动菜单DATA↑是两个箭头键中的一个,用于向后滚动菜单,当该键长按3秒左右后,显示器闪烁表示进入该级菜单或子菜单,相当于ENTER功能。

图中“3 Sensers for magnet slick operation”所指示的为磁感键位置,并一一与按钮键功能对应,用ABB配用的磁感笔进行操作,该操作避免现场开表盖操作而达到现场防爆功能。

基本参数修改操作显示为正常时的流向、流量瞬时值百分数(可选择显示工程单位)、流量累计值。

按键C/CE进行切换界面切换后显示随机参数,按STE P↓OR DATA↑对参数进行选择。

选择“Prog.Protection”参数程序保护,正常时为程序保护开启(ON)不允许参数的修改,在进行参数修改前应选择程序保护关闭(OFF)。

显示为程序保护开启状态,长按DATA↑键待屏幕显示闪烁后,ON位置出现光标闪烁,表示可以对其进行选择修改,单按DATA↑OR STE P↓将保护改为OFF显示为程序保护关闭状态,可以对其他参数进行修改,以上操作为要进行参数修改时的基本操作过程。

ABB流量计操作说明

1、瞬时流量计波动大?

A、信号强度波动大;

B、本身测量流体波动大;

解决方法:调整好探头位置,提高信号强度(保持在3%以上)保证信号强度稳定,如本身流体波动大,则位置不好,重新选点,确保前10D后5D的工况要求。

2、外夹式流量计信号低?

管径过大,管道结垢严重,或选择安装方式不对。

解决方法:对于管径过大、结垢严重,建议采用插入式探头,或选择“Z”型安装方式。

3、插入式探头使用一段时间后信号降低?

可能探头发生偏移或探头表面水垢厚。

解决方法:重新调整探头位置,清冼探头发射面。

4、开机无显示

检查电源属性是否与仪表的额定值相对应,保险丝是否烧断,如以上问题不荐在,对建议把仪器发回我司由专业技术人员检查。

5、开机后仪表仅有背光,无任何字符显示

此情况一般为程序芯片失,建议把仪器发回我司进行处理。

6、仪表在现场强干扰下无法使用?

供电电源波动范围较大,周围有变频器或强磁场干扰,接地线不正确。

解决方法:给仪表提供稳定的供电电源,仪表安装远离变频器

和强磁场干扰,有良好的接地线。

公司简介我们是一家世界著名的仪器设计与制造公司,产品用于工业过程控制、流量测量、气体及液体分析以及环保应用。

作为过程自动化技术全球领袖ABB的一员,我们为世界各地的客户提供专业的应用知识、服务及支持。

我们的宗旨是团队精神、高质量的生产、先进的技术以及卓越的服务与支持。

公司产品的质量、精度及性能来自于一百多年的经验,以及对于最新技术的创新设计与持续开发。

电磁流量计1 安全 (2)1.1 电气安全 (2)1.2 标识 (2)1.3 健康和安全 (3)2 引言 (4)2.1 质量控制 (4)3 机械安装 (5)3.1 打开包装 (5)3.2 安装条件 (5)3.3 尺寸 (10)3.3.1变送器尺寸 (10)3.3.2传感器尺寸 (11)4 电气安装 (16)4.1 接地 (16)4.2 分体型变送器/传感器设置 (18)4.3 变送器接线 (19)4.4 电缆准备(分体型) (21)4.5 变送器/传感器电缆连接 (21)4.5.1 传感器电缆的连接及推荐的电缆长度 (22)4.5.2 环境保护 (23)4.6 输出连接 (24)4.6.1 频率输出 (24)4.6.2 报警输出 (25)4.6.3 电流输出(4-20 mA)— HART(FEX100)型 (25)4.6.4 RS485通讯— PROFIBUS(FEX1000-DP)型 (26)4.6.5 测试点功能使用 (26)4.7 电源连接 (27)4.7.1 AC电源 (27)4.7.2 DC(及低压AC)电源 (28)4.7.3 DIP跳线开关设置 (29)4.8 重新装配电子单元模块和表盖 (29)5 启动及操作 (31)5.1 菜单及参数导航 (31)5.2 启动屏幕 (32)5.3 安全级别及密码访问 (34)5.3.1 默认密码 (34)5.3.2 输入密码 (35)5.4 Easy Setup (36)6 WaterMaster流量测量性能 (37)6.1 WaterMaster流量测量性能– m3/h (37)6.2 WaterMaster流量测量性能– gal/min (39)7 规格—传感器 (41)8 规格—变送器 (43)1 安全本手册中的信息仅用于帮助我们的用户高效地使用本公司生产的设备。

Anytime, anywhere flow measurementABB’s AquaMaster electromagnetic flowmeter – the most versatile flowmeter availableIntroductionMeasuring potable water has been one of the biggest challenges for the water industry. The need to measure not only water flows but also leakage demands the highest levels of accuracy and availability. Added to this is the cost of installing the meters. Traditionally, installing more meters has meant having to build costly installation chambers, incurring costs in construction and in purchasing and maintaining additional ancillary equipment such as isolation valves and bypass lines.With the requirement to monitor flow as widely as possible, there is also an increased need for meters to be installed in remote locations. This brings its own challenges in terms of maintenance and data collection, as well as powering the devices where electronic meters are used.T h e ApplicationThe growing realization of the need to manage and conserve potable water supplies is leading to an expanding demand for metering in a growing range of applications. These include:– Leakage management– District metering (DMAs)– Clean water applications– Abstraction– Water distribution and network management– IrrigationThe need to ensure that large-scale users are accurately billed for the water they use has also seen a demand for equipment capable of delivering the highest levels of accuracy for use inrevenue management applications.Maximize measurement flexibility through anytime, anywhere access to flow dataMeasurement made easyAnytime, anywhere flow measurementABB’s AquaMaster electromagnetic flowmeter – the most versatile flowmeter availableThe ChallengeGiven the size of water distribution networks, it is inevitable that some losses will occur during transit. These have to be accurately accounted for in order to gain the best possible estimate of water flows. When it comes to the type of flowmeter used, the accuracy of the measurement can be affected by various factors, including age, overall condition and the flowmeter technology being employed.Deposits accumulating in the pipeline can also lead to reduced accuracy, as well as increasing the risk ofunder-reading.Where mechanical meters are used, there is also the added likelihood of deteriorating accuracy caused by wear and tear. This will affect not only the water balance but also the estimation of leakage within the distribution system.Whichever meter type is used, regular verification of accuracy will be needed to help minimize the impact of any errors, which can bring its own challenges. The need for mechanical meters to be periodically tested, recalibrated and repaired, for example, means that they have to be removed, requiring users either to replace the meter with a temporary device or cease measurement until the meter is refitted back intothe line.Ultrasonic flowmeters, which use ultrasonic sound waves to help ascertain the velocity and volume of water passing through the pipe, also suffer various drawbacks. Transit time meters in particular can struggle to handle flows with high levels of particulate matter, requiring a strainer to be fitted.Both transit time and Doppler meters can also be affected by velocity profile distortions, requiring from 10 to 40 upstream diameters, depending on the severity of the disturbance.The turndown of ultrasonic meters is also limited within an ideal range of 20:1 to 40:1. Ultrasonic meters can also be difficult to install and set up, especially where high accuracy is required.The SolutionModern buriable electromagnetic flowmeters are helping to transform the cost and practicality of installation. With no need for chambers or connected equipment, such flowmeters offer a simple, low cost solution that can be installed in virtually any location. The need for meters to be excavated and/or removed from the line is also being met by the arrival of in situ verification technologies.New possibilities in communicating with an installed meter have also been opened up with developments in GSM-SMS technology. When used with a flowmeter, this technology can be used to provide operators with immediate access to a host of flow data, eliminating the time, cost and potential errors traditionally associated with the manual collection of flowmeter information.Remote programming via SMS allows alterations to be made to the configuration of the instrument after installation, such as changing the power mode of the meter for the purposes of achieving enhanced performance. It enhances maintenance by offering performance and condition monitoring throughout the equipment’s life, with options such as programming the meter to send an alarm out in case of problems.The ability to install meters in remote areas is also being further expanded by developments in renewable power technologies. Enabling the meters to draw power from solar and/or wind, these technologies eliminate the need for either mains or battery power.2 PG/FLOW/007–EN | Anytime, anywhere flow measurement | ABB’s AquaMaster electromagnetic flowmeter – the most versatile flowmeter availableAnytime, anywhere flow measurement | ABB’s AquaMaster electromagnetic flowmeter – the most versatile flowmeter available | PG/FLOW/007–EN 3What can ABB offerABB’s AquaMaster 3 flowmeter is ideal for watermeasurement applications in virtually any location. The AquaMaster 3 offers a choice of mains and battery power options, as well as a renewable power version which can draw power from either solar or wind-powered energy sources.A simple DC (6-21V) connection can be hooked up to sources as small as a 5W solar panel or 60W equivalent wind supply. When coupled with its use of super capacitor energy storage technology, this feature totally eliminates the need for either mains or battery power.By using electrostatic energy storage, super capacitors offer a reliable alternative to conventional battery technology.Unlike batteries, which experience a chemical reaction when-ever energy is stored or discharged, super capacitors can withstand thousands of charging cycles with no degradation.In the mains-power mode, the SuperCap technologymaintains continuous measurement and alarms reporting via SMS for up to seven days in the event of a power failure. This is expanded to up to three weeks for the renewable power mode, with the SuperCap also acting to power the meter during the night.A new development in the battery-only version of the AquaMaster 3 is the additional option of high poweredbatteries, offering an extended operating life of up to 10 years in standard applications and improved performance in harsh applications above 45°C. Where the battery is utilized, the SuperCap enables the battery to be replaced without loss of logger contents.Installing the AquaMaster 3 is made simple by its use of ABB’s ‘fit and flow’ intelligent installation technology.With this technology, all aspects of an installation are stored within the sensor, including the site settings, calibration factors and any serial numbers usually required duringinstallation, maintenance or replacement. When connected to a transmitter, all of this information is automaticallyuploaded from the sensor, greatly simplifying the installation and commissioning process.As a further assurance of a robust metering regime andlifelong accuracy, ABB also offers users its CalMaster2 in situ verification service for the AquaMaster 3. Performed by an ABB service engineer, this service verifies a meter’s current operational status and also predicts any potential futurefaults. Users are issued with traditional calibration verification certificate complete with an uncertainty statement.ABB has extensive experience in the design, manufacture and lifelong support of electromagnetic flowmeters for water, wastewater and process applications.For more information, visit /measurement orcontact your nearest ABB representative.Fig. 1: ABB’s AquaMaster 3 flowmeter is ideal for water measurement application in virtually any locationP G /F L O W /007–E N 06.2014Contact usNoteWe reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or pos-sible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utili-zation of its contents - in whole or in parts – is forbidden without prior written consent of ABB.Copyright© 2014 ABB All rights reserved 3KX1234567ABB LimitedProcess Automation Oldends Lane StonehouseGloucestershire GL10 3TA UKTel: +44 (0)1453 826661Fax: +44 (0)1453 829671ABB Inc.Process Automation125 E. County Line Road Warminster PA 18974USA Tel: +1 215 674 6000Fax: +1 215 674 7183Watch thevideo Find out more。

ABB电磁流量计安装电气连接要求:1、不要将转换器直接暴露在阳光下,不必要场合下需加遮蔽罩。

2、不要安装在有剧烈振动场合,有必要时在测量管左右两边加支撑件,振动允许程度低于 2.2G即20-50HZ范围内。

3、注意仪表铭牌上给出的电源电压和频率的要求。

4、不要将电源电缆线横跨或迂绕在置换接线盒上。

5、保护接地线必须连接到信号转换器接线盒的对应端子上。

传感器在管线上的安装要求:1、安装地点和位置可按照需要选择。

但是,二只电极的轴线必须大致在水平方向上。

2、传感器可以倾斜或垂直安装。

(不管采用何种形式的安装,都要求测量管内保证充满被测介质,不能有非满管或有气泡聚集在测量管中的现象。

3、流动方向(按传感器上的箭头所指的方向游动正方向)4、由于传感器的法兰与外壳之间的距离有限,连接螺栓应从管道侧穿入。

所以,要求与传感器连接的管道法兰处有足够的空间。

5、震动。

若管道系统有较强的震动,要求在传感器二侧的管道上加支撑。

6、若被测介质严重污浊液体或容易在管道上结垢的液体,最好把传感器安装在旁通管道上,便于清洁。

7、若被测介质海水、原水,在管壁上容易沉积污泥或生长海生物,因此要求对传感器进行定期清洗。

(周期一般为2年一次)8、在传感器的上游侧和直管段长度不小于5D,下游侧不小于2D9、对于测量不同的液体的混合,传感器应安装在混合点的下游至少30D处,否则流量计的输出信号可能不稳定。

注意:传感器在安装时必须正确接地。

所使用的接地导线必须不传导任何其他干扰电压。

因此,不要把接地线与其他带电的电气设备连在一起。

仪表启动1、供电前必须按照传感器安装要求进行检查2、启动前所有参数已有厂方按用户要求设定完毕3、电源接通后流量计立即进入流量测量过程状态参数设置:ABB电磁流量计的菜单访问只能应用ABB提供的专门软件或用windows的超级终端功能进行,通过计算机的串行接口,将连接线接到流量计的接口上。