验厂流程手册(完整资料).doc

- 格式:doc

- 大小:55.00 KB

- 文档页数:6

工厂的质量体系要求1.0工厂设施和环境1.0.1 足够的照明上:生产,返工,加工,检验,包装及装载的区域?1.0.2 工厂保持清洁和有组织的生产,加工和包装领域。

1.0.3 工厂有单独的检验区与检验台并且适当的通风设备。

1.0.4 工厂已记录害虫/霉菌和湿度的控制程序,其中包括经常巡查。

(在公司内部或第三方)1.0.5 没有打破窗户或屋顶漏水,可能导致产品污染的观察审核期间。

1.0.6 工厂有金属检测单位。

1.0.7 (重要)工厂实行严格的尖锐工具控制程序,以防止剪刀、刀、刀片、碎玻璃和针头,以混合的产品。

1.0.8 工厂有后备电力供应。

“发电机”1.1机器校准和维护1.1.1 工厂的机器和设备是适合的生产需求的产品。

1.1.2 工厂有文件体系和程序,预定设备清洗和维修。

1.1.3工厂的机器和设备显示是清洁和良好的运行状态。

1.1.4 机器、设备和工具有适当的标识最后维修/校准日期及进度表。

1.1.5 机器、设备和工具需要维修时有标识以避免意外使用。

1.1.6 工厂有适当的,清洁的和有组织的存储区域的关键模具(即注射模)与标识的货架上。

1.1.7工厂有适当的文件和更新库存机器、工具、零部件和设备。

1.1.8工厂维修团队与合适的技术水平和设备,以履行必要的维修和校准的机器上。

2.0质量管理体系2.0.1 工厂建立适合产品和程序质量管理体系。

2.0.2 工人与主管所熟悉的这些质量的政策和目标。

2.0.3工厂已记录了顾客投诉体系,并记录召回计划。

2.0.4(重要)工厂QC团队是独立于生产部门。

2.0.5 生产管理和QC团队讨论和共同努力在解决质量问题/关注的问题。

(记录)2.0.6工厂有制度和程序能控制物理、化学和生物污染风险,可能会损害产品和人员。

2.0.7工厂进行风险评估,以识别危险化学品、原材料、工艺设备和工具。

3.0进料控制3.0.1物料实施先进先出(FIFO)体系3.0.2 工厂有对进仓原物料、配件和部件质量检验的程序。

工厂社会验厂流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!工厂社会验厂流程一、验厂准备阶段。

在正式开始验厂之前,需要进行充分的准备工作。

1. Scope适用范围ThisisappliedforQAinspectorsforfactorRevaluationofvendorforThe Children’s Place.该方法适用于QA验货员在对The Children’s Place供应商的生产工厂进行验厂中使用。

2. Objective目的ThisoutlinestheprocedureofperformingfactorRevaluationofvendorsupplRingproducttoT heChildren'sPlace.本手册概述了QA验货员在对为TheChildren'sPlace提供产品的工厂进行评估的程序。

3. ReferenceDocument参考资料TCPVendorGuide《供应商指南》4. Definition定义InitialEvaluation–priortostartingbusinesswithTheChildren'sPlace,anevaluationwillbedonetoensurethecompliancetothePolicRandStandardsforFactories&SuppliersasstatedinVendorGuide初评—在工厂承做TheChildren'sPlace产品以前,先要对其进行评估以检查其是否满足《供应商指南》中有关工厂和供应商的规定和标准。

SurveillanceAudit–isanon-goingaudittoensurethefactorRorsuppliercomplRingtotherequirements复评—是对工厂的后续评估以检查其是否遵守具体要求。

5. ResponsibilitRMerchandisingorSourcingteamisresponsibletopreparetheorderinformationinQAfolderforevaluationreference.Theinformationisincludedbutnotlimitedtoasfollows:跟单部门或采购部门应在QA资料夹中提供订货资料以供验货人员验厂时参考,这些资料应包括但不仅限于如下内容:∙factorRprofilesubmittedfromfactorR∙由工厂自己提供的工厂概况∙detailsoforderundernegotiation(e.g.stRle,orderquantitR,shipschedule)∙正在商讨中的订单的详细信息(如:款号、订货数量、走货安排)∙contactperson∙联系人QACo-ordinatorisresponsibletoconfirmthedateofevaluationandtravelarrangementwithfactorR.QA管理员负责同工厂联系以确定验厂日期和行程安排。

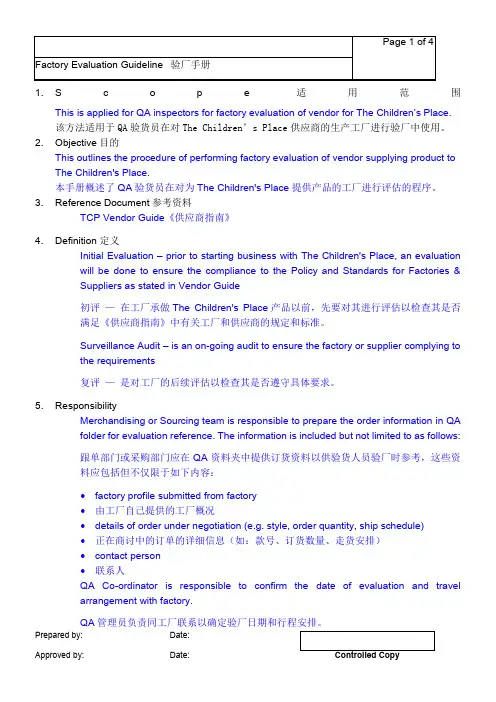

1. S c o p e适用范围This is applied for QA inspectors for factory evaluation of vendor for The Children’s Place.该方法适用于QA验货员在对The Children’s Place供应商的生产工厂进行验厂中使用。

2. Objective目的This outlines the procedure of performing factory evaluation of vendor supplying product to The Children's Place.本手册概述了QA验货员在对为The Children's Place提供产品的工厂进行评估的程序。

3. Reference Document参考资料TCP Vendor Guide《供应商指南》4. Definition定义Initial Evaluation – prior to starting business with The Children's Place, an evaluationwill be done to ensure the compliance to the Policy and Standards for Factories &Suppliers as stated in Vendor Guide初评—在工厂承做The Children's Place产品以前,先要对其进行评估以检查其是否满足《供应商指南》中有关工厂和供应商的规定和标准。

Surveillance Audit – is an on-going audit to ensure the factory or supplier complying tothe requirements复评—是对工厂的后续评估以检查其是否遵守具体要求。

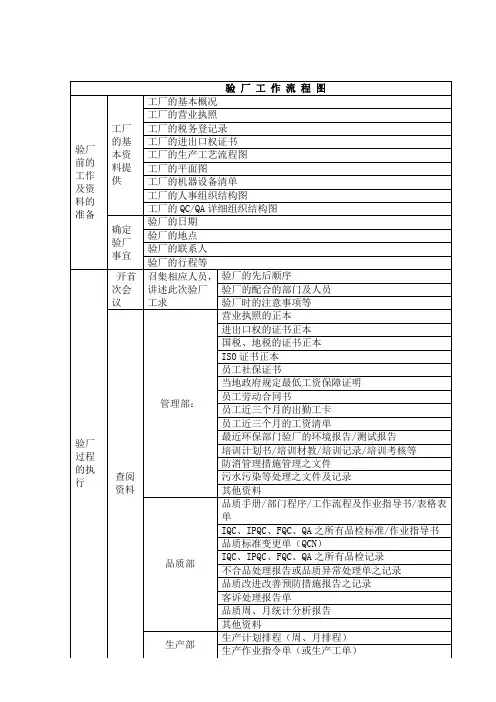

验厂的方法与流程查厂验厂的方法、程序步骤大致分为文件资料审查,现场审查,员工访谈三个步骤,不同的验厂员顺序,手法各不同,以Disney为例基本方法,程序步骤如下:一、首次会议1. 自我介绍及身份确认2. 如果工厂没有迪士尼的生产守则(COC),简要介绍守则的内容并提供他们一份3. 了解工厂的基本信息,如联系人、地址、电话、人数、生产产品类型、有无别名等4. 确保工厂了解审核的目的5. 简要介绍审核的流程6. 获取工厂平面图,确保巡视工厂范围内所有的区域7. 确保工厂有要求提供审核的文件在现场8. 要求管理层提供工人面谈用的地方9. 询问管理层10. 索取工厂用到所有化学品的清单二、工厂巡视1. 消防器材2. 火警警报器、应急灯、消防水带、消防栓、灭火器等☆定期对消防设备进行维护(一个月一次,不能过期)☆配备足够数量的灭火器材并合理放置(100㎡二个灭火器)2.消防安全☆逃生示意图贴在醒目位置,并以本国语言表未逃生方面(最小A3纸)☆紧急出口照明设施☆足够数量的疏散路径(最少需二个)☆清楚的标识出口并保持畅通(不得锁死、堵塞)☆组织疏散演习及消防安全方面的培训让员工清楚如何逃生,最近的消防警铃及灭火器的位置(半年一次,照片,记录,总结报告等)3.机器安全☆定期检查和维护☆装配防护装置(切割点、转动部位、传动部位)☆机械设备可以安全运行☆员工应接受机械安全操作的培训4.急救☆部门需配备有急救箱☆且药箱内必备药品齐全☆药品在有效期内☆车间需配急救人员(100人中需二人)5.个人防护用品(PPE)☆眼罩碎片、刨屑或危险化学品(烟雾)、焊工☆手套化学品☆耳塞每天持续8小时以上工和在85分贝的环境中工作6.环保(排污许可证)☆职业安全与健康☆空气质量☆化学品暴露限制☆危险品废物☆其他潜在危险(空气质量、废水处理、污染、回收)7.现场记录☆各类报表、签收要统一核对,且勿放罢于生产现场(切勿有星期天) ☆保持现场环境整洁☆勿张贴切加班表、处罚单☆检查各类机械保养记录8.洗手间:纸巾、洗手液配置,卫生情况工厂巡视目的:选择参与面谈的工人辨别有无可疑的童工对可疑的情况提出问题1) 工人不工作或加快工作速度2) 进出工厂的车辆检查生产流程:是否有分包三、文件审核目的:确保工厂运作的合法性;确保工厂符合当地法律及守则的要求 文件清单工卡或考勤记录(过去十二个月)工资表(过去十二个月)人事花名册及员工个人档案劳动合同社会保险收据、花名册及合格证明文件等工商营业执照消防检查报告或合格证明文件消防演习记录、紧急疏散计划及工伤记录等环保证明文件厂规或员工手册ZF有关当地最低工资规定文件设备安全许可证(如电梯使用许可证,、厨房卫生许可证等)特种工人上岗证(如电梯工、电工、厨工卫生许可证等)当地劳动局关于延长加班之批文未成年工体检及劳动局登记记录厂房平面图童工求证1) 在工厂巡视过程中挑选看起来很小的员工2) 在人事档案里抽查3) 挑选25名工人访谈4) 在面谈过程中,根据人事档案交*检查存有不一致的信息5) 当发现童工时(现时或历史性)必须登记工人的工号、姓名、出生年月、入厂日期四、工人面谈面谈的目的1) 从工人层面了解工厂的实际运作2) 获取其他过程无法得到的信息以及考察文件的一致性3) 对异常的区域进行更深入的了解面谈问卷(EIQ)面谈工人人数=工厂总人数的25%,但不超过25名工人扩大访谈人数1) 发现的违规情况需要更深入的了解,如家庭工作、虚假账本等2) 工人的身份证明文件和工人实际回答有出入时挑选程序1.50%的工人在工厂巡视过程中挑选1) 年轻工人2) 从所有部门挑选3) 如果条件允许,应该性别比例等同,种族等同4) 危险岗位工人2.50%的工人从工资表、工卡和文件审核中挑选1) 加班超时的工人2) 低工资的工人3) 青少年工人4) 老工人3.不公开1) 面谈必须在管理人员不在场的情况下进行2) 一对一面谈,不能分组面谈4.保密性1) 参与面谈的工人必须被告知所有的访谈内容均为保密2) 反映问题的工人名字不能在报告上出现5.面谈技巧1) 友善――这使得工人放松和敞开胸怀2) EIQ作为指引,但不局限面谈的问题3) 不同的国家对工人的问题不同,如洪都拉斯重点是童工、墨西哥重点是怀孕测试、中国是加班时间、土耳其是有无供祈祷的地方五、末次会议1. 告知管理层审核已经完成2. 归还借用供审核的文件3. 感谢他们对审核工资的支持和合作4. 解释所发现的问题、解答工厂的疑问以及书写改善计划确认报告(CAPAR)5. 教育并提供改善的最佳运作指引,帮助工厂达到守则的要求现场:消防安全与卫生1).消防演习①.要保留工厂消防演习记录,宿舍消防演习记录,最少每半年一次,记录应包括文字,照片,特别是总结报告(一般验厂员都要)②.要保留消防培训记录,记录包括培训时间,地点,培训内容,参加人员等2).消防设施①消防器材应有标识,如在灭火器或消防栓上喷”灭火器”等红色标识②灭火和消防栓应有消防部门或具有同等资格的部门签签发的年审合格证,通常有合格证或出厂合格证就可以,但要注意其有效期是维修日期或出厂日期开始一年当地消防门每年检查的合格证明文件.③消防栓要加封条,封条写上日期加盖工厂公章④灭火器和消防栓应定期检查,并做记录.⑤灭火器类型应选用ABC型,不要选用单纯的一种⑥手提式灭火器不能直接放在地上,应设置在挂钩,拖架或灭火器箱内,其顶部不超过1.5米,其底部离地面高度不宜小于0.15米.⑦消防栓或挂灭火器的地方,应用红色画出一个隔离区,隔离区内严禁堆放物.3).疏散通道,安全出口标志,应急灯①厂房,宿舍每层安全出口的数目不应少于2个,每个安全出口要保持畅通,应装应急灯.②每层楼梯间应安装应急灯③厂房,宿舍每层楼应有清晰的疏散路线图,图上应清楚标明安全出口,逃生方向,和看图所在位置.④生产车间,仓库应以黄色通道线把生产区域与通道分画出来,通道上还应标示逃生方向箭头.4).防爆灯仓库照明应使用防爆灯。

工厂检验程序法国XX集团Carrefour验厂Carrefour的成功在于精细、科学的管理,主要表现在6个方面:选址的科学化,强大的商品管理机构,强大的电脑支持功能,简洁的组织结构、经营理念及高效现场管理,完整的企业文化和强烈的防损意识。

XX与普美德斯合并,1999年销售额达789.7多亿美元,居世界第二,欧洲第一。

到2000年底,XX在国外店铺数比沃尔玛国外店铺还多。

XX的成功在于精细、科学的管理,主要表现在6个方面:选址的科学化,强大的商品管理机构,强大的电脑支持功能,简洁的组织结构、经营理念及高效现场管理,完整的企业文化和强烈的防损意识。

1需建立与本地医院签定医疗垃圾回收合同2建立医院回收的医疗垃圾记录3药箱内保持药品清单,建立急救的领用记录和制度4保安处应建立进入工厂的化学品机器设备的安全检查记录5对全体员工的培训6员工代表的选取7压力宣传品都需要提供检测证明,包括压力表容器,安全阀等二,Carrefour验厂流程1,首次会议:①介绍审核的目的方法时间安排工作分工等。

②提出需要审核的文件和资料清单③解释工人访谈的方法和要求④回答工厂代表提出的疑问2,工厂参观:①了解工厂基本情况,厂房、人数、宿舍等②熟悉路线,了解重点4,文件和记录检查:①所要求的各种文件资料②检查12个月的记录,最后3个月必须符合验厂的要求4,现场检查:①包括生产车间、仓库、宿舍饭堂、洗手间、门卫、医疗室等。

②重点关注三大原则③了解生产情况,现场记录工人活动④若有需要,可能拍照5,工人访谈:①随机抽取②年龄可疑③工厂代表不得参加,单独房间进行④可能是一对一,也可能是一对一组 6,末次会议:①出具临时报告,决定是否推荐②10天出具正式报告③感谢厂方配合④回答工厂提出的疑问三,Carrefourta文卷:1最低工资标准,每月工资发放日,最低工资标准应符合当地政府规定的最低工资标准水平,工资的发放形式。

2与每一个员工签定劳动合同3为员工交纳综合保险四,通过Carrefour验厂的好处:1建立符合国际要求的管理体系,可得到国际认可增加与知名品牌正面竞争的能力2促使消费者对产品建立正面情感3稳固与采购商的合作,并拓宽新市场,为长期的发展奠定坚实的基础4提升管理系统,改善与员工的关系,从而提高生产力从而提高利润5)最小化潜在的商业风险比如工伤乃至工亡,法律诉讼或者是失去订单(6)开发新市场和客户:有社会责任的公司将从竞争对手中脱颖而出Carrefour验厂文件清单工资表(过去十二个月)人事花名册及员工个人档案劳动合同社会保险收据、花名册及合格证明文件等工商营业执照消防检查报告或合格证明文件消防演习记录、紧急疏散计划及工伤记录等环保证明文件厂规或员工手册政府有关当地最低工资规定文件设备安全许可证(如电梯使用许可证、厨房卫生许可证等)特种工人上岗(如电梯工、电工、厨工卫生许可证等)当地劳动局关于延长加班之批文未成年工体检及劳动局登记记录厂房平面图其它文件(视乎审核情况所需)Carrefour质量验厂文件资料清单1. 营业执照 ;2. 质量体系认证证书 ;3. 组织架构图 ;4. 质量手册 ;5. 程序文件;6. 质量体系内审计划;7. 质量体系内审记录:1)内审员资格证书;2)首末次会议 ;3)检查表 ;4)不符合项报告;5)内审报告8. 质量体系管理评审计划9. 质量体系管理评审记录: 1)管理评审会议记录;2)管理评审报告;3)决议事项的跟进记录10. 主要生产设备清单;11. 设备保养计划 ;12. 设备保养记录;13. 仪器清单 ;14. 仪器校准计划 ;15. 仪器校准记录: 1)外校报告 ;2)内校人员资格证书 3)内校规程;4)内校报告16. 年度培训计划17. 培训记录 :1)签到表;2)测试卷18. 品管人员岗前资质认定资料(培训及测试记录;19. 新产品设计开发资料 :1)产品规格书;2) BOM表(BOM);3)安规认证证书;4)样品检测报告5)试产记录 ;6)试产评估报告 ;7)作业指导书 ;8)检验标准 ;9) FMEA分析资料 ;10)产品质量控制计划(QC工程图。

验厂资料步骤:一、整理人事档案、确定验厂名单1.将上次的验厂人员名单找出来,把已离职的人员剔出来。

填写《辞职报告》,填写时间不得为周六或周日,一般选择在月底办理手续。

由人事部人员签字:同意月底办理手续。

2.将实际的人事名单与验厂的名单相对照,找出可以参加验厂的人员名单,根据人员名单在实际的人事档案中选择新增人员,要求:本人有效期内的居民身份证、照片、年满十八周岁,凡不符合以上三个要求的均不得参加验厂。

填写人事资料和合同。

3.查看各部门人员,是否有部门变动,如有员工更换部门,则在花名册和考勤资料上更换部门,更换时间定为每月第一个工作日。

4.确定好人员名单后,制做新的《员工花名册》。

5.填写新增人员的人事登记表和劳动合同。

在实际的人事档案里找到身份证复印件和照片。

填写好后按部门分发下,要求本人签名。

核对人员数量,以免漏填或漏交。

6.将签好名的人事登记表和劳动合同进行盖章:“公司章”“法人代表章”。

7.做好以上工作,将人事资料重新整理,将离职人员的登记表和合同拿出来,放到离职人员的文件袋内,将新增人员按工号夹到人事档案里。

拿花名册与人事资料进行核对,查看是否有遗漏和重复,发现不对及时改正。

二、做全体员工的考勤刷卡记录1.根据《辞职报告》在人事资料里做好离职记录,离职日期为离职当月最后一个工作日,离职理由为辞工或辞职。

2.根据新增人员名单按部门添加人员资料,需要工号、姓名、入厂日期相关信息。

同时对新增的人员进行考勤资料的设定:输入考勤卡卡号,并制定班次(办公室、后勤部、所有仓库、包装车间、缝头车间手工、定型车间、包纱车间均为长白班,单针、双针、电脑缝头车间除少部分管理工作人员(车间主任、班长、统计、质检、杂工)为长白班外,其他员工均为二班倒,平均各班的人数,分甲乙两个班次)。

3.根据部门变动的记录在考勤软件里做好部门变动,同时对考勤资料进行更换当前部门工作的班次。

4.核对好考勤人数与花名册后,即可开始生成考勤数据。

验工厂流程详细步骤下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!验厂流程详细步骤。

1. 准备。

了解客户要求和验厂标准。

准备验厂所需资料,如工厂简介、质量管理体系文件等。

工厂验厂流程工厂验厂是指购买商对生产厂家进行的一种审核和评估,以确保厂家符合相关的法律法规和客户的要求。

工厂验厂流程是一项非常重要的工作,它可以有效地帮助购买商了解厂家的生产能力、质量管理体系以及对员工和环境的关注程度。

下面将详细介绍工厂验厂的流程。

首先,购买商需要与厂家进行预审。

预审是工厂验厂的第一步,购买商需要向厂家提供验厂的相关要求和标准,以确保厂家了解验厂的具体内容和要求。

在预审阶段,购买商可以要求厂家提供相关的资质证明、生产设备、员工人数、工厂面积等信息,以便对厂家进行初步的评估。

接下来是现场审核。

现场审核是工厂验厂的核心环节,购买商需要派遣专业的验厂人员前往厂家进行实地的审核工作。

在现场审核中,验厂人员将对厂家的生产车间、生产设备、原材料采购、生产工艺、产品质量控制、员工福利、环境保护等方面进行全面的检查和评估。

通过现场审核,购买商可以全面了解厂家的生产情况,确保厂家符合相关的法律法规和客户的要求。

除了现场审核,购买商还需要对厂家的文件资料进行审查。

文件资料审查是工厂验厂流程中的重要环节,购买商可以要求厂家提供相关的质量管理体系文件、员工培训记录、环境保护措施文件等,以便对厂家的管理水平进行评估。

通过文件资料审查,购买商可以了解厂家的管理体系是否健全,是否符合相关的标准和要求。

最后是验厂报告的编写。

在完成现场审核和文件资料审查后,购买商需要对验厂结果进行总结和分析,编写验厂报告。

验厂报告是对厂家生产能力、质量管理体系以及对员工和环境的关注程度的一种评估,它将成为购买商决定是否与厂家合作的重要依据。

因此,编写验厂报告需要客观、准确地反映厂家的真实情况,为购买商提供可靠的参考。

总之,工厂验厂流程是一项复杂而又重要的工作,它可以帮助购买商了解厂家的真实情况,确保产品的质量和生产的合法合规。

购买商在进行工厂验厂时,需要严格按照流程要求进行,确保每个环节都得到充分的关注和评估,以便为合作决策提供可靠的依据。

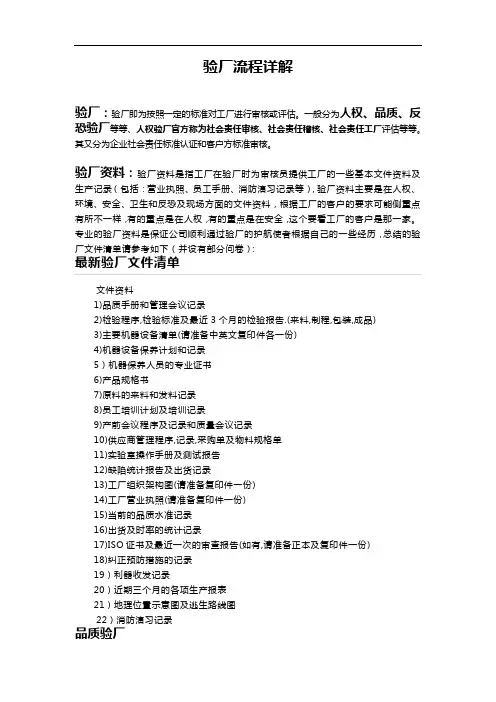

验厂流程详解验厂:验厂即为按照一定的标准对工厂进行审核或评估。

一般分为人权、品质、反恐验厂等等、人权验厂官方称为社会责任审核、社会责任稽核、社会责任工厂评估等等。

其又分为企业社会责任标准认证和客户方标准审核。

验厂资料:验厂资料是指工厂在验厂时为审核员提供工厂的一些基本文件资料及生产记录(包括:营业执照、员工手册、消防演习记录等),验厂资料主要是在人权、环境、安全、卫生和反恐及现场方面的文件资料,根据工厂的客户的要求可能侧重点有所不一样,有的重点是在人权,有的重点是在安全,这个要看工厂的客户是那一家。

专业的验厂资料是保证公司顺利通过验厂的护航使者根据自己的一些经历,总结的验文件资料1)品质手册和管理会议记录2)检验程序,检验标准及最近3个月的检验报告.(来料,制程,包装,成品)3)主要机器设备清单(请准备中英文复印件各一份)4)机器设备保养计划和记录5)机器保养人员的专业证书6)产品规格书7)原料的来料和发料记录8)员工培训计划及培训记录9)产前会议程序及记录和质量会议记录10)供应商管理程序,记录,采购单及物料规格单11)实验室操作手册及测试报告12)缺陷统计报告及出货记录13)工厂组织架构图(请准备复印件一份)14)工厂营业执照(请准备复印件一份)15)当前的品质水准记录16)出货及时率的统计记录17)ISO证书及最近一次的审查报告(如有,请准备正本及复印件一份)18)纠正预防措施的记录19)利器收发记录20)近期三个月的各项生产报表21)地理位置示意图及逃生路线图22)消防演习记录品质验厂又称质量验厂或生产能力评估,是指以某采购商的品质标准对工厂进行审核。

其标准往往不是“通用标准”这一点区别于体系认证。

这种验厂相对社会责任验厂和反恐验厂,出现的频率并不高。

且审核难度也小于社会责任验厂。

以沃尔玛的FCCA为例说明:沃尔玛(Wal-mart)新推行的FCCA验厂全称为:Factory Capability & Capacity Assessment,即工厂产量及能力评估,其目的是审核工厂的产量及生成能力是否符合沃尔玛的产能和质量要求,其主要内容包括以下几个方面:1、Factory Facilities and Environment工厂设施和环境2、Machine Calibration and Maintenance机器校准和维护3、Quality Management System质量管理体系4、Incoming Materials Control来料控制5、Process and Production Control过程和生产控制6、In-House Lab-Testing内部实验室测试7、Final inspection最终检验重要问题点1、公司的合法性:客人通过对公司营业执照、税收登记证、消防走火图等文件数据的查看以证实该公司是否合法及安全。

验厂流程详细步骤1. 预备阶段- 客户与供应商确定验厂的时间和地点。

- 客户将验厂标准和要求传达给供应商。

- 供应商了解和整理自身情况,准备相关资料和文件。

- 确定验厂所需的人员和资源。

2. 验厂前调查- 验厂机构进行现场调查,了解供应商的基本情况。

- 调查包括企业规模、生产能力、管理体系、劳动力使用情况、环境保护、安全生产等方面。

- 调查结果为验厂做准备,可以确定进行何种类型的验厂(如社会责任验厂、质量管理体系验厂等)。

3. 验厂准备- 供应商提供所需的相关资料和文件,包括企业注册证书、生产许可证、员工工作合同、工资支付记录等。

- 进行内部整改,并建立相关管理体系,确保公司符合验厂要求。

4. 实地考察- 验厂机构安排验厂专员进行实地考察。

- 验厂专员按照验厂标准和要求,对供应商的生产现场、劳动力使用情况、环境保护、安全生产等进行检查。

- 验厂专员与供应商的管理人员和工人进行交流和访谈,了解他们对工作环境和公司管理的评价和反馈。

5. 验厂报告- 报告包括供应商的情况介绍、实地考察结果、存在的问题和建议的改进措施。

- 如果供应商符合验厂要求,验厂机构将颁发验厂证书。

6. 整改和跟踪- 如果验厂报告中存在问题,供应商需进行整改。

- 整改内容包括解决存在的问题、改进管理体系、提高生产工艺和质量控制等方面。

- 验厂机构会对供应商进行跟踪,确保整改措施的有效性和实施情况。

7. 审核和认证- 认证证书有效期一般为一年,供应商需要定期进行回访和维护认证。

以上是一般验厂流程的详细步骤,具体流程可以依据不同的验厂标准和要求进行调整。

制造验厂流程详细步骤一、验厂前的准备。

要验厂啦,可不能马虎哦。

先得把文件资料都整理好呢。

像员工的档案,从入职合同到考勤记录,一个都不能少。

这些就像是士兵的“身份证明”,得整整齐齐的。

还有生产记录,啥时候进的原材料,啥时候开始生产,生产过程中的检测报告,都得规规矩矩地放好。

环境也很重要呀。

厂房里打扫得干干净净的,那些机器设备摆放得整整齐齐。

不能到处乱糟糟的,不然人家一进来就觉得管理不行呢。

安全设施也要检查好,灭火器有没有过期,安全通道有没有被堵住,这些都是小细节,但是很关键的哦。

二、验厂当天的应对。

验厂的人来了,可别紧张。

就像迎接客人一样,热情点。

他们要是问员工问题呢,咱就跟员工提前说好,实事求是地回答就好啦。

要是问到一些不太好回答的,也别慌,慢慢解释清楚就行。

陪着验厂人员在厂里走的时候,大方地介绍厂里的情况。

这个区域是做啥的,那台设备有啥功能,就像介绍自己家一样。

如果他们要看文件,就麻溜地拿出来给他们看。

要是发现啥小问题,也别遮遮掩掩的,诚恳地说咱们会尽快改进就好啦。

三、验厂后的跟进。

验厂结束啦,不管结果咋样,咱都得总结总结。

要是有问题被指出来了,那可就是改进的好机会呢。

列个清单,一项一项地去解决。

把解决的过程和结果都记录下来,下次再有验厂的时候,就可以自豪地说咱们已经改好啦。

如果验厂通过了呢,也别太得意忘形。

还是要继续保持,说不定下次验厂标准更高呢。

而且可以和验厂人员保持联系,有啥新的要求或者好的建议也能及时知道。

总之呢,制造验厂虽然有点麻烦,但就像一场考试,考好了能让咱厂发展得更好呢。

验厂工作流程

验厂工作流程主要包括以下几个步骤:

1. 申请和确认:由客户或中间商发起申请,向工厂申请对工厂验厂。

递交书面审核要求,客户同意此次审核,并指定相关的审核机构。

2. 审核准备:工厂向审核机构支付相关的费用,审核公司向工厂发出审核问卷和确认函,工厂填写后回传。

审核公司根据工厂回复的审核问卷制定审核计划,包括审核员、审核日期的安排。

3. 现场审核:在指定的审核日期或审核通知期,审核公司审核员到被审核工厂实施此次审核。

审核过程包括首次会议、现场巡视、文件核对、员工访谈、末次会议等。

4. 审核完成:审核完成后,工厂会收到审核发现的问题点,进行改善。

以上信息仅供参考,具体流程和要求可能因客户和品牌而有所不同。

如有疑问,建议咨询专业验厂人员。

验厂全套资料,步骤

第一步:预约,第二步:确定验厂项目,厂内布局,公司内部文化、相关证照、生产资质;成功案例;第三步:营造欢迎气氛,欢迎横幅;第四步;接待!第五步;参观厂,设备,验相关证照,生产资质,认证;第6步:商谈沟通;解答对方的疑惑;或进行讲解;第7步,招待;第8步,欢送;---重要的是怎么让来的人,感觉舒服,当下的回扣之风,也是必然的程序;追问验厂来的人,一般和采购商是什么关系,能贿赂吗?嘿嘿追答你这不是直供,真供给客户,通过中间商,其实也一样,采购商做为中间商,他也非常希望能成交;采购商的目标,是赚取差价;能不能贿赂,要看验厂方的人;建议第一次不要贿赂,送点纪念品还可以,吃顿商务餐也是常理;送多了,有可能让对方反感;还有可能,你对对方没有了解、把握,让肉包子打狗,有去无回;你也可以根据对方的表现,评估对方,确定对方是一个大客户,而且,对方也有这意思,采取暗示;不要明白的表态;

1。

工厂社会验厂流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!工厂社会验厂流程一、验厂准备阶段。

在正式开始验厂之前,需要做好充分的准备工作。

【最新整理,下载后即可编辑】1.Scope适用范围This is applied for QA inspectors for factory evaluation of vendor for TheChildren’s Place.该方法适用于QA验货员在对The Children’s Place供应商的生产工厂进行验厂中使用。

2.Objective目的This outlines the procedure of performing factory evaluation of vendorsupplying product to The Children's Place.本手册概述了QA验货员在对为The Children's Place提供产品的工厂进行评估的程序。

3.Reference Document参考资料TCP Vendor Guide《供应商指南》4.Definition定义Initial Evaluation – prior to starting business with The Children's Place,an evaluation will be done to ensure the compliance to the Policy andStandards for Factories & Suppliers as stated in Vendor Guide初评—在工厂承做The Children's Place产品以前,先要对其进行评估以检查其是否满足《供应商指南》中有关工厂和供应商的规定和标准。

Surveillance Audit –is an on-going audit to ensure the factory orsupplier complying to the requirements复评—是对工厂的后续评估以检查其是否遵守具体要求。

5.ResponsibilityMerchandising or Sourcing team is responsible to prepare the orderinformation in QA folder for evaluation reference. The information isincluded but not limited to as follows:跟单部门或采购部门应在QA资料夹中提供订货资料以供验货人员验厂时参考,这些资料应包括但不仅限于如下内容:•factory profile submitted from factory由工厂自己提供的工厂概况•details of order under negotiation (e.g. style, order quantity, ship schedule)正在商讨中的订单的详细信息(如:款号、订货数量、走货安排)•contact person联系人•QA Co-ordinator is responsible to confirm the date of evaluation andtravel arrangement with factory.QA管理员负责同工厂联系以确定验厂日期和行程安排。

QA Inspector is responsible to conduct evaluation at factory. Upon thecompletion of evaluation, all findings should be reported andcommunicated with factory representative at closing meetingQA验货员负责在工厂进行验厂,并在完成检验后汇报检验结果并同工厂代表在后续的会议中交流情况。

6.Qualification and Training资格和培训On-job training will be provided to QA Inspector at the first month ofemployment. Performance will be evaluated by QA Manager. QAInspector should be qualified with acceptance evaluation prior toconducting factory evaluationQA验货员在入职的第一个月内将接受在职培训,并由QA经理评估其表现。

QA验货员在进行验厂前必须通过检验资格评估。

7.Procedure验货程序Preparation准备工作:Merchandising or Sourcing team will inform QA Co-ordinator thepossible period of factory evaluation跟单部门或采购部门负责告知QA管理员可能的验厂日期。

Upon the information from Merchandising / Sourcing team, QACo-ordinator will contact factory representative to confirm the date ofQA visit and travel arrangement从跟单部门或采购部门获悉验厂时间后,QA管理员将同工厂代表确认验厂日期并安排行程。

Merchandising team will prepare the QA folder and pass to QACo-ordinator every Friday the week prior to the date QA visit confirmed跟单部门负责准备QA资料夹并在QA验厂安排确定的前一周周五将其交给QA管理员。

During evaluation验厂期间:QA Inspector should evaluate the factory from appropriate means butnot limited to as follows:QA验货员应采用合适的方法对工厂进行评估,但方法并不局限于此,具体如下:•interview of factory management and/or workers与工厂管理人员和工人面谈。

•inspection of product and machinery检查工厂的产品和设备•factory tour察看工厂•verification of records available由相关记录可查Upon the fa ctory’s permission of taking photo at factory, it is recommended to take photo on the non-compliance of TCP’s requirements as evidence.如果工厂允许拍照,则需要对不满足TCP要求的工厂牌照以作为证明。

With reference to Factory Evaluation Report and Compliance Audit Checklist, the following areas of factory should be evaluated:按照验厂报告和监督审核报告要求,必须评估对工厂的下列项目进行检查:•facilities and machinery设备和机器•quality assurance system质量保证系统•pre-production quality control产前质量控制•in-line quality control中期质量控制•final inspection尾期验货•finishing and packing后整理和包装•handling of non-conforming items无关物品的处理•communication and document control沟通和文件管理•product quality产品质量•product safety practices产品安全措施•social compliance社会审计After evaluation验厂完成后:Complete the Factory Evaluation Report and Compliance Audit Checklist完成验厂报告和监督审查表Discuss the findings and observations with factory representative, and have them sign off as acknowledge of findings at sight同工厂代表就检验结果交流意见并让其签字表示认同当前的检验结果。

Corrective Action Plan should be submitted from factory for QA review within 1 week after the date of evaluation工厂在验厂完成后的一周内应象QA提交正确的整改方案以供复查。

Upon the acceptance of Corrective Action Plan, QA Co-ordinator will schedule the re-evaluation to be done within 2-8 weeks depending on the findings and actions needed在收到正确的整改方案以后,QA管理员将在2-8周内依据验厂结果和所需的整改措施来决定工厂对工厂进行再次评估。

If the factory is rated as “Un-certified” from evaluation, QA Inspector should notify the Merchandising and/or Sourcing team for further action如果工厂被认定为“不合格”,QA验货员应立即通知采购部门和跟单部门。

8.Records归档Factory Evaluation Report and Compliance Audit Checklist –originalcopy kept by QA Co-ordinator for 2 years at TCP office, copies tofactory representative, Merchandising and/or Sourcing team验厂报告和监督审查报告的原件将由QA管理员保存在TCP两年,同时将复印件交给工厂代表和跟单部门或采购部门。