主要原辅材料消耗情况表

- 格式:doc

- 大小:74.00 KB

- 文档页数:2

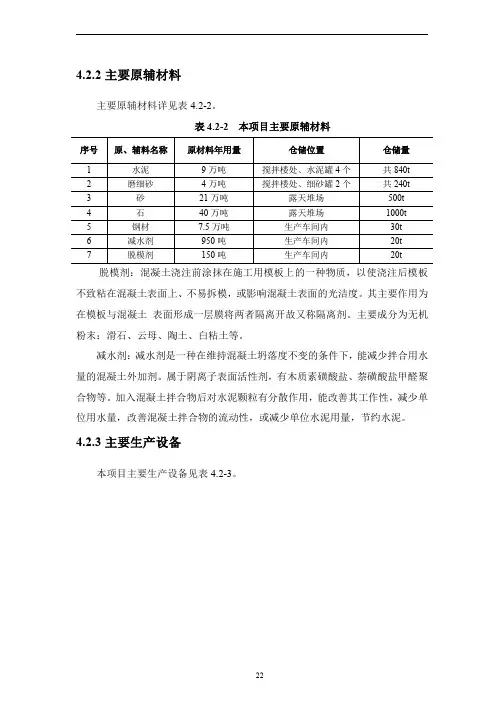

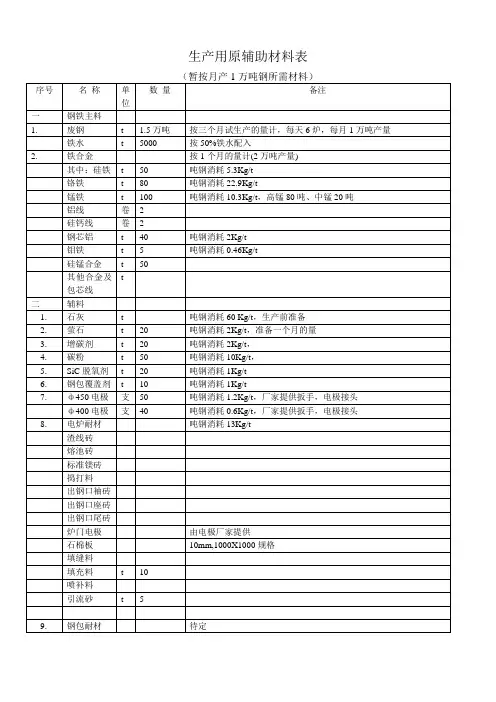

4.2.2主要原辅材料主要原辅材料详见表4.2-2。

表4.2-2本项目主要原辅材料序号原、辅料名称原材料年用量仓储位置仓储量1水泥9万吨搅拌楼处、水泥罐4个共840t 2磨细砂4万吨搅拌楼处、细砂罐2个共240t 3砂21万吨露天堆场500t 4石40万吨露天堆场1000t 5钢材7.5万吨生产车间内30t6减水剂950吨生产车间内20t7脱模剂150吨生产车间内20t脱模剂:混凝土浇注前涂抹在施工用模板上的一种物质,以使浇注后模板不致粘在混凝土表面上、不易拆模,或影响混凝土表面的光洁度。

其主要作用为在模板与混凝土表面形成一层膜将两者隔离开故又称隔离剂。

主要成分为无机粉末:滑石、云母、陶土、白粘土等。

减水剂:减水剂是一种在维持混凝土坍落度不变的条件下,能减少拌合用水量的混凝土外加剂。

属于阴离子表面活性剂,有木质素磺酸盐、萘磺酸盐甲醛聚合物等。

加入混凝土拌合物后对水泥颗粒有分散作用,能改善其工作性,减少单位用水量,改善混凝土拌合物的流动性,或减少单位水泥用量,节约水泥。

4.2.3主要生产设备本项目主要生产设备见表4.2-3。

表4.2-3项目主要生产设备一览表序号设备名称容量数量产地1搅拌机 2.5立方2珠海2起重机QE20.5、24.5、28.518浙江3离心机8组6江苏4蒸压釜Ø3.2*36.53江苏5装载机1山东6钢筋切断机2江苏7拔丝机1江苏8预应力张拉机2江苏9水泥罐210t410磨细砂罐210t24.2.4主要工艺流程本项目生产工艺流程见图4.2-3、图4.2-4。

图4.2-3管桩生产线工艺流程**以上环节均产生噪声,故不在工艺流程图上一一标注。

图4.2-4方桩生产线工艺流程**以上环节均产生噪声,故不在工艺流程图上一一标注。

方桩与管桩的工艺不同在于取消了离心及蒸压养护环节。

工艺说明:①物料输送、计量:砂子、碎石经皮带输送至搅拌楼料仓区经计量送入搅拌机;水泥*、磨细砂*分别由水泥罐、磨细砂罐从密闭管道、密闭电子计量称量后直接送入搅拌机内;减水剂、水分别由各自的水箱经计量泵入搅拌机内。

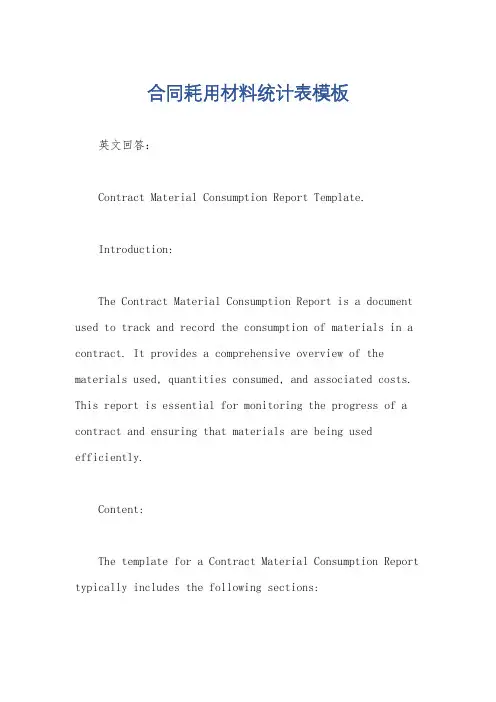

合同耗用材料统计表模板英文回答:Contract Material Consumption Report Template.Introduction:The Contract Material Consumption Report Template is a useful tool for tracking and analyzing the usage of materials in a contract. It provides a comprehensive overview of the materials consumed, their quantities, and associated costs. This template is designed to assist in monitoring material usage, identifying any discrepancies, and ensuring efficient resource allocation.Components of the Template:1. Contract Details: This section includes information about the contract, such as the project name, contract number, and duration. It helps to establish a context forthe material consumption analysis.2. Material List: This section lists all the materials used in the contract. Each material entry includes details such as the material name, description, unit of measure, and unit cost. This information is crucial for accurately calculating the total cost of each material used.3. Consumption Data: This section captures the consumption data for each material. It includes columns for recording the quantity used, the date of consumption, and the associated cost. This data can be entered on a regular basis to keep track of the ongoing material usage.4. Summary and Analysis: This section provides a summary of the material consumption data. It includes the total quantity consumed, the total cost incurred, and any variations from the estimated consumption. This analysis helps in identifying any over or underutilization of materials and enables better decision-making for future contracts.Benefits of Using the Template:1. Cost Control: By tracking material consumption and associated costs, the template helps in controlling expenses and avoiding budget overruns. It enables theproject manager to identify any excessive material usageand take corrective measures.2. Resource Optimization: The template allows for the analysis of material consumption patterns, therebyfacilitating better resource allocation. By identifying trends and patterns, the project team can optimize the procurement and utilization of materials, leading to improved efficiency.3. Transparency and Accountability: The template promotes transparency and accountability by providing aclear record of material consumption. It helps in ensuring that the materials are used as per the contractrequirements and that any deviations are promptly addressed.4. Decision-Making Support: The template providesvaluable insights into material consumption, enabling informed decision-making. The analysis of consumption patterns can guide future procurement strategies and helpin negotiating better contracts with suppliers.Example:Let's consider a construction project where the contract involves the installation of electrical wiring. The Contract Material Consumption Report Template can be used to track the usage of electrical wires, connectors, and other related materials.In the Material List section, the template would include entries for different types of wires, connectors, and other associated materials. The consumption data section would capture the quantity of each material used, the dates of consumption, and the associated costs.Using the template, the project manager can monitor the material consumption on a regular basis. They can identify any discrepancies, such as excessive usage of wires orunexpected costs due to changes in specifications. This information can then be used to take corrective actions, such as revising the procurement strategy or adjusting the project timeline.中文回答:合同耗用材料统计表模板。

合同耗用材料统计表模板英文回答:Contract Material Consumption Report Template.Introduction:The Contract Material Consumption Report is a document used to track and record the consumption of materials in a contract. It provides a comprehensive overview of the materials used, quantities consumed, and associated costs. This report is essential for monitoring the progress of a contract and ensuring that materials are being used efficiently.Content:The template for a Contract Material Consumption Report typically includes the following sections:1. Contract Details: This section includes information about the contract, such as the contract number, project name, and contract period. It provides a brief overview of the contract's scope and objectives.2. Material Details: This section lists all the materials that are being used in the contract. It includes the material name, code, unit of measurement, and cost per unit. Additionally, it may include information about the supplier or vendor from whom the materials are being procured.3. Consumption Details: This section records the quantity of materials consumed during a specific period. It includes the date of consumption, quantity consumed, and the corresponding cost. This information helps in tracking the material usage and identifying any discrepancies or inefficiencies.4. Cost Analysis: This section provides a summary of the total cost incurred for each material. It includes the total quantity consumed, unit cost, and the total cost.This analysis helps in evaluating the overall expenditureon materials and identifying opportunities for cost savings.5. Remarks: This section allows for any additional comments or observations related to the material consumption. It can be used to highlight any issues or challenges faced during the contract period or suggest improvements for future contracts.Example:To illustrate the usage of the Contract Material Consumption Report, let's consider a construction project. The contract involves building a commercial complex, and various materials such as cement, steel, bricks, and electrical fittings are required.In the Material Details section, the report will list these materials along with their respective codes, units of measurement (e.g., bags, tons, pieces, etc.), and costs per unit. For instance, cement may be listed as Material Code: CMT001, Unit: Bags, and Cost per Bag: $10.In the Consumption Details section, the report will record the quantity of each material consumed during a specific period. For example, if 100 bags of cement were used on a particular day, the report will include the date, quantity consumed (100 bags), and the corresponding cost ($1000).The Cost Analysis section will summarize the total cost incurred for each material. It will calculate the total quantity consumed (e.g., 500 bags of cement), multiply itby the unit cost ($10 per bag), and provide the total cost ($5000). This analysis will help in evaluating the overall expenditure on materials and identifying any cost variances.The Remarks section can be used to note any issues or observations related to material consumption. For instance, if there were delays in material delivery or if there were instances of material wastage, it can be mentioned here.中文回答:合同耗用材料统计表模板。

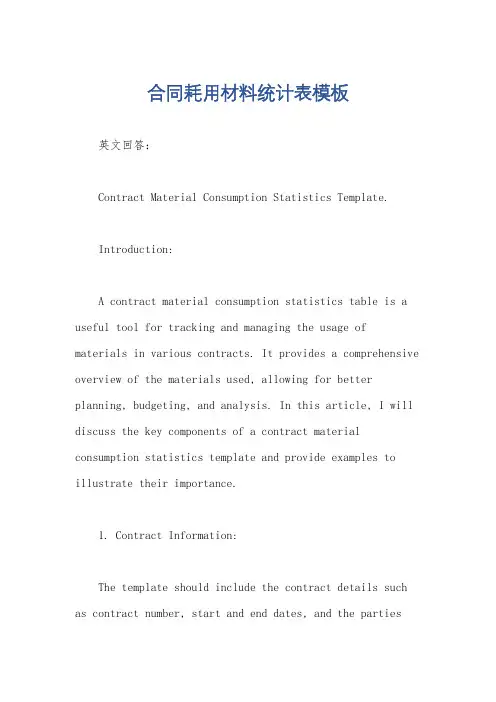

合同耗用材料统计表模板英文回答:Contract Material Consumption Statistics Template.Introduction:A contract material consumption statistics table is a useful tool for tracking and managing the usage of materials in various contracts. It provides a comprehensive overview of the materials used, allowing for better planning, budgeting, and analysis. In this article, I will discuss the key components of a contract material consumption statistics template and provide examples to illustrate their importance.1. Contract Information:The template should include the contract details such as contract number, start and end dates, and the partiesinvolved. This information helps in identifying which contract the materials are associated with and provides a reference for future analysis.Example: Let's say I am working on a construction project and have multiple contracts with different suppliers. The template will have separate sections for each contract, clearly indicating the contract number,start and end dates, and the names of the suppliers.2. Material Details:The template should have a section to record thedetails of the materials used, including the material name, quantity, unit of measurement, and cost. This information helps in understanding the consumption patterns and cost implications of different materials.Example: If I am managing a manufacturing contract, the template will have columns to enter the names of the materials used, such as steel, plastic, or rubber. I can then record the quantity of each material used in thecorresponding column and calculate the total cost based on the unit cost provided.3. Consumption Analysis:The template should include a section for analyzing the material consumption. This can be done by calculating the total quantity and cost of materials used for each contract, as well as the average consumption per unit or time period.Example: Let's say I have a contract for supplyingoffice stationery. The template will calculate the total quantity and cost of materials used, such as pens, papers, and staplers. It will also provide the average consumption per employee per month, allowing me to identify any excessive or insufficient usage.4. Variance Analysis:The template should include a section for variance analysis, comparing the actual material consumption withthe planned or budgeted consumption. This helps inidentifying any deviations and taking appropriate actions to control costs or improve efficiency.Example: If I have a contract for providing IT equipment, the template will compare the actual quantity and cost of materials used with the planned quantities and costs. If there is a significant variance, it may indicate issues such as overstocking or underutilization of resources, prompting me to investigate and make necessary adjustments.中文回答:合同耗用材料统计表模板。

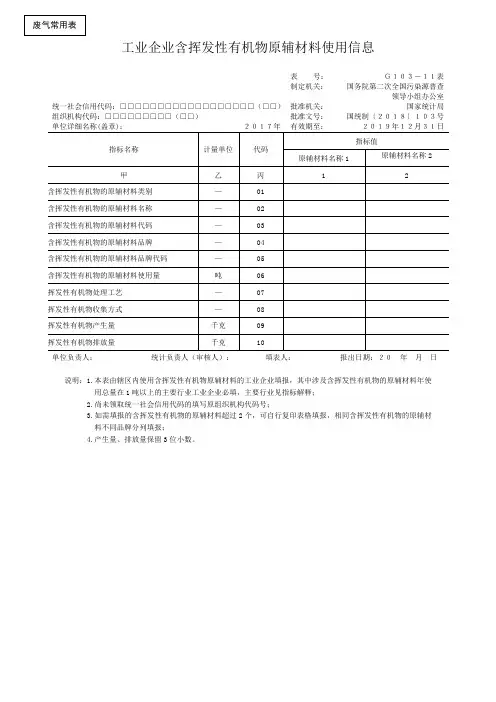

工业企业含挥发性有机物原辅材料使用信息单位负责人:统计负责人(审核人):填表人:报出日期:20年月日说明:1.本表由辖区内使用含挥发性有机物原辅材料的工业企业填报,其中涉及含挥发性有机物的原辅材料年使用总量在1吨以上的主要行业工业企业必填,主要行业见指标解释;2.尚未领取统一社会信用代码的填写原组织机构代码号;3.如需填报的含挥发性有机物的原辅材料超过2个,可自行复印表格填报,相同含挥发性有机物的原辅材料不同品牌分列填报;4.产生量、排放量保留3位小数。

工业企业其他废气治理与排放情况单位负责人:统计负责人(审核人):填表人:报出日期:20年月日说明:1.本表由辖区内有废气污染物产生与排放的工业企业填报;2.尚未领取统一社会信用代码的填写原组织机构代码号;3.普查对象若填报G103-1至G103-12中的一张或多张表后,仍有未包含的废气排放环节,须将未包含的废气情况填报在本表;或普查对象无G103-1至G103-12所涉及的排污环节、但有废气排放的,须填报本表;4.指标02、04、06、08、10、12的计量单位按照附录(四)工业行业污染核算用主要产品、原料、生产工艺分类目录填报;5.厂内移动源仅填报厂内自用,未在交管部门登记的机动车和机械;6.产生量、排放量保留3位小数。

指标解释《工业企业含挥发性有机物原辅材料使用信息》(G103-11表)以下表1内行业本报表必填。

表 1 填报含挥发性有机物原辅材料使用信息普查表的行业料的类别。

按照1.涂料,2.油墨,3.胶黏剂,4.稀释剂,5.清洗剂,6.溶剂,7.其他有机溶剂(包括涂布液、润版液、洗车水、助焊剂、除油剂等,请注明),分类填报类别名称。

含挥发性有机物的原辅材料名称及代码指普查对象使用的含有挥发性有机物的原辅材料的名称。

溶剂、清洗剂、稀释剂只需参考下表名称(包括但不限于),无需在普查表中明确具体名称。

可参照表2选择填报,如无可对应名称,则填入“其他”。

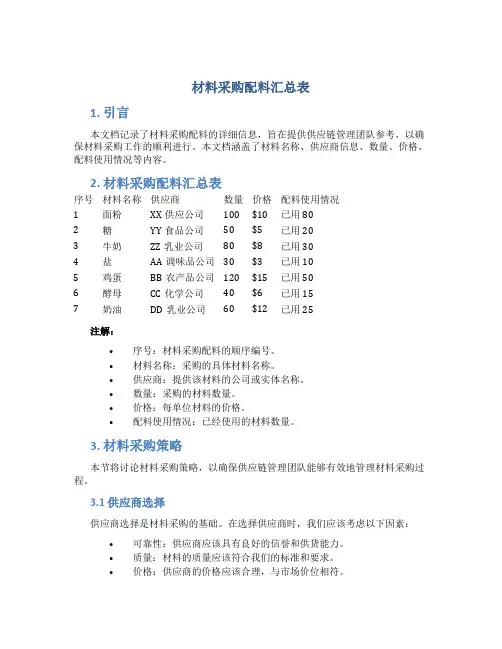

材料采购配料汇总表1. 引言本文档记录了材料采购配料的详细信息,旨在提供供应链管理团队参考,以确保材料采购工作的顺利进行。

本文档涵盖了材料名称、供应商信息、数量、价格、配料使用情况等内容。

2. 材料采购配料汇总表序号材料名称供应商数量价格配料使用情况1 面粉XX供应公司100 $10 已用802 糖YY食品公司50 $5 已用203 牛奶ZZ乳业公司80 $8 已用304 盐AA调味品公司30 $3 已用105 鸡蛋BB农产品公司120 $15 已用506 酵母CC化学公司40 $6 已用157 奶油DD乳业公司60 $12 已用25注解:•序号:材料采购配料的顺序编号。

•材料名称:采购的具体材料名称。

•供应商:提供该材料的公司或实体名称。

•数量:采购的材料数量。

•价格:每单位材料的价格。

•配料使用情况:已经使用的材料数量。

3. 材料采购策略本节将讨论材料采购策略,以确保供应链管理团队能够有效地管理材料采购过程。

3.1 供应商选择供应商选择是材料采购的基础。

在选择供应商时,我们应该考虑以下因素:•可靠性:供应商应该具有良好的信誉和供货能力。

•质量:材料的质量应该符合我们的标准和要求。

•价格:供应商的价格应该合理,与市场价位相符。

•服务:供应商应该提供及时的交货和良好的售后服务。

3.2 采购量控制为了控制成本和库存,我们需要合理地安排采购量。

在确定采购量时,我们应该考虑以下因素:•需求预测:根据产品销售预测和生产计划,预测材料的需求量。

•供应链周期:考虑供应链中的交货时间和生产周期,合理安排采购量和时间。

•库存控制:避免过多的库存积压,同时确保有足够的材料供应。

3.3 供应链协调为确保材料的及时交付,供应链各方应进行协调。

协调的重点包括:•信息共享:供应商和采购团队之间共享需求和供应信息,避免信息不对称。

•生产计划协调:与生产团队密切合作,确保采购与生产计划相一致。

•物流协调:管理物流过程,确保材料供应的及时和准确。

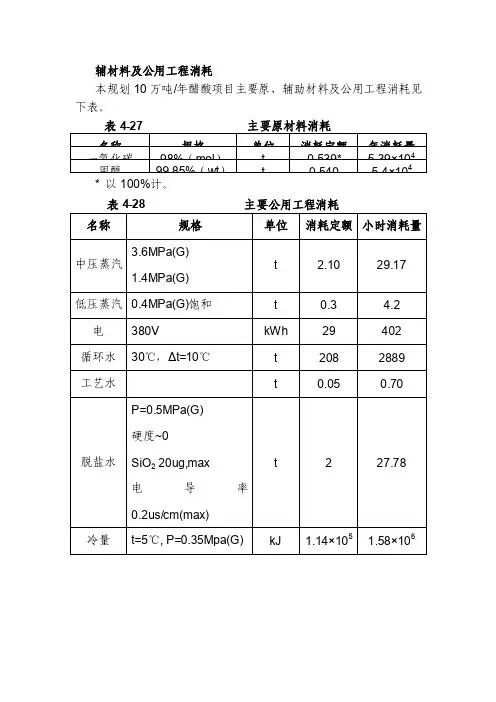

辅材料及公用工程消耗本规划10万吨/年醋酸项目主要原、辅助材料及公用工程消耗见下表。

* 以100%计。

十二、15万吨/年醋酸乙烯项目1. 项目概况醋酸乙烯,又名乙酸乙烯酯,简称VAc。

醋酸乙烯是一种重要的有机化工原料。

其化学结构中含有C=C不饱和双键,故极易发生聚合反应,通过自身聚合或与其它单体共聚,可以生成聚乙烯醇(PVA)、醋酸乙烯-乙烯共聚乳液(VAE)或共聚树脂(EVA)、聚醋酸乙烯(PVAC)、醋酸乙烯-氯乙烯共聚物、乙烯-乙烯醇共聚物(EVOH)等。

醋酸乙烯主要用途是合成聚醋酸乙烯,继而醇解得到聚乙烯醇(PVA)。

聚醋酸乙烯(PVAc)乳液和树脂主要用于胶粘剂、涂料、纸张涂层、纺织品加工、树脂胶等领域;聚乙烯醇则是生产维纶纤维的主要原料,并可用于胶粘剂、纺织浆料、纸张涂料、内墙涂料、精细化工和高吸水树脂等领域。

除自聚外,醋酸乙烯还能与其它单体进行二元或三元共聚,生产很多具有特殊性能的高分子合成材料,如乙烯-醋酸乙烯共聚物(EVA 和VAE)、氯乙烯-醋酸乙烯共聚物等,广泛用于发泡材、功能性棚膜、包装膜、热熔胶、电线电缆、玩具等生产领域。

随着科学技术的进步,新的醋酸乙烯应用领域还在不断拓展。

2. 市场分析(1)国外市场据ICIS统计,2008年全球醋酸乙烯生产能力达681万吨/年,主要集中在亚洲、北美和西欧。

按地区产能统计,亚太为336.4万吨/年,占49.4%;北美为206.3万吨/年,占30.3%;西欧为117.1万吨/年,占17.2%;其他地区占3.1%。

其中,中国醋酸乙烯的产能为146.1万吨/年,分别占亚太和全球产能的43.3%和21.5%。

在世界总产能中,82%以上采用乙烯法,17%采用乙炔法,其余为乙醛法。

美国是最大的生产国,其次为中国和日本。

美国还是世界最大的出口国,亚洲为最大的进口地区,其次是欧洲。

台湾大连化工在麦寮厂区兴建的第三座年产能35万吨/年醋酸乙烯工厂,已于2006 年建成投产,该厂落成后将成为世界最大的单一反应器的醋酸乙烯工厂。

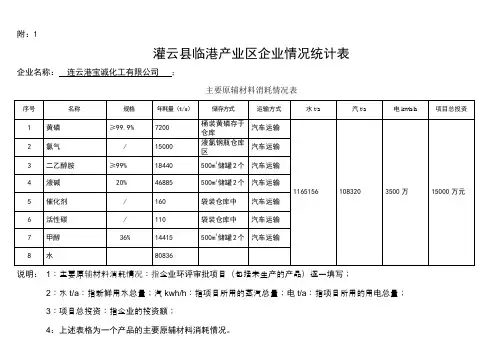

附:1

灌云县临港产业区企业情况统计表

企业名称:连云港宝诚化工有限公司;

主要原辅材料消耗情况表

说明:1:主要原辅材料消耗情况:指企业环评审批项目(包括未生产的产品)逐一填写;

2:水t/a:指新鲜用水总量;汽kwh/h:指项目所用的蒸汽总量;电t/a:指项目所用的用电总量;

3:项目总投资:指企业的投资额;

4:上述表格为一个产品的主要原辅材料消耗情况。

附:2

灌云县临港产业区企业情况统计表企业名称:连云港宝诚化工有限公司;

“三废”治理及排放情况一览表

说明:1:格不够,可以加;

2:其他特征污染物:环评批复后有;

3:危险废物:列出项目所产生的所有危险废物名称、总量等情况;

4:附2为企业“三废”治理及排放情况汇总表。

5:填好后,电子版发给我。

邮箱:*****************或发 QQ离线文件。

图6.1-1 施工流程及产污环节7.主要污染物产生及预计排放情况表7本项目噪声污染主要来源于机械设备运行时产生的噪声,其噪声值约为75~85dB(A),采取基础减振、消声、厂房隔声等措施减小对外环境的影响。

根据《环境影响评价技术导则声环境》(HJ/T2.4-2009)中推荐的模式,仅考虑厂房隔声及距离衰减对本项目噪声进行预测。

L(p2)=L(p1)-(TL+6)L(p3)=L(p2)-20lg(r3/r2)式中:L(p1)——室内受声点p1处的声级,dB(A);L(p2)——室外受声点p2处的声级,dB(A);L(p3)——室外受声点p3处的声级,dB(A);TL——隔墙隔声量,dB(A),取20;r3——声源至p3的距离,m;r2——声源至p2的距离,m;两个以上声源同时存在时,预测点总声压级采用以下公式:(3)预测结果厂界噪声预测结果见表8.7。

表8.7 拟建项目厂房厂界噪声预测结果单位:dB(A)预测点噪声源距场界距离(m)厂房隔声值dB(A)贡献值昼间夜间东厂界数控雕铣机14台,86.4dB(A) 10 20 60.4 /南厂界破碎机1台,注塑机1台,CNC钻床8台,83.3dB(A)2 20 57.3 /西厂界挤出造粒生产线2条,80dB(A) 2 20 54.0 /北厂界高速混合机2台、空压机1台,85.4dB(A)2 20 59.4 /拟建项目营运期为白班1班制生产,夜间不生产,经预测拟建项目厂界噪声均能够满足《工业企业场界环境噪声排放标准》(GB12348-2008)3类标准。

(4)敏感目标预测表8.8 环境保护目标受项目噪声影响预测结果单位:dB(A)敏感目标距场界距离(m)本底值预测值昼间夜间昼间夜间青山医院北侧,160m 48.1 42.1 48.2 42.1清明村安置小区南侧,90m 48.1 42.1 48.2 42.1本项目位于工业用地内,周边200m范围内的环境敏感保护目标为青山医院、清明安置8.环境影响分析表8凡涉及到十二种总量控制的污染物和特征污染物必须填写。

建设项目基本情况

一、主要产品方案及规模

1、产品方案

2、产品规格及技术要求

二、生产规模:

年产各类型混凝土砖万立方米

三.项目建设内容

各主要建筑物、构筑物一览表

四、主要生产设备

主要生产设备一览表

五、项目的总平面布局

项目平面布局方案:生产车间布置在用地范围,;办公室、员工宿舍、食堂布置在厂区;原材料堆场和成品堆码场主要布置在厂区交通组织:厂大门设在厂区临路,主要负责原料运输,成品运输,是车流的主要通道。

六、主要原辅材料消耗

表5 生产过程中原辅材料消耗情况一览表

七、项目的地理位置

东面临相距米

西面临相距米

南面临相距米

北面临相距米

八、供电是否有自备电源

九、给排水

给水:项目建设区的生产、生活(含消防)用水,主要来自于

排水:项目排水主要为生活废水,工艺废水,排入

十一、运输

十二、劳动定员及工作制度

a、劳动定员

该厂生产工人拟定为人,行管人员人,共人。

b、生产制度

年工作日:

生产班次:

生产方式:

十三、项目总投资及资金筹措

本新扩建工程总投资万元。

生产固定投资万元,流动资金万元,环保投资万元。

资

金来源

十四、项目所采取的环保措施

十五、建设进度

本项目已建成投产,属于补办环评,

主要技术经济指标

主要技术经济指标表

与本项目有关的原有污染情况及主要环境问题:一、原有污染情况

二、主要环境问题

一、工艺流程

工艺说明。

原辅材料节约措施情况汇报

近年来,我公司一直致力于提高生产效率,降低成本,实行节约型生产。

在原

辅材料使用方面,我们采取了一系列措施,取得了一定的成效。

现将具体情况进行汇报。

首先,我们加强了对原辅材料的管理和监控。

通过建立严格的原辅材料采购管

理制度,加强对供应商的审核和管理,确保原辅材料的质量和价格具有竞争力。

同时,我们还对原辅材料的库存进行了精细管理,避免因为过量采购而造成浪费。

其次,我们注重优化原辅材料的使用流程。

针对不同的生产工艺和产品要求,

我们对原辅材料的使用方法进行了调整和优化,确保在保证质量的前提下最大限度地减少原辅材料的消耗。

通过技术改进和工艺优化,我们成功地降低了原辅材料的使用量,提高了利用率。

此外,我们还积极推行废料回收再利用。

对于生产过程中产生的废料和副产品,我们进行了分类收集和处理,并通过技术手段进行再利用,减少了对新鲜原辅材料的需求。

这不仅有利于环保,还能有效地降低生产成本。

最后,我们加强了对员工的培训和管理,提高了员工对原辅材料节约利用的意识。

通过定期的培训和奖惩机制,我们鼓励员工积极参与到原辅材料节约工作中来,形成了全员参与的节约氛围。

总的来说,通过以上一系列措施的实施,我公司在原辅材料节约方面取得了一

定的成效。

但是,我们也清醒地意识到,原辅材料的节约利用是一个长期的工作,需要我们不断地进行改进和完善。

我们将继续加大力度,不断探索新的节约措施,为公司的可持续发展贡献力量。

附:1

灌云县临港产业区企业情况统计表

企业名称:连云港宝诚化工有限公司;

主要原辅材料消耗情况表

说明:1:主要原辅材料消耗情况:指企业环评审批项目(包括未生产的产品)逐一填写;

2:水t/a:指新鲜用水总量;汽kwh/h:指项目所用的蒸汽总量;电t/a:指项目所用的用电总量;

3:项目总投资:指企业的投资额;

4:上述表格为一个产品的主要原辅材料消耗情况。

附:2

灌云县临港产业区企业情况统计表企业名称:连云港宝诚化工有限公司;

“三废”治理及排放情况一览表

说明:1:格不够,可以加;

2:其他特征污染物:环评批复后有;

3:危险废物:列出项目所产生的所有危险废物名称、总量等情况;

4:附2为企业“三废”治理及排放情况汇总表。

5:填好后,电子版发给我。

邮箱:*****************或发 QQ离线文件。