QMS文件编写培训

- 格式:pptx

- 大小:427.95 KB

- 文档页数:32

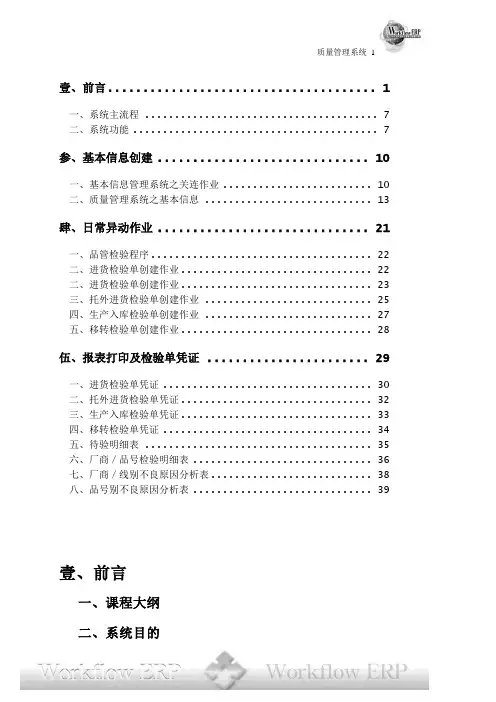

壹、前言一、课程大纲二、系统目的三、系统特色一、课程大纲(一) 、前言(二) 、质量管理之系统架构(三) 、基本信息创建(四) 、日常异动处理(五) 、品管报表介绍(六) 、课后测验及问卷二、系统目的近代工商企业竞争日益剧烈,商品与商品之间,常有剧烈的商业竞争。

为了确保产质量量符合标准,进而提高产质量,除对制造技术不断研究改进外,工厂操作的严格管制尤为重要。

通常在管制技术上有二个要求,一个是如何保持各种操作条件,及产质量量合乎规定的限度,另一个是如何减少损耗,提高效率。

鼎新质量管理系统乃是以统计数理分析为基础,应用在公司生产过程中,采购进货,生产入库,及托外进货的质量检验,其配合公司使用人员,管理人员的知识及经验,以数理的分析与客观的判断,谋求操作标准化,来提高生产效率及降低成本。

质量管理系统透过弹性参数设置,以符合不同行业,不同生产型态之品管要求,并与采购系统,工令/托外管理系统,应收 /应付管理系统搭配,以求达到全面整合的架构,且利用图形报表产出提供相关质量分析报表以提供质量改善参考,并以达到高质量要求为目标,让企业能在竞争激烈的环境中脱颖而出。

三、系统特色●提供采购/托外进料检验(),制程检验(),半成品检验(),制成品检验(),等相关检验程序功能。

●可针对不同品号定义不同检验项目,制程代号,检验水准,缺点等级,检验标准以配合生成检验单时可依不同检验项目生成检验信息。

●对于多厂、多车间线之质量管理作业型态亦可以适用。

●提供采购作业程序中,厂商进料交货暂收的信息登帐作业,并自动生成进料检验单可供品检人员检验处理。

●提供托外加工作业程序中,厂商进料交货暂收的信息登帐作业,并自动生成外包进料检验单可供品检人员检验处理。

●提供品管控制参数设置,105D 创建作业,料件检验项目创建作业提供进料检验单中,各料品之检验方式,抽样数量,及其允收水准…..等相关信息,以减少品检人员查表填单之工作。

●采购进料检验单若判定为允收或特采收料时,系统自动将检验信息结转至采购进货单将检验信息写入,以供相关部门处理,减少重复输入登帐的作业。

壹、前言 (1)一、系统主流程 (7)二、系统功能 (7)参、基本信息创建 (10)一、基本信息管理系统之关连作业 (10)二、质量管理系统之基本信息 (13)肆、日常异动作业 (21)一、品管检验程序 (22)二、进货检验单创建作业 (22)二、进货检验单创建作业 (23)三、托外进货检验单创建作业 (25)四、生产入库检验单创建作业 (27)五、移转检验单创建作业 (28)伍、报表打印及检验单凭证 (29)一、进货检验单凭证 (30)二、托外进货检验单凭证 (32)三、生产入库检验单凭证 (33)四、移转检验单凭证 (34)五、待验明细表 (35)六、厂商/品号检验明细表 (36)七、厂商/线别不良原因分析表 (38)八、品号别不良原因分析表 (39)壹、前言一、课程大纲二、系统目的三、系统特色一、课程大纲(一) 、前言(二) 、质量管理之系统架构(三) 、基本信息创建(四) 、日常异动处理(五) 、品管报表介绍(六) 、课后测验及问卷二、系统目的近代工商企业竞争日益剧烈,商品与商品之间,常有剧烈的商业竞争。

为了确保产质量量符合标准,进而提高产质量,除对制造技术不断研究改进外,工厂操作的严格管制尤为重要。

通常在管制技术上有二个要求,一个是如何保持各种操作条件,及产质量量合乎规定的限度,另一个是如何减少损耗,提高效率。

鼎新质量管理系统乃是以统计数理分析为基础,应用在公司生产过程中,采购进货,生产入库,及托外进货的质量检验,其配合公司使用人员,管理人员的知识及经验,以数理的分析与客观的判断,谋求操作标准化,来提高生产效率及降低成本。

质量管理系统透过弹性参数设置,以符合不同行业,不同生产型态之品管要求,并与采购系统,工令/托外管理系统,应收 /应付管理系统搭配,以求达到全面整合的架构,且利用图形报表产出提供相关质量分析报表以提供质量改善参考,并以达到高质量要求为目标,让企业能在竞争激烈的环境中脱颖而出。

qms相关培训计划1. IntroductionQuality Management System (QMS) plays a crucial role in ensuring the quality and efficiency of products and services within an organization. It encompasses the policies, processes, and procedures that are put in place to ensure that products and services meet the required standards and customer expectations. QMS training is essential for employees to understand the importance of quality, familiarize themselves with the QMS framework, and adhere to the established quality guidelines.This QMS training plan aims to provide a comprehensive overview of the key components of QMS, the importance of quality, and the role of employees in maintaining and improving the QMS. The training will be designed to cater to employees at different levels and departments within the organization, ensuring that everyone understands their responsibilities in upholding the QMS.2. Training ObjectivesThe objectives of the QMS training plan are as follows:- To familiarize employees with the concept of QMS and its importance in ensuring product and service quality- To provide an understanding of the key components of QMS, including policies, processes, and procedures- To equip employees with the necessary knowledge and skills to implement QMS requirements within their respective roles- To emphasize the role of employees in upholding and continuously improving the QMS- To ensure that employees are aware of quality standards, customer expectations, and the impact of QMS on business performance- To foster a culture of quality and continuous improvement within the organization3. Training ContentThe QMS training plan will cover the following key areas:- Introduction to Quality Management System: Understanding the concept of QMS, its purpose, and its significance in ensuring quality products and services- Key Components of QMS: Familiarizing employees with the different elements of QMS, including quality policies, objectives, processes, and procedures- QMS Documentation: Understanding the importance of documentation in QMS, including quality manuals, procedures, work instructions, and records- Roles and Responsibilities: Clarifying the roles and responsibilities of employees in upholding the QMS, including top management, quality assurance personnel, and frontline staff- Implementing QMS: Providing guidance on implementing QMS requirements within different departments and processes- Quality Standards and Customer Expectations: Educating employees about quality standards, customer requirements, and the impact of QMS on customer satisfaction- Continuous Improvement: Emphasizing the need for continuous improvement in QMS, including the use of quality tools and techniques to identify and address areas for enhancement- Audit and Compliance: Providing an overview of QMS audits, compliance requirements, and the importance of adhering to QMS guidelines4. Training MethodsThe QMS training will be delivered through a combination of methods to cater to different learning styles and preferences. The training methods will include:- Classroom Sessions: Instructor-led sessions to deliver theoretical knowledge and facilitate discussions on QMS concepts and requirements- Workshops: Interactive workshops to engage employees in practical activities related to implementing QMS within their roles and processes- Case Studies: Real-life case studies to demonstrate the impact of QMS on business performance and customer satisfaction- e-Learning Modules: Online modules to provide flexibility and accessibility for employees to learn at their own pace- Role-Playing and Simulations: Scenario-based activities to enable employees to apply QMS concepts in real-life situations- Q&A Sessions: Opportunities for employees to ask questions, seek clarification, and participate in discussions related to QMS5. Training ScheduleThe QMS training plan will be rolled out in phases to ensure effective implementation and engagement. The training schedule will be as follows:- Phase 1: Executive Management Briefing (1 day)- Phase 2: Departmental Workshops and Training (2-3 days per department)- Phase 3: Refresher and Continuous Improvement Training (1 day)The training will be conducted at regular intervals to accommodate new employees, changes in QMS requirements, and the need for ongoing reinforcement of QMS principles.6. Training ResourcesTo facilitate the QMS training, the following resources will be allocated:- Trainers: Qualified trainers with expertise in QMS and training facilitation- Training Materials: Printed materials, presentations, e-learning modules, and case studies - Training Venue: Suitable training facilities, including classrooms, workshops, and computer labs- Tools and Equipment: Audio-visual equipment, training aids, and simulation tools- Evaluation and Feedback Forms: Tools for assessing the effectiveness of the training and gathering feedback from participants7. Training EvaluationThe effectiveness of the QMS training will be evaluated through the following methods:- Knowledge Assessments: Pre- and post-training assessments to measure the knowledge gained by participants- Participant Feedback: Surveys and feedback forms to gather input on the training content, delivery, and relevance to employees' roles- Observations and Demonstrations: Monitoring employees' application of QMS principles in their roles and processes- Business Performance Metrics: Analyzing business performance indicators related to quality, customer satisfaction, and process efficiency before and after the trainingThe evaluation findings will be used to identify areas for improvement in the training and to measure the impact of the training on employees' understanding and application of QMS principles.8. ConclusionThe QMS training plan is designed to equip employees with the necessary knowledge and skills to understand, implement, and uphold the QMS within their roles and processes. By fostering a culture of quality and continuous improvement, the training aims to enhance the organization's ability to deliver high-quality products and services that meet customerexpectations and drive business performance. The training will be continually reviewed and updated to address changing QMS requirements and employee development needs.。

QMS质量管理系统培训手册1. 质量管理系统介绍1.1 什么是QMSQMS全称为质量管理系统,是指对组织的各个部门和流程进行管理和控制,以确保产品或服务满足客户要求和法规要求的体系。

1.2 QMS的好处•强化质量意识,提高产品或服务质量•降低成本,提高效率•提高客户满意度,增加市场竞争力•提高组织的信誉和声誉•降低质量事故发生几率和承担风险2. QMS的要素2.1 质量方针和质量目标组织的质量方针应当明确表述组织对质量的承诺,满足客户及法规要求,并通过持续改进来提高组织生产效率。

质量目标则是衡量质量系统效果的具体指标。

2.2 质量手册和程序文件质量手册应当描述组织的质量政策,程序文件则应当为执行质量政策提供具体步骤和操作指南。

2.3 资源管理•人力资源:为组织配备合适的质量管理人才和技术人员。

•物理资源:包括生产工艺,用于生产、测试和检验的设施、设备和环境条件等。

•财务资源:为质量管理体系提供必要的经费,包括人员培训、设备采购、质量改进等费用。

2.4 测量、分析和持续改进•测量:衡量质量目标的实现情况,有助于评估和改进组织绩效。

•分析:对数据进行分析,找到问题的原因,并提出改进措施。

•持续改进:建立和维护一个持续改进的体系。

识别问题、找到原因、解决问题,并对改进结果进行评估。

3. QMS培训3.1 培训内容•QMS 概述:学习质量管理的基本理论和知识,了解QMS的对组织的优势。

•质量手册和程序文件:深入了解质量手册和程序文件的具体要求和作用。

•测试、检验和监控:掌握各种测试、检验和监控方法。

•测量、分析和持续改进:了解如何使用各种工具来支持持续改进。

3.2 培训形式•班级培训:由专业培训机构、顾问或内部培训师组织培训班级。

•在线培训:利用互联网进行培训,通过学习平台或在线会议系统进行培训。

3.3 培训效果评估•学员满意度评估:采用问卷调查等方式,了解学员对培训质量的满意度。

•成果效益评估:通过绩效评估来评估培训课程和教学质量,包括检查组织和个人是否具有培训的目标和技能。