STICK包装线需求说明

- 格式:pdf

- 大小:282.77 KB

- 文档页数:12

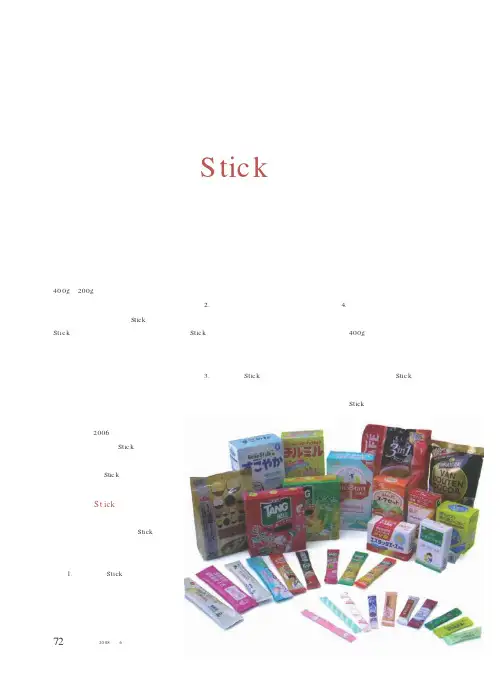

食品包装食品安全导刊年第6期□本刊记者房慧实习记者卜庆婧个性化,Stick 包装广受追捧——访仅一包装设备有限公司市场部经理许彩萍容易起皱的问题,可给消费者带来更高档、美观、精致的感官体验。

4.有效延长保质期,对于奶粉等产品,需要充入氮气来保证产品的品质,而以往400g 软包装一旦开启,其中的氮气就会完全散失,且每次重复开启包装都会对剩余产品的质量造成影响(如袋口的二次污染等),而Stick 包装则不会出现类似问题,同等质量的奶粉由多条独立的Stick 包装组成,消费者可根据实固体饮料市场在经历了玻璃瓶、400g 或200g 软袋包装、三边封或四边封方形袋等包装形式后,又出现了一种新概念——长条状包装(Stick )。

如今,Stick 包装已成为最流行的包装形式之一,在乳制品、固体饮料、药品等行业中的使用量不断增加,尤其为固体饮料中的高端产品所普遍采用,如雀巢咖啡、麦斯威尔咖啡、卡夫果珍等产品都已开始使用了该包装。

在包装行业历经二十年风雨的仅一包装设备有限公司顺应市场需求,于2006年与日本东阳合作,成功推出了高性能的Stick 包装机,本刊邀请到仅一公司市场部经理许彩萍请她讲述研制生产Stick 包装的心得。

优点诸多,St ick 包装成固体食品包装领域新秀与传统软袋包装相比,Stick 包装的诸多优点促进了其在市场的推广及使用量上的增长。

1.容易携带,Stick 包装因其造型小巧,可装进钱包、口袋或运动包中,便于携带,易于储存,其独特的双易撕口开口方式更是随时都可进行开包,方便食用,也给了产品独有的不可复制的防伪标识。

2.使用更方便,倾倒更彻底,不易造成粉末散落,与从前的方形袋相比,Stick 包装易于倾倒,绝不会将细粉类物料如咖啡或果汁粉等的粉末散落到杯子外面。

3.不易变形,Stick 包装产品通常放置在纸盒外包装内,所以避免了在展示、出售过程中软袋包装形状不规则、722008际需要逐条开启,不会因一条Stick包装的开启而影响其他的质量,从而延长了此类产品的保质期。

GEA Aquarius Be DifferentGEA AQUARIUS · 3 Be differentLine SolutionsGEA is widely recognized for its GEA Aquarius lollipop forming, cooling and wrapping machines, but less well-known for its capability to supply complete and upgradable lines. They are categorized according to capacity and lollipop type, and range from simple confi gurations to full-custom.The lines can also include control, interfacing, transport and monitoring. Technology Center WeertThe total package includes confi guration advice, training at the GEA Campus, global customer support and the opportunity to test and evaluate solutionsin the completely renewed GEA Technology Center in Weert, the Netherlands. Here you will not only see the latest lollipop- and vertical form-fi ll-seal machines in operation, but you can also experience the latest technologies such as label-on-stick, label-on-fi lm as well as state of the art stand-up confectionery pouches. GEA’s engineers and applications specialists are at your disposal to talk about your opportunities and requirements. You are most welcome to visit our production site and technology center in Weert.GEA is one of the largest suppliers of process technology for the food industry and a wide range of other industries.As an international technology group, the company focuses on world-leading engineering, equipment and componentsfor sophisticated production processes.GEA AQUARIUS · 5GEA Aquarius off ers you as a single source,versatility with our standard line solutions, startingfrom forming to cooling and wrapping of ball, fl atand three dimensional lollipop shapes. Startingspeeds from 300 up to 2100 lollipops per minute.These lines include our renowned machines such as the GEA Aquarius FlexFormer machines with best of its class GEA Aquarius PopCooler range for cooling. For highest performance and output our reliable wrapping machines the GEA Aquarius BunchWrapperand / or TwistWrapper machines can be included inthis solution. To complete the line solution we can off erour PopFeeder system which automatically feeds thelollipops towards the wrapping machines.GEA Aquarius Line Solutions Ball LollipopBall Lollipop lines according to capacityBall Lollipop Start-up lineUp to 550 lollipops per minute (upgradable)Ball Lollipop Medium capacity lineUp to 950 lollipops per minute Ball Lollipop Standard capacity lineUp to 1350 lollipops per minute (upgradable)Ball Lollipop High capacity lineUp to 2100 lollipops per minutePopCoolerGEA Ball Lollipop Line SolutionsPopFeeder systemBunchWrapperTwistWrapperFlexFormerSmartPackerolllipop Line Solution GEA Flat Lolllipop Line SolutionRUBRIC · 7 We make it easy goingBENEFITS GEA AQUARIUS FLATLOLLIPOP SOLUTIONS• Forming and wrapping in one single machine• Easy change forming set, within 20 - 25 minutes• Possibility to stripwrap together with perforation unit• Compact footprint8 · RUBRICHave 3D pops,shaped your wayGEA 3D PopLine10 · GEA AQUARIUSGEA Aquarius Line Solutions Coating LineInspired on the GEA Aquarius 3D PopLine wehave developed the GEA Aquarius Coating line. Next to the wish to diversify your lollipop shapes there is also the need to diff erentiate in tastes and appearance of the lollipop. With this modular coating line we give you the opportunity to do both and toThis full automatic line, including forming machine, cooling system, liquid and powder application systems, drying system and wrapping machine for the lollipops. Included are the overall line controls. Suitable for a large range of 3D and fl at lollipops. This line can include an automatic rejection systemGEA AQUARIUS · 11Double the pleasure,add a coatingBenefits GEA Aquarius Coating Line• Distinguish your lollipop by adding taste, color, texture or shine through coating with powder, syrups or granulates • Possibility of producing fl avorful lollipops with fi llings of gum, chewy candy powders or pastes • Positioning of colors• Easy change forming set, within 1 hour• Fully automatic line for production of high quality 3D coated lollipop shapes• Various quality checks and automatic reject points to assure effi cient continuous operation and product qualityGEA Coating LineEA Coating LineGEA AQUARIUS · 13The regular double-twist wrapper has an opensealing. With the overlapseal option available onthe GEA Aquarius Twistwrapper machines thewrapper is hermetically sealed. In areas where theatmospheric humidity is high the lollipops shelf lifecan be signifi cantly extended because the moisturecannot reach the lollipop. With the tearslit, theOverlapSeal double twist is extremely easy to open.The heating system with contactless transferof energy, seals the fi lm around the stick withconsistent sealing quality. The fi lm type ispolypropylene for which you need a fi lm witha double sealing layer (inner + outer side). GEA Aquarius inspiring optionsOverlapSealOverlapSeal capacityOverlapSeal Standard capacity Up to 800 lollipops per minuteGEA TwistWrapper14 · GEA AQUARIUSGEA Aquarius inspiring options Label on stick / Label on fi lmNext to beautiful wrapping options GEA Aquarius latest novelties label on stick and label on fi lm applications off er even more opportunities for product distinction and added value.Label on film / Label on stick capacity Label on film Wraps at speeds up to 600 lollipops per minute Label on stickWraps at speeds up to 800 lollipops per minuteThe label on stick applies a label around the stick which looks like a fl ag. On the label you can include product information, branding, themed actions and other promotional information.The label on fi lm applies a sticker or a tattoo on the inner site of the wrapping.BENEFITS LABEL ON STICK• Instant added value• Offers extra exposure to your branding • Promotions can be supported by the label through themed actionsGEA Label on film / Label on stickBENEFITS LABEL ON FILM• Instant added value• Stickers as collector’s items, promotional actions• Insert a variety of tattoos, i.e. related to yearly celebrations,like Halloween, Valentine’s day, Easter etcGEA AQUARIUS · 17 GEA Aquarius inspiring options Container fi lling systemThere is a clear trend for presenting lollipops on the counter or on the shelf in highly attractive displays. GEA developed several state of the art displaying concepts such as a container fi lling system forTherefore GEA developed a unit for fi lling lollipops into a container box which is directly linked to the wrapping machine. The container fi lling system is designed to run with one type of containers box at aGEA Container filling system18 · GEA AQUARIUSPillow bag:• Most common bag style • Simple to produce • High speeds possibleQuatro seal bag:• Flat bottom•Stand up pouch with four corner seals • Attractive on the shelf• Maximum promotional effectEasyDoy bag with re-closable tape:• Two full sides of printing for maximum exposure • Flat bottom for stand-up presentation • Re-closable tape• Excellent fi lling level which saves fi lm • Easy machine set up – within 10 minutesGEA Aquarius inspiring packaging optionsWe also off er you the opportunity to present your lollipops on the counter or shelf with highly attractive packaging. GEA has developed outstanding packaging options such as a Quatro seal bags with supreme stand up capacity that make an appealing shelf presentation. Next to this bag we also off er the EasyDoy packed lollipos or the Pillow packed lollipops.GEA SmartPackerRUBRIC · 19Let’s bagit upTHE GEA SMARTPACKER INCLUDES:• Very high speed and high capacity• Special bag formats, from very small to innovative shelf display formats• Able to handle sticky and fragile products.20 · GEA AQUARIUSTechnical data sheetGEA Aquarius FlexFormer Start Up (SU)GEA Aquarius FlexFormer Medium Capacity (MC)GEA Aquarius FlexFormer Standard Capacity (SC)Output (min) 300 lollipops / min 500 lollipops / min 700 lollipops / min Output (max) 550 lollipops / min 950 lollipops / min 1350 lollipops / min Dimensions H x W x D1900 x 1350 x 1100 mm 1900 x 1350 x 1100 mm 2050 x 2320 x 1655 mm Average machine efficiency (hard candy)98%98%98%Diameter/width lollipop (min to max)18 - 35 mm 18 - 35 mm 18 - 35 mm Lollipop length 16 - 41 mm 16 - 41 mm 16 - 45 mm Thickness lollipop 12 - 35 mm 12 - 35 mm 12 - 35 mm Filling inside lollipop up to 22%up to 22%up to 22%Type filling non fluid filling non fluid filling non fluid filling Lollipop width 3Donly round 3D only round 3D 22 - 35 mm Minimum rim, ball lollipops 4 mm 4 mm 4 mm Minimum rim 3D lollipops 2 mm 2 mm 2 mm Diameter stick (min to max) 3.2 - 5.5 mm 3.2 - 5.5 mm 3.2 - 5.5 mm Stick length (min to max)75 - 102 mm 75 - 102 mm 75 - 102 mm Stick material PVC, PP, Paper, Wood PVC, PP, Paper, Wood PVC, PP, Paper, Wood Power supply 1.5 kW 1.5 kW 3 kW Wrapping materialnot applicable not applicable not applicable Weight wrapping material (max)not applicable not applicable not applicable Diameter wrapping material (max)not applicable not applicable not applicable Advised thickness wrapping material not applicable not applicable not applicable Min spot dimension not applicablenot applicablenot applicable* For 3D lollipopsGEA Aquarius FlexFormer / FlatFormWraGEA FlexFormerGEA FlexFormGEA FlatFormWrapperTechnical data sheetGEA Aquarius PopCooler B Standard Capacity (SC)GEA Aquarius PopCooler B High Capacity (HC)GEA Aquarius PopCooler B airco + insulated cabinet Output (max)up to 1000 kg / hour up to 1850 kg / hour up to 1850 kg / hour Dimensions (L x W x H)3980 x 2940 x 2400 mm 3980 x 2940 x 2400 mm 3980 x 2940 x 2400 mm Dimensions enclosure with airco (L x W x H)not applicablenot applicable5260 x 4880 x 4765 mmEnclosure panel thickness not applicable not applicable 80 mm Number of tiers 353 or 5Cooling capacity ambient air ambient air ambient airPower consumption 2.6 kW 2.6 kW up to 30 kW / airco glycol based Air quantitynot applicable not applicable up to 15,000 m 3 / hour Average cooling time 4 to 5 min6 to 8 min4 to 8 minFloor levelness level 2.5 mm / per m 2level 2.5 mm / per m 2level 2.5 mm / per m 2Floor space2790 x 3645 mm2790 x 3645 mm5260 x 4880 mmGEA Aquarius PopCoolerGEA PopCooler BGEA PopCooler FGEA Aquarius BunchWrapperTechnical data sheet GEA Aquarius BunchWrapper 600 GEA Aquarius BunchWrapper 800 Output600 lollipops / min800 lollipops / minDimensions H X W x D2100 x 2355 x 1925 mm2100 x 2355 x 1925 mmAverage efficiency (hard candy)92 - 94%92 - 94%Diameter of ball candy Max18 - 35 mm18 - 35 mmDiameter of ball with overlapseal not applicable not applicableMinimum rim not applicable not applicableLollipop length15 - 45 mm15 - 45 mmDiameter stick (min to max) 3.2 - 5.5 mm 3.2 - 5.5 mmLength stick (min to max)75 - 102 mm75 - 102 mmWrapping material Cellophane, Polypropylene PVC wax paper Cellophane, Polypropylene PVC wax paper Weight wrapping material (max)35 - 45 gr / m235 - 45 gr / m2Length of wrapping material (max)82 - 140 mm82 - 140 mmDiameter wrapping material (max)420 mm420 mmAdvised thickness wrapping material25 - 40 mu25 - 40 muMinimum spot dimension 5 x 8 mm 5 x 8 mmPower supply 5.3 kW 5.3 kWLabel on film output600 p / m not applicableLabel on stick output600 p / m800 p / mLabel on film label dimension diameter/ width lollipop minus 3 mm not applicableLabel on stick dimension standard 60 x 20 mm standard 60 x 20 mmMax diameter label reel400 mm400 mmContainer filling system 140 - 230 mm140 - 230 mmWrapperwistWrapper GEA TwistWrapperGEA SmartPackerTechnical data sheet SmartPacker SX400SmartPacker CX400SmartPacker CX250 Output pillow up to 50 BPM up to 90 BPM110 BPMDimensions H X W x D2020 x 1280 x 2185 mm2020 x 1280 x 2185 mm2020 x 1130 x 2185 mm Average machine efficiency98%98%98%Pillow bag width minimum400 mm400 mm250 mmPillow bag length550 mm550 mm450 mmPillow zip possibility transdirectional zip inline zip transdirectional zip noBlock Bottom bag yes yes yesBlock Bottom zip possibility transdirectional zip transdirectional zip noQuatro seal bag yes yes yesQuatro seal zip possibility transdirectional zip transdirectional zip noEasy doy bag width reclosable tape yes yes yesWrapping material polyethyleen laminates polyethyleen laminates polyethyleen laminatesartPacker GEA SmartPackerDiameter (mm) Lollipop Minimum speed (p/m)FlexFormer SUMinimum speed (p/m)FlexFormer MCMinimum weight (g)LollipopMaximum weight (g)Lollipop18550950 3.3 6.3 20500875 4.88.5 22450800 6.512.1 244257508.615.2 254007009.817 2637567511.119 2835062514.123.2 3032560018.628 3230055022.733.2 3430052527.338 3530050029.839.4 GEA FlexFormer medium capacityFormer EA FlexFormer GEA FlexFormerGEA AQUARIUS · 31GEA Group is a global engineering company with m ulti-billion euro sales and o perations in more than 50 countries. Founded in 1881, the company is one of the largest providers of i nnovative equipment and process technology. GEA Group is listed in the STOXX ® Europe 600 Index.We live our values.Excellence • Passion • Integrity • Responsibility • GEA-versityB 14.02.13E N / 06/2016 - T h e i n f o r m a t i o n c o n t a i n e d i n t h i s b r o c h u r e m e r e l y s e r v e s a s a n o n -b i n d i n g d e s c r i p t i o n o f o u r p r o d u c t s a n d i s w i t h o u t g u a r a n t e e . B i ndi ngi n f o r m a t i o n , i n p a r t i c u l a r r e l a t i n g t o c a p a c i t y d a t a a n d s u i t a b i l i t y f o r s p e c i fi c a p p l i c a t i o n s , c a n o n l y b e p r o v i d e d w i t h i n t h e f r a m e w o r k o f c o n c r e t e i n q u i r i e s . S u b j e c t t o m o d i fi c a t i o n G E A ©GEA The NetherlandsP.O. Box 296 6000 AG Weert, The Netherlands Tel +31 (0)495 457 777 Fax +31(0)495 524 125************。

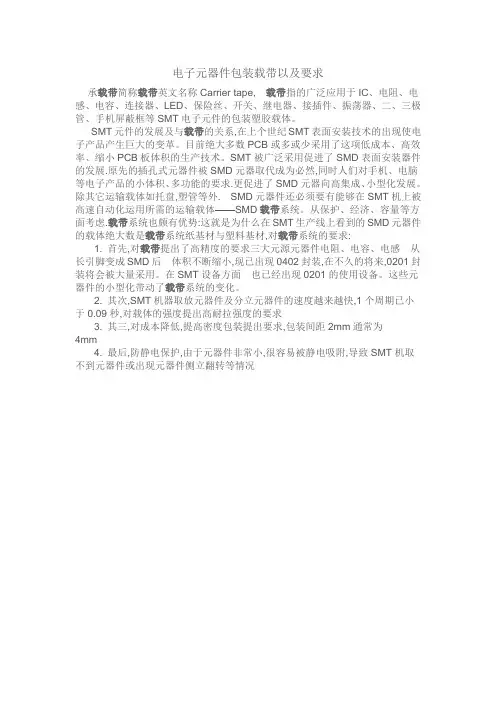

电子元器件包装载带以及要求

承载带简称载带英文名称载带指的广泛应用于IC、电阻、电感、电容、连接器、LED、保险丝、开关、继电器、接插件、振荡器、二、三极管、手机屏蔽框等SMT电子元件的包装塑胶载体。

SMT元件的发展及与载带的关系,在上个世纪SMT表面安装技术的出现使电子产品产生巨大的变革。

目前绝大多数PCB或多或少采用了这项低成本、高效率、缩小PCB板体积的生产技术。

SMT被广泛采用促进了SMD表面安装器件的发展.原先的插孔式元器件被SMD元器取代成为必然,同时人们对手机、电脑等电子产品的小体积、多功能的要求.更促进了SMD元器向高集成、小型化发展。

除其它运输载体如托盘,塑管等外元器件还必须要有能够在SMT机上被高速自动化运用所需的运输载体——SMD载带系统。

从保护、经济、容量等方面考虑.载带系统也颇有优势:这就是为什么在SMT生产线上看到的SMD元器件的载体绝大数是载带系统纸基材与塑料基材,对载带系统的要求

1. 首先,对载带提出了高精度的要求三大元源元器件电阻、电容、电感从

长引脚变成SMD后体积不断缩小,现已出现0402封装,在不久的将来,0201封装将会被大量采用。

在SMT设备方面也已经出现0201的使用设备。

这些元器件的小型化带动了载带系统的变化。

2. 其次,SMT机器取放元器件及分立元器件的速度越来越快,1个周期已小

于0.09秒,对载体的强度提出高耐拉强度的要求

3. 其三,对成本降低,提高密度包装提出要求,包装间距2mm通常为

4. 最后,防静电保护,由于元器件非常小,很容易被静电吸附,导致SMT机取

不到元器件或出现元器件侧立翻转等情况。

斜角丝带包装礼盒方法

斜角丝带包装礼盒是一种常见的包装方法,可以让礼盒看起来更加精致和美观。

下面是一种简单的斜角丝带包装礼盒的方法:

材料:

- 礼盒

- 礼盒包装纸

- 斜角丝带

- 剪刀

- 胶带

步骤:

1. 首先,将礼盒放在包装纸上,并确定纸的大小,使其能够完全包住礼盒。

2. 将礼盒放置在包装纸的中央,然后将纸的一侧折叠到盒子的上方,并使用胶带固定住。

3. 接下来,将纸的另一侧折叠到盒子的下方,与之前的一侧呈现出斜角形状,并使用胶带固定住。

4. 将包装纸的两侧折叠到盒子的两侧,形成完整的包装纸,然后使用胶带固定住。

5. 取一段斜角丝带,并将其叠放在盒子的一个角上。

6. 将丝带固定在盒子上,可以使用胶带或打个可爱的蝴蝶结来固定住。

7. 将斜角丝带的另一端叠放在盒子的对角线上,形成交叉样式。

8. 将丝带再次固定在盒子上,确保丝带交叉处不松动。

9. 根据需要,可以在丝带的交叉处打结、创意地扎成蝴蝶结,或者将丝带修剪成合适的长度。

10. 完成礼盒的斜角丝带包装。

这是一种简单的斜角丝带包装礼盒的方法,可以根据实际需要进行调整和创新,增加不同的装饰元素,打造出独特而美丽的包装效果。

恒量自动化包装产线的指标恒量自动化包装生产线是一种高精度、高效率的包装系统,它能够确保产品在包装过程中的重量、体积、数量等关键指标保持恒定。

这种生产线通常用于食品、化工、医药等行业,以确保产品的一致性和消费者的满意度。

以下是恒量自动化包装生产线的一些关键指标:1. 精度:恒量自动化包装生产线的主要指标之一是包装精度,即系统能够在设定的范围内保持恒定的包装量。

这通常以百分比或绝对值来表示,例如±1%或±2克。

高精度的包装线能够减少产品浪费,提高生产效率。

2. 速度:包装速度是指生产线每单位时间内完成的产品包装数量。

恒量自动化包装生产线需要在保证精度的同时,达到较高的包装速度,以满足生产需求。

速度通常以每分钟包装的产品数来衡量。

3. 可靠性:恒量自动化包装生产线的可靠性是指其在连续运行过程中的稳定性和故障率。

高可靠性的生产线能够减少停机时间,提高整体设备效率。

4. 灵活性:灵活性是指包装生产线能够适应不同产品规格和包装要求的能力。

这包括能够快速更换模具、调整机器参数以适应不同的包装尺寸和类型。

5. 安全性:安全性是指包装生产线在操作过程中对操作人员的保护程度。

这包括机器的安全防护装置、紧急停止按钮、安全操作规程等。

6. 易于维护:易于维护的包装生产线可以减少维修时间和成本。

这包括易于访问的部件、清晰的维护指南、预防性维护计划等。

7. 自动化程度:自动化程度是指包装生产线在包装过程中自动完成任务的比率。

高度自动化的生产线可以减少人工干预,提高生产效率和一致性。

8. 节能环保:节能环保是指包装生产线在运行过程中对能源的消耗和对环境的影响。

节能的生产线可以降低运营成本,减少对环境的影响。

9. 防止交叉污染:特别是在食品和医药行业,防止交叉污染是非常重要的。

恒量自动化包装生产线需要采取措施,如使用隔离系统、清洁设计、适当的材料选择等,以确保产品安全。

10. 数据追踪和集成:现代的恒量自动化包装生产线通常配备有数据追踪和集成系统,如物联网、工业4.0技术等,这些系统可以实时监控生产数据,提供生产效率分析,帮助优化生产过程。

数据线纸卡包装设计方案

1. 简洁明了的设计:数据线是一种功能性产品,因此包装设计应该简洁、明了,突出产品的特点和使用场景。

使用清晰的字体和图标,以及简洁的色彩搭配,让消费者一眼就能理解产品的功能和优势。

2. 品牌标识和主题色彩:在包装上突出品牌标识和主题色彩,以增强品牌的辨识度。

可以选择符合品牌形象的配色方案,并将品牌标识置于易于注意的位置,例如包装正面或顶部。

3. 产品特点的展示:通过设计元素和图形,突出数据线的特点,例如快速充电、高速传输等。

可以在包装上使用图表、示意图或文字说明,以便消费者快速了解产品的功能和用途。

4. 可持续包装:考虑使用环保材料制作包装,以符合现代消费者对可持续性的关注。

选择可回收、可降解的纸板或纸质材料,并避免使用过度包装,减少对环境的负面影响。

5. 便利性和保护性:为了提供方便的使用体验,可以在包装设计中考虑一些便利性的元素,例如易于打开的拉绳或翻盖设计。

此外,包装也应提供足够的保护,以确保产品在运输和存储中不受损。

巧克力涂层米棒自动化包装线的布局设计钱皓华;江楠;王彬【摘要】以巧克力涂层米棒包装线布局设计为研究对象,针对食品包装自动化项目常见的技术问题,提出了该物料自动化包装项目的设计过程方法和解决方案.重点阐述了巧克力涂层米棒自动包装线布局设计时需研究的速度匹配、缓存配置和剔除工位配置,最后给出了生产线实施后给企业带来的经济效益.%With the layout design of a packaging line for chocolate coated cereal bars as the research object and in view of the common technical problems in automation projects in the food packaging industry, the design process method and solution of this material packaging automation project. Focus was laid on the description of speed matching,buffer configuration and configuration of rejection station in the layout design of the packaging line,and finally the economic benefits brought to the enterprises after implementation of this automatic packaging line project were given.【期刊名称】《包装与食品机械》【年(卷),期】2018(036)002【总页数】4页(P35-38)【关键词】产品特性;速度匹配;产品缓存;产品剔除;布局设计【作者】钱皓华;江楠;王彬【作者单位】博世包装技术(杭州)有限公司,浙江杭州 310018;博世包装技术(成都)有限公司,四川成都 611630;博世包装技术(成都)有限公司,四川成都 611630【正文语种】中文【中图分类】TS213.3;TS206.50 引言食品包装机械行业作为食品行业和设备制造行业的交叉行业,在我国起步于80年代,经过30多年的发展,尤其是近10年,在自动化新技术层出不穷、劳动力成本逐渐攀升的背景下,得到了快速的发展,使得食品企业在包装工艺阶段的生产模式发生显著的改变,从半自动化,向全自动化、成套化、智能化以及柔性化的方向发展。

四边封袋、三边封袋和背封袋的优缺点对比四边封袋即成袋后四条边均经过热封的包装形式,目前最常见的颗粒剂包装形式,技术成熟,工艺简单。

设备运行稳定性高,造型相对美观,产品密封性较好。

四边封袋通常使用一整张膜等分为两半后相对包装,属于先整体热封制袋后进行单袋裁剪的方式,生产时只需要控制一条边对齐即可获得较好的包装效果,因此具有极高的包材/设备适应性和包装运行稳定性(这一点非常重要,由于四边封袋机速度通常慢于装盒机,常见的模式为多台四边封袋机配合一台装盒机使用,对于设备运行稳定性的要求较高)。

同时,由于每条边都经过均匀的热封,成袋后的产品密封性较好。

四边封袋的缺点是对大体积物料的包装适应性不足,由于是整张膜先制袋后裁剪,因此要求制袋时复合膜相对平整,制袋后袋体为平面,难以装入大体积物料,袋内空间利用率相对较低。

三边封袋即包装袋一侧为复合膜直接对折,另外三条边为热封边的形式。

实际上三边封袋可以视为四边封袋的补充。

相对于四边封袋来说,其优点是成袋后可以先展开成立体袋型,空间利用率高,适合大体积包装需求,常用于感冒冲剂等产品的包装。

三边封袋的缺点同样明显,首先是三条边热封造成的袋型不对称影响美观,当然美观问题仁者见仁,这里不多讨论。

其次是包装速度较慢,三边封袋机最常见的包装形式为单列包装(这也是三边封适合大体积包装的原因,由于只是单列可以不考虑复合膜平整性的要求),多列式的三边封袋机我没有见过,但可以想象如果有的话,多列式三边封袋只能采用先将复合膜裁剪为数条再分别卷制成袋的方式,其控制难度之高还不如多台单列包装机组合使用来的稳定。

背封袋(也称Stick包装)即卷膜先分切为数列,每列复合膜单独卷制纵封后将纵封边压向一侧,然后横封制袋的方式,最初由**企业发明。

背封袋的优点非常明显,首先是外形非常美观,背封袋采用的隐藏式纵封边和袋型特点决定了其外观特点鲜明,袋型精致美观,与同类型的四边封产品相比有明显的差异化优势。

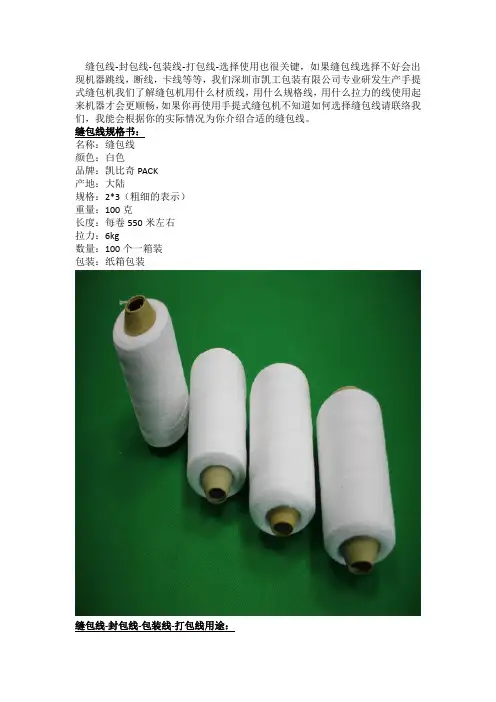

缝包线-封包线-包装线-打包线-选择使用也很关键,如果缝包线选择不好会出现机器跳线,断线,卡线等等,我们深圳市凯工包装有限公司专业研发生产手提式缝包机我们了解缝包机用什么材质线,用什么规格线,用什么拉力的线使用起来机器才会更顺畅,如果你再使用手提式缝包机不知道如何选择缝包线请联络我们,我能会根据你的实际情况为你介绍合适的缝包线。

缝包线规格书:名称:缝包线颜色:白色品牌:凯比奇PACK产地:大陆规格:2*3(粗细的表示)重量:100克长度:每卷550米左右拉力:6kg数量:100个一箱装包装:纸箱包装缝包线-封包线-包装线-打包线用途:1、这些词汇,包括缝包线、封包线、包装线和打包线,都是与包装和捆扎过程相关的线材类型。

它们通常用于将物品固定、封闭或包裹起来,以确保物品在运输和储存过程中的安全和整洁。

2、主要用于缝制包装袋,特别是布袋或纺织品袋,以确保袋子的封口牢固。

这种线通常具有一定的强度和耐磨性,以适应包装过程中可能出现的摩擦和张力。

主要用于封闭各种包装袋,如塑料袋或纸袋。

封包线通常与封口机或热封设备配合使用,以实现高效、快速的包装过程。

3、这是一个较为宽泛的术语,涵盖了用于包装的各种线材。

它可能包括缝包线、封包线等,具体取决于具体的包装需求和材料类型,主要用于大型物品或重物的打包和固定。

打包线通常具有较高的强度和韧性,能够承受重物在运输过程中产生的压力和振动。

常见的打包线材料包括塑料、金属或合成纤维。

4、这些线材在物流、仓储和制造等领域中发挥着重要作用,帮助企业和个人有效地管理和保护他们的产品。

每种线材都有其特定的用途和优势,选择合适的线材可以提高包装效率和质量,同时降低成本和风险。

工艺技术要求

王经理、高经理:你们好!

我方要求的参数如下:

1.珍珠岩版规格:600x600x17(mm);每包10块板;包装上面加一块纸板尺寸为585x585x4(mm);包装后尺寸约为:605x605x180(mm);

2.每条线包装速度:12块/分。

3.每个包装打包带4道,两横两纵。

打包机用4台,保证打包要紧密可靠。

最后有码垛。

4.包装线前要有储料库,防止后面生产线故障而前面主线造成停机。

5.控制部分要与我们的主线留有开放的接口,能够与主线统一控制联动。

控制系统要用国外进口元件,如伺服电机要用三菱品牌,气缸用SMC以此类推。

6.交货期限:80天。

其余要求与贵厂的对甲方的服务条款相同,签订合同时在做要求。

天津市思必德科技开发公司

关玉明

2013.12.4。

化学品安全技术说明书 (见条例 (EC) n° 1907/2006 - REACH)版本 : 第 3.1 (01/08/2019) - 页码 1/9 PRESI S.A.SSTICK LDM - 18000 A 18019化学品安全技术说明书(REACH 法规 (EC) n° 1907/2006 - n° 2015/830)第1 节: 标识1.1. 全球统一制度产品标识符产品名称: STICK LDM产品代码: 18000 A 180191.2. 化学品使用建议和使用限制研磨膏1.3. 供应商的详细情况注册公司名称: PRESI S.A.S.地址: 11 Rue du vercors.38320.EYBENS.France.电话: +33 (0)4.76.72.00.21. 传真: +33 (0)4.76.72.05.84.***************1.4. 紧急电话号码 : +33 (0)1.45.42.59.59.协会/组织: INRS / ORFILA .第2 节: 危险标识2.1. 物质或混合物的分类符合欧盟法规(EC)编号: 1272/2008及其修正案.急性毒性: 口服, 第 4 类 (Acute Tox. 4, H302).严重眼损伤, 第 1 类 (Eye Dam. 1, H318).该混合物不存在物理危险性.请参见现场存在的其他产品的相关推荐事宜.该混合物不存在环境危险性.在标准使用情况下,无任何已知的或可预见的环境破坏.2.2. 标签要素符合欧盟法规(EC) 第 1272/2008 号及其修正案.危险图形标志:GHS05GHS07警示性文字:危险产品标志:CAS 68131-40-8ETHOXYLATED SECONDARY ALCOHOLS ( C11 - 15)危险性说明:H302吞咽有害H318造成严重眼损伤。

预防措施:P264作业后彻底清洗...。

包装厂工艺流程及简要说明英文回答:The packaging process in a factory involves several steps to ensure that products are properly packaged and ready for distribution. Here is a brief overview of the packaging process:1. Design and Planning: Before the packaging process begins, the packaging team works on designing and planning the packaging materials and methods. This includes selecting the appropriate packaging materials, determining the size and shape of the packaging, and considering any special requirements or regulations.2. Material Preparation: Once the packaging design is finalized, the necessary materials are prepared. This may involve cutting and shaping cardboard or plastic sheets, printing labels or stickers, and assembling any additional components such as inserts or dividers.3. Product Placement: The next step is to place the products into the packaging. This can be done manually or with the help of automated machinery, depending on the volume and nature of the products. For example, in a food packaging factory, snacks may be placed into individual bags or boxes using automated filling machines.4. Sealing and Closure: After the products are placed in the packaging, the next step is to seal and close the packaging. This can be done using various methods such as heat sealing, adhesive sealing, or mechanical closure. For example, in a cosmetics packaging factory, lipstick tubes may be sealed with a heat shrink wrap.5. Quality Control: Throughout the packaging process, quality control checks are conducted to ensure that the packaging meets the required standards. This may involve checking for proper product placement, verifying the accuracy of labels or barcodes, and inspecting the overall appearance of the packaging.6. Packaging Labeling: Once the packaging is sealed and quality checked, labels or stickers are applied to provide important information such as product name, ingredients, expiration date, and barcode. This helps in identifying and tracking the products during distribution.7. Packaging Storage: After the packaging is labeled,it is stored in designated areas until it is ready for distribution. This may involve stacking the packaged products on pallets or storing them in shelves or racks.8. Distribution: Finally, the packaged products are loaded onto trucks or shipped to distribution centers for further transportation to retailers or customers. This involves careful handling to ensure that the packaging remains intact and the products are not damaged during transit.中文回答:包装厂的工艺流程包括多个步骤,以确保产品得到适当的包装并准备好分销。

简括常见的各类工厂包装线的功能特点包装线是一种线性生产流水线,它可以将工业生产的各工序进行完美的连接并传输,有助于提升工业生产量。

由于各类工厂生产的产品类型有差异,因此包装线的分类也比较的多。

关于这一点不知道大家有没有了解过。

下面小编就来给大家几种常见的包装线分类。

板链包装线:采用链板拖牵工件做平面传送运动,来达到生产工艺目的。

包装线采用组合式装配模式,工位数可按工艺要求设定。

工位配置有电源插座、工具箱、料盒等,使整个流程达到快递、有序。

插件包装线:采用链条拖动工装小车,成水平环运行,进行工件装配。

差速链包装线:采用特制铝合金型材作导轨,用增速链拖牵工装板作为输送介质。

包装线采用组合式装配模式,工位数可按工艺要求设定。

工位配置有脚踏开关、电源插座、工位阻挡器、工艺图板、照明等,线体上设有顶升平移机、顶升旋转台等,使整个流程达到自动化工作状态。

滚筒包装线:采用滚筒拖牵工作平面传送运动,来达到生产工艺目的。

包装线采用组合式装配模式,工位数、滚筒间距可按工艺要求设定。

皮带包装线:皮带线采用皮带拖牵工作平面传送运动,来达到生产工艺目的,也有人管这种皮带包装线叫做皮带机或皮带输送机。

这种皮带机采用组合式装配模式,工位数可按工艺要求设定。

皮带输送机工位配置有电源插座、工艺图板、照明等,使整个程流达到快速、有序。

手推包装线:通过手动方式来实现工位的传递。

型号种类包括:钢材结构、铝材结构为护边;单皮带、双边。

可配选项: 气管、风扇、工艺卡架、仪表台、插座,工具箱等。

该包装线可按客户要求定制长短,介质可选流利条,也可选用滚筒。

广泛应用于电子,塑胶,食品等行业。

婴儿奶粉stick自动包装工艺流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor.I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!婴儿奶粉stick自动包装工艺流程详解婴儿奶粉作为婴幼儿的重要营养来源,其生产过程中的每一个环节都至关重要,尤其是包装阶段。

包装盒易拉条设计方案易拉条,也叫拉环杯盖,是指由一条带有环状齿轮切割口的拉环,一般用于易拉盖饮品包装,方便消费者开启包装。

设计一个好的易拉条方案能够吸引消费者的注意,提高产品的销量。

下面是一个易拉条设计方案的详细说明。

第一步:确定易拉条的功能和使用场景。

易拉条主要用于打开饮品包装,因此需要具备较高的开启力度和稳定性。

另外,易拉条要能够与包装材料相匹配,不易变形,保持坚固性。

在使用场景上,易拉条一般用于小数量的饮品包装,因此设计时需要考虑易拉条的大小和形状,以适应不同包装容量的需求。

第二步:确定易拉条的尺寸和形状。

易拉条的尺寸和形状要与饮品包装相匹配,既要能够方便消费者使用,又要能够与包装容量相协调。

比如,对于小容量的饮品包装,易拉条可以设计成较小的尺寸,方便消费者抓握。

而对于大容量的饮品包装,可以设计成较大的尺寸,增加开启力度。

第三步:确定易拉条的材料和制作工艺。

易拉条所用材料应具备一定的韧性和耐用性,以保证易拉条不易变形和断裂。

常见的易拉条材料有塑料、金属和纸质等,根据不同的使用需求选择适当的材料。

制作工艺可采用注塑、冲压和印刷等方法实现。

第四步:确定易拉条的外观设计。

易拉条的外观设计要能够吸引消费者的注意,增加产品的吸引力和辨识度。

可以根据产品的品牌特点和市场定位进行设计,在易拉条上印刷产品商标、口号或图案等,以增加产品的识别度和差异化竞争优势。

第五步:进行易拉条的样品制作和测试。

设计师按照方案设计制作出易拉条的样品,并进行一些开启力度、稳定性和耐用性的测试,检验设计方案的可行性和适用性。

根据测试结果进行调整和改进,直至满足产品的使用需求和设计要求。

综上所述,一个好的易拉条设计方案需要考虑易拉条的功能、尺寸、材料、制作工艺和外观设计等因素。

通过合理的设计和测试,可以生产出符合市场需求和消费者喜好的易拉条产品,提高产品的销量和竞争力。