安费诺先进传感器推出IPT2000压力变送器

- 格式:pdf

- 大小:185.98 KB

- 文档页数:3

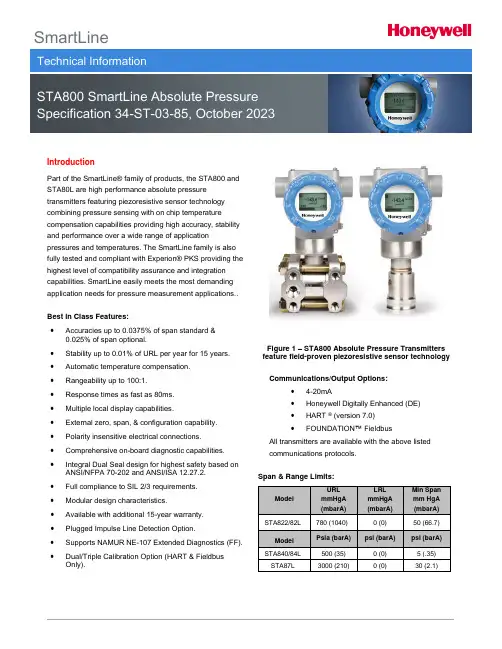

SmartLineIntroductionPart of the SmartLine® family of products, the STA800 and STA80L are high performance absolute pressuretransmitters featuring piezoresistive sensor technologycombining pressure sensing with on chip temperaturecompensation capabilities providing high accuracy, stability and performance over a wide range of applicationpressures and temperatures. The SmartLine family is also fully tested and compliant with Experion® PKS providing the highest level of compatibility assurance and integrationcapabilities. SmartLine easily meets the most demandingapplication needs for pressure measurement applications..Best in Class Features:•Accuracies up to 0.0375% of span standard &0.025% of span optional.•Stability up to 0.01% of URL per year for 15 years. •Automatic temperature compensation. •Rangeability up to 100:1.•Response times as fast as 80ms.•Multiple local display capabilities.•External zero, span, & configuration capability. •Polarity insensitive electrical connections. •Comprehensive on-board diagnostic capabilities. •Integral Dual Seal design for highest safety based on ANSI/NFPA 70-202 and ANSI/ISA 12.27.2.•Full compliance to SIL 2/3 requirements.•Modular design characteristics.•Available with additional 15-year warranty. •Plugged Impulse Line Detection Option.•Supports NAMUR NE-107 Extended Diagnostics (FF). •Dual/Triple Calibration Option (HART & Fieldbus Only).Figure 1 – STA800 Absolute Pressure Transmitters feature field-proven piezoresistive sensor technology Communications/Output Options:•4-20mA•Honeywell Digitally Enhanced (DE)•HART ® (version 7.0)•FOUNDATION™ FieldbusAll transmitters are available with the above listedcommunications protocols.Span & Range Limits:2 STA800 Smart Pressure TransmitterDescriptionThe SmartLine family of gauge pressure, differential pressure, and absolute pressure transmitters is designed around a high performance piezo-resistive sensor. This one sensor actually integrates multiple sensors linking process pressure measurement with on-board static pressure (DP Models) and temperature compensation measurements resulting in the best total performance available. This level of performance allows the ST 800 to replace virtually any competitive transmitter available today. (√)Unique Indication/Display OptionsThe ST 800 modular design accommodates a standard alphanumeric LCD display or a unique advanced graphics LCD display with many unparalleled features.Standard LCD Display Features•Modular (may be added or removed in the field). •Supports HART protocol variant.•0, 90,180, & 270 degree position adjustments.•Four configurable screens.•Standard and custom measurement units available. •Display calculated flow (square root) value in addition to analog output signal.• 2 Lines 6 digits PV (9.95H x 4.20W mm) 8 Characters. •Write protect Indication.•Built-in Basic Device Configuration through Internal or External Buttons – Range/Engineering Unit/Loop Test/Loop Calibration/Zero /Span Setting.•Multiple language capabilities (EN, RU).Advanced Graphics LCD Display Features•Modular (may be added or removed in the field). •0, 90, 180, & 270-degree position adjustments. •Standard and custom measurement units available. •Up to eight display screens with 3 formats are possible.•Large PV with Bar Graph or PV with Trend Graph. •Configurable screen rotation timing (1 to 30 sec). •Display calculated flow (square root) value in addition to analog output signal.•Unique “Health Watch” indication provides instant visibility of diagnostics.•Multiple language capability (EN, DE, FR, IT, ES, RU, TR, CN, & JP).DiagnosticsSmartLine transmitters all offer digitally accessible diagnostics which aid in providing advanced warning of possible failure events minimizing unplanned shutdowns, providing lower overall operational costs.Configuration ToolsIntegral Three Button Configuration OptionSuitable for all electrical and environmental requirements, SmartLine offer the ability to configure the transmitter and display via three externally accessible buttons when either display option is selected. Zero/span capabilities are also optionally available via these buttons with or withoutselection of a display option.Handheld ConfigurationSmartLine transmitters feature two-way communication and configuration capability between the operator and the transmitter. All Honeywell transmitters are designed andtested for compliance with the offered communication protocols and are designed to operate with any standards compliant handheld configuration device, such as the Honeywell Versatilis Configurator.Personal Computer ConfigurationOn a personal computer or laptop, Honeywell Field Device Manager (FDM) Software and FDM Express can be used for managing HART & Fieldbus device configurations.System Integration•SmartLine communications protocols all meet the most current published standards for HART/DE/Fieldbus.•Integration with Honeywell’s Experion PKS offers the following unique advantages.o Transmitter messaging.o Maintenance mode indication.o Tamper reporting.o FDM Plant Area Views with Health summaries.o All ST 800 units are Experion tested to providethe highest level of compatibility assurance.STA800 Smart Pressure Transmitter 3Modular DesignTo help contain maintenance & inventory costs, all ST 800 transmitters are modular in design supporting the user’s ability to replace meter bodies, add indicators or change electronic modules without affecting overall performance or approval body certifications. Each meter body is uniquely characterized to provide in-tolerance performance over a wide range of application variations in temperature and pressure and due to the Honeywell advanced interface, electronic modules may be swapped with any electronics module without losing in-tolerance performance characteristics.Modular Features•Meter body replacement•Exchange/replace electronics/comms modules*•Add or remove integral indicators*•Add or remove lightning protection (terminalconnection)** Field replaceable in all electrical environments (including IS) except flameproof without violating agency approvals.With no performance effects, Honeywell’s unique modularity results in lower inventory needs and lower overall operating costs. Plugged Impulse Line DetectionSTA800 models are offered with a PILD option which provides indication of a plugged impulse line or process connection. When used in conjunction with an advanced display, a non-critical diagnostic indication appears on the integral display. For units without an integral display, an indication can be seen via the host or handheld device when HART Protocol is utilized.Dual/Triple CalibrationSTA800 models are optionally offered with multiple calibrations. In lieu of a standard factory calibration, units can be supplied with 1, 2, or 3 customer specified calibrations. These calibrations are stored in the meter body and provide users with factory calibrated performance at up to three different calibrated ranges. This increases application flexibility without requiring any costly recalibration or additional inventory.4 STA800 Smart Pressure Transmitter Performance SpecificationsReference Accuracy:(conformance to +/-3 Sigma)Performance SpecificationsAccuracy at Specified Span and Temperature: (Combined Zero & Span, conformance to +/-3 Sigma)STA800 Smart Pressure Transmitter 5 Total Performance (% of Span):Total Performance Calculation: = +/- √(Accuracy)2 + (Temperature Effect)2Total Performance Examples (for comparison): standard accuracy 5:1 Turndown, +/-50o F (28o C) shiftTypical Calibration Frequency:Calibration verification is recommended every four (4) years.Notes:1. Terminal Based Accuracy - Includes combined effects of linearity, hysteresis, and repeatability. Analog output adds 0 .005% of span.2. For zero based spans and reference conditions of: 25o C (77o F), 10 to 55% RH, and 316 Stainless Steel barrier diaphragm.Operating Conditions – All ModelsLCD Display operating temperature -20︒C to +70︒C Storage temperature -30︒C to 80︒C.2Silicone 704 minimum temperature rating is 0o C (32o F). CTFE minimum temperature rating is -40︒C (-40︒F).3Short term equals 2 hours at 70︒C (158︒F)4 Units can withstand overpressure of 1.5 x MAWP without damage5Consult factory for MAWP of ST 700 transmitters with CRN approval6 STA800 Smart Pressure TransmitterFigure 2 - Measured pressure versus meter body temperature chart for STA722, 72LFigure 3 - Supply voltage and loop resistance chart & calculationsSTA800 Smart Pressure Transmitter 7 Performance Under Rated Conditions – All Models8 STA800 Smart Pressure Transmitter Materials Specifications(see model selection guide for availability/restrictions with various models)3 Monel® 400 or UNS N044004 Supplied as 316 SS or as Grade CF8M, the casting equivalent of 316 SS.5 Carbon Steel heads are zinc-plated and not recommended for water service due to hydrogen migration. For that service, use 316 stainless steel wettedProcess Heads.6 Hastelloy® C-276 or UNS N10276. Supplied as indicated or as Grade CW12MW, the casting equivalent of Hastelloy® C-2767 Monel® 400 or UNS N04400. Supplied as indicated or as Grade M30C, the casting equivalent of Monel® 400STA800 Smart Pressure Transmitter 9 Communications Protocols & DiagnosticsHART ProtocolVersion: HART 7Foundation Fieldbus (FF)* AI block may have two (2) additional instantiations.All available function blocks adhere to FOUNDATION Fieldbus standards. PID blocks support ideal & robust PID algorithms with full implementation of Auto-tuning.Link Active SchedulerTransmitters can perform as a backup Link ActiveScheduler and take over when the host is disconnected. Acting as a LAS, the device ensures scheduled data transfers typically used for the regular, cyclic transfer of control loop data between devices on the Fieldbus.Number of Devices/SegmentEntity IS model: 6 devices/segmentSchedule Entries18 maximum schedule entriesNumber of VCR’s: 24 maxCompliance Testing: Tested according to ITK 6.0.1 Software DownloadUtilizes Class-3 of the Common Software Download procedure as per FF-883 which allows the field devices of any manufacturer to receive software upgrades from any host. Honeywell Digitally Enhanced (DE)DE is a Honeywell proprietary protocol which provides digital communications between Honeywell DE enabled field devices and hosts.Standard DiagnosticsST 800 top level diagnostics are reported as either critical or non-critical and are readable via the DD/DTM/FDI tools or integral display. All critical diagnostics will appear on the Advanced and Standard integral displays, and some non-critical diagnostics will also appear on the Advanced integral display. Some of the diagnostics are listed below. Critical Diagnostics•Electronics Module Fault.•Meter body Memory Corruption.•Config Data Corruption.•Electronics Module Diagnostics Failure.•Meter body Critical Failure.•Sensor Communication Timeout.Non-Critical Diagnostics•Electronics Module Fault.•Display Failure.•Electronics Module Comm Failure.•Meter body Excess Correct.•Sensor Over Temperature.•Fixed Current Mode.•PV Out of Range.•No DAC Compensation.•Tamper Attempt Alarm.Refer to the product user manual for comprehensive list of diagnostics and details.Other Certification OptionsMaterialso NACE MRO175, MRO103, ISO1515610 STA800 Smart Pressure Transmitter Hazardous Areal CertificationsII 2 D Ex tb IIIC T95 Intrinsically Safe: SIRA 12ATEX2233XII 2 D Ex ia IIIC T125FISCO Field Device (Only for FF Option) Zone 2, Intrinsically Safe: SIRA12ATEX4234XFISCO Field Device (Only for FF Option) II 3 G Ex ic IIC T4 GcII 2 D Ex tb IIIC T95 Intrinsically Safe: CSAE 22UKEX1021XII 2 D Ex ia IIIC T125FISCO Field Device (Only for FF Option) Zone 2, Intrinsically Safe: CSAE22UKEX1008XFISCO Field Device (Only for FF Option) II 3 G Ex ic IIC T4 Gc1.Operating Parameters:Voltage = 11 to 42 VDC = 9 to 32 V (FF) Current = 4-20 mA Normal = 30 mA (FF)2.Intrinsically Safe Entity Parametersa. Analog/ DE/ HART Entity Values:Vmax = Ui = 30V Imax= Ii = 105mA Ci = 4.2nF Li = 984 uH Pi = 0.9WTransmitter with Terminal Block revision E or LaterVmax = Ui = 30V Imax= Ii = 225mA Ci = 4.2nF Li = 0 Pi = 0.9WNote : Transmitter with Terminal Block revision E or laterThe revision is on the label that is on the module. There will be two lines of text on the label:•First is the Module Part #: 50049839-001 or 50049839-002•Second line has the supplier information, along with the REVISION:XXXXXXX-EXXXX, THE “X” is production related, THE POSITION of the “E” IS THE REVISI ON.b. Foundation Fieldbus - Entity ValuesVmax= Ui = 30V Imax= Ii = 180mA Ci = 0nF Li = 984 uH Pi = 1WTransmitter with Terminal Block revision F or LaterVmax= Ui = 30V Imax= Ii= 225mA Ci = 0nF Li = 0 Pi = 1 WImax= Ii= 380 mA Ci = 0nF Li = 0 Pi = 5.32 W FISCO Field DeviceVmax= Ui = 17.5VNote : Transmitter with Terminal Block revision F or laterThe revision is on the label that is on the module. There will be two lines of text on the label:•First is the Module Part #: 50049839-003 or 50049839-004•Second line has the supplier information, along with the REVISION:XXXXXXX-EXXXX, THE “X” is production related, THE POSITION of the “E” IS THE REVISION.Approval CertificationsMounting & Dimensional DrawingsReference Dimensions:millimetersinchesMounting Configurations (Dual head design)Dimensions (Dual head design)Figure 4 – Typical mounting dimensions of STA822 & STA840 for referenceReference Dimensions:millimeters inchesMounting Configurations (Inline Designs)Dimension (Inline Design)Figure 5 – Typical mounting dimensions of STA82L, STA84L, & STA87L for referenceModel Selection GuideModel Selection Guides are subject to change and are inserted into the specifications as guidance only.Model STA800 & STA80LAbsolute Pressure TransmittersModel Selection Guide 34-ST-16-85, Issue 32Except Carbon Steel Heads shall use 316SS Vent/Drain & Plugs1aSTA822,840 supplied via 1/2" flange adapter same material as process head except carbon steel shall use 316 SS 1bReference head available only with Dual head models. In-line models supplied with process head only1cWhen selected for In-Line Gage models the Process Head / Bonnet is supplied in Dual Certified SS316/316LInstructions:Make selections from all Tables using column below the proper arrow. Asterisk indicates availability. Letter (a) refers to restrictions highlighted in the restrictions table. Tables delimited with dashes.List Price:Price equals the sum of prices for all selections made.3 NAMUR Output Limits 3.8 - 20.5mAdc can be configured by the customSTA800 Smart Pressure Transmitter211The PM option is available on all Smartline Pressure Transmitter process wetted parts such as process heads, flanges, bushings and vent plugs except plated carbon steel process heads and flanges. PM option information is also available on diaphragms except Gold plated and STG and STA in-line construction pressure transmitters.For more informationTo learn more about SmartLine Pressure Transmitters visit Or contact your Honeywell Account ManagerProcess Solutions Honeywell1250 W Sam Houston Pkwy S Houston, TX 77042Honeywell Control Systems LtdHoneywell House, Skimped Hill Lane Bracknell, England, RG12 1EB34-ST-03-85 October 2023©2023 Honeywell International Inc.Shanghai City Centre, 100 Jungi Road Shanghai, China 20061Sales and ServiceFor application assistance, current specifications, ordering, pricing, and name of the nearest Authorized Distributor, contact one of the offices below.ASIA PACIFICHoneywell Process Solutions, Phone: + 800 12026455 or +44 (0) 1202645583 (TAC) hfs-tac-*********************AustraliaHoneywell LimitedPhone: +(61) 7-3846 1255 FAX: +(61) 7-3840 6481 Toll Free 1300-36-39-36 Toll Free Fax: 1300-36-04-70China – PRC - Shanghai Honeywell China Inc.Phone: (86-21) 5257-4568 Fax: (86-21) 6237-2826SingaporeHoneywell Pte Ltd.Phone: +(65) 6580 3278 Fax: +(65) 6445-3033South KoreaHoneywell Korea Co Ltd Phone: +(822) 799 6114 Fax: +(822) 792 9015EMEAHoneywell Process Solutions, Phone: + 800 12026455 or +44 (0) 1202645583Email: (Sales)*************************** or (TAC)*****************************WebKnowledge Base search engine http://bit.ly/2N5VldiAMERICASHoneywell Process Solutions, Phone: (TAC) (800) 423-9883 or (215) 641-3610(Sales) 1-800-343-0228Email: (Sales)*************************** or (TAC)*****************************WebKnowledge Base search engine http://bit.ly/2N5VldiSpecifications are subject to change without notice.。

1-氯丙烷气体检测传感器变送模块一,产品分类二,产品介绍单一气体1-氯丙烷气体检测传感器变送模块(网络版)简介大部分单一气体1-氯丙烷气体检测传感器输出信号都是非标准信号,不能直接使用,需要经过输出信号放大、滤波等处理等才可以使用。

安帕尔单一气体1-氯丙烷气体检测传感器变送模块(网络版),正是为了解决这些问题而研发的产品。

安帕尔科技是全球单一气体1-氯丙烷气体检测传感器变送模块(网络版)种类最齐全的公司,不论从量程选择、结构尺寸、供电方式、信号输出、功能特点等安帕尔科技基本上都有非常丰富的产品供您选择。

公司成立到现在一直都在为各行业、各环境的客户OEM和ODM各种各样的单一气体1-氯丙烷气体检测传感器变送模块(网络版)。

如您有特殊的单一气体1-氯丙烷气体检测传感器变送模块(网络版)需要开发,请咨询我公司。

多年的技术经验和强大的技术实力您放心的选择保障!无线1-氯丙烷气体检测传感器变送模块(网络版)简介安帕尔科技的无线1-氯丙烷气体检测传感器变送模块(网络版)具有无线输出方式多样,产品种类齐全的特点;WIFI、Zigbee、LO1-氯丙烷A、433M、800M、GP1-氯丙烷S/3G/4G等各种无线输出方式随意选择,可以满足市场上各种客户对无线现场使用的要求。

如您需要开发它其功能的无线1-氯丙烷气体检测传感器变送模块(网络版),请咨询安帕尔科技。

我们公司有多年的研发经验和强大的技术实力可以满足您的需求,请您放心的选择我们。

市面上大部分1-氯丙烷气体传感器输出信号都是非标准信号,不能直接使用,需要经过输出信号放大、滤波等处理等才可以使用,安帕尔无线1-氯丙烷气体检测传感器变送模块(网络版)正是为了解决这个问题而研发的产品。

三,产品特点单一气体1-氯丙烷气体检测传感器变送模块(网络版)特点★产品质量可靠、性能稳定:10多年的气体检测传感器变送模块研发经验,保证了安帕尔单一气体1-氯丙烷气体检测传感器变送模块(网络版)质量、性能的可靠性。

idp10差压变送器说明书

IDP10差压变送器是一种用于测量流体流动中压力差的仪器,通常用于工业控制和监测系统中。

它可以测量液体、气体或蒸汽等流体的压力差,从而确定流体流速或流量。

以下是IDP10差压变送器可能包含的一些说明书内容:

1. 产品描述,说明书会包括IDP10差压变送器的基本参数和特性,比如测量范围、精度等。

同时还会介绍其外观特征、安装方式等信息。

2. 技术规格,说明书中会详细列出IDP10差压变送器的技术参数,包括输入/输出信号范围、工作温度、工作压力、防护等级等,这些参数对于用户选择合适的设备和安装环境非常重要。

3. 安装和使用说明,这部分会详细描述IDP10差压变送器的安装方法、使用注意事项、维护保养等内容,以确保用户能正确安装和使用设备,并且能够保持其性能。

4. 现场校准,说明书可能会包括IDP10差压变送器的现场校准方法和步骤,以确保其测量准确性和稳定性。

5. 故障排除,针对常见问题,说明书通常也会提供故障排除的方法和建议,帮助用户在设备出现问题时能够及时解决。

6. 安全注意事项,最后,说明书还会包括一些安全注意事项,以及设备的环保要求等内容,帮助用户正确、安全地使用IDP10差压变送器。

总的来说,IDP10差压变送器的说明书将会全面介绍设备的技术参数、安装使用方法、维护保养、故障排除等内容,以帮助用户正确、安全地使用该设备。

希望这些信息能够对你有所帮助。

压力变送器协议种类

1. 4-20mA模拟信号协议,这是最常见的压力变送器输出信号协议之一。

在这种协议下,压力变送器将压力信号转换为4-20mA的模拟信号输出,通常用于远程传输和连接到PLC或DCS系统。

2. HART协议,HART(Highway Addressable Remote Transducer)协议是一种数字信号协议,它可以在4-20mA模拟信号的基础上叠加数字信号,实现对压力变送器的远程监测和配置。

HART协议的应用使得压力变送器可以实现智能化管理和诊断功能。

3. Foundation Fieldbus协议,Foundation Fieldbus是一种数字通信协议,它提供了更高级的数据传输和控制功能,适用于对实时性要求较高的工业自动化系统。

压力变送器采用Foundation Fieldbus协议可以实现更复杂的控制和监测功能。

4. Modbus协议,Modbus是一种常用的工业通信协议,适用于建立压力变送器与上位机或其他设备之间的通信连接。

通过Modbus 协议,压力变送器可以实现与其他设备的数据交换和控制。

除了上述列举的几种协议外,还有一些专有的通信协议和接口

标准,如Profibus、DeviceNet等,它们也被广泛应用于压力变送器的通信连接中。

选择合适的协议种类取决于具体的应用场景和系统要求,以确保压力变送器能够与其他设备有效地进行通信和数据交换。

百易控(baykon)变送器1.TX1变送器模拟信号变送器TX1 模拟信号变送器是一款经济型的信号放大器,精度高,标准DIN导轨安装,适合集成到过程控制系统中。

利用按钮和LED实施等即可轻松实现其标定和设置。

信号输出可编程0-10V和4-20mA可选择接口提供了2个光电隔离的设定点,1个错误输出和1个外部的清零信号通过带RS232C串口的选装卡,由PC实现包括电子标定(eCal)和设定点值的设置及写入。

eCal-电子标定●利用“eCal-Transmitter”PC软件,无需加载砝码即可实现标定●适合大型称重料仓,筒仓及其他类似场合系统集成●可选择0-10V和4-20mA信号输出●零点输入●2个设定点输出●错误输出2.TX2数字变送器为您的PLC传送精确的数字称重数据TX2 数字式变送器是一款专为提供快速和准确的数字信号传输而设计的,所支持的数据接口有:RS232C,RS485,以太网,Modbus RTU,Modbus TCP/IP, Profibus,ProfiNet或者CANopen主要应用在称重,力和扭矩测试等过程控制系统中。

实现功能有:去零,去皮,开机清零,关机皮重恢复,运行状态检测,自动零点跟踪。

可配置的抗震自适应数字滤波器,通过现场总线或基于windows的baykon xFace 软件实现砝码标定或非砝码电子标定(eCal)。

标定可以在PLC端利用内码模式完成并且更换变送器无需重新标定。

DIN导轨式外壳可以方便的安装在您的控制柜中。

特点●接口:RS232C,RS485,以太网,Profibus,Modbus,RTU,Profinet,CANopen ●高速:最高800次/秒转换速率●抗震动滤波器:自适应抗震滤波器保证快速,稳定的数据输出。

●eCal:电子标定无需加载砝码。

●匹配:每个变送器都是经过标准化调整,保证性能一致性。

●称重功能:清零和去皮,开机清零。

●输入信号:双极性或者单极性称重传感器:最多可接6个阻抗为350欧的传感器。

目录目录概述 (1)特点 (1)工作原理 (1)CXT型差压(流量)变送器 (2)CXT型差压(流量)变送器(氢密封隔离膜片型) (12)CXT型压力变送器 (20)CXT型压力变送器(氢密封隔离膜片型) (29)CXT型绝对压力变送器 (36)CXT型双法兰远传差压变送器 (44)CXT型单法兰远传压力变送器 (53)CXT型液位变送器 (62)手持通讯器 (72)1概述CXT 型智能压力变送器采用了独特的硅微电容传感器、先进的浮动膜盒结构和最新的微处理器技术,具有变送准确度高、稳定性好、使用寿命长、安全可靠和使用方便等特点。

CXT 型智能压力变送器适用于石油、电力、化工、冶金、制药、轻工等行业中的压力、流量和液位测量等众多场合。

特点z准确度达到0.07%,量程比40:1 z兼容HART/FF/Profibus™协议 z不用标准压力的干校验 z高稳定性,三年≤±0.1% z 受温度和过压影响极小 z 通过调整旋钮即可调整零点 z 具有自诊断和远程维护功能 z NEPSI 认证, 隔爆型:Exd ⅡCT5 本安型:Exia ⅡCT4工作原理与传统微位移电容式变送器相比,CXT 型智能压力变送器的电容传感元件采用硅材料制成,体积特别小,仅9mm ×9mm ×7mm ,故称硅微电容传感器。

如图1所示,传感器是在单晶体硅薄片上刻蚀出来,具有体积小、响应快的特性;硅材料的热膨胀系数只有不锈钢的1/4,受环境温度变化的影响小;硅的弹性迟滞小,没有疲劳;硅微电容传感器的工作位移比传统微位移变送器工作位移小几十倍,仅4µm ,这样小的位移下,压力与位移呈精确比例关系,因而变送器的线性好,精度高。

硅微电容传感器采用整体封装,周围被封液包围,故称浮动膜盒结构,如图2所示。

CXT 型智能压力变送器的膜盒结构与传统膜盒结构有很大不同,硅电容传感器不在膜盒的下部,而是在上部。

传感器移到膜盒上部,远离测量介质,受介质温度变化的影响减小;同时检测器内部装有温度敏感元件来,根据敏感元件测量的温度,变送器微处理器随时修正变化带来的影响,所以仪表具有优异的温度特性;膜盒基座四周均受压力作用,所以受静压影响极小;图2中的保护膜片不再是测量膜片,当输入压力超过量程范围时,保护膜片产生变形,吸收部分封液压力,从而保护硅微电容传感器,变送器抗过压能力大大增强。

地址: 深圳市福田区天安数码城创新科技广场A座1706 邮编: 518040 电话:0755-8618652486186534传真**************深圳市特安仪器设备销售有限公司Shenzhen ExSaf Instrument Trading Co., Ltd.本资料所介绍的信息是对可选用技术的一般性介绍,并非与所有具体情况完全吻合。

因此,客户要求的技术选项应在合同中予以确定。

EXSAF致力于不断优化产品,因此文件中的技术数据会做相应更改。

版本号:A2深圳市特安工业技术有限公司Shenzhen ExSaf Industrial Technology Co., Ltd.地址: 深圳市南山区科技园朗山二号路五号洁净阳光园 邮编: 518057 电话**************传真**************产品说明书T350T智能压力变送器T350T 系列 (中文)T350T Series (English)131中文English提示注意与产品性能有关的重要信息和一般安全信息,如果不避免,可能产生较轻的损警告重要安全信息,可能导致重大事故、严重财产损失和人身伤亡的危险,必须 采取安全防范措施。

目录警告33.2 工作原理变送器的测量组件主要由压力传感器和测量电路组成。

3.2.1 压力传感器采用集成电路工艺在晶体硅片上制成压敏电阻,组成惠斯登电桥,作为压力转换的敏感器件。

介质压力通过隔离膜片和灌充液传递到敏感器件上,电桥失去平衡,为电桥施加一恒流激励,可将压力信号线性转换成电压信号。

以下是压阻式传感器结构示意图:3.2.2 测量电路测量电路对压力传感器信号进行调理和测量,送到数字处理芯片进行运算处理,得出压力值,然后通过显示屏、4-20mA电流和HART通讯等方式输出。

此外,测量电路还可以执行工程单位、量程、传递函数和阻尼等功能。

① 传感器连接座压阻式传感器剖面图② 压阻式测量元件③ 测量元件封装壳体④ 隔离膜片3.3 关键零部件清单序号零部件名称序号零部件名称1压力测量组件8EMC板2壳体组件9端子座组件3显示盖组件10按键挡板4端子盖组件11内六角紧定螺钉5按键组件12堵头6LCD组件13接地片7EMC组件14中文4. 技术特性4.1 性能指标量 程 比:100:1精度等级:0.075级、0.1级、0.2级稳 定 性:0.075级:36个月误差为最大量程的±0.15% 0.1级:36个月误差为最大量程的±0.2% 0.2级:36个月误差为最大量程的±0.25%温度影响:0.075级:零点或量程误差为最大量程的±0.15%/28℃ 0.1级:零点或量程误差为最大量程的±0.2%/28℃ 0.2级:零点或量程误差为最大量程的±0.25%/28℃输出信号:二线制,4~20mADC,HART ®协议数字信号 超下限电流:3.9mA;超上限电流:20.8mA 故障报警电流:3.75或21.75mA (1)阻 尼:0.1~32.0s (2)电 源:隔爆型:10.5~40V DC 本安型:10.5~28V DC 仅输出4~20mA DC 4~20mA DC及HART通讯注:HART通讯要求负载电阻范围是250~1000ΩE-10.50.02175R =1118100025010.5 16.2 33 36负载电阻R (Ω)防爆认证:隔爆型:Exd IIC T6 Gb本安型:Exia IIC T6 Ga或Exib IIC T4 Gb 防护等级:IP67环境温度:选用隔爆型,-30~70℃ 选用本安型,-30~60℃负载电阻:注:输出信号为RS485(ModBus协议)的变送器适用于隔爆环境的场所①②③④提示提示注意● 变送器壳体与压力测量组件的连接部分内有连接线。

Sensor Selection GuideSensing for Building ApplicationsCO 2SensorsThe Honeywell CO 2 sensor includes state-of-the-art non-dispersive infrared (NDIR) technology plus a corrosion-free-designed sensing chamber that provides accurate and stable CO 2 readings for years, avoiding costly and inconvenient re-calibration. A patented gold-plated sensing chamber eliminates a primary source of dirt. Paired with a Honeywell economizer, theHoneywell CO 2 sensor can triple year-round savings over “cooling only” economizing. The sensor is used in demand control ventilation applications to maintain acceptable levels of CO 2 in the space.Differential Pressure SensorsAll Honeywell differential pressure sensors offer field selectable 4-20 mA, 0-5 Vdc and 0-10 Vdc outputs, uni- and bi-directional outputs, push button and digital inputs to zero the output, and configurable pressure ranges. Use P7640 dry media sensors in applications where you want measure extremelylow pressure, such as clean rooms, hospitals, fume hoods and computer rooms. Use the PWT Series to monitor and control pump differential pressure, chiller/boiler differential pressure drop and CW/HW system differential pressure.Enthalpy SensorsHoneywell enthalpy sensors are used with Honeywell economizer logic modules to permit the use of outdoor air as the first stage of cooling in HVAC systems. Thelong-lasting solid-state sensing elements are accurate and stable over time. Maximum economizer savings are achieved when two enthalpy sensors are connected to one economizer logic module for differential enthalpy changeover control.Specify Honeywell Sensors And SaveHoneywell sensors have always been competitively priced, and today Honeywell sensors continue to be one of the industry’s best values. Add in the fact that their ease-of-installation increases your productivity and you’ll see that Honeywell sensors are the smart, cost-effective choice.2Honeywell’s complete line of sensor's cover all necessary control applications and mounting options, making Honeywell your best sensor source.Temperature SensorsYou can count on Honeywell temperature sensors for the latest technology, accurate performance and reliability. Honeywell temperature sensors feature solid-statecomponents and are impervious to dust and dirt.They cover a variety of applications that will fit your needs from averaging, immersion and outdoor sensors to duct-mount, wall mount and strap-on sensors.Current Sensors And SwitchesHoneywell current switches can detect whether current is flowing and then transmit the status to a building management system, DDC or PLC controller. Honeywellcurrent transmitters measure the level of operating current and can be used to monitor equipment or drive other equipment with a modulating output. Both current switches and transmitters can be used to detect a motor failure, belt loss or slippage, or a mechanical failure to help prevent further damage and reduce downtime. Because Honeywell current sensors are rated at up to 250 amps, you can meet high-amp applications without the need for a transformer. And Honeywell offers current switches with a very low trip point of 0.20 amps.Humidity SensorsHighly accurate, stable humidity transducers designed for use with HVAC controllers, thermostats and direct digital controllers, Honeywell humidity sensors feature a ceramic technology that’s affected by condensation. Applications include room comfort, rooftop units, air handlers, air conditioning and anywhere relative humidity is tightly controlled.Dew Point SensorsSuitable for mounting on flat and round surfaces, the Honeywell dew point sensor is used to regulate cooling performance, switch cooling systems ON and OFF, andsignal if the temperature is approaching the dew point.YOUR BeST SeNSOR SOURCe3thermostats and non-Honeywell thermostats with remote setpoint.* F or accessing virtually any point in thecontroller, balancing from wall module, etc. **TR75s also have over twice as much memory capacity for parameters as TR71's.4GeNeRAL TeMPeRATURe SeNSORST775-SENS-STRAPT775-SENS-OATT775-SENS-WRT775-SENS-WT50021579-001aFor use with T7350 applications. bFor use with W7100.* May be used with Duct Mounting Kit- Part # 50053060-001GeNeRAL TeMPeRATURe SeNSORS5NOTE: 20K ohms NTC sensors are used with excel 10, 15, 50, 100 and 500. See controller product data sheets for details. PT1000 sensors are used with excel 15, 100, 500, and 600. See controller product data sheets for details. PT3000 sensors are used on certain excel and Microcell products. See controller product data sheets for details. 3K ohm NTC sensors are used on W7100, W7459, W7215, W7212 an dall economizer modules. 10K ohms NTC Type II sensors are used with TB7600, TB7300, and TB7600 Series communicating thermostats. 10K ohms NTC Type III sensors are used with WeBs-AX I/OModules.C7041PC7041JC7041BTB-WALLC7041DC7041FC7041R6CURReNT SeNSORSSplit CoreSolid Core7HUMIDITY , DeW POINT, CO 2and PReSSURe SeNSORSH7655B, H7625B, H7635BC7600B, H7655AC7262A1008C7232BHSS-DPSAutomation and Control Solutions In the US: Honeywell1985 Douglas Drive North Golden Valley, MN 55422-3992In Canada: Honeywell Limited 35 Dynamic Drive Toronto, Ontario M1V 63-9285 PR October 2013© 2013 Honeywell International Inc.P7640BHUMIDITY , DeW POINT, CO 2and PReSSURe SeNSORS (CONT.)50035430PWT250Follow us on Twitter: @honeywellcproYouTube:@honeywellcpro。

目录电子说明书 (8)前言 (9)11重要的注意事项 ........................................................................................................... (11)序列号 (13) (13)13车架号 .........................................................................................................................13发动机号...................................................................................................................... (13)参数 (14)驾驶员安全 (17)17 (17)总体安全预警..............................................................................................................18 (18)设备改装......................................................................................................................21 (21)用户职责......................................................................................................................22防护装备...................................................................................................................... (22)避免危险驾驶行为 (25)车辆视图 (29)29左后视图...................................................................................................................... (29) (30)30右前视图......................................................................................................................操作部件 .. (31)31离合手柄...................................................................................................................... (31)制动手柄 ...........................................................................................................................................................................................................................................3131左手把开关 .................................................................................................................. ..................................................................................................................3232右手把开关 .................................................................................................................. ..................................................................................................................3333油门手把 ...........................................................................................................................................................................................................................................3333锁具 ............................................................................................................................. .............................................................................................................................3434换挡杆 ......................................................................................................................... . (3535)制动踏杆 ...........................................................................................................................................................................................................................................3636边撑 ............................................................................................................................. .. (3636)乘员扶手及脚踏装置................................................................................................... ....................................................................................................3737仪表 ............................................................................................................38仪表指示灯 .................................................................................................................. ..................................................................................................................3838仪表显示区 .................................................................................................................. ..................................................................................................................4040仪表调节 ...........................................................................................................................................................................................................................................4242如何驾驶本车 ..............................................................................................44磨合期 ......................................................................................................................... . (4444)日常安全检查 (4545)启动车辆 ...........................................................................................................................................................................................................................................4747车辆起步 ...........................................................................................................................................................................................................................................4848换挡,行驶 .................................................................................................................. ..................................................................................................................4848制动 ............................................................................................................................. .. (4949)停放 .............................................................................................................................50 (50)安全驾驶 (51)51 (51)安全驾驶技巧..............................................................................................................52 (52)高速驾驶特别注意事项 ................................................................................................维修保养 .. (53)53恶劣使用定义.............................................................................................................. (53)54 (54)推荐润滑......................................................................................................................55磨合期内保养表 ........................................................................................................... (55)58磨合期后保养表 ........................................................................................................... (58)离合手柄自由行程 (64)随车工具 (65)燃油系统 (66)66燃油箱 ......................................................................................................................... (66)67燃油要求...................................................................................................................... (67)67辛烷值等级 .................................................................................................................. (67)发动机总成 (68)机油油位检查..............................................................................................................68 (68) (69)69更换机油及机滤 ........................................................................................................... (70)70发动机机油容量 ...........................................................................................................71火花塞 ......................................................................................................................... (71)怠速 ............................................................................................................................. .. (7171)进排气系统 (72)排放油气监测系统 ....................................................................................................... .......................................................................................................7272进气门 ......................................................................................................................... .........................................................................................................................7272气门间隙 ...........................................................................................................................................................................................................................................7272空滤器 ......................................................................................................................... .........................................................................................................................7373节气门体 ...........................................................................................................................................................................................................................................7373冷却系统 .. (74)散热器及散热风扇 ....................................................................................................... .......................................................................................................7474散热器管路 .................................................................................................................. ..................................................................................................................7474冷却液 ......................................................................................................................... .........................................................................................................................7575冷却液检查 .................................................................................................................. (7676)冷却液添加 ....................................................................................................................................................................................................................................7676轮胎及链条..................................................................................................77轮胎规格 ...........................................................................................................................................................................................................................................7777轮胎载荷 ...........................................................................................................................................................................................................................................7878轮胎磨损 . (7979)驱动链条检查 (8080)驱动链条松紧度调整................................................................................................... . (8181)制动系统 (83)前制动手柄检查 ........................................................................................................... ...........................................................................................................8383后制动踏杆检查 ........................................................................................................... .. (8383)制动油位检查.............................................................................................................................................................................................................................8484制动液补充 .................................................................................................................. ..................................................................................................................8585制动盘检查 .................................................................................................................. ..................................................................................................................8787制动卡钳检查.. (8787)ABS ABS ............................................................................................................................. .. (88)88减震器 .........................................................................................................89减震器检查 .................................................................................................................. ..................................................................................................................8989后减震调节 .................................................................................................................. (8989)电气及光信号 ..............................................................................................90蓄电池 ......................................................................................................................... . (9090)蓄电池拆卸 ....................................................................................................................................................................................................................................9191蓄电池安装 .................................................................................................................. ..................................................................................................................9393灯光 ............................................................................................................................. .............................................................................................................................9494保险丝 ......................................................................................................................... . (9595)催化器 (96)燃油蒸发系统 (96)车辆清洁及储存 (97)一般预防措施 (9797)洗车 .............................................................................................................................98 (98) (99)99装饰表面......................................................................................................................99 (99)挡风玻璃和其它的塑料件............................................................................................铬合金和铝 ..................................................................................................................99 (99)储存前的准备工作 .....................................................................................................100 (100)从存储处取出车辆 .....................................................................................................101 (101)摩托车常见故障及原因 (102)整车通用扭矩表 (104)整车关键件扭矩表 (104)电子说明书本使用说明书包含印刷前最新的生产信息。

目 次前言 ................................................................................ I II1 范围 (1)2 规范性引用文件 ...................................................................... 1 3 通用术语 . (1)4 导航方式术语 (2)5 转向方式术语 ........................................................................ 3 6 驱动方式术语 ........................................................................ 4 7 驱动结构术语 ........................................................................ 4 8 性能参数 ............................................................................ 5 9 运动方向术语 (6)10 机构与零部件 (6)11 辅助零部件术语 ..................................................................... 7 12 软件功能术语 .. (8)13 充电/供电方式 (9)14 安全术语 .......................................................................... 10 英文索引 .. (12)中文索引 (14)全国团体标准信息平台前 言本标准按照GB/T1.1给出的规则起草。

OMA2000(V2.0.22[SO2,NO,O2,TPF流速])安装调试使用说明该程序是针对购买CEMS2000型产品并配套购买我公司自产的温压流一体化变送器TPF-100,同时不购买和使用工控机的应用。

由于我公司自产流速计4-20mA输出为差压信号,而不是流速信号,需要在上位机软件中再处理一道,因此如客户部购买上位机,就需要OMA表来完成差压到流速的换算。

使用中直接将温压流输出的差压4-20毫安信号接到OMA2000表模拟量输入端(模拟量输入2,在内部测试-模拟量输入中对应”预留”项),然后由OMA2000表通过计算差压与流速的对应关系计算出流速,并显示在界面上。

OMA-2000按照量程为0米每秒到40米每秒转换为4-20毫安信号由表的模拟量输出端输出。

示意图1.安装现场接线是将差压变送器的正端接至OMA2000表模拟量输入端的第4针,负端接至OMA2000表模拟量输入端的第17针(机柜电控上已经预留了接线端子,对应4-20mA输入2,接线时查看电控连线图)。

示意图现场流速的4-20毫安输出是OMA2000表模拟量输出端的第11针为流速4-20毫安输出正端,OMA2000表模拟量输出端的第3针为流速4-20毫安输出负端(机柜电控上已经预留了接线端子,对应4-20mA输出通道3,接线时查看电控连线图)。

示意图接好线路以后,依次点击界面进入ALL—>密码输入,然后输入“1226”,确认—>内部测试—>内部设置—>测量开关—>选择测量流速—>设置流速系数为1.1,流速上限为2000,流速下限为-2000—>设置,然后返回界面即可。

注:上限和下限对应的是差压变送器的量程,如上限为2000,下限为-2000,则差压变送器的量程为-2kPa~2kPa。

2.调试调试可选用回路校准仪,将回路校准仪调至电流输出4,正端接到OMA2000表模拟量输入端的第4针,负端接至OMA2000表模拟量输入端的第17针。

第29卷 第07期2022年07月仪器仪表用户INSTRUMENTATIONVol.292022 No.07SPPA-T2000系统AP离线分析及风险处理方案苏 正,文登宇,张启飞,冯 明(台山核电合营有限公司,广东 江门 529228)摘 要:介绍第三代中国先进压水堆(CEPR)SPPA-T2000系统AP 的构成及故障类型,并且阐述了各类AP 故障对机组运行造成的影响。

最后,选取对电站调试和运行过程中影响范围最大的AP 离线下装工作,给出了典型AP 离线下装过程中存在的风险、风险分析原则以及处理方案。

这对其它采用SPPA-T2000技术的核电、火电等项目都具有参考和借鉴意义。

关键词:SPPA-T2000;AP 离线下装;风险分析中图分类号:TP273 文献标志码:AAP Off-Line Analysis and Deal with Risk in SPPA-T2000 SystemSu Zheng ,Wen Dengyu ,Zhang Qifei ,Feng Ming(Taishan Nuclear Power Joint V enture Co., Ltd., Guangdong, Jiangmen, 529228, China )Abstract:Firstly, this paper introduces the AP unit of SPPA-T2000 system, which is used in the third generation advancedpressurized water reactor (CEPR) in China. Secondly, several kinds of AP maldunction are expounded, which can impact on the operation of nuclear plant unit. Finallly, chooses the AP off-line downloading which has the greatest impact on the commissioning and operation of the power station, then the risks existing in the typical AP off-line downloading process, the risk analysis princi-ple and treatment scheme was introdued. What’s more, it is significant to other projects which adopt SPPA-T2000 technology.Key words:SPPA-T2000;AP offline downloading;risk analysis收稿日期:2022-06-02作者简介:苏正(1983-),男,河北沧州人,本科,工程师,仪控部系统科科长,研究方向:DCS控制系统。

B-21MANÔMETRO ÚMIDO/Ou SENSOR DE PRESSÃO DIFERENCIALExemplo de pedido: PX26-030DV, intervalo bidirecional de ±30 psid.U Água e Muitos Outros Líquidos Podem Escoar em Ambos os Sentidos U Disponíveis em modelos para medir PressãoManométrica ou Pressão DiferencialU Projeto de Montagem em Placa PC MiniaturaESPECIFICAÇÕESExcitação: 10 VCC, 16 VCC máx a 2 mA Saída (a 10 VCC): 1 psi = 16,7 mV; 5 psi = 50 mV; >5 psi = 100 mV; 250 psi = 150 mVLinearidade: ±0,25% FE BFEL típico(±1% no máximo) P2 > P1Histerese e Repetibilidade: 0,2% FEEquilíbrio Zero: ±1,5 mVTolerância de Intervalo: ±3,0 mVEstabilidade de 1 Ano: 0,5% FETemperatura de Operação: -40 a 85°C (-40 a 185°F)Temperatura Compensada: 0 a 50°C(32 a 122°F)Efeitos T érmicos: Zero: 1 mV Intervalo: 1% da leituraPressão de prova: 20 psi paraintervalo ≤5 psi; 45 psi para 15 psi; 60 psi para 30 psi; 200 psi para 100 psiResistência de entrada: 7,5 k ΩResistência de Saída: 2,5 k ΩTempo de Resposta: 1 msTipo de Bitola: Sensor de silícioPartes úmidas: Polyethimide, silício,fluorosiliconePeso: 2 g (0,07 onça)PX26-005DV mostrado em escala maior que a real.Medidor DP25B-S, vendido separadamente, mostrado em escala reduzida.0-1 a 0-250 psi (0-0,07 a 17,2 bar) medidor e diferencialConector CX136-4vendido separadamente.Tubulação vendidaseparadamente.Os sensores de pressão da Série PX26 da OMEGA possuem a mais avançada tecnologia de silício que permite que ambos os lados dodiafragma atuem como sensores. Uma vedação única de condução entre o diafragma de silício e o alojamento de plástico permite utilizar em aplicações úmida/úmida com custos de produção menores do que os sensores de silício tradicionais de fio de ouro. Esta nova construção possui um diafragmamaior do que os sensores tradicionais de silício, resultando no aumento da estabilidade a longo prazo.Série PX26。

安费诺先进传感器推出IPT2000压力变送器

安费诺先进传感器推出一款IPT2000压力变送器,防护等级IP67,拥有优异的EMC性能,采用多种电气连接方式,可应用于工业过程控制、供热、HVAC控制、空压机、注塑机、工程机械、水处理、船舶、锅炉等领域。

安费诺先进传感器IPT2000压力变送器过载能力强,为满量程的6到10倍,拥有高灵敏度的输出功能同时微功耗;先进的数字补偿及放大工艺使产品具有更高的精度及低的温度系数;电子兼容设计使得抗干扰能力强,可以适用在各种恶劣环境。

作为安费诺授权分销商,Heilind可为市场提供相关服务与支持,此外Heilind也供应多家世界顶级制造商的产品,涵盖25种不同元器件类别,并重视所有的细分市场和所有的顾客,不断寻求广泛的产品供应来覆盖所有市场。

关于赫联电子(HeilindElectronics):

HeilindElectronics(赫联电子)创立于1974年,全球总部位于美国波士。