汽车外文翻译分析解析教学文案

- 格式:doc

- 大小:194.00 KB

- 文档页数:9

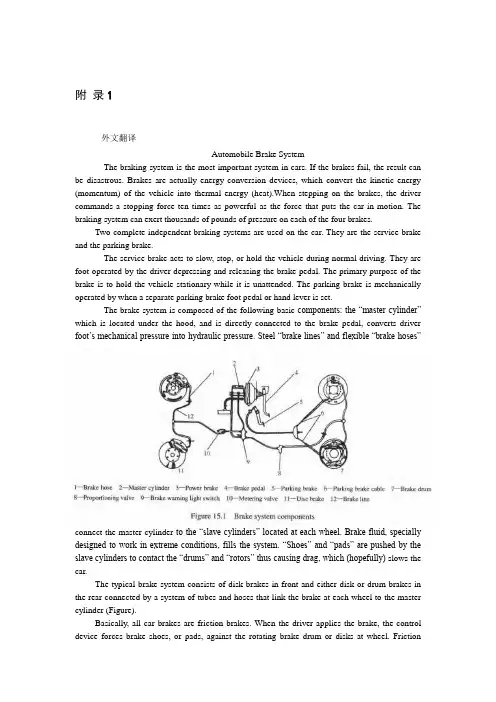

附录1外文翻译Automobile Brake SystemThe braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes.Two complete independent braking systems are used on the car. They are the service brake and the parking brake.The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set.The brake system is composed of the following basic components: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses”connect the master cylinder to the “slave cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. “Shoes” and “pads” are pushed by the slave cylinders to contact the “drums” and “rotors” thus causing drag, which (hopefully) slows the car.The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder (Figure).Basically, all car brakes are friction brakes. When the driver applies the brake, the control device forces brake shoes, or pads, against the rotating brake drum or disks at wheel. Frictionbetween the shoes or pads and the drums or disks then slows or stops the wheel so that the car is braked.In most modern brake systems (see Figure 15.1), there is a fluid-filled cylinder, called master cylinder, which contains two separate sections, there is a piston in each section and both pistons are connected to a brake pedal in the driver’s compartment. When the brake is pushed down, brake fluid is sent from the master cylinder to the wheels. At the wheels, the fluid pushes shoes, or pads, against revolving drums or disks. The friction between the stationary shoes, or pads, and the revolving drums or disks slows and stops them. This slows or stops the revolving wheels, which, in turn, slow or stop the car.The brake fluid reservoir is on top of the master cylinder. Most cars today have a transparent r reservoir so that you can see the level without opening the cover. The brake fluid level will drop slightly as the brake pads wear. This is a normal condition and no cause for concern. If the level drops noticeably over a short period of time or goes down to about two thirds full, have your brakes checked as soon as possible. Keep the reservoir covered except for the amount of time you need to fill it and never leave a cam of brake fluid uncovered. Brake fluid must maintain a very high boiling point. Exposure to air will cause the fluid to absorb moisture which will lower that boiling point.The brake fluid travels from the master cylinder to the wheels through a series of steel tubes and reinforced rubber hoses. Rubber hoses are only used in places that require flexibility, such as at the front wheels, which move up and down as well as steer. The rest of the system uses non-corrosive seamless steel tubing with special fittings at all attachment points. If a steel line requires a repair, the best procedure is to replace the compete line. If this is not practical, a line can be repaired using special splice fittings that are made for brake system repair. You must never use copper tubing to repair a brake system. They are dangerous and illegal.Drum brakes, it consists of the brake drum, an expander, pull back springs, a stationary back plate, two shoes with friction linings, and anchor pins. The stationary back plate is secured to the flange of the axle housing or to the steering knuckle. The brake drum is mounted on the wheel hub. There is a clearance between the inner surface of the drum and the shoe lining. To apply brakes, the driver pushes pedal, the expander expands the shoes and presses them to the drum. Friction between the brake drum and the friction linings brakes the wheels and the vehicle stops. To release brakes, the driver release the pedal, the pull back spring retracts the shoes thus permitting free rotation of the wheels.Disk brakes, it has a metal disk instead of a drum. A flat shoe, or disk-brake pad, is located on each side of the disk. The shoes squeeze the rotating disk to stop the car. Fluid from the master cylinder forces the pistons to move in, toward the disk. This action pushes the friction pads tightly against the disk. The friction between the shoes and disk slows and stops it. This provides the braking action. Pistons are made of either plastic or metal. There are three general types of disk brakes. They are the floating-caliper type, the fixed-caliper type, and the sliding-caliper type. Floating-caliper and sliding-caliper disk brakes use a single piston. Fixed-caliper disk brakes have either two or four pistons.The brake system assemblies are actuated by mechanical, hydraulic or pneumatic devices. The mechanical leverage is used in the parking brakes fitted in all automobile. When the brake pedal is depressed, the rod pushes the piston of brake master cylinder which presses the fluid. The fluid flows through the pipelines to the power brake unit and then to the wheel cylinder. The fluidpressure expands the cylinder pistons thus pressing the shoes to the drum or disk. If the pedal is released, the piston returns to the initial position, the pull back springs retract the shoes, the fluid is forced back to the master cylinder and braking ceases.The primary purpose of the parking brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by the driver when a separate parking braking hand lever is set. The hand brake is normally used when the car has already stopped. A lever is pulled and the rear brakes are approached and locked in the “on” position. The car may now be left without fear of its rolling away. When the driver wants to move the car again, he must press a button before the lever can be released. The hand brake must also be able to stop the car in the event of the foot brake failing. For this reason, it is separate from the foot brake uses cable or rods instead of the hydraulic system.Anti-lock Brake SystemAnti-lock brake systems make braking safer and more convenient, Anti-lock brake systems modulate brake system hydraulic pressure to prevent the brakes from locking and the tires from skidding on slippery pavement or during a panic stop.Anti-lock brake systems have been used on aircraft for years, and some domestic car were offered with an early form of anti-lock braking in late 1990’s. Recently, several automakers have introduced more sophisticated anti-lock system. Investigations in Europe, where anti-lock braking systems have been available for a decade, have led one manufacture to state that the number of traffic accidents could be reduced by seven and a half percent if all cars had anti-lock brakes. So some sources predict that all cars will offer anti-lock brakes to improve the safety of the car.Anti-lock systems modulate brake application force several times per second to hold the tires at a controlled amount of slip; all systems accomplish this in basically the same way. One or more speed sensors generate alternating current signal whose frequency increases with the wheel rotational speed. An electronic control unit continuously monitors these signals and if the frequency of a signal drops too rapidly indicating that a wheel is about to lock, the control unit instructs a modulating device to reduce hydraulic pressure to the brake at the affected wheel. When sensor signals indicate the wheel is again rotating normally, the control unit allows increased hydraulic pressure to the brake. This release-apply cycle occurs several time per second to “pump” the b rakes like a driver might but at a much faster rate.In addition to their basic operation, anti-lock systems have two other things in common. First, they do not operate until the brakes are applied with enough force to lock or nearly lock a wheel. At all other times, the system stands ready to function but does not interfere with normal braking. Second, if the anti-lock system fail in any way, the brakes continue to operate without anti-lock capability. A warning light on the instrument panel alerts the driver when a problem exists in the anti-lock system.The current Bosch component Anti-lock Braking System (ABSⅡ), is a second generation design wildly used by European automakers such as BWM, Mercedes-Benz and Porsche. ABSⅡsystem consists of : four wheel speed sensor, electronic control unit and modulator assembly.A speed sensor is fitted at each wheel sends signals about wheel rotation to control unit. Each speed sensor consists of a sensor unit and a gear wheel. The front sensor mounts to the steering knuckle and its gear wheel is pressed onto the stub axle that rotates with the wheel. The rear sensor mounts the rear suspension member and its gear wheel is pressed onto the axle. The sensor itself is a winding with a magnetic core. The core creates a magnetic field around thewinding, and as the teeth of the gear wheel move through this field, an alternating current is induced in the winding. The control unit monitors the rate o change in this frequency to determine impending brake lockup.The cont rol unit’s function can be divided into three parts: signal processing, logic and safety circuitry. The signal processing section is the converter that receives the alternating current signals form the speed sensors and converts them into digital form for the logic section. The logic section then analyzes the digitized signals to calculate any brake pressure changes needed. If impending lockup is sensed, the logic section sends commands to the modulator assembly.Modulator assemblyThe hydraulic modulator assembly regulates pressure to the wheel brakes when it receives commands from the control utuit. The modulator assembly can maintain or reduce pressure over the level it receives from the master cylinder, it also can never apply the brakes by itself. The modulator assembly consists of three high-speed electric solenoid valves, two fluid reservoirs and a turn delivery pump equipped with inlet and outlet check valves. The modulator electrical connector and controlling relays are concealed under a plastic cover of the assembly.Each front wheel is served by electric solenoid valve modulated independently by the control unit. The rear brakes are served by a single solenoid valve and modulated together using the select-low principle. During anti-braking system operation, the control unit cycles the solenoid valves to either hold or release pressure the brake lines. When pressure is released from the brake lines during anti-braking operation, it is routed to a fluid reservoir. There is one reservoir for the front brake circuit. The reservoirs are low-pressure accumulators that store fluid under slight spring pressure until the return delivery pump can return the fluid through the brake lines to the master cylinder.译文汽车制动系统制动系统是汽车中最重要的系统。

摘要:目前汽车专业英语的教学已经成为高职高专汽车工程学院各个专业的一门专业基础课,它的重要性也随着经济的发展而日益凸显。

本文主要对汽车专业英语的语言特点和翻译方法进行了分析。

关键词:汽车专业英语语言特点翻译方法1汽车专业英语词汇特点1.1技术词汇汽车专业英语主要用来介绍现代汽车,有其专门的词汇和术语,其专业性很强。

例如:crankcase(曲轴箱),camshaft(凸轮轴),detonation(爆震),turbocharger(涡轮增压器)等。

1.2次技术词汇这类词在各专业中出现的频率较高,在不同的专业中具有不同的含义,应联系上下文来确定它们的确切含义。

例如:在基础英语中eye 意思是“眼睛”,在专业英语中可以根据不同场合分别表示“孔”、“环”、“镜”、“圈”、“窗”、“吊眼”等;再如:spring(弹簧),part (零部件),valve face(气门锥面),springhouse (弹簧套)等。

1.3缩略词大量使用汽车专业英语中的缩略词主要是专业词组,一般是由词组中每个单词的首字母或由单词中的部分字母组成。

使用缩略词的目的是为了表达得简洁、直观。

汽车专业英语中的缩略词主要有节略词,缩略词,首字词和缩写词几种形式:①节略词:由单词后面的词根或者由单词前面的几个字母组成。

如:di(a)———diame-ter,chute———parachute,lab———laboratory 等。

②缩略词:由短语中的一些词的词头字母组成,按照正常词的发音规则发音。

如Radar———radio detecting and ranging (雷达)。

③首字词:由词组中每一个单词的首字母组成,发音时再逐个字母念出。

如:CPS———Camshaft Position Sensor (凸轮轴位置传感器),ECI———Electronic Con-trolled Ignition (电子控制点火)。

④缩写词:由一个单词变化而来,且大多数缩写词后面都附有一个圆点。

外文翻译(译文):第一章 活塞式发动机的工作客户的关注内燃发动机在各种尺寸和额定功率上的要求。

他们提出需要把机械能更好的用于中型和大型车的方案。

四缸发动机适应功率较小的车辆,并更好地提供比较大的发动机燃油经济性。

功能更强大的六缸和八缸发动机用于大多数中型和大型车。

十缸和十二缸发动机用于需要提供高性能的运动车型和主力电源功率的重型卡车。

发动机可能会有不同制造厂商来制造,但所有的活塞发动机具有相同的工作原理。

作为一个重要的汽车技术人员应该在你的事业上很好地理解这些原理。

技术人员面对的挑战作为一个汽车技术员,你需要找到这些问题的答案:1、如何让内燃发动机产生电力?它是如何转换成热能的?燃料在发动机内如何燃烧?2、什么是发动机的基本构造?发动机由哪些部分组成?什么是气缸、活塞、曲轴和凸轮轴?3、空气流量计、燃油系统、点火系统、润滑系统、冷却系统、排气系统的功用是什么?它们是如何配合工作的?第一部分 内燃式发动机目标:● 简述活塞功能。

● 简述连杆和曲轴的功用。

● 通过排气颜色、气味和声音诊断发动机的异常,确定必要的维修工作。

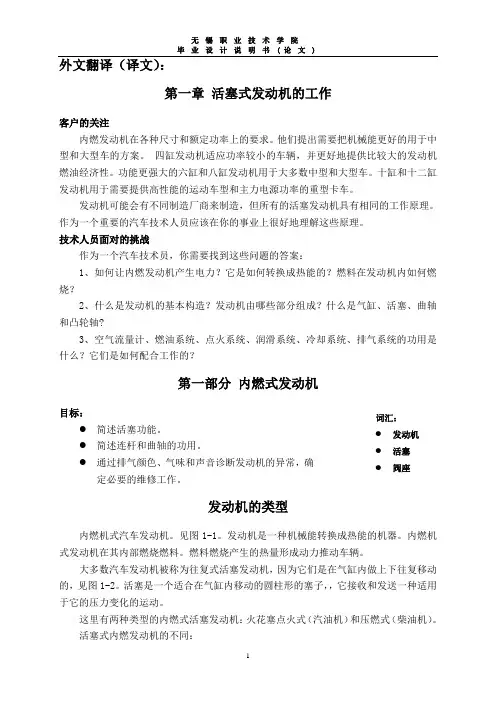

发动机的类型内燃机式汽车发动机。

见图1-1。

发动机是一种机械能转换成热能的机器。

内燃机式发动机在其内部燃烧燃料。

燃料燃烧产生的热量形成动力推动车辆。

大多数汽车发动机被称为往复式活塞发动机,因为它们是在气缸内做上下往复移动的,见图1-2。

活塞是一个适合在气缸内移动的圆柱形的塞子,,它接收和发送一种适用于它的压力变化的运动。

这里有两种类型的内燃式活塞发动机:火花塞点火式(汽油机)和压燃式(柴油机)。

活塞式内燃发动机的不同:词汇: ● 发动机 ● 活塞 ● 阀座●它们所使用的燃料类型。

●空气中的点火方式/燃料混合气的产生。

凸轮轴正时齿轮凸轮轴气门弹簧进气门排气门活塞连杆曲轴正时皮带曲轴正时齿轮图1-1 双顶置凸轮轴型V-6发动机。

火花点火式发动机使用什么燃料运行?往复运动旋转运动图1-2 往复运动是一种上下或者前后运动。

外文文献原稿和译文原稿A New Type Car -- Hybrid Electric VehicleWith skyrocketing fuel prices and changes in weather patterns, many car manufacturers claimed to develop the kind of vehicles that will increase the mileage and reduce the emissions. Hybrid car is a kind of vehicle which can meet above requirements. A hybrid car features a small fuel-efficient gas engine combined with an electric motor that assists the engine.The reasons of building such a complicated machine are twofold: to reduce tailpipe emissions and to improve mileage. Firstly, hybrid cars are good for the environment. They can reduce smog by 90 percent and they use far less gasoline than conventional cars. Meanwhile, hybrid cars burn less gasoline per mile, so they release fewer greenhouse gases. Secondly, hybrid cars are economical. Hybrid cars, which run on gas and electricity, can get up to 55 to 60 miles per gallon in city driving, while a typical SUV might use three times as much gas for the same distance! There are three reasons can mainly account for that: 1) Hybrid engines are much smaller than those on conventional cars. A hybrid car engine is to accommodate the 99% of driving time when a car is not going up hills or accelerating quickly. When extra acceleration power is needed, it relies on the battery to provide additional force. 2) Hybrid gasoline engine can shut off when the car is stopped and run off their electric motor and battery.3) Hybrid cars often recover braking energy. Electric motors could take the lost kinetic energy in braking and use it to charge the battery. Furthermore, hybrids are better than all-electric cars because hybrid car batteries recharge as you drive so there is no need to plug in. Most electric cars need to be recharged every 50-100miles. Also, most electric cars cannot go faster than 50-60 mph, while hybrids can.Hybrid cars bridge the gap between electric and gasoline-powered cars by traveling further and driving faster and hybrid gas-electric cars are proving to be a feasible alternative at a time of high gas prices. So, in my opinion, hybrid cars will have a bright future.How Does Hybrid Electric Vehicle Work?You probably own a gasoline or diesel-engine car. You may have heard ofelectric vehicles too. A hybrid vehicle or hybrid electric vehicle (HEV) is a combination of both. Hybrid vehicles utilize two or more sources of energy for propulsion. In the case of HEVs, a combustion engine and an electric motor are used.How it works depends on the type of drive train it has. A hybrid vehicle can either have a parallel or series or parallel-series drive train.Parallel HybridThe parallel hybrid car has a gas tank, a combustion engine, transmission, electric motor, and batteries.A parallel hybrid is designed to run directly from either the combustion engine or the electric motor. It can run using both the engine and the motor. As a conventional vehicle, the parallel hybrid draws its power from the combustion engine which will then drive the transmission that turns the wheels. If it is using the electric motor, the car draws its power from the batteries. The energy from the batteries will then power the electric motor that drives the transmission and turns the wheel.Both the combustion engine and the electric motor are used at the same time during quick acceleration, on steep ascend, or when either the engine or the motor needs additional boost.Since the engine is directly connected to the wheels in a parallel drive train, it eliminates the inefficiency of converting mechanical energy into electrical energy and back. This makes a very effective vehicle to drive on the highway.Series HybridThe series hybrid car also has a gas tank, a combustion engine, transmission, electric motor, and batteries with the addition of the generator. The generator can be the electric motor or it can be another separate component.The series configuration is the simplest among the 3. The engine is not connected to the transmission rather it is connected to the electric motor. This means that the transmission can be driven only by the electric motor which draws its energy from the battery pack, the engine or the generator.A hybrid car with a series drive train is more suited for city driving conditions since the engine will not be subjected to the varying speed demands (stop, go, and idle) that contributes to fuel consumption.Series-Parallel HybridThe series-parallel configuration solves the individual problems of the parallel and series hybrid. By combining the 2 designs, the transmission can be directly connected to the engine or can be separated for optimum fuel consumption. The Toyota Prius and the Ford Escape Hybrid use this technology.Honda’s hybridFor those of you who have toyed with the idea of buying a hybrid but were discouraged by the price, you are not alone. In fact, despite the growing concern for the environment, not to mention the skyrocketing price of gas, hybrid cars still only represent a small percentage of global car sales, and a major reason for this is the cost.Hybrids are considered the wave of the future because they not only reduce emissions, addressing the issue of climate change, but they get great gas mileage, animportant consideration with the current price of oil. It should be noted that hybrids can also improve the power of the engine, which compromises any advantages in fuel efficiency and emissions. Whatever the application, however, the technology makes the cars more expensive.Because of this, they are the vehicle of choice for only a small niche of people who can afford them, and they currently enjoy a special status amongst the image conscious celebrity-set. For most average consumers, however, they are not an option.That may soon change.Honda Motor Corporation, one of the largest car manufacturers in the world and a leader in fuel efficient technology, has unveiled it’s plan to introduce a low-cost hybrid by 2009. If they can pull it off, they hope to make the hybrid a more mainstream car that will be more appealing to the general public, with the ultimate goal of achieving greater sales and broader appeal than their current incarnation.This, of course, is making Detroit nervous, and may signal a need for American car makers to start making greener and more fuel efficient vehicles, something they could afford to ignore in the past because hybrid cars weren’t worth their attention (due to such a small market share) while gas-guzzling SUVs have such high profit margins.Honda, meanwhile, has had to confront a growing need to compete with Toyota, which has not only grown to be the world’s largest automaker, but makes the car that has become synonymous with the hybrid movement, the Prius. Honda is therefore faced with the seemingly insurmountable task of challenging Toyota’s dominance in the market.Concurrently, Toyota is racing to lower production costs on the Prius, as well, which would hopefully result in a lower cost to the consumer. All eyes are on a potentially favorable car buyers market in 2009.In the meantime, with even adamant global warming naysayers warming up (no pun intended) to the possibilities of an ecological disaster on the horizon, maybe it’s time that we got over our need to drive huge SUVs and start moderating our fuel consumption.Then again, as gas prices hovering around $4.00 and with no ceiling in sight, we may have little choice in the matter.Engine Operating PrinciplesMost automobile dngines are internal combustion, reciprocating 4-stroke gasoline engines, but other types have been used, including the diesel, the rotary ( Wankel ) , the 2-srtoke, and stratified charge.Reciprocating means up and down or banck and forth, It is the up and down action of a piston in the cylinder blick, or engine block. The blick is an iron or aluminum casting that contains engine cylinders and passges called water jackets for coolant circulation. The top of the block is covered with the cylinder head. Which forms the combustion chanber. The bottom of the block is covered with an oil pan or oil sump.Power is produced by the linear motion of a piston in a cylinder. However, this linear motion must be changed into rotary motion to turn the wheels of cars of trucks. The piston is attached to the top of a connecting rod by a pin, called a piston pin or wrist pin. The bottom of the connecting rod is attached to the crankshaft. The connecting rod transmits the up-and-down motion of the piston to the crankshaft, which changes it into rotary motion.The connecting rod is mounted on the crankshaft with large beaings called rod bearings. Similar bearings, called main bearings, are used to mount the crankshaft in the block. Shown in Fig. 1-1The diameter of the cylinder is called the engine bore. Displacement and compression ratio are two frequently used engine specifications. Displacement indicates engine size, and compression ratio compares the total cylinder volume to compression chamber volume.The term stroke is used to describe the movement of the iston within the cylinder, as well as the distance of piston travel. Depending on the type of engine the operating cycle may require either two or four strokes to complete. The 4-stroke engine is also called Otto cycle engine, in honor of the German engineer, Dr. Nikolaus Otto, who first applied the principle in 1876. In the 4-stroke engine, four strokes of the piston in the cylinder are required to complete one full operating cycle. Each stroke is named after the action it performs intake, compression, power, and exhaust in that order, shown in Fig1-2.1、Intake strokeAs the piston moves down, the vaporized mixture of fuel and air enters the cylinder through open intake valve. To obtain the maximum filling of the cylinder the intake valve opens about 10°before t.b.c., giving 20°overlap. The inlet valve remains open until some 50°after b.d.c. to take advantage of incoming mixture.2、 Compression strokeThe piston turns up, the intake valve closes, the mixture is compressed within the combustion chamber, while the pressure rise to about 1Mpa, depending on various factors including the compression ratio, throttle opening and engine speed. Near the top of the stroke the mixture is ignited by a spark which bridges the gap of the spark plug.3、 Power strokeThe expanding gases of combustion produces a rise in pressure of the gas to some 3.5Mpa, and the piston is forced down in the cylinder. The exhaust valve opens near the bottom of the stroke.4、Exhust strokeThe piston moves back up with the exhaust valve open some 50°before b.d.d., allowing the pressure within the cylinder to fall and to reduce ‘back’pressure on the piston during the exhaust stroke, and the burned gases are pushed out to prepare for the next intake stroke.The intake valve usually opens just before the exhaust stroke. This 4-stroke cycle is continuously repeared in every as long as the engineremains running.A 2-stroke engine also goes through four actions to complete one operatingcycle.However, the intake and the compression actions are combined in one seroke, and the power and exhaust actions are combined in the other stroke. The term2-stroke cycle or 2-stroke is preferred to the term 2-cycle, which is really not accurate.In automobile engines, all pistons are attached to a single crankshaft. The more cylinders an engine has, the more power strokes produced for cach revolution. This means that an 8-cylinder engine runs more smoothly bdcause the power atrokes are closer together in time and in degrees of engine rotation.The cylinders of multi-cylinder automotive engines arranged in one of three ways. 1、Inline engines use a single block of cylinder.Most 4-cylinder and any 6-cylinder engines are of this design. The cylinders do not have to be vertical. They can be inclined either side.2、V-type engines use two equal bands of cylinders, usually inclined 60degrees or 90degrees from the cach other. Most V-type engines have 6 or 8 cylinders, although V-4 and V-12 engines have been built.3、Horizontally opposed or pancake engines have two equal banks of cylinders 180degreeas apart. These space saving engine designs are often air-cooled, and are found in the Chevrolet Carvair, Porsches, Subaus, and V olkswagens. Subaus design is liquid cooled.Late-model V olkswagen vans use a liquid-cooled version of the air cooled VWhorizontally opposed engine.译文新型汽车----混合动力汽车在油价飞涨的今天,汽车制造商被要求发展一种排放低,行驶里程长的汽车。

保修对服务质量感知有影响吗?来自汽车维修和服务行业的研究Syed Saad Andaleeb;Amiya K Basu摘要检验了汽车维修行业中顾客总体满意度评价与它的五个评价因素——公平感知,同情心,敏感因素,可靠性和方便性五个因素之间的关系。

特别地,本文研究了担保对评价服务质量的影响。

并对之进行了调查。

结果发现,当服务没有担保时,同情心才是重要的。

公平和安全性也是重要的,当有担保时,这两项因素会得到提高。

有没有担保,敏感性和方便性都是重要的,并且不受担保的影响。

关键词:服务质量评估,顾客满意度SERVQUAL最近几年,服务业得到了大幅度的发展,并带动了世界经济。

这种趋势照目前看来,还会继续下去。

提供服务通常要求与大量的顾客进行联系。

市场必须提供非常好的服务才能取得成功,在当今这个以顾客为导向的市场上,竞争越来越激烈,为了存活下去,也必须提供很好的服务。

认识到服务的重要性,学术研究开始调查服务质量的观念是怎么建立和衡量的。

Parasuraman等在1988年识别出了影响服务质量的五个参数:同情心,敏感性,可靠性,方便和实用性,并且建议找出现有服务质量和顾客期望的服务质量之间的差距,并且把两者进行比率化,得出一个比率值。

这个模型就叫做SERVQUAL。

提出了一个服务质量评价的一般措施,这之后被广泛用于服务行业。

在此之后,大量的研究者在此基础上做了许多有用的研究,有的精炼了这个模型(Parasuraman等于1991年),有的在此基础上重新进行构建(Brown等于1993年,Peter 等也于1993年),甚至有的学者引入了新的模型(Carman于1990年)。

总结以上的变化如下:(1)在顾客观察到的服务质量和期望的服务质量之间,需要重点考察感知这个因素;(2)服务质量评估的参量需要进行一些特殊的范围修订;(3)为了解决特别的服务冲突部分,引入了一个新的参量。

本文整合了以上建议,并且聚焦于一个特殊的领域:美国汽车修理和维护行业。

The Car Modeling DesignFor car modelling, mention the word people often can produce immediately for lenovo in the form of various body, although it is not comprehensive, because car styling is the sum of outside and inside modelling, but had to admit that the appearance of the car is the most intuitive impression of automobile modeling for people. For the automobile modeling design, it covers knowledge engineering technology, art and so on various aspects of the application and market demand, to meet the consumers' taste and functional requirements.Literally what is undeniable is that the car modeling design is derived from the designers of creative expression, by the designer, to many human idea about the car for a reasonable attempt, constantly breakthrough self, challenge themselves. Car modelling design, whether it's like ordinary people use of household car, or royal family use limousine, or a professional driver favorite car, sports car, they all have very obvious differentiation on modelling, the people in the street to see what level of body, the brand, to the natural identity formed certain association of owners, and for different brands of automobile modeling design, which comes from different designers for car design. Car modelling design is also on the technical support of many other disciplines, here I am to have very important influence on development of automobile modeling design of some of the subject part lists are analyze.Since the emergence of the car, bionics started inadvertently used in the design of the model. For automobile modeling, the bionic design in automobile modeling with a unique code to liberate the inherent pattern design of modelling form, interpretation of power, speed, and the symbol of status, wealth, fashion, convey the entire design concept. Nowadays, bionics become guidance and aided automobile modeling design is an important subject, bionic design also gradually become an important means of design, it not only build the people and things, harmonious coexistence between man and nature, man and society, also prompted design found a new form.Bionic design is applied to the various design very early, so see it is not surprising that, in the car on modelling is my understanding of the bionics, it is the nature of some biological characteristics of the advantages of refining of science improving applied to other industries, it is the purpose of pursuing people to draw inspiration from the biological resources, such as car early in the development of a designer to design the "fish" car, maybe at that time did not rise up the subject of bionics, but stylist inadvertently used for fish in the water received by its own size decrease in water resistance and to speed up their swimming this, and apply onto the body modelling design, more typical case is 1952 gm buick brand "fish" type design, surface modeling is very dynamic, because the car interior ministry wide, wide field of vision, both passengers and drivers, inside the body will feel carefree, the affinity of car body itself has an irresistible, should allowstereotyped monotonous straight line in car design, is also a very important breakthrough at the time.There are a lot of examples, such as "viper" is a sports car, as America's most ferocious snake - "viper", has the characteristics of all nature disaster. "Viper" series of models, as a breakthrough point, the appearance of modelling design in particular the sharp front face and the spirit of the headlamps, give a person with terrible ferocity, good at dueling sensory stimulation, like soldiers courageous warrior, always ready to fight to the death, embodies the human eternal pursuit of the meaning of life. Viper, the second generation of 9 models, convey the intrinsic well. Automobile modeling bionic design with "from nature to the nature", as has been the pursuit of goals, the application of natural biological form surface is limited modelling space into endless spiritual awareness, create a bionic form of aesthetic value, to achieve the "personalized" demand and the state of "imitating the nature". Can reference on modelling human nature, The Times on the automobile modeling application development gradually, it seems to me is not only on the auto industry development and progress, is more of a human can live in the actual production of respecting nature, respect nature, from the development of bionics in the automobile modeling design process I can read the industry further development, it is also because modelling are close to the essence of life itself.Automobile modeling design purpose lies in the combination offunction and form aesthetic feeling, to give users in a certain emotional factors influence or impact on the market, on modelling design, different automobile modeling can bring a person different emotional experience, and to convey the designer wants to make people get on a car design.Automobile modeling design is applied art gimmick science express car function, structure and texture, and make people for its beauty. Automobile modeling design must reflect the style of the vehicle, such as streamlined can indicate the car has a higher speed, so as to shape a sporty image in the consumers' mind. Carbon fiber material can reflect the high-tech feeling and lightness of car, has a muscular body form can express powerful and protection of security. Excellent automobile modeling design can make consumers by aesthetic appreciation to deep understanding of its meaning, to produce the desire of the product. This is based on the perceptual technology this is not by many cognitive developed from cognitive psychology on the subject's important role on the automobile modeling design. It is stylist will be collected from the market information, through the analysis of consumer psychology that design more accord with human aesthetic and functional requirements of product evolutionary design, stylist is in perceptual information, consumer psychology and rational constraints (engineering) between coordination.In automobile product development model of "user as the center" in the early stage of the design need to study consumer's perceptual demand, andconsumers to seek in the perceptual demand often from the image of the car. Such as businessman to give reliable partners to form the image of good faith, the car for business occasions, modelling is generally very grave, composed, atmosphere; Racing car, for example, has very obvious streamline on modelling design, in order to display the car performance is strong, can run very fast, with enough instances of racer; Cultural entertainment venue such as car again, the modelling is compared commonly lively, fashion, have individual character, to show the meeting activities and the characteristics of representative. These are the perceptual technology on automobile modeling design is applied to car use and the appreciation of the most common level.Automobile modeling are actually very close to our daily life, on the streets everywhere the family car, taxi, bus, sometimes even see a cable car, luxury cars, sports car, saloon car. We have a lot of focus on automobile brand rather than modelling. But nature sense, any brand of car has its unique style of the modelling, we are to determine the brand car with its shape characteristics, such as seen in the street a lamborghini, its streamline appearance alone, we will be able to determine that it is lamborghini car, this is the car model represented by the car culture connotation. At the end of this course, the reason I chose to automobile modeling design analysis for class papers, but also for any automobile modeling design, as far as I'm concerned, is the designer of some design ideas of cultural interpretation,any design is necessarily comes from life, no experience and observation, can't make the products can be accepted by the public. Automobile modeling is not only the appearance, also is not only a decoration, interior space how to start from the Angle of human nature, and so on these elements are necessarily involve automobile modeling. So this is a worthy art, technology and market coordination aspects of creative achievement, no matter from what Angle to design the vehicle model, the ultimate goal is to continuously improve to meet the needs of users of the product.汽车造型设计对于汽车造型,提到这个词时人们往往能立即产生对于各种车身形态的联想,虽然它并不全面,因为汽车造型是汽车外部和车厢内部造型的总和,但不得不承认的是,汽车的外观的确是人们对于汽车造型的最直观印象。

一、教学目标1. 知识目标:学生能够掌握汽车英语的基本词汇,如引擎(engine)、轮胎(tyre)、刹车(brake)等,并能进行简单的汽车相关对话。

2. 能力目标:提高学生的英语口语表达能力,尤其是在实际情境中的交际能力。

3. 情感目标:激发学生对汽车文化的兴趣,培养学生热爱英语学习的情感。

二、教学重难点1. 重点:汽车英语词汇的记忆和运用。

2. 难点:在模拟情境中运用所学词汇进行对话。

三、教学过程(一)导入(5分钟)1. 教师展示一辆汽车图片,引导学生说出汽车的主要组成部分。

2. 提问:“Do you know how to describe a car in English?”,激活学生的英语思维。

(二)新课讲授(20分钟)1. 词汇教学:- 引导学生学习汽车英语词汇,如:engine, tyre, brake, door, window, seat, etc.- 通过图片、实物或PPT展示,帮助学生记忆词汇。

2. 句型教学:- 教授学生如何用英语询问汽车相关的问题,如:“What color is your car?”、“How many doors does your car have?”- 通过角色扮演,让学生练习对话。

3. 情境模拟:- 教师创设一个汽车维修店的情境,让学生分组进行对话练习。

- 学生扮演顾客和维修师傅,用英语询问汽车问题、描述汽车状况等。

(三)巩固练习(10分钟)1. 游戏环节:- 进行“Guess the Word”游戏,教师说出汽车英语词汇,学生根据提示猜出单词。

2. 小组讨论:- 分组讨论:如果去汽车展览,你会用英语介绍哪款汽车?请列举一些关键词汇。

(四)总结与作业(5分钟)1. 教师总结本节课所学内容,强调重点词汇和句型。

2. 布置作业:- 复习本节课所学词汇和句型。

- 准备一个简短的汽车介绍,下节课进行展示。

四、教学反思1. 本节课通过图片、实物、PPT等多种教学手段,激发学生的学习兴趣。

外文文献翻译附录A(英文原文)Adaptive Clutch Engaging Process Control Automatic Mechanical Transmission LIU Hai’ou(刘海鸥),CHEN HUI’yan(陈慧岩),DING Hua’rong(丁华荣),HE Zhong’bo(何忠波) Abstract: Based on detail analysis of cluch engaging process control targets and adaptive demands,a control strategy which is based on speed signal,different from that of based on main clutch displacement signal,is put forward.It considers both jerk and slipping work which are the most commonly used quality evaluating indexes of vehicle starting phase.The adaptive control system and its reference model are discussed profoundly.Taking the adaptability to different starting gears and different road conditions as examples,some proving field test records are shown to illusrate the main clutch adaptive control strategy at starting phase.Proving field test gives acceptable results. Key words: automatic mechanical transmission(AMT); transmission technology; adaptive control; main clutch engagement The engaging process control strategy of friction main clutch,whether wet or dry,is the focus in vehicle technology field.Some of the control strategies are based on main clutch displacement signal.An adaptive control strategy has been developed, which is based on main clutch out put shaft speed signal grounded on our research work.It is proved to have extensive adaptability. 1 Control Targets and Adaptive Demands The most commonly used quality evaluating indexes of vehicle starting phase are jerk and slipping work. Jerk—As an index evaluating the smoothness in vehicle starting phase, the jerk is the rate of vehicle longitudinal acceleration.According to this definition,the expression of jerk is given as j=da/dt=d2v/dt2 (1) where j is the jerk;v and a are the vehicle running speed and acceleration respectively. According to vehicle dynamics,the vehicle-run-ning speed is determined by the balance between engine traction force and running resistance and can be expressed as t v D e g gd Gd v A C f G T r i i 2 015 . 21 ) sin ( (2) Where e T is the engine out put torque;G is the vehicle total weight; r is the driving wheel radius; f and are the road resistance coefficient and ram p way angle respectively; D C is the air resistance coefficient. The function of a mechanism is to transform motion from one rigid body to another as part of the action of a machine,There are three types of common mechanical device that can be used as basic elements of a mechanism. 1.—Gear system,in which toothed members in contact transmit motion between rotating shafts. 2.Cam system,where a uniform motion of an input member I converted into a nonunifirm motion of the output member. 3.Plane and spatial linkages are also useful in creating mechanical motions for a point or rigid body. Mechanisms form thee basic geometrical element of many mechanical devices including automatic machinery,typewriters,mechanical toys,textile machinery,and others.A mechanism typically is designed to create a desired motion of a rigid body relative to a reference member.Kinematic design,or kinematic syntheses,of mechanisms often is the first step in the design of a complete machine.When forces are considered,the additional problems of dynamics,bearing loads,stresses,lubrication,and the like are introduced,aad the larger problem become one of machine design. Gear are machine elements that transmit motion by means of successively engaging teeth,Gears transmit motion from one ratating shaft to another, or to a rack that translates. Numerous applications exist in which a constant angular velocity ratio(or constant torque ratio)must be transmitted between shafts, Based on the variety of gear types available, there is no restriction that the input and the output shafts need be either in-line or parallel.Nonlinear angular velocity tratios are also available by using noncircccuar gear,In order to maintain a constant angular velocity,the individual tooth prifle must obey the fundamental law of gearing:for a pair of gears to transmit a constant angular velocity ratio,the shape of theircontacting profiles must be such that the common normal passes through a fixed point on the line of the centers. There are several standard gear types.For applications with parallel shafts,straight spur gear,parallel helical,or herringbone gears are usually used,In the case of intersecting shafts,straight bevel or spiral bevel gears are employed.For nonintersecting and nonparallel shafts,crossed helical,worm,face,skew bevel or hypoid gears would be acceptable choices.For spur gears,the pirch circles of mating gears are tangent to wach other.They roll on one another without sliding.The addendum is the height by which a tooth projects beyond the pitch circle(also the tadial distance between the pitch circle and the addendum circle).The clearance is the amount by which the dedendum (tooth height below the pitch circle)in a given gear exceeds the addendum of its mating gear,The tooth thickness is the distance across the tooth along the are of the pitch circle while the tooth space is the distance between adjacent teeth along the are of the pitch circle.TRhe backlash is the amount by which the width of the tooth space exceeds the thickness of the engaging tooth at the pitchi circle. Helical gears are used to transmit motion between parallel shafts.The helix angle I the same on each gear,but one gear must have a right-hand helix and the other a left-hand helix.The shape of the tooth is the angular edge of the paper becomes a helix.If wo unwind this paper,eachpoint on the angulaaar edge genetares an involute curve,The surface obtained when every point on the edge generates an involute is called an involute helicoids.in helical gears,the line is diagonal across the face of the tooth,It is this gradual engagement of the teeth and the smooth transfer of load from one tooth to another,which give helical gears the ability to transmit heavy loads at high soeeds,Helical gears subject the shaft bearings to both radial and thrust loads.When the thrust loads become high or are objectionable for other reasons,it may be desirable to use double helical gears.A doublehelical gear(herringbone)is equivalent to two helical gears of opposite hand,mounted side by side on he same shaft.They develop opposite thrust reactions and thus cancel at the thrust load.when two or more single helcal gears are mounted on the same shaft,the hand of the gears should be selected so as to produce the minimum thrust load. Straight bevel gears are easy to design and simple to manufacture and give very good results in service if they are mounted accurately and positively.As in the case of spur gears,however,they become noisy at higher values of the pitch-line velocity.In shese cases it is often good design practice to go to the spiral bevel gear,which is the bevel counterpart of the helical gear.As in the case of helicaal gears,spiral bevel bears give a much smoother tooth action than strain bevel gears,and hence are useful where high speed are encountered.It is frequently desirable,as in the case of automotive differential applications,to have gearing similar to bevel gears but with the shaft offset.Such gears are called hyoid gears because their pitch surfaces are hyperboloids of revolution,The tooth action between such gears is a combination of rolling and slidin along a straight line and has much in common with that of worm gears. A shaft is a rotating or stationary ually of circular cross section,having mounted power-transmission lements.Shafmay subjected to bending,tension,compression,or torsional loads,acting singly or in combination with one another,When they are combined,one may expect to find both static and fatigue strength to be important design considerations,since a single shaft may be subjected too static stresses,completely reversed,and repeated stresses,aii acting at the same time. The word “shaft” cover numerous variationgs,such as axles and spindles.An axle is a shaft,either stationary or rotating,not subjected to torsion load.A short rotating shaft is often called a spindle. When either the lateral or the torsional deflection of a shaft must be held to close limits,the shaft must besized on the basis of deflection,before analyzing the stresses,The reason for this is that,if the shaft is made stiff enough so that the deflection is not too large,it is probable that the resulting stresses will be safe,But by no means should the designer assume that they are safe;it is almost always necessary to calculate them so that he knows they are within acceptable limits.Whenever possible,the power-transmission elements,such as gears or pulleys ,should be located close to the supporting bearings.This reduces the bending moment,and hence the deflection and bending stress. According to the discussion of vehicle dynamics, the control of jerk and slipping work is related to the change rate of main clutch transmitting torque. However, the torque transducer cannot be installed in the control system,so the transient torque signal cannot be obtained directly.A method that some investigators use is to control the output torque through controlling main clutch engaging displacement.But the displacement can only reflect torque change indirectly. Their corresponding relationship is affected by many factors. And once the installed position changes or the signal drifts,it will be difficult to control the transmitting torque value accurately. The main clutch adaptive control strategy based on the speed signal adjusts the transmitting torque based on the jerk and the slipping work known from the change of rotating speed signal. 2 Conclusions ①The key technique of adaptive control strategy based on speed signal is the reference model. Different from the strategy based on main clutch displacement signal, it can reflect vehicle dynamics during engaging process and so can satisfy the engaging demands well. ②The reference model based on speed signal can be illustrated by the speed change course curve. Set the parameters for each sector correctly according to smooth and fast engaging demands, and the adaptive control target can be realized through adopting PWM/PFM control method. ③A large amount of tests that were conducted for along time show that thecontrol strategy based on speed signal has good adaptability and can adapt to different gears, road conditions, load, main clutch parameters(temperature, attrition wear and friction material) and driving styles. References: [1] Horn J,Bamberger J,Michan P,et al.Flatness-based clutch control for automated manual transmission[J]. Control Engineering Practice,2003(11):1353-1359.[2] Toshimichi Minowa,Tatsuya Ochi,Hiroshi Kuroiwa, et al. Smooth gear shift control technology for clutch-to-clutch shifting[R].SAE199120121054,1991. [3] Xi Jun qiang.Research on brushless electric motor driven automatic main clutch and its control strategy[D].Beijing:School of Vehicular and Transportation, Beijing Institute of Technology, 2001.(inChinese) [4] Lei Yu long, Ge An lin, Li Yong jun. Main clutch control strategy at vehicle starting phase[J]. Automotive Engineering,2000(4):266-269. (inChinese) [5] Andrew Szadkowski. Shiftability and Shift Quality Issues in Clutch Transmission Systems[R]. SAE 912697,1991. 附录B(译文)适应性离合器在机械自动传动中的加工控制刘海鸥,陈慧岩,丁华荣,何忠波(机械和车辆工程学校,北京技术学院,北京100081,中国)摘要:依靠对离合器运行过程的详细分析控制目标和适应的要求,一个主要依靠速度信号而不是那些依靠离合器的移动信号的控制策略被迅速发展。

驱动桥设计随着汽车对安全、节能、环保的不断重视,汽车后桥作为整车的一个关键部件,其产品的质量对整车的安全使用及整车性能的影响是非常大的,因而对汽车后桥进行有效的优化设计计算是非常必要的。

驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理地分配给左、右驱动轮,另外还承受作用于路面和车架或车身之间的垂直力力和横向力。

驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。

驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于载重汽车显得尤为重要。

驱动桥设计应当满足如下基本要求:1、符合现代汽车设计的一般理论。

2、外形尺寸要小,保证有必要的离地间隙。

3、合适的主减速比,以保证汽车的动力性和燃料经济性。

4、在各种转速和载荷下具有高的传动效率。

5、在保证足够的强度、刚度条件下,力求质量小,结构简单,加工工艺性好,制造容易,拆装,调整方便。

6、与悬架导向机构运动协调,对于转向驱动桥,还应与转向机构运动协调。

智能电子技术在汽车上得以推广使得汽车在安全行驶和其它功能更上一层楼。

通过各种传感器实现自动驾驶。

除些之外智能汽车装备有多种传感器能充分感知交通设施及环境的信息并能随时判断车辆及驾驶员是否处于危险之中,具备自主寻路、导航、避撞、不停车收费等功能。

有效提高运输过程中的安全,减少驾驶员的操纵疲劳度,提高乘客的舒适度。

当然蓄电池是电动汽车的关键,电动汽车用的蓄电池主要有:铅酸蓄电池、镍镉蓄电池、钠硫蓄电池、钠硫蓄电池、锂电池、锌—空气电池、飞轮电池、燃料电池和太阳能电池等。

在诸多种电池中,燃料电池是迄今为止最有希望解决汽车能源短缺问题的动力源。

燃料电池具有高效无污染的特性,不同于其他蓄电池,其不需要充电,只要外部不断地供给燃料,就能连续稳定地发电。

燃料电池汽车(FCEV)具有可与内燃机汽车媲美的动力性能,在排放、燃油经济性方面明显优于内燃机车辆。

另外,设计必须得考虑所选择材料的可加工性能。

外文文献原稿和译文原稿A New Type Car -- Hybrid Electric VehicleWith skyrocketing fuel prices and changes in weather patterns, many car manufacturers claimed to develop the kind of vehicles that will increase the mileage and reduce the emissions. Hybrid car is a kind of vehicle which can meet above requirements. A hybrid car features a small fuel-efficient gas engine combined with an electric motor that assists the engine.The reasons of building such a complicated machine are twofold: to reduce tailpipe emissions and to improve mileage. Firstly, hybrid cars are good for the environment. They can reduce smog by 90 percent and they use far less gasoline than conventional cars. Meanwhile, hybrid cars burn less gasoline per mile, so they release fewer greenhouse gases. Secondly, hybrid cars are economical. Hybrid cars, which run on gas and electricity, can get up to 55 to 60 miles per gallon in city driving, while a typical SUV might use three times as much gas for the same distance! There are three reasons can mainly account for that: 1) Hybrid engines are much smaller than those on conventional cars. A hybrid car engine is to accommodate the 99% of driving time when a car is not going up hills or accelerating quickly. When extra acceleration power is needed, it relies on the battery to provide additional force. 2) Hybrid gasoline engine can shut off when the car is stopped and run off their electric motor and battery.3) Hybrid cars often recover braking energy. Electric motors could take the lost kinetic energy in braking and use it to charge the battery. Furthermore, hybrids are better than all-electric cars because hybrid car batteries recharge as you drive so there is no need to plug in. Most electric cars need to be recharged every 50-100miles. Also, most electric cars cannot go faster than 50-60 mph, while hybrids can.Hybrid cars bridge the gap between electric and gasoline-powered cars by traveling further and driving faster and hybrid gas-electric cars are proving to be a feasible alternative at a time of high gas prices. So, in my opinion, hybrid cars will have a bright future.How Does Hybrid Electric Vehicle Work?You probably own a gasoline or diesel-engine car. You may have heard ofelectric vehicles too. A hybrid vehicle or hybrid electric vehicle (HEV) is a combination of both. Hybrid vehicles utilize two or more sources of energy for propulsion. In the case of HEVs, a combustion engine and an electric motor are used.How it works depends on the type of drive train it has. A hybrid vehicle can either have a parallel or series or parallel-series drive train.Parallel HybridThe parallel hybrid car has a gas tank, a combustion engine, transmission, electric motor, and batteries.A parallel hybrid is designed to run directly from either the combustion engine or the electric motor. It can run using both the engine and the motor. As a conventional vehicle, the parallel hybrid draws its power from the combustion engine which will then drive the transmission that turns the wheels. If it is using the electric motor, the car draws its power from the batteries. The energy from the batteries will then power the electric motor that drives the transmission and turns the wheel.Both the combustion engine and the electric motor are used at the same time during quick acceleration, on steep ascend, or when either the engine or the motor needs additional boost.Since the engine is directly connected to the wheels in a parallel drive train, it eliminates the inefficiency of converting mechanical energy into electrical energy and back. This makes a very effective vehicle to drive on the highway.Series HybridThe series hybrid car also has a gas tank, a combustion engine, transmission, electric motor, and batteries with the addition of the generator. The generator can be the electric motor or it can be another separate component.The series configuration is the simplest among the 3. The engine is not connected to the transmission rather it is connected to the electric motor. This means that the transmission can be driven only by the electric motor which draws its energy from the battery pack, the engine or the generator.A hybrid car with a series drive train is more suited for city driving conditions since the engine will not be subjected to the varying speed demands (stop, go, and idle) that contributes to fuel consumption.Series-Parallel HybridThe series-parallel configuration solves the individual problems of the parallel and series hybrid. By combining the 2 designs, the transmission can be directly connected to the engine or can be separated for optimum fuel consumption. The Toyota Prius and the Ford Escape Hybrid use this technology.Honda’s hybridFor those of you who have toyed with the idea of buying a hybrid but were discouraged by the price, you are not alone. In fact, despite the growing concern for the environment, not to mention the skyrocketing price of gas, hybrid cars still only represent a small percentage of global car sales, and a major reason for this is the cost.Hybrids are considered the wave of the future because they not only reduce emissions, addressing the issue of climate change, but they get great gas mileage, animportant consideration with the current price of oil. It should be noted that hybrids can also improve the power of the engine, which compromises any advantages in fuel efficiency and emissions. Whatever the application, however, the technology makes the cars more expensive.Because of this, they are the vehicle of choice for only a small niche of people who can afford them, and they currently enjoy a special status amongst the image conscious celebrity-set. For most average consumers, however, they are not an option.That may soon change.Honda Motor Corporation, one of the largest car manufacturers in the world and a leader in fuel efficient technology, has unveiled it’s plan to introduce a low-cost hybrid by 2009. If they can pull it off, they hope to make the hybrid a more mainstream car that will be more appealing to the general public, with the ultimate goal of achieving greater sales and broader appeal than their current incarnation.This, of course, is making Detroit nervous, and may signal a need for American car makers to start making greener and more fuel efficient vehicles, something they could afford to ignore in the past because hybrid cars weren’t worth their attention (due to such a small market share) while gas-guzzling SUVs have such high profit margins.Honda, meanwhile, has had to confront a growing need to compete with Toyota, which has not only grown to be the world’s largest automaker, but makes the car that has become synonymous with the hybrid movement, the Prius. Honda is therefore faced with the seemingly insurmountable task of challenging Toyota’s dominance in the market.Concurrently, Toyota is racing to lower production costs on the Prius, as well, which would hopefully result in a lower cost to the consumer. All eyes are on a potentially favorable car buyers market in 2009.In the meantime, with even adamant global warming naysayers warming up (no pun intended) to the possibilities of an ecological disaster on the horizon, maybe it’s time that we got over our need to drive huge SUVs and start moderating our fuel consumption.Then again, as gas prices hovering around $4.00 and with no ceiling in sight, we may have little choice in the matter.Engine Operating PrinciplesMost automobile dngines are internal combustion, reciprocating 4-stroke gasoline engines, but other types have been used, including the diesel, the rotary ( Wankel ) , the 2-srtoke, and stratified charge.Reciprocating means up and down or banck and forth, It is the up and down action of a piston in the cylinder blick, or engine block. The blick is an iron or aluminum casting that contains engine cylinders and passges called water jackets for coolant circulation. The top of the block is covered with the cylinder head. Which forms the combustion chanber. The bottom of the block is covered with an oil pan or oil sump.Power is produced by the linear motion of a piston in a cylinder. However, this linear motion must be changed into rotary motion to turn the wheels of cars of trucks. The piston is attached to the top of a connecting rod by a pin, called a piston pin or wrist pin. The bottom of the connecting rod is attached to the crankshaft. The connecting rod transmits the up-and-down motion of the piston to the crankshaft, which changes it into rotary motion.The connecting rod is mounted on the crankshaft with large beaings called rod bearings. Similar bearings, called main bearings, are used to mount the crankshaft in the block. Shown in Fig. 1-1The diameter of the cylinder is called the engine bore. Displacement and compression ratio are two frequently used engine specifications. Displacement indicates engine size, and compression ratio compares the total cylinder volume to compression chamber volume.The term stroke is used to describe the movement of the iston within the cylinder, as well as the distance of piston travel. Depending on the type of engine the operating cycle may require either two or four strokes to complete. The 4-stroke engine is also called Otto cycle engine, in honor of the German engineer, Dr. Nikolaus Otto, who first applied the principle in 1876. In the 4-stroke engine, four strokes of the piston in the cylinder are required to complete one full operating cycle. Each stroke is named after the action it performs intake, compression, power, and exhaust in that order, shown in Fig1-2.1、Intake strokeAs the piston moves down, the vaporized mixture of fuel and air enters the cylinder through open intake valve. To obtain the maximum filling of the cylinder the intake valve opens about 10°before t.b.c., giving 20°overlap. The inlet valve remains open until some 50°after b.d.c. to take advantage of incoming mixture.2、 Compression strokeThe piston turns up, the intake valve closes, the mixture is compressed within the combustion chamber, while the pressure rise to about 1Mpa, depending on various factors including the compression ratio, throttle opening and engine speed. Near the top of the stroke the mixture is ignited by a spark which bridges the gap of the spark plug.3、 Power strokeThe expanding gases of combustion produces a rise in pressure of the gas to some 3.5Mpa, and the piston is forced down in the cylinder. The exhaust valve opens near the bottom of the stroke.4、Exhust strokeThe piston moves back up with the exhaust valve open some 50°before b.d.d., allowing the pressure within the cylinder to fall and to reduce ‘back’pressure on the piston during the exhaust stroke, and the burned gases are pushed out to prepare for the next intake stroke.The intake valve usually opens just before the exhaust stroke. This 4-stroke cycle is continuously repeared in every as long as the engineremains running.A 2-stroke engine also goes through four actions to complete one operatingcycle.However, the intake and the compression actions are combined in one seroke, and the power and exhaust actions are combined in the other stroke. The term2-stroke cycle or 2-stroke is preferred to the term 2-cycle, which is really not accurate.In automobile engines, all pistons are attached to a single crankshaft. The more cylinders an engine has, the more power strokes produced for cach revolution. This means that an 8-cylinder engine runs more smoothly bdcause the power atrokes are closer together in time and in degrees of engine rotation.The cylinders of multi-cylinder automotive engines arranged in one of three ways. 1、Inline engines use a single block of cylinder.Most 4-cylinder and any 6-cylinder engines are of this design. The cylinders do not have to be vertical. They can be inclined either side.2、V-type engines use two equal bands of cylinders, usually inclined 60degrees or 90degrees from the cach other. Most V-type engines have 6 or 8 cylinders, although V-4 and V-12 engines have been built.3、Horizontally opposed or pancake engines have two equal banks of cylinders 180degreeas apart. These space saving engine designs are often air-cooled, and are found in the Chevrolet Carvair, Porsches, Subaus, and V olkswagens. Subaus design is liquid cooled.Late-model V olkswagen vans use a liquid-cooled version of the air cooled VWhorizontally opposed engine.译文新型汽车----混合动力汽车在油价飞涨的今天,汽车制造商被要求发展一种排放低,行驶里程长的汽车。

在混合动力车上系统选择动力传动系统结构和部件尺寸的方法Jonas Hellgren 和 Bengt Jacobson机械和车辆设计, Chalmers 科技大学版权 2000 汽车工程协会摘要节约能源和制造较少污染性能的汽车, 变成越来越紧急的主题。

一个原因就是世界上对快速的运输要求正在增加, 全球变暖的危险是一个事实。

混合动力汽车(HV:s) 被提出作为环境友好的候选者超过传统的车辆。

时下,有各种各样的不同类型的混合车和成分集合体,理论上, 用无限多的方法限制在规定的尺寸。

没有的简单答案如何做到在一个混合车辆上选择动力传动系统结构而且按规定尺寸安排各组成部分。

这篇文章描述一个方法,动力传动系统综合(DS),有系统地呈现了如何根据具体的要求和条件选择一个适当的动力传动系统。

具体示例:要求是驱动循环和在自由行驶区,条件是考虑燃料价格,污染交税和贴现率。

最适当的动力传动系统被定义为最具有花费效果的。

总成本被定义为以下的总和:组成物的成本,燃料成本,外部能源的成本和污染的成本。

遗传基因运算法则被当做一最佳化方法二个主要类型的动力传动系统在同一情况下比较研究, 一个具有柴油机和自动传动系统的传统公共汽车和一个具有不同类型的初级动力源(柴油机或者燃料电池)和储能装置(超级电容或 NiMH 电池)的串联混合动力公共汽车。

DS 提供合理的答案但是需要更进一步确认和发展。

得河北工程大学毕业设计出的结论是最适当的动力传动系统结构非常依赖要求,条件和当前的技术,也就是 HV : s 只是在特别的环境下比传统的较好的车辆。

关键字: 混合的动力传动系统,可供选择的动力传动系统,动力传动系统,动力传动系统结构,混合动力汽车,驱动系统,混合动力电动汽车,组成物,结构,涂上胶水,遗传基因的运算法则,最佳化,模拟。

介绍为什么使用混合动力汽车混合动力汽车(HV:s) 有减少燃料消耗和发散的潜能,由于全球变暖和地方污染的影响,这已经是紧急的议题。

附录A外文文献原文:In recent years, along with the social life of car motorization, increasing quantities, cause the traffic situation intricate, make drivers to offer the operating frequency increases, driving you need to lighten the fatigue, improve ma nipulation portability and flexibility, and thus power steering system requirements for more and more is also high.So far, automotive steering system through the traditional mechanical steering system, hydraulic steering system and electric hydraulic steering system and electric power steering system four stages of development, the future is likely to wire control power steering system development. Now automotive steering system is in hydraulic steering system and electric hydraulic steering system to electric power steering system development stages of transition .1. the traditional mechanical steering systemTraditional mechanical steering system (MS) mainly by steering control agencies, steering gear and steering transmission mechanism 3 parts. Steering control mechanism is the pilot control redirector work institutions, including the steering wheel at the input from components. The steering wheel steering is coming from torque according to certain transmission amplifier and output increases force device, steering the earliest USES is the worm type, later have a screw nut type, rack-and pinion type, circulation ball type and other forms. Steering transmission mechanism is passed to the output torque steering steering wheel agencies, including the steering wheel from pitman arm of components . When the car needs to change directions, the pilot through turned the steering wheel, steering moment, steering, via steering shaft, horizontal bars and straight bars such as the steering trapezoid arm parts, and to make the day deflection change of direction.Traditional mechanical steering system is the advantage of simple structure, reliable operation, the production cost is low. Its defect is also very obvious: (1) with the bus speed improvement and automotive quality increases, steering control, turning to more and more demanding increased the difficulty. (2) is the ratio is fixed, namely Angle transfer characteristics, cause the car can't change the steering response characteristics are unable to control and transmission in the process of steering cannot with speed and lateral acceleration and other parameters of the changes, the pilot must compensate for car before in turn the steering response characteristics of certain operating compensation, such virtually increased the mental and physical burdens driver .2. hydraulic steering systemHydraulic steering system (HPS) is the traditional mechanical steering system basis with a set of additional hydraulic booster, generally by oil pump, v-shaped belt wheel, oil injection equipment, power devices and control valves etc. It with hydraulicoil pump is the power, through the movement to promote produced mechanical redirector work.Because the system through hydraulic works used to promote the traditional mechanical steering mechanism of steering movement so as to reduce the labor intensity, a driver in a certain extent, solve the traditional mechanical steering system caused because of transmission ratio fixed to "light" and "sensitive" the contradiction between. But, this kind of power steering system is driven by the steering wheel rotates the hydraulic system directly change torsion bar is the channel area to provide oiling the instrumentality of variable. Namely the discretion of size and speed boost have no relation with steering Angle, only concerned. Steering dish of greater perspective, turn the instrumentality of hydraulic systems provide is bigger also. Meanwhile, this system has the following weakness: (1) no matter car turn not to, as long as the engine and hydraulic motor drive ZhuLiBeng will work under the energy, the extra consumption engine. (2) the steering characteristics not adjusted, high-speed and same speed dynamical characteristics. In low-speed steering need bigger boost, often for engine speed and low power poor effect, while in high-speed steering need smaller, will boost for engine speed high and power function big, bring about steering too sensitive, that the car manipulation stability becomes poor. (3) the inherent hydraulic system of the hydraulic oil leakage problems and steering noise makes steering comfort, meantime, dramatically reduced environmental pollution.Because of hydraulic steering system reliable work, mature technology, can provide the big steering and has been widely used.3. electrohydraulic power steering systemElectrohydraulic power steering system at work steering characteristics can be changed. It basically has two kinds: electric hydraulic steering system (ECHPS) and electric hydraulic steering system (EHPS). Now automotive applications is the largest electric hydraulic booster turn from system.3.1 electronic control hydraulic power steering systemElectric hydraulic steering system (ECHPS) in hydraulic steering system is based on the liquid flow rate increased control solenoid valves, torque sensor, the wheel speed sensors and steering control unit etc components. Ideally, car in spin to try to deft, request when in cars to different speed operation, which can real-time provide corresponding steering to overcome the running speed to make drivers to resistance to manipulate the steering wheel can both lightweight, and have enough way feeling.In steering process, through the torque sensor, speed sensor etc sensing device will shift to rate, speed transfer to parameters such as steering control unit. After decoding, control by electromagnetic valve with liquid flow speed changing, and change the size of the moment, make grants to individual driver according to speed and driving conditions, changes to manipulate portability and stability to harmony. But at the same time, ECHPS also exist because of oil pump continuous work caused by excess energy consumption, the hydraulic system occupies a large space, easy to leak, noise big shortcomings, and increased its speed detection control device. Andthe control valve of structure than HPS complex and cost is higher, which are mainly applied in limousines and sports by using the car.3.2 electric hydraulic steering systemElectric hydraulic steering system (EHPS) is in hydraulic steering system developed on the basis of. Its characteristic is driven by the engine turns ZhuLiBeng shifted the hydraulic motor drive, and increased its speed sensor, steering angular velocity sensor and steering control unit etc electricals. The system of hydraulic oil tank, oil pump, motors and steering control unit has integrated in motor oil pump in the group. Work steering control unit according to car of the speed and steering Angle calculated as the input signal output signal, control ideal appropriate power, motor output ZhuLiBeng driven hydraulic work. Through the hydraulic oil for steering gear provide power.Electrohydraulic power steering system although in hydraulic steering system basis of technology has greatly improved, but the existence of hydraulic equipment are still made the system, such as the hard to overcome shortcomings existing oil leakage, not easy installation and maintenance, etc. Although realized the change, but the dynamical characteristics in hydraulic booster system based on electronic control device increased again, making the system structure is complex, cost increases. Because electro-hydraulic steering system technology, may realize the mature electronic-controlled system integration, vehicle as traditional hydraulic steering system to electric power steering system of intermediate technology of transition, in certain time will continue to receive applications and development.4. electric power steering system (EPAS or EPS)Electric power steering system is the traditional mechanical steering system foundation, increased sensor device, electronic control devices and steering mechanism, etc. Its characteristic is to use electric actuators in different driving conditions for pilot provide appropriate support. System mainly consists of the electronic control unit ECU, torque sensor, the wheel speed sensors, motor, clutch and the steering assembly etc.Electric power steering system working principle is: the pilot control steering, the sensor will pilot role in steering wheel torque signal, speed signal, engine speed signal input ECU, ECU of the input signal calculations, inquires the booster form, determine the size and direction target current, so as to control motor current and the direction, by slowing institutions and clutch motor torque transfer to steering mechanism will be, so as to provide the proper power; driver When steering system malfunction, EPS system does not support. Don't turn circumstances, motor doesn't work. Electric power steering system can real-time in different speed for car turned to provide different under the instrumentality of guarantee in low-speed driving car deft and agile, high speed is stable and reliable. Electric power steering system generally consists of mechanical parts and controlling part. Mechanical parts mainly include transmission unit (the clutch, the steering assembly) and execution unit (electrical), etc. Control part mainly according to sensors to speed and torque signal for computing,drive motor control instructions issued to provide power for steering.EPS compared with HPS, except to save energy outside, due to the elimination of the hydraulic system and improve the environmental performance, solves the malpractices of hydraulic drive brings. The system is made of manufacturers to provide to the vehicle manufacturer, can be directly mounted. Under different conditions of different models, and different for different drivers steering properties, through software modification, convenient and quick. Complete EPS system also includes fault diagnosis and safety protection system. When malfunction happened, could stop booster, automatic recovery to manually control mode and warning signal, and show the memory of abnormal content such as torque sensor itself anomalies, and motor speed sensor abnormal work abnormal, battery abnormal etc.Electric power steering system has become the vehicle steering system technology development, but the system of mainstream has its limitations, because motor power steering and provide power is limited, if the body is heavier, steering system needs to have larger drive power, electric power steering system is ragged. So the system more for small cars, has lots of equipment to senior cars, and gradually to regular cars and small commercial vehicle development.5. wire control power steering systemWith power Steering technology development, the Wire control power Steering system (Steering By Wire, abbreviation SBW) is as automobile electronic technology development and grows the latest achievements of a brand-new Steering system. It through the wire transfer signals, control actuator action to replace traditional steering system of mechanical transmission and mechanical connection from the main controller, help torque in corresponding parameters, after decoding to turn his orders, by executive motor steering motor provides.SBW cancelled and steering wheel steering plate between mechanical connection device, now the steering wheel module, steering executive module and the main controller ECU, three main parts and automatic protection fault systems, power auxiliary module. It is made up of a real-time bus structure (for example, FlexRay HTTP or CAN) connected to the equipment. Can easily and other system integration, unified coordination control. System work, sensor test driver's steering data, then through the data bus would signals to the ECU, and getting feedback from steering control system command. Steering control system is also obtained from steering control agencies, and the steering instructions drivers from steering system obtain wheel situation, thus command the steering system of sports. Steering system KongZhiChe cycle to need Angle, and will wheel corner and rotationa l torque feedback to the rest of the system, such as steering control agencies, in order to make drivers get way feeling, the size of the road are according to different conditions can be controlled by steering control system. The steering system has many advantages: (1) the intervene problem to eliminate steering; (2) removed originally steering system modules of mechanical connection between rigid, has greatly facilitated the system's total decorate; (3) comfort enhancement; (4) can be personalized land suitable for specific driver and driving environment, and steering behavior could beabout driving through software to realize; (5) the crash to eliminate the possibility of hacking, don't hurt the driver set to prevent injury institutions; 6 the driver went leg activity space increases, more convenient.Ship-turning plate and the steering without mechanical connection between, generating let pilot able to perceive cars driving condition and actual road conditions "lk feeling" is more difficult, so current power steering system wire used only for some concept car. Has not conducted batch production and installation, its reliability and cost is the main cause of blocking its development. Mainly displays in if micro controller appears problem, steering system will completely failure, it is not like electric power steering system and electric hydraulic steering system and hydraulic steering system, in motor or hydraulic system problems, still can take the human to control the car. The system of micro controller if malfunction, because no mechanical system is connected the steering wheel and steering gear, so it could not control cars to turn around.6. for wire control power steering system outlookAlthough wire control power steering system now not satisfactory, but SBW still clear is car development direction. SBW system eliminates mechanical connection between the design of steering wheel, tyre will be greatly simplified. Not only improve the design efficiency, but also improve the economy, and car improve overall safety. SBW system work mainly by the electronic components to assume. The application of electronic components marks a considerable amount of mechanical parts reductions, and steering system the size and weight of ease. The whole process of steering by electronic device to achieve, which greatly improved vehicle fuel efficiency. Because only in need to, we have energy consumption. Based on instantaneous driver condition, the control unit of data from receiving other systems, actuator force needed only supply tires. Steering performance improvement is dependent on sensor receives speed, traction control system and other related variables. When the accident happened to the driver, the most dangerous is the steering wheel collisions. In the car with SBW system, many injuries and deaths due to the steering wheel can be eliminated.Due to the elimination of the mechanical connection, so to high reliability is absolutely necessary. In Europe, have related standards, such as IEC 61508 and EN 61511. Pure electronic system cannot guarantee failure conditional probability of less than 10 times failure/hour. Because of this and designed the system structure of the fault tolerance, and accurate processing strategy method is necessary. In the control strategies to avoid the failure data errors, and from, active detection, self diagnosis and protection will be used to achieve safety and reliability. For the foreseeable SWB system design and analysis of tolerance, it will become one of the important before SWB popular topic.附录B译文:近年来,随着社会生活的汽车化,汽车的数量不断增加,由此造成交通情况错综复杂,使得驾驶员转向盘的操作频率增大,这就需要减轻驾驶疲劳,提高操纵的轻便性和灵活性,因此对动力转向系统的要求也越来越高。