供应商物料环境管理体系调查表(中英文)

- 格式:pdf

- 大小:174.77 KB

- 文档页数:3

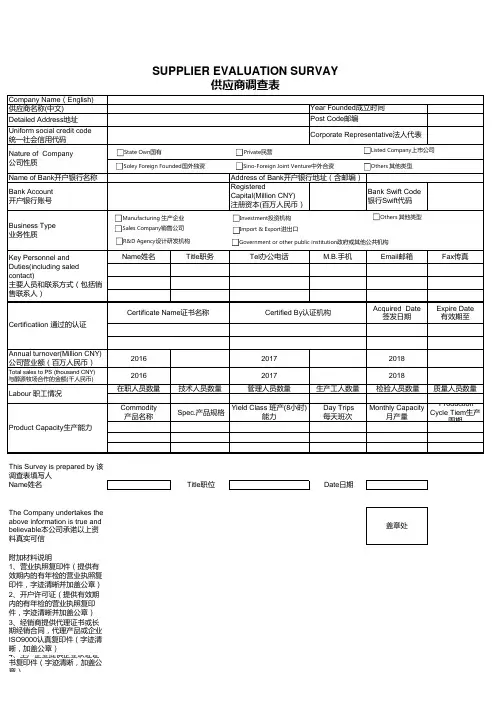

This Survey is prepared by 该调查表填写人Name 姓名

Title 职位Date 日期

The Company undertakes the above information is true and believable 本公司承诺以上资料真实可信附加材料说明

1、营业执照复印件(提供有效期内的有年检的营业执照复印件,字迹清晰并加盖公章)

2、开户许可证(提供有效期内的有年检的营业执照复印件,字迹清晰并加盖公章)

3、经销商提供代理证书或长期经销合同,代理产品或企业ISO9000认真复印件(字迹清晰,加盖公章)

4、生产企业提供企业认证证书复印件(字迹清晰,加盖公章)

5、企业情况介绍

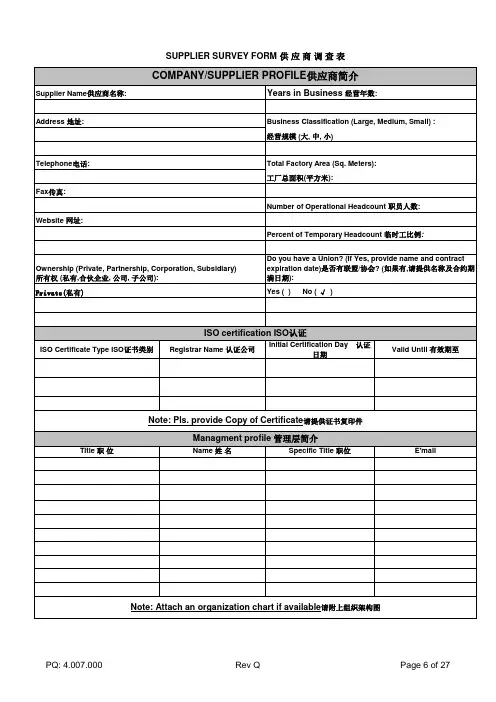

XXCo., Ltd recognises the confidentiality of the information you provide and will treat the information accodingly.XX 有限公司认可贵司对于提供信息的保密性,

please complete the survey and send the email to the following address 请认真填写该调查表并以邮件的形式发送到下面的地址Department 部门:Sourcing Superior 采购主管

Email 邮箱M.B.手机Address 地址

SUPPLIER EVALUATION SURVAY

供应商调查表。

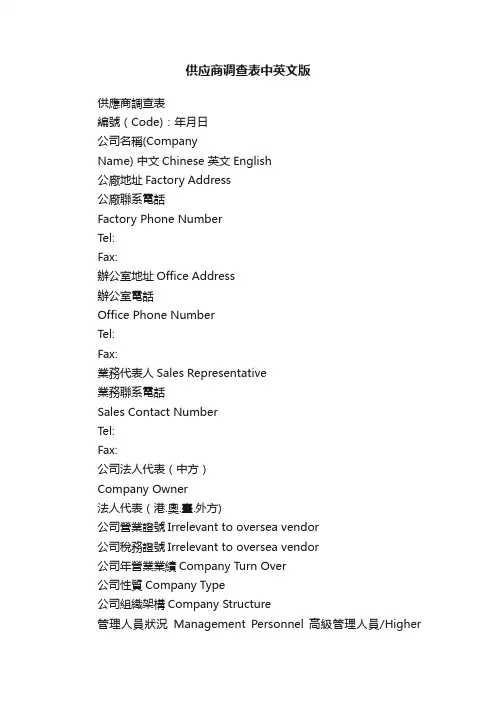

供应商调查表中英文版供應商調查表編號(Code):年月日公司名稱(CompanyName) 中文Chinese 英文English公廠地址Factory Address公廠聯系電話Factory Phone NumberTel:Fax:辦公室地址Office Address辦公室電話Office Phone NumberTel:Fax:業務代表人Sales Representative業務聯系電話Sales Contact NumberTel:Fax:公司法人代表(中方)Company Owner法人代表(港.奧.臺.外方)公司營業證號Irrelevant to oversea vendor公司稅務證號Irrelevant to oversea vendor公司年營業業績Company Turn Over公司性質Company Type公司組織架構Company Structure管理人員狀況Management Personnel 高級管理人員/HigherLevel Manager 人, 中層管理人員/Mid Level Manager 人, 基層管理人員/Supervisory 人.技術人員/Engineer 高級工程師/Senior Engineer 人,工程師/Engineer 人, 技術人員/Technician 人.品管人員Quality Control Personnel 品管管理人員/QC Manager 人,品質工程師/QC Engineer 人, QA 人,QC 人,IQC 人.員工狀況No. of Worker 1.員工人數/Worker 人.2員工通過培訓/Trained Worker 人.3員工有拿到上崗證/Worker with working permit 人.品質系統Quality Certificate 1.有無通過ISO品質系統/Factory passed ISO Audit: 有無2通過哪個論證系列/Certification passed: ISO9001 GMPC QS14001,其它/Others主要產品Mainstream Product 1. 2. 3. 4.5. 6.月產能MonthlyProduction主要設備List of Majore Machinery儲存狀況Storage area 工廠總面積/Factory Floor Area 平方米,倉庫總面積/Warehouse Floor Area 平方米,儲存量/Store Volume 立方米.運輸能力狀況Transportation Capability車輛/No. Of Truck 輛,噸位/No. of Tonne樣板/Sample:合格/Pass:不合格/Fail:驗廠員/Auditor: 采購部主管/Purchasing Supervisor: 經理/Purchasing Manager:。

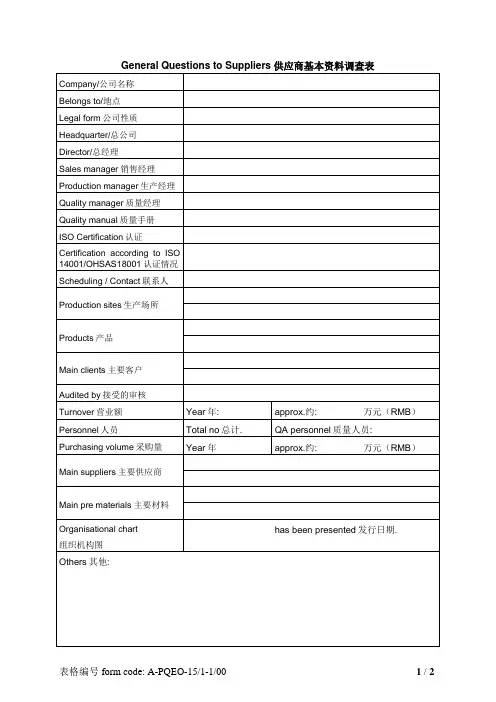

PREQUALIFICATION FORMFOR SUPPLIERS / CONTRACTORS供应商调查表A)PARTICULARS OF THE FIRM 企业概况: of the Firm公司全称:2.Registered Address注册地址:3.Mailing Address邮寄地址(If different from 2)4.Telephone No.电话:5.Fax No.传真::6.Web-site Address公司网址:7.E-mail Address 电子邮件:8.Type of Company公司性质Public/Private/ Partnership/ Sole Proprietor/Joint Venture/Others (Please specify)国营/私营/股份制/独资/合资/其他(请列出)9.Country of Incorporation国家:10.Registration No.营业执照号::11.Date of Registration/Incorporation注册日期NB : To attach a copy of the latest Business Instant Information from Registry ofCompanies请附上最近的公司登记情况表12.Registration with Professional, Trade or Quality Control Organisation, board and/orAssociation etc.在有关专业团体,贸易机构和质量控制机构的登记证书:(Please attach a copy of the certificate of registration请附上营业执照附本)13.Other Affiliations, Subsidiaries or Joint Venture (with indication of % owned)其他从属关系或合资关系(请用%指出)B)PARTICULARS OF HEAD QUARTERS (IF ANY) 总公司概况(如有): of the Firm公司全称:2.Registered Address注册地址3.Telephone No.电话:4.Fax No.传真::5.Web-site Address公司网址:6.Type of Company经济性质7.Country of Incorporation国家:C)FINANCIAL CAPACITY 财务概况: of Bank and Address银行全称和地址:2.Credits Facilities / Overdrafts信用设备/透支款项3.Financial Standing of the Last 3 Financial Years:过去三年里财务状况Year 20__ Year 20__ Year 20__ Authorized Capital 注册资金Paid up Capital 已缴资金Net Worth 净值Turnover 交易额Net Profit / <Loss> after Tax 除税后净利/损Current Assets 流动资金Current Liabilities 流动债务NB : To attach complete annual reports with corresponding Statements of Profit and Loss Account certified by accountants and a certified copy of the audited Balance Sheet for the last 3 years.请会计员附上过去3年完整的相应年度亏赢报告和审计对比报告。

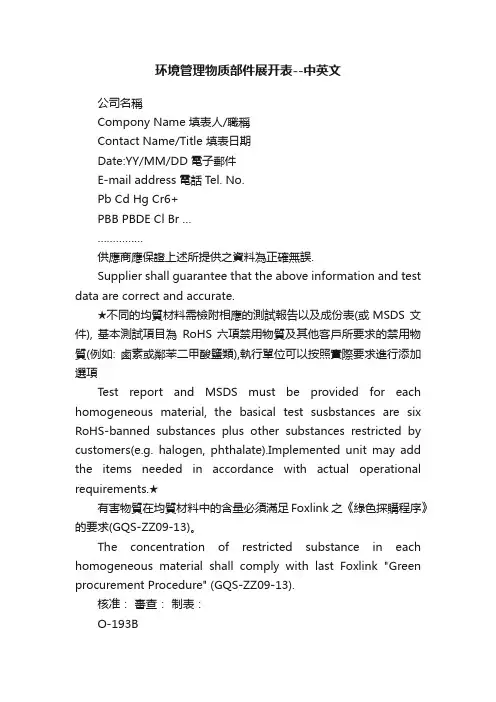

环境管理物质部件展开表--中英文公司名稱Compony Name 填表人/職稱Contact Name/Title 填表日期Date:YY/MM/DD 電子郵件E-mail address 電話Tel. No.Pb Cd Hg Cr6+PBB PBDE Cl Br ………………供應商應保證上述所提供之資料為正確無誤.Supplier shall guarantee that the above information and test data are correct and accurate.★不同的均質材料需檢附相應的測試報告以及成份表(或MSDS 文件), 基本測試項目為RoHS 六項禁用物質及其他客戶所要求的禁用物質(例如: 鹵素或鄰苯二甲酸鹽類),執行單位可以按照實際要求進行添加選項Test report and MSDS must be provided for each homogeneous material, the basical test susbstances are six RoHS-banned substances plus other substances restricted by customers(e.g. halogen, phthalate).Implemented unit may add the items needed in accordance with actual operational requirements.★有害物質在均質材料中的含量必須滿足Foxlink 之《綠色採購程序》的要求(GQS-ZZ09-13)。

The concentration of restricted substance in each homogeneous material shall comply with last Foxlink "Green procurement Procedure" (GQS-ZZ09-13).核准:審查:制表:O-193B`環境管理物質部件展開表The Parts List of Enviromental Management Substances產品訊息 Product Information供應商訊息 Supplier Contact Information成品名稱Product name 總重量Total weight (g)Foxlink 成品料號Foxlink Product No.供應商成品料號Supplier Product No.編號No.供應商料號Supplier's part no.零件名稱Part name/description 製造商名稱Manufacturer Name 製造地點Manufacurering site 測試報告Test report 重量百分比Weight(%)備註Remark製造商料號Manufacturer Part no.測試報告編號Test Report No.測試日期Test Date (YY/MM/DD)測試結果Test result (ppm)成份表或MSDS。

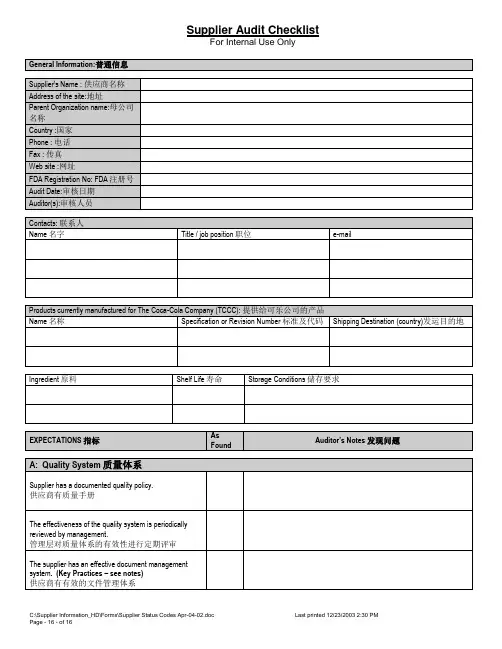

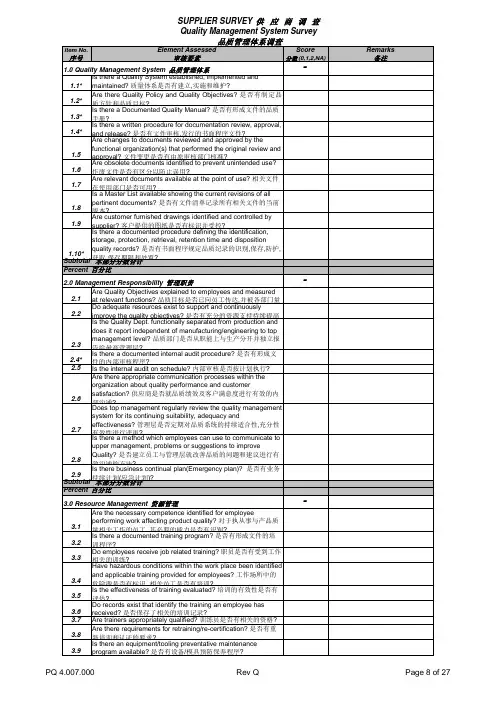

Item No.Element Assessed ScoreRemarks 序号审核要素分数(0,1,2,NA)备注-1.1*Is there a Quality System established, implemented andmaintained? 质量体系是否有建立,实施和维护?1.2*Are there Quality Policy and Quality Objectives?是否有制定品质方针和品质目标?1.3*Is there a Documented Quality Manual? 是否有形成文件的品质手册?1.4*Is there a written procedure for documentation review, approval,and release?是否有文件审核,发行的书面程序文件?1.5Are changes to documents reviewed and approved by thefunctional organization(s) that performed the original review and approval?文件变更是否有由原审核部门核准?1.6Are obsolete documents identified to prevent unintended use?作废文件是否有区分以防止误用?1.7Are relevant documents available at the point of use? 相关文件在使用部门是否可用?1.8Is a Master List available showing the current revisions of all pertinent documents? 是否有文件清单记录所有相关文件的当前版本?1.9Are customer furnished drawings identified and controlled by supplier?客户提供的图纸是否有标识并受控?1.10*Is there a documented procedure defining the identification,storage, protection, retrieval, retention time and dispositionquality records? 是否有书面程序规定品质纪录的识别,保存,防护,获取保存期限和处置?Percent 百分比-2.1Are Quality Objectives explained to employees and measured at relevant functions?品质目标是否已向员工传达,并被各部门量2.2Do adequate resources exist to support and continuously improve the quality objectives?是否有充分的资源支持持续提高Is the Quality Dept. functionally separated from production and does it report independent of manufacturing/engineering to top 2.0 Management Responsibility 管理职责1.0 Quality Management System 品质管理体系Subtotal 本部分分数合计SUPPLIER SURVEY 供 应 商 调 查Quality Management System Survey 品质管理体系调查2.3management level? 品质部门是否从职能上与生产分开并独立报告给最高管理层?2.4*Is there a documented internal audit procedure? 是否有形成文件的内部审核程序?2.5Is the internal audit on schedule? 内部审核是否按计划执行?2.6Are there appropriate communication processes within the organization about quality performance and customersatisfaction? 供应商是否就品质绩效及客户满意度进行有效的内部沟通?2.7Does top management regularly review the quality management system for its continuing suitability, adequacy andeffectiveness? 管理层是否定期对品质系统的持续适合性,充分性有效性进行评审?2.8Is there a method which employees can use to communicate to upper management, problems or suggestions to improveQuality? 是否建立员工与管理层就改善品质的问题和建议进行有效沟通的方法?2.9Is there business continual plan(Emergency plan)? 是否有业务持续计划(应急计划)?-3.1Are the necessary competence identified for employeeperforming work affecting product quality? 对于执从事与产品质量相关工作的员工其必要的能力是否有识别?3.2Is there a documented training program? 是否有形成文件的培训程序?3.3Do employees receive job related training? 职员是否有受到工作相关的训练?3.4Have hazardous conditions within the work place been identified and applicable training provided for employees? 工作场所中的危险源是否有标识相关员工是否有培训?3.5Is the effectiveness of training evaluated? 培训的有效性是否有评估?3.6Do records exist that identify the training an employee has received?是否保存了相关的培训记录?3.7Are trainers appropriately qualified? 训练员是否有相关的资格?3.8Are there requirements for retraining/re-certification? 是否有重新培训和认证的要求?39Is there an equipment/tooling preventative maintenance Subtotal 本部分分数合计Percent 百分比3.0 Resource Management 资源管理3.9program available?是否有设备/模具预防保养程序?PQ4.007.000 Rev Q Page 8 of 27序号审核要素分数(0,1,2,NA)备注3.10Is there is an equipment/tooling master list? 是否有设备/模具一览表?3.11Are preventative maintenance intervals defined and is maintenance on schedule?预防保养周期是否有确定并按期执3.12Does the Company have a list of equipment, which require Calibration?公司是否有要求校准的设备清单?3.13Is there a written instruction for calibrating tools and equipment?是否有书面指导书用于校验检验及测试设备和工具?3.14Are records of calibration kept on file? 仪器校验记录是否有存3.15Are the instruments used by production on a calibration program?用于生产的设备/仪器是否纳入校验程序/计划?3.16Is equipment suitably tagged with labels to show calibration status?设备是否贴有显示校验状态的校验标签?3.17Are defective or out of calibration instruments removed from use until repaired or calibrated? 有缺陷的或校准超差的设备在维修和校准前是否被移走以防止误用?3.18Are shop masters calibrated at periodic intervals to secondary standards traceable to NIST or other recognized Standard? 用于校验的工厂标准件是否有定期校验,并可追溯到NIST 或其它承认的标准?3.19Does the inspection and production area reflect adequate and clean working conditions? 检验及生产区域工作环境是否适合和清洁?-4.1Does the supplier have established procedures to review contracts?供应商是否已建立合同评审程序?4.2Is the content adequate to ensure appropriate parties review all customer requirements? 程序内容是否已充分确保相关部门了解所有客户要求?4.3Are review records maintained? 评审记录在是否有保存?Where product requirements such as contract/order/drawing are changed, are the related documents are amended and the relevant personnel are made aware of the changed Subtotal 本部分分数合计Percent 百分比4.0 Product Realization 产品实现4.4relevant personnel are made aware of the changedrequirements? 当产品的要求如合同,订单或图纸变更时,相关文件是否被修订且相关人员了解变更的要求?4.5Are channels for communication and interfacing with thecustomer's organization established? 是否已建立与客户进行有效沟通的渠道?4.6Is reliability data used in the development of new designs? 是否有可靠性数据用于新产品设计开发?4.7Is Quality history fed-back to engineering for improvement in future or current designs? 质量历史记录是否反馈到将来的工程改善或当前的设计?4.8Does the Quality department review new designs? 品质部是否审核新设计?4.9Does the Company have a prototype department? 公司是否有样品制作部门?4.10Does Quality review prototypes? 质量部门是否审核样品?4.11Is there a written procedure to control and verify the design of the product in order to ensure that the specified requirements are met? 是否有书面程序控制和验证产品设计,以确保符合已指定的要求?4.12Is there a written procedure to define the needs andresponsibility for reviewing design input information? 是否有书面程序定义评审设计输入的要求和职责?4.13Are the records of input and review maintained? 设计输入和评审的记录是否保存?4.14Is there a written procedure specifying that the design must be reviewed and verified at appropriate interval? 是否有书面程序说明在适当的阶段设计必须经过评审和验证?4.15Is there a documented procedure to ensure that customers are informed of design changes? 是否有书面程序确保通知客户设计变更?4.16Are Supplier & Customer Product Change Notices (PCN) and Engineering Change Notices (ECN) addressed in your system?对供应商和客户产品和工程变更通知是否有纳入自身系统?4.17Does the Company have a written system for incorporating customer changes into shop drawings? 公司是否有书面系统把客户变更合并到工厂图纸?4.18Are customer specifications interpreted into shop instructions?客户规格是否转译成工厂指导书?4.19Does the supplier have a documented procedure to control purchasing and supplier selection? 是否有文件化的程序来管制采购及供应商选择?序号审核要素分数(0,1,2,NA)备注4.20Is a list of approved suppliers used for material purchased? 是否有认可的供应商清单用于物料采购?4.21Are purchase orders made available to incoming inspection? 对于来料检验是否有对应的采购订单?4.22Are purchase orders supplied with documents defining what is to be purchased?书面订单是否充分已说明采购物料的规格/要4.23Is incoming material inspected upon receipt to assure conformance to requirements? 来料接收之前是否经过检验以确保符合要求?4.24Are written inspection instructions available for each item to be inspected?检验的每个项目是否有书面的检验指导书?4.25Are these instructions under document control? 指导书是否受4.26Are physical and chemical material test reports checked to assure conformance to specifications? 物理及化学物料测试报告是否被检查以确保物料符合规格?4.27Are records maintained of inspection results, including the cause of rejection?检验记录包括拒收原因是否有保存?4.28Is there any procedure used for the materials that are not subjected to inspection?对于免检材料,是否有相应的程序?4.29Does the supplier have a supplier performance rating system?是否有供应商等级评定系统?4.30Is the supplier rating system made available to the purchasing department?供应商等级评定系统在采购部门是否有效可用?4.31Does the incoming inspection department have adequate storage space to hold material until it is inspected? 来料检验部门是否有足够存储空间存放物料直至检验完成?4.32Is non-conforming material identified as such? 不良物料是否有标识?4.33Is non-conforming material held in a specific and controlled area until disposition can be made? 不良物料是否保存在特定的管制区直到不良物料处理完毕?4.34Is there ECO system to control the related production document?是否有使用ECO(工程变更指令)系统管制相关生产文4.35Is the raw material used in production tagged or identified? 是否所有用于生产的原材料都有标识?Are materials properly identified and controlled with the4.36Are materials properly identified and controlled with the inspection and test status throughout the manufacturing process?生产过程中所有物料/产品的检验和测试状态是否标识4.37Can raw material or components of a finished product be traced back to the manufacturer and receipt date? 成品的原材料及部件能否追溯到制造厂商及接收日期?4.38Are there appropriate documents used on production, such as process control plan, traveler/touting ticket, assembly instructions, inspection instructions, set-up instructions, test procedure, workmanship standard? 是否有适当的文件用于生产,如:工艺管制计划,工序记录单,生产指南,检验指南,设备设置指南,测试程序和工艺标准?4.39Are written inspection instructions/acceptance criteria available?书面的检验指导书/接收标准是否有有效可用?4.40Does the supplier have an in-process inspection function? 是否有制程检验职能?4.41Are process capability studies performed in production on a periodic basis to ensure process control? 是否有对生产定期进行工艺能力研究以确保过程受控?4.42Is there a statistical process control program defined for your operation?是否有统计技术SPC应用于生产和检验?4.43Does the supplier have final inspection function? 是否有最终产品检验职能?4.44Does the supplier have reliability function? 是否有信赖性测试职能?4.45Is sample inspection used? 是否使用抽样检验?4.46Are inspection records kept on file? 检验记录是否有存档?4.47Are records of inspection results used for corrective action purposes?检验结果记录是否用于纠正措施目的?4.48Is corrective action taken to prevent the recurrence of defective material?是否有纠正措施以防止不良品再次发生?4.49*Is there a documented procedure for control of nonconforming product?是否有不良品管制程序文件?4.50Are all defective products identified? 所有不良品是否有标识?4.51Are defective products segregated until disposition is made? 不良品在处置之前是否有隔离?4.52Are reworked products submitted for re-inspection? 返工品是否有重新检验?4.53Is there any appropriate procedure for the control of customer-supplied product?是否有适当的程序用于管制客户提供的产品?4.54Is there customer return goods policy/procedure? 是否有客退品处理程序?序号审核要素分数(0,1,2,NA)备注4.55Is there any method used to identify excessive customer returns?是否有方法用于识别过多客户退货?4.56Is there any method used to reduce customer returns? 是否有方法用于减少客户退货?4.57*Is there a documented closed-loop corrective action procedure?是否有文件化的纠正和预防措施程序?4.58Are packaging, storage, handling and labeling instructions available 是否有包装,存储,搬运和标识指南?4.59Is first-in/first-out practiced? 是否实施先进先出原则?4.60Are materials adequately packaged to prevent damage during handling and shipping?包装能否充分防止产品搬运中的破损?4.61Are cartons clearly identified as to contents? 包装箱内容标识是否清楚?4.62Where special packaging specifications are required, is this information readily available to production? 有特殊包装规格要求时生产部是否很容易了解到相关信息?4.63Are cartons containing perishable materials date-stamped? 易腐烂物品的包装箱是否有标识物料生产日期?4.64Are materials, which are subject to deterioration inspected periodically?易变质,退化的物料是否有进行周期性的检查?4.65Are materials removed if the expiration date has been reached?过期物料是否被移走?4.66Are aisles or storage areas clear of obstruction? 过道或存储区障碍物是否被清除?4.67Is material stored in such a manner that it presents no safety or fire hazard?物料是否保存在无安全和火灾危险的地方?-5.1Are methods established to collect customer satisfaction data?是否制定收集客户满意度信息的方法?5.2Are data analyzed and used to improve customer satisfaction?相关资料是否经分析并用于提高客户满意度?5.3Are customer complaint quickly reacted and the supply of parts Subtotal 本部分分数合计Percent 百分比5.0 Customer service, Customer satisfaction 客户服务/满意度secured?对顾客抱怨是否能快速反应并确保产品供应??5.4Is there a Cost of Quality reporting system? 是否有质量成本报告系统?Subtotal 本部分分数合计Percent 百分比。

供應廠商名稱:Vendor Name地址:Sales Office’s Address電話:Sales Office’s Telephone供應本公司之產品:Commodities Supplied主廠地址:Factory Main Address其他工廠的地址:Address Of Other Plant電話:Factory’s Telephone建廠年份:Company Is Established:Year資本額:US$Capitalization:US$年營業額:US$ 在年Annual Sales:US$ In Year土地面積:平方公尺Ground Area: Meter Square廠房面積:平方公尺Area Of Floor Space: Meter Square 員工總人數:No. Of Total Employee: ______________________________________________________________ 1. 是否有建立ISO 9001 品質管理系統? Yes( ) No( )If yes - Certification body:Certification number:Due date of certification:If No, ( )計劃中,預計什麼時候通過驗證?( )目前暫時沒有計劃2. 是否有建立其他相關品質管理系統? Yes( ) No( )( ) TL 9000, ( ) QS9000, ( ) Other3. 品管成員人數*經理 : 人 *課長 / 主任 : 人*組長 / 班長 : 人 *工程師 : 人*進料檢驗員 : 人 *製程檢驗員 : 人*最終檢驗員 : 人 *出貨檢驗員 : 人*稽核員: 人4. 貴公司是否有將產品再外包給其他供應商? Yes( ) No( )5. 是否有建立ISO 14001 環境管理系統? Yes( ) No( )If yes - Certification body: Certification number:Due date of certification:If No, ( )計劃中,預計什麼時候通過驗證?( )目前暫時沒有計劃6. 是否有通過綠色環保相關驗證? ( ) SONY's SS00259 ( ) Other7. 污染防治7.1貴公司是否有下列污染物產生?( ) 廢水是否有排放許可? Yes( ) No( )是否有防治設備? Yes( ) No( )( ) 廢氣是否有操作許可? Yes( ) No( )是否有防治設備? Yes( ) No( )( ) 廢棄物( ) 一般事業廢棄物 ( ) 有害事業廢棄物是否有委託合格的清運處理商處理? Yes( ) No( )( ) 噪音是否符合法規規定? Yes( ) No( )是否有防護措施? Yes( ) No( )( ) 毒化物是否有做控管? Yes( ) No( )7.2貴公司是否有使用下列燃料?( )重油 ( )柴油 ( )液化石油氣 ( )天然氣是否有做控管? Yes( ) No( )7.3貴公司製程是否有使用下列物質?( )有機溶劑 ( )毒化物 ( )化學藥劑是否有做控管? Yes( ) No( )8. 貴公司之產品是否有含明泰之禁用化學物質? Yes( ) No( )明細請參考”MIRAC化學物質管理明細表(附表一)”若有請列出: 9. 是否有專責單位負責環保相關任務? Yes( ) No( )負責單位名稱 : 10. 貴公司是否有下列文件資料?若有,煩請預先準備以供參考10.1 品質手冊 Yes( ) No( )10.2 公司組織圖 Yes( ) No( )10.3 品管組織圖 Yes( ) No( )10.4 製造流程圖 Yes( ) No( )10.5 進料檢驗程序 Yes( ) No( )10.6 製程檢驗程序 Yes( ) No( )10.7 最終檢驗程序 Yes( ) No( )10.8 出貨檢驗程序 Yes( ) No( )10.9 各類檢驗規範 Yes( ) No( )10.10 不合格品管制程序 Yes( ) No( )10.11 客戶抱怨處理程序 Yes( ) No( )10.12 藍圖與工程變更管制程序 Yes( ) No( )10.13 校驗計劃與紀錄 Yes( ) No( )10.14 可靠度/環境試驗計劃與紀錄 Yes( ) No( )10.15 廠內稽核計劃與紀錄 Yes( ) No( )10.16 供應商/外包管理程序 Yes( ) No( )10.17 各項污染之管制程序 Yes( ) No( )10.18 有關綠色產品之相關計劃與程序 Yes( ) No( )此份資料於月日人員至貴公司時提供This document was provided to on .此份資料於月日前寄至 .This document mail to on .。

PREQUALIFICATION FORMFOR SUPPLIERS / CONTRACTORS供应商调查表A)PARTICULARS OF THE FIRM 企业概况: of the Firm公司全称:2.Registered Address注册地址:3.Mailing Address邮寄地址(If different from 2)4.Telephone No.电话:5.Fax No.传真::6.Web-site Address公司网址:7.E-mail Address 电子邮件:8.Type of Company公司性质Public/Private/ Partnership/ Sole Proprietor/Joint Venture/Others (Please specify)国营/私营/股份制/独资/合资/其他(请列出)9.Country of Incorporation国家:10.Registration No.营业执照号::11.Date of Registration/Incorporation注册日期NB : To attach a copy of the latest Business Instant Information from Registry ofCompanies请附上最近的公司登记情况表12.Registration with Professional, Trade or Quality Control Organisation, board and/orAssociation etc.在有关专业团体,贸易机构和质量控制机构的登记证书:(Please attach a copy of the certificate of registration请附上营业执照附本)13.Other Affiliations, Subsidiaries or Joint Venture (with indication of % owned)其他从属关系或合资关系(请用%指出)B)PARTICULARS OF HEAD QUARTERS (IF ANY) 总公司概况(如有): of the Firm公司全称:2.Registered Address注册地址3.Telephone No.电话:4.Fax No.传真::5.Web-site Address公司网址:6.Type of Company经济性质7.Country of Incorporation国家:C)FINANCIAL CAPACITY 财务概况: of Bank and Address银行全称和地址:2.Credits Facilities / Overdrafts信用设备/透支款项3.Financial Standing of the Last 3 Financial Years:过去三年里财务状况Year 20__ Year 20__ Year 20__ Authorized Capital 注册资金Paid up Capital 已缴资金Net Worth 净值Turnover 交易额Net Profit / <Loss> after Tax 除税后净利/损Current Assets 流动资金Current Liabilities 流动债务NB : To attach complete annual reports with corresponding Statements of Profit and Loss Account certified by accountants and a certified copy of the audited Balance Sheet for the last 3 years.请会计员附上过去3年完整的相应年度亏赢报告和审计对比报告。

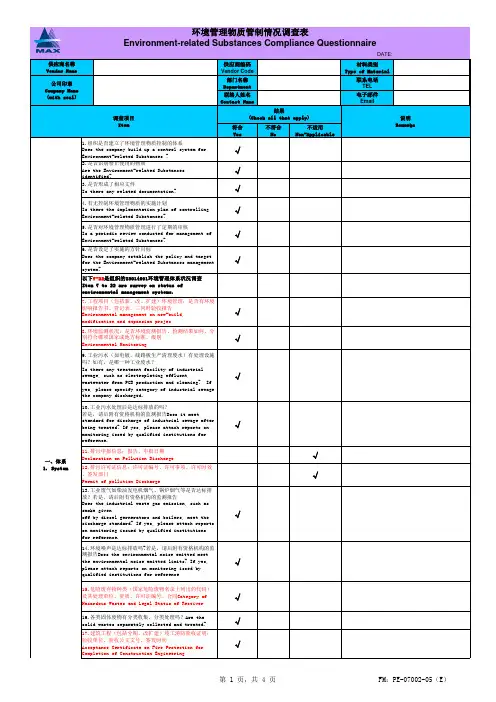

序号审核要素分数(0,1,2,NA)备注-1*Do you have an Environmental Management System(RoHS, REACH, Holagen Free)? 是否建立环境管理体系(RoHS, REACH, Holagen Free)?2*Do you have an Environmental Substance Management Database(RoHS, REACH, Holagen Free)? 是否建立环境物质管理数据库(RoHS REACH Holagen Free)?3*Does your company have an Environmental Policy? If so, please enclose/quote/give link-info.,the policy is covering the environmental controlled substances management.贵公司是否有环境方针? 如果有,请附上环境方针或提供链接信息,该方针包含环境管制物质的管理4*Does your company have a continuous environment improvement program/plan, including elimination and reduction for the environmental controlled substances? 是否有持续环境改善方案/计划包括消除和减少环境管制物质?5Is it ISO 14001 certified/EMAS registered/others? 是否已通过ISO14001认证?6*Is there a list of environmental controlled substances? and the controlled substances list is revised timely in response to applicable laws and regulations and the customer requirements.是否有环境管制物质清单,并依照相关法律法规或客户要求及时修订?7Are the responsibility and authority of the persons in charge of environmental management clearly defined? 负责环境管理的人员职责和权限是否已清楚定义?8Can the responsible department effectively get the laws, regulations and customer requirements? the related information is provided timely to the organization inside and suppliers. 责任部门是否能有效地获取法律法规和客户要求?相关信息及时传达到组织内部和供应商Are there the documented procedures used for environmentalManagement System管理体系9Are there the documented procedures used for environmental training(REACH, Halogen Free, RoHS…) ? 是否有文件化的环境培训程序?10Does your company submit the REACH declaration to Pulse? 是否对Pulse进行REACH声明?11Does your company submit the raw material bill of substance to Pulse?是否向Pulse提供原材料物质组成表?12*Are trainings conducted to the employees responsible for the environmental product compliance(REACH, RoHS, Halogen Free …)? The training records are kept. 负责环境产品符合的员工是否有经过培训并保存培训记录?13Have the used subtances been registered for REACH? If yes, please list the subtances name the registration ID.所用的物质是否已注册?若注册请列出被注册物质的注册号14*Are there SVHC substances list? Have the procedure for REACH notifiaction? Do you make the material declaration for REACH to your customers?是否有SVHC物质列表?是否有程序就REACH进行通报? 是否对客户进行材料通报?15Are environmental controlled substances included in internalaudit process? The related regulations and standards are usedfor internal audit. 内部审核是否包含环境管制物质,且相关法规和标准被用于内审?-16*Are there the environmental criteria for selecting the new supplier and raw materials/components?是否有建立选择新供应商和原材料/部件的环境标准?17Does your design process take into consideration environmental concerns?是否在产品设计中考虑到环境问题?18Is non-use of banned substances clearly identified in components/raw materials drawing/spec./purchase orders? 不使用禁用物质是否清楚地标识在物料图纸/规格书/采购订单上?19*Are there any inspection procedures for the environmental controlled substances to be used on the purchased materials inspection?是否有建立环境管制的物质检验程序,用于采购物料的检验?20Are the purchased materials verified not including the banned substances?采购的物料是否有验证不含禁用物质?Supplier Management 供应商管理序号审核要素分数(0,1,2,NA)备注21*Can the supplier provide the certificate of RoHS,HF and REACH compliance(RoHS,HF and REACH CoC)?是否能提供RoHS, HF and REACH符合保证书?22*Are MSDS/Chemical Ingredient List/Measurement data filed and managed for use?Test reports need be made by certified lab.是否有物料安全数据表/化学成分表/测试报告?测试报告是须由有资格的实验室提供23Do you use any tools to quantify/assess the environmental burden?是否有使用工具检测和评估环境影响?24Is there the schedule established for the supplier environmental management system survey? And the survey is implementedaccording to the schedule. 是否有供应商环境管理系统审核计划?并按计划执行-25*Is there a documented procedure on regulations/ requirements on hazardous substances (REACH, HF, RoHS European directive, Sony SS-00259 standard)? 是否有就危险物质限制使用的法规/要求(REACH, HF, RoHS指令,索尼SS-00259标准) 制订形成文件的程序?26*Are the environmental controlled substances controlled in the production?在生产过程中,是否有对环境管制物质进行管制?27Are checks performed to the production equipments,test equipments including environmental substance measurement equipment before use?生产设备,测试设备包括环境物质检测设备在使用前是否有检查?28Are verifications made to the equipments, fixtures and tools previously contacted the banned substances to ensure that they are not contaminated? 对曾接触过禁用物质的设备,治具和模具是否有验证以确保没有被污染?Are methods defined to prevent the products from contamination and mixture of the banned substances and verifications made to th l d t i l?Production Management 生产管理29the recycled materials? 是否有方法防止产品污染和混入禁用物质?再生料是否经验证?30Are the shipping goods inspected according to the outgoing inspection standards and inspection records available? 成品出货是否根据出货检验标准进行检验并保存相关记录?31Is there identification labels on the outer box of the RoHS/REACH/HF compliant materials/products? 符合RoHS/REACH/HF的物料及产品外包装是否有标签标识?32Are the RoHS/REACH/HF & non-RoHS/REACH/HF compliant products built on separate production equipment and line? 符合及不符合RoHS/REACH/HF的产品是否在分开的生产设备和生产线上生产?33Is there a separate storage location for RoHS/REACH/HF & non-RoHS/REACH/HF compliant parts including raw materials/sub-assembly/finish goods? 符合及不符合RoHS/REACH/HF的产品包括原材料/半成品/成品是否分开存储?34Is there a separate REWORK area for RoHS, REACH or HF compliant parts? 对于符合RoHS, REACH,或HF的产品是否有分开的”返工”区域?35Are there long term inventory management criteria, considering the possible change of legislation in the future? 考虑到将来法规的可能变更是否有长期库存管理办法?36Are actions taken to the inventories when there have changes inthe environmental laws, regulations and the customerrequirements? 环境的法律法规和客户要求变更时,是否对库存品采取必要的处理措施?-37*Is there any procedure to define the requirement of customer notification for any change to component related to RoHS/REACH/HF compliance?是否有程序定义任何有关符合RoHS/REACH/HF的产品变更须通知客户?38Are checks made to the changes to see if they can meet the customer requirements and verifications performed viaMSDS/material ingredient lists and test reports when necessary?是否有进行变更检查以确保符合客户要求,必要时通过MSDS/材料成分表和测试报告进行验证?Is a written change notification used for the change request and response of Pulse is documented? 是否有书面的变更通知用于申Change Control 变更管制39请变更并保存普思的回复?序号审核要素分数(0,1,2,NA)备注40Is there a similar change management procedure established for changes by secondary supplier? 对供应商的管理是否有类似的变更管理程序?-41Please provide your company’s definition of lead-free. 请提供贵公司的无铅标准定义(铅含量)42For all currently available lead-free product offerings, please specify, termination finishing (e.g. Sn, Sn/Ag/Cu, etc.), and moisture sensitivity levels per JEDEC standards. 请说明你们现有无铅产品端子镀层情况(如:锡,锡银铜合金等)和MSL防潮等级,按照JEDEC标准43Are the lead free components in compliance with a “high temperature soldering profile” with a peak of 260°C. 无铅产品是否能承受260°C峰值温度的高温回流焊接?44Is your qualification process for solder joint reliability in accordance with IPC 9701 standard? If no, please describe your process. 焊接点可靠性验证方法是否符合IPC 9701标准? 如果不符合请说明你们的验证方法45If pure Sn is one of the plating offerings, Is there any testingdone with regard to tin-whisker growth? 如果使用纯锡作为镀层,是否有进行锡须增长测试?-46*Do the transportation packaging materials comply with the European packaging directive? 运输包装物料是否符合欧洲包装指令?47Do you have a reuse and recycling program for these materials?是否有此类物料重复使用和再循环程序?-48Do you provide instructions for end-of-life treatment for delivered product?已出货的产品是否有提供产品终止使用处理说明? Have you a program for take back of products as delivered byLead-free Product (if applicable) 无铅产品 (如适用):Transportation Packaging Materials运输包装物料End-of-Life Treatment产品终止使用的处理49your company?是否有产品回收程序? Subtotal 本部分分数合计Percent 百分比。