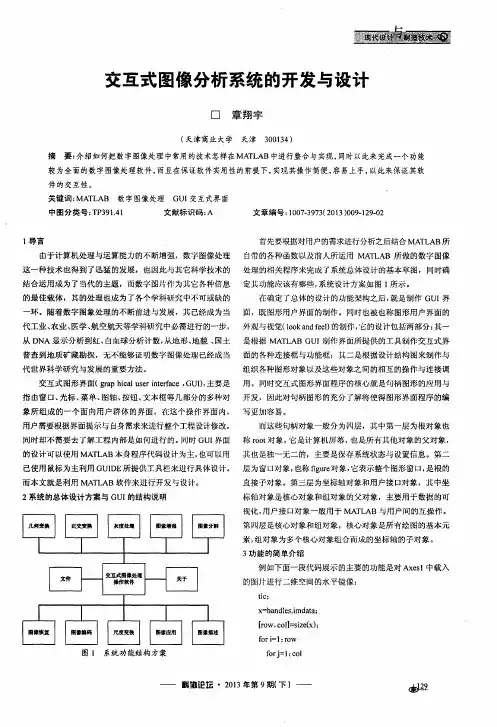

图像分析系统

- 格式:ppt

- 大小:99.50 KB

- 文档页数:16

mshotimage analysis system -回复什么是mshotimage分析系统(mshotimage analysis system)以及它的应用领域和功能。

mshotimage分析系统(mshotimage analysis system)是一款基于计算机视觉和图像处理技术开发的图像分析软件。

该系统可以通过对图像进行自动化分析和处理,提取出图像中的关键信息和特征,并进行相关数据的统计和分析。

mshotimage分析系统在各个领域中都有广泛的应用,比如医疗健康、工业制造、交通运输等。

下面将介绍它的一些常见的应用领域和功能。

一、医疗健康领域在医疗健康领域,mshotimage分析系统可以用于医疗图像的分析和诊断。

例如,对医学影像图像进行处理,提取出患者所受疾病的特征,并进行相关的统计和分析。

同时,该系统也可以用于医疗机构的数据管理和智能报告生成,提高工作效率和医疗服务的质量。

二、工业制造领域在工业制造领域,mshotimage分析系统可以用于产品质检和生产过程监测。

通过对产品图像的处理,该系统可以自动检测产品表面的缺陷和不良,提高质量检查的准确性和效率。

此外,mshotimage分析系统还可以监测生产线上的工艺参数,识别出异常情况并进行预警,帮助企业提高生产效率和产品质量。

三、交通运输领域在交通运输领域,mshotimage分析系统可以用于交通监控和智能交通管理。

通过对交通摄像头的取景图像进行处理,该系统可以自动检测和跟踪交通流量、车辆违法行为等关键信息,并进行相关的统计和分析。

借助该系统,交通管理部门可以更好地了解道路交通情况,优化交通信号控制和道路规划,提高交通运输效率和安全性。

四、其他领域除了上述应用领域,mshotimage分析系统还具有许多其他的功能和应用。

例如,在安防领域,该系统可以用于视频监控和行为识别,提高安全监控的效果和精度。

在农业领域,mshotimage分析系统可以用于作物识别、病虫害监测等,帮助农民提高农作物的生长质量和产量。

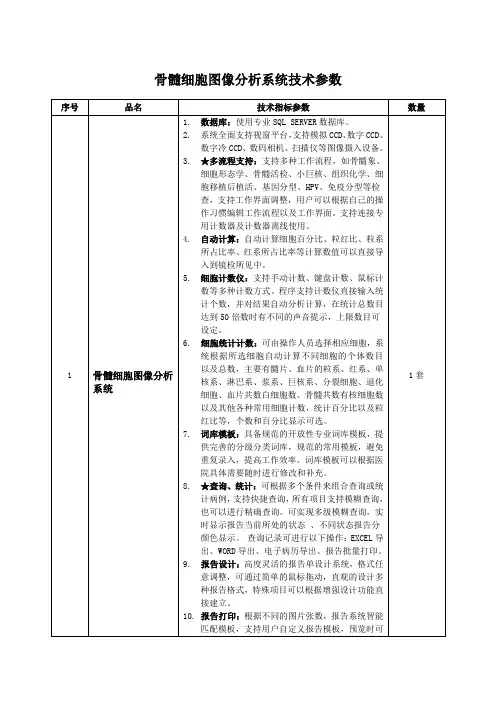

MVS3000 图像分析系统使用说明书V1.1目 录第一章 概述 (5)1.1 MVS3000功能概述 (5)1.2 MVS3000的主要特点 (11)1.3 MVS3000主要处理与分析功能 (12)1.4 MVS3000系统结构 (13)第二章 图象输入与输出 (16)2.1 图象输入 (16)2.2 图象输出 (17)第三章 分析区域选取 (22)3.1 魔杖区域选取工具 (22)3.2 椭圆形区域选取工具 (22)3.3 矩形区域选取工具 (22)3.4 任意形(套索)区域选取工具 (22)3.5 圆形区域修正工具 (23)3.6 方形区域修正工具 (23)第四章 分析区域处理 (24)4.1 分析区域反选 (24)4.2 分析区域消除 (24)4.3 分析区域边界圆滑 (24)4.4 分析区域自由变换 (24)4.5 非区域裁剪 (24)第五章 图象处理 (27)5.1 图象几何变换 (27)5.2 图象处理 (29)第六章 分析目标选取 (34)6.1 分析目标选取 (34)6.2 分析目标颜色设置 (37)第七章 分析目标处理 (38)7.1 分析目标区处理 (38)7.2 分析目标边界 (38)7.3 分析目标删除 (39)7.4 分析目标轮廓 (40)7.5 分析目标骨架 (42)7.7 分析目标孔洞填充 (40)第八章 目标分析 (44)8.1 直接分析 (44)8.2 自动切分分析 (47)8.3 含孔自动分析 (48)8.4 目标编号 (48)8.5 单目标观察分析 (49)8.6 视场观察分析 (49)8.7 分析数据存盘 (49)8.8 分类统计分析 (50)第九章样本分析报告 (51)9.1 文件操作 (51)9.2 样本数据分析 (42)9.3 报告观察 (54)9.4 报告编辑 (54)第十章 几何参数测量 (57)10.1 点位置测量工具 (57)10.2 直线参数测量工具 (57)10.3 圆形几何参数测量工具 (58)10.4 矩形参数测量工具 (58)10.5 角度参数测量工具 (58)10.6 测量工具颜色调整 (59)10.7 标记图像溶合 (59)10.8 形成标记图像 (59)10.9 测量图像清除 (59)10.10 测量结果打印 (59)第十一 章系统工具 (61)11.1 区域选取工具 (61)11.2 绘图工具 (61)11.3 测量工具 (63)11.4 图像几何变换工具 (64)11.5 目标工具 (65)11.6 几何参数测量工具 (67)11.7 主工具条工具 (68)第十二 章系统参数设置 (70)12.1 落射光分析 (70)12.2 透射光分析 (70)12.3 系统测量尺寸标定 (70)12.5 分析参数设置 (72)12.6 自动处理及分析步骤设定 (73)第十三 图像处理与分析实例 (74)13.1 彩色目标选取 (74)13.2 组织细胞抽取 (76)13.3 枪弹痕迹比对 (77)13.4 金相图像分析 (79)13.5破损药片检 (84)第一章 概 述图1.1 系统主界面1.1 MVS3000功能概述MVS3000提供的图像处理与分析功能,覆盖图像定量分析的几乎所有应用领域,包括材料、冶金、医药、生物、化工、摩擦学等各种需要利用图像手段进行统计学和形态学自动分析、测定的领域。

基于人工智能的智能图像识别系统设计智能图像识别系统设计:揭开人工智能的神秘面纱引言:随着人工智能的快速发展,智能图像识别系统成为了一个备受关注的热点技术。

该技术利用人工智能的算法和模型,对数字化图像进行分析和理解,实现文字、物体、场景等的智能识别。

本文将探讨基于人工智能的智能图像识别系统的设计原理、应用场景以及在各个领域内的潜在价值。

一、基于人工智能的智能图像识别系统的设计原理1. 图像采集和预处理:智能图像识别系统首先通过相机或图像传感器采集图像,并对图像进行预处理。

预处理包括图像去噪、图像增强和图像分割等。

2. 特征提取:系统会通过特征提取算法将图像转换为机器可以处理的数字表示。

常用的特征提取方法包括颜色直方图、纹理特征和形状特征等。

3. 模型训练与学习:智能图像识别系统利用机器学习和深度学习算法对训练集中的图像进行学习和训练,以建立模型。

常用的深度学习模型包括卷积神经网络(CNN)和循环神经网络(RNN)。

4. 目标检测与分类:经过模型训练后,智能图像识别系统可以对输入的图像进行目标检测和分类。

系统会自动识别图像中的物体、文字或场景,并进行分类或标记。

5. 输出与应用:智能图像识别系统将识别结果输出给用户或其他系统,如智能安防系统、智能医疗系统等。

输出结果可以是文字描述、标记框或场景分析报告等。

二、基于人工智能的智能图像识别系统的应用场景1. 智能安防系统:基于人工智能的智能图像识别系统被广泛应用于安防领域。

它可以通过监控摄像头实时识别人脸、车牌等,协助警方追踪犯罪嫌疑人或防止入侵事件。

2. 智能交通系统:智能图像识别技术可以应用于交通监控和交通管理。

系统可以自动检测交通违规行为,如闯红灯、逆行等,并进行实时记录和报警。

3. 智能医疗系统:智能图像识别系统可以辅助医生进行医学图像分析,如X光片、病理切片等。

系统可以自动识别和标注异常区域,提高医生的诊断准确性和效率。

4. 智能零售系统:基于人工智能的智能图像识别系统可以帮助零售商进行商品管理和销售预测。

产品规格产品智能影像分析系统智能分析功能存在检测闯入检测退出检测出现检测消失检测停留检测徘徊检测方向检测速度检测人/车流检测遗弃物检测物品搬移检测尾随检测视频输入输出压缩方式双码流分辨率压缩帧率抗锯齿移动侦测字符迭加音频输入输出压缩方式功能报警 输入报警 输出RS-485/422RS-232C 网络协议USB 2.0SD卡视频加密功能其它特性电压PoE 功能温度湿度尺寸重量1 路 (BNC)1 路智能分析视频 (BNC)H.264, MPEG-4, MJPEG 支持 (任意选择不同压缩格式)D1, 2CIF, CIF, QCIF 25/30 帧@D1支持在硬件上实现抗锯齿功能,提高图像质量(DSP)支持 (DSP)支持 (DSP)1 路1 路G.7114 路 (可扩展为 8 路)2 路 (可扩展为 4 路)支持支持10 / 100 Base-TTCP/IP, UDP/IP, HTTP, RTSP, RTCP, RTP/UDP, RTP/TCP, SNTP, mDNS, UPnP, SMTP, SOCK, IGMP, DHCP, FTP, DDNS,PPPoE, SSL v2/v3, IEEE 802.1X, SNMP, SSH, and IPv6支持支持AES 12V DC支持网络供电(选项)0 ℃ - 60 ℃Up to 85% RH (Non-condensing)12(L) x 9.3(W) x 3.3(H) c m342g●●●●●●●●●●●●●系统管理示意图智能影像分析系统系统功能:系统管理:多用户权限设置、配置管理、系统健康管理等功能;监控功能:通过网络,集中调看前端所有影像存储系统的警报事件分析影像,并支持实时监看和实时回放;语音告警提示:针对不同的警报事件,提供对应告警提示语音;检测排程: 预设检测功能启动时间段,并设置相应检测规则和警报提示动作;强大兼容性:可兼容各大 DVR 厂家品牌,如 GeoVision、AVTECH、 海康威视、QNAP 等影像存储系统;告警管理:提供警报 I/O 输出,并支持 Email 通知,可设定指定 Email 对应指定收件人;数据管理:查看历史事件信息,支持多用户通过网络根据时间、地点、事件等多种条件进行检索和回放;系统连接:可同时连接多台影像存储系统,无数量限制。

WinDIAS 3Image Analysis SystemImage analysis systemfor leavesWinDIAS provides rapid measurementand analysis of leaf area and leaffeatures - ideal for plant pathology andphenotyping applications• Advanced leaf area meter - plus perimeter,length, width, object count and more• Automated measurementof diseased, healthy andpest-damaged leaf area• Point and clickcolour selection• Choice of camera orscanner systems• Conveyor option for high speedleaf processingWinDIAS’s powerful analysis features are well suitedto applications in the plant sciences, particularly plantpathology and phenotyping, where precise colour discrimination is critical.Images are acquired using either a high resolution video or an A4 scanner. Alternatively, image files can be imported from other sources.With the conveyor belt option, WinDIAS can process up to 800 leaves per hour.The LED top-lights provide flicker-free illumination and achieve good colour balance. In addition, the LED lights are cool running, improving operator comfort. For reporting and further analysis, all results and images from WinDIAS are easily exchanged with other Windows applications.Applications• Plant pathology• Phenotyping• Agronomy and plant physiology • Forestry• Object countingRapid Analysis of Healthy and Diseased Leaf Area• Quick function tool bar (1)• Colours picked to set primarythreshold colour range (2)• Colours picked to set secondary (3)and tertiary (4) colour range WinDIAS 3• Results box showing healthy anddiseased areas (5)Point and click colour selectionRapid thresholding: Three thresholds can be set, each based on a different user-defined range of colours. The primary threshold is used for the main zones of interest in the image, e.g. healthy areas. The secondary and tertiary thresholds are used for other zones, e.g.diseased areas. Thresholds are set by a simple point and click with the mouse in a region of interest. The areas included are immediately visible as overlays on the image.Editing: Images can be edited on-screen to retouch boundaries, separate objects that overlap, remove undesirable “noise” and holes, add or erase lines or rectangles, and fill bounded areas in any colour.Measurement: WinDIAS analyses the thresholded regions to measure area, perimeter, length, width, circularity, elongation and shape factor. Calibration is carried out against a ruler.Object count: Seeds, needles, or other small objects can be quickly counted by WinDIAS. Colour thresholding enables easy discrimination of different types of object, or disease spots. Dust and debris can be excluded by defining a minimum object area.Exchange of data and images: WinDIAS imports images in .bmp, .jpg and .tif formats, and results can be saved as .txt files for easy import into Excel.WinDIAS FeaturesFast batch processing of image files: WinDIAS can automatically analyse large numbers of leaf images by operating as a virtual conveyor. This feature saves a great deal of time when processing images acquired in the field or when sent in for processing from a remote research lab. Images in bmp, jpg, or tiff format are all suitable for processing.Batch processing mode is simple to use - just select the folder holding the target images. WinDIAS will then automatically load each image in turn, measure it, and save the results back into the same folder.WinDIAS System Choices - WinDIAS is modular and expandableSystem typeFeatures and advantagesWinDIAS 3 Entry Level System The Entry Level System includes the scanner and WinDIAS software onlyThe Entry Level System enables the full set of analysis features and can beused at very high resolution up to A4 size, but is slow – it may take ~1 minuteto scan and analyse each image at higher resolutions.WinDIAS 3 Standard SystemIncludes USB colour video camera, camerastand, lightbox, overhead lighting rig and WinDIAS softwareThe Standard System enables full analysis of static objects illuminated by a lightbox and overhead lights. Typically 2 or 3 images can be processed per minute. The Standard System can be later upgraded to the Rapid specification by adding a Conveyor Belt Unit. (See upgrades on page 4).WinDIAS 3 Rapid SystemIncludes all the Standard System components plus the Conveyor Belt UnitThe Rapid System includes the Conveyor Belt Unit, enabling the rapidprocessing of leaves and the measurement of long leaves (up to 100 cm). Full analysis of static objects can also be performed, as with the Standard System.12354Delta-T DevicesAgronomy, plant physiology and phenotypingWinDIAS provides a flexible resource with countless laboratory applications - from simple leaf areameasurement to the analysis of complex distributions of colour. The addition of the Conveyor Belt accessory opens up further applications - see below. ApplicationsPlant pathology and crop protectionWinDIAS is optimised for the rapid analysis of area by colour difference, creating many applications in plant pathology and plant protection. Examples include: necrosis caused by fungi and bacteria, leaf tip burn and leaf spotting, nutrient deficiency symptoms, viral infection and leaf senescence. By pointing and clicking with the mouse on the leaf image, the colours of healthy regions can be tagged one by one, followed by the colours of two different types of diseased regions (e.g. diseased and necrotic).Regions whose colours are within the primary, secondary and tertiary colour ranges will show immediately as overlays on the video image, quickly indicating whether the required areas have been detected. WinDIAS can then measure the healthy and diseased areas and perform other measurements.Conveyor Belt UnitThe Conveyor Belt Unit works with WinDIAS to provide a rapid and convenient method of handling large batches of leaves. Twin transparent belts carry the leaves past the camera. A lightbox provides background illumination and top lighting optimises colour discrimination.Long leaves: With the addition of the Conveyor Belt Unit, WinDIAS can measure leaves which are too long to fit in the field of view of the video camera. WinDIAS software repeatedly samples the leaf image as it moves past the camera at constant speed. Stored data sets include total area and the percentages of healthy and diseased leaf area. Typically, a leaf 30 cm long by 2 cm wide can be measured in 4 seconds.Conveyor Belt Unit and LightboxForestryFor broadleaf species, all of the applications described above are applicable. It is also possible to use WinDIASwith conifers; the surface area of pine needles can be estimated by multiplying the projected area by a conversion factor. Factors for Corsican Pine (Pinus nigra var maritima ), Scots Pine (Pinus sylvestris ) and general conversion factors are included in the WinDIAS User Manual.• Rapid throughput of large numbers of leaves • Measurement of intact long leaves e.g. maize,sorghum, sugar cane and miscanthusStandard SystemOther applicationsWinDIAS can measure much more than leaves. For example, it can assist with the analysis of aerial photos to estimate ground cover, and can be used with a suitable zoom lens or a USB microscope to measure and count very small objects.Accuracyarea measurement ± 1% typical ± 4% typical ± 4% typical diseased/healthy area contrast dependent contrast dependent contrast dependent long leaf modenot applicablenot applicable± 5% typicalWinDIAS SpecificationsEntry Level SystemStandard SystemRapid SystemThroughput (leaves/hour)~50 (typical, depends on leaf size)~150~800ResolutionTypically >1000 dpi 2048 x 1536 pixels 2048 x 1536 pixels Minimum object size ~0.02 mm 1 pixel 1 pixelMaximum sample area 297 x 210 mm (A4)300 x 295 mm250 x 290 mm (conveyor)250 x >1000 mm (long leaf mode)Calibrationstatic measurements against object of known length, e.g. a ruler against object of known length, e.g. a ruler against a rulerconveyor measurementsnot applicable not applicable against a target of known area Colour depth WinDIAS works in 24 bit colour space (16 million colours)Image file formats .jpg, .bmp and .tif (WInDIAS is compatible with many scanners and cameras that are TWAIN compliant)Operating system & driversWindows 7,8 and 10 (32 and 64 bit)Conveyor belt speeds not applicablenot applicable60/100/140/190 mm/s(20% faster for 60 Hz model)Specifications apply to a WinDIAS system using standard components supplied by Delta-T Devices. Use of other cameras, lighting systems or camera stands may reduce accuracy due to reflections, poor contrast or image distortion.System ComponentsWinDIAS Software type WD-SW3 Software, Quick Start Guide and USB copy protection dongle Camera Stand type WD-CS1Camera type WD-CAM-R2 Colour Camera for use with the Standard and Rapid WinDIAS SystemsPrecision Lens type WD-LEN-1 for use with WD-CAM-R2Lightbox type WD-LB2 LED Lightbox for WinDIAS Overhead Lights type WD-OL1 LED Overhead Lights Conveyor Belt Unit type CB-230/50 (230 V/50 Hz)Flatbed Scanner type WD-FBS-1 A4 Flatbed Scanner Acrylic Sheets type WD-AS1 Transparent sheets to hold and flatten leaves (pack of 10)Mains Lead types PC-UK, PC-EU, PC-US, PC-IN, PC-CN connects national plug to WInDIAS IEC connector. Required for WinDIAS systems type WD-S3-230/110 and WD-R3-230.WinDIAS SystemsWinDIAS 3 Entry Level Image Analysis System type WD-E3(230v/110V) includes WD-SW3 Software and WD-FBS-1 Flatbed Scanner. WinDIAS 3 Standard Image Analysis System type WD-S3-230/110(230V/110V) includes WD-SW3 Software, WD-CS1 Camera Stand, WD-CAM-R1 USB Colour Camera, WD-LEN-1 Precision Lens, WD-LB2 Lightbox, WD-OL1Overhead Lights and acrylic sheets. Requires correct IEC mains lead – please see right “Mains Lead types”WinDIAS 3 Rapid Image Analysis System type WD-R3-230(230V/50Hz) contents as listed for Standard System, plus CB-230/50 Conveyor Belt Unit. Requires correct IEC mains lead – please see right: “Mains Lead types”110V 60 Hz and 220V 60 Hz Systems : The Entry Level and Standard Systems are both dual voltage 110V/230V. The Rapid System is 230V 50 Hz only. This is because we cannot supply 110 V Conveyor Belt Units. We can, however, supply 220 V 60 Hz Conveyor Belt Units - please enquire for further details.UpgradesSoftware: Customers using older version of WinDIAS software can upgrade tothe new version (v3.3) free of charge, by downloading it from (requires USB Copy Protection Dongle that came with the original software).Hardware: Users of Standard WinDIAS Systems supplied after March 2019 can upgrade to the Rapid System simply by ordering a Conveyor Belt Unit (subject to voltage type). Users of older WinDIAS systems wishing to update the lighting or add a Conveyor Belt Unit should contact Delta-T for guidance software.Ordering InformationDelta-T DevicesEntry Level System - Flatbed ScannerVisit our website to view WinDIAS introduction VIDEO >>>LAI - Leaf Area IndexThere are more ways of getting to LAI than just measuring individual leaves. We also offer SunScan and HemiView - two innovative techniques forestimating LAI non destructively in crop and forest canopies.Accessories and SparesReference Target Set type WD-RTS-1 Colour rendition chart and reference targets for WInDIASSpare Conveyor Belt Material type CBSP1 Enough to make 10 pairs of belts [for 50 pairs order type CBSP2]Conveyor Spares type CBSP3 Full set of “O” rings and two drive bands for Conveyor Belt UnitWinDIAS_datasheet_version_3。

显微图像分析系统——油液分析版铁谱显微图像分析在机械零件相互作用的接触面间,一般采用闭式润滑系统,不论其润滑状态如何,都不可避免地存在着摩擦和磨损,高度摩擦造成机械效率降低,异常磨损则导致机械损坏。

磨损所产生的磨粒随润滑油进入了润滑系统中。

润滑油就象机器的“血液”,铁谱诊断技术正是通过给机器“验血”,从而诊断机械的磨损类故障、监测机器的状态。

铁谱分析技术通过对磨损颗粒的分析,可以在不停机的前提下实时监测设备的磨损状况和失效状态,并对各种故障隐患进行早期预报,指导维护人员及时采取措施以保障系统正常运行。

它广泛的应用于石油、化工、液压、机床、航空、舰船、铁路、电站、汽车、拖拉机、矿山等机械设备的状态监测与故障诊断。

传统铁谱技术是采用人工观察显微镜谱片视场的方法,依赖于分析人员的知识、经验的多少,随机误差大,操作枯燥费时,重复性精度低。

我们研究开发的铁谱图像分析系统是一套从事油液分析处理的专业应用系统。

它将传统的工业显微镜铁谱分析与计算机视觉、图像分析、模式识别和人工智能技术相结合,实现了对油液磨粒的清晰实时图像拍摄,提供便捷快速的多种图像处理和定量定性分析手段,从而给出故障预报或状态诊断与定位。

为用户及时监测、诊断、维修管理、设备预警、作业控制提供了极大的方便性和灵活性。

铁谱图像分析系统可根据用户不同层次的应用需求,订制不同的产品档次及类型,满足不同领域的实际应用。

图像分析系统配置图系统特点及功能清晰实时图像拍摄▽系统配备CCD摄像机,可即时获得高清晰度的显微图像▽向导式软件界面,可控制显微图像的实时观测与拍摄。

▽系统支持动态图像模式AVI文件,可通过大量图像序列创建AVI动态文件或蒙太奇,显示动态过程与输出存盘。

图像采集技术领先先进数字成像高保真图像放大可插入图像说明图像数字化存储明暗场图像对比软件具有从基本到高级等多个专业功能模块,可控制系统获取高清晰的图像,实现动态图像、单幅图像、多幅序列图像等多种方式的采集工作,实现图像的数字化管理。

MiFas 快速参考手册概述欢迎使用MiFas图象分析软件。

MiFas显微图象分析系统是一工作在Windows操作系统下的24位真彩色通用图象检测与分析系统。

MiFas采用先进的图象分析算法,能对各种显微图象进行处理、分析和检测,是图象检测与分析的有效工具。

一、MiFas能完成那些工作MiFas提供的图象处理与分析功能,覆盖图象定量分析的几乎所有应用领域,包括材料、冶金、医药、生物、化工、摩擦学等各种需要利用图象手段进行统计学和形态学自动分析、测定的领域。

凡是与图象形态学有关的各种检测与分析都可以利用MiFas来完成。

例如组织细胞形态学分析,金属显微组织及晶粒度分析,油料中污染物含量分析,农业种子形态分析,各种微小异行零件几何尺寸测量,化学工业中各种反应物粒子的形态分析等都可以利用MiFas来完成。

利用MiFas提供的分析结果,可使企业质量控制更具科学依据,提高企业管理水平和对外形象,是企业从事科技新产品开发,产品质量监控的有效工具。

MiFas亦可作为理论教学、实验分析和基础科学研究的有效工具。

二、MiFas的主要特点z符合GB15445,美国ASTM112 及ISO9276标准;z支持TWAIN接口标准扫描仪及数字相机,支持多种图象采集卡;z充分利用WINDOWS系统资源,全面支持WIN98,WINme/WIN2K/WINXP操作环境;z最新的程序设计手段,全汉化图文界面,可泊位图形工具条,使用简洁、直观、方便、快捷,只需点击鼠标,便可完成分析;z提供在线中文帮助提示,无需专业培训,便可掌握使用方法;z提供多种功能强大的区域选取工具,可对任意形状的区域进行处理与分析;z可完成包括色度调整,图象变形,数学形态学处理,图象增强,图象匹配,纹理分析,特征识别等一百多种专业图象处理与分析功能;z支持24位真彩色图象采集、支持RGB、CMY、HSV、Lab、YUV等彩色模型的处理与分析;z分析数据的可视化处理使分析结果与图象之间构成直接映射关系,便于观察分析;z先进的颗粒自动识别、粘连颗粒自动切分功能,保证了复杂图象的准确分析;z自动分析处理步骤编辑功能,能够完成全自动分析过程的设置;z悔步、重复功能,使用户能够找到最佳处理路径;z几何参数测量功能,细长体、块状体、颗粒体、线状体等各种特征体的自动定量分析功能,分析参数达一万多项。