常用钢丝绳型号(图)、直径、拉力表

- 格式:docx

- 大小:574.39 KB

- 文档页数:9

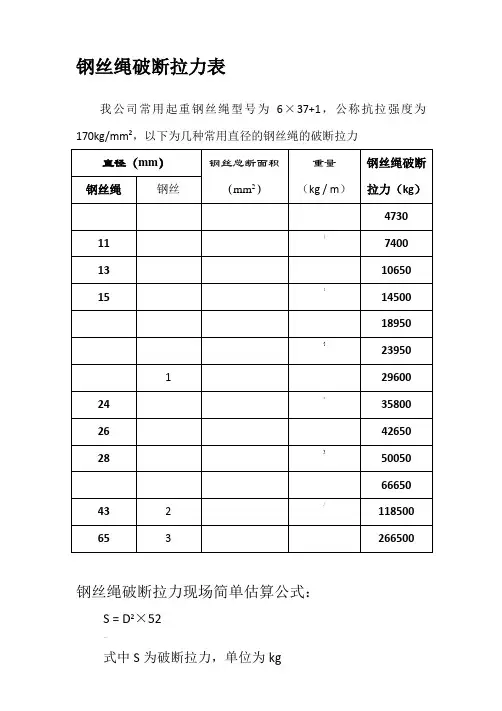

钢丝绳破断拉力表

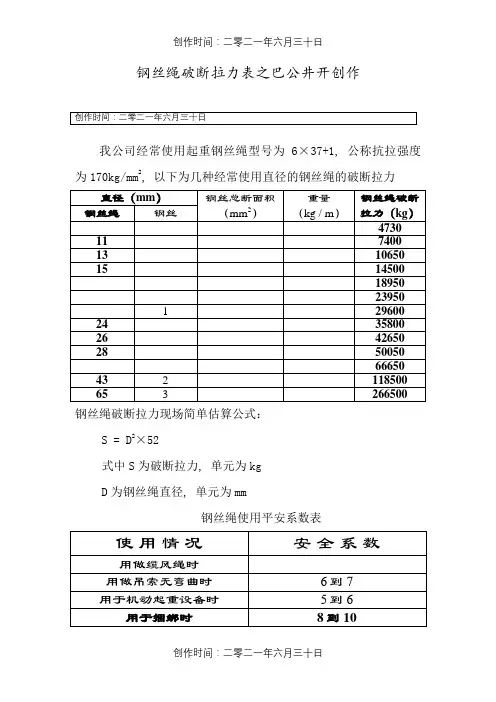

我公司常用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种常用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

—

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用安全系数表

钢丝绳拉力计算举例:

1.一根钢丝绳,吊装10t重设备,两股受力,是否满足要求

钢丝绳破断拉力为29600kg,安全系数取10,则单股可受力2960kg,两股共5920kg,不能满足要求;

反过来计算,现在使用钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算安全系数为,满足要求。

)。

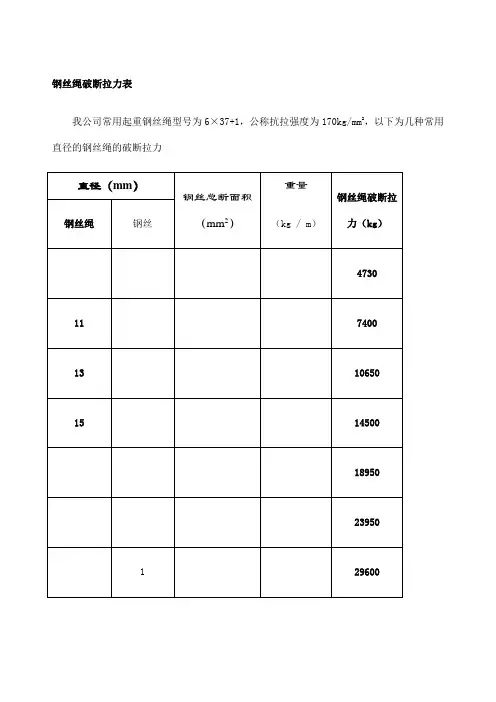

钢丝绳破断拉力表

我公司常用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种常用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用安全系数表

钢丝绳拉力计算举例:

1.一根钢丝绳,吊装10t重设备,两股受力,是否满足要求

钢丝绳破断拉力为29600kg,安全系数取10,则单股可受力2960kg,两股共5920kg,不能满足要求;

反过来计算,现在使用钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算安全系数为,满足要求。

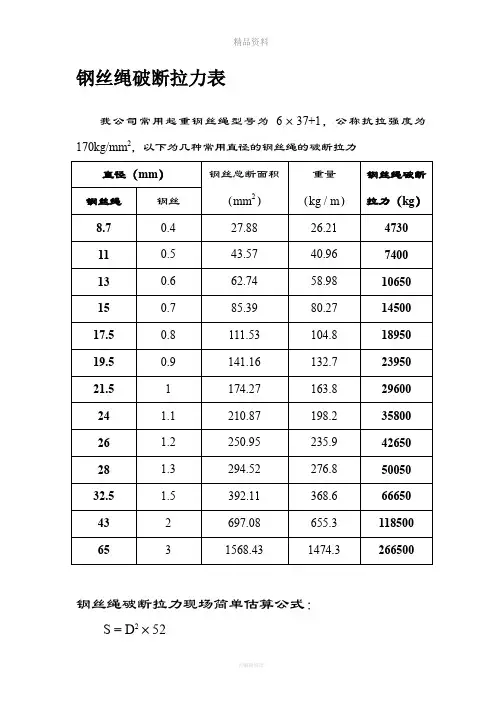

钢丝绳破断拉力表

我公司常用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种常用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用安全系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳,吊装10t重设备,两股受力,是否满足要求?

21.5mm钢丝绳破断拉力为29600kg,安全系数取10,则单股可受力2960kg,两股共5920kg,不能满足要求;

反过来计算,现在使用21.5mm钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算安全系数为11.84,满足要求。

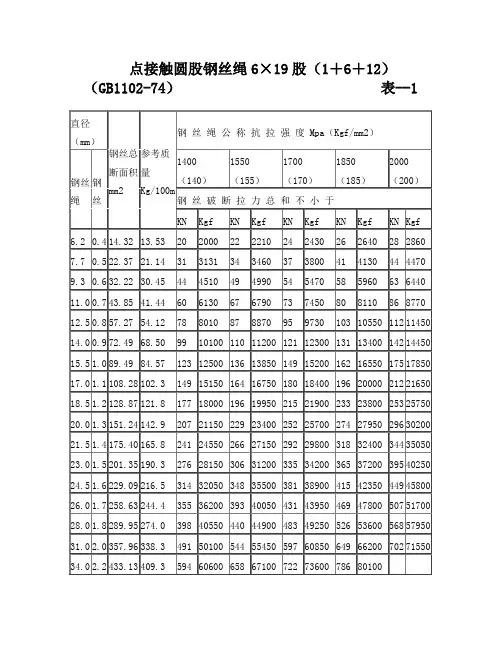

钢丝绳破断拉⼒表常见结构钢丝绳破断拉⼒表0 a5 h7 I( A( U) J4 v; l钢丝绳属性典型规格型号钢丝绳破断拉⼒计算公式点接触6*7-FCF(破断拉⼒)=直径*直径*1670/1000*0.33= KN6*7-IWSF(破断拉⼒)=直径*直径*1670/1000*0.36= KN, T9 h8 K9 ^ Q5 u* F& G& F 6x37-FCF(破断拉⼒)=直径*直径*1670/1000*0.29= KN/ Y4 O: ]& a7 N8 G [, Z6*19-FCF(破断拉⼒)=直径*直径*1670/1000*0.3= KN) h6 h+ I: n: ? G! k8 j6*19-iwsF(破断拉⼒)=直径*直径*1670/1000*0.33= KN起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租4 N, r6 `( V! V3 L# d7 g* _( E" X5 s6x37-iwrcF(破断拉⼒)=直径*直径*1670/1000*0.32= KN电梯钢丝绳-线接触8x19sF(破断拉⼒)=直径*直径*1670/1000*0.29= KN多层股线接触18x19SF(破断拉⼒)=直径*直径*1670/1000*0.339= KN起重机BBS0 r' C0 G2 s/ S" A7 D) d" ^点接触捆绑⽤6x12-7FCF(破断拉⼒)=直径*直径*1670/1000*0.28= KN起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租: S- Q( B' ?+ O2 s& l8 O, \线接触打井6x36SW-FC ⿇芯F(破断拉⼒)=直径*直径*1770/1000*0.33 = KN. y% F" C' ~8 c线接触6x36SW-IWRC 钢芯F(破断拉⼒)=直径*直径*1770/1000*0.36= KN4 I1 C e# m& ~& ?3 Z/ f( H/ l⾯接触及线接触6K*36SW-FC ⿇芯起重机BBS) d" K# b: q. X x* _' n⾯接触及线接触6K*36SW-IWRC 钢芯5 E0 W/ y! O8 G& t* m多层股18*7F(破断拉⼒)=直径*直径*1770/1000*0.327= KN19x7 35W*7 18*19SF(破断拉⼒)=直径*直径*1770/1000*0.318= KN起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租/ u8 @, {0 e+ n1 n1 m* Y0 l0 d4 k ⾯接触多层股18K*719*7K 35KW*7K起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租% ^6 |5 [9 r; @0 a; k+ /doc/e44f3d2f03d8ce2f006623f6.html . Y! |* p4 R' H钢丝绳属性典型规格型号钢丝绳破断拉⼒计算公式点接触6*7-FCF(破断拉⼒)=直径*直径*1670/1000*0.33= KN6*7-IWSF(破断拉⼒)=直径*直径*1670/1000*0.36= KN" t: N! H. n* B5 B2 ~6x37-FCF(破断拉⼒)=直径*直径*1670/1000*0.29= KN6*19-FCF(破断拉⼒)=直径*直径*1670/1000*0.3= KN6*19-iwsF(破断拉⼒)=直径*直径*1670/1000*0.33= KN6x37-iwrcF(破断拉⼒)=直径*直径*1670/1000*0.32= KN3 N% e3 `0 L' A0 A- b+ \# |电梯钢丝绳-线接触8x19sF(破断拉⼒)=直径*直径*1670/1000*0.29= KN多层股线接触18x19SF(破断拉⼒)=直径*直径*1670/1000*0.339= KN点接触捆绑⽤6x12-7FCF(破断拉⼒)=直径*直径*1670/1000*0.28= KN+ {/ I- J& i: o: ~5 X线接触打井6x36SW-FC ⿇芯F(破断拉⼒)=直径*直径*1770/1000*0.33 = KN线接触6x36SW-IWRC 钢芯F(破断拉⼒)=直径*直径*1770/1000*0.36= KN- H7 Q. I&F# b+ { I⾯接触及线接触6K*36SW-FC ⿇芯/ u: \+ y" i. I5 q⾯接触及线接触6K*36SW-IWRC 钢芯起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租, N8 u2 G- F$ Z- S- j. r- {多层股18*7F(破断拉⼒)=直径*直径*1770/1000*0.327= KN0 E! y2 a0 m3 |6 `/ D5Y0 ?$ w19x7 35W*7 18*19SF(破断拉⼒)=直径*直径*1770/1000*0.318= KN⾯接触多层股18K*72 S& p6 D8 J4 l5 x! _19*7K 35KW*7K# g8 |" \' {& y0 K$ C; U6 r" _这⾥给⼤家⼀个钢丝绳GB破断拉⼒计算表,注意是单根破断拉⼒,得出的数据是千⽜,如需转换成公⽄,则KN÷/doc/e44f3d2f03d8ce2f006623f6.html . F9 Y. y3 y- W( N( Y; d起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租7 o1 U# u9 Z2 j7 [钢丝绳属性典型规格型号钢丝绳破断拉⼒计算公式点接触6*7-FC F(破断拉⼒)=直径*直径*1670/1000*0.33= KN6*7-IWS F(破断拉⼒)=直径*直径*1670/1000*0.36= KN 起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租, N3 ^1 O- f1 R- _6x37-FC F(破断拉⼒)=直径*直径*1670/1000*0.29= KN6*19-FC F(破断拉⼒)=直径*直径*1670/1000*0.3= KN6*19-iws F(破断拉⼒)=直径*直径*1670/1000*0.33= KN /doc/e44f3d2f03d8ce2f006623f6.html / l9 U K0 F0 j- B6x37-iwrc F(破断拉⼒)=直径*直径*1670/1000*0.32= KN : n* ?$ t! s$ S& _' ]电梯钢丝绳-线接触0 F, A6 F* \# E6 q: a8x19s F(破断拉⼒)=直径*直径*1670/1000*0.29= KN起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租1 |9 F' f5 L0 y1 C7 r8 Q# J6 b6 {: ]9 J; ]; K! R4 J+ L多层股线接触" Z+ k8 I' V! a1 w8 y6 d) `18x19S F(破断拉⼒)=直径*直径*1670/1000*0.339= KN/doc/e44f3d2f03d8ce2f006623f6.html 2 q* f. |! Q: S, t点接触捆绑⽤起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租9 i/D" z& U- J) ?4 D9 `- J6x12-7FC F(破断拉⼒)=直径*直径*1670/1000*0.28= KN * z' \6 E- R/ a$ q线接触打井起重机BBS. _0 E; }; K# l: Q% f( U; N- b6x36SW-FC ⿇芯F(破断拉⼒)=直径*直径*1770/1000*0.33 = KN/doc/e44f3d2f03d8ce2f006623f6.html "h( c( A H3 ~0 h起重机论坛|吊车论坛|吊装论坛|⼯程机械论坛|起重机⽹|⼯程机械⽹|履带吊出租|汽车吊出租1 N4 [) ~' i) F9 ~: s线接触6x36SW-IWRC 钢芯F(破断拉⼒)=直径*直径*1770/1000*0.36= KN多层股/doc/e44f3d2f03d8ce2f006623f6.html % u; |. I! q# u9 U$ ~ 18*7 F(破断拉⼒)=直径*直径*1770/1000*0.327= KN19x7 35W*7 18*19S F(破断拉⼒)=直径*直径*1770/1000*0.318= KN钢丝绳属性典型规格型号钢丝绳破断拉⼒计算公式点接触6*7-FC F(破断拉⼒)=直径*直径*1670/1000*0.33= KN6*7-IWS F(破断拉⼒)=直径*直径*1670/1000*0.36= KN6x37-FC F(破断拉⼒)=直径*直径*1670/1000*0.29= KN6*19-FC F(破断拉⼒)=直径*直径*1670/1000*0.3= KN6*19-iws F(破断拉⼒)=直径*直径*1670/1000*0.33= KN6x37-iwrc F(破断拉⼒)=直径*直径*1670/1000*0.32= KN电梯钢丝绳-线接触8x19s F(破断拉⼒)=直径*直径*1670/1000*0.29= KN多层股线接触18x19S F(破断拉⼒)=直径*直径*1670/1000*0.339= KN点接触捆绑⽤6x12-7FC F(破断拉⼒)=直径*直径*1670/1000*0.28= KN线接触打井6x36SW-FC ⿇芯F(破断拉⼒)=直径*直径*1770/1000*0.33 = KN线接触6x36SW-IWRC 钢芯F(破断拉⼒)=直径*直径*1770/1000*0.36= KN⾯接触及线接触6K*36SW-FC ⿇芯⾯接触及线接触6K*36SW-IWRC 钢芯多层股18*7 F(破断拉⼒)=直径*直径*1770/1000*0.327= KN19x7 35W*7 18*19S F(破断拉⼒)=直径*直径*1770/1000*0.318=以上来之于南通⼒森特种钢丝绳有限公司⽹站上的技术参数F=30×30×1770/1000×0.33=525.69KN。

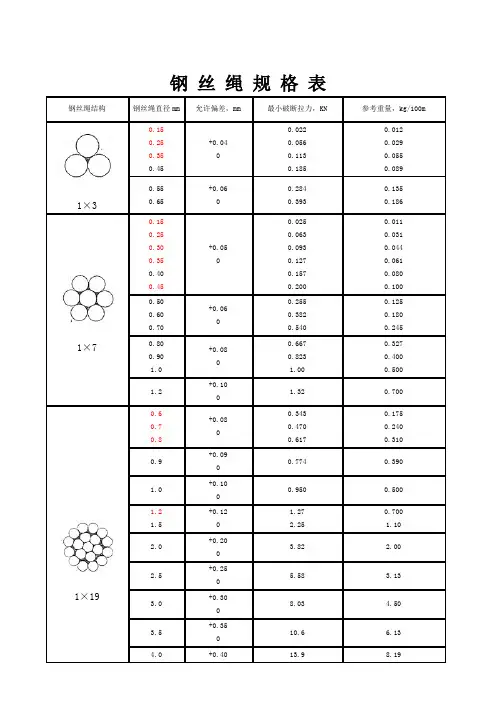

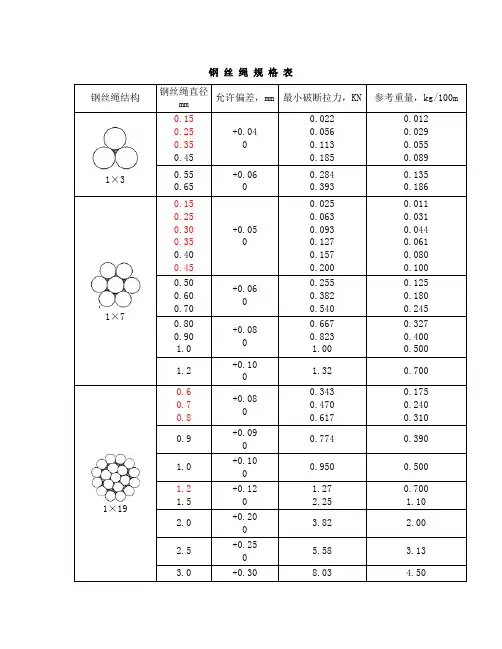

钢丝绳规格表钢丝绳结构钢丝绳直径mm 允许偏差,mm 最小破断拉力,KN 参考重量,kg/100m1×30.150.250.350.45+0.040.0220.0560.1130.1850.0120.0290.0550.089 0.550.65+0.060.2840.3930.1350.1861×7 0.150.250.300.350.400.45+0.050.0250.0630.0930.1270.1570.2000.0110.0310.0440.0610.0800.100 0.500.600.70+0.060.2550.3820.5400.1250.1800.245 0.800.901.0+0.080.6670.8231.000.3270.4000.5001.2+0.101.32 0.7001×19 0.60.70.8+0.080.3430.4700.6170.1750.2400.310 0.9+0.090.774 0.3901.0+0.100.950 0.5001.21.5+0.121.272.250.7001.102.0+0.203.82 2.00 2.5+0.255.58 3.13 3.0+0.308.03 4.50 3.5+0.3510.6 6.13 4.0 +0.40 13.9 8.196.0 +0.6030.4 18.5钢丝绳结构钢丝绳直径,mm 允许偏差,mm 最小破断拉力,KN 参考重量,kg/100m7× 7 6× 7 0.450.500.600.700.800.90+0.090.1420.1760.2530.3450.4610.5390.080.120.150.200.260.321.01.2+0.150.6731.200.400.651.51.62.0+0.201.672.152.940.931.201.652.43.0+0.304.106.372.403.703.54.0+0.407.649.515.106.50 5.0+0.5014.7 10.5 6.08.0+0.6018.640.615.126.6钢丝绳结构钢丝绳直径,mm 允许偏差,mm 最小破断拉力,KN 参考重量,kg/100m7×19 1.6+0.251.85 1.122.43.2+0.34.107.852.604.3 4.04.85.05.66.06.4+0.4010.716.516.722.323.528.56.709.7010.512.814.916.4 7.2+0.5034.7 20.8 8.0+0.5640.1 25.86×19 11.0+0.7672.5 53.0 12.7+0.84101.0 68.2 14.3+0.91127.0 87.8 16.0+0.99156.0 106.0 19.0+1.14221.0 157.0 22.0+1.22295.0 213 25.0+1.37380.0 2782、本产品规格为红色的,属于非常规产品,无库存,生产时按客户要求定做;3、除以上规格外,我公司还可提供其他规格钢丝绳,如:1×37、6×37、7×37等,规格最大可到Φ46mm,也可根据客户规格生产;4、可提供右交互捻(ZS)、右交互捻(SZ)、右同向捻(ZZ)、左同向捻(SS);5、可提供FC纤维芯(天然合成)、NF(天然纤维芯)、SF合成纤维芯、IWR(金属丝绳芯)、IWS(金属丝股芯)等,特殊规格按实际情况6、本公司产品均附力学检测报告、材质检验报告、产品合格证CAD中所有的线型均是由点和线段组成的,例如点画线或虚线。

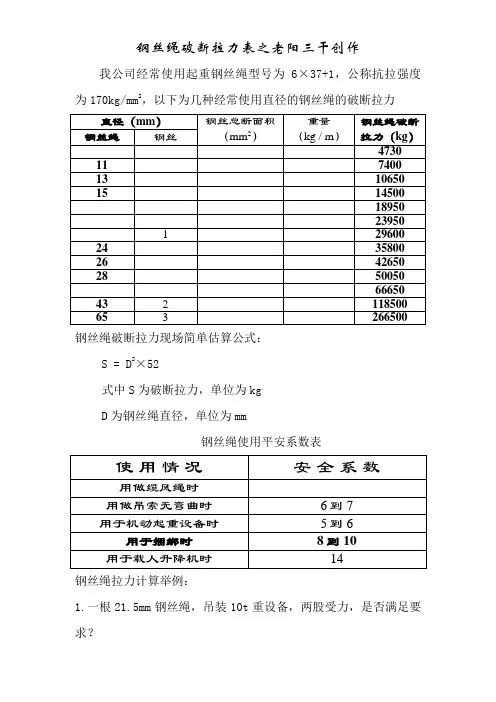

钢丝绳破断拉力表之老阳三干创作我公司经常使用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种经常使用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用平安系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳,吊装10t重设备,两股受力,是否满足要求?

21.5mm钢丝绳破断拉力为29600kg,平安系数取10,则单股可受力2960kg,两股共5920kg,不克不及满足要求;

反过来计算,现在使用21.5mm钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算平安系数为11.84,满足要求。

钢丝绳规格表钢丝绳结构钢丝绳直径mm允许偏差,mm 最小破断拉力,KN 参考重量,kg/100m1×3 0.150.250.350.45+0.040.0220.0560.1130.1850.0120.0290.0550.089 0.550.65+0.060.2840.3930.1350.1861×7 0.150.250.300.350.400.45+0.050.0250.0630.0930.1270.1570.2000.0110.0310.0440.0610.0800.100 0.500.600.70+0.060.2550.3820.5400.1250.1800.245 0.800.901.0+0.080.6670.8231.000.3270.4000.5001.2+0.101.32 0.7001×19 0.60.70.8+0.080.3430.4700.6170.1750.2400.310 0.9+0.090.774 0.3901.0+0.100.950 0.5001.21.5+0.121.272.250.7001.102.0+0.203.82 2.00 2.5+0.255.58 3.13 3.0 +0.30 8.03 4.503.5 +0.3510.6 6.134.0 +0.40 13.9 8.195.0 +0.5021.0 12.96.0 +0.6030.4 18.5钢丝绳结构钢丝绳直径,mm允许偏差,mm最小破断拉力,KN参考重量,kg/100m7× 7 6× 7 0.450.500.600.700.800.90+0.090.1420.1760.2530.3450.4610.5390.080.120.150.200.260.321.01.2+0.150.6731.200.400.651.51.62.0+0.201.672.152.940.931.201.652.43.0+0.304.106.372.403.703.54.0+0.407.649.515.106.50 5.0+0.5014.7 10.5 6.08.0+0.6018.640.615.126.6钢丝绳结构钢丝绳直径,mm允许偏差,mm 最小破断拉力,KN 参考重量,kg/100m1.6+0.251.85 1.122.43.2+0.34.107.852.604.34.0 +0.40 10.7 6.707×19 6×194.85.05.66.06.40 16.516.722.323.528.59.7010.512.814.916.4 7.2+0.5034.7 20.8 8.0+0.5640.1 25.8 9.5+0.6653.4 36.2 11.0+0.7672.5 53.0 12.7+0.84101.0 68.2 14.3+0.91127.0 87.8 16.0+0.99156.0 106.0 19.0+1.14221.0 157.0 22.0+1.22295.0 213 25.0+1.37380.0 278备注:1、以上产品可采用镀锌、201、202、301、304、316、316L钢丝生产,可进行涂塑处理;2、本产品规格为红色的,属于非常规产品,无库存,生产时按客户要求定做;3、除以上规格外,我公司还可提供其他规格钢丝绳,如:1×37、6×37、7×37等,规格最大可到Φ46mm,也可根据客户规格生产;4、可提供右交互捻(ZS)、右交互捻(SZ)、右同向捻(ZZ)、左同向捻(SS);5、可提供FC纤维芯(天然合成)、NF(天然纤维芯)、SF合成纤维芯、IWR(金属丝绳芯)、IWS(金属丝股芯)等,特殊规格按实际情况6、本公司产品均附力学检测报告、材质检验报告、产品合格证CAD中所有的线型均是由点和线段组成的,例如点画线或虚线。

钢丝绳破断拉力表之巴公井开创作

我公司经常使用起重钢丝绳型号为6×37+1, 公称抗拉强度为170kg/mm2, 以下为几种经常使用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力, 单元为kg

D为钢丝绳直径, 单元为mm

钢丝绳使用平安系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳, 吊装10t重设备, 两股受力, 是否满足要求?

21.5mm钢丝绳破断拉力为29600kg, 平安系数取10, 则单股可受力2960kg, 两股共5920kg, 不能满足要求;

反过来计算, 现在使用21.5mm钢丝绳四股吊装10t重设备, 则单股受力约为2500kg, 可计算平安系数为11.84, 满足要求.。

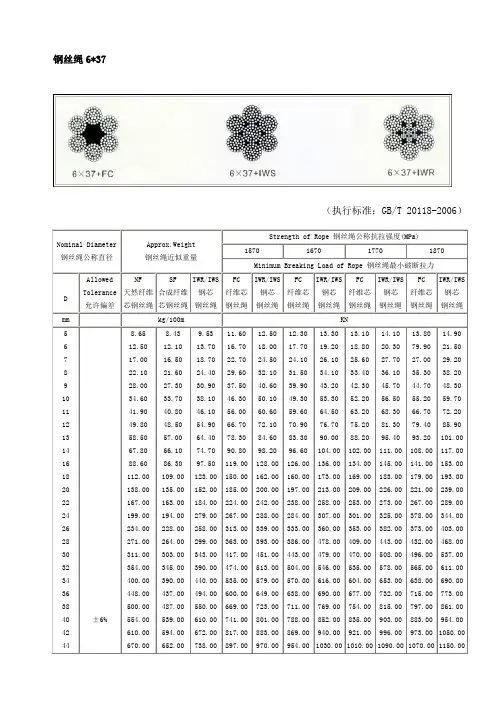

钢丝绳6*37(执行标准:GB/T 20118-2006)Nominal Diameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Strength of Rope 钢丝绳公称抗拉强度(MPa)1570 1670 1770 1870Minimum Breaking Load of Rope 钢丝绳最小破断拉力DAllowedTolerance允许偏差NF天然纤维芯钢丝绳SF合成纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳mm kg/100m KN 56789101112131416182022242628303234363840 42 44 ±6%8.6512.5017.0022.1028.0034.6041.9049.8058.5067.8088.60112.00138.00167.00199.00234.00271.00311.00354.00400.00448.00500.00554.00610.00670.008.4312.1016.5021.6027.3033.7040.8048.5057.0066.1086.30109.00135.00163.00194.00228.00264.00303.00345.00390.00437.00487.00539.00594.00652.009.5313.7018.7024.4030.9038.1046.1054.9064.4074.7097.50123.00152.00184.00279.00258.00299.00343.00390.00440.00494.00550.00610.00672.00738.0011.6016.7022.7029.6037.5046.3056.0066.7078.3090.80119.00150.00185.00224.00267.00313.00363.00417.00474.00535.00600.00669.00741.00817.00897.0012.5018.0024.5032.1040.6050.1060.6072.1084.6098.20128.00162.00200.00242.00288.00339.00393.00451.00513.00579.00649.00723.00801.00883.00970.0012.3017.7024.1031.5039.9049.3059.6070.9083.3096.60126.00160.00197.00238.00284.00333.00386.00443.00504.00570.00638.00711.00788.00869.00954.0013.3019.2026.1034.1043.2053.3064.5076.7090.00104.00136.00173.00213.00258.00307.00360.00478.00479.00546.00616.00690.00769.00852.00940.001030.0013.1018.8025.6033.4042.3052.2063.2075.2088.20102.00134.00169.00209.00253.00301.00353.00409.00470.00535.00604.00677.00754.00835.00921.001010.0014.1020.3027.7036.1045.7056.5068.3081.3095.40111.00145.00183.00226.00273.00325.00382.00443.00508.00578.00653.00732.00815.00903.00996.001090.0013.8079.9027.0035.3044.7055.2066.7079.4093.20108.00141.00179.00221.00267.00378.00373.00432.00496.00565.00638.00715.00797.00883.00973.001070.0014.9021.5029.2038.2048.3059.7072.2085.90101.00117.00153.00193.00239.00289.00344.00403.00468.00537.00611.00690.00773.00861.00954.001050.001150.0046 48 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80732.00797.00865.00936.001010.001090.001160.001250.001330.001420.001510.001600.001700.001790.001890.002000.002110.002210.00773.00775.00843.00911.00983.001060.001130.001210.001300.001380.001470.001560.001650.001750.001850.001950.002050.002160.00806.00878.00953.001030.001170.001190.001280.001370.001460.001560.001360.001760.001870.001980.002090.002200.002320.002440.00980.001070.001160.001250.001350.001450.001560.001670.001780.001900.002020.002140.002270.002400.002540.002680.002820.002960.001060.001150.001250.001350.001460.001570.001680.001800.001930.002050.002180.002320.002450.002600.002740.002890.003050.003210.001040.001140.001230.001330.001440.001540.007660.001770.007890.002020.002750.002280.002410.002550.002700.002850.003000.003150.001130.001230.001330.001440.001550.001670.001790.001920.002050.002180.002320.002460.002610.002760.002920.003080.003240.003410.001100.001200.001310.001410.001520.001640.001760.001880.002010.002140.002270.002410.002560.002710.002860.003020.003180.003340.001190.001300.001410.001530.001650.001770.001900.002030.002170.002310.002460.002610.002770.002930.003090.003260.003440.003610.001170.001270.001380.001490.001610.001730.001860.001990.002120.002260.002400.002550.002700.002860.003020.003190.003360.003530.001260.001370.001490.001610.001740.001870.002010.002150.002290.002440.002600.002760.002920.003090.003270.003450.003630.003820.00Main Applications:Various equipment for derricking,lfting and drawing钢丝绳6*37的主要用途:各种起重、提升和牵引设备钢丝绳6*37的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.226(纤维芯)或×1.321(钢芯)钢丝绳6*19(执行标准:GB/T 20118-2006)Nominal Diameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Nominal Tensile Strength of Rope 钢丝绳公称抗拉强度(MPa)1570 1670 1770 1870Minimum Breaking Load of Rope 钢丝绳最小破断拉力DAllowedTolerance允许偏差NF天然纤维芯钢丝绳SF合成纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳mm kg/100m KNMain Applications:Various equipment for derricking,lfting and drawing钢丝绳6*19的主要用途:各种起重、提升和牵引设备钢丝绳6*19的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.249(纤维芯)或×1.336(钢芯)钢丝绳6*19S、6*19W(执行标准:GB/T 20118-2006)Nominal Diameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Nominal Tensile Strength of Rope 钢丝绳公称抗拉强度(MPa)1570 1670 1770 1870Minimum Breaking Load of Rope 钢丝绳最小破断拉力DAllowedTolerance允许偏差NF天然纤维芯钢丝绳SF合成纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳mm kg/100m KN5 6 7 8 91011121314 16 18 20 22 24 26 289.2013.3018.1023.6029.9036.9044.6053.1062.3072.2094.40119.00147.00178.00212.00249.00289.009.0013.0017.6023.0029.9036.0043.5051.8060.8070.5092.10117.00144.00174.00207.00243.00282.0010.1014.6079.9025.9032.8040.5049.1058.4068.5079.50104.00731.00162.00196.00234.00274.00318.0013.0018.7025.4033.2042.0051.8062.7074.6087.60102.00133.00168.00207.00251.00298.00350.00406.0014.0020.1027.4035.8045.3055.9067.6080.5094.50110.00143.00181.00224.00271.00322.00378.00438.0013.8019.8027.0035.3044.6055.1066.7079.4093.10108.00141.00179.00220.00267.00317.00373.00432.0014.9021.4029.?038.0048.2059.5077.9085.60100.00117.00152.00193.00238.00288.00342.00402.00466.0074.6021.0028.6037.4047.3058.4070.7084.1098.70114.00150.00189.00234.00283.00336.00395.00458.0015.8022.7030.9040.3051.0063.0076.2090.70106.00124.00161.00204.00252.00305.00363.00426.00494.0015.4022.2030.2039.5050.0061.7074.7088.90104.00121.00158.00200.00247.00299.00355.00417.00484.0016.6024.0032.6042.6053.9066.6080.6095.90113.00130.00170.00216.00266.00322.00383.00450.00522.0030 32 3436 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 ±6%332.00377.00426.00478.00532.00590.00650.00714.00780.00849.00922.00997.001070.001160.001240.007330.001420.007510.001610.001700.001810.001970.002020.002130.002240.002360.00324.00369.00416.00466.00520.00576.00635.00697.00761.00829.00900.00973.001050.001130.001210.001300.001380.001470.001570.001660.001760.001870.001970.002080.002190.002300.00365.00415.00469.00525.00585.00649.00715.00785.00858.00934.001010.001100.001180.001270.001360.001460.001560.001660.001770.001870.001990.002100.002220.002340.002470.002590.00466.00531.00599.00671.00748.00829.00914.001000.001100.001190.001300.001400.001570.001620.001740.001870.001990.002120.002260.002400.002540.002690.002840.002990.003150.003320.00503.00572.00646.00724.00807.00894.00986.001080.001180.001290.001400.001510.001630.001750.001880.002010.002150.002290.002430.002580.002740.002900.003060.003230.003400.003580.00496.00564.00637.00714.00796.00882.00972.001070.001170.001270.001380.001490.001610.001730.001850.001980.002120.002260.002400.002550.002700.002860.003020.003180.003350.003530.00535.00609.00687.00770.00858.00951.001050.001150.001260.001370.001490.001670.001730.001860.002000.002140.002290.002440.002590.002750.002910.003080.003260.003430.003620.003800.00526.00598.00675.00757.00843.00935.001030.001130.001240.001350.001460.001580.001700.001830.007960.002100.002250.002390.002540.002700.002860.003030.003200.003370.003550.003740.00567.00645.00728.00817.00910.001010.001110.001220.001330.001450.001580.001700.001840.001980.002120.002270.002420.002580.002740.002910.003090.003270.003450.003640.003830.004030.00555.00632.00713.00800.00891.00987.001090.001190.001310.001420.001540.001670.001800.001940.002080.002220.002370.002530.002690.002850.003020.003200.003380.003560.003750.003950.00599.00682.00770.00863.00961.001070.001170.001290.001410.001530.001660.001800.001940.002090.002240.002400.002560.002730.002900.003080.003260.003450.003650.003850.004050.004260.00Main Applications:Various equipment for hoisting, derricking,lifting, towing, port load and unload, blast furnace hoisting and oil well drilling.The rope with wire core can be used under the shock load, heated and squeezed conditions.钢丝绳6*19S、6*19W的主要用途:各种起重、提升和牵引设备、港口装卸、高炉卷扬、石油钻井、金属芯绳适用于冲击负荷,受热和受挤压条件下。

钢丝绳破断拉力一览表集团标准化小组:[VVOPPT-JOPP28-JPPTL98-LOPPNN]

钢丝绳破断拉力表

我公司常用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种常用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用安全系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳,吊装10t重设备,两股受力,是否满足要求?

21.5mm钢丝绳破断拉力为29600kg,安全系数取10,则单股可受力2960kg,两股共5920kg,不能满足要求;

反过来计算,现在使用21.5mm钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算安全系数为11.84,满足要求。

钢丝绳破断拉力表之马矢奏春创作我公司经常使用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种经常使用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用平安系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳,吊装10t重设备,两股受力,是否满足要求?

21.5mm钢丝绳破断拉力为29600kg,平安系数取10,则单股可受力2960kg,两股共5920kg,不克不及满足要求;

反过来计算,现在使用21.5mm钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算平安系数为11.84,满足要求。

钢丝绳6*37(执行尺度:GB/T 20118-2006)NominalDiameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Strength of Rope 钢丝绳公称抗拉强度(MPa)1570167017701870Minimum Breaking Load of Rope 钢丝绳最小破断拉力D AllowedTolerance允许偏差NF天然纤维芯钢丝绳SF合成纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳FC纤维芯钢丝绳IWR/IWS钢芯钢丝绳mm kg/100m KN 5678910111213141618 20 22 24 26 28 30 32 34 36 38 ±6%8.6512.5017.0022.1028.0034.6041.9049.8058.5067.8088.60112.00138.00167.00199.00234.00271.00311.00354.00400.00448.00500.008.4312.1016.5021.6027.3033.7040.8048.5057.0066.1086.30109.00135.00163.00194.00228.00264.00303.00345.00390.00437.00487.009.5313.7018.7024.4030.9038.1046.1054.9064.4074.7097.50123.00152.00184.00279.00258.00299.00343.00390.00440.00494.00550.0011.6016.7022.7029.6037.5046.3056.0066.7078.3090.80119.00150.00185.00224.00267.00313.00363.00417.00474.00535.00600.00669.0012.5018.0024.5032.1040.6050.1060.6072.1084.6098.20128.00162.00200.00242.00288.00339.00393.00451.00513.00579.00649.00723.0012.3017.7024.1031.5039.9049.3059.6070.9083.3096.60126.00160.00197.00238.00284.00333.00386.00443.00504.00570.00638.00711.0013.3019.2026.1034.1043.2053.3064.5076.7090.00104.00136.00173.00213.00258.00307.00360.00478.00479.00546.00616.00690.00769.0013.1018.8025.6033.4042.3052.2063.2075.2088.20102.00134.00169.00209.00253.00301.00353.00409.00470.00535.00604.00677.00754.0014.1020.3027.7036.1045.7056.5068.3081.3095.40111.00145.00183.00226.00273.00325.00382.00443.00508.00578.00653.00732.00815.0013.8079.9027.0035.3044.7055.2066.7079.4093.20108.00141.00179.00221.00267.00378.00373.00432.00496.00565.00638.00715.00797.0014.9021.5029.2038.2048.3059.7072.2085.90101.00117.00153.00193.00239.00289.00344.00403.00468.00537.00611.00690.00773.00861.0040 42 4446 48 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80554.00610.00670.00732.00797.00865.00936.001010.001090.001160.001250.001330.001420.001510.001600.001700.001790.001890.002000.002110.002210.00539.00594.00652.00773.00775.00843.00911.00983.001060.001130.001210.001300.001380.001470.001560.001650.001750.001850.001950.002050.002160.00610.00672.00738.00806.00878.00953.001030.001170.001190.001280.001370.001460.001560.001360.001760.001870.001980.002090.002200.002320.002440.00741.00817.00897.00980.001070.001160.001250.001350.001450.001560.001670.001780.001900.002020.002140.002270.002400.002540.002680.002820.002960.00801.00883.00970.001060.001150.001250.001350.001460.001570.001680.001800.001930.002050.002180.002320.002450.002600.002740.002890.003050.003210.00788.00869.00954.001040.001140.001230.001330.001440.001540.007660.001770.007890.002020.002750.002280.002410.002550.002700.002850.003000.003150.00852.00940.001030.001130.001230.001330.001440.001550.001670.001790.001920.002050.002180.002320.002460.002610.002760.002920.003080.003240.003410.00835.00921.001010.001100.001200.001310.001410.001520.001640.001760.001880.002010.002140.002270.002410.002560.002710.002860.003020.003180.003340.00903.00996.001090.001190.001300.001410.001530.001650.001770.001900.002030.002170.002310.002460.002610.002770.002930.003090.003260.003440.003610.00883.00973.001070.001170.001270.001380.001490.001610.001730.001860.001990.002120.002260.002400.002550.002700.002860.003020.003190.003360.003530.00954.001050.001150.001260.001370.001490.001610.001740.001870.002010.002150.002290.002440.002600.002760.002920.003090.003270.003450.003630.003820.00Main Applications:Various equipment for derricking,lfting and drawing钢丝绳6*37的主要用途:各种起重、提升和牵引设备钢丝绳6*37的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.226(纤维芯)或×1.321(钢芯)钢丝绳6*19(执行尺度:GB/T 20118-2006)Nominal Diameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Nominal Tensile Strength of Rope 钢丝绳公称抗拉强度(MPa)1570167017701870Minimum Breaking Load of Rope 钢丝绳最小破断拉力DAllowedToleranceNF天然纤SF合成纤IWR/IWSFC纤维芯IWR/IWSFC纤维芯IWR/IWSFC纤维芯IWR/IWSFC纤维芯IWR/IWS76 78 802000.002110.002210.001950.002050.002160.001660.01760.001870.001980.02090.02200.02320.02440.01850.01970.002100.02230.02360.02500.02640.02780.002930.03080.01880.02000.02130.02270.002410.02550.02700.002850.03010.03170.03340.01970.002100.02230.02370.002510.02660.02810.02960.03120.03280.02270.002420.02560.02720.002870.003040.03200.03370.003550.02090.02230.02370.002510.02660.02820.02980.03140.03310.03480.02120.02260.02410.02560.02720.002880.03050.03220.03390.03580.03760.002070.002210.02350.02500.02650.02810.02980.03140.03320.03490.03670.02240.02390.02540.02700.002870.003040.03220.03400.03590.03780.003970.00Main Applications:Various equipment for derricking,lfting and drawing钢丝绳6*19的主要用途:各种起重、提升和牵引设备钢丝绳6*19的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.249(纤维芯)或×1.336(钢芯)钢丝绳6*19S、6*19W(执行尺度:GB/T 20118-2006)NominalDiameter 钢丝绳公称直径Approx.Weight钢丝绳近似重量Nominal Tensile Strength of Rope 钢丝绳公称抗拉强度(MPa)1570167017701870Minimum Breaking Load of Rope 钢丝绳最小破断拉力78 802240.002360.002190.002300.002470.002590.003150.003320.003400.003580.003350.003530.003620.003800.003550.003740.003830.004030.003750.003950.004050.004260.00Main Applications:Various equipment for hoisting, derricking,lifting, towing, port load and unload, blast furnace hoisting and oil well drilling.The rope with wire core can be used under the shock load, heated and squeezed conditions.钢丝绳6*19S、6*19W的主要用途:各种起重、提升和牵引设备、港口装卸、高炉卷扬、石油钻井、金属芯绳适用于冲击负荷,受热和受挤压条件下。

附录A(规范性附录)钢丝绳类别、直径和级的最小破断拉力表表A.1~表.A.11给出了钢丝绳类别、直径和钢丝绳级对应的最小破断拉力。

表A.14×K19类和4×K36类钢丝绳典型结构图典型结构直径范围/mm4×K36WS-FC 钢丝绳结构股结构外层钢丝数总数每股4×K19S 4×K26WS 4×K31WS4×K36WS1-9-91-5-5/5-101-6-6/6-121-7-7/7-1436404856910121422~3222~3222~3224~48钢丝绳公称直径mm 参考重量kg/100m 钢丝绳级别1570177019602160纤维芯/钢芯钢丝绳最小破断拉力/kN纤维芯/钢芯纤维芯/钢芯纤维芯/钢芯纤维芯/钢芯2224262830323436384042444648218259304353405461520583650720794871952104031237143550557965974483493010301140125013601480351418491569653743839941105011601280140015401670389463543630723823929104011601290142015601700185042951059969479790710201150------------注:最小破断拉力总和为最小破断拉力乘以1.191后的值。

表A.36×K19及6×K36类表A.36×K19及6×K36类(续)钢丝绳公称直径mm参考重量kg/100m钢丝绳级别1570177019602160纤维芯钢芯钢丝绳最小破断拉力/kN纤维芯钢芯纤维芯钢芯纤维芯钢芯纤维芯钢芯54 56 58 60 64 68 72 76 80 84 88 92 96 100 104 108 112 116 120124013301430153017401970220024502720--------------------1360146015601670190021502410269029803280360039404290465050305420583062606700171018401970211024002710304033803750--------------------1900204021902350260029403300367040704490492053805860636068807420798085609160193020702220238027003050342038104230--------------------21402300247026402940331037204140459050605550607066107170775083608990965010300213022902460263029903380379042204680--------------------23702550274029303250367041204580508056006150672073207940----------23502530----------------------------------261028103020323035804050------------------------注:最小破断拉力总和为最小破断拉力乘以1.214(纤维芯)或1.260(钢芯)后的值。

钢丝绳破断拉力一览表 Last revision date: 13 December 2020.

钢丝绳破断拉力表

我公司常用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种常用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用安全系数表

钢丝绳拉力计算举例:

1.一根钢丝绳,吊装10t重设备,两股受力,是否满足要求?

钢丝绳破断拉力为29600kg,安全系数取10,则单股可受力

2960kg,两股共5920kg,不能满足要求;

反过来计算,现在使用钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算安全系数为,满足要求。

钢丝绳拉力估算参照表(总4页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--钢丝绳拉力估算参照表(单根6×29)钢丝绳拉力估算参照表(单根6×37)一、现场估算钢丝绳极限负荷、安全负荷(运用公式:S P=1/2d2,其中d为钢丝绳的直径,单位必须化为英分,1英分=毫米;、为换算系数值;K为安全系数值):1、现有一根规格为6×37,直径为21毫米的钢丝绳,计算该钢丝绳的破断拉力及允许拉力。

破断拉力S P=1/2d2×=1/2×(21÷)2×=1/2××=(t)允许拉力S=S P÷K=÷6=(t)2、现有一根规格为6×29+1,直径为33毫米的钢丝绳,计算该钢丝绳的破断拉力及允许拉力。

破断拉力S P=1/2d2×=1/2×(33÷)2×=1/2××=(t)允许拉力S=S P÷K=÷6=(t)运用口诀:钢丝直径用英分,破断负荷记为吨,直径平方被二除,即为破断负荷数二、当知道吊物重量和钢丝绳角度时,计算钢丝绳的承受拉力(a为吊物重量;n为钢丝绳根数):例1.某施工现场有一个重16吨的集装箱需要吊运,有四根钢丝绳,钢丝绳与水平方向成45。

角,计算这四根钢丝绳每根在此角度时所承受的拉力。

每根钢丝绳承受拉力S=a/Sinx=16/Sin45。

=(t)根据所算的承受拉力参考《估算参照表》可选用合适的钢丝绳例2.某施工现场有重量为5吨的型钢,有两根钢丝绳吊运,钢丝绳与水平方向成50。

角,计算这两根钢丝绳每根在此角度时所承受的拉力。

每根钢丝绳承受拉力S=a/Sinx=5/Sin50。

- =(t)说明:钢丝绳的受力大小随着角度的增大而减小,角度的减小而增大,钢丝绳越长,角度越大,反之则越小。

钢丝绳破断拉力表之老阳三干创作

我公司经常使用起重钢丝绳型号为6×37+1,公称抗拉强度为170kg/mm2,以下为几种经常使用直径的钢丝绳的破断拉力

钢丝绳破断拉力现场简单估算公式:

S = D2×52

式中S为破断拉力,单位为kg

D为钢丝绳直径,单位为mm

钢丝绳使用平安系数表

钢丝绳拉力计算举例:

1.一根21.5mm钢丝绳,吊装10t重设备,两股受力,是否满足要求?

21.5mm钢丝绳破断拉力为29600kg,平安系数取10,则单股可受力2960kg,两股共5920kg,不克不及满足要求;

反过来计算,现在使用21.5mm钢丝绳四股吊装10t重设备,则单股受力约为2500kg,可计算平安系数为11.84,满足要求。

钢丝绳6*37

(执行标准:GB/T 20118-2006)

Main Applications:Various equipment for derricking,lfting and drawing 钢丝绳6*37的主要用途:各种起重、提升和牵引设备

钢丝绳

6*37的最小钢丝绳破断拉力总和

=钢丝绳最小破断拉力×1.226(纤维芯)或×1.321(钢

芯)

钢丝绳6*19

(执行标准:GB/T 20118-2006)

Main Applications:Various equipment for derricking,lfting and drawing

钢丝绳6*19的主要用途:各种起重、提升和牵引设备

钢丝绳6*19的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.249(纤维芯)或×1.336(钢

芯)

钢丝绳6*19S、6*19W

(执行标准:GB/T 20118-2006)

Main Applications:Various equipment for hoisting, derricking,lifting, towing, port load and unload, blast furnace hoisting and oil well drilling.The rope with wire core can be used under the shock load, heated and squeezed conditions.

钢丝绳6*19S、6*19W的主要用途:各种起重、提升和牵引设备、港口装卸、高炉卷扬、石油钻井、金属芯绳适用于冲击负荷,受热和受挤压条件下。

钢丝绳6*19S、6*19W的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.134(纤维芯)或1.214(钢芯)。

钢丝绳6*29Fi、6*25Fi、6*26SW、6*31SW、6*36SW、6*37S

(执行标准:GB/T 20118-2006)

Main Appplications:Various eqmuipment for derricking, lifting and drawing;the rope with wire core can be used under the shock load,heated and squeezed conditions such as electric shares.

钢丝绳6*29Fi、6*25Fi、6*26SW、6*31SW、6*36SW、6*37S的主要用途:各种起重、提升和牵引设备,金属绳芯适用于负荷、受热和受挤压条件下,例如:电铲。

钢丝绳6*29Fi、6*25Fi、6*26SW、6*31SW、6*36SW、6*37S的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.226(纤维芯)或×1.321(钢芯),其中6×37S纤维芯为1.191,钢芯为1.283。

不旋转钢丝绳18*7、18*19、17*7

(执行标准:GB/T 20118-2006)

Main Appplications:Various eqmuipment for derricking, lifting and drawing;the rope with wire core can be used under the shock load,heated and squeezed conditions such as electric shares.

不旋转钢丝绳18*7、18*19、17*7的主要用途:各种起重、提升和牵引设备,金属绳芯适用于负荷、受热和受挤压条件下,例如:电铲。

不旋转钢丝绳18*7、18*19、17*7的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.226(纤维芯)或×1.321(钢芯),其中6*37S纤维芯为1.191,钢芯为1.283

不旋转钢丝绳35W*7

(执行标准:GB/T 20118-2006)

Main Applications: equipment for port load and unload derrlck tower crane.

不旋转钢丝绳35W*7的主要用途:港口装卸和塔式起重机用。

不旋转钢丝绳35W*7的最小钢丝绳破断拉力总和=钢丝绳最小破断拉力×1.287。