精益生产之补充拉系统ReplenishmentPullSystems(中英

- 格式:ppt

- 大小:1.23 MB

- 文档页数:116

精益生产名词解析:先进先出、填补系统与生产均衡

柜

FirstIn,FirstOut(FIFO)(先进先出)

一种维持生产和运输顺序的实践方法。

先进入加工工序或是存放地点的零件,也是先加工完毕或是被取出的产品。

这保证了库存的零件不会放置太久,从而减少质量问题。

FIFO是实施拉动系统的一个必要条件。

Fill-UpSystem(填补系统)

在一个拉动生产系统中,前面的工序只生产“够用”的产品,来取代或是填补后续工序提取的产品。

参见:Kanban(看板),PullProduction(拉动系统),Supermarket(库存超市)

HeijunkaBox(生产均衡柜)

在固定的时间间隔里,利用看板来平衡产品的型号和数量的工具,称为生产均衡柜。

一个典型的生产均衡柜,其中的横行代表产品型号。

竖列表示有节奏的提取看板的时间间隔。

每天从早上7:00开始上班,每20分钟材料搬运员从柜中取出看板,并把它们送到工厂里各个生产工序。

由于看板槽代表了对材料和信息流的定时,因此看板槽内的每块看板,就代表了生产一种型号产品的一个批量时间(批量时间Pitch=节拍时间×每批次的产品数量)。

由上文阐述的方法可以看出,生产均衡柜是一个工具,能够在一定时间内,用看板平衡多种产品的混合生产与数量,例如,确保在半小时内,以一个稳定的产品比例,来制造小批量的D和E。

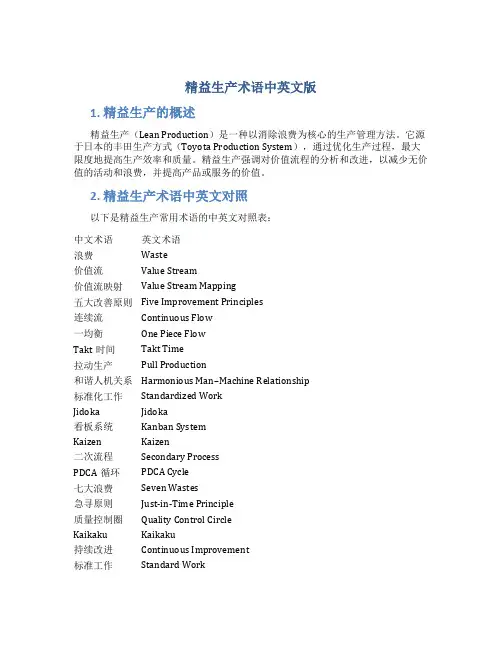

精益生产术语中英文版1. 精益生产的概述精益生产(Lean Production)是一种以消除浪费为核心的生产管理方法。

它源于日本的丰田生产方式(Toyota Production System),通过优化生产过程,最大限度地提高生产效率和质量。

精益生产强调对价值流程的分析和改进,以减少无价值的活动和浪费,并提高产品或服务的价值。

2. 精益生产术语中英文对照以下是精益生产常用术语的中英文对照表:中文术语英文术语浪费Waste价值流Value Stream价值流映射Value Stream Mapping五大改善原则Five Improvement Principles连续流Continuous Flow一均衡One Piece FlowTakt时间Takt Time拉动生产Pull Production和谐人机关系Harmonious Man–Machine Relationship标准化工作Standardized WorkJidoka Jidoka看板系统Kanban SystemKaizen Kaizen二次流程Secondary ProcessPDCA循环PDCA Cycle七大浪费Seven Wastes急寻原则Just-in-Time Principle质量控制圈Quality Control CircleKaikaku Kaikaku持续改进Continuous Improvement标准工作Standard Work3. 精益生产术语解释3.1 浪费(Waste)在精益生产中,浪费指的是任何不增加价值但增加成本和时间的活动。

这些活动是没有必要的,可以被消除或减少。

根据精益生产的理念,浪费被分为七类,即运输、库存、运动、等待、超生产、缺陷和过度加工。

3.2 价值流(Value Stream)价值流是指从原材料到最终产品或服务交付前的所有步骤和活动。

通过分析价值流,可以发现哪些步骤是无价值的或无必要的,并进行优化,以提高整体效率和质量。

How Many Pull Signals? What should be considered in establishing maximum inventory levels?如何设定最大库存•Long changeover times工装更换时间•Long lead times制造周期•Machine downtime停机时间•Schedule increases/ decreases计划变动•Large process or transfer batch sizes最小运输量•Poor quality质量•Long cycle times生产节拍•Bottleneck operations瓶颈工序How Will Pull System Change Your Job?拉动系统能带来什么?Pull system provides more time for constructive activitiesthat will make your job and working conditions bettertomorrow because with pull you run only the parts thatare needed. Shut down time can be spent on:拉动系统将使你以后的生产运作更顺畅,停线的时间可以花在:•Preventative maintenance 预防性维护•Quality improvements 质量改进•Team meetings 团队交流•Housekeeping 内部整顿•Training 培训•Continuous improvement 不断改进Benefits of Pull Systems拉动系统优点•Increases employee involvement促使员工参与•Allows decision-making at appropriate levels 使决策保持高水平•Allows manufacture of only what is needed by the customer只生产顾客需要的产品•Improves communications of customer needs through visual controls通过目视管理改善对客户需求的认知•Provides a common system for moving material through a plant在厂内提供一种通用的物流方式Benefits of Pull SystemsContinued•Eliminates scheduling complexities简化计划•Reduces lead time and work in process inventory 减少各种库存•Highlights quality issues quickly有利于质量问题快速解决•Organizes the workplace有利工作场所组织•Leads to lower unit cost降低成本•Supports continuous improvements有利于不断改进•Counts inventory by counting number of pull signals有利于盘库Pull Signal Calculations Standard Pack:1 standard pack = 1 container = 1 pull signal1 days production = ( )1 standard pack = 1 days production / 10( ) = ( ) / 10Maximum Inventory Level (Max):Weekly average = 8 weeks inventory / 8( ) = ( ) / 8Days of inventory = weekly average / planned daily production( ) = ( ) / ( )Safety stock *s.s.) = additional inventory that must be added dueto current non-synchronized operations.MAX = (days of inventory) X (daily planned production) + (s.s.)( ) = ( ) X ( ) + () Minimum inventory level (MIN):(MIN) = batch size = red zone = replenishment(MIN) = ( )Number of Pull Signals in a Loop (nps)*:(nps) = (MAX) / number of pieces in a standard pack( )* = ( ) / ( )Number of Pull Signals in a Red Zone (RZ)*:(RZ) = (MIN) / pieces in a standard pack( )* = ( ) / ( )Number of Pull Signals in a Yellow Zone (YZ)*:(YZ) = ((nps) -(RZ)) / 2( )* = (( ) -( )) / 2Number of Pull Signals in a Green Zone (GZ)*:(GZ) = (nps) -(RZ) -(YZ)( ) = ( ) -( ) -( )Designated Storage (dss):(dss) = (nps) X (length) X (width) / number of containers high( ) = ( ) X ( ) X ( ) / ( ) * Round up to the next highest number/ Means divided byX Means multiplied by。