美国亚适应FreeStyle便携式制氧机英文说明书

- 格式:pdf

- 大小:181.21 KB

- 文档页数:36

CAUTION: READ INSTRUCTIONS THOROUGHLY BEFORE OPERATION OF UNITOzone GeneratorManual1.0 IntroductionNOTE: All specifications stated in this manual may change without notice.1.1 What is ozone?Ozone series is to clean the air or water in the same way nature uses lightning to create ozone to clean the air naturally. Ozone is very unstable and attaches to contaminants, mold, odors, etc. This reaction results in previously contaminated areas smelling fresh and clean.1.2 Placement and Setting of Machine1.2.1. Do not use this product near high-precision electronic equipment, radio interference may be caused by the misuse of high-precision electronic equipment and other problems. Especially need to pay special attention to the vicinity of the following equipment: hearing aids, pacemakers and other medical electronic equipment, fire detectors, and other precision automatic control device.1.2.2. Do not disassemble or modify the product, otherwise it may cause the damage, leakage and circuit failure.1.2.3. Avoid excessive moisture, water or other liquids enter the product otherwise leakage and failure of the product may cause.1.2.4. Avoid volatile solution or organic solvents to wipe the device, as it may damage the surface of the device.1.2.5. Qualified dedicated grounding wire, secure and reliable grounding line capacity is required to ensure the elimination of fire hazards. Equipment installation personnel must be trained in order to boot repair.1.2.6. Use ozone generator in unoccupied room only. The staff should have Protective measures when ozone concentrations exceed the relevant standards in the space environment.1.2.7. Equipment maintenance or repair must be power off and drain the air pressure to ensure the safety of personnel maintenance.1.3. Environmental Conditions of Machine1.3.1 Indoor Installment should be non-flammable or explosive gases and conductive dust. Prohibiting the installation to where ammonia is easy to leakor explosion hazard danger zone1.3.2 220V/50HZ AC power supply, 110V/50Hz (optional, must specify when ordering)1.3.3 Environmental Temperature Requirements: -10 ℃ -33 ℃1.3.4 Environment humidity requirements: ≤ 55%.1.3.5 Keep the equipment working environment ventilation when install this equipment, the space required to install exhaust fans or air conditioning.2. Technical Specification3. Parts Include:Ozone generator (1)Air stone (1)3 meters of silicone tube (1)Operation manual (1)Warranty card (optional)4. Applications4.1 Air purify: Food processing plant, cosmetic plant, refrigerator, file room, Cafeteria, pharmaceutical factory, schools, hotel, hospitals, restaurants etc4.2 Water treatment: Mineral water, bottled water, pure water, swimming pool, aquaculture, farm feeding water, beverage plant, industrial wastewater, and cooling tower system, etc.5. Operation Instructions5.1Placed the ozone generator to a smooth, airy location.5.2 Connected cooling water (For water cooling type machine)5.3 Plug in the 220VAVC power, turn on the pump switch first.5.4 Extension of time to open the ozone switch (depend on air humidity, higher humidity, longer time, usually 1-30 seconds), ozone indicator light, the machine starts to work ozone output from outlet.5.5 Adjust the ozone concentration by switch the concentration knob5.6 Offer disinfection, manually shut down the machine (25g ozone generator don’t have a timer, additional configuration) unplug5.7 Ozone in the air will automatically broken down into oxygen in 1-2 hours, people should come in the room for a long time when there is no strong odor of ozone5.8 Take the machine to dry and airy location, in case of stagnant water cause by high temperature, high humidify environment in the machineNotes: Before turn on the power, this machine must be connected cooling water (For water-cooling type machine), prohibited from running without connected cooling water.6. WarrantyFrom the date of your purchase, free one-year warranty and lifetime maintenance.7. Fault Inspection and Analysis7.1 Fault Inspection ListIf the problem unsolved after above checking, contact our sales or service stuffs directly.7.2. Using Notes7.2.1 Machinery and equipment must be placed in the oilless, clean dry air environment location to extend the lifespan of the machinery and equipment.7.2.2 Handled gently when using, not abandonment.7.2.3 Machinery and equipment used in water treatment, ozone output port must be connected to the check valve to prevent backwater into the machine, and damage to the machine.7.2.4 Prohibition of placing the machine to disinfection area ,for safety , the device should have a separate working area, then use the silicone tube to deliver ozone to disinfection and chemical reaction zone.7.2.5 Machinery and equipment must check every day before using; any abnormal should immediately shut down, and identify the reasons, solve the problem then use.7.2.6 This machine must be well grounded to prevent lightning. Better to unplug the power when not working.7.2.7 According to the working environment, using requirements choose the corrective ozone generator.7.2.8 For a long time no use, the machine should be cleaned and place to a dry ventilated place to prevent damage from moisture.7.2.9 In order to prevent the machine from moisture and better maintenance , open pump switch or gas control switch; switch off "Density Adjustment" or "ozone switch" to work more than three hours weekly to clean the inside of water vapor8. Maintenances8.1Keep the equipment in a dry ventilated place, dust network (cooling fan ) cleaned once a month8.2 Non-professional electrician, do not open the box (with high pressure) ,+8.3 Silicone tube replaced every three months8.4 Checking whether inside connector is loose or hose aging. If the connector is loose, tighten with a screwdriver, hose aging, timely replacement 8.5 Our customer can get accessories from us with a low cost (lower than the market price)8.6 Power on, open air pump switch first, after 1-2 minutes open ozone switch, shut down, first turn off the ozone switch, after 1-2 minutes, turn off air pump switch.ANNEX 1 City Drinking Water TreatmentANNEX 2 Central Air-conditioning Ozone Generator Systems(注:可编辑下载,若有不当之处,请指正,谢谢!)[文档可能无法思考全面,请浏览后下载,另外祝您生活愉快,工作顺利,万事如意!]。

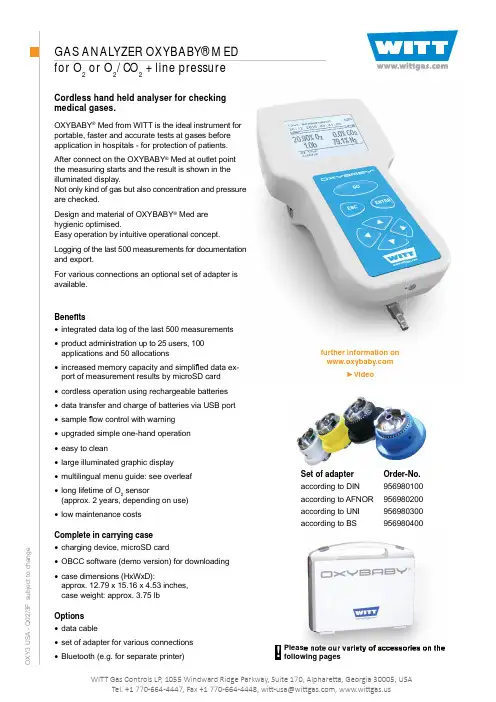

222O X Y 3 U S A - Q 02/3F s u b j e c t t o c h a n geCordless hand held analyser for checking medical gases.OXYBABY ® Med from WITT is the ideal instrument for portable, faster and accurate tests at gases before application in hospitals - for protection of patients.After connect on the OXYBABY ® Med at outlet point the measuring starts and the result is shown in the illuminated display.Not only kind of gas but also concentration and pressure are checked.Design and material of OXYBABY ® Med are hygienic optimised.Easy operation by intuitive operational concept.Logging of the last 500 measurements for documentation and export.For various connections an optional set of adapter is available.Bene fi ts●integrated data log of the last 500 measurements●product administration up to 25 users, 100applications and 50 allocations●increased memory capacity and simpli fi ed data ex-port of measurement results by microSD card ●cordless operation using rechargeable batteries ●data transfer and charge of batteries via USB port ●sample fl ow control with warning ●upgraded simple one-hand operation ●easy to clean●large illuminated graphic display ●multilingual menu guide: see overleaf ●long lifetime of O 2 sensor(approx. 2 years, depending on use)●low maintenance costsComplete in carrying case●charging device, microSD card●OBCC software (demo version) for downloading ●case dimensions (HxWxD):approx. 12.79 x 15.16 x 4.53 inches,case weight: approx. 3.75 lbOptions ●data cable●set of adapter for various connections ●Bluetooth (e.g. for separate printer)Please note our variety of accessories on the following pages!►Videofurther information onSet of adapter Order-No.according to DIN 956980100according to AFNOR 956980200according to UNI 956980300according to BS956980400OBCC So ware for gas analyzer OXYBABY® / PAC C 2 U S A - A 02/3F s u b j e c t t o c h a n g eSystem requirements Operating system WINDOWS ® 7 or aboveHardware1 free USB interface, graphic resolution min. 1024 x 768 PixelWindows-Software for OXYBABY ® 6.0, OXYBABY ® P 6.0,OXYBABY ® Med and PA 7.0.OBCC is the ideal complement for your WITT-Gas analyzer - with modern surface, clearly structured and conveniently operable.The application o ff ers rapid graphical analysis of measured values. Simplify a system comprehensive data management and o ff ers an uncomplicated export function for thecomplete digital storage.Bene fi ts●modern, clearly structured user interface ●intuitive operation●simple set up and administration of master data (products, user, packaging lines)●quality control by means of data recording and storing with date and time ●the graphical presentation of measured values o ff ers a fast overview ●knowledge by data analysis tool with fi lter options●completely digital documentation by simple CSV export function●1 click generate PDF report for assurance of proof (in addition to the CSV export)●time-saving by convenient data management and easy transfer of master data to new devices●available menu languages: English, German, French, Italian, Spanish, Portuguese, Polish, Russian, Finnish, Swedish,Turkish, Romanian, Hungarian30-day trial version with full function for download on 。

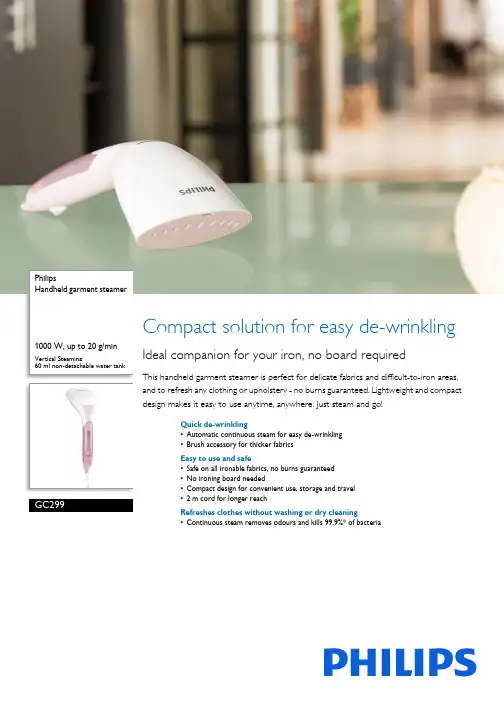

PhilipsHandheld garment steamer1000 W, up to 20 g/min Vertical Steaming60 ml non-detachable water tank GC299Compact solution for easy de-wrinkling Ideal companion for your iron, no board requiredThis handheld garment steamer is perfect for delicate fabrics and difficult-to-iron areas, and to refresh any clothing or upholstery - no burns guaranteed. Lightweight and compact design makes it easy to use anytime, anywhere. Just steam and go!Quick de-wrinkling•Automatic continuous steam for easy de-wrinkling•Brush accessory for thicker fabricsEasy to use and safe•Safe on all ironable fabrics, no burns guaranteed•No ironing board needed•Compact design for convenient use, storage and travel•2 m cord for longer reachRefreshes clothes without washing or dry cleaning•Continuous steam removes odours and kills 99.9%* of bacteriaHighlightsContinuous steamAn electric pump automatically provides continuous steam for easy and quick de-wrinkling.Brush accessory The brush attachment opens the fabric fibres and enables better steam penetration. It is especially good for thicker garments like jackets and coats. It can also help to remove dirt and pills.Safe on all ironable fabrics The steamer is safe to use on all ironable fabrics and garments. The steam plate can be safely pressed against any clothing with no risk of burning – a great solution for delicate fabrics, like silk.No ironing board neededUsing a clothes steamer on hanging garments eliminates the need for an ironing board, so de-wrinkling is easy and hassle free.Ergonomic designThe handheld garment steamer isergonomically designed to be light, compact and comfortable to use. Just press the trigger and watch wrinkles and creases disappear.2 m cordFor longer reach99.9% bacteria-free*Hot steam refreshes your clothes and kills up to 99.9% of bacteria*. Less-frequent washing and dry cleaning saves time and money, and helps clothes last longer.Issue date 2022-03-08 Version: 1.1.1EAN: 08 71010 39363 67© 2022 Koninklijke Philips N.V.All Rights reserved.Specifications are subject to change without notice. Trademarks are the property of Koninklijke Philips N.V. or their respective owners.SpecificationsEasy to use•Water tank capacity: 60 ml•Safe on all ironable fabrics: Even delicates like silk •non-detachable water tank•Refill anytime during use•Power cord length:2 m•Ready to use: Light indicatorAccessories included•BrushFast crease removal•Power: 1000 W•Continuous steam: Up to 20 g/min •Voltage: 220-240 V•Ready to use: < 1 minSize and weight•Packaging dimensions (W x H x D): 38 x 12.8 x15 cmGreen efficiency•Product packaging: 100% recyclable•User manual: 100% recycled paperGuarantee•2 year worldwide guarantee*Tested by external body for bacteria types Escherichia coli 8099,Staphylicoccus aureus ATCC 6538, Canidia albicans ATCC 10231with 1 minute steaming time.。

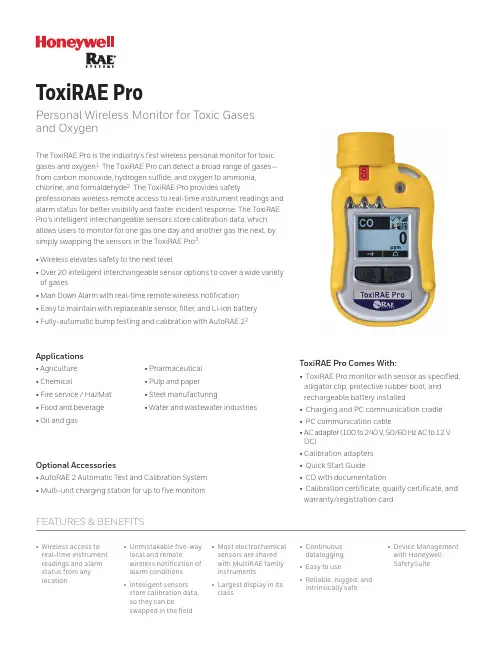

• Wireless elevates safety to the next level• Over 20 intelligent interchangeable sensor options to cover a wide variety of gases• Man Down Alarm with real-time remote wireless notification • Easy to maintain with replaceable sensor, filter, and Li-ion battery • Fully-automatic bump testing and calibration with AutoRAE 22Applications• Agriculture • Chemical• Fire service / HazMat • Food and beverage • Oil and gasToxiRAE ProPersonal Wireless Monitor for Toxic Gases and OxygenThe ToxiRAE Pro is the industry's first wireless personal monitor for toxic gases and oxygen 1. The ToxiRAE Pro can detect a broad range of gases—from carbon monoxide, hydrogen sulfide, and oxygen to ammonia, chlorine, and formaldehyde 2. The ToxiRAE Pro provides safetyprofessionals wireless remote access to real-time instrument readings and alarm status for better visibility and faster incident response. The ToxiRAE Pro’s intelligent interchangeable sensors store calibration data, which allows users to monitor for one gas one day and another gas the next, by simply swapping the sensors in the ToxiRAE Pro 3.• Wireless access to real-time instrument readings and alarm status from any location•Unmistakable five-way local and remotewireless notification of alarm conditions •Intelligent sensors store calibration data, so they can beswapped in the field•Most electrochemical sensors are shared with MultiRAE family instruments• Largest display in its class•Continuous datalogging • Easy to use•Reliable, rugged, and intrinsically safe•Device Management with Honeywell SafetySuiteFEATURES & BENEFITSToxiRAE Pro Comes With:• ToxiRAE Pro monitor with sensor as specified,alligator clip, protective rubber boot, and rechargeable battery installed• Charging and PC communication cradle • PC communication cable•AC adapter (100 to 240 V, 50/60 Hz AC to 12 V DC)•Calibration adapters• Quick Start Guide • CD with documentation• Calibration certificate , quality certificate, and warranty/registration card• Pharmaceutical • Pulp and paper • Steel manufacturing• Water and wastewater industriesOptional Accessories• AutoRAE 2 Automatic Test and Calibration System • Multi-unit charging station for up to five monitorsToxiRAE Pro Specifications1 Wireless units have a functioning RF modem and areready for wireless deployments; non-wireless units cannot be upgraded to wireless. Additional equipment and/orsoftware licenses may be required to enable remote wireless monitoring and alarm transmission.2 Contact Honeywell RAE Systems for availability.3 Honeywell RAE Systems recommends calibrating sensors on installation.4 Contact Honeywell RAE Systems for country-specificwireless approvals and certificates. Specifications are subject to change.Ordering Information•Wireless or non-wireless versions are available •Refer to the Portables Pricing Guide for part numbers for monitors, accessories, maintenance kits, gas, sensors, and replacement partsFor more information/Honeywell Sensing &Safety Technologies830 East Arapaho Road Richardson, TX 75081/gb/en/software/safety/connected-safety/safety-suiteDevice Management with Honeywell SafetySuite。

亚适制氧机使用的独特技术和产品特点

亚适制氧机VisionAire这个型号,是由美国AIRSEP CORPORATION公司研发生产,能达到医用级别的家用制氧机。

下面给大家讲一讲压制制氧机VisionAire这个型号的技术使用及特点分析。

这个型号的亚适制氧机,由于其设计小巧,使用方便,可24小时连续工作,超静音,氧浓度稳定,很受大家的喜爱。

Visionaire亚适制氧机使用变压吸附(PSA)物理制氧方式。

其秉承了上一代Newlife系列的高耐用度特点,经过技术更新进而设计的体积更小、更轻巧、更节能与更静音产品。

两个填有进口分子筛的筛床设计使Visionaire制氧机在1至5LPM可调流量皆可供应浓度达90%以上的氧气。

Visionaire使用坚固的设计,在部件选材上令机器更加可靠,减低故障几率。

简洁的工业设计亦方便维护与维修。

Visionaire标配氧浓度指示灯与运行时间计时器,并有雾化器的可选项。

Visionaire亚适制氧机采用的是最新设计的弹簧减震式安装,使压缩机运行更安静,工作时的噪音只有40dBA;而且机底配有360度万向脚轮,可轻松移动;操作也非常简便,一键即可开机;耗电量超低(电源规格230V/50HZ),正常运行期间仅需要290W的功率。

使用也很放心安全,Visionaire亚适制氧机配有自恢复过流保护器,计时表和明确定义的报警系统,使氧疗者在吸氧过程中更放心,当氧气浓度低于82%,监测器可使VisionAire发出声光报警;高强度的设计提供双面排风通道,有效降低箱体底部的温度,延长压缩机的寿命,整机寿命在30000小时以上,能24小时不停运作。

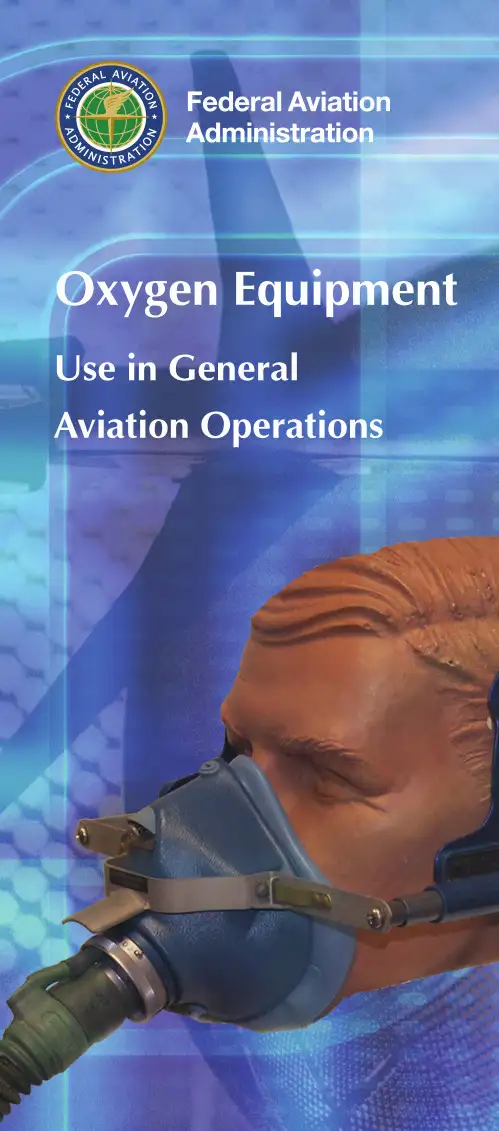

Oxygen Equipment Use inGeneral Aviation OperationsA basic knowledge of oxygen equipment can be critical whether you are flying a commercial, commuter, or a general aviation aircraft. This equipment is the first lineof defense against the potentially lethal effects of hypoxia and carbon monoxide poisoning. It is the responsibility of the pilot that all aboard the aircraft, crew-members and passengers, know how to use this life-saving equipment safely and efficiently.General PrecautionsThis pamphlet describes operational precautions to use with all types of oxygen systems. The basic principles and practices include:• Keep your equipment clean. The interaction ofoil-based products and oxygen creates a fire hazard.Additionally, oil attracts dirt particles, and these dirtparticles can contaminate storage containers,regulators, masks, and valves. For cleaninginstructions, check with the manufacturer’s guide.• Protect your oxygen mask from directsunlight and dust. Store in proper containers.• Inspect oxygen storage containers. Make sure thatthey are securely fastened in the aircraft, as turbulence or abrupt changes in attitude can cause them to come loose. Proper inspections are important, so your oxygen equipment should be inspected regularly at anauthorized Federal Aviation Administrationinspection station.• No smoking! Although oxygen itself is not flammable, it can cause other materials to ignite more easily andwill make existing fires burn hotter and faster. Do notallow anyone to smoke around oxygen equipment that is being used. Likewise, no one should smoke around oxygen equipment that is being recharged. Ensure that the aircraft is properly grounded before loading oxygen.• Mix and match components with caution. Wheninter-changing oxygen systems components, ensurecompatibility of the components - storage containers, regulators, and masks.Basic ComponentsThere are three components to most oxygen systems, whether they are portable or installed systems.• A storage system (containers)• A delivery system• Mask or nasal cannulaStorage SystemsOxygen can be stored in the aircraft as a gas, liquid,or a solid.Gaseous aviator’s breathing oxygen (ABO). Storing oxygen as a gas has the major advantage of being more economical. It can be stored in high-pressure (1800-2200 psi) containers or low-pressure (400-450 psi) containers. The major disadvantage is the weight and bulk of the storage containers, which may become an issue in smaller aircraft. Aviator’s oxygen must meet certain standards to ensure that it is safe to be taken to altitude. Only aviator’s-grade breathing oxygen meets this specification. Neither medical grade norindustrial gradeoxygen is safe tosubstitute becausethey do not meet thesame stringent standards as ABO.Liquid aviators breathing oxygen (LOX). Oxygen canbe serviced to the aircraft in a liquid state. The advantage of LOX is that it has a nine hundred-to-one expansion ratio. In other words, one liter of LOX will expand into 900 gaseous liters of ABO. This provides a three-to-one space and a five-to-one weight savings over gaseous ABO. The major disadvantages are that LOX is stored at its critical temperature of minus 197º F and its volatile nature when it comes in contact with petroleum products. If LOX comes in contact with exposed skin, severe frostbite may occur. Sodium chlorate candles (solid-state oxygen). Sodium chlorate is a chemical that, when heated to 350º F, will thermally decompose and release oxygen. Sodium chlorate candles have theadvantage of savingweight and spaceover ABO becausethey provide a six hundred-to-one expansion ratio. The major disadvantage is that once the chemical reaction starts (the candle is activated), it can’t be stopped easily. Additionally, the candle produces a great deal of heat and precautions must be taken to avoid a fire hazard. Molecular sieve oxygen generators (MSOG). The air we breathe contains 21% oxygen and the remainderis nitrogen and inert gases that play no major role in respiration. MSOGs take ambient air and separate oxygen from the nitrogen and inert gases. The separated oxygen is concentrated and used to supply the aircraft. . The military has used this system for many years, as well as medical patients who need a portable oxygen system. Civil aviation hasn’t embraced MSOG, but it may become more common in future aircraft.Oxygen Delivery SystemsContinuous flow. This system delivers a continuous flow of oxygen from the storage container. It is a very economical system in that it doesn’t need complicated masks or regulators to function. But it is also very wasteful—the oxygen flow is constant whether you’re inhaling, exhaling, or pausing in between breaths. This system is typically used at 28,000 feet and lower.Diluter demand. The diluterdemand system is designedto compensate for the short-comings of the continuous-flow system. It gives theuser oxygen on-demand(during inhalation) and stopsthe flow when the demandceases (during exhalation).This helps conserve oxygen.Additionally, the incoming oxygen is diluted with cabin air and provides the proper percentage of oxygen, depending on the altitude. This system is typically used at altitudes up to 40,000 feet.Pressure demand. Thissystem provides oxygenunder positive pressure.Positive pressure is aforceful oxygen flow thatslightly over-inflates thelungs. This will, in a sense, pressurize the lungs to a lower altitude, thus allowing you to fly at altitudes above 40,000 feet, where 100% oxygen without positive pressure is insufficient.Oxygen Masks and CannulasWhen considering an oxygen mask, you must ensure that the mask you are using is compatible with the delivery system you are using.Nasal cannulas. These arecontinuous-flow devicesand offer the advantage ofpersonal comfort. They arerestricted by federal aviationregulations to 18,000 feetservice altitude because ofthe risk of reducing bloodoxygen saturation levels if one breathes through the mouth or talks too much.Oral-nasal re-breather. Thismask is the most commonand the least expensive. Itis also the simplest to use;; it has an external plasticrebreather bag that inflatesevery time you exhale. Thepurpose of the rebreather bagis to store exhaled air, so thatit may be mixed with 100%oxygen from the system. These masks supply adequate oxygen to keep the user physiologically safe up to 25,000 feet.Quick-don mask. Thesemasks must have the capabilityto be donned with one handin 5 seconds or less, whileaccommodating prescriptionglasses. Quick-don masks aretypically suspended or storedto permit quick and unimpededaccess by flight deck crew. Thesemasks are typically rated toaltitudes up to 40,000 feet.Airline drop-downunits (Dixie cup).The continuous flow,phase-dilution (orphase-sequential)mask looks similarto a general aviationre-breather mask.However, the masksfunction differently andthe phase dilution maskallows the user to goto higher altitudes. This mask uses an external reservoir bag and a series of one-valves working in sequence to allow a mixture of 100% oxygen and cabin air into the mask. When activated by pulling down on a suspended mask, oxygen from a supply source flows continuously into the reservoir bag. During inhalation, a one-way valve allows the flow of oxygen from the reservoir bag into the lungs. If the reservoir bag empties before inhalation is complete, a second one-way valve on the mask face piece opens to permit the flow of cabin air into the mask, allowing the user to take a full breath. If the user is breathing rapidly the reservoir bag will appear to not fully inflate. Expired air is vented out of the mask into the cabin via a one-way exhalation valve; expired air is not returned to the reservoir bag.This mask can be safely used at emergency altitudes up to 40,000 feet.The PRICE CheckPrior to every flight, the pilot should perform the “PRICE” check on the oxygen equipment. The acronym PRICE is a checklist memory-jogger to help pilots and crewmembers inspect oxygen equipment.• PRESSURE. ensure that there is enough oxygen pressure and quantity to complete the flight.• REGULATOR. inspect the oxygen regulator for properfunction. If you are using a continuous-flow system,ensure that the outlet assembly and plug-in couplingare compatible.• INDICATOR. most oxygen delivery systems indicate oxygen flow by use of flow indicators. Flow indicators may be located on the regulator or within the oxygendelivery tube. Don the mask and check the flow indicator to ensure a steady flow of oxygen. • CONNECTIONS. ensure that all connections aresecured. This includes oxygen lines, plug-in coupling, and the mask.• EMERGENCY. have oxygen equipment in the aircraftready to use for emergencies that require oxygen(hypoxia, smoke and fumes, rapid decompressions/decompression sickness). This step should includebriefing passengers on the location of oxygen and its proper use.Be AwareFrom a safety-of-flight standpoint, oxygen equipment is an issue that should concern all pilots. Know the equipment you have on board, know when to use it, and mostimportantly, know its limitations. It’s your key to a safe and enjoyable flight.§91.211 Supplemental oxygen.(a) General. No person may operate a civil aircraft of U.S. registry—1) At cabin pressure altitudes above 12,500 feet (MSL) up to and including 14,000 feet (MSL) unless the required minimum flight crew is provided with and uses supplemental oxygen for that part of the flight at those altitudes that is of more than 30 minutes duration;(2) At cabin pressure altitudes above 14,000 feet (MSL) unless the required minimum flight crew is provided with and uses supplemental oxygen during the entire flight time at those altitudes; and(3) At cabin pressure altitudes above 15,000 feet (MSL) unless each occupant of the aircraft is provided with supplemental oxygen. (b) Pressurized cabin aircraft. (1) No person may operate a civil aircraft of U.S. registry with a pressurized cabin—(i) At flight altitudes above flight level 250 unless at least a 10-minute supply of supplemental oxygen, in addition to any oxygen required to satisfy paragraph (a) of this section, is available for each occupant of the aircraft for use in the event that a descent is necessitated by loss of cabin pressurization; andFederal Aviation Regulations and Oxygen Use (Title 14 of the Code of Federal Regulations)PART 91GENERAL OPERATING AND FLIGHT RULES(ii) At flight altitudes above flight level 350 unless one pilot at the controls of the airplane is wearing and using an oxygen mask that is secured and sealed and that either supplies oxygen at all times or automatically supplies oxygen whenever the cabin pressure altitude of the airplane exceeds 14,000 feet (MSL), except that the one pilot need not wear and use an oxygen mask while at or below flight level 410 if there are two pilots at the controls and each pilot has a quick-donning type of oxygen mask that can be placed on the face with one hand from the ready position within 5 seconds, supplying oxygen and properly secured and sealed.(2) Notwithstanding paragraph (b)(1)(ii) of this section, if for any reason at any time it is necessary for one pilot to leave the controls of the aircraft when operating at flight altitudes above flight level 350, the remaining pilot at the controls shall put on and use an oxygen mask until the other pilot has returned to that crew-member’s station.Sec. 135.89 Pilot requirements: Use of Oxygen.(a) Unpressurized aircraft. Each pilot of an unpressurized aircraft shall use oxygen continuously when flying—(1) At altitudes above 10,000 feet through 12,000 feet MSL for that part of the flight at those altitudes that is of more than 30 minutes duration; and(2) Above 12,000 feet MSL. (b) Pressurized aircraft. (1) Whenever a pressurized aircraft is operated with the cabin pressure altitude more than 10,000 feet MSL, each pilot shall comply with paragraph (a) of this section.(2) Whenever a pressurized aircraft is operated at altitudes above 25,000 feet through 35,000 feet MSL, unless each pilot has an approved quick-donning type oxygen mask–(i) At least one pilot at the controls shall wear, secured and sealed, an oxygen mask that either supplies oxygen at all times or automatically supplies oxygen whenever the cabin pressure altitude exceeds 12,000 feet MSL; and(ii) During that flight, each other pilot on flight deck duty shall have an oxygen mask, connected to an oxygen supply, located so as to allow immediate placing of the mask on the pilot’s face sealed and secured for use.(3) Whenever a pressurized aircraft is operated at altitudes above 35,000 feet MSL, at least one pilot at the controls shall wear, secured and sealed, an oxygen mask required by paragraph(b)(2)(i) of this section.(4) If one pilot leaves a pilot duty station of an aircraft when operating at altitudes above 25,000 feet MSL, the remaining pilot at the controls shall put on and use an approved oxygen mask until the other pilot returns to the pilot duty station of the aircraft.PART 135OPERATING REQUIREMENTS:Commuter and On Demand Operations and RulesGoverning Persons On Board Such Aircraft。

Portable auxiliaryair tanksowner's Manualaux05aaux10a Customer Support 1-866-409-4581TAbLe OF CONTeNTSIntroductIon Important Safety InStructIonScomponentSpre-operatIon checklISt package contents assembly Inspect for damage Save packaging operatIon maIntenancedraining the air tanktesting for leaks Warranty please contact us if you have any questions.record the model and serial numbers indicated on yourproducts nameplate:model no.________________________________________Serial no.________________________________________date of purchase:_________________________________Store/dealer:_____________________________________Customer Support: 1-866-409-4581how to find a local service center:even quality built equipment might need service or repair parts.Contact the California Air T ools Customer Service department:Phone: 1-866-409-4581Online: please provide the information below:Model number and Serial number and specifications shown on the Model number/Serial number plate.Part number or numbers shown in the parts list section of the owner’s manual.A brief description of the trouble with the product.do not return your item for service or parts to the store/dealer where purchased.IMPORTANT SAFeTy INSTRuCTIONSSafety messages & Signal Words:PRe-OPeRATION CheCkLISTpackage contents & assembly models: auX05a & auX10apackage contents:Air T ank1/4” Female universal/Industrial Quick Connector1/4” Male universal/Industrial Quick ConnectorAir hose & Air/Tire ChuckPressure GaugeAir Valve & Air Valve knobOwner's Manualassembly:Insert the 1/4” Male universal Quick Connector on the air hose into the 1/4” Female Quick Connector located on the Air Valve. Inspect for damagebefore using the air tank , make sure the air tank is not damaged, inspect all parts for damage, and check that all pipes are firmly connected.do not use the air tank if any damage is found. If damaged, contact California Air T ools Customer Service department1-866-409-4581Save packagingIMPORTANT: Save all outside packaging in case you ever need to return the product for service or repair.operationThis air tank is designed to contain air pressures of to 125 PSI. This air tank is intended only for use as a portable supply of compressed air for use in inflating tires, sports balls, inflatable and as a source of air for air tools.do Not Over Inflate or Over Pressurize this tank or harm may occur. do not exceed 125 PSI.Fill the air tank by connecting the 1/4” Male universal Quick Connector (on the Air hose) to an air compressor.Attach the Air Chuck (on the air hose) to the Air Valve on the tank to pressurize the air tank.T o use air, push the 1/4” Male universal Quick Connector (on the Air hose) into the 1/4” Female universal Quick Connector on the Air Valve.Open the air valve by turning the red air valve knob counter clockwise pressurizing the air hose. your tank is ready for use. MAINTeNANCe draining the air tankThe frequency at which you should drain the air tank depends on the environmental conditions and the amount of operating time logged. The average draining frequency is every day of use.1.Point the safety valve AWAy FROM yOuR bOdy whenreleasing the aire the pull ring on the safety valve to release any pressureinside the tank before draining the tank.3.Invert the tank with the Air Valve facing downward and pull thering on the safety. This will allow any water to escape from the tank..4. draining the air tank protects parts from rust and corrosion.Rusty water can appear.testing for leaksMake sure all connections are tight.T o test for small leaks, spray a small amount of soapy water on the area suspected of leaking. If the soap bubbles, replace the broken part.cleaningClean items with a soft brush, or wipe with a moistened cloth using a biodegradable solvent.do not use flammable liquids such as gasoline or alcohol. Always keep parts clean from dirt and dust for better performance.CALIFORNIA AIR TOOLS INC. LIMITed WARRANTyThis warranty is limited to products distributed by:California Air Tools, Inc.8560 Siempre Viva Road, unit 3San diego, CA 92154limited WarrantyCalifornia Air T ools Inc. will repair or replace, free of charge, to the original retail customer who purchased a California Air T ools, Inc. product from an authorized dealer, distributor or distributor’s dealer in North America.This warranty does not transfer to subsequent owners.California Air T ools Inc. will repair or replace, at its option, any parts that are proven by an authorized service center to be defective in material or workmanship under normal use during the applicable warranty time period as stated below. This limited warranty covers the cost of the replacement parts and labor for all defects when installed by an authorized service center. Transportation charges are the responsibility of the customer. Any part replaced under warranty becomes the property of California Air T ools Inc.All parts replaced under warranty will be considered as part of original product, and any warranty on those parts will expire coincident with the original product warranty.limited Warranty periodsNon-commercial / Non-rental (personal use by a retail customer): 1 year parts and laborThe limited warranty period begins on the date of retail purchase by the original purchaser.disclaimers, limitations of remedies & exclusionsThis warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.disclaimer of other WarrantiesT o the fullest extent permitted by applicable law, this limited warranty is exclusive and expressly in lieu of any and all other warranties, including, without limitation, any implied warranties of merchantability or fitness for a particular purpose or any other implied warranties that may arise from the course of dealing or usage of the trade. California Air T ools Inc. hereby declaims and excludes all other warranties. T o the extent that California Air T ools Inc. products are consumer products under applicable federal and state law with respect to any customer, the duration of any implied warranties (including but not limited to implied warranties of merchantability or fitness for a particular purpose) are limited to the shortest duration permitted by applicable law or the Limited Warranty period provided herein, whichever is longer.limitations of remediesCalifornia Air T ools Inc. shall not be liable to customer, or anyone claiming under customer, for any other obligations or liabilities, including but not limited to, obligations or liabilities airing out of breach of contract or warranty, negligence or other tort or any theory of strict liability, with respect to the product or California Air T ools Inc. acts or omissions or otherwise. T o the fullest extent permitted by applicable law, California Air T ools Inc. shall not in any event be liable for incidental, compensatory, punitive, consequential, indirect, special or other damages, including but not limited to loss of use, loss of income, loss of time, loss of sales, injury to personal property, or liability customer incurs with respect to any other person, or any other type or form of consequential damage or economic loss.exclusionsIn addition to the foregoing disclaimers, limitations and terms, this limited warranty shall not apply to and does not cover accessories, nor does it cover products that are in any way subject to any of the following:1.Improper setup, installation or storage.ck of proper maintenance and service.3.Accident, damage, abuse or misuse.4.Abnormal operating conditions or applications.5.Repair or modification by customer or any third party without written consent of California Air T ools Inc.e under operating conditions or in applications not recommended by California Air T ools Inc.7.Normal wear.8.The use of accessories or attachments not recommended by California Air T ools Inc.9.Acts of God.The application of these exclusions will be determined at the sole discretion of California Air T ools Inc.registrationWarranty registration with California Air T ools Inc. is required on all products.Please visit and register your product using the on-line registration form.how to VideosCalifornia Air T ools provides “hOW TO VIdeOS” on our website .The “how to Videos” provide valuable information regarding set-up, operation and maintenance.Please visit our website and view these videos for beneficial information.Service or partsWarranty is also available by keeping and showing your original receipt from the date of purchase to anAuthorized California Air T ools Service Center.For all customer service inquiries call 1-866-409-4581 or visitGo to the “customer Service” tabclick on “Service & parts” Button for the fastest Service.。

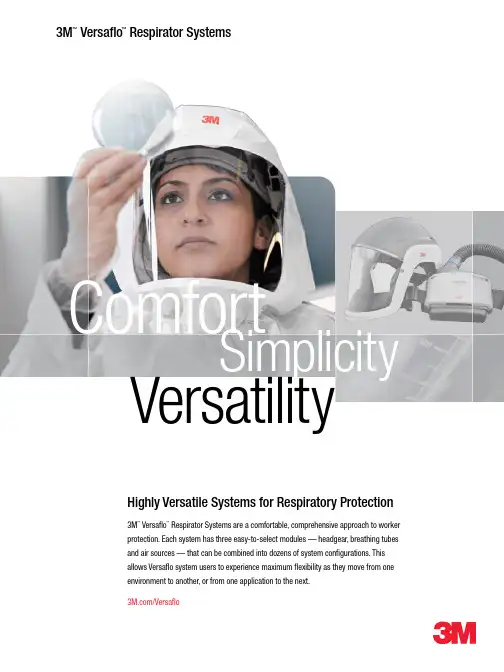

3M ™Versaflo ™Respirator SystemsVersatilityComfortSimplicity/VersafloNew Levels of Comfort and Simplicity All 3M™ Versaflo™ productsare light-weight, compactand well-balancedQRS (Quick Release Swivel)breathing tubes allow fastand easy connectionMultiple size adjustment optionsallow for a comfortable fitEquipped with automaticflow control, low batteryalarm, and low flow alarmThe air inlet draws air from thebottom of the unit, allowing thewearer to sit without blockingthe airflow intakeTR-300-ECKPerfect for many pharmaceutical, healthcare, and food and beverageapplications, the TR-300-ECK kit includes an S-655 Hood, a TR-307NPAPR with Easy Clean Belt, and a BT-30 Breathing Tube. A batterycharger, TR-3710N filter and TR-3600 prefilter are included as part ofthe TR-307N.GVP-PSK2/ 37335A complete PAPR solution for painters. Includes a GVP-CB PAPRAssembly (including battery, comfort belt, and charger), a GVP-441 OV/HE Filter with GVP-119 shower cover, a BT-20L Breathing Tube withBT-922 Breathing Tube Cover, and a M-101 Respiratory Faceshield witha M-925 Visor and M-936 Comfort Faceseal.3M™ Versaflo™ Complete System KitsBuild your own Versaflo™ system or choose from one of our complete system kits. These kits offer the convenience of a complete system tailored to your application — all in one box.TR-300-HIKA complete particulate PAPR system for industrial applications wherecombined respiratory, head, eye and face protection is required ordesired. Includes an M-307 Respiratory Hard Hat, a TR-306N PAPRwith High Durability Leather Belt, and a BT-40 Heavy Duty BreathingTube. A battery charger, TR-3710N filter, and TR-362 spark arrestor/prefilter are included as part of the TR-306N.TR-300-HKL (Large Headcover Kit)and pharmaceutical applications where an S-133, APF 25 Headcoveris appropriate. Includes an S-133 Headcover, a TR-307N PAPR withEasy Clean Belt, a BT-30 Breathing Tube, charger, TR-3710N filter and astorage bag. Available in two sizes: Small/Medium and Medium/Large.SA-100-PSK/ 37336For painters who want to use a Supplied Air Respirator. Includes a V-100Vortex Cooling Assembly, a BT-20L Breathing Tube with BT-922 BreathingTube Cover, and a M-101 Respiratory Faceshield with a M-925 Visor andM-936 Comfort Faceseal. A supplied air hose (sold separately) is requiredto complete the NIOSH-approved system. Contact 3M Technical Servicefor information on air source options and air quality requirements. HEAVY INDUSTRY PAPR KITBELT-MOUNTED PAPR PAINTER’S KIT HEADCOVER PAPR KITPAINTER’S SUPPLIED AIR RESPIRATOR KIT EASY CLEAN PAPR KIT/Versaflo3M Automotive Aftermarket Division (AAD) ProductNumbers are found in blue type on selected products.343M ™Versaflo ™Systems are Easy to SelectChoosing a Versaflo ™ system is as easy as 1, 2, 3. Just choose headgear, a breathing tube, and an air source that fits your needs from the product matrix below. All Versaflo components are interchangeable, giving you the flexibility to find different Versaflo solutions for different exposures, applications, locations, or tasks.S-Series Integrated S-Series Integrated APF 25 Respiratory BT-20S/BT-20LLight Duty Breathing TubeBT-30Length Adjusting Breathing Tube BT-40Heavy Duty Breathing TubeChoose Your HeadgearChoose Your Breathing Tube/VersafloM-105S-133S-533M-307125*OSHA assigned protection factors defined in 29 CFR 1910.134. 3M supports an APF of 1000 for the S-Series and H-Series Hoods, and M-Series and L-Series Helmets with TR-Series, V-Series, and GVP-Series air supply sources. Contact 3M Technical Service for supporting test procedures and data. In Canada, follow CSA Z94.4 or the requirements of the authority having jurisdiction in your region.†Operating Altitude approx. sea level to 2,600ft (800m). For altitudes above 2,600ft, contact 3M.†††ANSI Z89.1-2003 Type I Class E.††ANSI Z89.1-2003 Type II Class G. CAN/CSA Z94.1-05 Class G protective helmets.H-Series HoodsAPF 1000** Respiratory Protection, Head Protection, Reusable Suspension H-412 H ood with Hard Hat †††and Inner Collar H-422 H ood with Hard Hat †††and Inner Shroud H-612 S ealed Seam Hood withHard Hat and Inner CollarTR-300 Particulate PAPR TR-305N S tandard Belt &Economy Battery TR-306N H igh Durability Belt &High Capacity Battery TR-307N E asy Clean Belt &High Capacity BatteryIntrisically Safe/NiCd GVP-1 AssemblyGVP-1U with Vinyl Belt GVP-CB with Comfort BeltNiMH GVP-1NiMH GVP-1UNiMH with Vinyl Belt GVP-CBNiMH with Comfort BeltAll GVP-Series PAPRs require a cartridge or filter (both sold separately) to complete the NIOSH-approved respirator system.L-Series HeadgearAPF 25 (L-705SG) orAPF 1000* (L-901SG/L-905SG) Respiratory Protection,Head Protection, Eye/Face Protection L-705SG H ard Hat †† with Speedglas ™ WeldingShield and Wideview FaceshieldL-901SG H elmet †† with Wideview Faceshieldand ShroudL-905SG H elmet †† with Speedglas ™ Welding Shield,Wideview Faceshield and ShroudChoose Your Air Supply SourceAdditional 3M ™Headgear Options3M H-Series Hoods and L-Series Headgear can also be configured with the new Versaflo systems, and offer more choices and flexibility for your application. Contact your 3M representative for details./Versaflo3M ™VERSAfLO ™†3M ™ H-SERIES HOODS3M ™L-SERIES HEADGEAR3M ™GVP-SERIES POwERED AIR PURIfYING RESPIRATORS (PAPRS)V-Series ValvesV-100 Vortex Cooling Assembly V-200 Vortemp ™ Heating Assembly V-300 Air Regulating Valve Assembly V-400 L ow Pressure Connector AssemblyAll V-Series Supplied Air Valves require a supplied air hose to complete the NIOSH-approved respirator system. These hoses are available in many different lengths and are sold separately.3M ™VERSAfLO ™ V-SERIES SUPPLIED AIR VALVES36SElEction guidE/VersafloGeneral Maintenance and Manufacturing Sweeping, Grinding, Drilling, Sawing, Cutting Particles• TR-300 • GVP PAPR • V-Series Powder Painting Particles• TR-300 • GVP PAPR • V-Series Spray Painting, Coating, Surface Preparation Particles/ Gases and Vapors• GVP PAPR • V-SeriesPharmaceutical Manufacturing Powder Handling, Mixing, Pulverizing and Shaping Particles• TR-300 • GVP PAPR • V-Series Liquid Chemical Handling, Mixing and Spraying Particles/ Gases and Vapors• GVP PAPR • V-SeriesMedical and Health Care Infection Control and Cleaning Particles• TR-300 • GVP PAPR • V-Seriesfood and Beverage Powder Handling and Mixing Particles• TR-300 • GVP PAPR • V-SeriesChemical Industry Liquid Chemical Handling, Mixing and SprayingParticles/ Gases and Vapors • GVP PAPR • V-SeriesH -612 H -422H -412M -407M -405M -307M -305M -107M -105S -857 (S -807)S -855 (S -805)S -757 (S -707)S -657 (S -607)S -655 (S -605)S -533S -403S -133S -103Industry/Applications Contaminant Type Airsource OptionsPrimary Use Secondary Use Tertiary UseOccupational use of respirators must be in compliance with all applicable health and safety standards. Consult your safety professional or an industrial hygienist with questions about the personal protective requirements for your application.VersatilityComfortSimplicity3M ™V ersaflo™。

FAM OXYTRACE溶解氧测量仪操作手册ANAL YT ICAL INST RUM ENT SSwan Analytical Instruments AG CH-8616 Riedikon/UsterPhone: ++41 1 943 63 00 / Fax: ++41 1 943 63 01质保条件我们可以向用户保证FAM Oxytrace测量仪在正常使用过程中,仪表变送器在36个月内、仪表的其他部件在12个月内,不会出现任何由劣质原料或生产工艺而引起的故障和问题。

在正常使用的前提下,仪表出现故障,可以得到免费的修理、更换部件、服务和建议,甚至可以更换产品。

所有的更换部件都可以从厂家在当地的代理商直接获得。

质保期从交货之日起。

以下不在质保范围内:●由于非正确使用和缺乏维护、尤其是手工误操作而导致的损坏。

●由于事故、浸入水中或淋水、触电、化学药品、灰尘、过热等原因而导致的损坏。

●由误操作、堵塞、非授权修理或修改而引起的故障。

●由于正常磨损而引起的故障。

●严禁非正常操作,所有操作过程均按操作手册进行。

任何由于运输合同、质保条件或其他商务问题而引起的争议,可以通过法庭解决。

目录绪论与警告1 概述11.1 操作原理 11.2 显示值 21.3 系统描述 32 安装 42.1 仪器的安装 52.2 接线图 62.3 电气连接72.4 与其它仪器的连接103 操作113.1 显示和按键113.2 校准123.3 设置报警值和极限值143.4 编程和密码154 编程165 错误信息275.1 报警275.2 系统故障275.3 操作错误276 非连续测量287 维护288 更换保险管30 附录:维护规程31 初次启动步骤32绪论:FAM系列仪器采用了最先进的技术,操作十分简便。

本手册提供了大量信息即使经验不多的用户也能方便地掌握仪器的操作。

操作时你只需参考手册提供的一张速查表即可。

FAM系列仪器是一个完整的系统,传感器Swansensor OXYTRACE SC、流通池B-Flow、变送器FAM Oxytrace均装在一个盘上。

400 Series CD T4FPortable compressorStandard Scope of SupplyThe Atlas Copco 400 Series CD T4F is single-stage, oil-injected, air compressors, powered by a liquid-cooled, four-cylinder turbocharged diesel engine.The units consist of an air end, diesel engine with exhaust treatment, cooling circuit, air/oil separation and control systems - all enclosed within a sound dampened HardHat™ enclosure.A range of undercarriage formats, factory and locally installed options are available.Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.Pressure and FlowAvailable ModelsXATS 400 CD8 PE T4F single stage – max. 150 psi – Caterpillar engine XAVS 400 CD8 PE T4F single stage – max. 200 psi – Caterpillar engi neCaterpillar T4F engine Meets all current T4F emission regulations.Integrated exhaust aftertreatment makes T4F integration easyExtended warranty available through Caterpillar dealerAtlas Copco Controller XC2003 PACEPressure Adjusted through Cognitive Electronics Proven controller for easy operation and diagnostics of the compressor and engine.Allows operator to view compressor parameters including:Pressure setting, reading engine codes, two programmable service timers, all temperatures and pressures of compressor, fuel levels and consumptions, and load/unload compressor.Cold Weather Package Improved cold weather starting, includes synthetic compressoroil &Spillage Free Containment Frame(Standard XAVS, Optional XATS)Protects environment, avoids costly clean up liabilityLow Fuel Shutdown Reduces downtime on site when operator runs out of fuel asthere is no longer a need to “re-prime” the fuel systemHeavy Duty Single Axle Trailer w/ 15" tires Well balanced for safer towing or moving around siteHigh ground clearance for rough site and road conditionsHardHat TM heavy duty ¼” polyethelene enclosure Dent and UV ResistantKeeps looking new for longer and adds to resale valueClick here to watch our HardHat video onlineAftercooler, water separator w/ filters (Standard XAVS) Provides cool, dry, clean air for applications where instrument quality air is required.Optional Features BenefitsSpecial color doors (white only) Alternative to standard yellow door color schemeTechnical Data1 According to ISO 1217 ed.3 1996 annex D2 Measured in accordance with ISO 2151 under free field conditions @ 7m distance3 Consult Atlas Copco for proper de-rating instructions for operation beyond ambient limitations4 According to DIN 72311Support mountedWeight (Wet - Ready-to-operate)XATS 400 CD8 PE T4FXAVS 400 CD8 PE T4F Trailer mounted lb (Kg) 4620 (2095) Support mounted lb (Kg) 4528 (2053)DimensionsXATS 400 CD8 PE T4FXAVS 400 CD8 PE T4F Trailer mounted (Inches) L x W x H 158 ¾ x 72 x 77 ¾ Support mounted (Inches) L x W x H 113 x 72 x 72Caterpillar C4.4 T4F turbo charged four-cylinder, liquid-cooled diesel engine provides ample power to operate the compressor continuously at full-load.Meets all US EPA and Environment Canada exhaust legislations with Final Tier 4 compliance.US EPA engine family is “HPKXL04.4MT1” and rated at 148hp at 2200 rpm, in accordance to SAE Standard for the XATS 400 CD8 PE T4F. US EPA engine family is “HPKXL04.4MT1” and rated at 148hp at 2200 rpm, in accordance to SAE Standard for the XAVS 400 CD8 PE T4F.Engine starting capacity at 14°F (-10°C) without the addition of cold start options. Cold start options are available up to -4°F (-20°C).The 52Gal (192L) fuel tank enables operation for over 8 hours at full load and comes standard with a low fuel shutdown at 5%.Emissions TreatmentCaterpillar C4.4 T4F engine after treatment consists of a Diesel Oxidization Catalyst (DOC) and Selective Catalytic Reduction (SCR).Electrical SystemThe 400 Series CD T4F is equipped with a 12 Volt negative ground electrical starting syste m .InstrumentationThe instrument control panel is located on the back, curbside of the compressor canopy with easy access.Standard instrument package includes fully diagnostic ECU controller with large 3.5” display. The intuitive Atlas Copco XC2003 controller is easy to operate with all functions conveniently at your fingertips. The controller also manages the engine ECU operating system, and a number of safety warnings, shut downs on various parameters (listed below) and full digital pressure control with PACE.XC2003 Controller Functionality:Displayed while running - Hours - Fuel level - RPM - Outlet pressure Operational Buttons- Start and stop of the unit - View measurements, settings and alarms - Multi position cursor to navigate menus - PACE digital pressure controlCompressor measurements displayed- Running hours - Fuel level - Clock - Battery voltage - Running hours - Regulating pressure - Emergency stop count - Average fuel consumption - Minor/major service counters in hours and daysEngine measurements displayed- Fuel consumption per hour tally - Engine coolant temperature - Engine oil pressure - Engine RPMWarnings and Shutdowns- High temperature engine coolant - High temperature compressor oil - Engine oil pressure - Low fuel level - Low coolantAlarms- View current & historical alarms present- History of last 20 alarms and events with timeand date stamps- DM1 & DM2: View current engine codes(SPN/FMI)Settings- Reset service timers - Diagnostics for engine ECU - Language settings - Unit of measure changes - Electronic pressure adjustment (PACE ) - Presetting two (high/low) pressure settingBodywor kHardHat™: Our HardHat™ version comes standard with dual wall, ¼” thick, Polyethylene material providing superior corrosion, and UV protection against fading and discoloration. As well as unmatched dent and damage resistance. The canopy is sound attenuated to meet the most current legal noise requirements. A clamshell style hood offers easy service access to all co mponents. Undercarriage & FrameThe 400 Series CD T4F compressors are available with two undercarriage alternatives, providing utmost flexibility in installation or towing require m ents.Single axle trailer setup with:DOT approved light packageAdjustable height pintle hitch (3” lunette)5,200 lbs torsional axle15” Rims w/ ST225/75D15 8 Ply Tires (weight rating 2,540 lbs @ 65psi)Electric trailer brakes as standard (with 7 pin flat blade connector)750lbs jack leg stand, with wheelSupport mo unted version, on steel frame, less undercarriage is availableFactory Options AvailableSkid mountedLoose Ball Couplings 2” or 2-5/16” and Loose Bulldog 2” couplingOSHA ¾” valveAftercooler & Water Separator (optional XATS only)Aftercooler & Water Separator & DD/PD coalescing & high efficiency filters (Standard XAVS, optional XATS only)Special color canopy doorsLojack anti-theft deviceManufacturing & Environmental StandardsThe 400 Series CD T4F are manufactured following stringent ISO 9001 regulations, and a fully implemented Environmental Management System fulfilling ISO 14001 require m ents.Attention has been given to ensure minimum negative impact to the environ ment.The 400 Series CD T4F meets all current EPA and Environment Canada exhaust and noise emission dir ectives.Supplied Do cu men t ationThe unit is delivered with documentation regarding:Hard copies of the Atlas Copco Operators Safety and Instruction Manual, Caterpillar Engine Operators Manual, as well as electronic copies, available upon request.Warranty Registration card for Caterpillar Engine and Atlas Copco Compressor (Units must be registered upon receipt).Test certificate for air delivery pressure and capacity, acc. ISO 1217 (Upon request only).Certificate for air/oil separator vessel and safety valve approval, ASME (Upon request only).Warranty Co verag eCaterpillar Engine: Caterpillar Diesel engines are warranted to be free from defects with regard to materials and workmanship for the period of twelve (12) months from the date of initial startup without limitation in running hours or for the period of thirty six (36) months from the date of initial startup prior to the accumulation of 4000 running hours.Atlas Copco Compressor: Warrantied to be free from defects with regard to material and workmanship for the period of eighteen (18) months from date of shipment from the factory, or twelve (12) months from date of initial start-up, whichever occurs first, withoutlimitation of running hours.Air compressor element assemblies used in Atlas Copco portable air compressors, is warranted to be free from defects with regard to materials and workmanship for the period of thirty (30) months from date of shipment from the factory, or twenty four (24) months from date of initial start up, whichever occurs first, without limitation of running hours. Atlas Copco service kits including parts and oils (PAR Oil’s) must be used to maintain warranty. Failure to register warranty upon initial start-up may cause warranty claim delays or rejection of claims.。