Sikaflex-252 高强度结构胶粘结剂

- 格式:docx

- 大小:21.91 KB

- 文档页数:5

结构胶粘剂的种类和应用结构胶粘剂是一种具有高强度、高粘接性的粘合材料,通常用于连接各种材料并提供持久稳固的粘合效果。

结构胶粘剂的种类繁多,应用领域广泛,本文将就结构胶粘剂的种类和应用进行详细介绍。

一、结构胶粘剂的种类1. 丙烯酸类结构胶粘剂丙烯酸类结构胶粘剂是一种常见的结构胶粘剂,具有快速固化、高强度、耐候性好的特点。

它广泛应用于金属、玻璃、塑料、橡胶等多种材料的粘接,尤其适用于需要耐久性和高强度粘接的场合。

2. 硅酮类结构胶粘剂硅酮类结构胶粘剂具有耐高温、耐候性好、耐化学腐蚀等特点,适用于高温环境下的粘接,如汽车引擎室内部件的粘接、玻璃幕墙的安装等。

3. 聚氨酯类结构胶粘剂聚氨酯类结构胶粘剂是一种多功能结构胶粘剂,其特点是固化后具有柔韧性和强韧度,适用于各种材料的粘接,尤其适用于需要经受振动和冲击的场合。

4. 硫化类结构胶粘剂硫化类结构胶粘剂具有优异的耐高温和耐化学腐蚀性能,常用于需要在恶劣环境下长期使用的场合,如航空航天领域、石油化工设备等领域。

5. 双组分环氧类结构胶粘剂双组分环氧类结构胶粘剂是一种两部分混合固化的结构胶粘剂,具有优异的耐化学腐蚀性能和高强度粘接效果,适用于金属、陶瓷、混凝土等多种材料的粘接。

二、结构胶粘剂的应用1. 汽车制造结构胶粘剂在汽车制造中有着广泛的应用,包括车身焊接替代、风挡玻璃粘接、车身件粘接等。

结构胶粘剂能够提高汽车结构的整体强度,降低汽车的噪音震动,提高汽车的安全性和舒适性。

2. 建筑领域在建筑领域,结构胶粘剂被广泛应用于玻璃幕墙的组装、金属构件的粘接、混凝土构件的粘接等方面。

结构胶粘剂能够提高建筑材料的整体性能,降低材料的重量,简化建筑工艺,减少施工周期。

3. 航空航天在航空航天领域,结构胶粘剂的应用尤为重要。

航空航天设备需要经受复杂的力学环境和极端的工作条件,结构胶粘剂能够提供可靠的粘接效果,确保航空航天设备的安全可靠性。

4. 电子产品在电子产品制造过程中,结构胶粘剂被广泛用于电路板的粘接、电子元件的固定、设备的组装等方面。

SIKA MARINE APPLICATION GUIDEGeneral Marine Elastic Bonding ApplicationsGENERAL MARINE ELASTIC BONDING APPLICATIONSVersion 2/2017SIKA MARINE APPLICATION GUIDEGeneral Marine Elastic Bonding Applications CONTENT03Bedding and Sealing Fittings and Hardware05Bonding of Rub Rails and Fenders07Bonding Decorative Panels and Work Surfaces09Bonding Lightweight Internal Partitions11Elastic Thick Layer BondingBEDDING AND SEALING FITTINGS AND HARDWAREGENERAL DESCRIPTION All kinds of deck fittings and hardware need to be securely fixed and totally watertight. Some of these fittings can be subject to very high forces, suchas tensile, torsion and shear stresses. Poorly sealed joints can suffer serious damage such as metal corrosion, osmosis and water leaks which can cause damage to interior furnishings and fittings.BEDDING AND SEALING OF FITTINGSSUBJECT TO HIGH MECHANICALSTRESSESDeck fittings such as chain plates,winches and guide rollers must absorbvery high dynamic stresses.For this purpose a high-performanceproduct, such as Sikaflex®-292i, shouldbe used in conjunction with additionalmechanical fixings.BEDDING AND SEALING OF FITTINGSSUBJECT TO MINIMAL MECHANICALSTRESSESDeck fittings, such as ventilators and coverstrips, need to be waterproofed, but arenot subject to high tensile or torsionstresses.These fittings can be effectively beddedand sealed with only Sikaflex®-291i or ifthe joint remains visible and is exposedto weathering, the use of Sikaflex®-295UV is recommended.Fig. 1 A selection of cleats that can be sealed orbonded using Sika adhesivesFig. 2 Applying Sikaflex®-292iFig. 3 A port-hatch, both bonded and sealed usingSikafl ex®BEDDING AND SEALING FITTINGS AND HARDWARESUBSTRATE PREPARATIONTIMBER DECKSPAINTED DECKSBRONZE, BRASS ORSTAINLESS STEEL FITTINGSFor coloured metals please use onlySikafl ex®-295 UV or Sikafl ex®-591.ALUMINUM FITTINGSAPPLICATION OF Sikafl ex®-291i, -292i OR -295 UV ADHESIVESIMPORTANT:For the preparation of other sub-strates, please refer to the Sika Pre-Treatment Charts for Marine Applications.BONDING OF RUB RAILS AND FENDERSGENERAL DESCRIPTION Rub rails and fenders are designed to protect the hull of a vessel against damage. These act as a bumper to absorb impacts and scrapes, and the more elastic these are, the more effectively they perform this function.The elastic behaviour varies according to the type of material used, so the shock- absorbing performance of the rub rail can be significantly improved by the use of an elastic adhesive joint.This provides maximum protection to the hull.Rub rails of timber, PVC or polyurethane can be securely bonded to marine hulls using Sikaflex®-292i. The resulting elastic joint helps to absorb most of the shear and tensile stresses to which they are sub-jected when a vessel is docking or casting off.If rub rails are secured with screws, a similar effect can be obtained by back- filling the rail profile with Sikaflex®-291i;a highly elastic polyurethane sealant. As well as absorbing torsional stresses, this technology also seals the screw holes and prevents water or dirt from gettingbehind the rub rail.APPLICATION OF Sikafl ex®-292i OR Sikafl ex®-291iFig. 5 Sealing the edge of a chrome hand-railFINISHED PAINTED HULLS OFALUMINUM OR STEEL, COATED WITH A TWO-PART LACQUERTIMBER RUB RAILSMOULDED PVC OR POLYURETHANE BONDING RUB RAILS TO THE HULLSUBSTRATE PREPARATIONGRP HULLSTriangular beads of adhesive Hull (section)Rub railPress into positionFig. 4 Assembly of a rub railBONDING DECORATIVE PANELS AND WORK SURFACESGENERAL DESCRIPTIONThe interiors of many boats are based on a variety of traditional and modern materials including mirrored glass. These panels can be used functionally as working surfaces (galley worktops, etc.) or cosmetically. Either way, elastic bonding provides an easy, durable method of fi xing without visible and unsightly mechanical fi xings.As the variety of materials used for panels, surfaces and supporting substrates is so vast, please consult the local Technical Service of Sika Industry or proceed topreliminary trials.Fig. 9 Application of Sikafl ex®-291iAPPLICATION OF Sikafl ex®ADHESIVE TO HORIZONTAL PANELSFig. 7 Bonding a decorative panel verticallyBONDING DECORATIVE Fig. 6 Bonding a decorative panel verticallyBONDING LIGHTWEIGHT INTERNAL PARTITIONSGENERAL DESCRIPTIONThese lightweight panels are usually con-structed of wood sandwiches with internal polyurethane foam or honeycomb core. They are particularly suited as partitions for cabins and technical rooms as they are of lighter weight than wood fi lled panels and have good soundproofi ng properties. Due to the low density core, lightweight panels cannot be mechanically fi xed to the hull structures in the same way as tradi-tional plywood panels. However, bonding with Sikafl ex®-292i isan ideal replacement fi xing method thatalso possesses the fl exibility to respondto the movements and stresses of theassembly.The uniform stress distribution preventsdamages which may be result of stressconcentration (example screw).This process is also endorsed by themanufacturers of the lightweight panels.PartitionSupportTrimSikafl ex®-292iFig. 10 Sikafl ex®-292i bead application for bonding to the supportBONDING LIGHTWEIGHT INTERNAL PARTITIONSSUBSTRATE PREPARATIONPlease refer to the Sika Pre-Treatment Chart for Marine Applications. APPLICATION OF Sikaflex®-292i ADHESIVEFig. 11 Sikaflex®-292i applied to a lightweight panel prior to fitting Fig. 12 Lightweight panels being fitted to an open hullFig. 13 High-quality lightweight panels finished in traditional high-gloss wood veneer and bonded using Sikaflex®-292iELASTIC THICK LAYER BONDINGINTRODUCTIONFrom the earliest of times, boat construc- tion has relied upon the available techno- logy. Structural members needed to be attached to one another and everything would depend on the reliability of the bond. Trial and error would have exposed the weaknesses in design and construction and one of the costs would have been the loss of the vessel, if not of lives.As knowledge and experience was shared, so technology improved and in a symbiotic advancement, boat building and other industries benefited.Today, significant advances in adhesive technology have spurred a revolution in assembly techniques across all of industry. But none reap the benefits more than the marine industry.APPLICATIONDESCRIPTIONElastic thick layer bonding in respect ofthis manual refers to the method ofjoining the main structural componentsor components that contribute to thestrength and stability of the structure ofthe vessel.Elastic thick layer bonding is responsiblefor a completely different approach tovessel design. Whereas earlier techniquesworked from a rigid skeleton that had tobe strong enough to support the deck,hull, superstructure, windows, and fittings,the new approach uses all of these majorcomponents as the primary structuralmembers and uses the old skeletal partsin a lighter form to provide stiffening tothe structure.Each time that a screw was used to holda major component to the skeleton, itintroduced weaknesses in every part itpassed through and became a focal pointfor stresses.Marine architects had to take this intoconsideration during the design phaseand ensure that there were sufficientfixings placed evenly along the joint linesin order to distribute the stresses. Thelocation, size and type of every screwhad to be specified, drawn onto the plans,bought in and stored.The laminating method (taping) providesa far better alternative to this approachin most applications, with fewer compo-nents, a simplified design and betterstress distribution. But this method ishighly labour intensive and comes withnumerous health and safety issues.Elastic thick layer bonding from Sika isrelatively simple to design, tolerant ofdissimilar materials, very strong and dur-able, and besides having few health andsafety requirements, takes a fraction ofthe time of other techniques to assemble.DISCLAIMERThe information, and, in particular, the recommendations relating to theapplication and end-use of Sika products, are given in good faith based on Sika’s current knowledge and experience of the products when properly stored, handled and applied under normal conditions. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of mer- chantability or of fitness for a particular purpose, nor any liability arising out ofIn service, the inherent flexibility of the Sika structural adhesives evenly distrib-utes the stresses and the lightweight construction techniques result in a major weight saving and correspondingbuoyancy and performance increase in the vessel.For every structural application, national and international rules, regulations andapprovals must be observed.any legal relationship whatsoever, can be inferred either from this information, or from any written recommendations, or from any other advice offered.The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users should always refer to the most recent issue of the Sika Product Datasheet for the product concerned, copies of which will be supplied on request.SIKA MARINE APPLICATION GUIDEGeneral Marine Elastic Bonding ApplicationsGLOBAL BUT LOCAL PARTNERSHIPOur most current General Sales Conditions shall apply.Please consult the Data Sheet prior to any use and processing.© S i k a S e r v i c e s A G / N D U S T R Y / M A R I N E / S I K A M A R I N E A P P L I C A T I O N G U I D E / T Z / 2.2017Who we areSika is a specialty chemicals company with a leading position in the de-velopment and production of systems and products for bonding, sealing,damping, reinforcing and protecting in the building sector and the motor vehicle industry. Sika has subsidiaries in 94 countries around the world and manufactures in over 170 factories. Its more than 17,000 employees generated annual sales of CHF 5.49 billion in 2015.FOR MORE MARINE INFORMATION:Sika Services AG Tueff enwies 168048 ZurichContact:Phone: +41 58 436 40 40Fax: +41 58 436 45 30/marine。

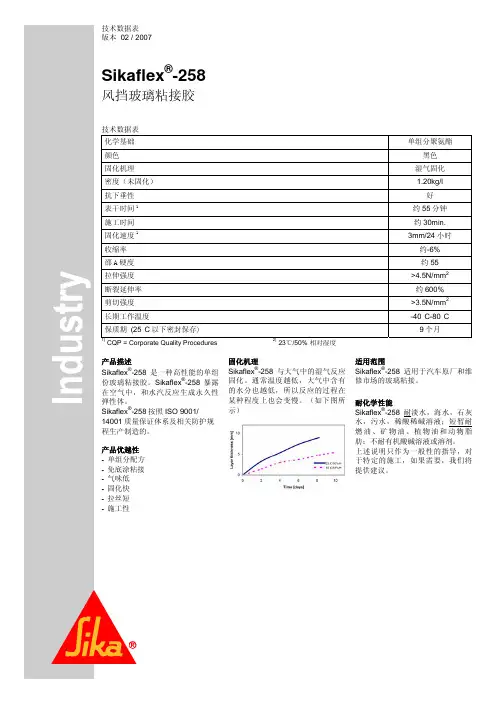

技术数据表版本 02 / 2007Sikaflex®-258风挡玻璃粘接胶技术数据表化学基础 单组分聚氨酯 颜色 黑色固化机理 湿气固化密度(未固化) 1.20kg/l抗下垂性 好表干时间1约55分钟施工时间 约30min. 固化速度13mm/24小时收缩率 约-6%邵A硬度 约55拉伸强度 >4.5N/mm2断裂延伸率 约600%剪切强度 >3.5N/mm2长期工作温度 -40°C-80°C 保质期 (25°C以下密封保存) 9个月1) CQP = Corporate Quality Procedures 2) 23℃/50% 相对湿度产品描述Sikaflex®-258是一种高性能的单组份玻璃粘接胶。

Sikaflex®-258暴露在空气中,和水汽反应生成永久性弹性体。

Sikaflex®-258按照ISO 9001/ 14001质量保证体系及相关防护规程生产制造的。

产品优越性-单组分配方-免底涂粘接-气味低-固化快-拉丝短-施工性固化机理Sikaflex®-258与大气中的湿气反应固化。

通常温度越低,大气中含有的水分也越低,所以反应的过程在某种程度上也会变慢。

(如下图所示)适用范围Sikaflex®-258适用于汽车原厂和维修市场的玻璃粘接。

耐化学性能Sikaflex®-258耐淡水,海水,石灰水,污水,稀酸稀碱溶液;短暂耐燃油、矿物油、植物油和动物脂肪;不耐有机酸碱溶液或溶剂。

上述说明只作为一般性的指导,对于特定的施工,如果需要,我们将提供建议。

更多信息请登陆: 西卡(中国)建筑材料有限公司 工业部 苏州工业园区泾东路28号 邮编:215121 电话:(86)512 62732888 传真:(86)512 62877070 E-mail: marketing@施工方法表面处理粘结面应清洁、干燥,无油脂、油和灰尘。

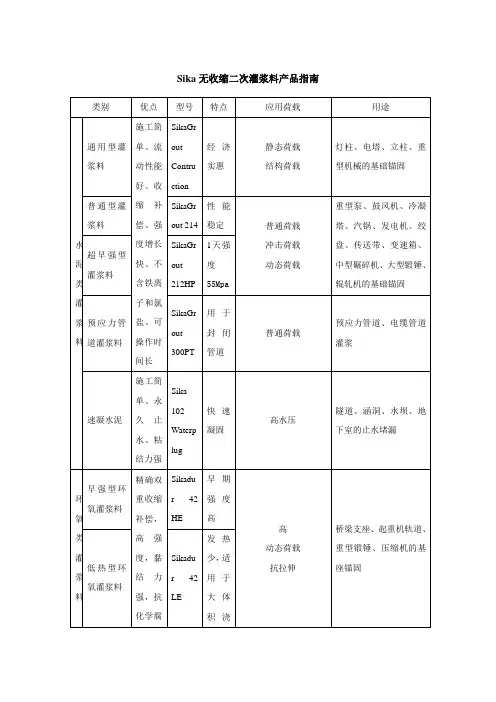

Sika无收缩二次灌浆料产品指南类别优点型号特点应用荷载用途水泥类灌浆料通用型灌浆料施工简单、流动性能好、收缩补偿、强度增长快、不含铁离子和氯盐、可操作时间长SikaGroutContruction经济实惠静态荷载结构荷载灯柱、电塔、立柱、重型机械的基础锚固普通型灌浆料SikaGrout 214性能稳定普通荷载冲击荷载动态荷载重型泵、鼓风机、冷凝塔、汽锅、发电机、绞盘、传送带、变速箱、中型碾碎机、大型锻锤、辊轧机的基础锚固超早强型灌浆料SikaGrout212HP1天强度55Mpa预应力管道灌浆料SikaGrout300PT用于封闭管道普通荷载预应力管道、电缆管道灌浆速凝水泥施工简单、永久止水、粘结力强Sika102Waterplug快速凝固高水压隧道、涵洞、水坝、地下室的止水堵漏环氧类灌浆料早强型环氧灌浆料精确双重收缩补偿,高强度,黏结力强,抗化学腐Sikadur 42HE早期强度高高动态荷载抗拉伸桥梁支座、起重机轨道、重型锻锤、压缩机的基座锚固低热型环氧灌浆料Sikadur 42LE发热少,适用于大体积浇蚀筑注射型环氧灌浆料Sikadur 752超高流动性封闭各种裂缝、大幅度提高结构的抗压、抗拉能力。

各品牌结构胶耐候胶对比结构胶是一种常见的粘接材料,用于固定和连接各种建筑和工程构件,如木材、金属、玻璃、混凝土等。

在选择结构胶时,耐候性是一个重要的考虑因素,特别是在户外使用的情况下。

本文将比较几种不同品牌的结构胶的耐候性能。

1.3M结构胶:3M是全球领先的品牌,其结构胶在耐候性方面表现出色。

3M的结构胶具有出色的耐候性,可以在负温度和高温环境下保持稳定的性能。

它们还能抵御紫外线辐射,防止颜色褪色和材料老化。

2. Sika结构胶:Sika是另一个著名的品牌,其结构胶也具有很高的耐候性。

Sika结构胶能够在恶劣的气候条件下保持稳定的性能,不会因高温或低温而脆化或变形。

此外,Sika结构胶还具有耐紫外线辐射和化学腐蚀的能力。

3.华夏结构胶:华夏结构胶是国内知名品牌,其产品在耐候性方面也有一定的优势。

它们可以承受不同温度和湿度条件下的使用,并保持良好的粘接性能。

然而,与国际品牌相比,华夏结构胶在耐候性上可能稍逊一筹。

4.BASF结构胶:BASF是另一家全球知名的化工公司,其结构胶具有出色的耐候性能。

BASF结构胶能够抵抗极端温度、紫外线以及化学腐蚀的影响,能够在户外环境中持久使用而不失效。

5. H.B.Fuller结构胶:H.B.Fuller是一家专业化学品制造商,其结构胶在耐候性方面表现不俗。

H.B.Fuller结构胶能够在不同气候条件下提供持久的粘接性能,经过很长时间的使用仍然保持稳定。

它们还具有抗紫外线辐射的特性,延缓颜色褪变和老化。

总之,各个品牌的结构胶都具有一定的耐候性能,但在选择时需要根据具体的使用环境和要求进行综合考虑。

一般来说,国际知名品牌如3M、Sika、BASF等具有更加可靠的耐候性能,而国内品牌如华夏、H.B.Fuller等虽然在耐候性上略逊一筹,但仍然能够满足大部分普通建筑和工程的需求。

在购买时,建议查看产品规格和说明,选择适合自己需要的结构胶。

双组份丙烯酸结构胶

双组份丙烯酸结构胶是一种由两个不同的组分组成的结构胶。

其中一组分是丙烯酸酯单体/预聚体,另一组分是引发剂/活性

剂/助剂等。

在使用前,将两个组分混合在一起,通过引发剂

引发聚合反应,从而形成聚合物网络结构。

双组份丙烯酸结构胶具有以下特点:

1. 高强度:由于聚合物网络结构的形成,该结构胶具有较高的强度和耐久性。

2. 高粘接性能:能够粘接多种不同的材料,如金属、塑料、玻璃等。

3. 快速固化:通过选择合适的引发剂和控制固化条件,可以实现快速固化,缩短生产周期。

4. 抗老化性能好:具有优良的耐候性和耐化学品性能,能够在恶劣环境下长期使用。

双组份丙烯酸结构胶广泛应用于建筑、汽车、航空航天、电子、家具等领域。

在建筑行业,常用于粘接和修补混凝土、石材、玻璃幕墙等;在汽车行业,常用于车身结构粘接和镶嵌密封等;在电子行业,常用于电子组件的粘接和密封等。

需要注意的是,双组份丙烯酸结构胶在使用过程中应遵守相关的安全操作规程,避免接触皮肤和眼睛,确保良好的通风条件。

研究报告及专论粘 接 2007,28(1)高强度双组分聚氨酯胶粘剂的研制罗纪明,桂武标,杨足明,马德军,夏进强(湖北回天胶业股份有限公司,湖北襄樊441003)收稿日期:2006-06-24作者简介:罗纪明(1967-),男,硕士,从事胶粘剂的研究。

已发表论文20余篇。

摘要:合成了E-己内酯-MOCA 加成物。

以聚碳酸酯二元醇,E -己内酯-MO CA 加成物以及M D I 为主体材料制备的双组分结构胶综合性能优异:剪切强度为27.7M Pa ,180b 剥离强度为5.22k N /m,定位时间为5m i n ,耐温100~120e 。

M OCA 或者E -己内酯-M OCA 加成物在聚氨酯胶粘剂中的含量大于临界含量时,胶粘剂的固化速度明显加快,粘接性能显著提高。

制备的双组分胶粘剂甲乙组分的最佳配比为10B 15.5,此时粘接强度最高,甲乙组分的配比对粘接强度影响较大。

关键词:双组分;聚氨酯结构胶;聚碳酸酯二元醇中图分类号:TQ 433.4+32 文献标识码:A 文章编号:1001-5922(2007)01-0005-03双组分聚氨酯胶粘剂广泛应用于食品包装、纸塑复合、土木建筑以及结构粘接、超低温粘接等场合。

在汽车制造业中已广泛采用塑料、玻璃钢、聚氨酯等作为结构材料,双组分聚氨酯胶粘剂以其优异的抗冲击性、耐久性、耐低温性、耐疲劳性和良好的施工性能而成为首选的胶粘剂。

但是,双组分聚氨酯胶在耐高温性能和粘接强度方面与环氧树脂和第2代丙烯酸酯等结构胶相比还存在较大的差距。

研究高强度双组分聚氨酯胶的国内文献很少,而且强度不高,文献[1]报道的一种双组分胶的剪切强度为14.9M P a ,文献[2~5]报道的最大剪切强度不足11.2M Pa ;瑞士SIKA 公司在其申请的专利[6]中介绍的一种快固型双组分聚氨酯胶的拉伸强度也不超过8.0M P a 。

因此,双组分聚氨酯胶在结构粘接方面的应用受到了很大的限制。

凯思密高强度焊接胶使用说明书

在决定粘合金属之前,可以首先考虑焊接,焊接可以为连接金属件提供更坚固、更稳定的保持。

但是,如果没有合适的设备或者是工艺需求,请按照以下步骤将金属成功地粘接到金属上。

第1步:选择合适的胶水

凯思密高强度焊接胶提供了更快速的粘接,当粘接面尺寸不大,同时金属表面无间隙地紧密贴合在一起时推荐使用,因为额外的空间可能会影响结合的牢固程度。

凯思密高强度焊接胶粘接金属基本上几十秒内就可初步粘接,具有一定的粘接强度,24h之后达到最大强度。

第2步:清洁

首先,通过清洁和打磨彻底清除表面上的任何碎屑。

另外,请小心不要用裸手触摸粘合表面,因为皮肤上的油脂会粘在表面上并干扰粘合剂。

用细砂纸打磨两个表面以增加质感,因为这样可以更容易形成一个结合点。

第3步:应用胶水

胶水应用,是胶水粘接效果的重要影响因素,无论使用何种胶水,请务必按照包装上的说明进行操作,避免粘合剂太多或太少,影响使用效果。

使用胶水时,注意不要让自己或其他材料溅入工作区域,并且始终确保您的空间通风良好。

第4步:夹紧

建议可以将两个部件夹紧在一起,或在胶合后找到另一种施加压力的方法。

这样可以获得更强的粘合力,因为大多数高强度胶水在完全固定之前都会经过化学固化过程。

按照胶水包装上的干燥时间进行操作,以便两块胶片有足够的时间形成粘合。

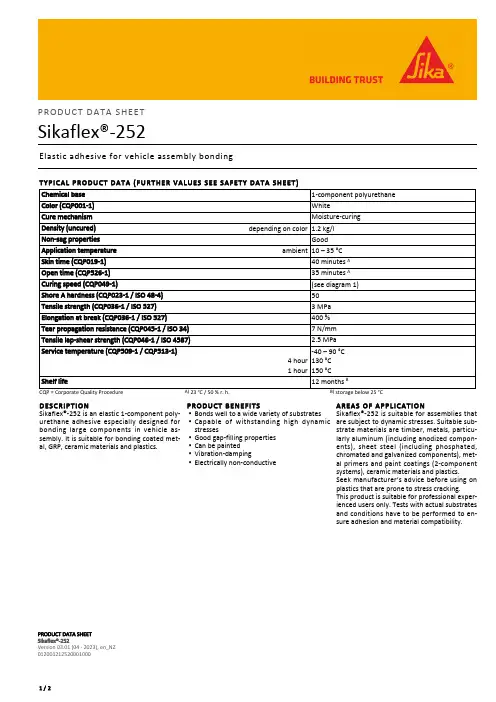

PRODUCT DATA SHEET Sikaflex®-252Version 03.01 (04 - 2023), en_NZ012001212520001000PRODUCT DATA SHEETSikaflex®-252Elastic adhesive for vehicle assembly bondingTYPICAL PRODUCT DATA (FURTHER VALUES SEE SAFETY DATA SHEET)Chemical base 1-component polyurethane Color (CQP001-1)WhiteCure mechanism Moisture-curing Density (uncured)depending on color1.2 kg/l Non-sag propertiesGood Application temperature ambient10 ─ 35 °C Skin time (CQP019-1)40 minutes A Open time (CQP526-1)35 minutes A Curing speed (CQP049-1)(see diagram 1)Shore A hardness (CQP023-1 / ISO 48-4)50Tensile strength (CQP036-1 / ISO 527) 3 MPa Elongation at break (CQP036-1 / ISO 527)400 %Tear propagation resistance (CQP045-1 / ISO 34)7 N/mm Tensile lap-shear strength (CQP046-1 / ISO 4587) 2.5 MPa Service temperature (CQP509-1 / CQP513-1)4 hour 1 hour-40 ─ 90 °C 130 °C 150 °CShelf life12 months BCQP = Corporate Quality ProcedureA) 23 °C / 50 % r. h.B) storage below 25 °CDESCRIPTIONSikaflex®-252 is an elastic 1-component poly-urethane adhesive especially designed for bonding large components in vehicle as-sembly. It is suitable for bonding coated met-al, GRP, ceramic materials and plastics.PRODUCT BENEFITSBonds well to a wide variety of substrates ▪Capable of withstanding high dynamic stresses▪Good gap-filling properties ▪Can be painted ▪Vibration-damping▪Electrically non-conductive▪AREAS OF APPLICATIONSikaflex®-252 is suitable for assemblies that are subject to dynamic stresses. Suitable sub-strate materials are timber, metals, particu-larly aluminum (including anodized compon-ents), sheet steel (including phosphated, chromated and galvanized components), met-al primers and paint coatings (2-component systems), ceramic materials and plastics.Seek manufacturer’s advice before using on plastics that are prone to stress cracking.This product is suitable for professional exper-ienced users only. Tests with actual substrates and conditions have to be performed to en-sure adhesion and material compatibility.1 / 2CURE MECHANISMSikaflex®-252 cures by reaction with atmo-spheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds more slowly (seediagram 1).Diagram 1: curing speed Sikaflex®-252CHEMICAL RESISTANCESikaflex®-252 is generally resistant to fresh water, seawater, diluted acids and dilutedcaustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycol-ic alcohol, concentrated mineral acids and caustic solutions or solvents.METHOD OF APPLICATIONSurface preparationSurfaces must be clean, dry and free from grease, oil, dust and contaminants.The surface treatment depends on the specif-ic nature of the substrates and is crucial for a long lasting bond. Suggestions for surface pre-paration may be found on the current edition of the appropriate Sika® Pre-treatment Chart. Consider that these suggestions are based on experience and have in any case to be verified by tests on original substrates.ApplicationSikaflex®-252 can be processed between10 °C and 35 °C (climate and product) butchanges in reactivity and application proper-ties have to be considered. The optimum tem-perature for substrate and adhesive is between 15 °C and 25 °C.Consider that the viscosity will increase at low temperatures. For easy application, condition the adhesive at ambient temperature prior to use. To ensure a uniform thickness of the bondline it is recommend to apply the adhes-ive in the form of a triangular bead (see figure1).Figure 1: Recommended bead configurationSikaflex®-252 can be processed with manual, pneumatic or electric driven piston guns as well as pump equipment. The open time is significantly shorter in hot and humid cli-mates. The parts must always be installed within the open time. Never join bonding parts if the adhesive has built a skin.Tooling and finishingTooling and finishing must be carried out within the skin time of the product. Finishing agents must be tested for suitability and com-patibility prior to use.RemovalUncured Sikaflex®-252 can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes or a suitable industrial hand cleaner and water.Do not use solvents on skin.FURTHER INFORMATIONThe information herein is offered for general guidance only. Advice on specific applications is available on request from the Technical De-partment of Sika Industry.Copies of the following publications are avail-able on request:Safety Data Sheets▪Sika Pre-treatment Chart For 1-componentPolyurethanes▪PACKAGING INFORMATION Unipack600 mlBASIS OF PRODUCT DATAAll technical data stated in this document are based on laboratory tests. Actual measured data may vary due to circumstances beyond our control.HEALTH AND SAFETY INFORMATION For information and advice regarding trans-portation, handling, storage and disposal of chemical products, users shall refer to the ac-tual Safety Data Sheets containing physical, ecological, toxicological and other safety-re-lated data.DISCLAIMERThe information, and, in particular, the re-commendations relating to the application and enduse of Sika products, are given in good faith based on Sika's current knowledge and experience of the products when prop-erly stored, handled and applied under nor-mal conditions in accordance with Sika's re-commendations. In practice, the differences in materials, substrates and actual site condi-tions are such that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any writ-ten recommendations, or from any other ad-vice offered. The user of the product must test the product's suitability for the intended application and purpose. Sika reserves the right to change the properties of its products. The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the product concerned, copies of which will be supplied on request.PRODUCT DATA SHEET Sikaflex®-252Version 03.01 (04 - 2023), en_NZ012001212520001000Sika (NZ) Limited85-91 Patiki RoadAvondale, Auckland 1026New Zealand 0800 745 2 / 2。

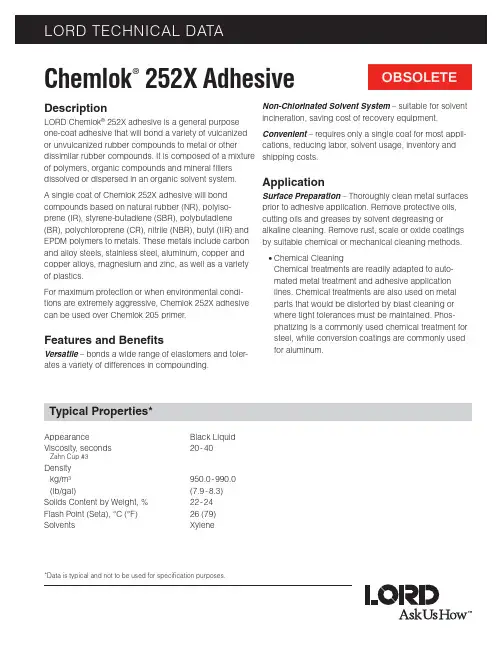

DescriptionLORD Chemlok ® 252X adhesive is a general purpose one-coat adhesive that will bond a variety of vulcanized or unvulcanized rubber compounds to metal or other dissimilar rubber compounds. It is composed of a mixture of polymers, organic compounds and mineral fi llers dissolved or dispersed in an organic solvent system.A single coat of Chemlok 252X adhesive will bond compounds based on natural rubber (NR), polyiso-prene (IR), styrene-butadiene (SBR), polybutadiene (BR), polychloroprene (CR), nitrile (NBR), butyl (IIR) and EPDM polymers to metals. These metals include carbon and alloy steels, stainless steel, aluminum, copper and copper alloys, magnesium and zinc, as well as a variety of plastics.For maximum protection or when environmental condi-tions are extremely aggressive, Chemlok 252X adhesive can be used over Chemlok 205 primer.Features and Benefi tsVersatile – bonds a wide range of elastomers and toler-ates a variety of differences in compounding.Chemlok ®252X AdhesiveNon-Chlorinated Solvent System – suitable for solvent incineration, saving cost of recovery equipment.Convenient – requires only a single coat for most appli-cations, reducing labor, solvent usage, inventory and shipping costs.Application Surface Preparation – Thoroughly clean metal surfaces prior to adhesive application. Remove protective oils, cutting oils and greases by solvent degreasing oralkaline cleaning. Remove rust, scale or oxide coatings by suitable chemical or mechanical cleaning methods.•Chemical CleaningChemical treatments are readily adapted to auto-mated metal treatment and adhesive application lines. Chemical treatments are also used on metal parts that would be distorted by blast cleaning or where tight tolerances must be maintained. Phos-phatizing is a commonly used chemical treatment for steel, while conversion coatings are commonly used for aluminum.Typical Properties*AppearanceBlack Liquid Viscosity, seconds20 - 40Zahn Cup #3Density kg/m 3 950.0 - 990.0(lb/gal)(7.9-8.3)Solids Content by Weight, % 22 - 24Flash Point (Seta), °C (°F) 26 (79)SolventsXylene*Data is typical and not to be used for specification purposes.• Mechanical CleaningGrit blasting is the most widely used method ofmechanical cleaning. However machining, grindingor wire brushing can be used. Use steel grit to blast clean steel, cast iron and other ferrous metals. Usealuminum oxide, sand or other nonferrous grit to blast clean stainless steel, aluminum, brass, zinc and other nonferrous metals.For further detailed information on surface preparation of specifi c substrates, refer to Chemlok Adhesives appli-cation guide. Handle clean metal surfaces with clean gloves to avoid contamination with skin oils.Mixing – Thoroughly stir Chemlok 252X adhesive before use, and agitate suffi ciently during use to keep dispersed solids uniformly suspended. Mix drums for 8 hours at30-60 rpm before using. If needed, proper dilution for the various application methods is best achieved by experi-ence.Applying – Apply Chemlok 252X adhesive by spray, dip or brush methods. Chemlok 252X adhesive is best suited for spray application.When using Chemlok 252X adhesive as a one-coat adhesive, the dry fi lm thickness should be 20.3-25.4 micron (0.8-1.0 mil) for optimum adhesion and environmental resistance. When used as a covercoat over Chemlok 205 primer, the dry fi lm thickness of the Chemlok 252X adhesive should be 10.2-17.8 micron (0.4-0.7 mil).• SprayingDilute adhesive to a Zahn Cup #2 viscosity of 25-28seconds. Use xylene or toluene in a ratio of approxi-mately 60 parts adhesive to 40 parts solvent, byweight or by volume. Tip sizes of 1.07-1.40 mm(0.042-0.055 in) are appropriate. Maintain atomiza-tion pressures at 0.345-0.379 MPa (50-55 psi) for best atomization.• DippingUse full strength. In many instances, a single dipapplication of Chemlok 252X adhesive will be suffi -cient to provide excellent adhesion. A single dipis appropriate when Chemlok 205 primer is usedunder Chemlok 252X adhesive. Where rubber-to-metal bonded assemblies are likely to be exposedto aggressive environmental conditions, it may benecessary to double dip Chemlok 252X adhesivediluted at a ratio of 5 parts adhesive to 1 part solvent, by volume, in order to achieve dry fi lm thicknesses of20.3-25.4 micron (0.8-1.0 mil).• BrushingApply full strength.Drying/Curing – Allow the applied adhesive to dryuntil visual examination of the fi lm has shown that all solvent has evaporated. This will take approximately30-60 minutes at room temperature. Drying time can be shortened by either preheating the metal inserts or oven drying after application. Metal parts may be preheated to a maximum of 65°C (150°F) prior to adhesive applica-tion. For coated parts, moderate drying temperatures should be used, but temperatures as high as 149°C (300°F) may be used for very short periods of time. Maximum air fl ow at minimum temperatures will give the best results.Dried fi lms of Chemlok 252X adhesive are non-tacky; therefore, coated parts can be piled into tote pansfor subsequent processing. Wear clean gloves when handling coated parts and cover the tote pans to prevent contamination by dirt, dust, grease, oil, etc. If coated parts are properly protected, long layover times between adhesive application and bonding usually have no adverse effect on the bond. If Chemlok 252X adhe-sive has been removed by chipping or abrasion during handling, these damaged areas can be recoated before bonding.Chemlok 252X adhesive can be used to bond rubberby compression, transfer, injection or other molding procedures used to make bonded parts. As with other Chemlok adhesives, maximum adhesion is obtained when the rubber has completely cured. Ideal bonding conditions exist when both the adhesive and the rubber cure at the same time. To accomplish this, load the adhe-sive coated metal parts in the mold and quickly fi ll the cavity with rubber.While it is desirable to keep mold loading cycles to a minimum to prevent pre-cure of the adhesive and the rubber, Chemlok 252X adhesive will resist prebaking times up to 15 minutes at 160°C (320°F) or the equiva-lent at other temperatures without affecting bond performance. Transfer or injection molds need properly designed runners and sprues, as well as adequate pres-sures. This prevents rubber pre-curing before the mold cavities are completely fi lled.Post-Vulcanization Bonding – Chemlok 252X adhe-sive exhibits excellent post-vulcanization (PV) bonding capability with vulcanized compounds of NR, SBR, chlo-roprene, nitrile, butyl, Hypalon® and EPDM. For further details on post-vulcanization bonding, refer to Post-Vulcanization Bonding Guide for Chemlok Adhesives.Shelf Life/StorageShelf life is one year from date of shipment when stored at 21-27°C (70-80°F) in original, unopened container. Do not store or use near heat, sparks or open fl ame.Cautionary InformationBefore using this or any LORD product, refer to the Mate-rial Safety Data Sheet (MSDS) and label for safe use and handling instructions.For industrial/commercial use only. Must be applied by trained personnel only. Not to be used in household applications. Not for consumer use.Hypalon is a registered trademark of E.I. DuPont de Nemours.Values stated in this technical data sheet represent typical values as not all tests are run on each lot of material produced. For formalized product specifi cations for specifi c product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as LORD Corporation has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, LORD Corporation does not guarantee the perfor-mance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fi tness for a particular purpose concerning the effects or results of such use.Chemlok and “Ask Us How” are trademarks of LORD Corporation or one of its subsidiaries.LORD provides valuable expertise in adhesives and coatings, vibration and motion control, and magnetically responsive technologies. Our people work in collaboration with our customers to help them increase the value of their products. Innovative and responsive in an ever-changing marketplace, we are focused on providing solutions for our customers worldwide ... Ask Us How.LORD CorporationWorld Headquarters111 Lord DriveCary, NC 27511-7923USACustomer Support Center (in United States & Canada)+1 877 ASK LORD (275 5673)For a listing of our worldwide locations, visit .©2012 LORD Corporation OD DS3126 (Rev.6 9/12)。

bz_zj xh xh_px类别名称牌号固化条件特性适用范围接触压力,120℃,3h固化。

胶接强度高,用于金属、非1 1.2.25.1 1.2.25.1胶粘剂常用结构胶粘K H-511胶粘剂(环氧-丁腈胶)(纱网胶膜)胶接强度高,用于金属、非接触压力,120℃,3h固化。

1 1.2.25.2 1.2.25.2胶粘剂常用结构胶粘K H-511胶粘剂(环氧-丁腈胶)(纱网胶膜)接触压力,120℃,3h固化。

胶接强度高,用于金属、非1 1.2.25.3 1.2.25.3胶粘剂常用结构胶粘K H-511胶粘剂(环氧-丁腈胶)(纱网胶膜)胶接强度高,用于金属、非接触压力,120℃,3h固化。

1 1.2.25.4 1.2.25.4胶粘剂常用结构胶粘K H-511胶粘剂(环氧-丁腈胶)(纱网胶膜)胶接强度高,用于金属、非接触压力,120℃,3h固化。

1 1.2.25.5 1.2.25.5胶粘剂常用结构胶粘K H-511胶粘剂(环氧-丁腈胶)(纱网胶膜)使用方便。

用于铸铁件的25℃,6h或80℃,1h固化。

1 1.2.4.1 1.2.04.1胶粘剂常用结构胶粘H J-112胶粘剂(室温固化环氧胶)使用方便。

用于铸铁件的1 1.2.4.2 1.2.04.2胶粘剂常用结构胶粘H J-112胶粘剂(室温固化环氧胶)25℃,6h或80℃,1h固化。

用于结构件的5~10℃能固化,蒸气压小,吸湿小,耐热1 1.2.5.1 1.2.05.1胶粘剂常用结构胶粘T G-3胶粘剂(低温固化环氧胶)接触压力,℃,24h固化。

用于结构件的5~10℃能固化,蒸气压小,吸湿小,耐热1 1.2.5.2 1.2.05.2胶粘剂常用结构胶粘T G-3胶粘剂(低温固化环氧胶)接触压力,℃,24h固化。

胶接强度高,用于各种金属接触压力,80℃,2h固化。

1 1.2.7.1 1.2.07.1胶粘剂金属-金属胶粘剂J-32胶粘剂(中温固化环氧胶)胶接强度高,用于各种金属压力0.03~0.05MPa,室温,4.8h固化。

⽤Sikaflex粘接剂进⾏粘接的综合基础Arbeitsanweisung⼯作说明TS TR UPTS MT SPTS集团列车部乌丁根⼚TS集团公共交通部销售与项⽬处 Allgemeine Grundlagen zum Kleben mitSikaflex Klebstoffen⽤Sikaflex粘接剂进⾏粘接的综合基础Verteiler: TS MT SP, TS TR UP, Lieferanten der TS分发⼈:TS集团公共交通部销售与项⽬处、TS集团列车部乌丁根⼚、TS集团的供货商Allgemeine Grundlagen zum Kleben mit TS TR UP A6Z40109420165 1 Sikaflex Klebstoffen AS TDatum Revision: 306.2006 vonInhalt /⽬录1. Zweck /⽬的 (3)2. Geltungsbereich /适⽤范围 (3)3. Zu verwendende Materialien und Arbeitsmittel /待⽤材料和⼯作介质 (3)4. Grundlagen zum Kleben mit Sikaflex /⽤Sikaflex进⾏粘接的基础 (3)4.1 Temperatur und Luftfeuchtigkeit im Fertigungsbereich Kleben /粘接⽣产区域内的温度和湿度 (3)4.1.1 Offene Zeit /晾置时间 (4)4.1.2 Hautbildezeit (nur Verfugung / Abdichtung) /表层形成时间(仅指接缝/密封) (4)4.1.3 Aush?rtezeiten /硬化时间 (5)4.1.4 Ablüftzeiten (nur Reiniger und Primer) /通风时间(仅指清洗剂和底剂) (5)4.2 Techniken beim Vorbehandeln von Klebfl?chen /粘接⾯预处理技术 (6)4.2.1 Reinigen von Klebfl?chen /粘接⾯的清洗 (6)4.2.2 Auftragen von Primer auf Oberfl?chen /将底剂涂敷到表⾯上 (7)4.2.3 Klebstoff Applikation /粘接剂的应⽤ (9)5. Prüfungen und Messungen /检验及测量 (10)5.1 Impr?gnierungsprüfung /浸渍试验 (11)5.1.1 Allgemeines /概述 (11)5.1.2 Durchführung /实施 (11)5.1.3 Dokumentation und Stichprobenprüfung /⽂件及抽检 (12)5.2 Messung der Klebschichtdicke vor dem Kleben /粘接前粘接层厚度的测量 (12)5.2.1 Allgemeines /概述 (12)5.2.2 Durchführung /实施 (13)5.3 Funktionstest der 2K Pumpanlage für Sikaflex 254+Booster / Sikaflex 254+硬化加速剂双组分泵装置的功能试验 (13) 5.4 Haftungsprüfung parallel zur Fertigung /与⽣产同时进⾏的粘合试验 (14)5.4.1 Allgemein /概述 (14)5.4.2 Anfertigung der Testbleche /试验板的制作 (15)5.4.3 Haftungstests /粘合试验 (15)5.4.4 Dokumentation /⽂件 (16)6. Richtlinien /导则 (16)7. ?nderungsübersicht /修改⼀览表 (16)Allgemeine Grundlagen zum Kleben mit TS TR UP A6Z40109420165 1 Sikaflex Klebstoffen AS TDatum Revision: 306.2006 von1. Zweck /⽬的Diese Arbeitsanweisung legt grundlegende Regeln bei der Verarbeitung des Sikaflex Klebstoffsystems fest. Sie ist ein allgemeines Dokument und erg?nzt die Arbeitsanweisungen die sich auf spezielle Baugruppen beziehen.本⼯作说明规定了加⼯Sikaflex系列粘接剂时的基本原则。

Product Data Sheet Sika® Block Paving Seal March 2018, Version 01.01020815110020000021PRODUCT DATA SHEETSika® Block Paving SealA clear resin for impregnating, enhancing and sealing block pavingPRODUCT DESCRIPTIONSika® Block Paving Seal is a low odour clear resin which impregnates and seals block paving, improving the overall appearence of the block paving with a matt finish.USESSika® Block Paving Seal may be used for both vehicle and pedestrian areas.▪New and existing drives, forecourts, parking areas, walkways and paths can all be treated.▪CHARACTERISTICS / ADVANTAGESSimple and quick to apply ▪Enhances appearance ▪Matt finish▪Easier to clean and maintain ▪Improves wear resistance▪PRODUCT INFORMATIONPackaging5ltr and 25ltr metal tin Appearance / Colour ClearShelf Life 12 months if stored in original, tightly closed containers Storage Conditions Protect from frost and store between 5°C and 25°C.Density~ 0.9 kg/I (at +20°C)APPLICATION INFORMATIONConsumptionAs a guide Sika® Block Paving Seal will treat up to 5-8m² per litre. Coverage will depend on surface finish, permeability and profile of block pavers.Ambient Air Temperature +5°C min. / +30°C max.Relative Air Humidity 80 % r.h. max.Dew PointBeware of condensation!The substrate and uncured floor must be at least 3°C above dew point to reduce the risk of condensation or blooming on the floor finish.Substrate Temperature +5°C min. / +30°C max.Allow previous coats to become tack free before applying additional coats.Waiting Time / Overcoating1 / 2Substrate temperature Foot traffic Full cure +10 °C ~ 16 hours ~ 24 hours +20 °C ~ 8 hours ~ 20 hours +30 °C ~ 6 hours ~ 16 hoursTimes are approximate and will be affected by changing substrate and am-bient conditions, particularly temperature and relative humidity.APPLICATION INSTRUCTIONSSUBSTRATE QUALITY / PRE-TREATMENTFor new block paving areas, remove all loose materi-als by brush or vacuum.▪Ensure the joints are filled with compacted Sika® Set-ting Sand or kiln dried sand before treating with Sika® Block Paving Seal.▪For existing block paved areas remove all traces of weeds, algae and lichens with Sika® Mould Buster.▪Remove oil, grease and diesel stains.▪Ensure all areas are completely dry before applying Sika® Block Paving Seal.▪To ensure the paving is completey dry, scrape out some jointing sand to a depth of up to 10mm. If the sand is dry then the blocks may be treated.▪APPLICATIONMix thoroughly before use.▪Treat the perimeter of the block paving area first.▪Apply the first coat by roller, spreading liberally and uniformly, making sure the Sika® Block Paving Seal does not puddle.▪During application always ensure a wet edge is main-tained to avoid a striping affect.▪Repeat the process leaving a maximum of 24 hours between coats.▪Apply the second coat at right angles to the first.▪Do not over-apply.▪Allow at least 6 hours before pedestrian traffic and 24 hours for vehicle.▪Protect from moisture during curing.▪It is always recommended that a trial area be treated to ascertain an accurate measure of consumption and to ensure the finished appearence is acceptable.▪CLEANING OF TOOLSClean all tools and application equipment with white spirits immediately after use. Hardened/cured materi-al can only be removed mechanically.LIMITATIONSIn hot weather (above +25°C) store Sika® Block Pav-ing Seal in a cool place prior to use.▪In low temperatures (below +5 ºC) the product may thicken and be difficult to spray.▪Do not use sprayers, which have been used to spray silicones or release agents.▪Do not mix differing formulations of Sika® or other curing membranes.▪Ensure spraying equipment is cleaned thoroughly be-fore use and residues of previous membranes are re-moved.▪Sika® Block Paving Seal must be removed prior to the▪application of a coating system.Sika® Block Paving Seal will gradually degrade and be removed by environmental exposure and trafficking.▪VALUE BASEAll technical data stated in this Data Sheet are based on laboratory tests. Actual measured data may vary due to circumstances beyond our control.LOCAL RESTRICTIONSNote that as a result of specific local regulations the declared data and recommended uses for this product may vary from country to country. Consult the local Product Data Sheet for exact product data and uses.ECOLOGY, HEALTH AND SAFETY LEGAL NOTESThe information, and, in particular, the recommenda-tions relating to the application and end-use of Sika products, are given in good faith based on Sika's cur-rent knowledge and experience of the products when properly stored, handled and applied under normal conditions in accordance with Sika's recommenda-tions. In practice, the differences in materials, sub-strates and actual site conditions are such that no war-ranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written recom-mendations, or from any other advice offered. The user of the product must test the product’s suitability for the intended application and purpose. Sika re-serves the right to change the properties of itsproducts. The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the product concerned, copies of which will be supplied on request.EVERBUILD BUILDING PRODUCTS LTD Site 41, Knowsthorpe Way Cross Green Industrial Estate Leeds, LS9 0SW Tel: 0113 240 3456Web: Twitter: @everbuild SIKA LIMITED Watchmead Welwyn Garden City Hertfordshire, AL7 1BQ Tel: 01707 394444Web: Twitter: @SikaLimited SikaBlockPavingSeal-en-GBEVER-(03-2018)-1-1.pdfProduct Data Sheet Sika® Block Paving SealMarch 2018, Version 01.010208151100200000212 / 2。

78·September-CHINA 栏目编辑:文二霞 ******************事故车维修中的车身防腐(四)臧联防(本刊编委会委员)全国技术能手、全国交通技术能手、第五届全国交通运输行业职业技能竞赛钣金项目冠军、中国汽车维修行业协会专家委员。

◆文/江苏 臧联防(接2015年第7期)三、结合面防腐结合面腐蚀是腐蚀类型中的一种常见形态,很多主机厂也会明确要求,车身修复时结合面部位需要进行防腐处理。

结合面是指相邻个体间接触的面,在车身上主要有折边、凸缘、单纯搭接等主要表现形式(图56)。

折边结合面常见于车门、发动机盖及行李箱盖的边缘连接处;凸缘常见于密封条、玻璃等安装部位,如门框、风窗框等,有些部位钢板拼接时也会采取这种方式,以便于施工及增加连接强度,如纵梁、横梁接合部位;单纯搭接是车身上最为常见连接方式,如车身底板、后围板及加强板等。

结合面内侧也为空腔结构,从严格意义上讲,结合面防腐应属于空腔防腐的一种类型。

但是结合面内侧空间较小,间隙一般只有十几甚至几微米,后期施工难度较大,一般要求在车身修理过程中及时进行防腐操作,与空腔防腐操作有一定区别。

结合面一般可采取以下几种方式进行防腐操作。

图56 结合面主要表现形式1.空腔注蜡常用于折边结合面防腐,这些部位内侧空间小、结构复杂,电泳涂层及常规的油漆涂层一般难以达到防腐要求(图57)。

车门、发动机盖及行李箱盖更换后,应使用抽拉式防腐枪,从内侧维修孔处伸入,沿车门边缘采取注蜡方式进行防腐。

图57 车门破拆后折边结合面出现锈迹 2.施涂折边胶折边胶主要用于折边部位(图58),可以替代电阻焊点,保证外观平滑、美观,还可以增加强度、密封车体及防止腐蚀的作用。

折边胶需要高温固化(约180℃,30min),维修企业的设备、设施难以满足施工要求,一般仅在车身制造厂使用。

车身维修时可使用合适型号的次结构胶替代。

图58 车门折边胶3.施涂锌粉漆锌粉漆,一种富锌涂料,常见的有刷涂型和自喷型两种(图59)。

Sikaflex-252 高强度结构胶粘结剂Sikaflex-252 结构胶粘结剂说明Sikaflex-252结构胶粘结剂是一种不下垂、高密度的膏状单组份聚氨酯粘结剂,其与大气中的湿气反应固化形成一种永久性的弹性物质。

Sikaflex-252是严格按照ISO9001/14001质量保证体系生产制造的粘结剂。

Sikaflex-252结构胶粘结剂优越性:—单组份构成—具有弹性—表面可喷漆—良好的填缝性能—承受高强度动载荷—无腐蚀—减震—不导电—可粘结多种材料Sikaflex-252结构胶粘结剂是按照汽车原厂最高级别标准质量控制,严格生产制造出的胶粘剂,为全球各大汽车原厂、机场、改装厂、4S维修中心广泛使用。

Sikaflex-252结构胶粘结剂技术数据:化学组份单组份聚氨酯密度(DIN 53479)(未固化) 1.16-1.22kg/L 取决于颜色稳定性(不下垂性) 很好颜色白,黑固化方式湿气固化表干时间* 约40分钟固化率* 约4mm/24小时邵A硬度(DIN 53505)约为55断裂延伸率(DIN 53504)>300%拉伸强度(DIN 53504)约为4N/平方毫米剪切强度(EN 1465) 使用厚度4mm 约为2.5N/平方毫米撕裂强度(DIN 53515)约9N/mm收缩率(DIN 52451)约6%电阻系数(DIN 53482)约为10个十次方Ωcm 玻璃转化温度(DIN 53445)约为-40℃移动修正系数20%工作温度(连续)短期(最多8小时)-40℃~+90℃ 120 ℃保质期(储存温度低于20℃)9个月注:* 在23℃及50%相对湿度下Sikaflex-252结构胶粘结剂应用范围:Sikaflex -252适合于在受动载荷的部位进行结构性的粘结。

适用的材料包括木材、金属、尤其是铝(包括阳极氧化的部件)、钢板(包括磷化过、镀铬和镀锌的部件)、金属底漆和漆面(双组份)、陶瓷材料及塑料。