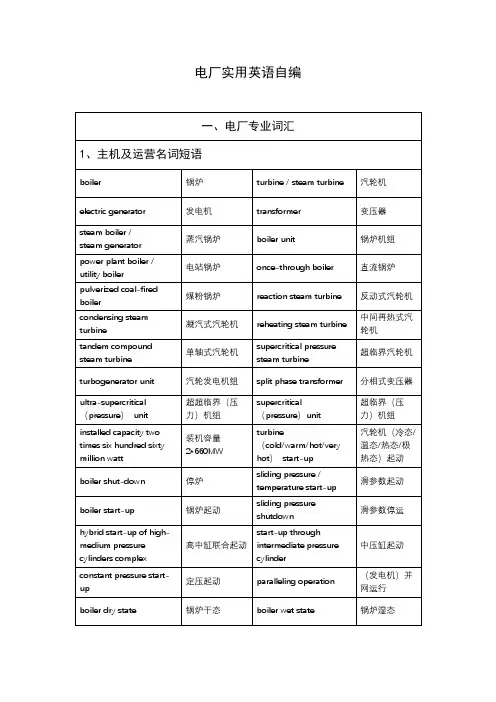

发电厂运行维护常用英语

- 格式:doc

- 大小:45.50 KB

- 文档页数:7

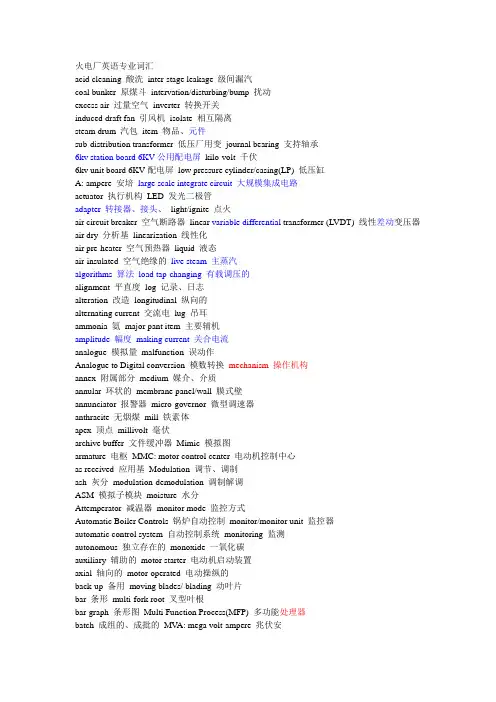

火电厂英语专业词汇acid cleaning 酸洗inter-stage leakage 级间漏汽coal bunker 原煤斗intervation/disturbing/bump 扰动excess air 过量空气inverter 转换开关induced draft fan 引风机isolate 相互隔离steam drum 汽包item 物品、元件sub-distribution transformer 低压厂用变journal bearing 支持轴承6kv station board 6KV公用配电屏kilo-volt 千伏6kv unit board 6KV配电屏low pressure cylinder/casing(LP) 低压缸A: ampere 安培large scale integrate circuit 大规模集成电路actuator 执行机构LED 发光二极管adapter 转接器、接头、light/ignite 点火air circuit breaker 空气断路器linear variable differential transformer (LVDT) 线性差动变压器air dry 分析基linearization 线性化air pre-heater 空气预热器liquid 液态air-insulated 空气绝缘的live steam 主蒸汽algorithms 算法load tap-changing 有载调压的alignment 平直度log 记录、日志alteration 改造longitudinal 纵向的alternating current 交流电lug 吊耳ammonia 氨major pant item 主要辅机amplitude 幅度making current 关合电流analogue 模拟量malfunction 误动作Analogue to Digital conversion 模数转换mechanism 操作机构annex 附属部分medium 媒介、介质annular 环状的membrane panel/wall 膜式壁annunciator 报警器micro-governor 微型调速器anthracite 无烟煤mill 铁素体apex 顶点millivolt 毫伏archive buffer 文件缓冲器Mimic 模拟图armature 电枢MMC: motor control center 电动机控制中心as received 应用基Modulation 调节、调制ash 灰分modulation-demodulation 调制解调ASM 模拟子模块moisture 水分Attemperator 减温器monitor mode 监控方式Automatic Boiler Controls 锅炉自动控制monitor/monitor unit 监控器automatic control system 自动控制系统monitoring 监测autonomous 独立存在的monoxide 一氧化碳auxiliary 辅助的motor starter 电动机启动装置axial 轴向的motor-operated 电动操纵的back-up 备用moving blades/ blading 动叶片bar 条形multi-fork root 叉型叶根bar-graph 条形图Multi Function Process(MFP) 多功能处理器batch 成组的、成批的MV A: mega volt-ampere 兆伏安baud rate 波特率natural gas 天然气bay 隔间natural/thermal circulation 自然循环bearing house 轴承座network 电网bearing pad 轴瓦neutral point 中性点binary 二进制的nitrogen 氮binary cell 二进制单元node 节点binary counter 二进制计数器notch V形凹槽bit 比特、位ohm 欧姆bituminous 烟煤oil 石油blank 毛胚oiled-cable 油浸式电缆blow 熔断open loop 开环blow/purge 吹扫open-cycle 开环blowdown pipe 排污管operation 运行/操作boil 沸腾operation condition 运行工况boiler/steam generator 锅炉optimum control 最优控制Boil out 煮炉order polynomial 多项式breaking current 开断电流orientation 定位brown coal/lignite 褐煤outage 停运bubble 汽泡outdoor 户外的burner 燃烧器outer casing 外缸bus interface module(BIM) 总线接口模块overhaul 大修busbar/bus 母线overhead 架空的cable 电缆overhead transmission line 架空输电线calibration 检验overview 全貌、总的看法capacitance 电容oxidized condition/atmosphere 氧化气氛capacitive current 电容电流oxygen 氧capacitor 电容器palm terminal 星型capacity 容量panel 配电盘、屏、板carbon 碳parallel interface 并行接口cast resin transformer 树脂浇注变压器pedestal 轴承座casting 锻造pedestal 轴承座centerline 中心线peer 同类的central control room (CCR) 集控室permanent 长久的channel 通道、信道permanent magnet 永久磁铁character 符号字符permeability 磁导率charger 充电器PF burner/pulverized fuel burner 煤粉燃烧器chronological 按时间顺序的phase change 相变circuit breaker 断路器photo-electric 光电circular 圆形的pick-ups 采样器circumferential 周围的pilot exciter 副励磁机clearance 间隙pipe 管道closed loop 闭环plane 平面coal 煤plant-loop 厂环coal feeder 给煤机pneumatic pilot valve 启动控制阀coil 线圈power plant 电厂cold junction compensation 冷端补偿power station (水)电站collar 轴环power supplies 电源Commission 试运行pressure 压力commissioning operation 试运行pressure firing 正压燃烧common service system 公用系统pressure meter 压力表compatibility 兼容性、相容性probe 探针compatible 能共存的、兼容的Process Control Unit (PCU) 过程处理单元complete functional set 全功能组件programmable logic controller(PLC) 可编程逻辑控制器concentricity 中心度、同心度programmable read only memory(PROM) 可编程只读存储器condensate 凝结prolong outage 长期停机conductance 导纳protection and trip 保护和跳闸conductibility 电导率provision 备用conductor 导体proximate analysis 工业分析cone 锥体PT: potential /voltage transformer 电压互感器configure 组态pulverizer/mill 磨煤机conical 圆锥形的push button 按钮connected in star 星型连接push contact 按钮触点consumption 消耗pushbutton 按钮control accuracy 控制精度pyramid 锥体control action 控制作用quality 质量control and instrumentation(C&I) 控制仪表系统quench 灭弧control button(knob) 控制按钮radial 半径的、辐射状的control console(desk) 控制台Rotor 转子controller 控制器reactance 电抗convection pass 对流烟道reaction turbine 反动式汽轮机converter 变送器rear end 后端、末端cooling fin 散热片rectify 整流coordination control system(CCS) 协调控制系统reducing condition/atmosphere 还原气氛core 铁芯redundancy 冗余的coupling 联轴器redundancy bit 冗余位crack/cracking 裂纹redundancy testing 冗余测试creep 蠕变reheater 再热器critical pressure 临界压力reliability 可靠性CT :current transformer电流互感器reserve 备用cubical 机柜resistance 电阻cylinder 汽缸resolution 分辨率cylindrical 圆柱形的reverse video 反相显示D.C. resistance 直流电阻roll 毛胚deaerator(D.A)除氧器roof tube 顶棚管decimal 十进制的root 叶根demineralized water 除盐水rotor 转子density 密度RTD 热电阻diaphragm 隔板stator 定子dielectric 不导电的、绝缘的saturated water 饱和水digit display 数字显示scheme: system 系统digit signal 数字信号screw 螺钉dimension 尺寸search coil 控制线圈diode 二极管semiconductor 半导体directed forced-oil and forced-air cooled(ODAF) serial access 串行存取disconnecter 隔离开关serial interface 串(行接)口discrete 不连续的serpentine tube 蛇形管distribute control system(DCS) 分散控制系统shadow 跟随distribution 配电shaft 轴diverter 分压器shroud/shrouding 围带division wall 分隔墙shunt 使分流double shell structure 双层缸结构shut down 停机double-flow 双向流动side wall 侧墙dowel 销钉signal conditioning 信号调节drain pipe 疏水管silicon 硅Drain 疏水single-flow 单向流动dry 干燥基slave module 子模块dry and ash free 可燃基Slipping 滑环dry -core cable 干式电缆Solenoid 电磁dual 双重的solid 固态duct 风道sootblower 吹灰器dump 转存sophisticated 高级的、先进的duodecimal 十二进制square root 平方根duplicate 复制的、备用的stabilization 稳定性duration 持续时间start up 启动dynamic stability 动稳定start up/standby transformer 启/备变eccentricity 偏心度state-of the-art 有目前发展水平的economizer 省煤器stationary blades/ blading 静叶片ECR: economic continuous rating 额定负荷stator frame 定子机座eddy current proximity detector 电涡流式检测器steady-state 稳态EHV :extra-high voltage 超高压steam air header 蒸汽热风器electric pressure converter 电压转换器steam/water vapor 水蒸气electrical equipment/apparatus 电气设备steam-water -mixture 汽水混合物electro-hydraulic 电动液压的stop/emergency valve 截止阀emergency 紧急的stress 应力energy 能量stud/stub 管接头engineering unit 工程单位sub system 子系统error checking and recovery 错误检验和恢复subbituminous 次烟煤error detector 错误指示器subcooled water 过冷水error rate 误差率substation 变电站evaluate 求出的数量suction firing 负压燃烧evaporate 蒸发suite 一组exception report 例外报告sulfur/sulphur 硫excite 励磁sulphur hexa fluoride 六氟化硫exciter 励磁机superconductor 超导体expansion 膨胀superheater 过热器expansion tank 油枕supervise 监督管理extinction 熄灭、灭火surge 浪涌facia/fascia 仪器仪表板surge diverter 避雷器facility 设备、工具switch block 开关组fatigue 疲劳、软化switch cabinet 开关柜feed back 反馈switcher 开关feeder speed 给煤机转速信号Switchgear 开关柜finish 光洁度symmetry 对称度fir-tree root 枞树形叶根synchronization 并网fixed carbon 固定碳tap 分接头flow meter 流量计tapping winding 分接头绕组flow rate 流量temperature 温度flue 烟道tenon 榫头flue gas 烟气terminal 终端、端子forced draft fan 鼓风机terminal box 端子箱、出线盒forced/pumped circulation 强迫循环terminal device 终端设备forced-oil and forced-air cooled(OFAF) the action of a magnetic field 磁场作用forging 铣制the bottom half 下半部fossil fuel 化石燃料the control room 控制室frame 机座the dew point temperature 露点free standing 独立的the front pedestal 操作台front/rear wall 前/后墙the horizontal joint 水平接合面fuel /flue 燃料/烟道the operations panel 控制屏furnace 炉膛the top half 上半部furnace tube 水冷壁thermal efficiency 热效率fuse 熔断器thermal power plant 热电厂galvanic isolation 绝缘thermal stress analysis 热应力分析gas air header 烟气热风器thermocouple 热电偶gaseous 气态thermocouple 热电偶gauge glass 水位计thermodynamic instrumentation 热工仪表generator 发电机thrust bearing 推力轴承generator transformer 主变tip 叶顶gland segment/packing 汽封片token 令牌governing valve 铸造tolerance 公差governor 调速器transformer 变压器gravity 重力transmitter 变送器grid 电网transport 传送、运输ground coal /pulverized fuel 粉状燃料transverse 横向的harmonious 协调的trap 阻波器header 联箱trip 切除、切断、脱扣heat 热量/加热tube 管子hexadecimal 十六进制tube bundle 管排hierarchical 分层(级)的tube seat 管座high pressure cylinder/casing(HP) 高压缸tube sheet 管板horizontal 水平的tubular 管形的hydraulic power plant 水电站turbine 汽轮机hydrazine 联氨turbine supervisory instrument(TIS) 汽机监视仪表hydrogen 氢turning gear 盘车装置hydrostatic test 水压实验two-tier terminals 双列端子排igniter 点火器ultimate analysis 元素分析impeller/wheel/disk 叶轮Uniform :the same 相同的impulse turbine 冲动式汽轮机Uninterruptible power supply(UPS) 不断电电源impulse withstand voltage 冲击耐受电压unit transformer 厂用变indoor 户内的utility boiler 公用锅炉inductance 感抗V: volt 伏特inductive 感应的vacuum contactor 真空断路器inductive current 电感电流Vane 导叶industrial boiler 工业锅炉Vertical 垂直的inner casing 内缸Via 经由INNIS 网络接口子模块Vibration 振动instrument 测试仪表visual (inquiry)display terminal 直观显示终端instrument board 仪器盘visual communication 可视通讯instrument correction 仪表校正visual display unit (VDU) 直观显示元件instrument range 仪表量程visual frequency 视频instrument sensitivity 仪表灵敏度visual scanner 视像扫描器instrument terminal 端子、接线柱volatile 挥发分insulator 绝缘子volt free contact 电压自由触点integration 使完整W: watt 瓦特interconnection 相互water 水interface 接口water level 水位interlock 联锁wet-steam 湿蒸汽interlocking contact 联锁触点wind box 风箱interlocking signal 联锁信号winding 绕组interlocking switch system 联锁开关系统workhouse 模块intermediate pressure cylinder/casing(IP) 中压缸Zener diode 齐纳二极管internally 内部的zig-zag rod Z型拉筋interruption 开断。

发电工程常用英语词汇及短语AN ENGLISH-CHINESE GLOSSARYOFPOWER GENERATION ENGINEERING河北电力勘测设计院一九九六年十月目录综合部分................................................................ 1~9 机务部分热机................................................................ 9~22 输煤................................................................ 22~25 化学水................................................................ 25~28 除灰................................................................ 28~29 电气自动化部分热控................................................................ 29~41 电气................................................................ 41~57 土建部分................................................................ 57~71 水工部分................................................................ 71~78 系统部分电源网络................................................................ 78~80 网络保护................................................................ 80~84 远动................................................................ 84~87 通信................................................................ 87~88 环保部分................................................................ 88~92 技经部分................................................................ 92~111 勘测部分................................................................ 111~120英汉对照 1 综合部分综合部分Aa board of directors 董事会acceptable risk 可接受的风险addendum of contract 合同附录advanced and proven technique, high quality and good performance 先进成熟的技术,高的质量和良好的性能a letter of intent 意向书alternative 两者之一,可供选择的方案(方法)analysis of normal, abnormal and emergency conditions 正常、不正常和事故情况分析annex, appendix 附录annex (appendix) of contract 合同附件a point(problem) of (under) negotiation正在谈判中的问题applicable standards 适用标准argon arc welding 氩弧焊接as-built conclusion 竣工结论(总结)as-built drawing 竣工图as-built drawings and other associated technical information 竣工图及其它有关的技术资料as specified 按照说明assure smooth completion of the plant construction and facilitate fulfillment of the design requirements 保证电厂施工顺利完成并便于实现设计要求at the time of placing of the order在发出定货单时authorized inspector 公认的检查员Bback up each other 相互备用based on industrial standard or equivalent以工业标准或相当的标准为依据basic design information to be provided by the Buyer 买方提供的基本设计资料basic information required for seller’s design 买方设计所需基本资料basic requirement for power plant design电站设计基本要求be duly taken into account (consideration)给予适当考虑be of similar design if possible 如果可能采用类似的设计be (go) on stream 投入运行be responsible for explaining the design documents and relevant design intention 负责解释设计文件和有关的设计意图be standardized as possible 尽可能标准化bidder 投标者bid bond 契约bid for the project 对该工程投标bid specification 召标技术条款bill of material (quantities) 材料(数量)清单boiler yard elevator 锅炉场地电梯break the terms of agreement违反协议条款Buyer’s participants witness reports and co-signatory reports of the Buyer representative 买方参与见证报告和买方代表联名签署的报告B uyer’s construction team for directconstruction 买方直接施工的施工队by this design 按照这种设计by way of open international bid采用公开的国际召标方式Ccall for tenders 召标candidate firms 后选厂家capability of the manufacturer to meet the construction schedule 制造厂家满足施工进度的能力英汉对照综合部分2certificate of delivery (C/D) 交货证明书英汉对照3综合部分closed tender 非公开召标collect design information 收集设计资料come into force upon signature 签字后立即生效come to (arrive at,make) a technical agreement through mutual negotiation and discussion 通过互相协商讨论达成技术协议commencement date 开工日期commercial personnel 商务人员competitive-bid 召标,投标竟争competitive bidding system, competitive price召标制,标价complete without missing any items完整而不遗漏任何项目completion of commissioning 试运行的完成conceptual (preliminary) design 概念(初步)设计working drawing design 施工图设计condition of economy and rationality经济合理条件confirm the vendors and subvendors of equipment selected by the seller确认卖方选定的设备售货商和分售货商conform to contractual clauses遵守合同条款construction (working) drawing delivery schedule 施工图交付进度construction machineries and tools施工机械和工具construction master (milestone) schedule and delivery of equipment 施工主进度及设备交付construction period 施工期间construction scale of the contract power plant and its present construction capacity 合同电厂的建设规模及目前的建设容量construction scheme 施工方案(计划) construction site visit 施工现场调查construction stage of the contract plant合同电厂的施工结段consumable for erection work安装工作用消耗性材料consumable and consumable materials消耗品和消耗性材料continue in force 继续生效contract date (drawing, number, price)合同日期(图纸,号,价格)contract work (construction)发包或承包工程(施工)contract effective date. effective date of the contract 合同生效日期contract power plant 合同电厂contracting packaged deal projects of power plant construction 承包电站建设整套工程项目contractor 承包商contractual obligation 合同义务contractual specifications 合同规定Ddate of delivery 交货期deliver the goods 交货,常用来表达“完成任务”的意思delivered equipment 交付的设备delivery schedule 交付进度delivery sequence and schedule specified in the contract on the basis of overall construction 根据总施工进度在合同中规定的交付顺序和进度design basis 设计依据design boundary definition 设计边界定义design boundary point 设计边界点design change 设计变更综合部分 4 英汉对照design criteria and site conditions设计准则和现场条件design data to be provided in due time(in time) 在适当的时候(及时)提供的设计依据design document and design intention设计文件和设计意图design liaison meeting 设计联络会design phase (stage) of the contract power plant 合同电厂的设计阶段design procedure: preliminary feasibility study,project proposal,feasibility study设计工序:初步可行性研究,项目建议书,可行性研究design representative 设计代表design service and delivery of technical documentation 设计服务和技术文件交付design for high operating efficiency and maximum reliability 按高运行效率和最高可靠性设计designated type 指定型号desirable overall schedule 合乎需要的总进度detailed construction drawings and technical information 详细施工图和技术资料details of construction drawing content施工图内容的细节details of work of the design representative 设计代表的工作细节developed through extensive and intensive research 通过广泛深入地研究发展起来的director 董事长discrepancies between general technical specifications in the contract appendices and standards concerned 合同附件中一般技术规范与有关标准的不一致dispatch and treatment of seller’s and Buyer’s personnel 卖方和买方人员的派遣和待遇draft 草案during final (preliminary) design stage在最后(初步)设计阶段during normal start-up of the power plant在电厂正常起动时Eeffectiveness of relevant minutes of meeting 有关会议记录的效力eligible experienced and well reputable manufacturers and trading companies合格的,有经验的,信誉良好的制造厂家和贸易公司engineering and design service工程和设计服务equipment inspection procedure content and method 设备检验程序、内容和方法equipment prestart-up inspection 设备起动前的检验equipment tabled hereinafter 以下表中所列设备equity capital 投资于新企业的资本erection tool and provisional material安装工具及临时性材料estimated shipping dimensions and weight估计装船(发货)尺寸和重量event sequential recording 事件顺序记录exclusive clause 专一条款exclusive right 独家购买权,专买权ex dock (factory, goddown)码头(工厂,仓库)交货executive 计划实施人,高级职员exemplary records and good reputation模范实践及良好信誉expertise 提出(作出)专业性意见(鉴定) export-oriented industry 面向出口的工业英汉对照5综合部分Ffavorable loan term 合适的贷款条件field quality control 现场质量控制final adjustment of the site layout现场布置的最后调整finalize the work details of technical service 最终确定技术服务的工作细节first major overhaul 第一次大修for the reference of the seller’s detailed design为卖方详细设计参考forced outage rate 强迫停运率force majeure 不可抗拒力foreign exchange 外汇for the convenience of maintenance and inspection 为便于维护和检查free on board (FOB) 船上交货(离岸价) fully consider questions raised by the Buyer 充分考虑买方提出的问题fully experienced manufacturer有充分经验的制造厂家fully satisfy the requirements for direct construction 完全满足直接施工的需要Ggas welding, welding torch (blowpipe)气焊, 焊枪general welding rod 一般焊条general(technical) requirements一般(技术)要求give technical advice and design service提供技术建议和设计服务goods exchange and payments agreement换货和付款协定grand total 共计total, sub-total 总计, 小计guarantee a market for 包销, 保证…的销路guaranteed value 保证值Hhigher economic effectiveness较高的经济效益hold technical talks with foreign manufacturers 与外国制造厂家举行技术会谈hybrid operation 混合式运行Iif any 如果有的话if necessary 如果需要的话index-linked price 指数化价格industrial(technical,engineering) standard工业(技术、工程)标准initial a contract 草签合同in(out of) operation 运行中(停止运行) inquiry, request for proposal 询价书in-service, out of service 投入运行, 退出运行inspection, commissioning and acceptance test 检验、试运行和验收试验interface of works carried out by both parties 双方进行工作的衔接International Tendering Company of China National Technical Import Corporation中国国家技术进口公司国际召(投)标公司invite tenders 召标invited firms 被邀请的厂商irrevocable contractual clauses不可废止的合同条款Jjoint approval meeting, approval agreement 联合审批会议, 查批协议joint venture agreement合资协议Kkeep the construction cycle to the minimum duration 使建设周期缩短到最短期限L综合部分 6 英汉对照laboratory tests 室内试验list of basic design information基本设计资料清单loan agreement 贷款协议local fabrication 就地制造Mmain contents of conceptual design概念设计的主要内容main contract 主合同main negotiator(talker) 主谈人main site service item 主要现场服务项目maintenance cycle, schedule and items维修周期、进度和项目major specification and attached drawings主要技术规范和附图make appropriate arrangement 作出适当的安排make (enter into) a contract with M for N就M同N签合同make use of existing equipment and facilities to the great practical extent 在最大实际可能的程度上使用现有设备和设施mandatory clause 必须遵守的条款master(primary) and slave(secondary) clock 母钟和子钟material to be shipped by the first shipment 第一批装船的船运材料mature technology and proven equipment成熟的技术和经过验证的设备maximum continuous rating 最大连续出力mean time between failures (MTBF)平均无故障时间meeting agenda 会议日程medical service 医疗服务metric system 米制系统microfilm of complete design document完整设计文件的微缩胶片minimum duration 最短持续时间minutes of meeting 会议记录minutes of talks, notes on talks会谈记要moving, lifting and storing of equipment设备的搬运、起吊和储存multi-discipline 多工种(学科)mutual agreement 共同(相互)协议Nname-plate rating 铭牌额定值necessary equipment other than these除这些设备以外的所需设备nondestructive examination 非破坏性检查normal or abnormal plant operation正常或不正常的电站运行情况number of personnel of different specialties 不同专业的人员数量number of start-ups and life consumptions起动次数和寿命消耗Ooffer 报价, 报盘official submission 公开投标on-site heat treatment equipment现场热处理设备on-site technical service 现场技术服务open a sealed bid 开标open tender 公开召标operation (maintenance, production,management) personnel运行(维护、生产管理)人员optimization study and calculation最优化研究和计算option 选择自由,选择权outline outer shape 外形outside relationship 外部关系overall construction schedule 总施工进度overhaul inspection 大修检验overreach or underreach 动作区(时间)延英汉对照7综合部分长或缩短Ppackage bid 一揽子要价,一揽子承包performance assurance, test and inspection, witnessed test 性能保证, 试验和检查, 见证检查performance test during maintenance维护时的性能试验pitch bead welding 斜坡堆焊焊缝place special emphasis on operating reliability特别强调运行的可靠性pre-acceleration, post-acceleration 前加速, 后加速precautions(measures) taken in accordance with actual situation 根据实际情况采取的措施prefix 词头mono- 一di- 二tri 三tetr(a)- 四pent(a) 五hex(a)- 六hept(a) 七oct(a)- 八non(a)- 九dec(a)- 十predicted (guaranteed) performance预计(保证)性能preliminaries 准备工作(措施),初步行动preoperational test-run 运行前试运转previously confirmed equipment delivery schedule 早先确认的设备交付进度produce the first set of construction drawings 绘制第一批图纸product inspection record, testing report and quality certificate 产品校验记录, 试验报告和质量证书progress report on the development of the construction drawings 绘制施工图的进度报告project construction manager 工程(施工)经理project milestone 工程里程碑proposal and loan conditions建议(报价)和贷款条件protective clauses 保护性条款proven quality and advanced technology证明是令人满意的质量和先进技术provide technical service in the design at seller’s expense 在设计中提供由卖方承担费用的技术服务provisional materials 临时性材料proviso, provisory clause 附带条款put in(or make) a tender for sth 为某事投标put into effect(action, practice, play) 实行, 付诸实践put into operation(service) 投入运行(使用)put M in(into) force 使M生效put out to contract, contract out 包出去Qqualification and bidding document合格证明及投标文件(标书)quality assurance and quality control质量保证和质量控制qualify the product by means of a certificate 用证明书证明产品合格questions raised by the Buyer 买方提出的文题quotation document 报价书Rraise funds to build a power plant集资建电站综合部分8 英汉对照reference power plant 参考电站represent the current technical level代表当前的技术水平reproducible copy 能复印的复制图纸(考贝)request for proposal 询价书requirements of quick action,selectivity sensitivity and reliability 速动性、选择性、灵敏性和可靠性要求reserve the right to…保留…的权利resolve any design problems during the construction phase 解决施工期间的任何设计问题respondent 响应者(厂家)return immediately to its stable and continuous operating condition立即恢复到(它的)稳定和连续运行情况review and confirm the conceptual design审查和确认概念设计review of construction drawings and make suggestions of design improvements施工图审查和提供设计改进的建议Sscope of responsibility 职责范围scope of technical service 技术服务范围sealed bid 密封投标seller’s (Buyer’s) country 卖方(买方)国家separate negotiation 个别协商service life 使用(服务)寿命settlement of balances in RMB差额以人民币结算shipment condition 装运条件shipping schedule 装船进度shipping sketch of heavy and bulky cargo重件和大件装船(运输)草图shorten manufacturing period 缩短制造周期sign a contract 签定合同signing of design agreement 签定设计协议similar power plant 同类型电厂similar size power plant 相似规模的电厂special tool 专用工具special tools and tackles necessary for erection and overhaul 安装和大修所需的专用工具和装备special tools for installation and maintenance 安装维修用专用工具special welding equipment 专用焊接设备specific requirements for proposal对询价书的具体要求standard penetration test 标准贯入试验stipulations concerning the delivery of technical information 有关提交技术资料的规定stream time 连续开工时间, 工作周期submit a tender 投标subsidiary company 子公司sub-supplier 分供货厂家suggestions on the production and working organization and various personnel of the power plant 对电厂的生产工作组织机构和各种人员的建议supplier 供货厂家systematic guidance necessary demonstration 系统指导和必要的示范Ttake appropriate measures 采取适当的措施take full responsibility of the construction work 对施工工作负全责talks participants(attendants) 谈判参加人technical advisory personnel 技术咨询人员technical coordination discussion and negotiation 技术协调、讨论和协商technical coordination for technical criteria英汉对照9综合部分of conceptual design 概念设计技术准则的技术协调technical talks 技术会谈technically skillful,healthy and competent technical personnel 技术熟练、健康和有能力的技术人员technical review 技术审查technicians of both parties 双方技术人员tender (bid) 投标, 召标tender document 交单tender(bid) evaluation 投标评估tender for the whole project on a turnkey basis在整体投标的基础上为整个工程投标tentative regulations暂行规定terms of grace宽限条款terms of reimbursement偿付条款test pieces for training high pressure part welders 培训高压部件焊工的试件testing equipment, calibrating equipment试验设备, 校准设备test report with certificate附有证明的试验报告test,trial run,maintenance and training servicing 试验、试运行、维护和培训服务the first set of construction drawing第一批图纸the time of acceptance of the equipment设备验收时间the turnkey delivery of complex installations concerning generation,distributation and application of electric power 承包有关电力生产、分配和应用的整套综合装置的安装和启用thorough and comprehensive scope of services完善而全面的服务范围to be complete without missing any items完整而无任何遗漏to be delivered by stages and lots分期分批交付to be provided in A copies 提交A 份to be signed by both parties 双方签署topography of the site greatly effected by human activities 受到人类活动很大影响的厂址地形to prepare official technical document编制正式技术文件to submit conceptual design document提交概念设计文件total contract price 总合同价格total working time …man-month总工作时间…人月to the Buyer F.O.B 用船上交货方式交付买方F.O.B. date 船上交货日期trade contract 贸易合同training of operation,maintenance,test and management personnel 对运行维护、试验和管理人员的培训training program,training duration and trainee’s specialties 培训规划、培训持续时间和(受)训人员的专业turnkey 交钥匙turn-key bid 整体承包投标turnkey contract 整套承包(合同),交钥匙承包turnkey delivery承包(建筑安装工程的)安装和启用turnkey job (使建筑安装工程达到投产或使用的)承包turnkey project 交钥匙工程综合部分10 英汉对照turnover 成交量Uunanimously agreed by both parties(sides)双方一致同意unless otherwise specified in thespecification除非在技术规范中另有规定(说明)use RMB for quitting prices and settlingaccounts 用人民币计价结算Vvariations of the site conditions 现场条件的变化verification,linarization compensation and英汉对照机务部分:热机专业11filtrating as well as the conversion ofengineering units 校准,线性化补偿和过滤以及工程单位算visa application 签证申请visit a construction site of similar power plant调查同类型电厂的施工现场Wwelds of structural members 构件的焊缝wharf(dock,pier), port, berth 码头,港口、泊位with adequate margin under variousoperating modes 在各种运行方式下具有足够的裕度within 15 minutes per one time and less than80 hours per any 12 months 每次在15分钟内并且在任一12个月中小于80 小时witness inspection items 见证检验项目witness report 见证报告win a tender 中标working hours based on 6 days of work per week 以每周工作6天为基础的工作小时(数)机务部分热机Aaccumulated water in the sump pit污水坑中的积水adequate pressure relief facility适当的压力释放装置adjustable tilting angle 可调倾斜角adjustable (fixed pitch) vane; guide vane可调(固定节距)叶片; 导向器叶片admission, exhaust, extraction steam进汽、排汽、抽汽air (band) brake 气(带)闸hydraulic (water) brake 液压(水力)制动air distributor 空气分配器air extraction equipment 抽气设备air gap length 气隙长度bearing span 轴承跨距air intake valve 进气阀air leakage of the air preheater 空气预热器的空气泄漏all the equipment installed outdoors 安装在室外的所有设备allowable main steam pressure at the main stop valve inlet 主汽阀入口处允许的主蒸汽压力allowable momentary maximum pressure during abnormal condition 不正常情况下允许的短时最大压力allowable steam pressure (temperature)允许蒸汽压力(温度)allowable stress 允许应力allowance, tolerance 容差aluminum corrugate(d) sheet 铝波纹板an allowance of 15% for contingencies留出15%的裕度作为应急费angle of internal friction, allowable bearing capacity, allowable frictional resistance内摩擦角,容许承载能力,容许摩擦阻力annealed copper wire 退火(软铜)导线annual mean pressure during no-load operation 空载运行时年平均压力anti-contamination type 防污型arrangement and location of major equipment主设备部置和位置artesian groundwater 自流地下水assembly longitudinal (transverse) section drawing 组装纵(横)断面图atmosphere relief diaphragm 防爆门机务部分:热机专业英汉对照12at rated output with 0.12 back pressure and 3% make-up 在0.12背压和3%补给水时额定出力情况下autoignition of brown coal 褐煤的自燃automatic start and stop device for oil recovery pump 油回收泵的自起停装置auxiliary boiler 辅助锅炉avoid oxygen introduction to the boiler steam drum 避免氧气进入锅炉汽包axial-flow 轴流式axial vibration 轴向振动eccentricity of rest 静态偏心率Bback pressure 背压backup, reserve, spare, standby 备用baffle plate 隔板bar screen 条筛, 清污机barring speed 盘车速度barter 易货base for skidding 滑动用底板balance piston 平衡活塞bearing and pedestal 轴承和支座bearing bracket 轴承支架bearing cooling water system (cooler, pump, head, tank) 轴承冷却水系统(冷却器,水泵,高位水箱)belt skimmer 带式撇沫器plastic-made plate pack 塑料制迭板bend pipe 弯管elbow bend, Y-bend 弯头, 三通管bending stress 弯曲应力hoop stress 环向应力be on duty for 8 hours in day time and no-man operation during other time 白天为8小时值班,其它时间为无人(值班)运行be (become) operational 可供使用(开始运行) better aerodynamic efficiency 较好的气动效率blade-attachment groove 叶片固定槽blade ring 叶栅blow tank, drain trap 疏水箱boiler acid cleaning equipment 锅炉酸洗设备boiler casing 锅炉护板refractory and insulation 耐火材料和保温boiler feed pump turbine with driven steam from main turbine IP exhaust extraction or cold reheat steam 驱动蒸汽来自主汽机中压抽汽或冷端再热蒸汽的锅炉给水泵汽轮机boiler front (rear, side) 炉前(后,侧) boiler make-up water pretreatment system锅炉补给水预处理系统boiler proper (itself) being tightly enclosed 锅炉本体紧身封闭boiler steam drum 锅炉汽包boiler thermal efficiency 锅炉热效率boiler,turbine and generator (BTG) board and auxiliary panel 锅炉、汽机和发电机空制台和辅助盘bolt fastening method 螺栓固定方法bottom level at entrance 入口底部标高brake 制动(刹车)breakthrough capacity 漏过(贯流)能量brief technical description and general layout (arrangement) of the reference power plant 参考电厂的简要技术说明和总布置bunker gate 煤斗闸板regulating gate, sliding gate 调节门,滑动闸门by burning coal only,and without support oil firing 仅烧煤而不投烧辅助燃油by using thermometer method 采用温度计英汉对照机务部分:热机专业13法Ccam 偏心轮cam gear, crank shaft 凸轮装置,曲轴capability of overload 过负荷能力casing, cylinder 汽缸casing-rotor differential expansion(differential expansion between casing and rotor) 汽缸—转子间胀差,汽缸膨胀chlorinator 加氯器injector, evaporator 注入器,蒸发器circular orifice 圆形孔板plate orifice, throttle orifice 盘式孔板,节流孔板circulating water pipes and valves in turbine hall 汽机房内的循环水管和阀门clockwise 顺时针方向的(地)counter clockwise 逆时针方向的(地) coal burner and coal pipe 煤粉燃烧器和输煤管coal chute 落煤管coal feeder and pulverizer 给煤机和磨煤机coal-fired unit 燃煤机组coal for boiler design 锅炉设计煤质kind of coal 煤种coal sampling tap 取煤样口coal (water) source, ash storage,communication and transport 煤(水)源,贮灰,交通及运输coefficient of permeability, permeability coefficient 渗透系数colorimetric analysis 比色分析molybdenum 钼come (go) into (or bring…into) operation投入运行common services for a power plant电厂的公用设备common to two turbines 两台汽机公用completely enveloped by water spray被水喷雾完全包围condensate pump head 凝结水泵压头condensate recovery tank 凝结水回收水箱condensation point 凝固点condenser on-load cleaning equipment凝汽器带负荷清洗设备condenser performance curve 凝汽器性能曲线condenser vacuum pump 凝汽器真空泵condenser water box air vent pump凝汽器水室排空气泵considerable reduction of overall length大大缩短总长度constant live steam temperature 恒定的新蒸汽温度constant pressure or sliding pressureoperation定压或滑压运行consumption calculation of the required fuel 需要燃料消耗计算continuous automatic sampling and periodic manual sampling of feedwater at selected points 在选定点给水的连续自动采样和定期手动采样control valve piston 控制阀活塞convert steam energy into electric energy by rotating the generator directly coupledwith turbine 借旋转与汽机直接藕合的发电机,将蒸汽能转变成电能cooler unit 冷却器装置coordination between turbine and boiler机炉协调correct alignment of the valve stem throughout the entire stroke 在整个行程中阀杆的正确找正correspond to approximately 15 days of coal机务部分:热机专业英汉对照14consumption for boilers of A units of B MW turbosets相当于A台B兆瓦机组锅炉大约15天的耗煤量corrosion and erosion resistant alloy防腐蚀和冲蚀合金crane and hoisting device 吊车和起吊装置crude oil 原油petroleum石油current carrying part of equipment设备的载流部件cylinder distortion气缸变形Ddaily load fluctuating operation日负荷变动运行damper档板deaerator bay and coal bunker bay除氧间和煤斗间deaerator recirculating pump 除氧再循环泵deformation (softening, melting) temperature 变形(软化,熔化)温度degasifier of vacuum type with steam ejector 具有蒸汽抽汽器的真空式除气器dehydrating breather with silicagel具有硅胶的脱水呼吸器demineralized water除盐水deoxidization (deoxygenization) indeaerator在除氧器中除氧depressurized residual oil 减压渣油design ambient temperature 设计环境温度design criteria of a similar plant or of a generic plant 类似电站或通用电站的设计准则designed differential head 设计压差designed to suit sliding pressure operation设计的适合滑压运行desuperheater (exhaust) spray 减温器(排汽)喷水desuperheating water 减温水deviation (departure) from design value对设计值的偏差dewatering via drain valves 通过疏水阀排水diameter, inside (outside) diameter 直径,内(外)径diesel oil (fuel)柴油diesel generator set 柴油发电机组differential expansion胀差(相对膨胀)diffuser outlet扩散器出口direction of rotation旋转方向discharge (delivery) head扬程discharge water of condenser cooling water 凝汽器冷却水的排水dissolved oxygen in the condensate pump outlet water 凝结水泵出口水中的溶解氧dosing equipment (pump)加药设备double amplitude (peak-to-peak) vibration of rotor shaft 转子轴双振幅(峰峰值)振动downcomer, riser, connecting pipe下降管,上升管,连接管downtime停机(停工,修理,不工作)时间draught system and boiler purge通风系统和锅炉清洗drawings for installation安装图drip-proof type防滴式driving steam source驱动汽源drum type rotor and radial sealing strips圆筒形转子和径向密封垫dual channel criterion双通道准则ductile iron 球墨铸铁dummy ring 填密环duration of vacuum extraction 抽真空(持续)时间dynamic (kinetic) head 动压头英汉对照机务部分:热机专业15Eearlier comprehension of the equipment and technical states of the power bloc 对主厂房的设备和技术状况较早的了解eccentric weight 偏心重锤economical thickness of the thermal insulation determined by the method minimum annual cost用最小年利用法确定的保温(层)的经济厚度economizer省煤器effective tube length有效管长ejector discharge抽汽器排汽管elevation (hydrostatic, hydraulic pressure) head 静压头elongation and contraction due to temperature change 由于温度变化引起的伸长和缩短emergency diesel generator set事故柴油发电机组emergency loads required for plant to shut down safety during power failure供电事故时使电厂安全停机所需事故负荷enthalpy, entropy焓,熵optimum parameters for the unit startups, shutdowns and emergency operations机组起停和事故运行时的最佳参数equipment fault rate设备事故率evaporation and thermal efficiency of the boiler 锅炉的蒸发量和热效率feed water heater drain tank and pump给水加热器疏水箱和水泵exhaust steam moisture (water) content排汽湿度exhaust shroud排汽管套expansion joint 膨胀接头expansion line膨胀线expected (estimated) value of heat rate热耗的期望(估计)值oxygen content of condensate 凝结水的含氧量Ffeed heating extraction供热抽汽feedwater heater drain pump给水加热器疏水器cooling water booster pump冷却水升压泵feedwater heater drain tank and pump给水加热器疏水箱和水泵feedwater temperature matching with turbine operation 与汽机运行配合的给水温度fiber (fibre) reinforced plastics 纤维增强塑料filter area (medium)过滤面积oil filter, filter plate and scraping plant油过滤器,过滤板和刮板fin (blade) pitch, tube pitch 肋片(叶片)节距,管距fine (heavy) mesh strainer细(粗)滤网fire-proof (resistant, retardant), nonflame propagating 防火(耐火,阻燃)的,不延燃的fire-retardant type belt 阻燃型皮带five pulverizers with four working and one standby 五台磨煤机四台工作一台备用flange connection 法兰接头flexible joint伸缩接头rubber (aluminum) bellows 橡胶(铝)波纹管flexible pipe软(蛇形)管flow (capacity) margin 流量(容量)裕度flue gas velocity 烟气流速flues and ducts and their dampers烟,风道及其挡板fluid coupling液力联轴器forced (induced) draft fan (centrifugal)送(引)风机(离心式)机务部分:热机专业英汉对照16forced-oil forced-air cooled heat exchanger 强油强风冷热交换器forward (axial) thrust前(轴力)推力thrust (force)推力foundation work of turbine hall, heater bay, silo bay and boiler area汽机房,加热器间,煤仓间和锅炉区的基础工程fracture appearance transition temperature, fracture-arrest temperature出现裂纹过渡的温度,裂纹终止的温度free from casing cracking 汽缸不致裂纹freeze protection for mechanical equipment by thermal insulation or heating (steam or electric) 用保温或加热(蒸汽或电)实现机械设备的防冻保护from start-up of steam generator and TG set under cold, warm and hot conditions to synchronization and then to full loading 从锅炉起动和汽轮发电机组在冷,温和热态下到同期,并随后达到满负荷front (rear, side) wall rifled tubing前(后,侧)壁内螺纹管fuel oil燃(料)油fuel oil used for ignition, start-up and flame stabilization purpose 用于点火、起动和火焰稳定目的的燃油fulcrum bearing 支承full atomization of the oil 油的完全雾化functional test (including margin tolerance) and corrected curves 功能试验(包括容差)和校正曲线furnace flame monitoring炉膛火焰监视furnace roof炉顶furnace water wall炉膛水冷壁Ggas (air) duct烟(风)道gasoline汽油gate 闸门,闸板gland exhauster fan轴封抽气器风机gland steam system轴封抽汽系统governor oil impeller 调速器油泵叶轮grade of surface preparation 表面预处理等级guaranteed temperature rise保证升温guide bearing导引轴承guide way导向槽sealing strip密封垫片Hhaving 1/1000 gradient具有1/1000的坡度header联箱heat balance diagram热平衡图heat losses due to radiation and convection 由于辐射和对流引起的热损失heat rate, coat consumption, auxiliary power consumption and unit efficiency热耗,煤耗,厂用电耗和单元机组效率heat rate conrrection curve热耗校正曲线heat transfer coefficient 传热系数heating surface, total (radiant convective) heating surface 受热面,总(辐射,对流)受热面heavy fuel oil tank and light oil tank重燃油箱和轻燃油箱heavy (light) oil 重(轻)油heavy fuel oil flow diagram 重燃油流程图high availability, high thermal efficiency and low consumption 高可用度,高热效率和低消耗high damping coefficient for vibration高的防振阻尼系数high (low) flush tank高(低)位冲冼水箱high grade alloy steel pipe 高级合金钢管high (low) heating value (as fired, as。

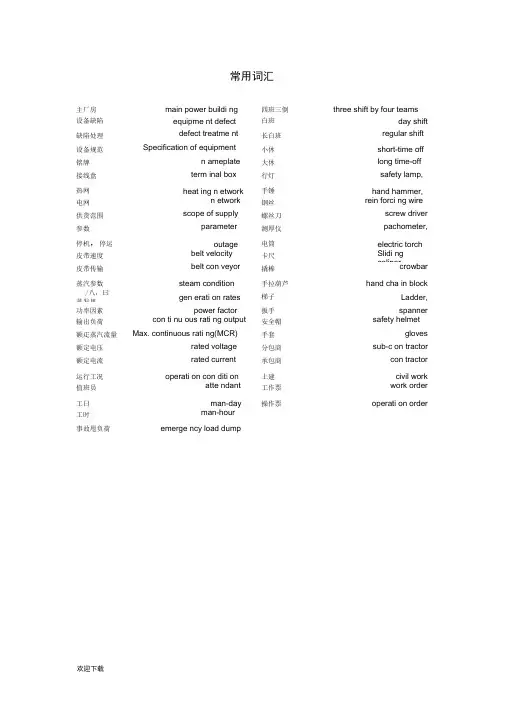

常用词汇主厂房main power buildi ng 四班三倒three shift by four teams设备缺陷equipme nt defect 白班day shift 缺陷处理defect treatme nt 长白班regular shift 设备规范Specification of equipment 小休short-time off 铭牌n ameplate 大休long time-off 接线盒term inal box 行灯safety lamp, 热网heat ing n etwork 手锤hand hammer, 电网n etwork 钢丝rein forci ng wire 供货范围scope of supply 螺丝刀screw driver 参数parameter 测厚仪pachometer, 停机,停运outage 电筒electric torch 皮带速度belt velocity 卡尺Slidi ngcaliper皮带传输belt con veyor 撬棒crowbar 蒸汽参数steam condition 手拉葫芦hand cha in block/八,曰gen erati on rates 梯子Ladder, 蒸发里功率因素power factor 扳手spanner 输出负荷con ti nu ous rati ng output 安全帽safety helmet 额疋蒸汽流量Max. continuous rati ng(MCR) 手套gloves 额定电压rated voltage 分包商sub-c on tractor 额定电流rated current 承包商con tractor 运行工况operati on con diti on 土建civil work 值班员atte ndant 工作票work order 工日man-day 操作票operati on order 工时man-hour事故甩负荷emerge ncy load dump锅炉循环流化床(锅炉) the circulati ng fluidized bed boiler (CFB)固体颗粒soiled particles 输煤机coal tran sporter 底渣bottom ash 煤粉锅炉pulverized coal-fired boiler循环灰circulat ing ash 上升管riser渣场slag yard 下降管dow ncomer 磨煤机coal pulverizer 烟囱stack 输煤系统coal handing system 过滤器stra iner 送灰器ash con veyer 母管mai n pipe 吹灰器soot blower 母线busbar除尘器precipitator 烟道flue 空气过滤器air filter 烟道挡板chi mney damper石灰石仓limesto ne silo 烟窗帽chi mney hood 给煤机coal feader 冷渣机slag cooler 返料装置material returning device 汽包steam drum布风板air distributor 流化风室fluidized air chamber 风嘴air no zzles 水冷壁water-cooled wall 风帽air cap 引风机induced draught fan 燃烧室combusti on chamber 送风机forced draught fan旋风分离器cyclone separator 一次风primary air 床料bed material 二次风sec on dary air布袋除尘器bag filter 排水设备drain age 静电除尘器electrostatic precipitator 排污箱blow dow n tank密相区dense region 排污系统blow dow n system 稀相区dilute regi on 烟道净化器flue gas purifier 煤仓coal bunker 联箱header (汇集分配工质)炉膛furnace过热器superheater再热器reheater管束(排)tube bun dle 蛇形管coil管屏tube plate n 吊挂管support ing tube鳍片管finned tube, fin tube, gilled tube风门air damper 变电站substati on 炉膛容积furn ace volume 避雷针lighte ning rod漏风试验air leakage test膨胀补偿节expa nsion joint 配电盘distribution board阻波器line trap 阻尼绕组damper winding 污油泵Sump pump 卸油泵Oil uni oadi ng pump 锅炉附件(锅炉辅助设备)boiler accessories 辅助设施auxiliary pla nt 烟道净化器flue gas purifier净热值Net heati ng value= :低位发热量low point heat value总热值total heat ing value= 高位发热量high point heat value空气干燥基水分Air dry radicle waterAir dry radicle bomb container heat Received radicle low point heat Boiler sand injectio n system 3-phase In ducti on motor Explosi on-proof循环流化床20. Limest one fan;「电除尘器 除尘器《布袋除尘器 稀相区dense regi on炉膛内*呻 、密相区 dilute region1 锅炉系统boiler proper system燃烧系统Combustion system空气干燥基弹筒发热量 收到基低位发热量 锅炉加沙系统 三相感应电机 防爆连接处有百叶窗(shutter )3跟2 1、煤仓; 4、 返料器; 7、冷渣器; 10、汽包; 13、空气预热器; 16、烟囱; 19、上二次风;1. Coal bun ker2. Fur nace 5. Exter nal heat excha nger 出来3内有旋风分离器(cyclone separator)2、炉膛;5、外置式热交换器;&石灰石仓;11、对流过热器; 14、电除尘器; 17、一次风; 20、石灰石风机3. Backpass of separators 6. Coal feeder8. Limest one silo; 11. convection superheater 9. Fluidized air chamber; 12. E c ono mizer; 14. Electrostatic precipitator (ESP); 15. I.D. fan;17. Primary air;18. Lower sec on dary air;3、分离器尾部烟道; 6、给煤机; 9、流化风室; 12、省煤器; 15、引风机; 18、下二次风;4. Material-retur ning device 7. Slag cooler 10. steam Drum; 13. Air preheater; 16. Stack19. Upper sec on dary air;electrostatic precipitator(ESP) bag filter蒸汽水系统2锅炉辅件系统stea m& water system boiler auxiliary equipme nt system「煤和石灰石系统coal and limest one system烟风系统€灰处理系统锅炉控制系统fuel gas and air system ash han dli ng system boiler con trol system点火系统3燃烧系统炉膛燃烧器〈煤道风帽空气预热器4汽水系统igniition systemIcombusti on system旋风分离器布风板点火装置(furnace返料器burnercoal ductair capair preheater steam and water system广汽包过热器低温过滤器高温过滤器「steam drumsuperheater<再热器联箱reheater省煤器减温器I下降管上升管econo mizer< dow ncomercyclone seperatorair distributorign iti on device material-retur ning devicelow temperature filterhigh temperature filterheadertemperature reducerriser5 循环流化床the circulating fluidized bed boiler ( CFB锅炉除尘排渣系统(boiler dust clean and slag extracting system 汽水系统烟风及燃烧系统steam-water system flue gas & air and combusti on system 输煤系统 f coal handling system辅机(风机)6煤粉炉*炉膛燃烧器煤道空气预热器j 一次风机二次风机I auxiliary system pulverized fuel boiler'furnaceburner* coal ductair preheater7汽包装置「排污装置蒸汽清洗装置加药汽水分离器steam turb ine equipme ntr blow down devicesteam clea ningdevice]dosingsteam-water separator8锅炉辅助设备广通风设备给煤设备给水设备运煤设备除尘设备boiler auxiliary equipment「draft equipme ntcoal feeder waterfeeder]coal transporterprecipitatorslag disposal equipme ntdraft equipme ntf primary air ( forced air ) sec on dary air in duced air 'material returni ng fan flue duct stackIslag disposal equipme nt'precipitatorash tran sporter 'slag cooler slag tran sporterLboiler accessoriesrsafety valvesoot blower i control device water level in dicator thermodynamic instrument除渣设备9通风设备J 次风(送风) 二次风 引风 (返料风机 烟风道 烟囱k10除渣设备 f除尘器 输灰机"冷渣机 ,输渣机11锅炉附件 「安全门 吹灰器 <控制设备 水位计 ;热工仪表汽机轴承beari ng分流器shu nt 锅炉补水处理boiler make-up watertreatme nt断路器circuit breaker 电路electric circuit 分流器shunt trip 电容器capacity 排气压力steam pressure at exhaust 排气消音器exhaust silencer 抽汽系统steam extracti on system 主蒸汽及盘路系统main and bypass system 凝结水系统conden sate water system 加热器疏水系统heater drains and ventssystem辅助系统auxiliary steam system 润滑油系lubricat ing oil system水处理系统water treatme nt system 闭式水循closed circle cooli ng water system 闭式冷却塔系closed cooli ng Tower system 主蒸汽及再热蒸汽系统main steam and reheat steam system 厂用及仪用压缩空气系统stationand 高压缸球阀闸阀疏水阀节流阀电磁阀截止阀主汽门(主蒸汽截止门)调节门逆止门抽汽调节阀主汽净化系统挡板调节自来水high pressure cyli nderglobe valve gate valvedrain valve throttlevalve Sole noid valvestop valve main stopvalve con trol valvecheck valveextract ion con trol valve mainsteam cleaning system damperadjustment raw waterin strume nt air compressed air system 过热器蒸汽系superheater and steam system 主厂房内厂用水系统service water systemin main building 顶轴油系统jacking oil system密封油系统seali ng oil system 轴封油系统gla nd and steam seali ng system轴封凝汽器gland (steam) condenser轴封供气阀gla nd seali ng valve 汽机盘路系统turb ine bypass system 汽水取样系统steam water sampli ng system 液压系统hydraulic system 液压选择阀hydraulic selector 排气消音器exhaust sile ncer 排气系统exhaust system 自动同步self-timi ng 畜压器accumulator鼓风机air blower 真空系统vacuum system 疏水泵循环泵灰泵胶球泵胶球清洗系统负压支吊架原料斗膨胀补偿节空气压缩器灰斗风门沸点盘车盘车投入振动报警振动给煤器振动除灰装置轴外部伸轴位移遥控限制器空气凝汽器drain pump circulat ing pumpash pump (rubber) ball pumprubber ball clea ning system negative pressure supports andhan gers raw material bunkerexpa nsion joint aircompressor ash hooper airdamper boili ng temperaturetur ning gear turning gearstart-up vibrati on alarm vibrating feederoscilating-type blower unitshaft exte nsion shaftdisplaceme nt remote con trollimiterair condenser注油器 oil injector 除盐水 dem ineralized water滤油网 oil filter排气过滤器 air vent filter机力通风塔 in duced draught tower热井hot well 机力通风冷却塔 forced draught cooli ng tower减温水 attempti ng water 汽蚀cavitati on 密封垫 gasket 扩容器 flash tank 除氧器 deaerator旁路bypass valve汽机冲转 run up 保安电源系统 Emerge ncy power supply system保安断路器safety cutout锅炉(水加热)一►蒸汽 一汽轮机(水释热)一〜 凝结器 一►给水泵一*锅炉Boilersteam steam turbi ne conden ser feed water pump boiler 2主蒸汽系统高低压主蒸汽 一 主汽门一 调门 一•高低压缸High pressure main steam main steam valve k control valvekhigh pressure cylinder一主蒸汽系统1郎肯循环二循环水系统(1.凉水塔,2•机力通风塔)循环泵 胶球泵in duced draught tower J circulat ing pumpball pumphigh pressure feed water pump service oil cooler chemistry sampli ng coolerlow pressure econo mizer recirculat ing pump gas turb ine closed water air compresser headi ng n etwork circulati ng pump cooler gas turb ine gen erator air cooler steam turb ine gen erator cooler gas turbine lubricating cooler steam turbine lubricating cooler expa nsion tank dem in eralized water feed water closed water pumpthe differe ntial pressure is too high of filter closed water heat excha nger rotary stra iner循环水泵一*凝结器一►机力通风塔胶球泵:清洗脏污四凝结水系统Hot well 一 " condensate pump * service main pipe ( attemptingwater )、mainpipe for miscellaneous use(temprature-reduction water)Steam turb ine gla nd seal heater三闭式水冷却系统 高压给水泵工作油冷却器 化学取样冷却器 低压省煤器再循环泵 燃机闭式水空压机 热网循环泵冷却器 燃机发电机空气冷却器<汽轮发电机冷却器燃机润滑油冷却器 汽机润滑油冷却器 膨胀水箱 除盐水补水 闭式水泵滤网压差大(报警)、闭式水换热器旋转滤网汽机轴封加热器盜展31MA热井 *■凝结水泵 ►杂用母管(减温水)轴封加热器出口调门 ----------------\燃煤炉低压加热器»高压加热器除氧加热器water- feedi ngpumpoutlet control valve of gland seal heater ----------------- ►- (feedpump)*■ high pressureheatercoal-fired boiler low pressure heart deaerati ngheater直流润滑油泵排烟风机注油器五油系统交流润滑油泵润滑油系统q板式换热器高压油泵r顶轴油泵顶轴油系统滤网模块'机械超速保安系统汽机胀差轴向位移]轴振瓦振低真空低油压I f-Alternate lubricating oil pumpLubricating oil system 彳plate exchangerHigh pressure oil pumpdirect lubricati ng oilpump vapor extractor oilinjectorJack ing oilpumpJacking oil system < filterModuleSecurity system六辅汽系统辅汽联箱轴封供气联箱辅汽联络母管mach ine overspeedsteam turb ine differe ntial expa nsion axial displacement( Shaft vibration watt vibrationLow vacuum pressure low oil pressure l{auxiliary steam headergla nd and steam seali ng air supply headerauxiliary steam linking main pipe{gla nd and steam seali ng heater exhaust fan厂 heat supply stationheating network circulating pump 彳 heat ing n etwork dra in pump rotat ing diaphragm < extraction check valveffi 1200 MW 供J® 廉统I 心由早星2 ii V©副汨|爲・J 冷血;K.4 尙扁仃 虞跆■ 7 H I *一馬片的谜用制tJ小H 剋用丼泊门电气八抽汽供热系统 七轴封系统:轴封加热器 排气风机 厂供热站热网循环泵 <热网疏水泵旋转隔板•抽气逆止门(防止倒流)1主要设备厂电机 励磁机 变压器开关(断路器) 隔离开关(刀闸) 熔断器(保险) 电动机母线(铜排 铝排)小母线:(控制回路,信号回路J 控制电缆tran sformer switch ( circuit breaker ) disc onnecting switch (isolati ng switch)fuse(safety fuse)motor busbar secondary busbar: con trol loop cable就地local控制箱 con trol box 就地盘表local pannel 油箱净化装置 oil purifier就地安装local mounted 启动准备就绪 ready for start up运方就地启动direct-on starting ( line-start )自动automatically远程启动 remore boot手动manu ally照明(箱) light ing自动-手动开关auto-manual switch电源进线power incoming line 试验trial 电源出线 outwards line outgo ing feeder ? 解除disma ntle出线端 outlet term inal 分闸ope n gate ( switch off )滤水器 water strainer合闸switch on 胶球清洗 rubber ball clea ning储能power storage汽机保安系统 steam turb ine security system退出quit 中间继电器 in termediate relay 退出运行outage压差pressure differenee 温度自动temperature automatic con troller单侧无(电)压 sin gle non e-voltage电源自动加热器power source automatic双侧无压 double side none voltage heat紧急终止同期 emerge ncy stop 外部联跳(低周减载)synchroni zati on 进线开关in-comi ng line switch启动同期工作 start-up synchroni zati on work进线端子in put term inal y自动校正 (同期)automatic correct ion 启动柴油发电机start-up diesel gen erator手动校准manual calibrati on配电盘switch board〜定子接地stator grounding液压油泵hydraulic oil pump 转子接地rotator grounding 防爆风机explosi on-proof fan定子接地保护stator ground protect ion调速油泵oil pump of speed adjustmentsystem排水泵drip pump厂 generatorexciter变压器变压器投运 In-service of tran sformer低压厂用干式变压器(三相环氧浇注式)Low voltage auxiliary dry type transformer(three-phase epoxy molded type) 变压器调压装置规定 Specificati on of tran sformer voltage regulati ng device 变压器的异常运行及事故处理 Accide ntal treatme nt and abno rmal operati on oftran sformer1所有有关工作票应办理终结并有可投运交待,拆除临时安全措施,恢复常设安全措施,现场清洁。

停运stop工作票work permit箱tank巡检site operator热机thermal mechanical网调grid dispatch center负荷load脱硝SCR除灰ash removal取水泵intake water pump启动炉start up boiler班shift值长shift supervisor拉灰ash transported by vehicle 拉渣slag transported by vehicle 交代事项instructions交待对象to交待人from交代事项content各值each shift混床mixed bed交代日期date高低加HP and LP heater调总 Commissioning Engineer电建Electric construction company 存煤coal storage投运put into operation传动remote control testing拉弧arcing凝泵condensate pump调试commissioning除盐Demineralization化学水池chemical water tank门valve发票issue work permit除尘ESP电除尘ESP发现discovered联系contact试运trial run抽真空vacuum extraction监视monitoring投入put into operation母管main pipe投put into operation除盐Demineralization运行operation结票completed the work permit联启combined start up进行start碱洗alkali cleaning循泵circulation pump门valve进氨门ammonia inlet valve泄露leakage启动炉start up boiler联系contact一种票first type work permit票work permit启动锅炉start up boiler上水feed water滤网filter换油oil replacement入口门inlet valve火检fire detector控制柜control cabinet火检风机flame detector cooling air fan 火检flame detector继保relay protection报警alarm瓦顶轴油压bearing jacking oil pressure报故障reported defects凝结水泵condensate water pump.电源开关power switch状态status查明原因to check the reason段失电stage lose power氨区ammonia area油库fuel oil tank area注意交接please pay attention to handover 投put into operation除盐Demineralization运行operation结票completed the work permit联启combined start up进行start碱洗alkali cleaning循泵circulation pump水位water level消防fire fighting振打rapping输灰ash conveying启动start up滤网filter换油oil replacement入口门inlet valve火检fire detector控制柜control cabinet火检风机flame detector cooling air fan 火检flame detector继保relay protection报警alarm瓦顶轴油压bearing jacking oil pressure 报故障reported defects凝结水泵condensate water pump.电源开关power switch。

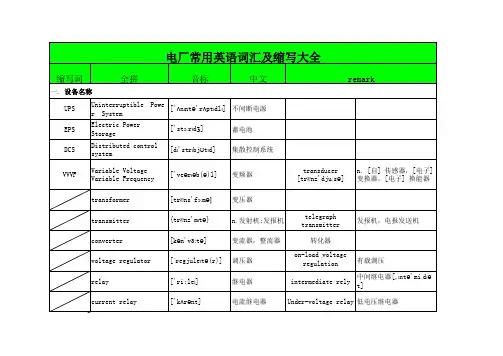

电厂常用英语词汇及缩写大全缩写词全拼音标中文remarkSQE Supplier qualityengineer供应商质量工程师SQD Supplier QualityDevelopment供应商质量改善SQ improvement供应商质量提高QA Qualityassessment/assurance[əˈsesmənt][əˈʃʊərəns]质量评价/保证ensure[ɪn'ʃʊə(r)] Vt.保证,确保,使安全QC Quality control[kən'trəʊl] 质量控制,质量管理QI Quality improvement[ɪm'pru:vmənt]质量改进QAP Quality AssurancePlanning[əˈʃʊərəns] 质量保证计划MQAP measuement qualityassurance procedure计量质量保证方案PO Production order[prəˈdʌkʃn] 生产订单CCC China Compulsory Certification[kəmˈpʌlsəri] 中国强制认证(3C认证)compulsory [kəm'pʌls(ə)rɪ]adj. 义务的;必修的;被强制的IBR INDIAN BOILERREGULATIONS [regjʊ'leɪʃ(ə)nz]印度锅炉规程n. [管理] 条例;规程;章则BV Bureau Veritas [ˈbjuərəu][ˈveritæs]法国国际检验;法国船级社BVQI法国国际检验局Corporation Shanghai Electric Corporation缩写词Siemens AG缩写词缩写词LR缩写词INC电厂常用英语词汇及缩写大全缩写词全拼音标中文remarkNPSHR Net Positive SuctionHead Required必需汽蚀余量UNEF Unified Extra FineThread统一标准超细牙螺纹1/4-28 UNF -2BUNF unified national fine美制细牙"仙人掌GG"的文档thank you!。

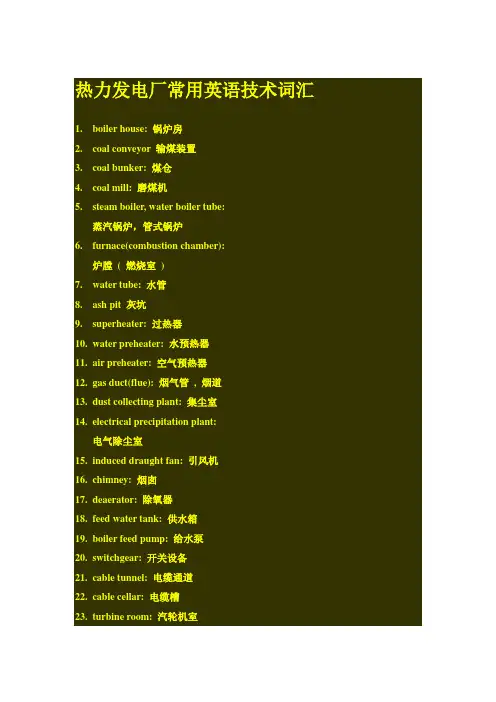

热力发电厂常用英语技术词汇1.boiler house: 锅炉房2.coal conveyor 输煤装置3.coal bunker: 煤仓4.coal mill: 磨煤机5.steam boiler, water boiler tube:蒸汽锅炉,管式锅炉6.furnace(combustion chamber):炉膛( 燃烧室)7.water tube: 水管8.ash pit 灰坑9.superheater: 过热器10.water preheater: 水预热器11.air preheater: 空气预热器12.gas duct(flue): 烟气管, 烟道13.dust collecting plant: 集尘室14.electrical precipitation plant:电气除尘室15.induced draught fan: 引风机16.chimney: 烟囱17.deaerator: 除氧器18.feed water tank: 供水箱19.boiler feed pump: 给水泵20.switchgear: 开关设备21.cable tunnel: 电缆通道22.cable cellar: 电缆槽23.turbine room: 汽轮机室24.steam turbine with alternator:a)蒸汽汽轮发电机组25.economizer: 省煤器26.steam drum: 汽包27.surface condenser: 表面凝汽28.low-pressure preheater:a)低压预热器29.circulating water pipe(pump):a)循环水管30.control room: 控制室31.electrostatic dust remover(precipitator):a)静电除尘器32.pulverizer 磨煤机33.slag pump 灰渣泵34.thermal cycle: 热力循环35.(net)heat rate: (净)热耗率36.Assemblie: 集合,集结,组装ment 注释,评论38.module : 模块39.standby: 备用40.proximity 相近,接近,亲近41.detector: 探测器42.bracket: 支架43.interlocks: 互锁,联锁44.axial: 轴向的45.surge conditions: 喘振:46.accessory: 附件47.pulsation: 有节奏的跳动,跳动48.fossil fired: 燃煤49.intent: 意图,目的,意向50.intend: 意指,想要,打算51.consistent: 一致的,调和的52.practice: 惯例,实习,实践53.intrinsic: 固有的,内在的54.procurement 获得,获取55.fabrication: 制作,构成,伪造物56.vent: 通风孔,出烟孔,出口,放出,排出,57.noncondensible gas: 不凝结气体58.intermittent 间歇的,断断续续的59.blowdown : 排污60.tank: 桶,箱,罐61.diagram: 图表62.deaerator: 除氧器63.corrosion : 侵蚀,腐蚀状态64.concentrationa)集中,集合,浓缩,浓度65.recommenda)推荐,介绍,托付,劝告66.abnormal and normal conditions:a)变工况和额定工况67.warm up: 暖机68.acid wash: 酸洗69.scale:a)范围;b)水垢,水锈;c)比例,刻度70.sludge :: 污泥,淤泥71.foreign matter: 不相关的物质72.facilitate: 推动,促进,使简化73.multistage: 多级的74.remote control: 遥控75.safety relief valve: 安全卸压阀76.gauge: 量规,量表,测量77.manhole: 人孔,检修孔78.equivalent: 等价物,相等的79.forging:: 锻造80.seat: 部位,座81.socket welding: 管座焊接82.enthalpy: 焓83.estimate: 评价,评估,估价84.parameters 参数,参量85.nominal :a)名义上的,额定的,标称的86.MS —Main Steam : 主蒸汽87.Cycle:: 循环88.Intercept: 截止89.Fetting: 附件90.Gage:: 规,表,压力计91.Taps: 接头92.test wells: 测点插孔93.stress-relieved: 应力消除94.thermometer: 恒温计95.steam purge system:a)蒸汽吹扫系统96.centrifugal type pumps:a)离心式泵97.friction losses: 磨擦损失98.solenoid: 螺线管99.modulat: 调整,调节100.criteria: 标准101.wrenches: 扳手102.pipe taps: 管接头.A List of Abbreviations and Symbols in English-Chinese1. A ::Ash Handling System: 除灰系统2.AH :Air Heater: 空气预热器3.AAh :Analyzer, Alarm High :a)分析器,高值报警::4.AIV :Air Intake Valve: 进气阀5.ALIGN :Alignment: 校正6.ALKF :Airlock Feeder: 锁气器7.AP ::Ash Slurry Pump: 灰浆泵8.ATM :Atmosphere 大气9.AC ::Air Conditioner: 空气调节器10.AFT :Atmosphere Flash Tank:a)大气扩容器11.AC :Alternating Current: 交流电12.ALM :Alarm:: 报警13.AMP :Ampere: 安培14.AX THR BRG :Axis Thrust Bearing:a)轴向推力轴承15.ATMZ :Atomizing: 雾化16.AUTO :Automation 自动17.AUX :Auxiliary: 辅助的18.BA :Bottom Ash 底灰19.BAH ::Bottom Ash Hopper: 底灰斗20.BLR ::Boiler: 锅炉21.BSD ::Boiler Shut Down: 停炉22.BUSH :Bushing: 衬套23.BYPS :Bypass:: 旁路24.BVD ::Boiler Vents and Drains::a)锅炉疏水放气25.BFP :Boiler Feedwater Pump ::a)锅炉给水泵26.BFPT ::Boiler Feedwater Pump Turbine:a)锅炉给水泵汽机27.BFW ::Boiler Feedwater: 锅炉给水28.BM :Boiler Master 锅炉主控29.BMCR :Boiler Maximum Continuous Rating:a)锅炉最大连续出力功率30.BFBP:: Boiler Feed Booster Pump:a)锅炉给水增压泵31.BNR :Burner: 燃烧器32.BOP :Balance Of Plant: 电厂辅机设备33.BPC :Blade Pitch Control: 叶片节距控制34.BT :Boiler Tube: 炉管35.CH: Crusher House: 碎煤房B ::Combustion 燃烧P ::Compressed Air: 压缩空气38.CONV ::Conveyer: 输送机39.CPL :Control Pannel Local: 就地控制盘40.CPM :Control Pannel Main: 主控盘41.CRT :Cathode Ray Tube: 阴极射线管:42.CT Current Transformer: 变流器43.CYCL :Cyclone: 旋风分离器44.CAS :Casing:: 缸、壳45.CB Circuit Breaker: 断路器P :Complete: 完成CW :Closed Circulating Cooling Water:a)闭式循环冷却水W :Cycle Cooling Water: 循环水WHF ::Closed Cooling Water Heatera)闭式冷却水冷却器WP :Closed Cooling Water Pump:a)闭式冷却水泵51.CS :Closed Cooling Water Systema)闭式冷却水系统52.CH Coal Handling 煤的装卸53.CHK VLV :Check Valve: 逆止阀54.CIRC: Circulation: 循环55.CLR: Cooler: 冷却器56.CLOW :Cooling Water: 冷却水57.CMPR :Compressor: 压缩机TL :Control: 控制TLE :Controller:: 控制器60.COND :Condensate: 凝结水61.CONDTY :Conductivity: 导电率62.CP: Condensate Pump: 凝结泵63.CIR: Circuit: 回路64.COUPI :Coupling: 联轴器65.CP: Condensate Polisher: 除盐装置66.CS: Control Switch 控制开关67.CRSV :Cold Reheat Safety Valve:a)再热器冷段安全阀68.CV: Control Valve : 控制阀69.CWP: Circulation Water Pump:a)循环水泵70.DMPR: Damper : 挡板71.DP :Difference Pressure: 差压72.DPIC: Differential Pressure Indicating Controller:a)压差指示控制器73.DPT: Differential Pressure Transmittera)压差变送器74.DRN: Drain: 疏水75.DV: Drain Valve: 疏水阀76.DC: Direct Current: 直流电77.DSH: Desuperheater: 减温器78.DCA: Drain Cooler Approach:a)疏水冷却器通道79.DEAER: Deaerator: 除氧器80.DEV: Deviation: 偏差81.DIFFRLY: Differential Relay: 差动继电器82.DISCH VLV :Discharge Valve 排放阀83.DIST: Disturbance: 故障、扰动84.DSCH: Discharge: 排出85.ECON: Economizer: 省煤器86.EP :Electrical Static Precipitator: 静电除尘器87.ECC: Eccentricity :: 偏心88.EFF :Efficiency: 效率89.EHC :Electric Hydraulic Control: 电液控制90.EO: Electric Operate: 电气操作91.EQ: Equipment: 设备92.ER: Error: 误差93.ES :Extraction System 抽气系统94.ESC: Escape: 逃逸、超出95.ESS: Engineering Safety System: 保安系统96.EU: Engineering Unit : 工程单位97.EXH: Exhaust: 排汽98.EXT: Extract: 抽出99.FA: Fine Ash: 细灰100.FDR: Feeder: 给料机101.FE :Flow Element: 流量元件102.FI :Flow Indicator:: 流量指示件103.FDBK: Feedback: 反馈104.FITG: Fitting: 连接件105.FLW: Flow 流量106.FO :Fail Open: 故障时自动打开107.FT: Flow Totalizer: 流量累加器108.FT :Flow transmitter: 流量变送器109.FV :Flow Control Valve 流量控制阀110.FY :Flow Relay or Valve 流量传送器111.FA: Failure Alarm: 故障报警112.FD :Forced Draft : 强制通风113.FDF: Forced Draft Fan: 送风机114.FIC :Flow Indicate Controller:a)流量指示控制器115.FLT :Flash Tank : 扩容箱116.FLD :Field 磁场117.FLG :Flange: 法兰118.FLM: Flame: 火焰119.FWH: Feed Water Heater 给水加热器120.FO :Fuel Oil: 燃油121.FREQ: Frequency: 频率122.FURN: Furnace: 炉膛123.GLD: Gland: 密封124.GRDR: Grinder: 碎渣机125.GND: Grounding: 接地126.GC :Generator Cooling: 发电机冷却127.GESE: Gland Steam Condenser Exhauster:a)轴加风机128.GMT: Generator Main Transformer:a)发电机变压器129.GRAD: Grandient: 梯度130.GS :Gland Steam: 轴封蒸汽131.GSC :Gland Steam Condenser: 轴封加热器132.GV :Governor Valve: 高压调门133.H ::Heat Conservation 保温134.HS: Hand Switch:: 手动开关135.HTR: Heater: 加热器136.HV: Hand Control Valve: 手动控制器137.HY: Hand Relay or Transducera)手动继电器(转换器)138.H :Hand: 手动的139.HB :Heat Balance: 热平衡140.HD :Heater Drain:: 加热器疏水141.HDR :Header: 联箱142.HL ::Heat Loss: 热损失143.HMDY: Humidity: 湿度144.HPH: High Pressure Heater: 高压加热器145.HPR :Hooper: 漏斗146.HPT :High Pressure Turbine: 高压汽机147.HR: Hot Reheat: 再热器热段148.HR: Heat Rate: 热耗率149.HSV: Hot Reheat Safety Valve:a)再热器热段安全阀150.HV AC :Heating Ventilation & Air Conditioning::a)暖通151.HW :Hotwell: 热井152.HV ::Hand Control Valve: 手动控制器153.HYD :Hydraulic: 液力的154.INTLK :Interlock : 联锁155.IC :Instrument and Control::a)仪表与控制(热工)156.ICV : Intermediate Control Valve :a)中压控制阀157. ID :Induced Draft 抽风,引风158.IDF ::Induced Draft Fan: 引风机159.IGN ::Ignition: 点火装置160.INLT :Inlet: 入口161.IPR ::Initial Pressure: 初压162.INST :Instrument: 仪表163.INVR :Inverter: 逆变器164.I /O:: Input/Output 输入/ 输出165.IP :Intermediate Pressure: 中压166.ISV : Intermediate Pressure Turbine Steam Valve:a)中压缸进汽阀167.JP :Jet Pump: 喷射器168.LG :Level Gauge 液位计169.LVL ::Level: 水位,液位 :Level Alarm: 液位报警171.LIM(LMIR): Limiter: 限制器172.LKG:: Leakage:: 泄漏173.LP :Low Pressure 低压174.L.P :Low Point : 低位175.LPH: Low Pressure Heater: 低压加热器176.LSH: Local Switch Hand: 就地开关177.LUB: Lubricating Oil: 润滑油178.M :Mechanical: 机械179.M :Motor: 马达180.MAG:: Magnetic: : 磁性181.MOD ::Mode: 方式:182.M/A :Manual/Automatic: 手动/ 自动183.MAN ::Manual :: 手动184.MARG: Margin:: 裕量185.MAX ::Maximum: 最大的,最大值的186.MCR ::Maximum Continuous Ratinga)最大连续出力187.MCV:: Main Control Valve: 主控制阀188.MD :Modulation Damper: 调节挡板189.MDBFP: Motor Driven Boiler Feedwater Pump:a)电动给水泵190.MEAS ::Measure : 测量191.MFT: Master Fuel Trip: 主燃料跳闸192.MIN :Minimum: 最小的193.MKUP (MU) :Make-up: 补充194.ML :Mill: 磨煤机195.MN :Main: 主要的196.M.O. :Manual Operation: 手操197.MPT :Main Power Transformer: 主变压器198.MS :Main Steam 主蒸汽199.MSV :Main Steam Valve: 主汽阀200.NOZ: Nozzle: 喷嘴201.NPSH :Net Pump Suction Head:a)泵的静吸压头202.OL: Overload: 过载203.OLR :Overload Relay: 过载继电器204.OPER :Operation: 运行205.OSC :Oscillograph: 示波器206.OTLT: Outlet: 出口207.PA: Primary Air: 一次风208.PAF :Primary Air Fan: 一次风机209.PAH :Pressure Alarm High:a)高压报警210.PAL :Pressure Alarm Low: 低压报警211.PB: Push Button 按钮212.PC :Power Centre: 动力中心213.PC: Pressure Controller: 压力控制器214.P.C. :Pressure Control: 压力控制215.PCP :Precipitator 除尘器216.PCV :Pressure Control Valve::a)压力控制阀217.PDI :Pressure Differential Indication:a)差压指示218.PDT :Pressure Differential Trandsmitter:a)差压变送器219.PED :Pedestal:: 轴承座220.PERF CALC: Performance Calculation::a)性能计算221.PF: Power Factor 功率因数222.PHTR: Preheater: 预热器223.PMP :Pump: 泵224.PNEU :Pneumatic: 气动的225.PR: Pressure Recorder: 压力记录计226.PRG :Purge: 吹扫227.PRV :Pressure Relief Valve: 泄压阀228.PRO :Protection: 保护229.PROGR:: Program: 程序230.PT: Pressure Transmitter: 压力变送器231.PULV: Pulverizer: 磨煤机232.PVSV :Pressure Vacuum Safety Valve:a)压力真空安全阀233.PW: Plant Water 厂用水234.PY: Pressure Relay: 压力继电器235.QA: Quality:: 质量,性能236.RB: Run Back: 快速降负荷237.RCV :Recovering: 回收238.RECIRC:: Recirculation 再循环239.RECT :Rectifier: 整流器240.RET :Return: 返回241.RH: Reheater: 再热器242.RO: Restriction Orifice: 节流孔板243.ROT :Rotor: 转子244.RTU :Remote Telemetry Unit::a)遥测装置245.SA :Secondary Air: 二次风246.SAT: Saturate: 饱和的247.SC :Steam Coil Air Heater:: 暖风器248.SCA V :Scavenge: 吹扫249.SD: Shut-off Damper: 关断挡板250.:Shut-Down 停机251.SEP :Separator 分离器252.SG: Switchgear 开关装置253.SH: Superheater: 过热器254.SLS :Seals:: 密封255.SO: Shut Off: 关闭256.SPD :Speed: 转速257.SPRA: Spray: 喷水258.SPT :Support: 支持:259.ST: Start: 启动,开始260.STD-BY :Stand By: 备用261.ST: System:: 系统262.STM :Steam: 蒸汽263.STR: Stator:: 定子264.STRNR: Strainer: 滤器265.SU: Start Up: 启动266.SV: Solenoid Valve: 电磁阀267.SUCT: Suction: 吸入268.SW: Switch: 开关269.:Steam Water: 汽水270.SBLWR: Soot Blower 吹灰器271.TBFP :Turbine Driven Boiler Feedwater Pumpa)锅炉汽动给水泵272.TCV :Temperature Control Valvea)温度控制阀273.T.B.: Transfer Damper: 转换挡板274.TE: Temperature Element: 温度元件275.TG: Turbine-generator: 汽轮发电机276.Turbine-gear: Turbine-gear: 汽机盘车277.THERM :Thermal 热力的278.TMS: Turbine Master System:a)汽机主控系统279.TRANS :Transfer: 转换280.TRBL: Trouble: 故障281.TRKG: Tracking: 跟踪282.TT: Temperature Transmitter:a)温度变送器283.TTD: Terminal Temperature Difference:a)温度端差284.TW: Thermowell: 热电偶套管285.UAM :Unit Automatic Master:a)机组自动系统286.V AC: Vacuum: 真空287.V AL: Value: 数值288.VB: Vibration 振动289.VLV: Valve: 阀门290.WH: Watthour 瓦小时291.WP: Working Point: 工作点292.WW: Water Wall 水冷壁293.WX: Watt Transducer: 功率转换器294.COVER :Crossover 切换管295.CV: Control Valve: 控制阀英汉对照表1.A/H :AUTOMATION/HAND : 自动/ 手动;2.A/M :AUTOMATION/MANUAL: 自动/ 手动;3.ALARM 报警;4.AUX :AUXILIARY :: 辅助;5.BYPASS 旁路6.CLOSE 关(状态,常指阀门);7.CODE: 代码;编码8.COLD START —UP: 冷态启动PUTER : 计算机10.CURVE ,LINE: 曲线,线11.DATA: 数据;文件;资料12.DECREASE : 减少13.DESK: 台,桌14.DIGIT: 数字15.DISK: 磁盘16.DYNAMIC ;DYNAMICAL: 动态17.F :FLOW 流量;18.FAST: 快19.FIGURE: 图示20.HIGH: 高21.HOT START —UP: 热态启动22.I &C :INSTRUMENT AND CONTROL 仪表与控制23.INCREAS: 增加24.INDICATION ;DISPLAY : 指示;显示;25.INLET 入口;26.INPUT 输入;27.INTERMEDIATE 中28.KEYBOARD: 键盘29.KW :KILOWATT 千瓦30.L :LOAD 负荷,负载;31.LOC :LOCAL : 就地32.LOW: 低33.MCS :MANAGMENT COMMAND SYSTEM管理命令系统34.MODE : 方式,模式35.MW :MEGAWATT 兆瓦36.NORMAL: 正常37.OFF : 关(状态);38.ON : 开(状态);39.OPEN: 开( 状态,常指阀门);40.OPERATE : 运行;操作;41.OUTLET 出口;42.OUTPUT 输出;43.P :PRESSURE: 压力;44.PANEL 盘45.PARAMETER : 参数46.PIPE ;TUBE: 管道,管子47.PLANT: 厂,站48.POWER: 功率,电源;49.PRINT: 打印50.R :RATE : 比率,速率;51.R :RESISTANCE: 电阻;52.REM :REMOTE : 摇控;53.RESET 复位54.ROOM : 室55.RPM:: 转/ 分;56.S :SPEED 速度;57.SELECT 选择58.SET POINT 设定点59.SHUTDOWN : 停机;60.SIDE (某)侧,边;61.SILENCER 消音器62.SLOW : 慢63.STAND BY: 备用;64.START : 启动;65.STARTUP : 起动;启动;66.STATIC 静态67.STATION 站68.STOP: 停止;69.SYMBOL 符号70.SYSTEM: 系统71.T :TEMPERATURE:: 温度;72.TEST: 试验;73.TRANSMITTIER ;TRANSDUCER:变送器;传感器74.TRIP 跳闸;75.TRIP ACKNOW: 跳闸确认76.UNA V AIL 不允许( 不能投用的)77.UNIT : 单元、机组78.V ALVE 阀门79.WARM START —UP: 温态启动80.ZOOM: 摄像机镜头锅炉部分81.ACTUAL MEGAWATT: 有功82.AIR DRAFT SEQUENCE: :●风机程序控制(顺控)83.AIR HEATER A MOTOR: 空预器马达A84.AIR HEATER LOC/REM SELECT:●空预器就地/ 遥控选择85.AIR HEATER MOTOR LEAD: 空预器马达选择86.AIR HTR A SEC AIR OUT TEM●空预器A 二次风出口温度87.AIR PREHEATER: 空预器88.AIR SVCE SUPPLY: 服务空气89.ALARM LIMITS: :: 报警限制90.ALL AIR HTRS RUNNING 各空预器运行91.ALL PULV GRP SHUTDOWN 所有磨组停运92.ASH —HOPPER: : 灰斗93.ATTEMPERATOR: : 减温器94.AUX .ST: SPLY FOR ATOMIZ 辅助蒸汽供雾化蒸汽95.BOIL MILL A BNR MET TEMP●炉A 磨组喷燃器金属温度96.BOIL MILL A GR1 WDBOX PR●炉A 磨组第一组风箱压力97.BOILER AIR REQUIRED 锅炉风量需求(>30% )98.BOILER EFFLUENT STORAGE: POOL 锅炉废水池99.BOILER FOLLOW MODE: 炉跟随方式100.BOILER MASTER: 锅炉主控器101.BOILER TRIP RESET: : 锅炉跳闸复位102.BOILER: 锅炉103.BURNNER: : 燃烧器104.CHIMNEY ;STACK:: : 烟囱105.CLEAN: 清扫106.COAL BANKER: :: 煤仓107.COAL FEEDER : 给煤机BUSTION : 燃烧109.CONVEYOR: 皮带机110.COORDINATE MODE 协调方式111.CRUSHER: 破碎机112.DECR/INCR PRESS AT FIX LOAD::固定负荷方式增减压力113.DOWM COMER:: 下降管114.DRAIN & VENT: 疏水和排气115.ECONOMIZER : 省煤器116.EITHER FAN RUNNING : 任一风机运行117.EITHER ID FAN RUNNING 任一吸风机运行118.ELECTROSTATIC PRECIPITATOR : 静电除尘器119.FD FAN A FLOW:: A 送风机流量120.FD FAN/ID FAN A CONT DAMPER A●送/ 吸风机控制挡板121.FEED WATER FLOW: 给水流量122.FEEDER LOCAL SELECT: 给煤机就地控制选择123.FEEDER REMOTE SELECT: 给煤机遥控选择124.FLUE GAS: 烟气125.FORCED DRAFT FAN : 送风机126.FUEL GAS ID FAN A OUTLET PRESS A●吸风机出口压力127.FURNACE PRESS: 炉膛压力128.FURNACE: 炉膛129.GAS COAL: :: 烟煤130.HEADER : 联箱、母管131.IGNITOR: : 点火器,油枪132.INDUCED DRAFT FAN : 引风机133.INDUCED&FORCED DRAFTS: 吸送风机134.INITIATE: 启动、引燃、激发、触发135.ISOLATION: 隔离;绝缘136.LFO .DISCH .PRESS : 轻油出口压力137.LIGHT OIL SEL GRP 1: 第一组轻油枪选择138.LIGHT OIL: 轻油139.LUB OIL PUMP:: 润滑油泵140.MAIN STEAM STOP VLV: 主蒸汽截止阀141.MAIN STEAM TEMP/PRESSURE/FLOW●主汽温度/ 压力/ 流量142.MAINTAINED IGNITORS PULVERIZER A :●磨煤机A 油枪操作143.MANUAL LOAD SET/RATE: :●手动负荷设定/ 负荷率144.MANUAL MODE: 手动方式145.MANUAL THROTTEL PRESS SET POINT :●手动节流压力设定值L A GROUP MASTER : A 磨组主控器L A LOAD: A 磨组负荷L A OUT TEMP CONT DAMPER :● A 磨组出口温度控制挡板149.MIN /MAX LOAD (LIMITS ):●最大/最小负荷(限制)150.MMMC =MILLIMETER MERCURY ;MMH2O:●毫米汞柱;毫米水柱151.O2 IN THE FUEL GAS 烟气含氧量152.OPEN/CLOSE SWING VLVS 摆阀开/ 关153.OPERATE MODE SELECT: 运行方式选择154.PENDANT: : 悬吊管155.PLATEN SPARY CONTROL VLVS SIDE A :●屏过减温水A 侧控制阀156.PLATEN SUPERHEATER: 屏过157.PRESSURE DIFFERENCE: 压差158.PRI AIR DUCT PRESS 一次风管压力159.PRI AIR FAN A CONT DAMPER:● A 侧一次风机控制挡板160.PRI AIR FAN A OUTLET PRESS A●一次风机出口压力161.PRI AIR FLOW MILL A CONT DAMPER●磨组一次风控制挡板162.PRI/SEC AIR FLOW MILL A A●磨组一次/ 二次风流量163.PRIMARY AIR FAN: 一次风机164.PRIMARY AIR SEQUENCE: 一次风控制165.PULVERIZER : 磨煤机166.PULVERIZER EMERGENCE TRIP●磨煤机紧急跳闸167.PULVERIZER INERT MODE SELECT:●磨煤机惰性方式选择168.PULVERIZER NORMAL MODE SELECT:●磨煤机正常方式选择169.PULVERIZER SELECTION A :: 磨煤机A 选择170.PULVERIZER: M/A: SELECT 磨煤机手/ 自动选择171.PURGE 吹扫172.RH ;REHEATER: 再热器173.SAFETY V ALVE:: 安全阀174.SCANNER BLOWERS: 火检吹扫器175.SEAL AIR FAN PRESS: 密封风机压力176.SEAL AIR FAN:: : 密封风机177.SEC AIR DUCT PRESS: 二次风管压力178.SEC AIR FLOW MILL A CONT DAMPER● A 磨组二次风流量控制挡板179.SEC SH OUT STEAM TEM●二级过热器出口蒸汽温度180.SEC SH SPARY CONT VLVS SIDE A●二级过热器减温水A 侧控制阀181.SECONDARY SH INLET TEMP●二级过热器进口温度182.SECONDARY AIR 二次风183.SH ;SUPERHEATER: : 过热器184.SH STEAM ELECTR VLV: 过热器电磁阀185.SH STEAM TEMP SET POINT:: 过热温度设定点186.SH/RH SPARY WATER STOP VLVS::●过热器/ 再热器减温水截止阀187.SH/RH SPRAY CONTROL VLVS SELECT●过热器/ 再热器减温水控制阀选择188.SLIDING PRESS MODE: 滑压运行方式189.SOOT BLOWER: 吹灰器190.SPARK 火花,点火花191.SPEED CHANGE (NOT) PERMISSIVE:●速度切换(不)允许192.SPRAY : 喷水193.STACKER RECLAIMER :: 堆取料机194.START IGNITOR GRP 1: 第一组油枪点火195.STEAM DRUM: : 汽包196.STEAM 蒸汽197.STONE COAL: 无烟煤198.STOP IGNITORS GRP 1: 第一组油枪停止199.STOP/START FEEDER 给煤机停止/ 启动200.STOP/START IGNITORS: 油枪停止/ 启动201.STOP/START MILL: 磨组停止/ 启动202.STOP/START PA FLOW: 一次风停止/ 启动203.STOP/START PULVERIZER 磨煤机停止/ 启动204.STOP/START SEQUENCE PULVERIZER A: 磨煤机A 程序停止/ 启动205.THROTTLE PRESS:: 节流压力206.TRANSPORT AIR SEQUENCE●风量程序控制(顺控)207.TURB FIRST STAGE PRESS●汽机第一级( 调节级) 压力208.TURBINE FOLLOW MODE: 机跟随方式209.TURBINE MASTER: 汽机主控器210.TWIN FLOW AIR HTR A CONT VLV: :双流式空预器控制阀211.UNLOADER: :: 卸煤机212.WATER 水213.WATERWALL: : 水冷壁?汽机部分1.:EMERG OIL PUMP: 事故油泵2.CICR PMP DISCHARGE VLV: 循环泵出口阀3.1ST STAGE PRESS: 第一级压力4.ACTUAL MEGA WATT: : 实际负荷数5.AMS :ADMISSION: MODE SELECTION 进汽方式选择6.AUX STEAM HEADER: : 辅汽联箱7.AUX STEAM TEMP CONTROL: 辅汽温度控制8.AUX STM HEADER PRESS CONTROL VLV 辅汽联箱压力控制阀9.BALANCE: : 平衡10.BEARING BRASS:: 轴瓦11.BEARING: : 轴承12.BLADE 叶片13.BOILER FOLLOW MODE: 锅炉跟随方式14.BOOSTER FEED PUMP: 前置给水泵15.CICR WTR PUMP: 循环泵16.CIRCULATING PUMP: : 循环泵17.CIRCULATING: 循环18.CLOSED COOLING WATER: 闭式冷却水19.CLOSED COOLING WTR PUMP: 闭式冷却水泵20.CMPTR: : 计数器21.CONDENSATE PUMP: 凝泵22.CONDENSER AIR SUCTION VLV: 凝汽器抽空气阀23.CONDENSER HOT WELL: : 热井24.CONDENSER LEVEL CONTROL VLV: 凝汽器水位控制阀25.CONDENSER: 凝汽器26.CONDS EXTR PUMP DISCH : 凝结水抽吸泵出口27.CONDS STOR TANK LEVEL: 凝结水储水箱水位28.COOLER: : 冷却器29.COOLNG WTR PUMP: 水冷泵30.COORDINATE MODE: : 协调方式31.CV :CONTROL V ALVE 高压调门32.CYLINDER 、CASING: 汽缸33.DEAERATOR LEVEL CONTROL VLV: 除氧器水位控制阀34.DEAERATOR: : 除氧器35.DECR PRESS AT FIX LOAD: 在负荷不变下减压36.DEMI WATER: 除盐水37.DISPATCH PARTICIPATION 调度(参与)指令38.DURM PRESSURE:: 汽包压力39.EJECTOR: 喷射器,抽气器40.EMERGENCY GOVERNOR 危急保安器41.EXHAUST: 排汽42.EXPANSION: 膨胀43.EXTR ST TO HP HTR 抽汽至高加44.EXTRACTION STEAM 抽汽45.FILTER: : 滤网46.FLANGE 法兰47.FUNCTION GROUP: 功能组48.FW CONTROL V ALVE ' S BYPASS VLV: 给水控制阀的旁路阀49.FW FLOW 30% CONTROL VLV : 30% 给水控制阀50.FW FLOW MASTER CONTROL: 给水流量主控51.FW HP HTR DISCH TEMP: 给水高加出口温度52.FW PUMP RECIRCUL CONTROL VLV 给水泵循环控制阀53.FW VLV: 给水阀门54.GEARING: 盘车ERNOR: 调速器56.HP ATTEM PRESS CONTROL VLV: 高旁减温水压力控制阀57.HP ATTEMP BLOCK VLV: 高旁减温水闭锁阀58.HP BYPASS &HP ATTEMP VLVS: 高压旁路及减温水阀59.HP BYPASS PRESS CONTROL VLV 高旁压力控制阀60.HP BYPASS PRESS SET POINT: 高旁压力设定值61.HP BYPASS TEMP CONTROL V ALVE 高旁温度控制阀62.HP &LP BYPASS COMMAND 高压及低压旁路指令63.HPH :HIGH PRESSURE HEATER : 高加64.HYDRAULIC OIL STATION PUMP: 液压油站泵65.INCR PRESS AT FIX LOAD: 在负荷不变下增压66.INT POS: 中间状态67.IV :INTERMEDIATE V ALVE 中压联合汽门68.JACKING OIL PUMP 顶轴油泵69.LP HTR STOP VLV 低加截止阀70.LP &HP BYPASS PRESS SIDE A 低压或高压旁路A 侧压力71.LP &HP BYPASS TEMP SIDE A 低压或高压旁路A 侧温度72.LPH :LOW PRESSURE HEATER: 低加73.LUBE OIL PUMP: 润滑油泵74.MAKE -UP WATER: 补给水75.MANUAL LOAD RATE 手动负荷率76.MANUAL LOAD SET 手动负荷设定77.MANUAL THROTTLE PRESS SET POINT 手动节流压力设定值78.MEASURE SELECTION 测量选择站79.MOP :MAIN OIL PUMP: 主油泵80.MOTOR DRIVEN FEED WATER PUMP 电动给水泵81.MSV :MAIN STOP V ALVE: 主汽阀82.NOZZLE 喷嘴83.OIL PURIFIER: 净油器84.OIL STORAGE TANK : 储油箱85.OPERATE MANUAL MODE: 手动方式86.OPERATE MODE SELECT: 运行方式选择87.PILOT V ALVE: 错油门88.PLATEN SH INLET TEMP SIDE A:: A 侧屏过入口温度89.PRIMARY SH STOP V ALVE: 一级过热器截止阀90.PUMP A DISCH PRESS : A 泵出口压力91.RH SPRAY BLOCK VLVSTRIP INIT 再热器喷水闭锁阀跳闸启动92.RH SPRAY WTR STOP VLVS: 再热器喷水截止阀93.RH STEAM ATTEM FLOW: 再热喷水流量94.RH STEAM TEMP OUTLET: 再热器出口温度95.ROTOR 转子96.SEAL: 密封97.SHAFT 轴98.SILENCER: 消音器99.SLIDING PRESS MODE: 滑压方式100.SPEED INDICATOR OR SPEED METER: : 转速表101.STATOR 定子102.STEAM TURBINE : 汽轮机103.ST -UP BOIL FDW PUMP: 启动给水泵104.SUCTION PUMP: 抽吸泵105.SURGE APPROACH: 喘振106.SYNCHRONIZER: 同步器107.TFW PMP DISCHARGE VLV: 汽动泵出口阀108.TFW PUMP MAIN OIL PMP: 汽动给水泵的主油泵109.THROTTLE ORIFICE 节流孔板110.TURBINE DRIVEN FEED WATER PUMP: 汽动给水泵111.TURBINE FW PUMP AUX &VLV 小机给水泵辅汽及阀门112.TURBINE GENERATOR: 汽轮发电机组113.TURBINE INLET PRESS: 汽机入口压力114.TURBINE MASTER : 汽机主控器115.TURBING FOLLOW MODE: 汽机跟随方式116.V ACCUM 真空117.V ACUUM BROKEN V ALVE: 真空破坏门118.V ACUUM SEQ : 真空程控119.VIBRATION: 振动电液调节及控制部分1.1STAGE PRESSURE FEEDBACK: 第一级压力反馈2.ABNORMAL CONDITION: 异常状态3.ACCELERATION: 加速度4.ACTIVE POWER:: 有功功率5.ADMISSION MODE: 进汽方式6.ADS(ALARM DISPLAY SELECT PANELS) 报警显示选择屏7.AERIAL LINE: 架空线8.ALTERNATING CURRENT (AC): 交流9.AMPERE: 安培10.ANGLE OF LAG: 滞后角11.ANGLE OF LEAD: 超前角12.ANODE: 阳极13.ARC: 电弧14.ARMATURE 电枢15.AST :AUTO SHUT-DOWN TRIP: 自动停机遮断16.ASYNCHRONOUS MOTOR: 异步电动机17.AT SET SPEED: 在设定速度位置18.ATC :AUTO TURBINE CONTROL: 自动汽轮机控制19.AUTOFORMER: 自藕变20.AUTORECLOSING : 自动重合闸21.AUXI TRANSFORMER : 厂用变22.BACK UP TRANSFORMER 备用变23.BACK-UP OVERSPEED TRIP TEST 备用超速跳闸试验ELECTRICALTRIP TEST 电气跳闸试验24.BACK-UP SPDSIG LOST: : 后备速度信号失去25.BARRING OIL PUMP 盘车油泵26.BASE LOAD: 基荷27.BATTERY : 电池28.BATTERY BACKED CLOCK 电池备用时钟29.BDV :BLOWDOWN VLV: 泄放阀30.BOOSTER PUMP: 前置泵31.BULB : : 灯泡32.BUS SECTION : 母线分段33.BUS: 母线34.BUSBAR FRAME: 母线架35.BUSCOUPLER: 母联36.BUSHING 套管37.CABLE 电缆38.CAPACITANCE: 电容39.CARRIER 载波40.CATHODE : 阴极R: 中控室42.CHARGING EQUIPMENT : 充电设备43.CHEST /ROTOR WARMING: 腔室/ 转子预暖44.CIU : 计算机接口单元45.CLOSE : 合闸46.CLOSED V ALVES OVERSPEED TEST 关闭阀超速47.CLOSED-LOOP : 闭环48.COIL:: 线圈BINED RECLOSING 综合重合闸BINED REHEAT V ALVES: 中压联合阀MON SERVICES LOGIC SUITE:: 公用系统逻辑柜MUNICATION: 通讯53.CONDUCTOR : 导体54.CONFIGURATION: 结构,布置,外形:55.CONTROL OIL: 控制油56.CORE: 铁芯57.CPU(CENTARL PROCESSING UNIT: 中心处理单元58.CRT: 显示屏59.CURRENT TRANSFORMER: 电流互感器60.CURRENT 电流61.CV:: 控制阀62.DAS: 数据采集系统63.DECREASING LOAD RATE: : 减负荷率64.DIESEL GENERATOR : 柴油发电机65.DIRECT CURRENT (DC) 直流66.DISCONNECTOR : 隔离开关67.DISTRIBUTED CONTROL SYSTEM: 分散控制系统68.E.W.S.: 工程师工作站69.EHC STATUS: 电液调节系统状态70.EHC :ELECTRO-HYDRA CONTROL SYSTEM: 电液调节控制系统71.EHV MIMIC PANEL : 电气高压模拟屏72.ELECTRICAL MALFUNCTION SYSTEM FAULT : 电气失灵系统故障73.EMERGENCY OIL PUMP: 事故油泵74.EMERGENCY SEAL OIL PUMP: 事故密封油泵75.ETS :EMERGENCY TRIP SYSTEM: 危急跳闸系统76.EXCEPTION REPORT: 例外报告77.EXCITE 励磁78.EXCITOR 励磁机79.FA/PA POSITION : 全周/ 部分(进汽)位置80.FAST-ACTING SOLENOID: 快动电磁阀81.FIRST STAGE PRESS 调节级压力82.FIS :: 流量显示开关83.FREQUENCY: 频率84.FRF :FIRE RESISTANT FLUID:: 抗燃油85.FULL ARC : 全周进汽86.GAS : 瓦斯87.GEN. SHAFT SEAL&STATOR WIND : 发电机密封及静子绕组88.GENERATOR : 发电机89.GROUNDING(EARTHING) 接地90.H2 TEMP CONT V : 氢气温度控制阀91.HARDWARE 硬件92.HOLD: 保持93.HYDRAULIC FLUID PRESS: 抗燃油压力94.I.C.S: 数字控制站终端模件95.IN STANDBY: 在备用状态96.IND: :: 指示器97.INDUCTANCE: 电感98.INHIBITED: 停止进行、禁止99.INSULATOR 绝缘子100.INTERCEPT V ALVE: 中间截流阀101.INTERCEPT V ALVES: 中间截止阀102.INTERFACE 接口103.KILOWATT 千瓦104.LC: 液位控制器105.LI: 液位显示106.LIGHT: 照明107.LINE 线路108.LK: 液位控制站109.LOAD DECREASING ;AT SET LOAD 负荷减;在设定负荷110.LOAD FLOW : 负荷潮流分布111.LOAD INCREASING: 负荷增112.LOAD LIMITING SET: 负荷极限设定113.LOAD MONITORING: 负荷监视114.LOAD SELECT: :: 负荷选择115.LOAD SET: 负荷设定116.LOAD: 负荷117.LOADING RATE LIMIT : 负荷(增、减)率限定118.LOCKED OUT: 闭锁119.LOSS : 损耗120.LOSS OF PWR:: 失去电源121.LVDT :线性位移差动变送器122.MAGNETIC FIELD: 磁场123.MAIN OIL PUMP: 主油泵124.MAIN SEAL OIL PMP : 主密封油泵125.MAIN STEAM PRESS 主蒸汽压力126.MAIN TRANSFORMER STEP-UP TRANSFORMER: 主变127.MANUAL: 手动128.MCC: 马达控制中心129.MEGAWATT: 兆瓦130.MFP : 多功能控制器131.MOTOR: 电动机132.MSPL :MAIN STEAM PRESSURE LIMITER : 主汽压力限制器133.MSV: 主蒸汽阀134.NEUTRAL POINT: 中性点135.OHM: 欧姆136.OIL GAUGE: 油位表137.OPC :OVERSPEED PROTECTION CONTROL: 超速保护控制138.OPEN-LOOP : 开环139.OPER AUTO: 操作员自动::140.OPERATING MODE : 操作方式141.ORP :OIL RESET PISTON: 油复位活塞142.ORSV :OIL RESET SOLENOID VLV 油复位电磁阀143.OTSV :OIL TRIP SOLENOID VLV: 油跳闸电磁阀144.OVER CURRENT: 过流145.OVER VOLTAGE : 过压146.OVERLOAD: 过载147.PART ARC : 部分进汽148.PC: 动力中心149.PDIS : 压差显示开关150.PEAK LOAD: 峰荷151.PERMANENT MAGNETIC GENERATORDF 永磁发电机152.PG: 压力计153.PHASE ANGLE : 相角154.PHASE: 相155.PIC: 压力显示控制器156.PK: 压力控制站157.PLUG : 插头158.PLUG SOCKET: 插座159.POLE:: 电极160.POTENTIAL TRANSFORMER 电压互感器161.POWER 功率162.POWER FACTOR: 功率因数163.POWER LOAD UNBALANCE: 功载不平衡164.PP :: PREESSURE POINT 压力检测点165.PRI SPD SIG LOST 一次速度信号失去166.PS: 压力开关167.PT: 压力变送器168.REACTANCE: 电抗169.REACTIVE POWER: 无功功率170.RECLOSING : 重合闸171.REHEAT PRESS:: 再热汽压力172.REMOTE AUTO: 远方自动173.REMOTE OPERATION : 远操174.RESISTANCE: 电阻175.RSM :ROTOR STRESS MONITORING: 转子热应力监视: 176.RSV: 再热汽截止阀177.SAFELY OIL : 安全油178.SCR CONTROLLER: 可控硅整流控制器179.SEAL OIL: 密封油180.SHUT-OFF V ALVE:: 切断阀181.SIGNAL: 信号182.SLOW MEDIUM FAST: 慢、中、快183.SPEED INCREASING: 速度增184.SPEED MONITORING: 速度监视185.SPEED SET RPM : 转速设定转/ 分186.SPEED: 速度,转速187.START UP TRANSFORMER 启动变188.STATOR WIND COOLING WATER PUMP: 定子绕组冷却水泵189.STEAM SEAL BY-PASS UNLOAD VLV: 蒸汽密封旁路泄放阀190.STEAM SEAL DIVERING V ALV: 密封汽分流阀191.STEAM SEAL SYS:: 蒸汽密封系统192.SUCTION PMP A/M SEL: 抽吸泵手/ 自动选择193.SUCTION PUMP: 抽吸泵194.SUPERVISORS DESK: 值长台195.SWITCH 开关196.SWITCHGEAR : : 配电盘、开关装置197.TELEPHONE: 电话198.TEST SELECT: 试验选择(联锁)199.THERMO-COUPLE: : 热电偶200.THREE ELEMENTS LEVEL CONTROLLER: 三冲量水位控制器201.THRUST BEARING WEAR DETECTOR TEST 推力轴承磨擦检测试验202.TI : 温度显示器203.TIC :: 温度指示控制204.TIME DELAY: 时间延迟205.TP: 温度检测点206.TRANSFER AND FILTER PUMP: 输送和过滤油207.TRANSFORMER: 变压器208.TRANSMISSION: 传输209.TRIP 跳闸210.TS: 温度开关211.TSI: 汽机监视仪表212.TT:: 温度变送器213.TURB LUBE OIL TEMP CONTROL V : 汽机润滑油温度控制阀214.TURBIN DRAIN V ALVES: 汽机疏水阀215.TURBINE LATCHED: 汽机挂闸216.TURN GEAR CONTROL SEQUENCE 盘车控制程序217.TURN GEAR MOTOR: 盘车主电机218.TURN GEAR PIGGY: BACK MOTOR 盘车啮合电机219.UNINTERRUPTED POWER SUPPLY: 不间断电源220.UNIT CONTROL DESK: 机组控制台。

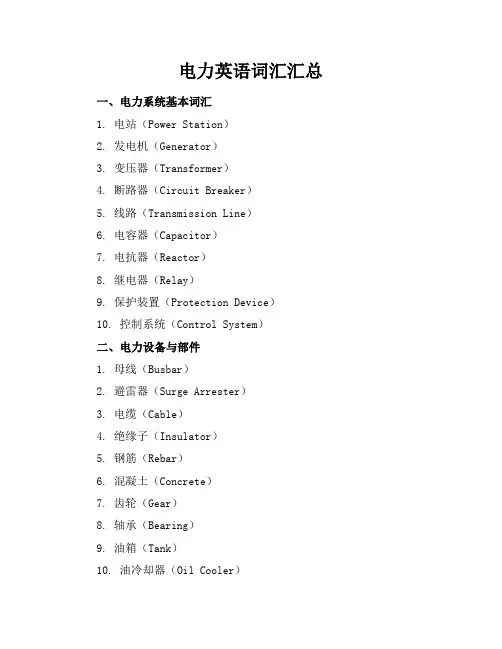

电力英语词汇汇总一、电力系统基本词汇1. 电站(Power Station)2. 发电机(Generator)3. 变压器(Transformer)4. 断路器(Circuit Breaker)5. 线路(Transmission Line)6. 电容器(Capacitor)7. 电抗器(Reactor)8. 继电器(Relay)9. 保护装置(Protection Device)10. 控制系统(Control System)二、电力设备与部件1. 母线(Busbar)2. 避雷器(Surge Arrester)3. 电缆(Cable)4. 绝缘子(Insulator)5. 钢筋(Rebar)6. 混凝土(Concrete)7. 齿轮(Gear)8. 轴承(Bearing)9. 油箱(Tank)10. 油冷却器(Oil Cooler)三、电力工程术语1. 电力工程(Electric Power Engineering)2. 设计规范(Design Specification)3. 施工图纸(Construction Drawing)4. 工程预算(Project Budget)5. 施工方案(Construction Scheme)6. 质量验收(Quality Acceptance)7. 安全生产(Safety Production)8. 环境保护(Environmental Protection)9. 节能减排(Energy Saving and Emission Reduction)10. 智能电网(Smart Grid)四、电力行业组织与机构1. 国家能源局(National Energy Administration)2. 电力公司(Electric Power Corporation)3. 电力设计院(Electric Power Design Institute)4. 电力科学研究院(Electric Power Research Institute)5. 电力行业协会(Electric Power Industry Association)6. 电力工会(Electric Power Trade Union)7. 电力市场(Electricity Market)8. 电力监管机构(Electric Power Regulatory Authority)9. 电力消费者协会(Electric Power Consumer Association)10. 国际电力组织(International Electric Power Organization)五、电力技术与发展1. 火力发电(Thermal Power Generation)2. 水力发电(Hydroelectric Power Generation)3. 核能发电(Nuclear Power Generation)4. 风能发电(Wind Power Generation)5. 太阳能发电(Solar Power Generation)6. 新能源(New Energy)7. 分布式发电(Distributed Generation)8. 电动汽车(Electric Vehicle)9. 能源互联网(Energy Internet)10. 电力系统自动化(Electric Power System Automation)六、电力运行与维护1. 电网调度(Power Grid Dispatching)2. 运行监控(Operation Monitoring)3. 设备巡检(Equipment Patrol Inspection)4. 预防性维修(Preventive Maintenance)5. 故障处理(Fault Handling)6. 状态检修(ConditionBased Maintenance)7. 安全操作(Safe Operation)8. 电力可靠性(Electric Power Reliability)9. 负荷预测(Load Forecasting)10. 电力质量(Power Quality)七、电力法律法规与政策1. 电力法(Electricity Law)2. 电力市场监管条例(Electricity Market Regulation)3. 电力设施保护条例(Regulations for the Protection of Electric Power Facilities)4. 电力供应与使用条例(Regulations on Electric Power Supply and Use)5. 电力价格政策(Electricity Pricing Policy)6. 电力体制改革(Electricity System Reform)7. 能源发展战略行动计划(Energy Development Strategy Action Plan)8. 环境保护法律法规(Environmental Protection Laws and Regulations)9. 节能减排政策(Energy Saving and Emission Reduction Policy)10. 电力行业发展规划(Electric Power Industry Development Plan)八、电力市场与交易1. 电力市场交易规则(Electricity Market Trading Rules)2. 电力中长期合同(Longterm Electricity Contract)3. 电力现货市场(Electricity Spot Market)4. 电价形成机制(Electricity Price Formation Mechanism)5. 售电公司(Electricity Sales Company)6. 用户侧响应(Customer Side Response)7. 跨区电力交易(Crossregional Electricity Trade)8. 电力市场分析(Electricity Market Analysis)9. 电力市场竞争(Electricity Market Competition)10. 电力市场风险管理与控制(Electricity Market Risk Management and Control)九、电力行业发展趋势1. 电力行业数字化转型(Digital Transformation of Electric Power Industry)2. 电力系统灵活性(Flexibility of Electric Power System)3. 电力储能技术(Electricity Storage Technology)4. 电力需求侧管理(Electricity Demand Side Management)5. 电力行业智能化(Intelligence of Electric Power Industry)6. 电力行业绿色低碳发展(Green and Lowcarbon Development of Electric Power Industry)7. 电力行业国际合作(International Cooperation inElectric Power Industry)8. 电力行业人才培养(Talent Training in Electric Power Industry)9. 电力行业科技创新(Technological Innovation in Electric Power Industry)10. 电力行业可持续发展(Sustainable Development of Electric Power Industry)十、电力行业热点问题1. 电力供需平衡(Electricity Supply and Demand Balance)2. 电力系统安全稳定(Safety and Stability of Electric Power System)3. 电力扶贫(Electricity Poverty Alleviation)4. 电动汽车充电基础设施建设(Electric Vehicle Charging Infrastructure Construction)5. 电力行业去产能(Capacity Reduction in Electric Power Industry)6. 电力行业环境保护(Environmental Protection in Electric Power Industry)7. 电力行业信用体系建设(Credit System Construction in Electric Power Industry)8. 电力行业反垄断(Antitrust in Electric Power Industry)9. 电力行业对外开放(Openingup of Electric Power Industry)10. 电力行业社会责任(Social Responsibility of Electric Power Industry)十一、电力技术创新与应用1. 智能电网技术(Smart Grid Technology)2. 分布式能源系统(Distributed Energy Systems)3. 微电网技术(Microgrid Technology)4. 能量管理系统(Energy Management System)5. 高压直流输电(High Voltage Direct Current Transmission)6. 超导技术(Superconductivity Technology)7. 电力电子技术(Power Electronics Technology)8. 量子计算在电力领域的应用(Application of Quantum Computing in Electric Power Field)9. 大数据与电力系统分析(Big Data and Electric Power System Analysis)10. 云计算在电力行业的应用(Application of Cloud Computing in Electric Power Industry)十二、电力工程项目管理1. 项目可行性研究(Project Feasibility Study)2. 项目立项(Project Approval)3. 项目招投标(Project Bidding)4. 项目合同管理(Project Contract Management)5. 项目进度控制(Project Schedule Control)6. 项目成本管理(Project Cost Management)7. 项目质量管理(Project Quality Management)8. 项目风险管理(Project Risk Management)9. 项目验收与移交(Project Acceptance and Handover)10. 项目后评价(Project Postevaluation)十三、电力行业职业素养与技能1. 电力工程师职业道德(Professional Ethics for Electrical Engineers)2. 电力行业职业技能培训(Vocational Skills Training in Electric Power Industry)3. 电力行业职称评定(Professional Title Evaluation in Electric Power Industry)4. 电力行业从业资格证书(Qualification Certificates in Electric Power Industry)5. 电力行业创新能力培养(Innovation Ability Training in Electric Power Industry)6. 电力行业团队协作(Team Collaboration in Electric Power Industry)7. 电力行业沟通与协调能力(Communication and Coordination Skills in Electric Power Industry)8. 电力行业应急处理能力(Emergency Handling Ability in Electric Power Industry)9. 电力行业法律法规知识(Legal Knowledge in Electric Power Industry)10. 电力行业国际视野(International Perspective in Electric Power Industry)十四、电力行业国际合作与交流1. 国际电力组织(International Electric Power Organizations)2. 国际电力展览会(International Electric Power Exhibitions)3. 国际电力技术交流(International Electric Power Technology Exchange)4. 国际电力项目合作(International Electric Power Project Cooperation)5. 国际电力市场分析(International Electric Power Market Analysis)6. 国际电力标准制定(International Electric Power Standards Development)7. 国际电力人才培养与合作(International Electric Power Talent Training and Cooperation)8. 国际电力政策研究(International Electric Power Policy Research)9. 国际电力环境保护合作(International Electric Power Environmental Protection Cooperation)10. 国际电力行业发展趋势探讨(Discussion on International Electric Power Industry Development Trends)。

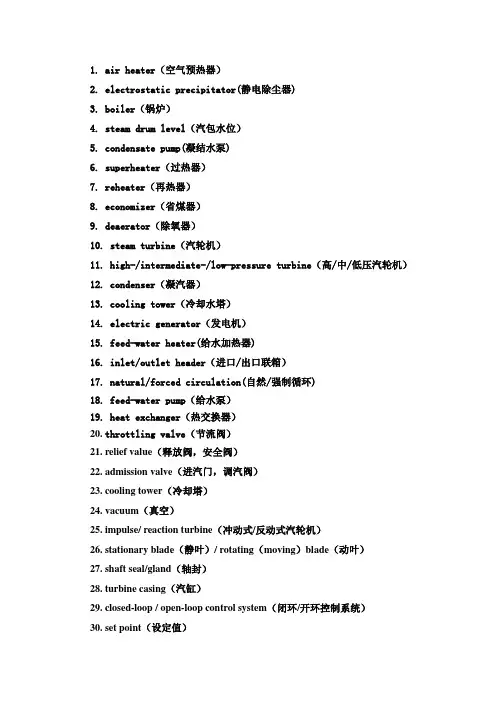

1.air heater(空气预热器)2.electrostatic precipitator(静电除尘器)3.boiler(锅炉)4.steam drum level(汽包水位)5.condensate pump(凝结水泵)6.superheater(过热器)7.reheater(再热器)8.economizer(省煤器)9.deaerator(除氧器)10.steam turbine(汽轮机)11.high-/intermediate-/low-pressure turbine(高/中/低压汽轮机)12.condenser(凝汽器)13.cooling tower(冷却水塔)14.electric generator(发电机)15.feed-water heater(给水加热器)16.inlet/outlet header(进口/出口联箱)17.natural/forced circulation(自然/强制循环)18.feed-water pump(给水泵)19.heat exchanger(热交换器)20.throttling valve(节流阀)21.relief value(释放阀,安全阀)22.admission valve(进汽门,调汽阀)23.cooling tower(冷却塔)24.vacuum(真空)25.impulse/ reaction turbine(冲动式/反动式汽轮机)26.stationary blade(静叶)/ rotating(moving)blade(动叶)27.shaft seal/gland(轴封)28.turbine casing(汽缸)29.closed-loop / open-loop control system(闭环/开环控制系统)30.set point(设定值)31.master controller(主控制器)32.proportional / integral / derivative control(比例/积分/微分控制)33.spray attemperature(喷水减温器)34.steam drum level(汽包水位)35.level swell(虚假水位)36.load dispatch system(负荷调度系统)37.current(电流)/ voltage(电压)ernor(调速器)39.overspeed protection(超速保护)40.synchronous(同步)41.feedforward(前馈)/ feedback(反馈)42.Electro-Hydraulic Speed Control Systems 电液调速系统43.manual/automatic operation 手动/自动操作44.IGV 进口导叶inlet air guide vane45.HRSG 余热锅炉heat recovery steam generator46.ADS 自动调度系统automatic dispatch system47.AGC 自动发电控制automatic generation controlS 协调控制系统coordinated control system。