橱柜安装说明书

- 格式:docx

- 大小:19.91 KB

- 文档页数:5

Kitchen CabinetInstallation GuideThe instructions given here serve as a general guideline on how to install frameless cabinets in a reasonably simple installation. Many cabinet designs and installations may be far more complex and beyond the scope of these instructions and require a professional installer.∙Tools Required∙Layout and Planning the Installation∙Cabinet Installation Order∙Installing Cabinets Level∙Fastening Cabinets to the Wall∙Fastening Cabinets Together∙Installing Fillers∙Installing Trim∙Adjusting Hinges and DrawersWarning: Kitchen installations typically involve gas, high voltage wiring, plumbing and mechanical details like heating and AC vents. This guide only covers cabinet installation. At a minimum, if you’re not well versed in these areas make sure that all power is shut off to exposed wiring and gas valves are closed to gas supply lines.∙Tools Required• Tape Measure • Pencil • 3 to 4 foot Level • 3/16" Drill Bit • Phillips Head Screwdriver •#2 Square Drive Bit*• Electric Drill • Hammer • Wood Shims • Phillips Head Screw Gun • Handsaw • Chalk Line • Step Ladder • Extension Cord • Pry Bar • Clamps • Carpenter’s Square • NOTE: If “C” clamps are used, protect material between finished case of the cabinet and the clamp.∙Additional tools that make the job easier:Small Table saw •Power Miter Saw • Laser Level • Stud FinderLocating the Highpoint on the Floor for a WallLayout andPlanning the Installation1. Take inventory of the cabinets as per the plan or order.2. Find the high spot in the floor using a level as shown below.3. Measure up the wall 34 ½” above the high spot and draw a level line anywhere that base cabinets will be installed. (This means that this line will measure greater than 34 ½” above the floor in most places along the wall.)4. Find and mark the studs. This can be done by trial and error of driving a nail in the wall until you find a stud or use an electronic stud finder. Studs will usually be every 16” center to center.Locating the Highpoint on the Floor for an Adjacent WallLocating the Highpoint on the Floor Between Two WallsStep 2Place a mark 34 ½” up from the high spot in floor5. It is best when installing a larger kitchen to mark the cabinet positions and code (size) on the wall. Better to find out now if things aren’t going to fit just right than after you’ve installed several cabinets.6. Unbox the cabinets and be cautious not to drag them across the floor. Save some cardboard to rest thecabinets on to prevent damage to the cabinets and the floor.7. Remove all doors, drawers and shelves, being careful to mark them so that they go back on correct cabinets. Removing the doors can be done without tools as the hinges are “clip ‐on”.Removing drawer boxes are different depending on the type drawer.Standard drawers can be removed by simply pulling the drawer out until it stops, then lift up the front of the drawer and remove the drawer.Dovetail drawers can be removed by pulling the drawer out until it stops. Then reach under the drawer box onboth sides just behind the drawer front. Pull the clipsholding both of them simultaneously while lifting up on the drawer box. Then slide the drawer out.∙Cabinet Installation Order1.Determining the installation order of the cabinets depends on the plan. As a general rule it is better tostart with wall cabinets in the corner and work out. However, if you have “tall” cabinets, like a pantry or oven cabinet in the plan, it is critical to make sure that the tall cabinet is used to determine the top alignment of wall cabinets.∙Installing Cabinets Level1.Nearly every floor, in any house, will not be level and flat. The illustrations below show an exaggeratedview of why leveling cabinets to the high point in the floor is critical.Wrong Right2.Cabinets should be shimmed up from the floor level to the 34 ½” line with wood or composite shims.3.Cabinets should also be shimmed out from the wall to maintain a straight line. Hampton Bay DesignerSeries cabinets are designed to be a “frameless construction” which means when the cabinets arescrewed together they will be forced into a straight line regardless of how wavy or bowed the wall orsurface they’re fastened to may be.WrongRightFastening Cabinets to the Wall1. Screw wall cabinets and tall cabinets to the predetermined height through the back panel into a stud. Make sure to place screws 1” below the top and 1” above the bottom. Measure and mark the studlocation on the cabinet before drilling. Use #8 x 2‐1/2” flat head screws when fastening through a single layer of drywall into wood studs.2. Place a screw at the top of the cabinet and the bottom of a cabinet in as many studs as can be located in the cabinet width.3. Level the cabinets.4. Important: Make sure the cabinets are square by placing a framing square inside or outside of the cabinet. Frameless cabinets can be racked (or slightly twisted) before they are fastened in place.W3036W3036W3036Correcting for a “Bowed In”or “Bellied”Wall ConditionBoxes are at an angle to each otherBox faces are not alignedW3036W3036W3036Proper shimming will allow cabinet boxes to be aligned along a flat plane and the door facia to be adjusted within acceptable tolerancesPlace screws 1” below the inside top ofPlace screws 1” above the inside bottom of cabinet∙Fastening Cabinets Together1. Align cabinet frames together carefully.2. Cabinet cases can be clamped together using various kinds of clamps, however use caution with any kind of steel clamp to not damage the surface material of the cabinet.3. Screw cabinets together with #7 x 1‐1/8” flat head screws.∙ Installing fillers1. Cabinets come is 3” increments in width, therefore fillers will be required when cabinets are to fit between walls.2. Measure the space between the wall and the cabinet at the top, middle and bottom. If the dimensionsare close to the same you can rip (saw) the filler in a straight line to the proper width to fit.3. Next, predrill holes for 1¼” screws and screw the fillers from the inside of the cabinet.4. In a case where the wall is not plumb, the filler will have to be cut to fit to the uneven wall.3”2¾”Installing Trim1. Installing crown molding can be accomplished in a variety of ways depending on the application. Using “frameless cabinets” means that a sub ‐crown molding will always have to be screwed to the top of the cabinet case to attach the crown molding to.ATSM as Sub Crown-Crown Spans to CeilingATSM by Itself as TopscribeATSM as Sub CrownABU PB58as Sub Crown AMLR 2as Sub CrownSide ViewFront ViewSide ViewFront ViewHinge Removal and ReinstallationTo Remove a Mounted Hinge:Push the Release Plunger in from the Back of the Hinge The Hinge Will Disengage from the Mounting PlateHingeMounting PlateRelease PlungerTo Remount a Hinge:Align and Insert theHinge Hooks into the Front of the Mounting PlatePush the Back of the Hinge into the Plate Until it ClicksHinge HooksAdjusting Doors and DrawersHinge AdjustmentUp and Down AdjustmentSide to Side Adjustment and Out Open DoorViewOut of AlignmentCondition Alignment ConditionCorrected10Drawer AdjustmentStandard DrawerDovetail Drawer Adjustment ‐ To Adjust the dovetail drawer for alignment, slide the white plastic clip on the under side of the drawer back and forth to raise and lower the left and right side of the drawer.Rear View ofOpen Drawer Out of Alignment Condition Alignment ConditionCorrectedScrewScrews Raises RaisesLowersThis warranty covers substantial defects in materials and workmanship in your Hampton Bay Designers Series products under normal home use. This warranty is offered only to the original consumer purchaser and may not be transferred. The coverage of this warranty lasts for the lifetime of the original purchaser, so long as he or she owns the home in which the product was first installed.What This Warranty Covers: RSI Home Products, Inc. (“RSI”) warrants its parts and products to be free of substantial defects in materials and workmanship from the original date of purchase under normal home use. This warranty is offered to the original consumer purchaser only and may not be transferred.How Long The Warranty Lasts: Coverage for all Kitchen Cabinets and Accessories lasts for the life of the product. What RSI Home Products Will Do Under The Warranty: During the warranty period, RSI, at its option, will repair or replace any part or product that proves to have substantial defects in materials or workmanship, or RSI will provide an equivalent replacement product. In keeping with our policy of continuous product improvement, RSI reserves the right to change specifications in design and materials without notice and with no obligation to retrofit products we previously manufactured.How State Law Applies: This warranty gives you specific legal rights, and you may also have other rights that vary from state to state.Implied Warranties: RSI disclaims any implied warranty of merchantability, and there are no warranties that extend beyond the descriptions on the face hereof. T o the extent that such disclaimer is not valid under applicable law, any implied warranty shall be coextensive in duration with this warranty.Wood, Aging And Printing Limitations: Because of the varying natural characteristics of wood and the effects of aging, product shown in displays and/or printed materials will not be an exact match to new cabinetry you will receive. Depending on the wood characteristics, the age of a sample and the environment of the showroom, samples will show some degree of variation from new product. In addition, you should not expect all doors, drawer fronts, trim or molding to match exactly in either finish or grain. Variation in wood is normal and unavoidable. In addition, it is not possible to match our colors exactly in printed materials. Therefore, you should view the actual samples when making your color selection.What This Warran ty Does Not Cover: T his warranty does not cover any problems or damage which result from improper transportation, improper installation, mishandling, misuse, abuse, neglect, abnormal use, commercial use, improper maintenance, non-RSI repairs, accidents, or acts of God, such as hurricanes, fire, earthquakes or floods. This warranty, and any applicable implied warranties, does not cover incidental or consequential damages arising from any defects in the product, such as labor charges for installation or removal of the product or any associated products. This warranty does not cover defects or damage caused by normal wear and tear, alterations, environmental conditions, humidity absorption, or mold. In addition, variations in hand carved items, wood grain, finish color, aging or other natural wood and stain characteristics are not considered defects and are not covered by this warranty. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. U180215 09/15Limited Lifetime WarrantyVendor InformationEmail: ***************************Address: 11350 Riverside Dr. Mira Loma, CA 91752Customer Service #: 800-230-5661Fax # for Order Processing: 844-554-0636。

安装作业指导书1.出厂前的核对、装车及运输1.1 检查及核对:1.1.1每位安装人员按照部门负责人的安排,到成品库根据合同号领取相对应的橱柜图纸;1.1.2正常一套图纸含:⑴平立面图纸一份、⑵门板下料单一份、⑶箱体板下料单一份、⑷橱柜材料明细表一份;1.1.3核对图纸后,按照⑴平面图纸、⑵门板下料单、⑶箱体下料单进行检查:共有几个箱体、多少包门板、有无天棚挡板、包管附件等;1.1.4根据⑷橱柜材料明细表详细核对:铰链有多少种型号共几付、拉手几种型号共几个、组合镙丝、踢脚板、各种型号镙丝钉、所有装饰盖(白帽、挂码盖、铰链盖、排孔盖等)有无电器配件、水槽等(为防止有损坏或少件现象,电器、配件及水槽检查必须开包进行);1.2 如何合理装车:1.2.1根据车辆安排,装车之前:首先清理车厢内的卫生,根据柜体的高度及宽度进行合理装车;1.2.2装地柜时应把所有的底脚全部卸下来统一包装放入柜内,尽可能的把小柜及门板附件等杂物放到大底柜里面(带防水铝板的水槽柜杜绝接触外露物品,以免摩擦造成染上污渍);1.2.3柜与柜之间必须用包装物进行包装防止碰撞或磨坏,所有柜体表面不能直接接触车厢,必须用物品遮盖;1.2.4所有物品装完后,把工具等全部装上车内(核对工具是否少带);1.2.5最后再进行确认和检查是否少装物品,然后用绳子进行封车,绳子接触柜体处必须用包装物垫上;1.3 出厂前的准备工作:1.3.1封完车后清理车周边的卫生,然后与客户联系大约到达时间(应先与司机沟通)、准确的楼牌号、房内装修到何程度是否应带防护措施等;1.3.2正常情况下在8:20前必须出厂(非正常时间安装以实际情况为准);1.4 运输过程中的注意事项:1.4.1约好时间后开车出厂,运行过程中时刻注意所装物品是否松动、碰撞等现象;1.4.2天气变化时应提前作好准备,带上雨布等防护措施;1.4.3如由于特殊情况不能够按照预订时间到达,必须提前与客户进行沟通;2.卸车及搬运2.1 如何安全卸车:2.1.1到达小区找到楼号及门洞后,安装人员应先到楼上对楼号进行核对,无误后准备卸车;2.1.2卸车时听司机指挥合理卸车,所卸物品必须做到:不能违犯物业的规定,不能挡住过往行人的通行,所有物品的安全:防止刮倒与丢失(所有物品及工具应放在一起);2.2 搬运的要点:2.2.1搬运时应做防护措施:如是否应带上手套,鞋套,如客户地板铺好应盖上包装膜等措施保护;2.2.2易碰部分(包括客户物品及橱柜)作出包装,以免碰坏。

骊住轻松抽800型按裝说明书厨房装修中,最重要的就是选择对一个合适的骊住轻松抽800型橱柜,并且安装好,骊住轻松抽800型橱柜虽然是可移动的家具,但是如果一旦确认位置安装好的话,那么一般不会轻易移动,所以对安装的过程还有注意事项有非常高的要求,一步安装到位最好,省的以后出现问题,还得重新再装一遍,那么你们大家知道骊住轻松抽800型橱柜安装的流程吗?这样自己知道的话如果出现问题也会更直接的找到原因。

接下来就给大家介绍一下骊住轻松抽800型橱柜安装的流程以及注意事项。

骊住轻松抽800型橱柜的安装是一个值得注意的地方,现在大部分的骊住轻松抽800型橱柜都是实木做的,不管是成品还是定制,安装都非常复杂。

虽然现在很多人都会选择定制的骊住轻松抽800型橱柜,有人上门来安装,但是我们还是需要知道一些骊住轻松抽800型橱柜安装的知识的,这样如果遇到问题就可以自己解决。

那么安装骊住轻松抽800型橱柜到底要注意哪些细节呢?小编今天就介绍一下骊住轻松抽800型橱柜安装的流程及注意事项!一起来了解看看吧!一、骊住轻松抽800型橱柜安装——安装流程骊住轻松抽800型橱柜是由上柜、地柜和五金件组成。

首先要熟悉下流程,骊住轻松抽800型橱柜安装需要满足以下三个条件:厨房门套安装好,水电改造好,瓷砖铺好。

1、装好门套:安装好厨房门套,施工人员可以测量设计骊住轻松抽800型橱柜所尺寸大小,结构布局图。

2、铺好水电线路:水电改造是基础工程,在安装骊住轻松抽800型橱柜之前,一定要铺设好厨房的水电线路。

如果骊住轻松抽800型橱柜安装之前没有铺设水电线路,需要重新挖地道、铺设管线等,在这个过程中一定会影响到骊住轻松抽800型橱柜的设计。

3、铺好瓷砖:在厨房贴完瓷砖之后再安装骊住轻松抽800型橱柜,地面和墙面施工完毕,骊住轻松抽800型橱柜的地面和背面将不会发生改动。

二、骊住轻松抽800型橱柜安装——注意事项1、安装顺序:一般来说骊住轻松抽800型橱柜的安装顺序是地柜、吊柜、水龙头与水槽、灶具与电器。

厨房橱柜成品质量标准1. 引言本文档旨在制定厨房橱柜成品的质量标准,以确保客户接收到符合标准的产品。

该标准适用于所有制造和销售的厨房橱柜成品。

2. 外观质量标准2.1 橱柜外观应整洁无瑕疵,表面应平滑一致。

2.2 无明显的划痕、凹陷或起泡。

2.3 无明显的色差,同一批次产品颜色应一致。

2.4 边角整齐,无裂缝或接口不紧密。

3. 结构质量标准3.1 橱柜结构牢固稳定,不应有明显松动或倾斜。

3.2 门、抽屉等开启顺畅,无卡滞现象。

3.3 金属五金件应牢固固定,不应出现脱落或损坏的情况。

3.4 木板应采用优质材料制作,无明显变形或开裂。

4. 功能质量标准4.1 所有橱柜组件应完全符合设计要求,包括层板、隔板、拉篮等。

4.2 所有门、抽屉等开启、关闭应灵活顺畅。

4.3 门、抽屉等应有有效的开启方式,如手柄、推拉轨道等。

4.4 橱柜内部储物空间充足,且布局合理。

5. 安全质量标准5.1 橱柜的安装固定应稳固可靠,不应存在不稳定或易倾覆的情况。

5.2 使用环保材料,无有害气味。

5.3 无锐利边缘或突出的硬件,以免对用户造成伤害。

6. 维修与保养质量标准6.1 提供清晰的使用说明书,包括安装、使用和维护注意事项。

6.2 橱柜材料易于清洁,不易积累污垢。

6.3 提供合理的保修期限和售后服务。

7. 检验与验收7.1 在出厂前,厂家应对橱柜进行全面的质量检查和测试。

7.2 在产品交付时,客户应按照验收标准对产品进行检查确认。

以上为厨房橱柜成品的质量标准,希望能够在制定和销售过程中用于参考和实施。

The step-by-step guide to installing your new kitchen rightThis brochure is your guide to preparing and installing your new kitchen. Inside you’ll find tips and ideas, clear steps to follow, and the tools you’ll need. Use this guide along with your assembly instructions to make sure your kitchen is installed correctly.You can do it yourself but you don’t have toOur kitchens are designed to be simple to install and assemble yourself, but we’re here to help as muchas you would like along the way. Whether you’d like a hand with delivery or a complete installation service, we’re happy to put together a service package that suits you. For more details, see the kitchen section of or contact your local IKEA store. Before you beginTake a look at this brochure to see what steps are involved in installing your new kitchen and organize what tools you’ll need.Once you’ve received your kitchen, double-check that all the parts have arrived. A good way to do this is by checking what packages you have at home against the order list. You should only dismantle your old kitchen when you have all your new parts and appliances. Your kitchen parts and countertop should be stored indoors, with normal room temperature and humidity levels. It’s helpful if you arrange your cabinets in the order you will be installing them. Use your shopping list and IKEA home planner drawing to help you. Remove your old kitchen making sure that electric, water and gas are off before you begin. Use a qualified, licensed professional to disconnect and connect your gas, water, and electricity.23The tools you’ll need depend on how much of yourkitchen you are doing yourself. See the assemblyinstructions for the tools you’ll need to use. It’s a goodidea to wear safety glasses when using power tools.Miter box and saw Fine-toothed handsawBar clampsElectric screwdriver/drill JigsawCircular saw LevelAwl Square Pencil Rubber mallet Claw Hammer Phillips screwdriver Flat screwdriver Hole cutter – for drilling the hole for the faucet in the sink.4Prepare your roomOnce you have removed your old kitchen, prepareyour room by making sure your walls and floorare even, and that your walls are suitable forsupporting your new kitchen. Now is also thetime to prime and paint your walls, put in tiles orchange your flooring.Marking cabinet positionsDraw a layout of your new kitchen directlyon the wall. Check that everything fits withthe measurements from your plan and yourelectricity, water, gas, and ventilation connectionsare where you want them. Also mark where toattach your new kitchen’s suspension rails.Prepare your space by making sure your corners are even and your walls and floor are squareand plumb. Use your square for the corners and a level for the walls and floor. Make sure younote the highest point of the floor and where the corners are not square.Check that your wall is strong enough tohang your suspension rail and cabinets.Depending on your wall material, it’s bestSet your suspension railWith the new IKEA kitchen system, your cabinets can be hung directly onto a suspension rail making them easier to install and easier to adjust.It’s important to make sure your suspension rail is straight and level, and to secure it with the right screw type for your wall.Marking the right height for your suspension rail Your base suspension rail needs to be hung 32 3/16" above your floor’s highest point (measure to the underside of the rail). You should allow 22 5/16" between the bottom of your wall cabinets and the bottom of your base rail when measuring for your upper rail.Fasten your rails, base rail first. Make sureyou’ve found suitable points in the wallwhere the rails can be fastened and that therails are level before drilling.If your wall is uneven use shims between the rail and the wall to make sure the rail is e a level to check that each rail is level.6Install your cabinetsIn most kitchens it’s best to install your wallcabinets first. This will allow you to move aroundwithout base cabinets in the way. One exceptionis if you are installing a single line kitchen with ahigh cabinet at one end. In this case install thehigh cabinet first.Before you begin, mark down all plumbing andother utilities. Some cabinets have ready-madeopenings for plumbing and utilities, but you canuse a jigsaw to create your own openings, ifneeded. Do this before fitting the cabinet in place.Be aware that these openings can affect how youcan arrange drawers in a cabinet.to the assembly instructions. Wait until laterbefore fitting drawers, doors, and internalfittings.corner. Hang all remaining cabinets in thesame way. If you’re installing a cornercarousel now is the time to place it in thecabinet.aligned with your plumbing.tightening the screws. Hang the remainingcabinets and connect them with the includedscrews. Wait to tighten the screws untilthe base cabinets are in place and you canensure alignment.previous cabinet by adjusting the legs.assembly instructions. Make sure to havethe legs attached in the order the cabinetswill be installed.installing. Remember to use the distance ring included with the legs.cover panel first.Filler piecesFiller pieces are used between yourcabinets and walls for a streamlinedappearance and to ensure there isenough room to fully open doors anddrawers. They are especially useful ifyour walls are not perfectly straight.If the wall is not level and flat, the filler piece must be cut to fit to the wall’s shape. To do this,you’ll need a filler piece, measuring tape, small block of wood about 1 1/4" thick and a pencil.Cut the filler piece so it’s the same height as the cabinet. Place the edge of the filler pieceagainst the wall. Hold the block of wood flat against the wall with the pencil against it. Keepthem pressed against the wall as you slide them down the length of the filler piece. Now youhave traced the shape of the wall onto the filler piece. Cut along your trace line.Place the newly cut edge of the filler piece against the wall, it should fit perfectly. Mark theedge of the cabinet on the top and bottom of the filler piece. Draw a straight line from theseCheck the wall with your level to see if it is straight. If the wall is even, measure between the wall and the cabinet and mark this distance at the top and bottom of the filler piece.To ensure the filler piece stays in place, first attach a support strip to the wall. Drill holes in the cabinet for the screws you’ll use to attach the cabinet and filler piece together.Put the filler piece into place. Put screws through the holes you have drilled. When all your filler pieces are in, caulk around each one with silicone for an airtight seal.8Install your worktop, sink, lighting, appliances, and kitchen island.With your cabinet frames in, it’s time to installyour countertop, sink, lighting, and appliances.Check that your countertop is the correct sizebefore fitting it in place. Now is also the time ifyou need to customize your countertop for a sinkor cooktop, see your assembly instructions forhelp.Once your countertop is in, you’re ready toget your water, gas, lighting and appliancesconnected. All water, gas, and electricityconnections must be done by qualified, licensedprofessionals according to valid local safetyregulations.All electrical connections must be made by aqualified, licensed electrician.straight-edge to your pre-cut countertopwhen you cut to customize the size. It’shelpful to use a pair of sawhorses.countertop apply polyurethane siliconeacross the sawn edges.Install your lighting and appliances.the assembly instructions.Measure your countertop. If you have a pre-cut countertop, now is the time to cut itto the right length.countertop in place. Trace the inside ofthe base cabinet onto the underside of thecountertop. This helps you align your sink.Turn your countertop over and trace theoutline of your sink onto masking tape.the assembly instructions.It’s helpful to drill a hole on the insidecorners of your outline before cutting, soyou can make a cleaner cut.9Customize your countertop for your cooktopin the same fashion as for your sink. Seeyour cooktop’s assembly instructions forhelp.Install the extractor hood. The extractor hoods from IKEA can be installed in two ways: either vented to the outside, called extraction, or used in recirculation mode fitted with a charcoal filter. Each installation option is described in the assembly instructions that come with the product.Saw the hole either in the back panel or in the top of the cabinet. See the assembly instructions.For safety and functionality reasons, follow precise measurements in the instructions forinstallation that come with the extractor hood/fan.Supporting brackets are used to fasten kitchen islands to the floor.Legs/toe kicks must then be fitted around the outside of the island.The kitchen island assembly kit is used to connect cabinets back toback, or for attaching a cover panel to the back of cabinets.10Install your shelves, drawers, doors, knobs, and handles.Now that the cabinet frames, countertops andappliances are in, attach the drawer slides intothe cabinets. Remember that the slides for innerand standard drawers are attached differently,see the assembly instructions for help.Once the slides are in, attach the drawers beforethe doors and shelves. Finish by adding knobsand handles as well as any other internalsolutions, like wire baskets.outer drawers. Outer drawer slides shouldbe attached to the outer row of holes in thecabinet.the inner drawer slides. The inner drawerslides are attached to the inner row of holesin the cabinet.assembly instructions.cabinets.width by adjusting the screws on the hingeplate.Now its time to attach a toe kick. Follow theassembly instructions for help.If using a ventilation grill, place it betweentwo pieces of toe kick.You’re done! Congratulations on your new kitchen!Caring for your cabinetsClean the doors, cabinet interiors, and wood surfaces with a soft, damp cloth. Only use cleaning products intended for these materials. Do not use products that contain ammonia, alcohol, bleach, or abrasives. Rinse with clean water, then dry with a clean, dry cloth. Make sure to clean up spills quickly.Keep your sink sparklingAfter each use, wipe the sink clean with a cloth or sponge damped in water or a non-abrasive scratch the stainless steel surface. The damp surface can be discolored if substances containing iron are allowed to remain on it.Long-lasting countertopsKeep your countertop in top condition by cleaning up spills quickly with water and a mild detergent. Be sure to keep them as dry as possible after use. For wood and solid wood countertops use BEHANDLA wood treatment oil. The oil protects the wood from marks, stains, and cracks, and prevents water from penetrating the surface.11Services and prices may vary, please see /services or your local IKEA store for details.ALL THE HELP YOU NEED TO MAKE YOUR DREAM KITCHEN A REALITYAt IKEA we believe everyone has the right to a new kitchen. Apart from offering a wide range of kitchens, we also offer a wide range of services, including measuring, planning, and installation. Everything you need to make getting your dream kitchen as easy as possible. And at your local IKEA store you’ll find our team of kitchen experts who are on hand to answer questions, give practical advice, and help you through the buying process.Save time and effort with professional installation. Kitchen Installation isprovided by an Independent Service Provider and is priced per cabinet.INSTALLATION SERVICEWe can arrange for an Independent Service Provider to deliver your newkitchen directly to your home or office. Prices are based on distance.DELIVERY SERVICEA professional Measurement Technician will visit you in your home toprovide all measurement services. A Kitchen Planner will then contact youto discuss the details of your kitchen plan, and start the planning process.Performed by an Independent Service Provider. The Measurement andPlanning fee is refunded to you when you purchase your IKEA kitchen.MEASUREMENT AND PLANNING SERVICE MEASUREMENT SERVICEAn experienced professional from an Independent Service Provider willcome to your home to assess the conditions and provide accuratemeasurements. This service is available to customers living in our servicearea. The Measurement fee is refunded to you when you purchase your IKEAkitchen.© Inter IKEA Systems B.V. 2015/August 2018。

橱柜使用说明书一、产品概述橱柜是一种家居装饰家具,主要用于存储厨房用品和器具。

它由高品质的材料制成,具有耐磨、耐腐蚀和耐高温的特性。

橱柜不仅提供了充足的储物空间,还能为厨房带来整洁的外观和舒适的使用体验。

二、安装1. 在安装橱柜之前,请确保选择合适的位置。

根据您的厨房布局和个人习惯,选择一个方便操作和容易清洁的位置。

2. 准备好所需的安装工具,例如螺丝刀、电钻等。

3. 按照橱柜安装指南进行安装。

确保橱柜的固定牢固,避免不必要的晃动或摇晃。

三、使用方法1. 打开橱柜门时,请用适当的力道轻拉门把手,避免对门板和门把手施加过大的压力。

2. 使用橱柜时,请避免将过重或过热的物品放置在橱柜上方,以防止压力过大或导致橱柜变形。

3. 当打开橱柜时,请注意不要将门板打开过大,以免撞到障碍物或划伤相邻的物品。

4. 使用橱柜时,请尽量避免使用过多的力量关闭门板,以免对门板和铰链造成损坏。

5. 清洁橱柜时,请使用柔软的湿布轻轻擦拭,避免使用含有腐蚀性的清洁剂或硬质刷子,以防刮伤橱柜表面。

四、保养与维护1. 定期清洁橱柜并保持干燥。

避免在橱柜表面积水或存放湿润的物品,以防腐蚀和发霉。

2. 请勿在橱柜表面切割食材,以防刀具划伤橱柜表面。

3. 对于橱柜门板上的污渍或油渍,可以使用中性清洁剂轻轻擦拭。

如遇顽固的污渍,请咨询专业人员进行处理。

4. 当橱柜遇到磕碰或损坏时,请及时联系厂家或专业人员进行修复。

切勿私自拆卸或修复橱柜。

五、注意事项1. 请勿在橱柜上方放置易燃物品,以防火灾发生。

2. 使用橱柜过程中,如发现橱柜存在异味、松动或其他异常情况,请及时联系厂家或专业人员进行检查和维修。

3. 请务必按照橱柜的承重限制使用,以免超载导致橱柜变形或破裂。

六、售后服务我们提供全面的售后服务,如有任何问题,欢迎随时联系我们的客服团队。

我们将尽快为您解答疑问并提供专业的技术支持。

总结:橱柜作为家居装饰家具,不仅提供了充足的储物空间,还能为厨房带来整洁的外观和舒适的使用体验。

成品橱柜安装工程方案1. 前期准备工作1.1 确定橱柜安装位置在进行成品橱柜安装之前,首先需要确定好橱柜的安装位置。

通常情况下,橱柜会安装在厨房的墙面上,因此需要确认好橱柜的布局和位置,以便后续的施工。

1.2 测量墙面尺寸在确定好橱柜安装位置之后,需要进行墙面尺寸的测量工作。

通过使用测量工具,如卷尺等,来准确地测量墙面的尺寸,包括宽度、高度和深度等参数。

1.3 准备安装工具和材料在进行橱柜安装之前,需要准备好相应的安装工具和材料。

常用的安装工具包括螺丝刀、电钻、锤子、尺子等,而安装材料则包括螺丝、膨胀螺丝、角铁、木板等。

1.4 清理施工现场在进行橱柜安装之前,需要对施工现场进行清理工作。

清理施工现场可以清除杂物和灰尘,保证施工环境整洁,并为后续的安装工作提供一个良好的工作环境。

2. 橱柜安装工作2.1 拆除旧橱柜如果需要更换旧橱柜,那么首先需要进行旧橱柜的拆除工作。

拆除旧橱柜时需要小心操作,以免损坏周围墙面和地面。

2.2 安装橱柜基台在进行橱柜安装之前,需要先安装橱柜基台。

橱柜基台的安装需要使用膨胀螺丝和角铁等材料,以保证橱柜的稳固性和均衡性。

2.3 安装上橱柜安装橱柜时,首先需要将上橱柜的吊架安装到墙面上,然后再将橱柜悬挂到吊架上。

在悬挂橱柜时,需要使用水平仪和尺子等工具,确保橱柜的安装位置水平和垂直。

2.4 安装下橱柜安装下橱柜时,首先需要将橱柜放置在预定位置上,然后使用螺丝将橱柜固定在墙面或地面上。

在固定橱柜时需要注意,螺丝的紧固力要适中,以防止损坏橱柜。

2.5 连接橱柜在橱柜安装完成之后,需要进行橱柜之间的连接工作。

通常情况下,橱柜之间会使用角铁或木板进行连接,以增加橱柜的稳固性和承重性。

2.6 安装橱柜门板最后一步是安装橱柜门板。

安装门板时需要小心操作,以免划伤门板表面。

安装完毕后,可以使用调整螺丝来调整门板的开合角度,以保证橱柜的美观性和使用性。

3. 安装完工验收3.1 检查橱柜外观在橱柜安装完成之后,需要对橱柜的外观进行检查。

橱柜合同范本通用版本5篇篇1甲方(购买方):__________________乙方(销售方):__________________鉴于甲方需要购买橱柜,乙方同意按照本合同规定的条款和条件向甲方提供橱柜产品,双方经友好协商一致,达成如下协议:一、产品描述1. 乙方同意向甲方提供以下橱柜产品:(请在此处详细描述橱柜的材质、颜色、尺寸、配置等)。

二、价格及支付方式1. 橱柜总价:人民币______元(大写:______元整)。

2. 支付方式:甲方应按照以下方式支付款项:(1)合同签订后,甲方支付乙方总金额的______%作为预付款;(2)橱柜安装完毕并经验收合格后,甲方支付乙方剩余款项。

三、交货与安装1. 交货时间:乙方应在合同生效后______天内将橱柜产品交付给甲方。

2. 交货地点:______________________________________。

3. 安装:乙方负责安装橱柜,安装应在交货后______天内完成。

四、质量标准和保证1. 乙方提供的橱柜产品应符合国家和行业标准。

2. 乙方应保证其提供的橱柜产品在材料、工艺、品质等方面均达到合同约定的标准。

3. 如甲方发现橱柜产品有质量问题,应当在______天内通知乙方,乙方应负责免费更换或修理。

五、违约责任1. 若甲方未按合同约定支付款项,乙方有权顺延交货期或解除合同。

2. 若乙方未按合同约定提供橱柜产品或未按约定时间完成安装,应支付违约金。

3. 若因一方违约导致另一方产生损失,违约方应赔偿守约方的实际损失。

六、售后服务1. 乙方承诺提供______年的质保期,质保期内免费维修。

2. 质保期后,乙方提供有偿维修服务。

3. 乙方应提供电话支持服务,对甲方使用橱柜过程中遇到的问题进行解答。

七、争议解决1. 如双方在执行合同过程中发生争议,应首先通过友好协商解决。

2. 如协商不成,任何一方均有权向合同签订地的人民法院提起诉讼。

八、其他条款1. 本合同自双方签字盖章之日起生效。

Portable security and cabinet locks2 • Schlage • Portable securityI n t r o d u c t i o nK e y s y s t e m sK S S e r i e sK C S e r i e s C y l i n d e r sP a r t s C a b i n e t l o c k s ****************************eFax: 1.833.312.3669Ordering/schlagesecurityUS 877.671.7011Canada 800.900.4734*****************************************************************Information and customer care4 • Schlage • Portable securityI n t r o d u c t i o nK e y s y s t e m sK S S e r i e sK C S e r i e sC y l i n d e r sP a r t sC a b i n e t l o c k sOne key convenienceSchlage portable security products provide single-key convenience throughout any facility or security area. These locks can be master keyed into any new or existing Schlage key system, allowing you to integrate padlocks with door hardware and eliminating the need for separate keys. These products are also available in Everest 29TM restricted keyways or as part of the Primus ® XPprogram for applications that require extra security.Education§Perimeter security§Storage facilities§Athletic equipment storage §Gym, auditorium, cafeteria seating §Cafeteria food storage §Utility/mechanical control cabinets §Janitorial storage§Classroom mechanical and electronic equipment immobilizationAirport§Perimeter security§Equipment storage facilities §Utility mechanical control cabinets §Janitorial storage§Fuel distribution and storage §Retail/kiosk security and immobilizationCommercial job site §Perimeter security§Outbuildings/storage facilities §Office/model home §Tools and equipmentTransportation §Perimeter security §Storage facilities §ContainersRetail loss prevention §Kiosk security and immobilization §Outdoor product displays §Valuable indoor product displays §Storage facilitiesHealthcare§Perimeter security§Outbuildings/storage facilities §Medical equipment storage §Utility/mechanical control cabinets §Cafeteria food storageCylinders and key systemsEnd user controlled; non-exclusiveAuthorized dealer onlyNo authorizationPrimus®XPgeographicallyexclusivesidebitmillingoptionsSchlage Everest 29™SchlageClassicEnd user exclusive nationwide4N9NEnd user exclusive within time zone/country4Z9ZEnd user exclusive within zip code3G9GEnd user controlled; non-exclusive3U9UDealer exclusive within time zone/country28Dealer exclusive within zip code1+7Authorized dealer only; non-exclusive1• Duplicate anywhere• Patented design• Check pin in cylinder• Requires letterof authorization• Patented design• Check pin in cylinder• 5 levels of side bitmilling exclusivity• Patent protectionto 2024• Independent sidebarand fi nger pinlocking mechanisms• 5 levels of side bitmilling exclusivity• Patent protectionto 2029• Independent sidebarand fi nger pinlocking mechanisms• Hardened steeldrill pins• Proven pick anddrill resistant• Withstands extremephysical attack OPENRESTRICTED1SFIC, FSIC2 andConventional2UL 437 OptionUL listedPrimus XPRESTRICTEDFSIC22Primus XPRESTRICTED-Proximity credentials•Easily duplicatedMIFARE Classic®smart credentials•Secure encrypted dataand communications•Di cult to duplicateMIFARE Plus® and MIFARE® DESFire® EV1 smart credentials•Advanced data encryption makes duplication nearly impossible•Most secure credentials available from Schlage1. Limited dealer controlled programs available.2. FSIC and Conventional in the form of SL cylinders that accept an SFIC key.Primus® XP access controland high security cylindersThe Primus® XP program is designed to allow the highest levels ofsecurity to be applied in buildings on doors where it counts mostbut still within a single keyway family making it easy to manage.Distribution of both cylinders and keys is tightly controlled andpatent protection ensures keys cannot be copied.Most facilities need higher levels of key control and physical securityon at least a few openings. Large businesses with high-risk assets willwant to apply the greatest precautions and may opt for end usercontrolled Primus XP cylinders with keys milled for their exclusive useon a national or regional basis. Mid-size and smaller facilitiescan gain the same benefits of key control on a more local level byengaging a locksmith who offers dealer exclusive Primus XP products.Buildings keyed to a Classic open keyway can upgrade security toPrimus XP at critical points of entry to improve overall security.Visit for more information.Primus XPprogramenhancements§Enhanced physical security withpatented independent, duallocking mechanisms§Patent protection and uniquekey design makes unauthorizedduplication nearly impossible§Geographically exclusivekey distribution§Compatible to all Everest 29and legacy Everest keyways§Optional UL 437 listedcylinders are made towithstand extreme attackSchlage • Portable security • 5I n t r o d u c t i o nK e y s y s t e m sK S S e r i e s K C S e r i e sC y l i n d e r sP a r t s C a b i n e t l o c k sSchlage • Portable security • 7Part #Body size Shackle dimension Shackle dimension(metric)Cylinder type Case pack Master packWidthHeight Depth A B C A B C Keyed different KS23D2300 125⁄32"23⁄16"7⁄8"5⁄16"11⁄2"3⁄4"8 mm 38 mm 19 mm Conventional 624KS23F2300 125⁄32"23⁄16"7⁄8"5⁄16"2"3⁄4"8 mm 51 mm 19 mm Conventional 624KS43D2300 115⁄16"23⁄16"7⁄8"3⁄8"11⁄2"3⁄4"9.5 mm 38 mm 19 mm Conventional 624KS43F2300115⁄16"23⁄16"7⁄8"3⁄8"2"3⁄4"9.5 mm 51 mm 19 mm Conventional 624Less cylinder - Conventional 1KS23D2200125⁄32"23⁄16"7⁄8"5⁄16"11⁄2"3⁄4"8 mm 38 mm 19 mm Conventional 624KS23F2200125⁄32"23⁄16"7⁄8"5⁄16"2"3⁄4"8 mm 51 mm 19 mm Conventional 624KS43D2200115⁄16"23⁄16"7⁄8"3⁄8"11⁄2"3⁄4"9.5 mm 38 mm 19 mm Conventional 624KS43F2200115⁄16"23⁄16"7⁄8"3⁄8"2"3⁄4"9.5 mm 51 mm 19 mm Conventional624Less cylinder - FSIC 1KS43D3200 115⁄16"23⁄16"7⁄8"3⁄8"11⁄2"3⁄4"9.5 mm 38 mm 19 mm FSIC 624KS43F3200115⁄16"23⁄16"7⁄8"3⁄8"2"3⁄4"9.5 mm51 mm19 mmFSIC6241. Less cylinder padlocks ship without a cylinder. Driver and all other internal padlock parts are included.KS Series brass padlocks§Meets or exceeds ASTM standards for standard steel shackle, shackle cutting- and corrosion-resistance §Solid brass body resists corrosion for all-weather performance §Molybdenum hardened steel shackle offers greater cut resistance §Double deadbolt locking mechanism provides extra security §Patented interchangeable shackle design allows for easy disassembly§Standard cylinder features include:− S chlage conventional cylinder −6-pin solid brass cylinder (pinned 5), keyed different−Classic obverse Schlage C keyway − T wo nickel silver cut Schlage keys23 Series43 SeriesBody: 606 satin brassShackle: 625 bright chromeShackle dimensions8 • Schlage •Portable security§Meets or exceeds ASTM standards for standard steel shackle, shackle cutting- and corrosion-resistance §Case hardened solid steel body resists impact§Molybdenum hardened steel shackle offers greater cut resistance §Double deadbolt locking mechanism provides extra security §Patented interchangeable shackle design allows for easy disassembly §Standard cylinder features include:− S chlage conventional cylinder−6-pin solid brass cylinder (pinned 5), keyed different−Classic Obverse Schlage C keyway −Two nickel silver cut Schlage keysPart #Body sizeShackle dimension Shackle dimension(metric)Cylinder type Case pack Master packWidthHeight Depth AB C A B CKeyed different KS72F230025⁄8"23⁄8"13⁄32"7⁄16"2"7⁄8"11 mm51 mm22 mm Conventional618KS Series steel padlock72 SeriesBody: 626 satin chromeShackle: 625 bright chromeSchlage • Portable security • 9§Meets or exceeds ASTM standards for standard steel shackle, shackle cutting- and corrosion-resistance §Chrome-plated solid brass body resists corrosion for all-weather performance §Molybdenum hardened steel shackle offers greater cut resistance §Double deadbolt locking mechanism provides extra security §Patented interchangeable shackle design allows for easy disassembly§Offered less cylinder, made to fit Small Format Interchangeable Cores (SFIC)−Compatible with Schlage, Falcon, Best, Master Lock and Arrow SFIC cylindersPart #Body sizeShackle dimension Shackle dimension(metric)Cylinder type Case pack Master packWidth Height DepthAB C A B C Less cylinder 1KS11D1200125⁄32"23⁄16"7⁄8"1⁄4"11⁄2"3⁄4" 6.4 mm 38 mm 19 mm SFIC 624KS11F1200125⁄32"23⁄16"7⁄8"1⁄4"2"3⁄4" 6.4 mm 51 mm 19 mm SFIC 624KS21D1200 125⁄32"23⁄16"7⁄8"5⁄16"11⁄2"3⁄4"8 mm 38 mm 19 mm SFIC 624KS21F1200 125⁄32"23⁄16"7⁄8"5⁄16"2"3⁄4"8 mm 51 mm 19 mm SFIC 624 KS41D1200 115⁄16"23⁄16"7⁄8"3⁄8"11⁄2"3⁄4"9.5 mm 38 mm 19 mm SFIC 624 KS41F1200115⁄16"23⁄16"7⁄8"3⁄8"2"3⁄4"9.5 mm51 mm19 mmSFIC6241. Product is shipped without cylinder. For cylinder and keying options, refer to your Schlage price book.21 Series 41 SeriesKS Series chrome-plated brass padlocksShackle dimensionsBody: 625 bright chrome Shackle: 625 bright chrome10 • Schlage •Portable securityKC Series locking cables§Braided steel, vinyl coated cable provides greater cut-resistance than twisted cable § I ntegrated die-cast zinc locking head (619 satin nickel finish) §Offered less cylinder, made to fit Small Format Interchangeable Cores (SFIC)−Compatible with Schlage, Falcon, Best, Master Lock and Arrow SFIC cylinders§Triple heat-treated boron manganese steel chain§ R ecommended for use with KS72F2300 solid steel padlock1 P roduct is shipped without cylinder and with driver. For cylinder and keying options, refer to your Schlage price book.Note: 1) F or master keyed or keyed alike product, order chain and padlocks separately.Order chains #999478 or #999461 with padlock KS72F 2300. Prices are for chains only. Chains and padlocks must be ordered separately.Padlock sold separatelySecurity chains and padlocksPart #Cable size Cab le size (metric) Cylinder type Case pack Master packLength DiameterLength Diameter Less cylinder 1KC215A1302'5⁄8"60 cm 15 mm SFIC 1 5 KC215B1304'5⁄8"120 cm15 mmSFIC 15Part #Chainsize Chain size(metric)Shackle dimensionShackle dimension (metric)Cylinder type Case pack Masterpack LengthLength A B C A B C Chain only (no cover)9994785'150 cm N/A N/A N/A N/A N/A N/A N/A 1 1 9994613' 3"100 cmN/AN/AN/AN/AN/AN/AN/A11Schlage • Portable security • 11Notes: 1) Falcon and Primus cylinders will ship separately. 2) Control keys must be ordered separately. 3) Specify keyway for existing systems.4) 80-033 and 80-043 cores are available in Best keyways. Specify keyway using B suffix:AB = A, BB=B, CB=C, DB = D, DDB=DD, EB = E, FB = F, GB = G, HB = H, JB = J, KB = K, LB = L, NB=N, MB = M, RB=R, TBB=TB, TDB=TD, QB=Q. 5) 80-036 and 80-037 restricted keyway cores require a letter of authorization from the end user.6) For details see Keys and Keying section of your Schlage price book.Full Size Interchangeable Core (FSIC)Schlage Full Size Interchangeable Core (FSIC) configured locks allow immediate rekeying simply by using a special control key to replace the core. Available in KS43 Series, FSIC cylinders can be used with any 5 or 6-pin Schlage key system.Small Format Interchangeable Core (SFIC)The SFIC option is designed for Everest ® 29 R restricted keyway family. Based on an industry standard SFIC design, Schlage locks configured for use with SFIC cylinders will also work with Best, Falcon, and other small format interchangeable cores.KS and KC Series cylindersKS SeriesConventionalKC Series23-03023-031FSIC80-03380-037SFICCylinder mechanism KS Series part number KC Series part number Standard pin and tumbler 47-41347-414Primus ® XP 47-743-XP 47-744-XP Primus XP UL43747-542-XP47-543-XPConventionalCylinder mechanism Part number Standard pin and tumbler23-030Standard pin and tumbler less logo 23-031Primus ® XP20-740-XP Primus XP less Schlage logo20-741-XPDescriptionPart number 7-pin uncombinated Everest 29 R family restricted keyways80-036 7-pin combinated Everest 29 R family restricted keyways80-037 6-Pin uncombinated Falcon/Best keyways 80-0437-Pin uncombinated Falcon/Best keyways80-03312 • Schlage •Portable securityKS Series padlock partsKC Series cableConventional key-in-knobSmall format interchangeable coreDust cover screwsDust coverCylinder Lock headWasherThrow membermounting screwDrivermounting screwDriver Throw memberExploded View - SFICShackleShackle springLocking ball bearingsLocking camLocking camThrow memberSteel retaining plateBumperCylinderShacklemounting screwSteel retainer plate screwShackleShackle springLocking ball bearingsLock bodyLocking camKey stopDriverBumperCylinderCylinder housingCylinderhousing screwShacklemounting screwConventional key-in-knobSmall Format Interchangeable CoreSchlage • Portable security • 13Part #Shackle DimensionShackle Dimension (metric)Box qty Carton qtyAB C A B C Hardened steel shackles - for use with 20 Series padlocksKZ11D20 5⁄16"11⁄2"3⁄4"8 mm 38 mm 19 mm 636KZ11G205⁄16"4"3⁄4"8 mm 102 mm 19 mm 636Hardened steel shackles - for use with 40 Series padlocksKZ11F403⁄8"2"3⁄4"9.5 mm 51 mm 19 mm 636KZ11G403⁄8"4"3⁄4"9.5 mm 102 mm 19 mm 636Brass shackles - for use with 20 Series padlocksKZ12D20 5⁄16"11⁄2"3⁄4"8 mm 38 mm 19 mm 636KZ12G205⁄16"4"3⁄4"8 mm 102 mm 19 mm 636Brass shackles - for use with 40 Series padlocksKZ12D40 3⁄8"11⁄2"3⁄4"9.5 mm 38 mm 19 mm 618KZ12G40 3⁄8"4"3⁄4"9.5 mm102 mm19 mm618AccessoriesStainless steel shackles - for use with 20 Series padlocks KZ13D205⁄16" 1 1⁄2"3⁄4"8mm 38mm 19mm 636KZ13F205⁄16"2"3⁄4"8mm 51mm 19mm 636Stainless steel shackles - for use with 40 Series padlocksKZ13D403⁄8" 1 1⁄2"3⁄4"9.5mm 38mm 19mm 636KZ13F403⁄8"2"3⁄4"9.5mm51mm19mm636Shackle dimensionsParts and accessories - replacement shacklesI n t r o d u c t i o nK e y s y s t e m sK S S e r i e sK C S e r i e sC y l i n d e r sP a r t s C a b i n e t l o c k sSchlage • Portable security • 15Cabinet deadbolt locksDrawer deadbolt locksRim deadbolt lockRim latchCL100PBCL771GCL775GCL725GCylinder formats:CL100PB - Conventional format Interchangeable Core formats: CL777R - Full Size IC (FSIC)CL721G - Small Format IC (SFIC)Rekeying: Release mechanism allows Conventional cylinder replacement. Interchangeable cores replaced using control key Certifications: ANSI 156.11 - Conventional Grade 1; FSIC and SFIC Grade 2Body: Die cast zincBolt: Steel 15/16" projection; 3/4" SFICDoor thickness: 7/8" to 1 3/8"Barrel diameter: 1 1/8"Finishes: Conventional and FSIC formats - 605 and 626; SFIC format - 626 onlyCylinder formats:CL200PB - Conventional format Interchangeable Core formats: CL888R - Full Size IC (FSIC) CL771G - Small Format IC (SFIC)Rekeying: Release mechanism allows Conventional cylinder replacement. Interchangeable cores replaced using control key Certifications: ANSI 156.11 - Conventional Grade 1; FSIC and SFIC Grade 2Body: Die cast zinc Bolt: Steel 3/4" projection Door thickness: 7/8" to 1 3/8"Barrel diameter: 1 1/8"Finishes: Conventional and FSIC formats - 605 and 626; SFIC format - 626 onlyInterchangeable Core format: CL775G - Small Format IC (SFIC)Rekeying: Interchangeable core replaced using control keyBody: Die cast zinc cylinder housing, stamped steel back plate and steel case Bolt: 1/2" projectionMaterial thickness: up to 1 1/16"Barrel diameter: 1 1/8"Compatibility: Retrofits Best 5L Series Finish: 626Interchangeable Core format: CL725G - Small Format IC (SFIC)Rekeying: Interchangeable core replaced using control keyBody: Die cast zinc cylinderhousing, stamped steel back plate and steel case Material thickness: up to 1 1/16"Barrel diameter: 1 1/8"Compatibility: Retrofits Best 5L Series Finish: 626Cam locks Rachet locks Mailbox lockKeying optionsLarge format keying:Conventional and FSIC cylinder formats available in standard pin and tumbler, Primus XP and Primus XP UL 437 high-security mechanisms. Everest 29 S123 keyway standard. Classic and restricted keyways also available.Small format keying:SFIC cylinder format available in standard pin and tumblermechanism (A2 pinning); Everest 29 R keyway.Available keyed alike (KA), keyed different (KD) and master keyed.FSIC and SFIC construction cores available.CL920RCL729GCL728GInterchangeable Core formats: CL920R - Full Size IC (FSIC)CL720G - Small Format IC (SFIC)Rekeying: Interchangeable core replaced using control key Body: Die cast zincBody diameter: 1 1/8"; across flats 7/8"Mounting cutout: 1 5/32"Material thickness: .08” to 1 1/8"Finish: 626Interchangeable Core formats: CL929R - Full Size IC (FSIC)CL729G - Small Format IC (SFIC)Rekeying: Interchangeable core replaced using control key Body: Die cast zinc Body diameter: 1 1/8"Material thickness: up to 1/4"Finish : 626Interchangeable Core format: CL728G - Small Format IC (SFIC)Rekeying: Interchangeable core replaced using control key Body: Die cast zinc housing; steel bodyBarrel length: Adjustable Handing: RH standard Retrofits: Best BL Finish: 626Cabinet locks with cylinderFinishesBright brass 605Satin chrome 626About AllegionAllegion (NYSE: ALLE) is a global pioneer in safety and security, with leading brands like CISA®, Interflex®, LCN®, Schlage®, SimonsVoss® and Von Duprin®. Focusing on security around the door and adjacent areas, Allegion produces a range of solutions for homes, businesses, schools and other institutions. Allegion is a $2 billion company, with products sold in almost 130 countries.For more, visit © 2019 Allegion005279, Rev. 10/19/us。

简尚橱柜创意设计说明书作者:刘浩指导老师:白榕一、概念表述橱柜家家都有,怎样设计才能完美的平衡实用与美观?现代厨柜对于实用与美观提出了更高的要求。

赶快来欣赏我们为您设计的经典橱柜装修效果图吧,都是高端大气的设计,让你的生活也充满幸福的味道吧!让你的居室充满光彩,你的厨房不再单一的只有一种功能,它可以实现的多功能化,更好的节约资源和空间发挥出它更大的用途。

譬如,我的这款橱柜,它的造型简单时尚,符合形式美法则。

它既是一个具有观赏的艺术品也是一个很实用的橱柜。

采用彩色巧克力面板材料,不仅在视觉上给你一种欣赏,更是味觉上的喜爱。

二、目前的发展现状及存在的问题1. 发展现状90年代,随着发达国家密集型的橱柜产业转移到发展中国家,世界上许多著名的厂商纷纷到中国寻求发展,从而把先进的技术工艺,设备带进了中国。

加上国内生活质量的提高,对生活的环境要求更高。

重视及对橱柜的实用性与美观性、艺术性、装饰性的需求,我国橱柜生产技术正在向国际水平发展,橱柜的品种、质量、工艺均进步很快。

近几年我国橱柜产量每年以40%以上的速度增长,目前橱柜的总产值、出口已超过电光源工业。

随着现代对美食的追求的发展与新材料、新科技成果的不断出现,对各种橱柜原理及其使用环境的深入研究,都丰富了现代橱柜对嫁妆环境的表现力和其独特的艺术魅力。

那么,现代橱柜有些什么新的发展趋势呢?首先,现代橱柜设计已不仅仅是为了单纯制作美食,美化产品,更重要的是采用技术,通过对橱柜的结构及功能的合理设计,来满足实需求和最大限度地发挥服务我们的生活。

现在的橱柜发展现状是,大多数消费者会更愿意去买一些造型简单又具有艺术感的产品。

我觉得我设计的橱柜很符合当下发展的趋势。

向高效实用、美观的方向发展。

首先是靠与实用,然后是按橱柜的尺寸、形状,精心设计橱柜的美观性,真正提高效利用率。

如在夜晚中,选用彩色的高强巧克力面板,可造成一个光线弥散、均匀柔和的环境,且橱柜的保护角小、效率高,能较好地融入居室环境。

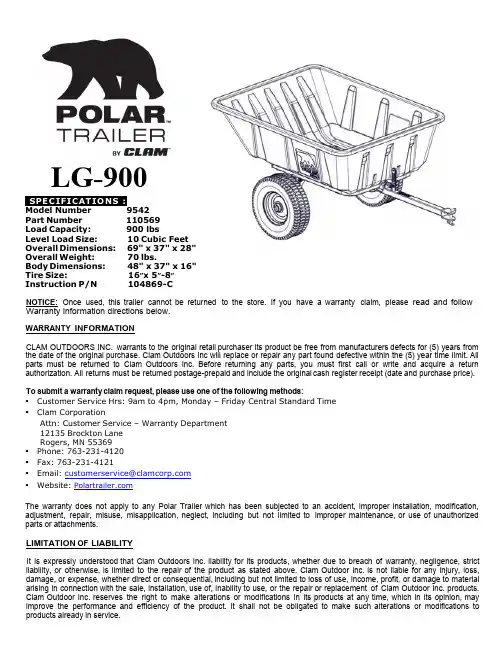

LG-900E C IF I C A T I O N S:Model Number 9542Part Number 110569Load Capacity: 900 lbsLevel Load Size: 10 Cubic FeetOverall Dimensions: 69" x 37" x 28"Overall Weight: 70 lbs.Body Dimensions: 48" x 37" x 16"Tire Size: 16”x 5”-8”Instruction P/N 104869-CNOTICE:Once used, this trailer cannot be returned to the store. If you have a warranty claim, please read and follow Warranty Information directions below.WARRANTY INFORMATIONCLAM OUTDOORS INC. warrants to the original retail purchaser its product be free from manufacturers defects for (5) years from the date of the original purchase. Clam Outdoors Inc will replace or repair any part found defective within the (5) year time limit. All parts must be returned to Clam Outdoors Inc. Before returning any parts, you must first call or write and acquire a return authorization. All returns must be returned postage-prepaid and include the original cash register receipt (date and purchase price). To submit a warranty claim request, please use one of the following methods:▪ Customer Service Hrs: 9am to 4pm, Monday – Friday Central Standard Time▪ Clam CorporationAttn: Customer Service – Warranty Department12135 Brockton LaneRogers, MN 55369▪ Phone: 763-231-4120▪ Fax: 763-231-4121▪ Email: ****************************▪ Website: The warranty does not apply to any Polar Trailer which has been subjected to an accident, improper installation, modification, adjustment, repair, misuse, misapplication, neglect, including but not limited to improper maintenance, or use of unauthorized parts or attachments.LIMITATION OF LIABILITYIt is expressly understood that Clam Outdoors Inc. liability for its products, whether due to breach of warranty, negligence, strict liability, or otherwise, is limited to the repair of the product as stated above. Clam Outdoor Inc. is not liable for any injury, loss, damage, or expense, whether direct or consequential, including but not limited to loss of use, income, profit, or damage to material arising in connection with the sale, installation, use of, inability to use, or the repair or replacement of Clam Outdoor Inc. products. Clam Outdoor Inc. reserves the right to make alterations or modifications in its products at any time, which in its opinion, may improve the performance and efficiency of the product. It shall not be obligated to make such alterations or modifications to products already in service.THE FOLLOWING STATEMENTS ARE SUGGESTIONS AND DO NOT SUPERCEDE OR ELIMINATE ANY TOWING AND SAFETY INSTRUCTIONS LISTED IN ANY OWNERS MANUALS FOR ANY PRODUCT BEING USED FOR THE PURPOSE OF TOWING ANY CLAM OUTDOORS INC. PRODUCTS. ALWAYS REFER TO THE TOWING VEHICLES MANUAL, GUIDELINES OR INSTRUCTIONS.Transporting Loads Safely•Stopping distance increases with speed and weight of towed load. Travel slowly and allow extra time and distance to stop.•Total towed weight must not exceed limits specified in towing vehicle operator’s manual.•Excessive towed load can cause loss of traction and loss of control on slopes. Reduce towed weight when operating on slopes.•Never allow children or others in or on towed equipment.•Use only approved hitches. Tow only with a machine that has a hitch designed for towing. Do not attach towed equipment except at the approved hitch point.•Follow the manufacturer’s recommendations for weight limits for towed equipment and towing on slopes.•Do not turn sharply. Use additional caution when turning or operating under adverse surface conditions.Use care when reversing.•Do not shift to neutral and coast downhillProtect Bystanders•Keep bystanders away when you operate a towed attachment.•Before you back machine and attachment, look carefully behind attachment for bystanders.Keep Riders off Towed Attachment•Keep riders off of a towed attachment.•Riders on a towed attachment are subject to injury, such as being struck by objects and being thrown off the attachment during sudden starts, stops and turns.•Riders obstruct the operato r’s view, resulting in the attachment being used in an unsafe manner.•Keep riders off of the hitch bracket or trailer tongue.Disconnecting Towed Attachment •Unload trailer.•Stop attachment on level ground.•Stop machine engine.•Lock machine park brake.•Block attachment wheelsLock Pin Hole• A hole has been provided in the Latch Plate to lock the Latch Mechanism if desired.VISIT OUR WEB-SITE FOR ADDITIONAL ACCESSORIES THAT MAY BE AVAILABLE FOR YOUR TRAILER。

橱柜安装方法橱柜是厨房中必不可少的家居用品,它不仅可以提供充足的存储空间,还可以美化整个厨房的装饰效果。

因此,正确的安装橱柜对于厨房的整体效果和使用体验至关重要。

下面,我们将介绍橱柜的安装方法,希望能够帮助大家更好地完成橱柜的安装工作。

首先,准备工作是非常重要的。

在安装橱柜之前,我们需要对厨房空间进行测量,并根据实际情况确定橱柜的尺寸和位置。

在购买橱柜时,一定要根据测量结果选择合适尺寸的产品,以确保安装时不会出现尺寸不合适的问题。

此外,还需要准备好安装工具,如螺丝刀、螺丝批、电钻等,以及安装所需的辅助材料,如膨胀螺丝、地脚螺丝等。

接下来,开始安装橱柜。

首先,根据预先测量的位置,在墙面上标记出橱柜的安装位置,并使用电钻在墙面上打孔,然后将膨胀螺丝安装在墙面上。

接着,将橱柜的主体部分放置在安装位置上,并使用螺丝将橱柜固定在墙面上。

在安装橱柜的过程中,需要确保橱柜的水平和垂直度,以保证安装完成后整体效果美观、稳固。

在安装好主体橱柜后,接下来是安装橱柜的门板和抽屉。

首先,将门板和抽屉的滑轨安装在橱柜的相应位置上,然后将门板和抽屉安装在滑轨上并调整好位置。

在安装门板和抽屉时,需要特别注意它们的平整度和间隙,以确保开关顺畅、无噪音。

最后,进行橱柜的调整和固定。

在安装完成后,需要对橱柜进行调整,确保所有部件的位置和间距都符合要求。

同时,还需要使用地脚螺丝将橱柜固定在地面上,以增加整体稳固性。

在进行固定时,需要注意地脚螺丝的位置和深度,避免对地面造成损坏。

总结一下,正确的橱柜安装方法包括准备工作、主体橱柜的安装、门板和抽屉的安装以及最后的调整和固定。

在进行安装时,需要注意尺寸的准确性、水平和垂直度的调整、部件的平整度和间隙以及固定的稳固性。

希望以上介绍能够帮助大家更好地完成橱柜的安装工作,让厨房空间焕然一新。

尊敬的客户!

感谢您选择ASKO的优质产品。

衷心希望我们的产品能够达到您的期望,并在未来多年内满足您的需求。

北欧风格的设计使简洁的线条,日常功能性与高质量完美结合。

这些是我们产品最大的特点,同时也使我们的产品享誉世界。

安装说明书

2

3

4

5

6

7

8

9

10

必备工具

• 4 mm 内六角扳手• 美工刀

• 折梯

• 水桶

• 水平仪

• 手推工具车

• 13 mm 开口扳手• 11 mm 开口扳手• 32 mm 开口扳手• #2 十字螺丝刀

• 钻孔套件

• 8 mm 插座

• 护目镜

• 老虎钳

• 10 mm 套筒

• 梅花扳手 T-20, T-30

硬件设备

• 防倾斜支架和螺钉• 面板安装支架和螺钉• 干墙塑料膨胀管和锚钉• 滤水器

• 水管配套元件材料准备

• 冷藏室,冷冻室及可自定义抽屉用的定制面板。

• 尼龙搭扣/粘合剂,如使用定制踢脚板。

地面

要使冰箱正确安装,冰箱必须稳固水平放置于与其他表面等高的坚实的平面。

此平面需要足够的强度支撑满载的冰箱或大约500kg。

注意: 保护表面完整。

剪切一大块纸板箱并放在正在安装的冰箱下面。

安装说明

21

22

23

zh (08-15)。

厨柜安装合同范本甲方(业主):________乙方(供应商及安装方):________鉴于甲乙双方就厨房橱柜的购买与安装达成一致,特此签订本合同,以便明确双方的权利义务。

一、产品详情1. 厨柜品牌:_____2. 厨柜型号:_____3. 材质描述:_____4. 颜色规格:_____5. 尺寸要求:_____6. 配件清单:_____7. 其他特殊要求:_____二、价格条款1. 厨柜总价为人民币(大写)_______元整(¥_______)。

2. 支付方式:a. 签订合同时支付定金_______元;. 厨柜安装前支付_______元;c. 安装验收合格后支付余款_______元。

三、交付与安装1. 乙方应在合同签订后_______个工作日内将厨柜交付至甲方指定地点。

2. 乙方负责厨柜的运输及安装,确保产品质量符合国家标准及合同约定。

3. 安装过程中,乙方应采取合理措施保护现场环境,如有损坏,应负责修复或赔偿。

4. 安装完成后,乙方应对厨柜进行清洁并邀请甲方共同验收。

四、质量保证1. 乙方保证提供的厨柜为全新正品,质量符合国家相关标准。

2. 厨柜自验收合格之日起,享有不少于_______年的质保期。

3. 在质保期内,如出现非人为因素导致的质量问题,乙方负责免费维修或更换。

4. 质保期外的维修,乙方提供有偿服务。

五、违约责任1. 如乙方延迟交付或安装,每逾期一天,需向甲方支付合同总额_______%的违约金。

2. 如甲方未按约定时间支付款项,每逾期一天,需向乙方支付应付款项_______%的违约金。

3. 因一方原因导致合同无法履行,违约方应承担由此给对方造成的损失。

六、争议解决本合同在履行过程中,如发生争议,双方应友好协商解决;协商不成时,可提交至甲方所在地人民法院诉讼解决。

七、其他约定1. 本合同一式两份,甲乙双方各执一份,具有同等法律效力。

2. 本合同自双方签字盖章之日起生效。

3. 未尽事宜,双方可另行签订补充协议。

Page 1 of 5SPRING RETRACTABLE BENCH REELS:SERIES LGCOXREELSThe technical data and images which appear in this manual are for informational purposes only. NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE CREATED BY THE DESCRIPTIONS AND DEPICTIONS OF THE PRODUCTS SHOWN IN THIS MANUAL. COXREELS makes no warranty (and assumes no liability) as to function of equipment or operation of systems built according to customer design or of the ability of any of its products to interface, operate or function with any portions of customer systems not provided by COXREELS.COXREELS agrees to repair or exchange the goods sold hereunder necessitated by reason of defective workmanship and material discovered and reported to COXREELS within two years after original invoice date.Except where the nature of the defect is such that it is appropriate, in COXREELS’ judgment, to effect repairs on site, COXREELS’ obligation hereunder to remedy defects shall be limited to repairing or replacing (at COXREELS’ option) FOB COXREELS Factory, any part returned to COXREELS at the risk and cost of Buyer. Defective parts replaced shall become the property of COXREELS.COXREELS shall only be obligated to make such repair or replacement if the goods have been used by Buyer only in service recommended. COXREELS is not responsible for defects which arise from improper installation, neglect, improper use of or from normal wear and tear.COXREELS obligation shall be limited by the manufacturer’s warranty (and is not further warranted by COXREELS) for all parts procured from others according to published data, specifications or performance information not designed by COXREELS.COXREELS further agrees to replace or at COXREELS’ option to provide a refund of the sales price of any goods that do not conform to applicable specifications or which differ from that agreed to be supplied which non-conformity is discovered and forthwith reported to COXREELS within 30 days after shipment to the Buyer. COXREELS’ obligation to replace or refund the purchase price for non-conforming goods shall arise once the Buyer returns such goods FOB COXREELS Factory at the risk and cost of Buyer. Goods replaced by COXREELS shall become property of COXREELS.COXREELS liability on any claim, whether in contract, tort (including negligence), or otherwise, for any loss or damage arising out of, connected with, or resulting from the manufacture, sale, delivery, resale, repair, replacement or use of any products or services shall in no case exceed the price paid for the product or services or any partthereof which give rise to the claim. In no event shall COXREELS be liable for consequential, special, incidental or other damages, nor shall COXREELS be liable in respect of personal injury or damage to property not the subject matter hereof unless attributable to gross misconduct of COXREELS, which shall mean an act or omission by COXREELS demonstrating reckless disregard of the foreseeable consequences thereof.COXREELS is not responsible for incorrect choice of models or where products are used in excess of their rated and recommended capacities and design functions or under abnormal conditions. COXREELS assumes no liability for loss of time, damage or injuries to property or persons resulting from the use of COXREELS products. Buyer shallhold COXREELS harmless from all liability, claims, suits and expenses in connection with loss or damage resulting from operation of products or utilization of services, respectively, of COXREELS and shall defend any suit or action which might arise there from in Buyer’s name – provided that COXREELS shall have the right to elect to defend any such suit or action for the account of Buyer. The foregoing shall be the exclusive remedies of the Buyer and all persons and entitles claiming through the Buyer.WARNING – APPLICATIONTHE PRODUCTS IN THIS INSTALLATION AND MAINTENANCE MANUAL HAVE BEEN TESTED UNDER CONTROLLED LABORATORY CONDITIONS TO MEET SPECIFIC TEST CRITERIA. THESE TESTS ARE NOT INTENDED TO REFLECT THE PERFORMANCE OF THE PRODUCTS OR ANY OTHER MATERIAL IN ANY SPECIFIC APPLICATION, BUT ARE INTENDED TO PROVIDE THE USER WITH APPLICATION GUIDELINES. THE PRODUCTS AREINTENDED FOR USE BY KNOWLEDGEABLE PERSONS HAVING THE TECHNICAL SKILL NECESSARY TO EVALUATE THEIR SUITABILITY FOR SPECIFIC APPLICATIONS.WARNING – USER RESPONSIBILITYTHE USER, THROUGH ITS OWN ANALYSIS AND TESTING, IS SOLELY RESPONSIBLE FOR MAKING THE FINAL SELECTION OF THE SYSTEM AND COMPONENTS AND ASSURING THAT ALL PERFORMANCE, ENDURANCE, MAINTENANCE, SAFETY AND WARNING REQUIREMENTS OF THE APPLICATION ARE MET.TO THE EXTENT THAT COXREELS PROVIDE COMPONENT OR SYSTEM OPTIONS BASED UPON DATA OR SPECIFICATIONS PROVIDED BY THE USER, THE USER IS RESPONSIBLE FOR DETERMINING THAT SUCH DATA AND SPECIFICATIONS ARE SUITABLE AND SUFFICIENT FOR ALL APPLICATIONS AND REASONABLY FORESEEABLE USES OF THE COMPONENTS OR SYSTEM.WARNING – SAFETYREAD ALL SAFETY INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR MAINTAIN THIS PRODUCT. ONLY QUALIFIED PERSONNEL SHOULD UNDERTAKE THE INSTALLATION AND COMMISSIONING OF THIS PRODUCT. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.FAILURE TO FOLLOW RECOMMENDED APPLICATION INFORMATION AND RECOMMENDED PROCEDURES FOR SELECTION, INSTALLATION, CARE, MAINTENANCE AND STORAGE OF REEL ASSEMBLY, SWIVEL, HOSE, COUPLINGS OR HOSE ASSEMBLIES MAY RESULT IN FAILURE TO PERFORM PROPERLY AND MAY RESULT IN DAMAGE TO PROPERTY AND SERIOUS BODILY INJURY.FOLLOW GOOD MAINTENANCE PRACTICES – ESTABLISH A PROGRAM OF INSPECTION, TESTING AND REPLACEMENT OF REEL COMPONENTS, ACCESSORIES AND OR BRACKETS FROM FACTORS INCLUDING:o SEVERITY OF APPLICATION, FREQUENCY OF EQUIPMENT USE, AND PAST PERFORMANCE OF REEL COMPONENTSONLY PROPERLY TRAINED PERSONS SHOULD INSPECT, TEST OR SERVICE REEL AND HOSE/CABLE ASSEMBLIES. PERIODIC UPDATING OF TRAINING IS RECOMMENDED. DOCUMENT MAINTENANCE, INSPECTIONS AND TESTING.PROP 65 WARNING : Handling of brass material on this product exposes you to lead, a chemical known to the State of California to cause birth defects or other reproductive harm.“WASH HANDS AFTER USE ”PRESSURE WARNINGS• This equipment should be properly installed before use in accordance with local codes and ordinances.• The pressure to and from the hose reel should be released and disconnected from the hose reel before any service functions are performed. • This hose reel must not be used for pressure greater that the rating listed in the COXREELS catalog / website .OPERATIONAL WARNINGS• Exercise care when handling the hose reel during normal operation. Some hose reels have a rotating drum powered by a spring under tension or chain, sprocket and gears.• Do not use hose different from that for which the reel is intended. Changes in diameter, weight per foot, length of hose or flexibility (Minimum Bend Radius) will affect the operation of the reel.• Mounting hardware and fasteners should be installed to maintain tightness under vibration and checked periodically to ensure tightness.• Overhead installation mountings should be such that the reel is not supported solely by bolts in tension. A safety chain, cable, enclosure or netting is strongly recommended to minimize damage and/or possible injury in the event of a mounting failure.MAINTENANCE WARNINGS• Modification of the equipment may cause excessive wear and will void the warranty. Contact COXREELS regarding changes or modifications of equipment which could affect reliability or safety.•DO NOT DISASSEMBLE A SPRING MOTOR FOR ANY REASON! Serious personal injury could result. Some hose reels are equipped with a spring under tension. Contact COXREELS for assistance.800-COX-REELTool Free Fax: 800-229-REEL Email: *****************SAFETYSPECIFICATIONS & LISTINGS•The identified Series of Hose Reel products within this manual are not certified or listed by any independent certifying or regulatory body.•This series of hose reels is intended for industrial use and are provided with permanent mounting means, with the exception of the portable reel models.PRESSURE & TEMPERATURE RATING•All reels covered in this manual with or without hose have specific P.S.I. ratings. (Please refer to the COXREELS catalog, website or contact Customer Service for reel specific data). Reels should not be used at pressures greater that the rating of the hose, swivel, plumbing or overall reel rating.•Multipurpose hose is installed with tube compounded for maximum oil resistance. Hose can be used for air, water, oil and many other chemical applications. •Operational temperature ranges vary across the wide range of hose options. (Please refer to the COXREELS catalog, website or contact Customer Service for hose specific data). Hose reels should not be used at temperatures below or above the rating of the hose.•The operational rating of a reel not equipped with hose is determined by the capacity of the installed hose. The pressure rating of the reel without hose must not be greater than the than the operational capacity of a reel. (Please refer to the COXREELS catalog, website or contact Customer Service for reel/hose specific data). Variations in the OD of higher rated hose will affect the operational capacity of the reel.LABELS & MARKINGSHose Reels with and without hose•The marking of the hose reel provide with or without hose includes the followingo The label on the frame includes the COXREELS name and Logo, the product catalog number, the individual product serial number, PSI rating and what type and length of hose intended for use on the reel.o The maximum pressure rating for every hose reel supplied without hose is marked on the COXREELS Identification Label. Actual rating is determined by the installed hose and is not to exceed the indicated maximum operational rating. The pressure rating of the hose installed on reelsprovided without hose must be marked on the label upon installation.NOTE: If for any reason the information is not included or the label has become illegible, please refer to the COXREELS catalog, website or contact Customer Service for reel specific data.PERSONAL SAFETY•Ensure reel has been properly installed before connecting supply line.•Before connecting to reel, be certain supply line does not exceed rated pressure of the hose reel or voltage / amperage rating on cable reel.•Thoroughly review the “Hose Installation” instructions to properly install hose.•Perform “Operational Check” per instructions to ensure reel is operating properly.•If a leak should occur after applying pressure to the reel, immediately turn off pressure source and discontinue supply line pressure.WARNING: Prevent static sparking. When working around flammables, ensure that the hose reel, hose, and equipment are properly grounded.INSTALLATIONWARNING: READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR MAINTAIN THIS PRODUCT. ONLY QUALIFIED PERSONNEL SHOULD UNDERTAKE THE INSTALLATION AND COMMISSIONING OF THIS PRODUCT. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.WARNING: REEL SHOULD NOT BE INSTALLED ABOVE 15 FEET MAXIMUM FROM THE FLOOR.MOUNTING OF REEL•The LG-Series spring-retractable reel is designed to be attached horizontally to a bench top, upside down underneath a bench top, or vertically along a wall or beam.•The reel base is equipped with four mounting holes to utilize 3/8” diameter hardware (not included).INSTALLATION•Apply thread sealant to inlet hose and connect to the swivel joint on reel. Note: A swivel type connector is required on supply line.CAUTION: IT IS IMPORTANT TO USE A “FLEXIBLE” INLET HOSE. DO NOT USE SOLID PIPING OR RESTRAIN INLET HOSE AS TO CAUSE ANY SIDE FORCE ON SWIVEL JOINT. THE WARRANTY IS VOID IF NOT PROPERLY INSTALLED.•Flush some product through the system before connecting inlet hose to the source. Connect end to supply source.•If reel includes hose (Otherwise, See Installation of Outlet Hose), flush some product through system before connecting end fitting, nozzle, or tool.•Apply thread sealant to outlet hose fitting. Connect end, nozzle, or tool as desired.•Hose stop adjustment may be required to attain desired location. Loosen (two) hose stop clamp bolts. Move hose stop and tighten bolts. Secure hose in hand while adjusting hose stop. Latch reel to secure if latching option is provided.OPERATIONAL CHECKNOTE: Steps 1-3 only apply to reels with latching option.•Check reel for correct operation by slowly pulling out hose. A clicking noise will be heard after each half revolution of the drum.•LATCH the reel. Pull out the hose and allow it to slightly retract after the first, second or third “click” is heard.•UNLATCH the reel. Slowly pull the hose until the clicking noise stops, and then allow the hose to retract. The hose stop should rest against the hose guide.CAUTION: DO NOT ALLOW HOSE TO RETRACT WITHOUT RESTRAINING RECOIL SPEED. NEVER LET GO OF THE HOSE WHEN REWINDING.•Apply line pressure and inspect for leaks. Periodically check hose for improper wear and swivel for possible leaks.•Reels are shipped with approximately three pre-wraps of tension. This is adequate for most applications. However, if your application requires more or less tension, see “Spring Tension Adjustment” instructions.•Lubrication is NOT required.INSTALLATION OF OUTLET HOSENOTE: Before proceeding, ensure that you are installing the proper size, length and type of hose that the reel is rated for. Consult factory if unsure of rating.Damage may occur if wrong hose and/or length is installed.•Securely stabilize the reel.•Insert the male fitted end of the hose through the cutout in the side of the disk flange.•The male hose fitting should now be on the outside of the drum. Apply thread sealant, connect hose fitting to the swivel joint and secure the hose rigid to the side of the disk with the hose clamp.•Wind the hose onto the reel counterclockwise facing the swivel.•When fully wound, pull the hose out approximately three turns of the reel and latch reel in place.•While reel is in latched position, pull slack hose back and wrap onto reel. This will give an initial pre-load of approximately three turns on the spring.NOTE: The hose clamp restrains the hose when fully extended, preventing strain between the fittings and swivel joint.•CAREFULLY release the locking ratchet (if so equipped) and SLOWLY allow the hose to retract onto the reel.SPRING TENSION ADJUSTMENTNOTE: Spring tension adjustment is accomplished by adding wraps of hose around the drum (to increase tension) or subtracting wraps of hose (to decrease tension).CAUTION: Improper tensioning of spring or adding too many pre-wraps may cause damage to spring mechanism. Only authorized personnel should make adjustments.•Release line pressure prior to making spring adjustments.• Disconnecthose.inlet•Pull out approximately 6 feet (2m) of hose and latch the drum (if so equipped).•Add or subtract one wrap of hose as desired to acquire the proper tension on the reel.•Unlatch drum (if so equipped) and check for proper tension. Connect Inlet hose.SWIVEL SEAL REPLACEMENT•Remove inlet hose from swivel.•Remove swivel from reel by unscrewing swivel from shaft. Disconnect hose from swivel.•Remove retaining ring on swivel; pull out shaft from body.•Replace the seals, lubricate and reassemble swivel.•Fit hose to swivel then fit swivel to reel. Do not over-tighten.• Reconnectinlethoseand test for leakage.TROUBLE SHOOTING GUIDETROUBLE CAUSE REMEDYHOSE WILL NOT FULLY RETRACT a) Outlet nozzle, gun or tool is too heavy.b) Spring is fatigued.c) Field installed hose is too long.a) Add spring tension. See "Spring Tension Adjustment".b) Add spring tension. See "Spring Tension Adjustment".c) Call local Distributor for correct specified hose length.HOSE WILL NOT RETRACT AT ALL Spring has lost all tension or has possibly broken. a) AdjustSpringTensionb) Call local distributor for drum/spring assembly replacement.REEL WILL NOT LATCH (APPLIES IF EQUIPPED WITH LATCH OPTION) a) Incorrectoperation.b) Dog spring or locking cam is broken or worn.a) Reel latches on first, second, third or fourth "click".After forth "click" it automatically rewinds.b) Replace dog spring or locking cam.FLUID LEAKS FROM SWIVEL Swivel seals are damaged or worn. Replace swivel seals. See "Swivel Seal Replacement". Caution: Be sure leak is not at Hose Fitting!。

全屋定制衣柜橱柜装修安装服务手册1. 服务介绍本手册旨在提供全屋定制衣柜橱柜装修安装服务的详细指南和流程,帮助客户了解我们的服务内容和操作步骤。

2. 服务流程2.1 上门测量在开始定制衣柜橱柜装修安装服务前,我们将安排专业团队上门进行测量。

测量过程包括对空间尺寸、墙壁结构和其他特殊要求进行详细测量和记录。

2.2 设计方案确认基于客户的需求和测量结果,我们将制定一个个性化的设计方案。

设计方案将包括衣柜橱柜的样式、材料选择、配件配置等内容。

客户可以根据自己的喜好和需求提出修改意见,并在最终确认前与我们进行沟通。

2.3 生产制造一旦设计方案获得客户的最终确认,我们将开始进行生产制造。

我们将使用高质量的材料和先进的加工设备,确保衣柜橱柜的质量和精确度。

2.4 安装调试完成生产制造后,我们将安排专业安装团队上门进行安装调试。

安装过程将根据实际情况进行,确保衣柜橱柜的稳固性和功能性。

安装完成后,我们将进行调试和检查,确保衣柜橱柜的正常使用。

3. 注意事项在使用我们的全屋定制衣柜橱柜装修安装服务时,请注意以下事项:- 在测量和设计过程中,提供准确的空间尺寸和特殊要求,以确保最终结果符合您的期望。

- 在设计方案确认前,请仔细审查并提出修改意见,确保设计方案符合您的需求。

- 在安装过程中,请确保房间内的其他家具和物品已经移除或保护好,以免受到损坏。

- 在使用衣柜橱柜时,请注意遵守使用说明和注意事项,以延长其使用寿命。

4. 联系方式如有任何疑问或需要进一步了解我们的全屋定制衣柜橱柜装修安装服务,请随时联系我们的客服团队。

- 客服我们将竭诚为您提供满意的服务。

全屋个性化家具橱柜衣柜安装规程1. 引言本文档旨在提供全屋个性化家具橱柜衣柜的安装规程,以确保安装过程顺利进行并确保最终效果符合客户的要求和期望。

2. 准备工作在进行安装之前,需要进行以下准备工作:- 确定安装位置:根据客户的需求和设计方案确定橱柜衣柜的安装位置。

- 测量空间尺寸:准确测量安装空间的尺寸,确保橱柜衣柜能够完全适应该空间。

- 检查安装材料:确保所需的安装材料齐全,并检查其质量和完好性。

- 清理安装空间:清理安装空间,确保没有障碍物和杂物。

3. 安装步骤按照以下步骤进行全屋个性化家具橱柜衣柜的安装:1. 拆卸旧家具(如果适用):如果存在旧家具,需要先进行拆卸和清理工作。

2. 根据设计图纸进行布局:根据设计图纸和客户要求,进行橱柜衣柜的布局,并确定安装位置和顺序。

3. 安装底座和脚轮:根据橱柜衣柜的设计和结构,安装底座和脚轮,确保稳固和平衡。

4. 安装底柜和吊柜:按照设计图纸和安装顺序,逐个安装底柜和吊柜,并使用适当的连接件进行固定。

5. 安装门板和抽屉:安装橱柜衣柜的门板和抽屉,确保它们的平整和顺畅运动。

6. 安装配件和附件:根据设计要求,安装橱柜衣柜的配件和附件,如拉手、挂钩等。

7. 进行调整和清理:对安装好的橱柜衣柜进行调整,确保各部件的平整和对齐,并清理安装现场。

8. 进行最终检查和验收:对安装完成的全屋个性化家具橱柜衣柜进行最终检查,确保质量和外观符合要求,并与客户进行验收。

4. 注意事项在安装过程中,需要注意以下事项:- 确保安装过程安全:在进行安装工作时,要注意自身的安全和周围环境的安全。

- 保护好家具和地板:在安装过程中,使用合适的保护措施,以防止家具和地板受到损坏。

- 严格按照图纸和说明进行安装:在安装过程中,严格按照设计图纸和安装说明进行操作,确保安装正确。

- 注意细节和质量:在安装过程中,注重细节和质量,确保橱柜衣柜的外观和使用效果达到最佳状态。

5. 总结本文档提供了全屋个性化家具橱柜衣柜的安装规程,包括准备工作、安装步骤和注意事项。

橱柜安装说明书

1、地柜的安装

a)地柜从包装中打开后,将其倒放在打开的包装膜上,把调节脚按已打开的调节脚孔位将其装在柜体的底板上(注:调节脚座较长的一端必须搭在柜体的侧板上),然后将已装好调节脚的地柜按设计图纸所示摆放(注:摆放前将地脚与踢脚板调成同高)。

b)装铝支腿与调节脚不同的是两个相连柜体间的支腿是共用的,其装法从柜体的一头装起。

c)如摆放的柜体需要躲管道挖豁口的,必须量好管道的直径尺寸大小,用曲线锯在其对应柜体的位置按其大小开孔。

开孔的部位必须抹上玻璃胶使其不受潮。

d)摆完的地柜必须用水平尺测量其面上是否成一水平线,不水平的必须重新调整地脚使之在同一水平线。

e)柜体调平后,柜体与柜体间必须用对接螺丝将连接固定于一体,其对接孔位必须打在柜体侧板的系统孔内(两侧板的对应孔位对应一致)。

孔的位置在排列的系统孔上部,进深方向前后各一个,在前排系统孔的下部打一个孔位,每两个地柜连接需要三个对接螺丝。

f)打对接螺丝孔,必须在摆放地柜前单独的在其侧板上用Φ5的电钻头从系统孔内向外延伸打透,必须保证两柜相连侧板的连接孔位对应一致。

g)地柜调整完毕后方可将台面小心摆放在地柜面上。

2、吊柜的安装

a)安装吊柜时,必须按图纸所示标高(或根据现场实际测量情况)划好所挂吊柜高度的水平线,(若图纸或客户对此都无明确要求,一般吊柜与台面间距离应为600mm)然后将吊柜的墙板按已划好线的相对位置用膨胀螺丝固定好,同一组吊柜墙板的安装必须保证在同一水平线上,以保证往上挂的吊柜在一条水平线上。

b)安装时若图纸或客户对此都无明确要求,一般吊柜与台面间距离应为600mm

c)用电锤往墙上打膨胀螺栓(或膨胀螺丝)孔时,必须用与其相对应的电锤头孔的深度应比螺栓自身长1-2厘米。

往孔内打膨胀螺丝时,必须先将螺帽拧出螺杆端头1-2mm,方可用铁锤打入孔内,然后用扳手将螺母拧紧。

d)挂吊柜时,有需要躲开管孔的操作方法同地柜一样。

e)挂烟机吊柜前,必须先量好烟机的烟管所对应的在柜的位置,在其位置上按烟机的尺寸大小用曲线锯开孔,之后再往墙上挂。

3、桶柜的安装

a)桶柜与地柜为一组摆放时,必须将桶柜调平,然后安装对接螺丝。

(操作方法与地柜相同)

b)若是冰箱桶柜或是装高深拉兰的桶柜,其底板必须加装2-4个调节脚。

4、装完所有的橱柜后必须调试门和内置五金

a)调门板调试:主要是通过调节铰链的可调螺母来使门板左右协调。

调节门板必须保证同一组柜体从正面看门缝隙均匀、上下平齐,侧面看门与柜体平行,在调节门板的同时必须检查铰链与门板、柜体连接的牢固性。

b)抽屉调节包括木抽、铝抽、法尼尼弧抽,检查其滑轨是否抽拉匀和顺畅及屉面是否平整。

c)木抽主要通过调节滑轨与侧板(或与屉胆)连接的松与紧(拧滑轨与侧板或屉胆连接的自攻钉)来调整其抽屉。

d)法尼尼弧抽、铝抽则是通过调节屉帮与屉面连接处的调节螺丝来调整其抽屉的抽拉。

e)五金拉兰的调节:主要对其拉兰的滑轨进行检查,如拉兰抽拉时晃,一是调整其滑轨与板连接的紧密程度,二是调整拉兰与滑轨的连接部位。

5、踢脚板的安装

A.装踢脚板之前,必须把地柜底部的粉尘及垃圾清理干净,然后踢脚板上装好卡子,再将装好卡子的踢脚板装在地柜底部使卡子扣到调节脚上。

B.如需安装挡水压条,应在上踢脚板前顺序安装在踢脚板立面的槽孔内。

C.安装完的踢脚板应与地面同齐。

6、顶线、底线的安装

A.装铝合金顶线(必须搭配装堵头)、碧西顶线前,先用角铁将顶线与顶线辅助板连接为一体,使顶线与辅助板的夹角成135度,然后将其平放于吊柜的顶板上与前檐平齐,之后用自攻钉将吊柜顶板与顶线辅助板连接在一起。

安装45度对接的顶线时接缝整齐、对接角严密(在吊柜顶部与顶棚距离过小时,铝顶也可以直接装在吊柜顶部)。

B.装芬妮尔欧松顶线(必须配装堵头)时,先将其所配的支座用4*16的自攻钉均匀的固定在已安装完的吊柜的顶板上,且距顶板前檐10-20mm,然后将顶线装在地支座上。

C.装U型铝底线时,用4*16的自攻钉从铝底线的内部顶面与吊柜(地柜)底部相连接,且保证底线与吊柜(地柜)底部前檐平齐。

装碧西底线使用的是直角铁将底线与吊柜底板相连接,其方法大致与装顶线相同。

D.铝装饰条(北欧系列)是柜体与柜体之间的间隔条,它的安装是用4*16的自攻钉从装饰条的内部较宽的一侧往柜体侧板的外侧固定,并使其平齐于侧板。

E.装顶线时必须检查所用自攻钉是否过长,以确保顶线与角铁连接时不被其穿透。

7、台面的安装

A.防火板台面的安装:按图纸所示将台面平放于已调平的柜面上,然后把台面及台面挡水与墙壁相交的部位打上玻璃胶,L台面必须使用台面连接器连接,如有管道需开孔时,其方法、步骤与地柜开孔操作一样。

B.人造石台面的安装:与防火板台面的安装不同的是台面与台面连接处需现场手工粘接,粘接时根据现场实际情况用角磨机及砂布修整台面的拼接处,然后将专用胶水抹在拼缝处两侧,并由两边向拼缝处挤紧,待胶干后再进行抛光打磨。

(因打磨粉尘较大,故在此之前必

须将已安好的电器、橱柜该遮的地方必须用膜或其它物品遮好,在粘台面的过程中不允许用502胶,打磨范围一般应在接缝处左右300mm为宜)。

8、电器安装

A.安装壁挂式电器(如消毒碗柜、烟机等)必须按照电器说明书,根据要求按现场实际尺寸用膨胀螺丝把挂件固定于墙上(操作方法与挂吊柜一样),然后将其电器挂于挂件上。

B.安装电器时必须小心,不能允许外壳与其它硬质物体相碰、摩擦,造成电器外壳的损伤。

C.电烤箱的安装:在安装前必须先将电源引到位,再把其按说明要求嵌入柜体内,如有固定件需与柜体连接。

D.射灯的安装(包括探头灯、内卧灯、柜底灯等):

a)探头灯:按图示位置用角铁支座固定在吊柜顶部且探出顶线,然后接好探头灯电线并联引到电源处。

b)内卧灯:一般安装在玻璃门吊柜内部顶板已预开好的灯孔上(若没开灯孔的,在现场根据灯的大小,将孔开在吊柜顶板的正中位置处),灯孔与灯咬合紧密后,然后接好电线,将其从吊柜顶部灯孔处引到电源处(注:多灯并联)。

c)柜底灯:是安装在吊柜底板下射灯,其方法同上。

E.碎渣机的安装:按客户所指定的位置,按说明书要求先把纯水机主体装好,再接进水管,然后对其进行调整;调整完后通电,通水调试。

(注:再接纯水机电源时,应保证电源与纯水机有一定的距离1-2米)

G.安装完的电器必须一一通电调试达到正常使用状态。

9、嵌入式燃气灶的安装

A.安装前必须在已开好的灶孔周边贴上隔热锡纸,再用软管把出气管与灶的进气管连接好,软管的两端必须用管箍将其卡紧,以防漏气。

软管装好后可将灶嵌入孔内,同时把橡胶垫条

塞入灶的底檐周边,安装完毕后必须通气试火,进行调整。

B.注意应将灶进气管为防进粉尘的封堵物拆去再装软管。

10、安装水盆、龙头

A.在装水盆的同时也装上水、下水,装上水管必须用生胶带在出水管的螺口上缠数圈再将上水软管与对接拧紧,以防漏水。

用同样的方法把上水管与龙头对接,水盆嵌入孔内,然后安装下水,下水有螺口对接的,装法与上述一致,无螺口对接的必须是逆水流方向,大口对小口装下水软管,接口处必须打玻璃胶或用卡子箍紧,以防漏水。

B.水龙头固定于台面或水盆时,拧螺帽时必须垫橡胶垫圈和金属垫片。

C.水盆装完下水、水龙头后,水盆扣于台面的交接处必须打上玻璃胶和装固定卡。

D.水盆、龙头、上下水装完后必须通水调试,检查是否有漏水现象。

11、护墙板的安装(包括钢护墙、铝护墙)

A.安装前必须根据其护墙的尺寸在吊柜与地柜间留出其余地(设计合理的情况下),安装时按设计要求结合现场实际情况将其立放于墙上,一人扶着护墙板,一个用电锤通过其往墙上打膨胀螺栓孔。

将膨胀螺栓或膨胀螺丝塞入孔内拧紧,固定其护墙板。

B.装完的护墙板与柜体、台面挡水交接的地方必须打玻璃胶将缝隙填平。

12、安装收尾工作

A.自检工作:待全部产品安装完毕后,应按公司“厨房家具及配置产品的安装要求和检查检验方法”中规定的方法及标准进行自检。

B.保洁工作:待自检工作完成后就清除现场的一切废物,做好场地及公司产品的保洁工作。

C.收拾工具,带走垃圾。