医疗器械生产工艺流程图

- 格式:doc

- 大小:23.50 KB

- 文档页数:1

医疗器械工艺流程图编写要求英文回答:Medical Device Process Flow Diagram Writing Requirements.Purpose:To establish guidelines for the creation of process flow diagrams for medical devices.Scope:This document applies to all medical device processes, including design, development, manufacture, and distribution.Requirements:Accuracy: Process flow diagrams must accuratelyreflect the actual flow of activities and materials.Clarity: Diagrams should be easy to understand and interpret.Consistency: Diagrams should use standard symbols and terminology throughout.Completeness: Diagrams should include all relevant steps and activities.Validation: Diagrams must be validated to ensure that they accurately represent the intended process.Procedure:1. Identify the process to be diagrammed.2. Gather data on the process.3. Create a draft diagram.4. Review and validate the diagram.5. Implement the diagram.Specific Requirements:Symbols: Use standard symbols to represent activities, materials, and decisions.Terminology: Use clear and concise terminology that is consistent throughout the diagram.Flow lines: Use arrows to indicate the flow of materials and activities.Decision points: Use diamonds to represent decision points.Validation: Validate diagrams by comparing them to actual observations of the process.Additional Considerations:Software tools: Consider using software tools to create and manage process flow diagrams.Collaboration: Involve all relevant stakeholders in the creation and validation of diagrams.Continuous improvement: Regularly review and update diagrams to ensure accuracy and relevance.Benefits of Using Process Flow Diagrams:Improved communication: Diagrams provide a clear and concise way to communicate complex processes.Increased efficiency: Diagrams help identify bottlenecks and areas for improvement.Reduced errors: Diagrams help ensure that all steps in a process are followed correctly.Enhanced compliance: Diagrams help demonstratecompliance with regulatory requirements.中文回答:医疗器械工艺流程图编写要求。

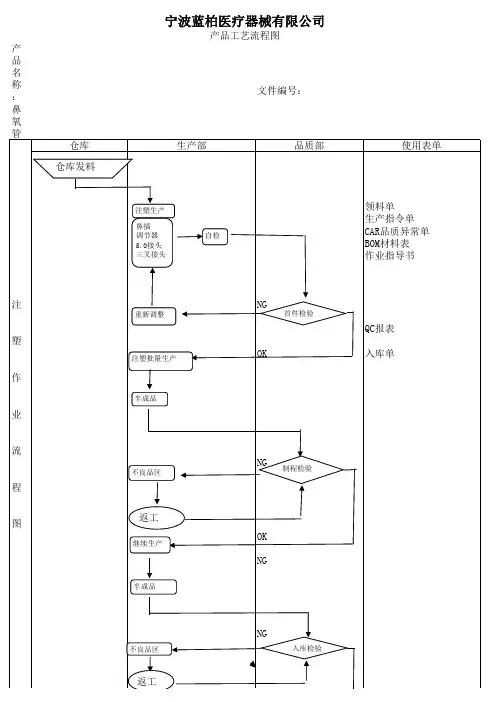

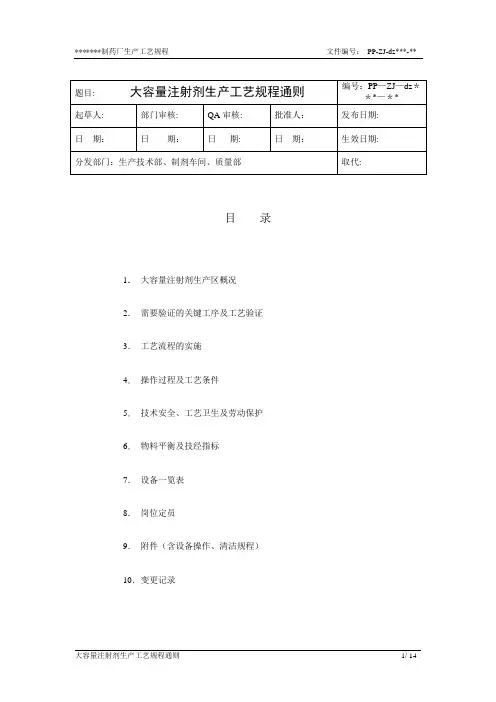

目录1.大容量注射剂生产区概况2.需要验证的关键工序及工艺验证3.工艺流程的实施4.操作过程及工艺条件5.技术安全、工艺卫生及劳动保护6.物料平衡及技经指标7.设备一览表8.岗位定员9.附件(含设备操作、清洁规程)10.变更记录1.大容量注射剂生产区概况本生产区面积904㎡,其中1万级净化区域167㎡,10万级净化区域174㎡.大容量注射剂车间采用10万级和1万级(局部百级)空气净化洁净级别,10万级区域设置缓冲、更衣、洗涤、洁具、称量、配碳、浓配、洗瓶等,1万级区域设置缓冲、更衣更鞋、稀配、化验、灌装、加塞、轧盖、洗涤、存放、洁具等功能间,所有隔断采用无粉尘产生的静电喷涂彩钢板,结合处采用圆角处理,不易产生积灰;人员经过三次更衣和二次更鞋后进入洁净区操作,物料进入洁净区均采用传递窗或气闸进行传递,人流、物流的进入相对分开,保证了洁净区空气洁净度要求;生产设备均采用优质不锈钢材料制造,采用洗瓶、灌装、压塞、轧盖联动线生产,其中洗瓶出口、灌装、加塞采用百级层流保护,灭菌器采用水浴式灭菌器。

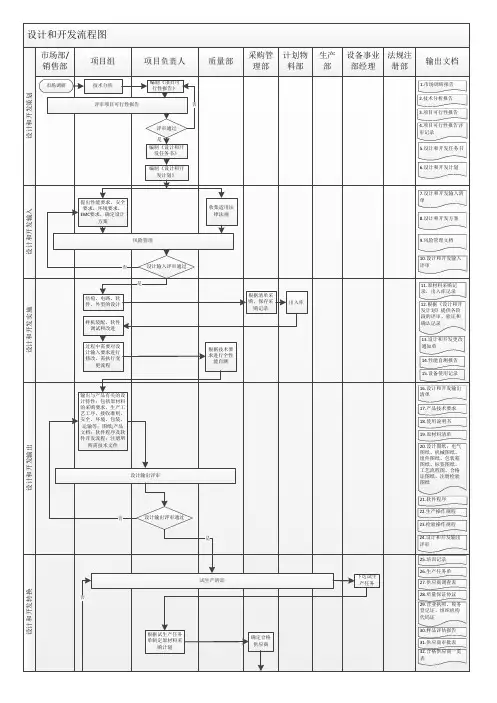

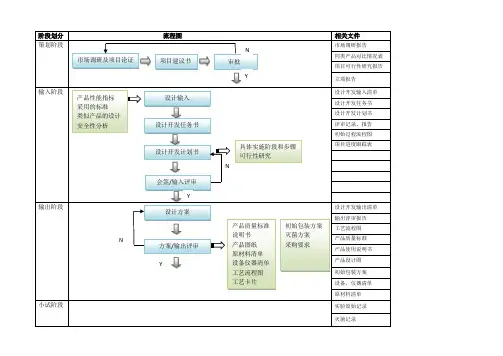

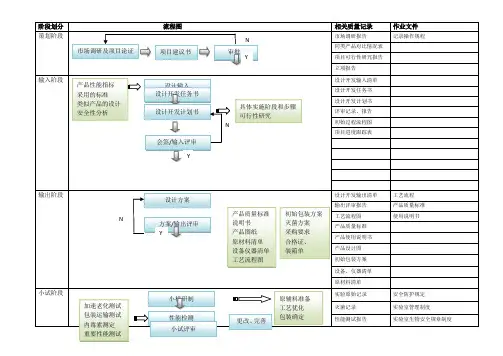

1.1 大容量注射剂生产工艺流程图(见后页)1.2 大容量注射剂生产区工艺布局布置图(见后页)1.3 大容量注射剂生产区工艺设备布置图(见后页)1.4 大容量注射剂生产区送回风口平面布置图(见后页)以上项目按验证文件规定,均已在规定周期内进行相关的验证,验证方案及报告见相应文件。

大容量注射剂生产工艺流程图3.工艺流程的实施3.1 批生产指令的签发3.1.1 批生产指令由车间技术负责人根据生产计划表起草,并依据产品工艺规程于生产前一个工作日制定。

3.1.2 批生产指令应经QA质监员审核并签字,由车间主任签字批准后生效。

3.2 生产批记录的发放3.2.1 除配制工序和包装工序外,工序相应的生产批记录于生产当日由车间工艺质监员发放给各工序负责人,并于工序结束当日填写完整返回车间工艺质监员处汇总。

3.2.2 配制工序和包装工序的生产批记录于生产前一天由车间工艺质监员随同批生产指令或批包装指令一同发放,并于工序结束当日填写完整返回车间工艺质监员处汇总。