Time study_时间研究模板

- 格式:xls

- 大小:34.50 KB

- 文档页数:1

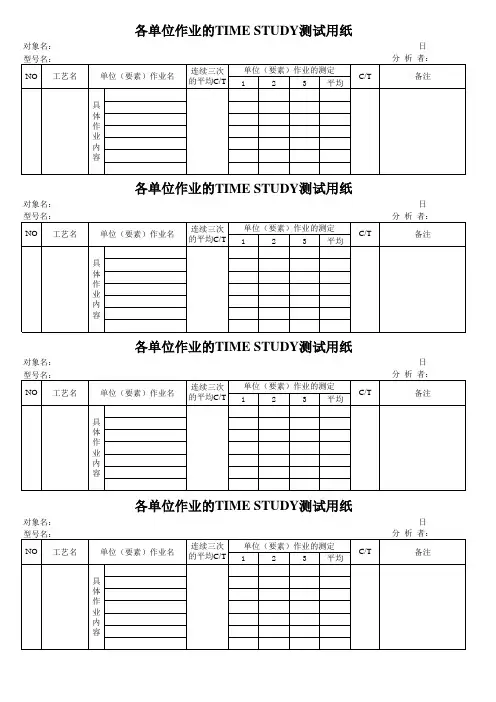

时间研究T i m e S t u d y教程Pleasure Group Office【T985AB-B866SYT-B182C-BS682T-STT18】O r g a n i s a t i o n&P r o g r e s s R e f e r e n t i a l “D e t e r m i n a t i o n o f U n i t T i m e s”.A A I I M MThis referential describes the methods and tools to be implemented for establishing unit times.A A R R E E A A O O F F A A P P P P L L I I C C A A T T I I O O N NThis referential is to be applied by 01/09/2005 at the latest in all the industrial entities in theGroup. The users of the referential are the members of the Organisation and Progress métierwho have been validated for the post of Study Organiser.D DE EF F I I N N I I T T I I O O N N S S▪Unit Time :This is the time it takes a capable and trained operator to complete a Unit ofProduction or a Unit of Work in determined conditions, using the method, machinesand equipment provided.You will find an example of a Unit Time sheet at the end of this document.▪Chronométrage (Time-study):▪Time-study is the operation which consists in:▪Checking that the Method of Work is correctly applied.▪Assessing and recording the working rate of the operator observed.▪Measuring and recording times.You will find an example of a time recording sheet at the end of this document.▪Work Element :This is a portion of work demarcated by two measurement references and consistingof an ordered sequence of defined actions of a homogeneous nature.▪Concept of rate :An operator’s working rate is his instantaneous speed of execution of a useful piece of workwhen this speed is dependent solely on the operator’s working rhythm. This rate or speedtakes account of the execution conditions (difficulty, precision, ergonomics, etc.).▪Rating :This is the operation by which a qualified organiser assesses the working rate of an operatorin relation to his mental image of a rate of 100.▪Reference rate :The reference rate is known as “Rate 100”.This is the working rate which any average operator, capable, trained and qualified to occupythe post, can maintain constantly throughout his working time at the post (generally an 8 hourshift), without damaging his health.▪This rate is calibrated on the pre-determined time standards times (Tt) :These are elements the duration of which depends only on technological constraints independent of the operator. The operator can only respect these constraints or suffer them.▪Manual or human times (Tm) :These are elements the duration of which depends only on the operator’s action. This operation may be performed using an inert means.▪Techno-manual or techno-human times (Ttm) :These are elements of intermediate nature, . the duration of which depends both on the operator’s action and on technological constraints which are combined with it.▪Linked irregular (Unavoidable Anomaly) :This is an event with a random frequency of occurrence, linked directly to a work elementplanned in the method of work (manual or techno-manual).The irregular has a direct impact on the duration of the work element . slippage of the rollerwhen joining a laize on a finishing post, re-opening of a bandage bead on a before-cureverification post following its unexpected closure).I I N N S S T T R R U U C C T T I I O O N NPrecondition :➢The determination of work element times must be done on an optimised method of work, that is, within the context of a post study after the analysis and critique stages.➢The unit of time used for the determination of work elements is :▪The Cmn (hundredth of a minute) for time-study.The TMU (time measurement unit) for the predetermined timemethods or TMU = 1/100,000th of an hour.➢Unit times are expressed in Cmn (Hundredths of a minute).The different methods of time determination (Tm and Ttm) :Two methods can be used for determining times :Predetermined time methods, or of method :See flowchart below.:M aynard O perations S equence T echniqueis a technique for the analysis and measurement of work, based on a system of sequences of predetermined movements.Example of sequence (Basic MOST) : A6 B6 G1 A1 B0 P3 A0 = 17*10 = 170 TMU- There are different versions of MOST in use within the company (Mini or Basic) which will be employed according to a number of criteria represented in the flowchart below :Precision :Interest of MOST :➢Speed of establishment of elementary times :▪Basic MOST is 40 times quicker than MTM1,▪Mini MOST is 14 times quicker than MTM1,▪Mini and Basic MOST are times quicker than Time-study.➢MOST is very efficient in optimisation phases (analysis and critique made easier).➢MOST favours uniformity of the results obtained.➢MOST is easy to explain and understand (common language for operators, supervisors and organisers).➢This method enables the operators to be more involved in the improvement of their methods of work.➢The tables of predetermined times correspond to a rate of 100. There is no need for rating.➢Possibility of estimating times in advance (simulation).➢Easier in the updating phases.➢Less laborious technique than time-study and more rewarding for organisers.➢Less restricting for operators.Disadvantage:➢More difficult to identify and put a value on irregulars compared with Time-study.➢Potentially, less organiser presence on the ground.Time-study :Implementation of time-study involves breaking down the method of work into work elements.▪Work Element :➢This is a portion of work demarcated by two measurement references and consisting of an ordered sequence of defined actions of a homogeneous nature.➢This is the smallest portion of work we analyse.▪Phase:➢This is a defined set of work elements.. – The breakdown into phases is optional ; it depends on the cycle duration.▪Regular cycle :➢This is a set of phases, and consequently work elements, which recur in a determined order when each Production Unit .) or Unit of Work is being executed.Minimum precision required :The time-study method proposed was developed by the PE3/ET department (M. Serge LAROUX).The document describing the statistical method can be obtained from the O&P school.▪Case 1 :with a frequency of 1 per Unit of Production at the post.These elements will enable us to define the duration of the minimum period of the simogram.Example : join a laize to produce a roll.See flowchart below :The time adopted is called the elementary time or ET.The normality test and the precision calculation take place using the form referred to at the end of the document.▪Case 2 : with a frequency of < 1 per Unit of Production at the post.These elements will enable us to define the duration of the maximum period of the simogram.Example : evacuation of a pallet of rolls from a cutter.See flowchart below :The time adopted is called the elementary time or ET.The normality test and the precision calculation take place using the form referred to at the end of the document.▪Case 3 : Activities outside Production Unit . start and end of shift, safety instructions).See flowchart below :The time adopted is called the elementary time or ET.The precision calculation is done using the form referred to at the end of the document.Implementation of the normality test according to the SHAPIRO-WILK method involves the installation of the BUS application under Excel. You must submit a request to your RUL who will give you installation rights.Rating :Validation criterion for rating :➢the organiser must demonstrate that he has the ability to practise rating. He is qualified in this practice when he is considered stable on the criteria of “Mean deviation” (tolerance of ±3%) and “Standard deviation” (tolerance = . This stabilisation is monitored using theform referred to at the end of the document.➢After stabilisation, he must carry out a minimum of 6 exercises of 15 sequences per quarter, .24 exercises a year.➢Maintained qualification in rating is one of the essentials of the Métier Guarantee and is the responsibility of the ROPs in the sites.Technological times :The determination of technological times is based on :➢Measured times, analysed using the form (identical to the one used for time-study) referred to at the end of the document and in accordance with the precision rules explained in the “Time-study” section.➢Times calculated by a technical or methods group (for example, of the speed type in preparation or dependent on advance and speed for machining time).➢Times coming from control systems which will be analysed manually so as to identify the unforeseen elements.Technological times must be standardised and maintained long-term in all cases. This responsibility lies with the Organiser.Linked Irregular times (Unavoidable Anomalies) :The determination of Linked Irregular times is based on :➢MOST analysis if the nature of the anomaly permits . eliminate defects from a laize).➢Times measured when taking time readings.➢The frequency of occurrence of the anomaly, determined from the data collected during the time-study session or by continuous observation.The unit time sheet :It must be totally consistent with the chronology of operations coming from the simogram.It is an essential component of the study dossier.It is the base document for measuring the activity of people and machine loads.It must show :Identification of the production workshop.Identification of the work postIdentification of the organiser.Identification of the production unit.Page numbering and date of execution.Simogram references.Numbers of the elements of the simogram (consistent with the numbers used in time-study sessions or by the predetermined time methods).Descriptions of the elements of the simogram (consistent with the descriptions used in time-study sessions or by the predetermined time methods).Frequencies of occurrence of the elements of the simogram (the frequency calculation will be noted as an appendix to the Unit Time sheet).Elementary times of technological work elements.Elementary times of manual and techno-manual work elements.Calculation of unit times of work elements . * Frequency).Identification of manual and techno-manual work elements masked by a technological time.Identification of technological times masked by manual or techno-manual work elements.Calculation of the sum of technological times.Calculation of the sum of manual and techno-manual Times.Calculation of the sum of determinant Times (manual and techno-manual).Calculation of unit Time (Tt + Tm determinant + Ttm determinant)Calculation of the % occupation of the operator (Sum of Tm and Ttm / Unit time)Identification of the units produced – Item and quantity.Creation of new unit times :Unit times are to be determined when starting up a new installation or taking new dimensions in hand.See flowchart below :Updating frequency for unit times :Unit times must be updated and maintained in the long term.The updating of unit times is one of the essentials of the Métier Guarantee and is the responsibility of the ROPs in the sites.The methods of operation are described and documented locally.Updating must be demonstrated and recorded (traceability).A unit time must be updated as soon as a modification occurs.See flowchart below :This modification may arise from various sources :Change of method of work.Evolution of technological times.Evolution of the organisation.Product/Process evolution.Etc …If no modifications have been identified within 1 year, the validity of the UT must be checked.See flowchart below :TU not modifiedfor 1 yearTechno Times modifiedTU updated immediatelyNoUpdate of the updatingdate of the TUYesMethod of work modifiedNoYesD D O O C C U U M ME E N N T T R R E EF F E E R R E E N N C C E E S SDocument titleDocumentreferencesFormExample of “Unit Time Sheet”Example of “Time Record Sheet”Determination of ET with sample size of 15 or 30 elementsDetermination of ET outside production activity.Maintained qualification in rating.。

O r g a n i s a t i o n&P r o g r e s s R e f e r e n t i a l “D e t e r m i n a t i o n o f U n i t T i m e s”.A A I I M MThis referential describes the methods and tools to be implemented for establishing unit times.A A R R E E A A O O F F A A P P P P L L I I C C A A T T I I O O N NThis referential is to be applied by 01/09/2005 at the latest in all the industrial entities in theGroup. The users of the referential are the members of the Organisation and Progress métierwho have been validated for the post of Study Organiser.D DE EF F I I N N I I T T I I O O N N S S▪Unit Time :This is the time it takes a capable and trained operator to complete a Unit ofProduction (U.P) or a Unit of Work in determined conditions, using the method,machines and equipment provided.You will find an example of a Unit Time sheet at the end of this document.▪Chronométrage (Time-study) :Time-study is the operation which consists in:▪Checking that the Method of Work is correctly applied.▪Assessing and recording the working rate of the operator observed.▪Measuring and recording times.You will find an example of a time recording sheet at the end of this document.▪Work Element :This is a portion of work demarcated by two measurement references and consistingof an ordered sequence of defined actions of a homogeneous nature.▪Concept of rate :An operator’s working rate is his insta ntaneous speed of execution of a useful piece of workwhen this speed is dependent solely on the operator’s working rhythm. This rate or speedtakes account of the execution conditions (difficulty, precision, ergonomics, etc.).▪Rating :This is the operation by which a qualified organiser assesses the working rate of an operatorin relation to his mental image of a rate of 100.▪Reference rate :The reference rate is known as “Rate 100”.This is the working rate which any average operator, capable, trained and qualified to occupythe post, can maintain constantly throughout his working time at the post (generally an 8 hourshift), without damaging his health.This rate is calibrated on the pre-determined time standards (M.T.M.).▪Technological times (Tt) :These are elements the duration of which depends only on technological constraints independent of the operator. The operator can only respect these constraints or suffer them.▪Manual or human times (Tm) :These are elements the duration of which depend s only on the operator’s action. This operation may be performed using an inert means.▪Techno-manual or techno-human times (Ttm) :These are elements of intermediate nature, i.e. the duration of which depends both on the operator’s action and on technological constraints which are combined with it.▪Linked irregular (Unavoidable Anomaly) :This is an event with a random frequency of occurrence, linked directly to a work elementplanned in the method of work (manual or techno-manual).The irregular has a direct impact on the duration of the work element (e.g. slippage of theroller when joining a laize on a finishing post, re-opening of a bandage bead on a before-cureverification post following its unexpected closure).I I N N S S T T R R U U C C T T I I O O N NPrecondition :➢The determination of work element times must be done on an optimised method of work, that is, within the context of a post study after the analysis and critique stages.➢The unit of time used for the determination of work elements is :▪The Cmn (hundredth of a minute) for time-study.▪The TMU (time measurement unit) for the predetermined time methods (M.O.S.T. or M.T.M.).1 TMU = 1/100,000th of an hour.➢Unit times are expressed in Cmn (Hundredths of a minute).The different methods of time determination (Tm and Ttm) :Two methods can be used for determining times :1. Predetermined time methods, M.T.M. or M.O.S.T.2. Time-study.Choice of method :See flowchart below. Times to be measured-Technological times,-Very variable times and methods (e.g. repair),-Mental activity (checks,verification).1/ Use of predetermined time methods.2/ Chronométrage.Yes1/ Time measurement.2/ Chronométrage.NoM.O.S.T :M.O.S.T.M aynard O perations S equence T echniqueM.O.S.T. is a technique for the analysis and measurement of work, based on a system of sequences of predetermined movements.Example of sequence (Basic MOST) : A 6 B 6 G 1 A 1 B 0 P 3 A 0 = 17*10 = 170 TMU- There are different versions of MOST in use within the company (Mini or Basic) which will be employed according to a number of criteria represented in the flowchart below :-Cycle less than 3235 TMU-Resulting weight < 5KG-Distance < 2 StepsAll distances < 25 cm-Need for detailed analysis Right hand / Left handYesMini MOST analysis No Basic MOST analysisMOST analysis tobe performedPrecision :M.O.S.T. guarantees a level of precision of ± 5%and 95% confidence for unit times.Interest of MOST :➢Speed of establishment of elementary times :▪Basic MOST is 40 times quicker than MTM1,▪Mini MOST is 14 times quicker than MTM1,▪Mini and Basic MOST are 2.5 times quicker than Time-study.➢MOST is very efficient in optimisation phases (analysis and critique made easier).➢MOST favours uniformity of the results obtained.➢MOST is easy to explain and understand (common language for operators, supervisors and organisers).➢This method enables the operators to be more involved in the improvement of their methods of work.➢The tables of predetermined times correspond to a rate of 100. There is no need for rating.➢Possibility of estimating times in advance (simulation).➢Easier in the updating phases.➢Less laborious technique than time-study and more rewarding for organisers.➢Less restricting for operators.Disadvantage:➢More difficult to identify and put a value on irregulars compared with Time-study.➢Potentially, less organiser presence on the ground.Time-study :Implementation of time-study involves breaking down the method of work into work elements.Regular cyclePhaseWork Element▪Work Element (E.d.T.) :➢This is a portion of work demarcated by two measurement references and consisting of an ordered sequence of defined actions of a homogeneous nature.➢This is the smallest portion of work we analyse.▪Phase :➢This is a defined set of work elements.N.B. – The breakdown into phases is optional ; it depends on the cycle duration.▪Regular cycle :➢This is a set of phases, and consequently work elements, which recur in a determined order when each Production Unit (U.P.) or Unit of Work is being executed.Minimum precision required :The time-study method proposed was developed by the PE3/ET department (M. Serge LAROUX).The document describing the statistical method can be obtained from the O&P school.▪Case 1 :E.d.T. with a frequency of 1 per Unit of Production at the post.These elements will enable us to define the duration of the minimum period of the simogram.Example : join a laize to produce a roll.See flowchart below :E.d.T with afrequency >= 1per U.PTest of accepted normality according to the SHAPIRO-WILK method at an alpha riskof 5%.Analysis required tounderstand why the distribution is not normal. Measurement of 30 furthertimes. Deletion of the first 30 times.YesCalculation of time precision.NoChronométrage or measurement of 30 timesTime precision<= 5%YesTime adopted = arithmetical mean of thesamplesAdditional Chronométrage or timemeasurement to reach a level ofprecision of 5%.NoThe time adopted is called the elementary time or ET.The normality test and the precision calculation take place using the form referred to at the end of the document.▪Case 2 : E.d.T. with a frequency of < 1 per Unit of Production at the post.These elements will enable us to define the duration of the maximum period of the simogram.Example : evacuation of a pallet of rolls from a cutter.See flowchart below :E.d.T with afrequency of < 1per U.PTest on accepted normality according to SHAPIRO-WILK method at an alpha risk of 5%.Analysis required tounderstand why the distribution is not normal. Measurement of a further 15times. Deletion of the first 15 times.YesCalculation of time precision.NoChronométrage or measurement of 15 timesTime precision<= 5%YesTime adopted = arithmetical mean ofsamplesAdditional Chronométrage or timemeasurement to arrive at a level ofprecision of 5%.NoThe time adopted is called the elementary time or ET.The normality test and the precision calculation take place using the form referred to at the end of the document.▪Case 3 : Activities outside Production Unit (e.g. start and end of shift, safety instructions).See flowchart below :Activity outsideproductionunitBreakdown intoE.d.TTime precision <= 25%YesTime adopted = arithmetical mean of samplesAdditional Chronométrage or time measurement to arrive at a level of precision of 25%.Chronométrageor measurementof 3 times foreach E.d.T.NoThe time adopted is called the elementary time or ET.The precision calculation is done using the form referred to at the end of the document.Compliance with the proposed method guarantees a level of precision of ± 5%and 95% confidence for unit times.Implementation of the normality test according to the SHAPIRO-WILK method involves the installation of the BUS application under Excel. You must submit a request to your RUL who will give you installation rights.Rating :Validation criterion for rating :➢the organiser must demonstrate that he has the ability to practise rating. He is qualified in this practice when he is considered stable on the criteria of “Mean deviation” (tolerance of± 3%) and “Standard deviation” (tolerance = 5.5). This stabilisation is monitored usingthe form referred to at the end of the document.➢After stabilisation, he must carry out a minimum of 6 exercises of 15 sequences per quarter,i.e. 24 exercises a year.➢Maintained qualification in rating is one of the essentials of the Métier Guarantee and is the responsibility of the ROPs in the sites.Technological times :The determination of technological times is based on :➢Measured times, analysed using the form (identical to the one used for time-study) referred to at the end of the document and in accordance with the precision rules explained in the “Time-study” section.➢Times calculated by a technical or methods group (for example, of the speed type in preparation or dependent on advance and speed for machining time).➢Times coming from control systems which will be analysed manually so as to identify the unforeseen elements.Technological times must be standardised and maintained long-term in all cases. This responsibility lies with the Organiser.Linked Irregular times (Unavoidable Anomalies) :The determination of Linked Irregular times is based on :➢MOST analysis if the nature of the anomaly permits (e.g. eliminate defects from a laize).➢Times measured when taking time readings.➢The frequency of occurrence of the anomaly, determined from the data collected during the time-study session or by continuous observation.The unit time sheet :It must be totally consistent with the chronology of operations coming from the simogram.It is an essential component of the study dossier.It is the base document for measuring the activity of people and machine loads.It must show :Identification of the production workshop.Identification of the work postIdentification of the organiser.Identification of the production unit.Page numbering and date of execution.Simogram references.Numbers of the elements of the simogram (consistent with the numbers used in time-study sessions or by the predetermined time methods).Descriptions of the elements of the simogram (consistent with the descriptions used in time-study sessions or by the predetermined time methods).Frequencies of occurrence of the elements of the simogram (the frequency calculation will be noted as an appendix to the Unit Time sheet).Elementary times of technological work elements.Elementary times of manual and techno-manual work elements. Calculation of unit times of work elements (E.T. * Frequency).Identification of manual and techno-manual work elements masked by a technological time. Identification of technological times masked by manual or techno-manual work elements. Calculation of the sum of technological times.Calculation of the sum of manual and techno-manual Times.Calculation of the sum of determinant Times (manual and techno-manual). Calculation of unit Time (Tt + Tm determinant + Ttm determinant)Calculation of the % occupation of the operator (Sum of Tm and Ttm / Unit time) Identification of the units produced – Item and quantity.Creation of new unit times :Unit times are to be determined when starting up a new installation or taking new dimensions in hand.See flowchart below :Creation of a new TU.Post under incentive schemeCreation of the TU within a period of1 MonthYesPost under activity monitoringBottleneckpostNoYesYesNoImmediate creation of the TU after stabilisation of thepost.NoUpdating frequency for unit times :Unit times must be updated and maintained in the long term. The updating of unit times is one of the essentials of the Métier Guarantee and is the responsibility of the ROPs in the sites.The methods of operation are described and documented locally. Updating must be demonstrated and recorded (traceability). A unit time must be updated as soon as a modification occurs.See flowchart below : Modification identifiedPost on incentive schemeTU updated within a period of 3 monthsYesPost under activity monitoringBottleneckpostNoTU updated within a period of 1 Month.YesTU updated immediatelyYesNoTU updated immediatelyNoThis modification may arise from various sources : Change of method of work.Evolution of technological times. Evolution of the organisation. Product/Process evolution. Etc …If no modifications have been identified within 1 year, the validity of the UT must be checked.See flowchart below :TU not modifiedfor 1 yearTechno Times modifiedTU updated immediatelyNoUpdate of the updatingdate of the TUYesMethod of work modifiedNoYesD D O O C C U U M ME E N N T T R R E EF F E E R R E E N N C C E E S SDocument titleDocumentreferencesFormExample of “Unit Time Sheet”Example of “Time Record Sheet”Determination of ET with sample size of 15 or 30 elementsDetermination of ET outside production activity.Maintained qualification in rating.。