霍尼韦尔HC900控制系统价格表

- 格式:pdf

- 大小:87.22 KB

- 文档页数:3

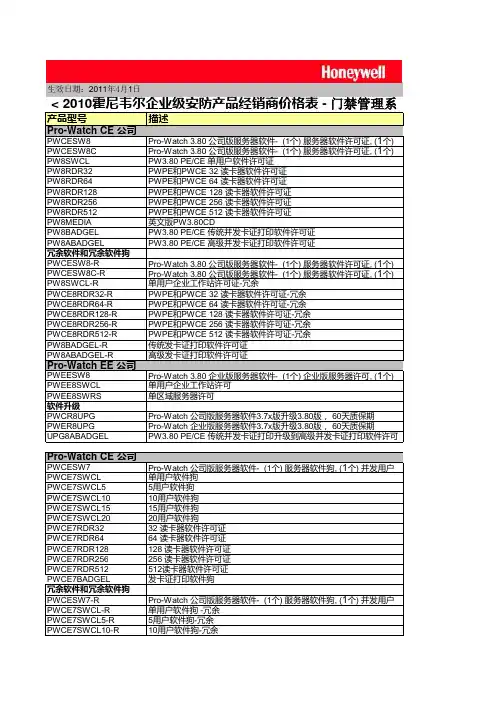

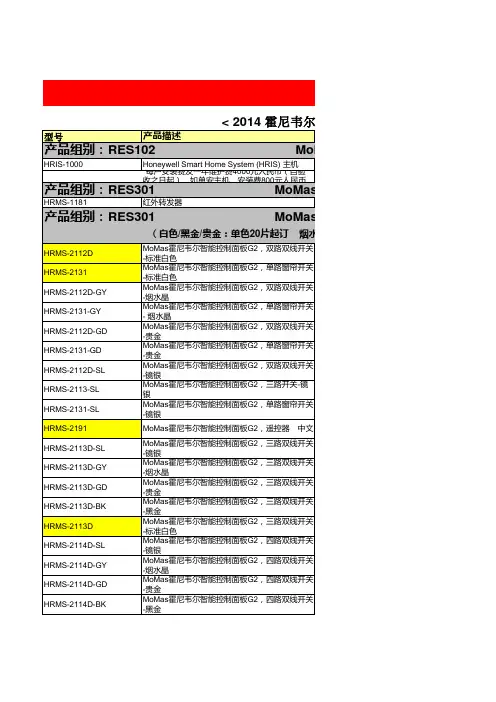

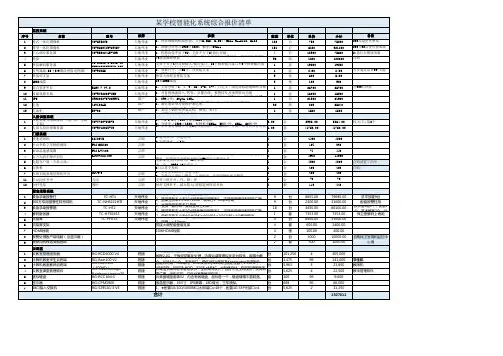

产品型号描述Pro-Watch CE公司版管理软件 (CE) 3.8PWCESW8Pro-Watch 3.80 公司版服务器软件- (1个) 服务器软件许可证, (1个)PWCESW8CPro-Watch 3.80 公司版服务器软件- (1个) 服务器软件许可证, (1个)PW8SWCLPW3.80 PE/CE 单用户软件许可证PW8RDR32PWPE 和PWCE 32 读卡器软件许可证PW8RDR64PWPE 和PWCE 64 读卡器软件许可证PW8RDR128PWPE 和PWCE 128 读卡器软件许可证PW8RDR256PWPE 和PWCE 256 读卡器软件许可证PW8RDR512PWPE 和PWCE 512 读卡器软件许可证PW8MEDIA英文版PW3.80CD PW8BADGELPW3.80 PE/CE 传统并发卡证打印软件许可证PW8ABADGELPW3.80 PE/CE 高级并发卡证打印软件许可证冗余软件和冗余软件狗PWCESW8-RPro-Watch 3.80 公司版服务器软件- (1个) 服务器软件许可证, (1个)PWCESW8C-RPro-Watch 3.80 公司版服务器软件- (1个) 服务器软件许可证, (1个)PW8SWCL-R单用户企业工作站许可证-冗余PWCE8RDR32-RPWPE 和PWCE 32 读卡器软件许可证-冗余PWCE8RDR64-RPWPE 和PWCE 64 读卡器软件许可证-冗余PWCE8RDR128-RPWPE 和PWCE 128 读卡器软件许可证-冗余PWCE8RDR256-RPWPE 和PWCE 256 读卡器软件许可证-冗余PWCE8RDR512-RPWPE 和PWCE 512 读卡器软件许可证-冗余PW8BADGEL-R传统发卡证打印软件许可证PW8ABADGEL-R高级发卡证打印软件许可证Pro-Watch EE 公司版管理软件 (EE) 3.8PWEESW8Pro-Watch 3.80 企业版服务器软件- (1个) 企业版服务器许可, (1个)PWEE8SWCL单用户企业工作站许可PWEE8SWRS单区域服务器许可软件升级PWCR8UPGPro-Watch 公司版服务器软件3.7x 版升级3.80版, 60天质保期PWER8UPGPro-Watch 企业版服务器软件3.7x 版升级3.80版, 60天质保期UPG8ABADGEL PW3.80 PE/CE 传统并发卡证打印升级到高级并发卡证打印软件许Pro-Watch CE 公司版管理软件 (CE) 3.7PWCESW7Pro-Watch 公司版服务器软件- (1个) 服务器软件狗, (1个) 并发用户PWCE7SWCL单用户软件狗PWCE7SWCL55用户软件狗PWCE7SWCL1010用户软件狗PWCE7SWCL1515用户软件狗PWCE7SWCL2020用户软件狗PWCE7RDR3232 读卡器软件许可证PWCE7RDR6464 读卡器软件许可证PWCE7RDR128128 读卡器软件许可证PWCE7RDR256256 读卡器软件许可证PWCE7RDR512512读卡器软件许可证PWCE7BADGEL发卡证打印软件狗冗余软件和冗余软件狗PWCESW7-RPro-Watch 公司版服务器软件- (1个) 服务器软件狗, (1个) 并发用户PWCE7SWCL-R单用户软件狗 -冗余PWCE7SWCL5-R5用户软件狗-冗余PWCE7SWCL10-R 10用户软件狗-冗余< 2010霍尼韦尔企业级安防产品经销商价格表 - 门禁管理系Honeywell Security -China 生效日期:2011年4月1日¥58,928.99¥56,033.34¥12,192.20¥12,446.21¥24,384.41¥45,720.77¥90,425.51¥171,706.87¥406.41¥20,117.14¥30,277.31¥29,464.49¥26,360.56¥6,096.10¥6,223.10¥12,192.20¥22,860.38¥45,212.76¥85,853.44¥10,058.57¥15,138.65¥396,185.67¥18,288.31¥104,852.95¥36,820.46¥118,264.38¥10,160.17¥63,265.35¥19,507.53¥79,249.33¥158,498.65¥205,865.36¥262,193.35¥12,446.21¥24,384.41¥45,720.77¥90,425.51¥171,706.87¥24,140.56¥31,632.67¥9,753.76¥39,624.66¥79,249.33¥131,096.67¥6,223.10¥12,192.20¥22,860.38¥45,212.76¥85,853.44¥12,070.28¥396,187.43¥19,202.72¥91,187.53¥172,824.49¥244,809.30¥307,243.54¥104,852.95¥239,475.21¥480,017.23¥722,946.90¥971,413.86¥55,880.94¥19,583.65¥164,228.33¥30,480.51¥20,269.54¥0.00¥8,493.90¥8,397.38¥8,204.34¥0.00¥4,572.08¥4,368.87¥5,080.09¥1,097.30¥5,740.50¥279.24¥5,689.70¥1,428.59¥1,538.48¥3,186.86¥61.28¥61.12¥61.28¥112.42¥809.73¥809.73¥1,110.49¥17.35¥23.14¥1,388.11¥2,602.70¥2,487.02¥4,800.54¥3,123.24¥6,535.67¥74.50¥74.50¥125.20¥124.93¥92.54¥108.27¥179.98¥179.59¥201.89¥199.85¥174.47¥80.97¥169.04¥126.66¥1,214.59¥1,214.59¥1,850.81¥2,834.05¥2,834.05¥3,817.29¥7,923.78¥32.39¥2,240.00¥8,800.00¥12,724.31¥13,881.07¥14,459.45¥4,627.02¥5,783.78¥13,881.07¥462.70¥853.15¥853.15¥924.32¥1,086.73¥1,782.48¥1,144.88¥1,306.29¥200.50¥335.84¥174.44¥155.39¥453.14¥420.06¥374.94¥150.38¥114.29¥114.29¥194.49¥219.55¥501.26¥250.63¥310.78¥310.78¥323.81¥323.81¥1,306.29¥1,306.29¥36,240.47¥59,940.78¥3,840.05¥3,600.05¥3,600.05¥124,561.63¥56,640.74。

hc900综合控制器技术概述说明书HC900综合控制器是一种先进的工业自动化控制设备,它具有广泛的应用范围和可靠的性能。

本文将对HC900综合控制器的技术进行概述,介绍其主要特点和应用领域。

HC900综合控制器是霍尼韦尔公司推出的一款集控制、测量、调节和通信于一体的设备。

它采用了先进的控制算法和可编程逻辑控制器(PLC)技术,能够实现对工业过程的精确控制和监测。

同时,HC900综合控制器还具有高度可靠性和灵活性,能够适应各种复杂的工业环境和应用需求。

HC900综合控制器具有多种输入和输出接口,可以连接各种传感器和执行器,实现对不同参数的测量和调节。

它支持多种通信协议和网络接口,能够与其他设备进行数据交换和远程监控。

此外,HC900综合控制器还具有丰富的功能模块和编程接口,用户可以根据实际需求进行定制和扩展。

HC900综合控制器适用于各种工业自动化领域,如化工、石油、电力、制药等。

它可以应用于过程控制、温度控制、压力控制、液位控制等各种控制任务。

同时,HC900综合控制器还支持多种控制策略和算法,如PID控制、模糊控制、神经网络控制等,能够满足不同应用场景的需求。

HC900综合控制器具有可靠性高、操作简便、维护方便等优点。

它采用了先进的硬件和软件设计,具有强大的抗干扰和故障诊断能力,能够确保工业过程的稳定运行。

同时,HC900综合控制器还提供了友好的人机界面和操作界面,用户可以通过触摸屏或计算机进行参数设置和监控。

HC900综合控制器是一种功能强大、性能稳定的工业自动化控制设备。

它在各个行业的应用中取得了良好的效果,得到了广大用户的认可和赞赏。

随着工业自动化的不断发展,HC900综合控制器将继续发挥其独特的优势,为工业生产提供更加可靠和高效的控制解决方案。

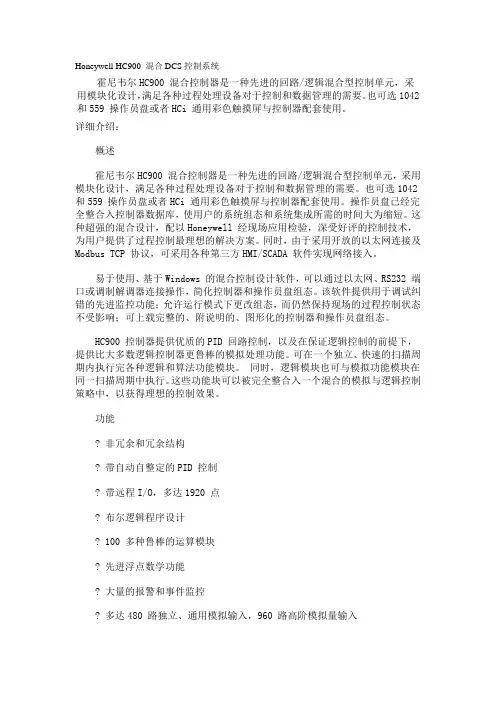

Honeywell HC900 混合DCS控制系统霍尼韦尔HC900 混合控制器是一种先进的回路/逻辑混合型控制单元,采用模块化设计,满足各种过程处理设备对于控制和数据管理的需要。

也可选1042 和559 操作员盘或者HCi 通用彩色触摸屏与控制器配套使用。

详细介绍:概述霍尼韦尔HC900 混合控制器是一种先进的回路/逻辑混合型控制单元,采用模块化设计,满足各种过程处理设备对于控制和数据管理的需要。

也可选1042 和559 操作员盘或者HCi 通用彩色触摸屏与控制器配套使用。

操作员盘已经完全整合入控制器数据库,使用户的系统组态和系统集成所需的时间大为缩短。

这种超强的混合设计,配以Honeywell 经现场应用检验,深受好评的控制技术,为用户提供了过程控制最理想的解决方案。

同时,由于采用开放的以太网连接及Modbus TCP 协议,可采用各种第三方HMI/SCADA 软件实现网络接入。

易于使用、基于Windows 的混合控制设计软件,可以通过以太网、RS232 端口或调制解调器连接操作,简化控制器和操作员盘组态。

该软件提供用于调试纠错的先进监控功能;允许运行模式下更改组态,而仍然保持现场的过程控制状态不受影响;可上载完整的、附说明的、图形化的控制器和操作员盘组态。

HC900 控制器提供优质的PID 回路控制,以及在保证逻辑控制的前提下,提供比大多数逻辑控制器更鲁棒的模拟处理功能。

可在一个独立、快速的扫描周期内执行完各种逻辑和算法功能模块。

同时,逻辑模块也可与模拟功能模块在同一扫描周期中执行。

这些功能块可以被完全整合入一个混合的模拟与逻辑控制策略中,以获得理想的控制效果。

功能? 非冗余和冗余结构? 带自动自整定的PID 控制? 带远程I/O,多达1920 点? 布尔逻辑程序设计? 100 多种鲁棒的运算模块? 先进浮点数学功能? 大量的报警和事件监控? 多达480 路独立、通用模拟输入,960 路高阶模拟量输入? 远程I/O 机架? 带电I/O 热插拔? 数字I/O 的on/off 发光二极管指示灯? 图形化功能模块组态– 400,2000 或5000 个模块? 快速扫描– 27 ms 逻辑,0.5 sec 模拟? 使用Modbus/TCP 开放的10MB 或10/100MB 以太网接口? 通过以太网的对等通讯? 根据权限E-mail 发送报警/事件讯息? 预置处方,设定点程序,顺序控制,设定点程序组? 斜坡/保持设定点程序模块? 带多路输出的设定点程序组模块? 每个顺序控制模块带16 路输出HC900 混合控制器? 基于机架的HC900 控制器有三种机架尺寸可供选择:4,8 或12 个I/O 槽,能满足客户的不同需求。

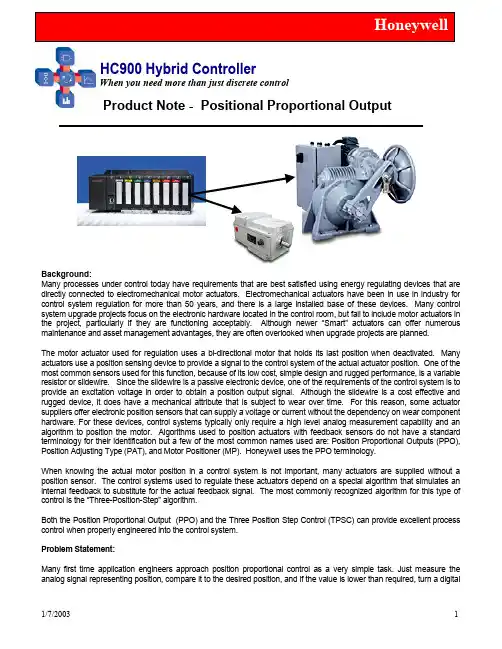

HC900 Hybrid ControllerWhen you need more than just discrete controlProduct Note - Positional Proportional OutputBackground:Many processes under control today have requirements that are best satisfied using energy regulating devices that are directly connected to electromechanical motor actuators. Electromechanical actuators have been in use in industry for control system regulation for more than 50 years, and there is a large installed base of these devices. Many control system upgrade projects focus on the electronic hardware located in the control room, but fail to include motor actuators in the project, particularly if they are functioning acceptably. Although newer “Smart” actuators can offer numerous maintenance and asset management advantages, they are often overlooked when upgrade projects are planned.The motor actuator used for regulation uses a bi-directional motor that holds its last position when deactivated. Many actuators use a position sensing device to provide a signal to the control system of the actual actuator position. One of the most common sensors used for this function, because of its low cost, simple design and rugged performance, is a variable resistor or slidewire. Since the slidewire is a passive electronic device, one of the requirements of the control system is to provide an excitation voltage in order to obtain a position output signal. Although the slidewire is a cost effective and rugged device, it does have a mechanical attribute that is subject to wear over time. For this reason, some actuator suppliers offer electronic position sensors that can supply a voltage or current without the dependency on wear component hardware. For these devices, control systems typically only require a high level analog measurement capability and an algorithm to position the motor. Algorithms used to position actuators with feedback sensors do not have a standard terminology for their identification but a few of the most common names used are: Position Proportional Outputs (PPO), Position Adjusting Type (PAT), and Motor Positioner (MP). Honeywell uses the PPO terminology.When knowing the actual motor position in a control system is not important, many actuators are supplied without a position sensor. The control systems used to regulate these actuators depend on a special algorithm that simulates an internal feedback to substitute for the actual feedback signal. The most commonly recognized algorithm for this type of control is the “Three-Position-Step” algorithm.Both the Position Proportional Output (PPO) and the Three Position Step Control (TPSC) can provide excellent process control when properly engineered into the control system.Problem Statement:Many first time application engineers approach position proportional control as a very simple task. Just measure the analog signal representing position, compare it to the desired position, and if the value is lower than required, turn a digitaloutput ON to increase the position, and if the value is too high, turn the decreasing output ON. To keep the motor from oscillating, add some dead-band, or said another way, compromise position accuracy to improve motor life. This is typically not more than a few program statements in a PLC.Before putting the system on-line the following problems must be addressed:1. The passive slidewire position sensor of the actuator requires electrical excitation, (typically DC power source with avoltage low enough not to cause the resistive element to heat up or burn out). If the controller does not provide this voltage, an external power supply must be used.Once on-line, other problems surface:2. Once the slidewire is powered and the actuator is moved to its 0% and 100% travel limits based on the setting of themotor limit switches, a common observation is that the limit switches stop the motor before the slidewire contact reaches its 0% and 100% voltage limits. If the power supply used to excite the slidewire was 5 volts, the feedback voltage measured between 0% and 100% may typically be between ~0.3V and ~4.8V. A measurement of feedback based on a 5V span would have an error of 0.5V or a 10% error. To correct this error the actual span value of the feedback signal as measured on a 5V analog input range must be re-spanned to have 0.3V and 4.8V represent 0% and 100% travel of the motor.3. Once the feedback is addressed, positioning the motor becomes the next issue. If a simple compare algorithm isused to determine when to increase or decrease the motor, an oscillation of the motor is guaranteed. This is because it takes time to measure the analog feedback, process the compare function, and turn an output OFF. During this time the motor is still moving. When the motor is finally deactivated, it will have already passed the compare point that initiated the action to turn off. The amount of overshoot is based on the algorithm processing time and motor speed. Also, if the update rate of the algorithm is not consistent or varies with processor loading, the amount of overshoot will also vary.To avoid this overshoot condition, a timed output approach is typically used to position the motor. With this approach, if a 15 second motor is at its 0% position and a new request comes in for a 50% position, the output algorithm would turn ON its output for 7.5 seconds. This feature adds a new complexity, to measure the time for full scale motor travel and use this value in the output algorithm calculation.4. Another variable that must be considered is the amount of motor over-travel that may occur after power to the motor isremoved. To minimize this condition, many actuators employ a gearing or braking system, but it can seldom be reduced to zero. To optimize control of this variable, a combination of timed pulses and a dead-band are typically used.When fully implemented the final program often requires significantly more work than initially planned. The Solution:The HC900 “Position Proportional Output” (PPO)The HC900 Position Proportional Output is designed to provide optimum actuator position control with a minimum of setup complexity. From a standard analog input range for feedback slidewire measurements to a fully automatic feedbackcalibration feature, the HC900 PPO algorithm excels. Once on-line, the PPO algorithm provides additional benefits with a scaled output of the actual motor position that may be used on displays or integrated into the control strategy, and diagnostics routines that run in the background that detect actuator problems. The following are a few of the HC900 PPO algorithm highlights and benefits.1. Standard analog ranges embedded in the PPO algorithm to measure slidewire resistances between 100 and 1000ohms. (No external power supply required. Uses a simple 3-wire connection to the standard universal AI module.) Voltage ranges of 0 to 5V, 0 to 1V, and current ranges 0 to 20mA , 4 to 20mA are also supported for feedback inputs.2. Flexibility to use any type of digital output module with the PPO algorithm, AC, DC or Relay. (No special outputmodules or incompatible voltages.)3. Complete actuator control setup from a single PPO function block including analog input hardware and range, digitaloutput hardware, actuator feedback scaling and motor speed, actuator sensitivity (dead-band). ( Easy to setup, easy to troubleshoot.)4. Fully automatic feedback signal calibration. Scales the actual feedback signal values to represent 0 to 100% outputand calculates motor speed. (The easy choice for easy to use.)5. Semi-automatic feedback calibration (user initiated step-by-step process) and manual feedback calibration (usermanually moves the motor) also supported. (Offers flexibility when required.)6. User entered dead-band support for values from 0.5% to +/- 5.0%. Ideal for actuators without braking action.7. Input scaling support is included to allow reverse scaling for heating/cooling applications using Duplex control (0 to 50,50 to 0).8. User entered output limit values supported. For users who want to limit actual actuator travel to values less than 0and 100%.9. Actuator position output pin provided for displays or connection to other function blocks.10. Feedback failure detect output pin provided. Digital output turns ON if the algorithm detects a failed slidewire.11. Automatically defaults to Three-Position–Step control on feedback failure.12. Fault output pin turns ON upon detection of a failed or stalled motor.The HC900 controller can support up 64 PPO algorithms, or two for each PID loop. The algorithms also execute independently from the PID algorithms, allowing them to accept setpoint signals from other sources. For example, a single manually entered variable from an OI overview display could be used to set the position of multiple actuators simultaneously. Another application might connect two actuators to the same PID algorithm with the actuators operating in series, applying unique input scaling to each actuator. These are only a few examples of the control flexibility afforded users with the HC900 PPO algorithm.How to Order:The PPO algorithm is offered in the HC900 controller at no additional cost in CPU versions 900C51-0011, 900C52-0011, 900C31-0011, 900C32-0011 and later versions. If direct slidewire measurements are required, analog input module 900A01-0002 is required. This module is a direct replacement for module 900A01-0001 in all applications.Use the HC900 PPO algorithm in retrofit applications and in new applications when accurate positioning of drive actuators is required.Typical Position Proportional Configuration and Wiring:Analog Input Module AC Output Module。

HC900控制系统用户培训手册北京东方诚益通科技开发中心2007.5HC900中小型控制系统【摘要】美国Honeywell(霍尼韦尔)公司是世界上第一套真正的分散型控制系统(DCS 系统)的设备生产厂家,其最新推出的中小型控制系统HC900是Honeywell针对现代控制技术的进步;结合其百年来在工业控制领域的丰富经验;兼顾全厂管理和控制一体化;整和批量控制、连续控制和离散控制;同时注重节约用户成本的新型集散控制系统,本文将把HC900的主要特点介绍给读者。

【关键词】HC900 混合控制 DCS系统HC900是Honeywell公司于2002年4月份开始向全球推出的面向中小型过程用户和设备集成控制的开放型控制系统。

该系统由精练设计的先进集成控制器HC900和采用独立的或开放的以太网络互联的高性能工程师站/操作员站组成一套完整的并能真正满足工业行业所有从简单到复杂的各种控制应用要求集散控制系统。

HC是英文Hybrid Control即混合控制的字母缩写,也就是该系统将连续控制、逻辑控制、顺序控制等多种控制策略集成为一体。

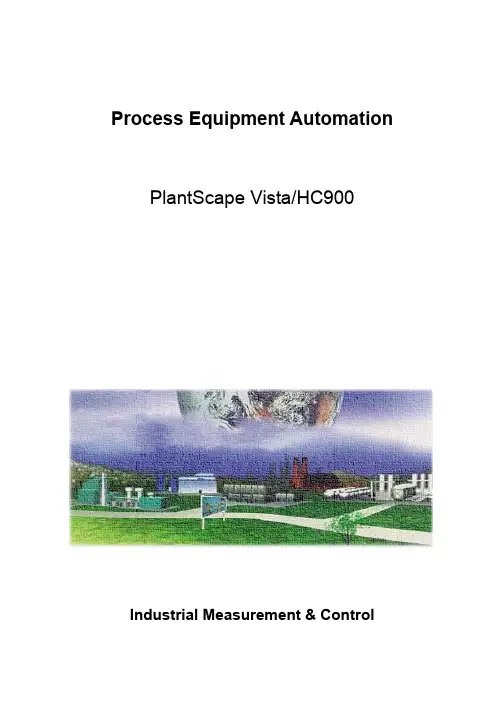

HC900以分散的模块化结构、先进的控制功能,将用户对过程设备的连续与离散控制要求集成为一体,采用全开放的通讯标准,以Honeywell自行开发的网络版厂景实时监控软件PlantScape Vista或第三方软件为系统应用管理层,以精炼设计的先进集成控制器HC900为设备控制层,在接近PLC的价格水平上,为用户提供性价比优越的集散控制系统。

下面介绍HC900的主要特点:硬件部分上位计算机操作员面板控制器HC900控制系统的硬件主要由上位管理/监控/编程计算机、控制器及I/O模件和操作员盘三部分组成,其中可选本地操作员盘,为10.4英寸彩色液晶屏,预制100幅监控画面,带数据记录/趋势显示功能,是最佳的本地操作员界面。

A.通讯接口1.通过100M以太网接口和上位机通讯,使用开放的MODBUS/TCP协议,所以上位机软件可用Honeywell公司生产的PlantScape Vista,也可选用支持该协议的第三方软件,该接口最多支持5个并发连接;2.通过以太网实现点对点通讯,即各控制器间可实现数据交换;3.通过RS-232串口支持本地和远程拨号进行通讯组态/诊断;4.通过RS-485接口和使用特定协议实现与操作员盘的连接。

型号产 品 描 述报价(RMB)4110DL 系统4110DL 6 防区先进控制/通讯主机1,250.00 6148CH 控制主机中文键盘/带夜光720.00 4116布撤防锁,不带锁,需配合2147-70使用285.00VISTA-10P 6 防区先进控制/通讯主机,带防拆开关及变压器1,220.00 6148CH 控制主机中文键盘/带夜光720.00 6160可变文字英文键盘1,500.00 42044继电器模块1,290.00 TELECOMMAND 电话语音模块1,805.00 7845i-ENT Internet 网络通讯器5,580.00 8132iPKInternet 带有触摸屏键盘的网络通讯器9,810.00VISTA-20P 8防区先进控制/通讯主机/带2子系统,可扩充至48个防区,带防拆开关及变压器1,920.00 6148CH 控制主机中文键盘/带夜光720.00 6160可变文字英文键盘1,500.00 6164可变文字英文键盘,内置4个防区和1个继电器1,710.00 42198防区扩充器1,100.00 42298防区扩充器/带2继电器1,370.00 42044继电器模块1,290.00 TELECOMMAND 电话语音模块1,805.00 7845i-ENT Internet 网络通讯器5,580.00 8132iPKInternet 带有触摸屏键盘的网络通讯器9,810.00VISTA-120多功能型主机,带8个子系统,可扩充至128个防区,带防拆开关及变压器4,660.00VISTA-250BP 大型多功能安防套机,可划分8个子系统,扩展到250防区、15个智能卡门禁系,带防拆开关及变压器6,270.00 6160可变文字英文键盘1,500.00 4146主机布撤防开关,不带锁,适用于VISTA-120720.00 VISTAVIEW-100VISTA 视频切换模块,4路输入2路输出2,490.00 42044继电器模块1,290.00 4100SM 主机串行打印机接口模块1,670.00 4286电话语音接口模块2,530.00 4400电子地图接口模块(VISTA-120)15,580.00 7845i-ENTInternet 网络通讯器5,580.00VISTA-10PLUS 系统VISTA-20PLUS 系统VISTA-120 / VISTA-250BP 大型主机系统防 盗 产 品 价 目 表(2006)生效日期:2006.8.14110DL 控制主机VISTA 控制主机系列控制/通讯主机8132iPK Internet 带有触摸屏键盘的网络通讯器9,810.00IP-ALARM/4报警监控软件,支持4台一下报警主机(含4台)8,500.00 IP-ALARM/10报警监控软件,支持10台一下报警主机(含10台)12,800.00 IP-ALARM/F 报警监控软件,支持无限台报警主机19,200.00 IP-2000主机网络接口模块,适用于Vista-120/250BP 系列主机,每台主机一块5,150.004190SN 2防区总线扩充器380.00 4193SN 2防区扩充模块290.00 4293SN 1防区扩充模块290.00 4208SN 8防区总线扩充模块1,410.00 4209U 防火防区总线扩充模块1,410.00 4191SN-WH 埋藏式门磁开关/智能型380.00 4944SN-WH 埋藏式门磁开关/智能型247.00 4939SN 表面式门磁开关/智能型342.00 4959SN 卷匝门磁开关/智能型608.00998MX 998式被动红外探测器/智能型停产Q2260SN 总线双鉴探测器,18米1,140.00 4192CP 离子式烟感探测器1,330.00 5192SD 光电式烟感探测器1,100.00 5192SDT 光电式烟感探测器(带温感)1,750.00 4101SN 单个继电器输出模块740.00 4297增强型总线延伸模块1,310.00VISTA-KEY VISTA 读卡器模块2,700.00 OP30-FWM 感应式读卡器(用于 VISTA-KEY)2,070.00 PTPROX25感应卡,25个一套 - ADEMCO 34位编码格式1,980.005881ENH 无线接收器,跟VISTA 主机配套,345MHz 1,480.00 5802MN 便携式无线按钮800.00 5804-2无线按钮,2键570.00 58044键无线按钮760.00 5808LST 无线烟感探测器(带温感)1,690.00 5809无线温感发射器870.00 5814小型通用发射器437.00 5815门窗发射器(带门磁)610.00 5816小型门窗发射器720.00 5817三防区门窗发射器870.00 5818埋藏式发射器1,020.00 5819震动处理器910.00 5853玻璃破碎器探测器1,330.00 5869手持式紧急按钮650.00 5890无线被动红外探测器1,330.00 5890PI无线被动红外探测器(防宠物)1,330.00VISTA-120 / VISTA-250BP 双线总线器件VISTA-250BP 专用门禁模块VISTA 配套无线设备 -- 345MHZVISTA-120 系列网络报警系统IP-ALARM5899磁铁(用于5816,4只/包)150.00 5800RP天线转发器,345MHz1,480.00一体化无线控制主机系列LYNXR-PK套装:LYNXR一体化主机, 5890PI 红外探测器, 5816 门磁x 25,700.00OMNI 控制主机系列OMNI-400 系统OMNI-400N OMNI 4-8 防区控制/通讯主机820.00 XK108-CH OMNI 8 防区LED键盘,中文530.00 OMNI-KPCH OMNI 固定字符LCD键盘,中文700.00 OMNI-LCD OMNI 可变字符LCD键盘1,420.00OMNI-600 系统OMNI-600N OMNI 6-12 防区控制/通讯主机1,050.00 XK108-CH OMNI 8 防区LED键盘,中文530.00 OMNI-KPCH OMNI 固定字符LCD键盘,中文700.00 OMNI-LCD OMNI 可变字符LCD键盘1,420.00OMNI-624 系统OMNI-624OMNI 6-24 防区有线/无线控制主机1,620.00 OMNI-KPCH OMNI 固定字符LCD键盘,中文700.00 OMNI-LCD OMNI 可变字符LCD键盘1,420.00 OMNI-EXP8OMNI 8 防区扩展器760.00 XL4705 5 继电器扩展模块910.00OMNI-848 系统OMNI-848OMNI 8-48 防区有线/无线控制主机2,160.00 OMNI-KPCH OMNI 固定字符LCD键盘,中文700.00 OMNI-LCD OMNI 可变字符LCD键盘1,420.00 OMNI-EXP8OMNI 8 防区扩展器760.00 XL4705 5 继电器扩展模块910.00OMNI-624/848配套无线设备(345MHz)ZR401无线接收器,跟OMNI-624/848主机配套,345MHz950.00 5802MN便携式无线按钮800.00 5804-2无线按钮,2键570.00 58044键无线按钮760.00 5808LST无线烟感探测器(带温感)1,690.00 5809无线温感发射器870.00 5815门窗发射器(带门磁)610.00 5816小型门窗发射器720.00 5817三防区门窗发射器870.00 5818埋藏式发射器1,020.00 5819震动处理器910.00 5853玻璃破碎器探测器1,330.00 5869手持式紧急按钮650.005890无线被动红外探测器1,330.00 5890PI 无线被动红外探测器(防宠物)1,330.00 5899磁铁(用于5816,4只/包)150.00CE2R 遥控接收器与无线按钮(钥匙扣型)970.00 CEREM 与CE2R 一起使用的无线按钮(钥匙扣型)340.00 CEREMLR 长距离遥控按钮(钥匙扣型)460.00 TELECOMMAND电话语音模块,可与OMNI 系列主机配合使用1,805.00236 系列236TL 6防区通讯主机,带防拆开关及锁,1.5A 变压器,CCC 认证936.00 236LEDP 配236主机的LED 键盘,CCC 认证313.00238 系列238C 8防区通讯主机,带防拆开关及锁,1.5A 变压器,CCC 认证986.00 238LEDP 配238C 主机的LED 键盘,CCC 认证363.002316 系列2316TL 16防区通讯主机,带防拆开关及锁,1.5A 变压器,CCC 认证2,111.00 2316LEDP 配2316主机的LED 键盘,CCC 认证688.00238C Plus 系列238C PLUS,1.5A 8防区通讯主机,带防拆开关及锁,(1.5A)987.50 238C PLUS,3.0A 8防区通讯主机,带防拆开关及锁,(3A)1,040.00 238C Plus LEDP 配238C Plus 主机的LED 键盘363.002300系列主机附件ALPHA1液晶键盘,236、238、2316主机通用900.00 2300DVR2300系列主机继电器模块880.00型 号产 品 描 述报价(RMB)685-220数字报警接收机(含两块685-8,定购时请注明)84,000.00 685-8685多格式报警接收电话卡8,300.00 659EN 电话线监控器1,220.00 CIA 报警主机遥控编程通讯接口3,040.00 FE-100多功能数字报警接收机,完美兼容ADEMCO 、IntelliSense 等众多流行主机(出厂配置:2条电话线;可扩充至8条电话线)62,500.00 FE-100LX 多格式报警接收电话卡,可接2条电话线(适用于FE-100)9,630.00 FE-10A 2线200户小型中央接警系统(含软件)17,800.00 FE-10B 4线500户小型中央接警软件(含软件)23,800.00 MX-8000-3数字报警接收机(含3条电话线),总共可以扩充到36条电话线84,000.00 MX-8000-LC3MX-8000电话卡,每块卡可以接3条电话线15,000.00 7810iR-ENT网络报警接收机12,160.00报警中心接收机报警网络中心设备以及附件OMNI 系列附件INTELLISENSE 控制主机系列探测器/传感器型号产品描述报价(RMB)双鉴移动探测器IntelliSense DT系列DT72257.6米 x 9米,常闭触点,CCC认证450 DT7235T11米 x 11米,常闭触点,CCC认证500 DT743511米 x 11米,常闭触点,防宠物,CCC认证650 DT745015米 x 18米,常闭触点,CCC认证750 DT7450C15米 x 18米,常开/闭触点,CCC认证800 DT7550C15米 x 18米,常开/闭触点,防遮挡980 DT6360STC360° 吸顶安装,直径15米,CCC认证1100 DT90015米 x 12米/ 27米 x 21米,防遮挡,CCC认证2130 DT90637米 x 3米/61米 x 5米,防遮挡,CCC认证2500Optex双鉴移动探测器MX4012m x 12m,双技术探测器874 MX5015m x 15m,双技术探测器,长距离978被动红外探测器Ademco 被动红外探测器996EX被动红外探测器,带防拆380 998EX带下望窗被动红外探测器,带防拆460 997360度吸顶式被动红外探测器420IntelliSense 被动红外探测器IS150T15 米x 12米,普通型,CCC认证230 IS215T12 米x 12米,普通型,CCC认证183 IS220T15 米x 12米,智能型,CCC认证230 IS2260T智能型,防宠物,带幕帘式镜片;CCC认证320 IS216T-CUR10米 x 1.6米幕帘式被动红外探测器199IntelliSense 红外门控器IS310WH红外开门器-白色(进口)1102 IS310BL红外开门器-黑色(进口)1102 IS320WH红外开门器-白色带蜂鸣器(进口)1330 IS320BL红外开门器-黑色带蜂鸣器(进口)1330Optex被动红外探测器RX4012m x 12m,PIR,四元红外,CCC认证288 CX50215m x 15m PIR 双功能镜片834 CX502AM15m x 15m PIR 带防遮盖功能1541 CX70221m x 21m双功能镜片 PIR1259 FX360360 度吸顶式, PIR771 SX360Z360 度吸顶式,PIR1760玻璃破碎探测器Ademco玻璃破碎探测器2100EX音频和振动双技术玻璃破碎探测器610 2520智能微处理器玻璃破碎探测器720IntelliSense 玻璃破碎探测器FG1615T墙挂式,4.6米,CCC认证350 FG1625T墙挂式,7.6米,CCC认证450 FG1625RT圆形,7.6米,CCC认证530 FG1608玻璃破碎探测器(2.4米),带门磁500 FG1025Z吸顶式,7.6米,具方向性,CCC认证580 FG701玻璃破碎仿真器850红外对射探测器Optex红外对射探测器AX100S30m 室内红外对射探测器1113 AX100SR30m室内红外对射探测器,埋墙式安装1113 AX70T21m 室外红外对射探测器1199 AX130T40m室外红外对射探测器1346 AX100PLUS30m室外红外对射探测器,CCC认证1786 AX200PLUS60m室外红外对射探测器,CCC认证2007 AX250PLUS75m室外红外对射探测器,CCC认证4773 AX500PLUS150m室外红外对射探测器,CCC认证5629 AX350MKII100m室外红外对射探测器6509 AX650MKII200m室外红外对射探测器7584 BX100PLUS周界红外探测器2093户外被动式红外探测器Optex户外被动式红外探测器LX402室外PIR, 12m x 15m 广角1199 LX802N室外 PIR, 24m x 2m 长距离1199 BX80N12 x 2m,室外周界红外探测器1760 VX402多重稳定被动红外探测器(户外)1794 VX402REC多重稳定被动红外探测器(户外带录音功能)3013 Optex系列探测器附件FA3RX/MX 系列探测器墙面/吸顶安装架69 CA1W LX 系列墙面安装架104 CA2C LX 系列吸顶式安装架104 FL60N适用于RX40的长距离镜头35 BC1AX250和AX500背盖725 BC2AX100 和 AX200背盖610 HU1AX250和AX500加热器1771 HU2AX100 和 AX200加热器1426 CL80N CX502用长距离镜片35 WC1BX100PLUS用白色装饰盒109MG1BX100PLUS及BX80N用金属支架506震动探测器Ademco震动探测器11WH机械式振动开关,白色与棕色60 SD3振动探测器,白色230 MA100T多重计数震动分析器,用于SD3610 UN3电子震动探测器2565 UN3-ATM电子震动探测器(适用于ATM)2700烟感探测器JTY-LZ-14124线离子式烟感探测器 12VDC450 JTY-LZ-24124线光电式烟感探测器 12VDC550 4WT-B4线光电式烟感探测器带温感/57.2ºC 12VDC800 CC601温升探测器/固定温度探测(57ºC)200 CC602温升探测器/固定温度探测(93ºC)200其它探测器470-12水探测器1180 470PB水探测器探针190 TS300温度探测器950 TS300R温度探测器探针290IntelliSense探头附件SMB10旋转安装支架,白色,5只/包60 SMB10C吸顶安装支架,与SMB10一起使用,5只/包60 SMB10L长旋转安装支架,白色,5只/包60门磁和开关型号产品描述报价(RMB)Ademco紧急开关264钱夹开关170.00 266脚挑紧急开关1,240.00 268双按钮紧急开关190.00 269R锁定型紧急开关,金属壳170.00 270R锁定型紧急开关,塑料壳150.00Ademco门磁与开关7940WH多用型SPST门磁,白色或棕色60.00 7939WH SPST门磁,白色,棕色或灰色60.00 943WH小型表面式门磁,白色或棕色60.00 944-2GY SPDT埋藏式门磁,灰色100.00 947-75WH3/4" 埋藏式铁门门磁,白色或棕色80.00 947WH1" 埋藏式铁门门磁,白色或棕色80.00 950GY大型表面式门磁,棕色或灰色100.00951WH小型埋藏式门磁,白色或棕色60.00 957小型卷匝式门磁290.00 958可调磁铁卷匝式门磁290.00 958-2可调磁铁卷匝式门磁,SPDT340.00 960商业用表面安装门磁,适用于户外580.00 7945WH超小型表面安装门磁,白色152.00IntelliSense门磁开关MPS9WGW 3.175cm闭/5.08cm开,暗装,白色,CCC认证28.00 MPS9WGB 3.175cm闭/5.08cm开,暗装,棕色,CCC认证28.00 MPS20WGW 3.175cm闭/5.08cm开,表面安装,白色,CCC认证28.00 MPS20WGB 3.175cm闭/5.08cm开,表面安装,棕色,CCC认证28.00 MPS45WGW 2.54cm闭/5.08cm开,表面安装,白色,CCC认证28.00 MPS45WGB 2.54cm闭/5.08cm开,表面安装,棕色,CCC认证28.00 MPS70WGW 1.905cm闭/2.54cm开,暗装,白色,CCC认证34.00 MPS70WGB 1.905cm闭/2.54cm开,暗装,棕色,CCC认证34.00 MPS80WGW 5.08cm闭/7.62cm开,表面安装,白色,CCC认证34.00 MPS80WGB 5.08cm闭/7.62cm开,表面安装,棕色,CCC认证34.00IntelliSense卷帘门门磁MPS50 5.08cm闭/7.62cm开,地面安装,CCC认证140.00 MPS51 5.08cm闭/7.62cm开,地面安装,CCC认证140.00IntelliSense紧急按钮PB2白色塑料壳60.00 PB110金属壳110.00警号、闪灯、其它附件型号产品描述报价(RMB)Ademco警号与闪灯702117dB 电子警号6-12Vdc ,30W460.00 719109dB 电子警号6-12Vdc ,15W290.00 74795dB 电子警号6-15Vdc ,400mA190.00 710RD闪灯, 6-12vdc, 红色400.00IntelliSense警号SP20S白色方型,12VDC,107dB150.00IntelliSense可编程密码键盘EDS18P可编程密码键盘450.00 EDS18P/AL可编程密码键盘,铝护框500.00Ademco其它硬件2174钥匙开关带2平匙130.00 2174-70回转式钥匙开关130.00 4073钥匙开关带2圆匙190.00 4073-70回转式钥匙开关210.00。

霍尼韦尔推出HC900控制系统触摸屏操作员界面

无

【期刊名称】《自动化信息》

【年(卷),期】2009(000)007

【摘要】霍尼韦尔宣布推出触摸屏操作员界面帮助工厂操作员使用霍尼韦尔

HC900控制系统,更加简化管理流程。

霍尼韦尔900系列控制站采用面板安装界面,适用于全部新型HC900安装。

它同样可以进行改造,以适用于现有兼容系统。

【总页数】1页(P15)

【作者】无

【作者单位】无

【正文语种】中文

【中图分类】TP316

【相关文献】

1.霍尼韦尔推出HC900操作员界面 [J],

2.霍尼韦尔推出PlantScape Vista/HC900 [J],

3.霍尼韦尔推出用于触摸屏显示器的创新材料 [J],

4.霍尼韦尔推出用于触摸屏显示器的创新材料 [J], 无

5.霍尼韦尔推出质量控制系统(QCS)升级服务,帮助造纸厂控制成本——质量控制系统(QCS)升级服务帮助客户充分利用现有硬件,最小化干扰的同时升级系统关键部件 [J],

因版权原因,仅展示原文概要,查看原文内容请购买。

Section 4Page: HC-1

Effective Date: January 31, 2005

HC900 Hybrid Controller Model Selection Guide

Assemblies

with Price Data

Model Selection Guide Honeywell Proprietary

51-51-16-70 Issue 8RACKS

U.S. $4 I/O Slot Rack 3758 I/O Slot Rack 48012 I/O Slot Rack 550

Power Supplies

120/240VAC, 60W 675120/240VAC, 28W Note 5 385

CPU Assemblies

Controller C50 CPU Config.SW & Docs 3,175Controller C50 CPU Note 1 2,800Controller C30 CPU Config. SW & Docs 1,575Controller C30 CPU Note 1 1,200I/O Scanner (for remote rack) 900

I/O Card Selections

Analog Input (8 channel) 900Analog Output, 0 to 20mA, (4 channel) 600Digital Input, Contact type, (16 channel) 460Digital Input, 24VDC (16 channel) 415Digital Input, 120/240 VAC, (16 channel) 375Digital Output, Relays ( 8 channel) 600

Digital Output, 24VDC (16 channel) 475Digital Output, 120/240 VAC (8 channel) 395Terminal Blocks, Cables, Jumpers

Low VoltageTerminal Block (Euro style) Note 3 45

Low VoltageTerminal Block (Barrier Style) Note 3 45High VoltageTerminal Block (Euro style) Note 3 42High Voltage Terminal Block (Barrier Style) Note 3 42Analog Input Remote Terminal Panel (RTP) Note 6 300Relay Output Remote Terminal Panel (RTP) Note 6 240DI, DO, AO Remote Terminal Panel (RTP) Note 6 175Low Voltage RTP Cable (1.0M, 3.28ft.) Note 6 165Low Voltage RTP Cable (2.5M, 8.2ft.) Note 6 180Low Votage RTP Cable (5.0M, 16.4ft.) Note 6 220High Voltage RTP Cable (1.0M, 3.28ft.) Note 6 190High Voltage RTP Cable (2.5M, 8.2ft.) Note 6 205High Votage RTP Cable (5.0M, 16.4ft.) Note 6 235

Filler Block Terminal Cover 18Shield Terminal Strip (package of 2) 53Terminal board jumpers (10, two pos jumpers) Note 4 23Terminal board jumpers (10, ten pos.jumpers) Note 4 45

Manuals

Full Document set on CD Note 2 75Full document set, hard copy - Engish Note 2 150

Software

HC Designer Config. Software CD 600

HC Utilities Software/Documentation CD 300900P02 -0001900ME2-0021900H03 - 0001

900H02 - 0001

900A01 - 0002900B01 -0001900G01 - 0001900G02 - 0001900G03 - 0001900H01 - 0001 NUMBER 900C52 - 0021900C53 - 0021900R12 - 0001900P01 -0001900R04 - 0001900R08 - 0001900C51 - 0021900C31 - 0021900C32 - 0021900TNF - 0001

900TEK - 0001900TBK -0001900TER - 0001900TBR - 0001900RTA - L001900RTR - H001900RTS - 0001900RTC - L010900RTC - L025900TSS - 0001900J02 - 0001

900RTC - L050900RTC - H010900RTC - H025900RTC - H050900J10 - 0001900ME1-0021900W01 - 0021Industrial Measurement and Control - 1100 Virginia Drive, Ft. Washington, PA 19034

Printed in U.S.A. Copyright 2005 - Honeywell International Inc.

900W02 - 0021

Section 4Honeywell Proprietary

Page: HC-2

Effective Date: January 31, 2005

Card Type Analog Input (8 channel) Analog Output, 0 to 20mA, (4 channel) Digital Input, Contact type, (16 channel) Digital Input, 24VDC (16 channel)

Digital Input, 120/240 VAC, (16 channel)

Digital Output, Relays ( 8 channel)

Digital Output, 24VDC (16 Channel)

Digital Output, 120/240 VAC (8 channel)Note 4: Jumpers available for Barrier Style terminals only.Note 5:

900TER-0001900TBK-0001900TBK-0001900TBK-0001900TER-0001900TBR-0001900TBR-0001900TBK-0001900TBR-0001

900TEK-0001900TEK-0001900TBK-0001900TER-0001Terminal Blocks

900TEK-0001900TEK-0001900TEK-0001

Note 1: Documentation and Hybrid Control Designer Configuration Software are not provided with this model. If required, specify CPU model numbers 900C51-0011, 900C31-0011 or order items separately. Note 2: A full documentation set on CD is provided with CPU 900C51-0011 and 900C31-0011. If additional copies or if a hard copy manual set is desired, specify them as separate items. The manual set contains one each of all HC900 product manuals. Documenta

Note 3: Terminal blocks for I/O modules must be ordered separately. Two styles are available for each of the two types, Euro style and Barrier style. The type of terminal block (gold or tin contacts) must be matched to the appropriate I/O board type. S

Honeywell Proprietary Section 4

Page: HC-2a

Effective Date: January 31, 2005

Note 6

Using the table below, select a Remote Terminal Panel and Cable Assembly to match the module type.。