MidasGTSN报错信息提示原因分析及操作建议

- 格式:docx

- 大小:36.57 KB

- 文档页数:20

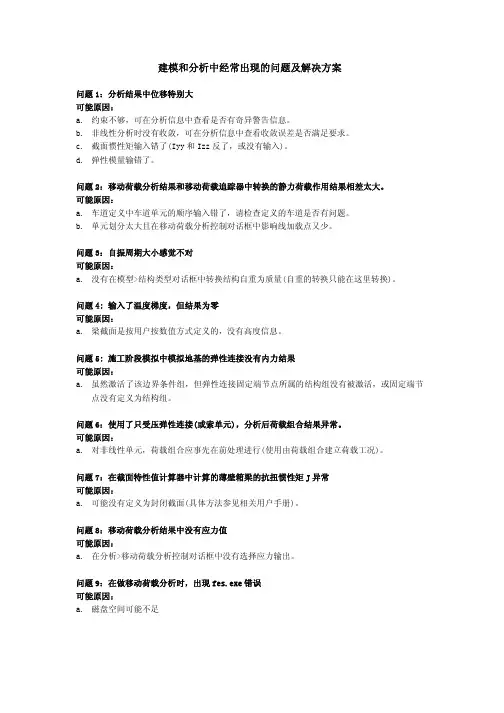

MIDAS/GTS常见问题释疑 21.问题:四面体和六面体直接耦合有没有影响答:有影响,因此建议四面体和六面体之间用五面体过度。

2.问题:两台机子上计算结果显示不一样答:有可能是其中一台机子的操作系统有问题,建议重装操作系统。

3.为什么荷载结构法和地层结构法计算下来结果相差很大,应该采用那个计算结果进行设计?答:应该从受力的角度看,对于荷载结构法来说,计算受力的对象是衬砌结构;而地层结构法的受力对象是衬砌和土层。

因此就会有这种情况:荷载结构法的全部荷载是由衬砌结构承担的,反映的是围岩垮塌的情况下,支护结构能够承担不至于倒塌;地层结构法的全部荷载由岩土和结构来承担,这样从设计的角度来看是偏于不安全的,但是能够充分考虑围岩自稳的状态。

4.[单元23109错误]: 输出坐标系垂直于单元局部坐标系。

是什么意思?答:遇到这种情况,可以通过调整特性里面面单元的材料坐标系。

5.荷载释放系数问题?答:当某个单元被钝化时,定义了荷载释放系数,当荷载释放没有完成的时候你不能把它再激活。

a)有两种方法:一种是不要定义荷载释放系数;还有一种就是把这个网格组再复制一次,钝化的时候把这个网格组钝化,激活的时候把复制的网格组激活就可以了。

6.后处理结果,云图中有数值怎么解决答:后处理模式中,第四个里面有结果数值,可以调整。

7.桁架与植入式桁架的计算区别?答:计算得到的岩土结构受力差不多;植入式桁架的轴力很小。

8.多次对同一个网格组进行修改单元属性命令,在程序中是否起作用?答:在施工过程中,可以计算,在模拟材料转换的时候是可以的。

但是如果单元没有经过激活钝化的,应力应变位移状态是会继承的。

因此如果考虑挖掉再回填其他的工况的话,建议采用复制单元。

9.在导入CAD的时候,为什么有些曲线导进来不对?10.答:在CAD中需要将这些线炸开再导进来。

11.为什么有的时候进行渗流分析的时候报错信息提示自由度有问题?答:造成这种的原因是渗透系数偏小。

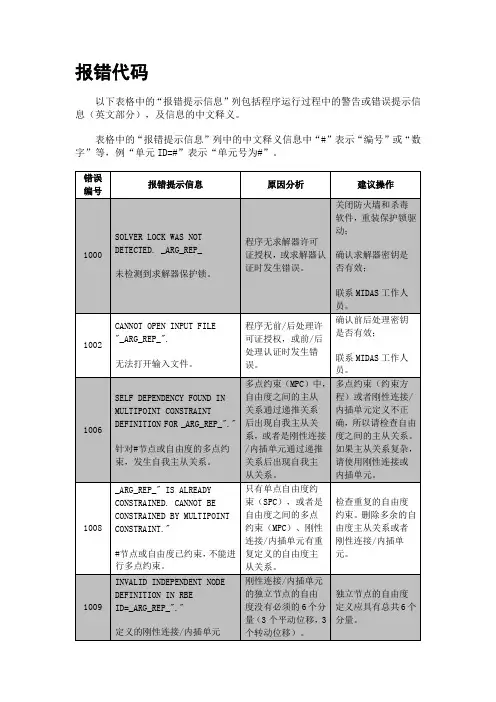

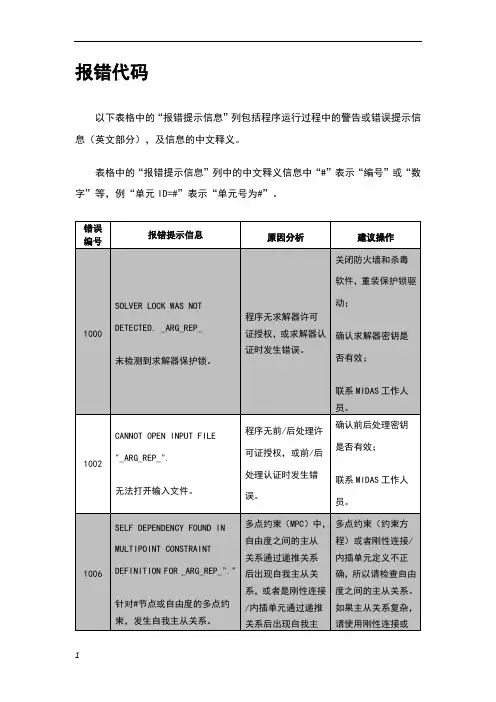

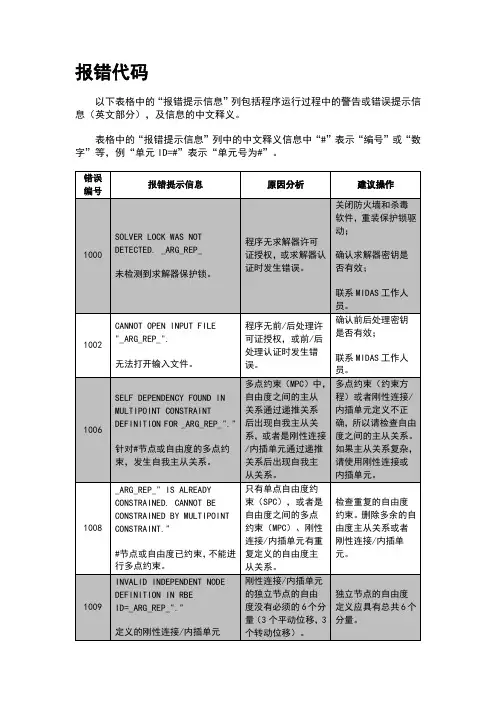

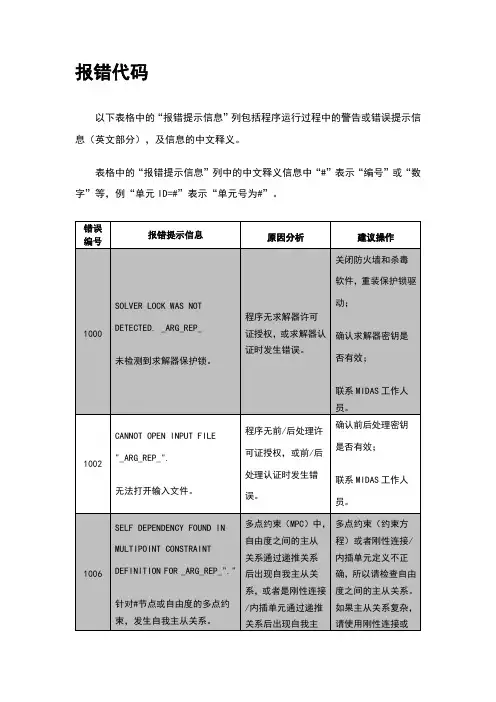

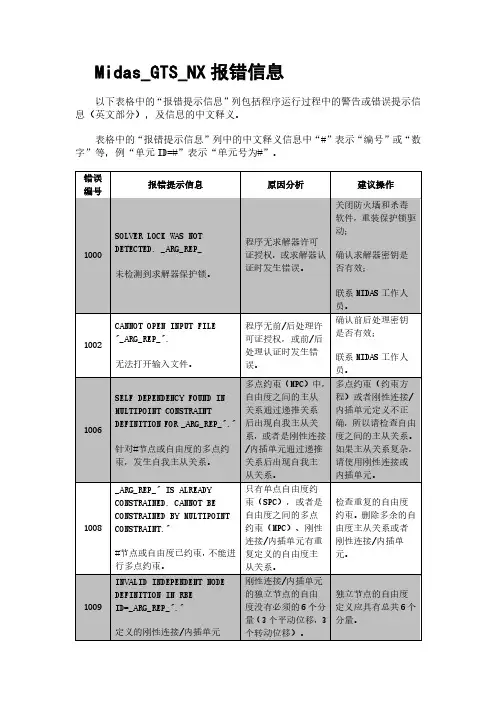

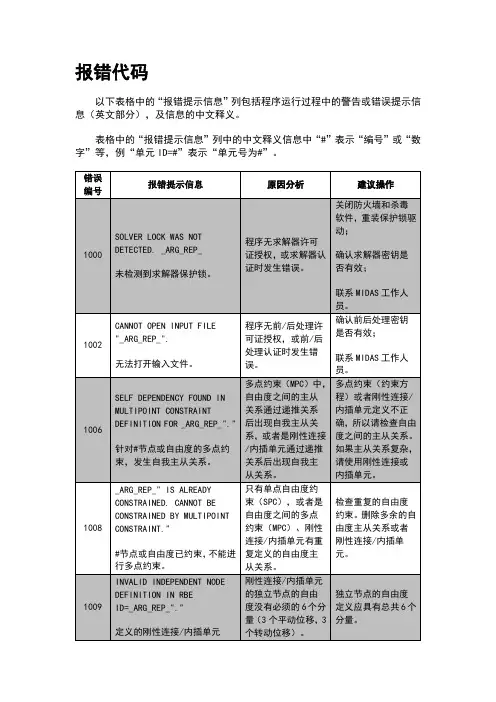

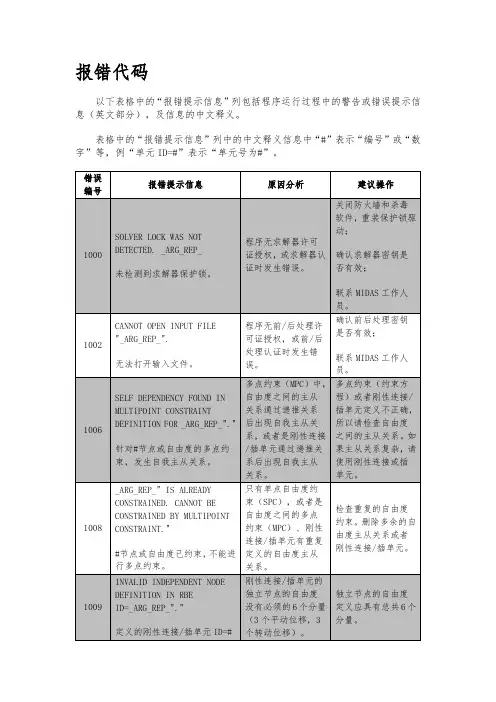

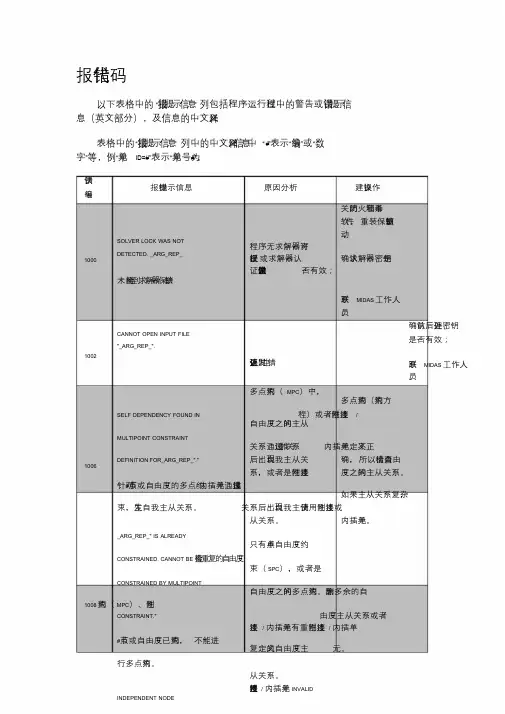

报错代码以下表格中的“报错提示信息”列包括程序运行过程中的警告或错误提示信息(英文部分),及信息的中文释义。

表格中的“报错提示信息”列中的中文释义信息中“#”表示“编号”或“数字”等,例“单元ID=#”表示“单元号为#”。

错误编号报错提示信息原因分析建议操作关闭防火墙和杀毒软件,重装保护锁驱1000 SOLVER LOCK WAS NOTDETECTED. _ARG_REP_程序无求解器许可证授权,或求解器认动;确认求解器密钥是证时发生错误。

否有效;未检测到求解器保护锁。

联系MIDAS工作人员。

CANNOT OPEN INPUT FILE"_ARG_REP_".1002处理认证时发生错确认前后处理密钥是否有效;联系MIDAS工作人员。

多点约束(MPC)中,多点约束(约束方SELF DEPENDENCY FOUND IN 程)或者刚性连接/自由度之间的主从MULTIPOINT CONSTRAINT关系通过递推关系内插单元定义不正1006 D EFINITION FOR_ARG_REP_"." 后出现自我主从关系,或者是刚性连接确,所以请检查自由度之间的主从关系。

针对#节点或自由度的多点约/内插单元通过递推如果主从关系复杂,束,发生自我主从关系。

关系后出现自我主请使用刚性连接或从关系。

内插单元。

_ARG_REP_" IS ALREADY只有单点自由度约CONSTRAINED. CANNOT BE检查重复的自由度束(SPC),或者是CONSTRAINED BY MULTIPOINT自由度之间的多点约束。

删除多余的自1008约束(MPC)、刚性CONSTRAINT." 由度主从关系或者连接/ 内插单元有重刚性连接/ 内插单#节点或自由度已约束,不能进复定义的自由度主元。

行多点约束。

从关系。

刚性连接/ 内插单元 INVALIDINDEPENDENT NODEDEFINITION IN RBE的独立节点的自由独立节点的自由度1009 ID=_ARG_REP_"." 度没有必须的 6 个分定义应具有总共 6 个量(3 个平动位移,3分量。

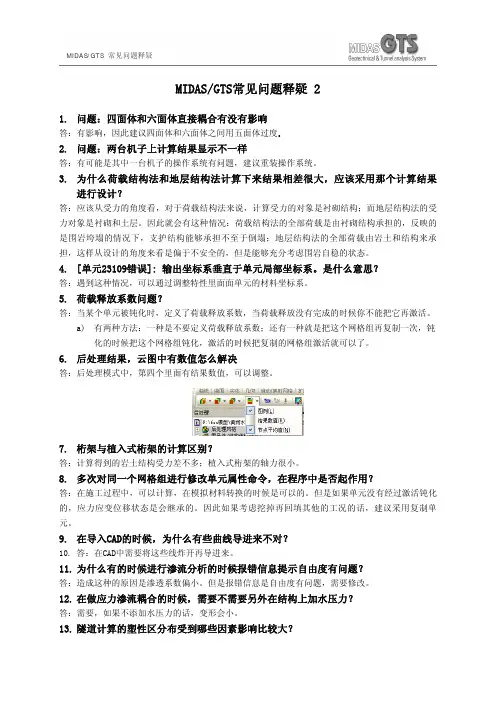

MIDAS/GTS常见问题释疑第一部分:程序安装 (2)1.问:启动程序时提示没有发现保护锁? (2)2.问:启动程序时提示密钥号错误? (2)第二部分:前处理 (2)1.问:顶点拟合曲面为何有时不能实现? (2)2.问:NURSS面与边界面的区别? (2)3.问:检查重复形状应注意哪些问题? (3)4.问:几何/合并面线的作用是什么? (3)5.问:利用‘填充网格’命令将二维单元转变为三维单元时,为什么提示上下面单元数不同? (3)6.问:为什么在连续点选缩放、平移、分行视图及旋转的时候功能会产生混淆? (3)7.问:将二衬定义为实体的时候需要注意什么问题? (3)8.问:“the quadratic 1-dimensional element type is supported”错误命令是什么意思? (3)9.问:匹配面线命令的作用和用法? (3)10.问:设置桩单元的时候,为什么在检查网格的时候,在桩单元处会出现自由线,这影响结果吗? (4)11.问:在加‘面压力’时,其对象类型有‘单元,单元-面’ 有什么区别? (4)12.问:GTS可以导入导出哪些格式,如何导入电子地图,电子地图抓图的精度如何? (4)13.问:我们建立地表面的栅格面都是等间距的,但实际的勘测点都是随意的不等间距点,那么该如何生成地表面?可否通过3点坐标生成地表面或地层面? (4)14.问:在水头边界定义时,怎样查看水头边界是总水头还是压力水头? (4)15.问:在几何线或面上加了荷载,可以将荷载直接转化到节点或单元上吗? (5)16.问:水头边界有哪些类型? (5)17.问:在GTS里面可不可以显示结构单元的截面特性? (5)19.问:在GTS里面可不可以对某些常用的功能设置快捷键? (5)20.问:在GTS里面可不可以实现对某个单元的显示或隐藏? (5)21.问:出现如图2所示的提示? (5)22.问:出现如图3所示的提示? (5)23.问:出现如图4所示的提示? (6)24.问:在GTS里都否实现单元、节点信息的输入输出? (6)25.问:为什么加了梯形荷载之后,窗口中显示的荷载数值是梯形变化的,而图形显示是矩形的? (6)第三部分 分析功能 (6)1.问:K0法与有限元法有什么区别? (6)2.问:计算边坡的时候需要注意的哪些问题? (6)3.问:荷载释放率如何定义? (7)4.问:本构模型采用邓肯-张模型为什么不容易收敛? (7)5.问:为什么没有勾选位移清零,在第一步里面位移值也是零? (7)6.问:GTS的动力分析,采用什么方法?可以做非线性分析吗? (7)7.问:GTS的动力分析中,阻尼是怎么考虑的? (7)8.问:GTS的动力分析中,动力荷载有哪些形式? (8)9.问:在GTS中,动力边界是如何考虑的? (8)10.问:在GTS中,质量矩阵采用何种形式? (8)11.问:在GTS中,如何模拟移动荷载? (8)12.问:在GTS中,爆破可以模拟吗?荷载是如何确定的? (8)13.问:在GTS中,可以做场地的反应谱分析吗?有国内的场地规范吗? (8)14.问:如何取得模型中某个点的加速度、速度、位移的时程图和时程序列? (8)15.问:地震荷载是否可以仅施加在子结构上,另外在动力分析中是否可以施加位移荷载? (8)16.问:在施工阶段考虑渗流问题,怎么考虑? (8)17.问:在边坡稳定计算中怎么考虑渗流作用? (8)18.问:渗流计算的时候,如何判断非稳定流和稳定流? (9)19.问:在施工阶段分析中,包含非稳定流计算时,需要注意哪些问题? (9)20.问:排水和非排水计算,在GTS中如何区别设置? (9)21.问:在施工阶段渗流分析中出现如图6所示的提示? (9)第四部分 后处理 (9)1.问:GTS里面前后处理之间可以直接切换吗? (9)2.问:GTS中单元的内力怎么考虑? (9)3.问:在特性/变形中变形前的线宽可否小于1? (9)4.问:为什么在定义剖面图时候改变定义平面命令显示不变? (10)5.问:梁单元的轴力和弯距方向怎么判断? (10)6.问:梁单元的combined 1-4是什么意思? (10)7.问:定义多个剖分面或剪切面来参看后处理结果时,为什么不能同时显示已定义的多个剖分面和或剪切面? (10)8.问:在用剖分面、剪切面查看后处理结果后,怎么退出到基本视图? (10)9.问:屈服比的定义是什么?屈服比和安全系数有什么关系? (10)第一部分:程序安装1.问:启动程序时提示没有发现保护锁?答:1.驱动程序没有安装好,请在“控制面板/添加或删除程序”中删除Sentinel Protection Inst aller 7.1.0,重新手动安装Sentinel Protection Installer 7.1.0。

1、程序分析时报错可能的原因?输出结果如下:>ENTRY LOAD_BLOCK>ENTRY ASSM_STIFF_LOAD ( FORM GLOBAL EQUILIBRIUM EQUATIONS IN BLOCKS )> In class [MultifrontalSolver] : Factorization failed in DSYTRFINCOMPLETEMULTI-FRONTALSOLVER > IERROR= -1>不正常的执行中断!1)问题分析:出现如上提示时,最常见的原因是模型中出现了不确定的刚体位移。

在分析中必须对模型中所有的节点都定义足够的约束条件,以保证它们在各个平移和转动自由度上都不会出现不确定的刚体位移。

2)类试问题A-桁架单元不能受弯,而在模型中没有约束它的转动自由度,就出现了不确定位移值。

B-施加接触单元后因为分割节点,导致分割产生的节点没有约束条件,也会出现不确定位移值。

C-单元异常,例如单元过度变形D-应力应变关系中有负斜率2、程序计算不收敛可能的原因?输出结果如下:X-COORDINATE OF C.G ....: 1.49753E+01MY-COORDINATE OF C.G ....: 1.50000E+01MZ-COORDINATE OF C.G ....: 1.12137E+01MINCREMENT NO. :1ITERATION NO. :1LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.478E-02 INCREMENT NO. :1ITERATION NO. :2LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.516E-02 INCREMENT NO. :1ITERATION NO. :3LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.249E-01 INCREMENT NO. :1ITERATION NO. :4LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.165E-01 INCREMENT NO. :1ITERATION NO. :5LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.953E-02 INCREMENT NO. :1ITERATION NO. :6LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.318E+02 INCREMENT NO. :1ITERATION NO. :7LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.300E+00 INCREMENT NO. :1ITERATION NO. :8LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.353E+00 INCREMENT NO. :1ITERATION NO. :9LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.847E-01 INCREMENT NO. :1ITERATION NO. :10LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.133E+00 INCREMENT NO. :1ITERATION NO. :11LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.715E-01 INCREMENT NO. :1ITERATION NO. :12LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.964E-01 INCREMENT NO. :1ITERATION NO. :13LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.629E-01 INCREMENT NO. :1ITERATION NO. :14LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.324E-01 INCREMENT NO. :1ITERATION NO. :15LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.454E+01 INCREMENT NO. :1ITERATION NO. :16LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.385E+00 INCREMENT NO. :1ITERATION NO. :17LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.164E+00 INCREMENT NO. :1ITERATION NO. :18LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.111E+00 INCREMENT NO. :1ITERATION NO. :19LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.512E+02 INCREMENT NO. :1ITERATION NO. :20LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.269E+00 INCREMENT NO. :1ITERATION NO. :21LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.151E+00 INCREMENT NO. :1ITERATION NO. :22LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.896E-01 INCREMENT NO. :1ITERATION NO. :23LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.339E+01INCREMENT NO. : 1 ITERATION NO. : 24 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.120E+00 INCREMENT NO. : 1 ITERATION NO. : 25 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.129E+00 INCREMENT NO. : 1 ITERATION NO. : 26 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.711E-01 INCREMENT NO. : 1 ITERATION NO. : 27 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.271E-01 INCREMENT NO. : 1 ITERATION NO. : 28 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.588E-01 INCREMENT NO. : 1 ITERATION NO. : 29 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.108E-01 INCREMENT NO. : 1 ITERATION NO. : 30 LOAD FACTOR : 0.100E+01 DISPL. NORM : 0.700E-021)问题分析:和的关系是在试验基础上由本构模型给定的,在做有限元计算时,它是已知的。

Gen中分析报错总结1、MAXIMUM NUMBER OF ITERATION HAS BEEN REACHEDCHECK TOLERANCE IN THE VIBRATION RESULT TABLERECOMMENDATION FOR BETTER CONVERGENCE :INCREASE THE SUBSPACE DIMENSION GREATER THANMIN(2Nf, Nf+8) (Nf=NUMBER OF FREQUENCIES)得到最大迭代次数,请在振动结果表中检查公差。

建议增加子空间维数,大于MIN(2Nf, Nf+8) Nf=数量的频率解:修改“子空间大小”2、节点奇异解:要查看边界条件及荷载加载3、静力弹塑性分析的报错,例题“上海建工林晨”[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 20171[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 2024[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4059[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4306[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4323[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4570[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4587[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4834[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4850[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5098[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5114[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5131[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5367[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5384[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5401[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING :1[My_I-End] COMP. OF BEAM NO. 5422[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5645[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5647[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5652[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5652[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5653[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5661[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5678[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5699[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5717[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5891< PUSHOVER LOADCASE NO. 1 / 1 >* INCREMENT METHOD : DISPLACEMENT CONTROL( Maximum Translational Displacement )* ANALYSIS OPTION : P-DELTA* CONSIDERING INITIAL LOADCASE* LOADCASE LOAD TYPE : MODE SHAPE* INCORE MULTI-FRONTAL SOLVER1----INC. STEPS- ----SUBSTEP- --ITERATION- --LOAD PARAMETER- --ELAPSED / TOTAL TIME----43 / 100 67 561 ************ 552.320 / 1284.465 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 563 ************ 553.740 / 1287.767 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 564 ************ 555.450 / 1291.744 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 565 ************ 556.850 / 1295.000 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 566 ************ 558.070 / 1297.837 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 567 ************ 559.110 / 1300.256 [sec]1>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 568 ************ 560.450 / 1303.372 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERSDISTANCES BETWEEN NODES IN SOME ELEMENTS ARE ABNORMALWHEN CALCULATING STIFFNESS OR STRESS FOR THEM.PLEASE CHECK INPUT DATA (ELEMENTS SHAPES, MESH SIZE & PATTERNS,MATERIAL PROPERTIES, AND FORCE INCREMENT, Etc).NODAL(UPDATED) COORDINATE IS SAVED FN.OUT FILE-------------------------------------------------------------ERRORS ENCOUNTERED. MIDAS JOB TERMINATED. REFER TO .OUT FILE-------------------------------------------------------------解:检查模型相应单元处的铰定义4、警告信息:在节点处方程无效,解:边界设置问题5、导入过程中,提示如下。

Gen中分析报错总结1、MAXIMUM NUMBER OF ITERATION HAS BEEN REACHEDCHECK TOLERANCE IN THE VIBRATION RESULT TABLERECOMMENDATION FOR BETTER CONVERGENCE :INCREASE THE SUBSPACE DIMENSION GREATER THANMIN(2Nf, Nf+8) (Nf=NUMBER OF FREQUENCIES)得到最大迭代次数,请在振动结果表中检查公差。

建议增加子空间维数,大于MIN(2Nf, Nf+8) Nf=数量的频率解:修改“子空间大小”2、节点奇异解:要查看边界条件及荷载加载3、静力弹塑性分析的报错,例题“上海建工林晨”[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 20171[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 2024[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4059[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4306[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4323[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4570[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4587[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 4834[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 4850[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5098[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5114[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5131[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5367[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5384[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5401[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING :1[My_I-End] COMP. OF BEAM NO. 5422[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5645[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5647[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5652[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5652[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5653[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5661[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5678[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5699[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_J-End] COMP. OF BEAM NO. 5717[WARNING] : THE YIELDING OCCURRED IN THE INELASTIC HINGE BY INITIAL LOADING : [My_I-End] COMP. OF BEAM NO. 5891< PUSHOVER LOADCASE NO. 1 / 1 >* INCREMENT METHOD : DISPLACEMENT CONTROL( Maximum Translational Displacement )* ANALYSIS OPTION : P-DELTA* CONSIDERING INITIAL LOADCASE* LOADCASE LOAD TYPE : MODE SHAPE* INCORE MULTI-FRONTAL SOLVER1----INC. STEPS- ----SUBSTEP- --ITERATION- --LOAD PARAMETER- --ELAPSED / TOTAL TIME----43 / 100 67 561 ************ 552.320 / 1284.465 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 563 ************ 553.740 / 1287.767 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 564 ************ 555.450 / 1291.744 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 565 ************ 556.850 / 1295.000 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 566 ************ 558.070 / 1297.837 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 567 ************ 559.110 / 1300.256 [sec]1>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERS43 / 100 67 568 ************ 560.450 / 1303.372 [sec]>>> ITERATIVE SOLUTION DIVERGED.>>> CHANGE INCREMENT SIZE OR (AND) NONLINEAR ANALYSIS CONTROL PARAMETERSDISTANCES BETWEEN NODES IN SOME ELEMENTS ARE ABNORMALWHEN CALCULATING STIFFNESS OR STRESS FOR THEM.PLEASE CHECK INPUT DATA (ELEMENTS SHAPES, MESH SIZE & PATTERNS,MATERIAL PROPERTIES, AND FORCE INCREMENT, Etc).NODAL(UPDATED) COORDINATE IS SAVED FN.OUT FILE-------------------------------------------------------------ERRORS ENCOUNTERED. MIDAS JOB TERMINATED. REFER TO .OUT FILE-------------------------------------------------------------解:检查模型相应单元处的铰定义4、警告信息:在节点处方程无效,解:边界设置问题5、导入过程中,提示如下。