供应链 英文加翻译

- 格式:docx

- 大小:45.73 KB

- 文档页数:14

供应链专业术语缩写及含义供应链管理是一个涉及多个领域的复杂系统,其中涉及到大量的专业术语和缩写。

这些术语和缩写的理解对于供应链管理人员来说至关重要,因为它们涉及到供应链管理的方方面面,包括采购、生产、物流、库存管理等。

在本文中,我将介绍一些常用的供应链专业术语的缩写及其含义,以帮助读者更好地理解供应链管理。

1. SCM:Supply Chain Management,供应链管理。

这是供应链管理领域中最常见的缩写,它涉及到整个供应链的规划、控制和执行,以实现最大化的价值。

2. ERP:Enterprise Resource Planning,企业资源规划。

ERP系统是一种集成的管理软件,它可以帮助企业实现信息的统一管理,包括采购、生产、销售等方面的信息。

3. MRP:Material Requirements Planning,物料需求计划。

MRP 系统是一种用于生产计划和控制的方法,它通过精确地计划所需的物料,并将其与生产计划相匹配,以确保生产的顺利进行。

4. WMS:Warehouse Management System,仓库管理系统。

WMS系统是用于实现仓库内物流管理的软件系统,它可以帮助企业实现仓库内的货物管理、库存控制和订单处理等功能。

5. TMS:Transportation Management System,运输管理系统。

TMS系统是用于管理运输和物流的软件系统,它可以帮助企业实现货物的运输计划、运输管控和运输成本的优化。

6. OMS:Order Management System,订单管理系统。

OMS系统是用于管理订单流程的软件系统,它可以帮助企业实现订单的处理、跟踪和配送等功能。

7. JIT:Just-In-Time,准时制。

JIT是一种生产和库存管理的方法,它通过在需要时才生产和供应物料,以减少库存和提高生产效率。

8. OTD:On-Time Delivery,准时交货。

OTD是一个衡量供应链绩效的指标,它表示供应链能否按时交付订单。

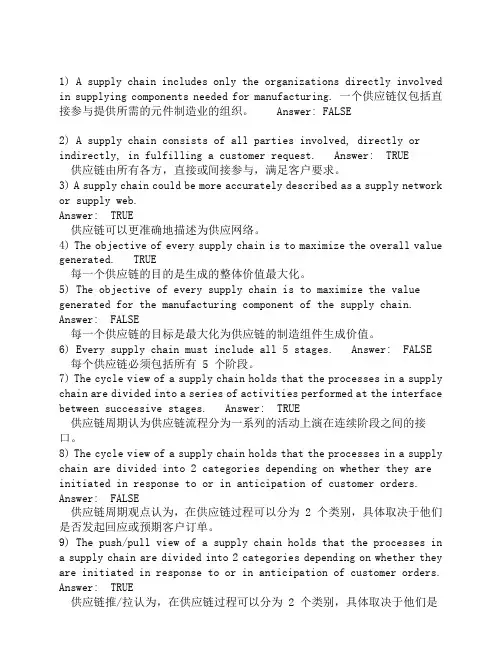

1) A supply chain includes only the organizations directly involvedin supplying components needed for manufacturing.一个供应链仅包括直接参与提供所需的元件制造业的组织。

Answer: FALSE2) A supply chain consists of all parties involved, directly or indirectly, in fulfilling a customer request. Answer: TRUE供应链由所有各方,直接或间接参与,满足客户要求。

3) A supply chain could be more accurately described as a supply network or supply web.Answer: TRUE供应链可以更准确地描述为供应网络。

4) The objective of every supply chain is to maximize the overall value generated. TRUE每一个供应链的目的是生成的整体价值最大化。

5) The objective of every supply chain is to maximize the value generated for the manufacturing component of the supply chain. Answer: FALSE每一个供应链的目标是最大化为供应链的制造组件生成价值。

6) Every supply chain must include all 5 stages. Answer: FALSE每个供应链必须包括所有 5 个阶段。

7) The cycle view of a supply chain holds that the processes in a supply chain are divided into a series of activities performed at the interface between successive stages. Answer: TRUE供应链周期认为供应链流程分为一系列的活动上演在连续阶段之间的接口。

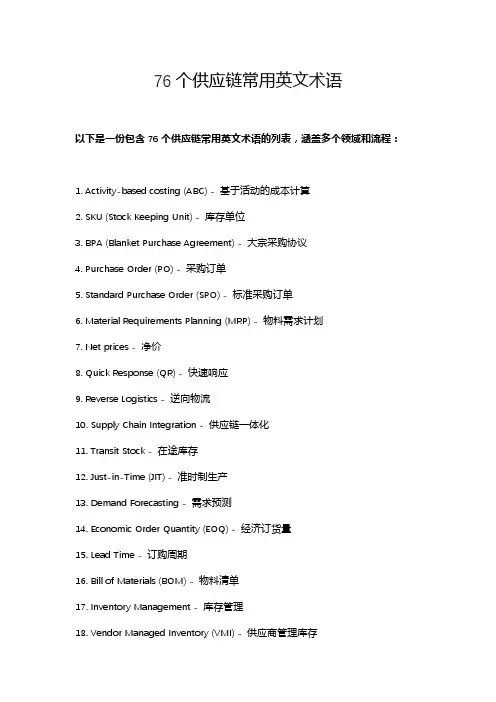

76个供应链常用英文术语以下是一份包含76个供应链常用英文术语的列表,涵盖多个领域和流程:1. Activity-based costing (ABC) - 基于活动的成本计算2. SKU (Stock Keeping Unit) - 库存单位3. BPA (Blanket Purchase Agreement) - 大宗采购协议4. Purchase Order (PO) - 采购订单5. Standard Purchase Order (SPO) - 标准采购订单6. Material Requirements Planning (MRP) - 物料需求计划7. Net prices - 净价8. Quick Response (QR) - 快速响应9. Reverse Logistics - 逆向物流10. Supply Chain Integration - 供应链一体化11. Transit Stock - 在途库存12. Just-in-Time (JIT) - 准时制生产13. Demand Forecasting - 需求预测14. Economic Order Quantity (EOQ) - 经济订货量15. Lead Time - 订购周期16. Bill of Materials (BOM) - 物料清单17. Inventory Management - 库存管理18. Vendor Managed Inventory (VMI) - 供应商管理库存19. Distribution Center (DC) - 分销中心20. Transportation Management System (TMS) - 运输管理系统21. Enterprise Resource Planning (ERP) - 企业资源规划22. Third-Party Logistics (3PL) - 第三方物流23. Fourth-Party Logistics (4PL) - 第四方物流24. Finished Goods Inventory - 成品库存25. Work in Process (WIP) - 在制品26. Cycle Counting - 循环盘点27. Cost of Goods Sold (COGS) - 销售成本28. Freight Forwarder - 货运代理29. Incoterms - 国际贸易术语解释通则30. Dock Scheduling - 码头调度31. Drop Shipping - 直接配送32. Pick and Pack - 拣选包装33. Cross-Docking - 越库作业34. Sales & Operations Planning (S&OP) - 销售与运营计划35. Customer Relationship Management (CRM) - 客户关系管理36. Total Quality Management (TQM) - 全面质量管理37. Supplier Relationship Management (SRM) - 供应商关系管理38. Return Merchandise Authorization (RMA) - 商品退货授权39. Barcode / QR Code - 条形码/二维码40. Hazardous Materials (HazMat) Handling - 危险品处理41. Cold Chain - 冷链物流42. Lean Manufacturing - 精益生产43. Six Sigma - 六西格玛44. KPIs (Key Performance Indicators) - 关键绩效指标45. Port of Origin - 起运港46. Port of Destination - 目的港47. Customs Clearance - 海关清关48. Free On Board (FOB) - 船上交货49. Cost, Insurance, and Freight (CIF) - 成本、保险费加运费50. Delivered Duty Paid (DDP) - 完税后交货51. Ex Works (EXW) - 工厂交货价52. Inbound Logistics - 入库物流53. Outbound Logistics - 出库物流54. Order-to-Cash (OTC) - 订单到收款55. Procure-to-Pay (P2P) - 采购到付款56. Global Trade Management (GTM) - 全球贸易管理57. EDI (Electronic Data Interchange) - 电子数据交换58. Takt Time - 节拍时间59. Kanban - 看板管理60. FIFO (First In, First Out) - 先进先出61. LIFO (Last In, First Out) - 后进先出62. Safety Stock - 安全库存63. Lot Size - 批量大小64. Containerization - 集装箱化65. MRP II (Manufacturing Resource Planning) - 制造资源计划66. DRP (Distribution Resource Planning) - 分销资源计划67. Drop Trailer Program - 拖车卸货计划68. Consolidation - 集拼69. Deconsolidation - 拆箱分拨70. Value-Added Services (VAS) - 增值服务71. Trade Compliance - 贸易合规72. Shipment Tracking - 运输追踪73. Carrier Selection - 承运商选择74. Multi-modal Transport - 多式联运75. Green Supply Chain - 绿色供应链76. Blockchain Technology - 区块链技术(在供应链中的应用)请注意,这并非一个详尽无遗的列表,但涵盖了供应链管理中广泛使用的许多关键术语。

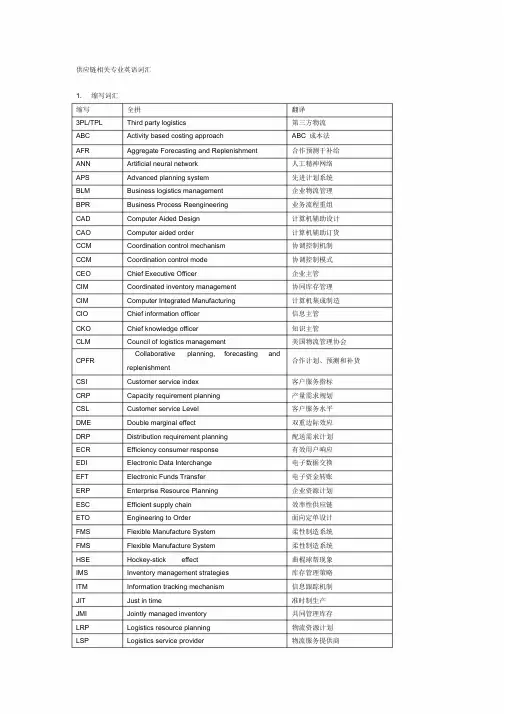

供应链相关专业英语词汇1. 缩写词汇缩写全拼翻译3PL/TPL Third party logistics 第三方物流ABC Activity based costing approach ABC 成本法AFR Aggregate Forecasting and Replenishment 合作预测于补给ANN Artificial neural network 人工精神网络APS Advanced planning system 先进计划系统BLM Business logistics management 企业物流管理BPR Business Process Reengineering 业务流程重组CAD Computer Aided Design 计算机辅助设计CAO Computer aided order 计算机辅助订货CCM Coordination control mechanism 协调控制机制CCM Coordination control mode 协调控制模式CEO Chief Executive Officer 企业主管CIM Coordinated inventory management 协同库存管理CIM Computer Integrated Manufacturing 计算机集成制造CIO Chief information officer 信息主管CKO Chief knowledge officer 知识主管CLM Council of logistics management 美国物流管理协会CPFRCollaborative planning, forecasting andreplenishment合作计划、预测和补货CSI Customer service index 客户服务指标CRP Capacity requirement planning 产量需求规划CSL Customer service Level 客户服务水平DME Double marginal effect 双重边际效应DRP Distribution requirement planning 配送需求计划ECR Efficiency consumer response 有效用户响应EDI Electronic Data Interchange 电子数据交换EFT Electronic Funds Transfer 电子资金转账ERP Enterprise Resource Planning 企业资源计划ESC Efficient supply chain 效率性供应链ETO Engineering to Order 面向定单设计FMS Flexible Manufacture System 柔性制造系统FMS Flexible Manufacture System 柔性制造系统HSE Hockey-stick effect 曲棍球帮现象IMS Inventory management strategies 库存管理策略ITM Information tracking mechanism 信息跟踪机制JIT Just in time 准时制生产JMI Jointly managed inventory 共同管理库存LRP Logistics resource planning 物流资源计划LSP Logistics service provider 物流服务提供商MIS Measuring index system 评价指标体系MPS master production scheduling 主生产排程MRP Material Requirement Planning 物料需求计划MRP ⅡManufacturing Resource Planning 制造资源计划MTO Make to order 按订单生产MTS Make to stock 备货生产NSM Negotiation selection method 协商选择法OEM Original equipment manufacturer 原始设备制造商POS Point of sale 销售终端QFD Quality function development 质量功能开发RSC Responsive supply chain 响应性供应链RSC Revenue sharing contracts 收益共享契约RCCP rough-cut capacity planning 粗能力计划SCC Supply chain coordination 供应链协调SCD Supply chain design 供应链设计SCM Supply chain management 供应链管理SCN Supply chain network 供应链网络SCP Supply chain planning 供应链计划SCP Supply chain partnership 供应链合作关系SFA Sales Forecast Accuracy 预测准确率SKU Stock Keeping Unit 库存进出计量的单位SI Sell in 销售进入渠道SO Sell out 销售给消费者SRM Supplier relationship management 供应商关系管理S&OP Sales and operation planning 销售运营计划TOC Theory of constraint 约束理论TPM Traditional purchase mode 传统采购模式TMS Transportation management system 运输管理系统VMI Vendor Managed Inventory 供应商管理库存WMAPE Weighted Mean Percentage Error 加权平均绝对百分比误差WMS Warehouse management system 仓储管理系统2. 非缩写核心词汇ABC classification ABC 分类Accessory 附件Action Report 行动报告Aggregate Planning .总体规划Agile Manufacturing 灵活制造Allocated Inventory 保留量Alternate BOM 替代物料表Anticipation Inventory 预期库存Assemble to Order 定单组装Automation 自动化Available Inventory 可用库存Available to Promise 可答应量Backlog 待交货Back Order 逾期订单Bill of Labor 人力表BOM Bill of Material 材料表bill of resources 资源表BOM Code 材料表码Bom Explosion 材料表展开Bom Implosion 材料表逆展Bom Structure 材科表结构Built-on-the-Iine parts 线上生产零件Bulk lssue 大批发料Bullwhip Effect 长鞭效应Business Plan 事业计划Capacity 产量Capacity Control 产量控制Capacity requirement planning 产量需求规划Check-in 结入Check-Out 结出Common part Bom 共享件材料表constraint management 限制因素管理continuous production 连续式生产critical capacity 关键产量critical part 关键零件customer order 客户定单customization 客制化customer service level 顾客服务水准cycle count interval 周期盘点区间cycle counting 周期盘点cycle time 周期时间Demand Management 需求管理demonstrated capacity 验证产量iscret manufacturing 装配式生产distribution center 配销中心distribution requirement planning 分销资源计划economic order quantity 经济订购量economic part period 经济量期emergency kanban 紧急看板finished goods 完成品firm planned order 固定计划定单first in first out 先进先出forecast 预测forecast horizon 预测期间fundamental data 基本资料gross requirement 总需求inbound queue control 输入端队列控制independent demand 独立需求input/output control 输入/输出控制intermittent production 问歇式生产inventory management 库存管理inventory status 库存状态inventory type 库存形态job 工件,工作job shop 工件生产工厂just in time 及时供补kanban 看板kanban ceiling 看板界限lead time 前置时间lead time offset 前置时问冲销least total cost 最低总成本批量法least unit cost 最低单位成本批量法level scheduling 平准化排程level production(linearity) 平准化生产linearity 定率生产load 负荷look ahead/look back 瞻前顾后法lot for lot 逐批批量法lot number 批号lot size 批量lot size inventory 批量库存lot sizing rule 批量法则maintenance, repair and operational supplies 间接物料make to order 定单生产make to stock 计划生产manufacturing bom 制造单元manufacturing cell 指令单manufacturing order 制造规划与控制manufacturing planning and control 制造资源规划master production scheduling 主生产排程material requirement planning 材料需求规划(计划)modular bom 模块材料表modular production 模块化生产mps item MPS 项目net requirement 净需求offset time 冲销时问on-hand inventory 在库量on-order inventory 在途量operations planning and control 作业规划与管制operations process chart 作业程序图order interval 订购区间order point 订购点parent/component 父件/子件pan number 件号past due 逾期量peg file 溯源文件pegging 溯源periodic order quantity 定期批量法periodic review system 定期评估法picking order 领料单plan-do-check-action cycle 计划一执行-检查-行动循环planned order receipts 计划定单收料planned order releases 计划定单发出planning bom 计划材料表planning horizon 计划期间planning time fence 计划时栅priority control 优先次序控制prioriry planning 优先次序规划preventive maintenance 预防性维护process manufacturing 流程式生产product family 产品族product line 产品线product structure 产品结构表product sub-line 产品副线production activity control 生产活动管制production rate 生产速率production plan 生产计划production planning 生产规划production run 生产连project-based production 项目式生产projected available balance 预计可用量pull system 拉式系统purchase order 订购单purchase reuisition 请购单quantity-per 单位用量quick response 快速反应rated capacity 评估产量raw material 原材料reasonableness test 合理测试receiving order 收料单refill kanban 补充看板re-order point 再订购点法repetitive manufacturing 重复性生产replacement part 替代件replenishment plan 补充计划replenishment time 补充时间resource requirement planning 资源需求规划rework kanban 重加工看板rolling kanban 滚动看板rolling schedule 滚动式排程rough-cut capacity planning 粗略产量规划safety stock 安全存量safety time 安全时间sales order 销售定单.scheduled receipts 在途量(已订未交货)scarp rate 报废率secondary stockroom 次级仓semi-finished goods 半成品serial number 序号shop calendar 厂历shop floor 制造现场shop floor control 制造现场控制stock keeping unit 材料库存单位subsontract order 外包单supply chain management 供应链管理synchronized control 同步控制synchronized production 同步生产theoretical capacity 理论产量Lime bucket 时段time phased order point 分期间订购点法transferring order 调拨单transportation inventory 运输库存total employee involvement 全员参与total preventive maintenance 全面预防型维护total productive maintenance 全面生产性维护total quality management 全面质量管理unit of measure 单位visual review system 目视评估法where-used report 用途表WIP inventory 在制品库存WIP tracking 在制品追踪work flow control system 工作流程控制系统work-in-process 在制品yield 良品率。

供应链英语翻译(译文和原文)Perspectives in supply chain risk managementChristopher S. TangUCLA Anderson School, 110 Westwood Plaza, UCLA, Los Angeles, CA 90095,USAReceived 3 November 2005; accepted 16 December 2005Available online 2 March 2006AbstractTo gain cost advantage and market share, many firms implemented various initiatives such as outsourced manufacturing and product variety. These initiatives are effective in a stable environment, but they could make a supply chain more vulnerable to various types of disruptions caused by uncertain economic cycles, consumer demands, and natural and manmade disasters. In this paper, we review various quantitative models for managing supply chain risks. We also relate various supply chain risk management (SCRM) strategies examined in the research literature with actual practices. The intent of this paper is three-fold. First, we develop a unified framework for classifying SCRM articles. Second, we hope this review can serve as a practical guide for some researchers to navigate through the sea of research articles in this important area. Third, by highlighting the gap between theory and practice, we hope to motivate researchers to develop new models for mitigating supply chain disruptions.Keywords:Supply chain risk management; Quantitative models; Review1. IntroductionOver the last 10 years, earthquakes, economic crises,SARS, strikes, terrorist attacks have disrupted supply chain operations repeatedly. Supply chain disruptions can have significant impact on a firm’s short-term performance. For example, Ericsson lost 400 million Euros after their supplier’s semiconductor plant caught on fire in 2000, andApple lost many customer orders during a supply shortage of DRAM chips after an earthquake hit Taiwan in 1999. Supply chain disruptions can have long-term negative effects on a firm’s financial performance as well. For instance, Hendricks and Singhal (2005) report that companies suffering from supply chain disruptions experienced 33–40% lower stock returns relative to their industry benchmarks.T o mitigate supply chain disruptions associated with various types of risks (uncertain economic cycles,uncertain consumer demands, and unpredictable natural andman-made disasters), many researchers have developed different strategies/models for managing supply chain risks. In this paper, we review primarily quantitative models that deal with supply chain risks. Also, we relate various supply chain risk management (SCRM) strategies examined in the literature with actual practices. The intent of this paper is threefold. First, we develop a unified framework for classifying SCRM articles. Second, we hope this review can serve as a practical guide for some researchers to navigate through the sea of research articles in this important area. Third, by highlighting the gap between theory and practice, we hope to motivate researchers to develop new models for mitigating supply chain disruptions.2. Supply managementTo gain cost advantage, many firms outsourced certain non-core functions so as to maintain a focus on their core competence (cf., Porter (1985)). Since the 1980s, we witnessed a sea change in which firms outsourced their supply chain operations including design, production, logistics, information services, etc. Essentially, supply management deal with five inter-related issues:1. supply network design,2. supplier relationship,3. supplier selection process (criteria and supplierselection),4. supplier order allocation,5. supply contract.3.Demand managementIn Section 2, we describe how manufacturers can use different supply management strategies to mitigate various supply chain operational risks However, these supply management strategies are ineffective when the underlying supply mechanism is inflexible. For instance, in the service industry or in the fashion goods manufacturing industry, the supply mechanism is inflexible because the capacity is usually fixed. When the supply capacity is fixed, many firms have attempted to use different demand management strategies so that they can manipulate uncertain demands dynamically so that the modified demand is better matched with the fixed supply.Due to space limitation, we are unable to review the dynamic pricing or clearance pricing literature. The reader is referred to Elmaghraby and Keskinocak (2003) for an extensive review of dynamic pricing models and clearance pricing models for selling a fixed number of units over a finite horizon. Also, we do not plan to review literature that deal with coordination ofpricing and ordering decisions. The reader is referred to Yano and Gilbert (2004),Petruzzi and Dada (1999), Eliashberg and Steinberg (1993) for three comprehensive reviews in this area. Instead, we shall focus on articles that emphasize on the use of demand management strategies to‘‘shape’’ uncertain demand so that a firm can use an inflexible supply to meet the modified demand.4. Product managementTo compete for market share, many manufacturers expand their product lines. As reported in Quelch and Kenny (1984), the number of stock keeping units (SKUs) in consumer packaged goods has been increasing at a rate of 16% every year between 1985 and 1992. Marketing research shows that product variety is an effective strategy to increase increasing market share because it enables a firm to serve heterogeneous market segments and to satisfy consumer’s variety seeking behavior. However, while product variety may help a firm to increase market share and revenue, product variety can increase manufacturing cost due to an increasein manufacturing complexity. Moreover, product variety can increase inventory cost due to an increase in demand uncertainty. These twoconcerns have been illustrated in an empirical study conducted by MacDuffie et al. (1996). They show that the production and inventory costs tend to increase as product variety increases. Therefore, it is critical for a firm to determine an optimal product portfolio that maximizes the firm’s profit. The reader is referred to Ramdas (2003) for a comprehensive review of literature in the area of product variety.5. Information managementAs explained in Fisher (1997), most consumer products can be classified as fashion products or functional products. Basically, fashion products usually have shorter life cycles and higher levels of demand uncertainties than the functional products. Therefore, different information management strategies would be needed to manage for different typesof products especially in the presence of supply chain risks. For this reason, we shall classify the work in this section according to the product types: fashion products and functional products.6.Robust strategies for mitigating operational and disruption risksUpon examining the underlying assumptions of the models reviewed so far, it appears most of the quantitative models are designed for managing operational risks. Even though these quantitative models often provide cost effective solutions for managing operational risks, there do not address the issue of disruption risks in an explicit manner. Before we present some potential research ideas for managing supply chain disruption risk in the next section, we shall examine how disruptions risks are managed in practice and relate these practices to the models reviewed earlier. After reviewing some qualitative analyses presented in various risk management and SCRM articles, we can summarize the key findings as follows:1.Managers’attitude towards risks:Sharpira (1986) and March and Sharpira (1987) study managers’ attitude towards risks and they conclude that:(1)Managers are quite insensitive to estimates of the probabilities of possible outcomes.(2) Managers tend to focus on critical performance targets, which affect the way they manage risk.(3) Managers make a sharp distinction between taking risks and gambling.2.Managers’ attitude towards initiatives for managing supply chaindisruption risks.7. ConclusionsIn this paper, we have reviewed various quantitative models for managing supply chain risks. We found that these quantitative models are designed for managing operational risks primarily, not disruption risks. However, we argue that some of these strategies have been adopted by practitioners because these strategies can make a supply chain become more efficient in terms of handling operational risks and more resilient in terms of managing disruption risks. Since there are few supply chain management models for managing disruption risks, we would like to present six potential ideas for future research.1.Demand and supply process:Virtually, all models reviewed in this paper are based on the assumption that the demand or the supply process is stationary. To model various types of disruptions mathematically, one may need to extend the analysis to deal with non-stationary demand or supply process. For instance, one may consider modeling the demand or the supply process as a ‘‘jump’’ process to capture the characteristics of major disruptions.2.Objective function:The performance measures of the models reviewed in this paper are primarily based on the expected cost or profit. The expected cost or profit is an appropriate measure for evaluating different strategies for managing operational risks. When dealing with disruption risks that rarely happen, one may need to consider alternativeobjectives besides the expected cost/profit.3.Supply management strategies:When developing supply management strategies for managing disruption risks, both academics and practitioners suggest the idea of ‘‘back-up’’ suppliers.4.Demand management strategies: Among the demand management strategies presented in Section 3, it appears that dynamic pricing/ revenue management has great potential for managing disruption risks because a firm can deploy this strategy quickly after a disruption occurs. In addition, revenue management looks promising especially after successful implementations of different revenue management systems in the airline industry for managing operational risks.5. Product management strategies: When selling products on line, e-tailers can change their product assortments dynamically according to the supply and demand of different products. This idea can be extended to brick and mortar retailers for managing disruption risks./doc/a12863039.html,rmation management strategies: Among the information management strategies described in Section 6, we think the CPFR strategy is promising because it fosters a tighter coordination and stronger collaboration among supply chain partners.站在供应链风险管理的角度作者:Christopher S. Tang摘要:为了获得成本优势和抢占市场份额,很多企业采取了各种措施,比如外包生产制造和产品多样化生产。

供应链管理外文翻译文献供应链管理外文翻译文献(文档含中英文对照即英文原文和中文翻译)Supply Chain ManagementThe so-called supply chain, in fact, from suppliers, manufacturers, warehouses, istribution centers and channels, and so constitute a logistics network. The same enterprise may constitute the different components of this network node, but the situation is different from a corporate network in different nodes. For example, in a supply chain, companies may not only in the same manufacturers, storage nodes, and in distribution centers, such as possession node location. In the more detailed division of labor, the higher the rofessional requirements of the supply chain, different nodes are basically composed by different enterprises. In the supply chain flows between the member units of raw materials, finished products, such as inventory and production constitutes the supply chain of goods flow.That is, to meet a certain level of customer service under the conditions, in order to make the whole supply chain to minimize costs and the suppliers, manufacturers, warehouses, distribution centers and channels, and so effectively organized together to carry out Product manufacturing, transport, distribution and sales management.From the above definition, we can be interpreted to include supply chain anagement of rich content.First of all, supply chain management products to meet customer demand in the process of the cost implications of various members of the unit are taken intoaccount, including from raw material suppliers, manufacturers to the warehouse distribution center to another channel. However, in practice in the supply chain analysis, it is necessary to consider the supplier's suppliers and customers of the customers, because their supply chain performance is also influential.Second, supply chain management is aimed at the pursuit of the whole supply chain's overall efficiency and cost effectiveness of the system as a whole, always trying to make the total system cost to a minimum. Therefore, the focus of supply chain management is not simply a supply chain so that members of the transportation costs to minimize or reduce inventory, but through the use of systems approach to coordinate the supply chain members so that the entire supply chain total cost of the minimum so that the whole supply chain System in the most fluent in the operation.Third, supply chain management is on the suppliers, manufacturers, warehouses, distribution centers and organically integrate the channel into one to start this problem, so many businesses, including its level of activities, including the strategic level, tactical and operational level Level, and so on.Although the actual logistics management, only through the organic supply chain integration, enterprises can significantly reduce costs and improve service levels, but in practice the supply chain integration is very difficult, it is because: First of all, in the supply chain There are different members of different and conflicting objectives. For example, providers generally want manufacturers to purchase large quantities of stable, and flexible delivery time can change; desire to the contrary with suppliers, although most manufacturers are willing toimplement long-term production operations, but they must take into account the needs of its customers and to make changes Positive response, which requires manufacturers choice and flexibility in procurement strategy. Therefore, suppliers and manufacturers to the goal of flexibility in the pursuit of the objectives inevitably exist between the contradictions.Secondly, the supply chain is a dynamic system, with time and constantly changing. In fact, customers not only demand and supply capacity to change over time, supply chain and the relationship between the members will change over time. For example, the increased purchasing power with customers, suppliers and manufacturers are facing greater pressure to produce more and more personalized varieties of high-quality products, then ultimately the production of customized products.Research shows that effective supply chain management can always make the supply chain of enterprises will be able to maintain stability and a lasting competitive advantage, thus increasing the overall supply chain competitiveness. Statistics show that, supply chain management will enable the effective implementation of enterprise total cost of about 20 per cent decline in the supply chain node on the enterprise-time delivery rate increased by 15 percent or more, orders to shorten the production cycle time 20 percent to 30 percent, supply chain Node on the enterprise value-added productivity increased by 15 percent or more. More and more enterprises have already recognized that the implementation of supply chain management of the great benefits, such as HP,IBM, DELL, such as supply chain management in the practice of the remarkable achievements made is proof.Supply chain management: it from a strategic level and grasp the overall perspective of the end-user demand, through effective cooperation between enterprises, access from the cost, time, efficiency, flexibility, and so the best results. From raw materials to end-users of all activities, the whole chain of process management.SCM (supply chain management) is to enable enterprises to better procurement of manufactured products and services required for raw materials, production of goods and services and their delivery to clients, the combination of art and science. Supply chain management, including the five basic elements.Plan: This is a strategic part of SCM. You need a strategy to manage all the resources to meet our customers for your products. Good plan is to build a series of methods to monitor the supply chain to enable it to effective, low-cost delivery of high quality for customers and high-value products or services.Procurement: you can choose the products and services to provide goods and services providers, and suppliers to establish a pricing, delivery and payment processes and create methods to monitor and improve the management, and the suppliers to provide goods and services Combined with management processes, including the delivery and verification of documentation, transfer of goods to your approval of the manufacturing sector and payments to suppliers and so on.Manufacturing: arrangements for the production, testing, packaged and ready for delivery, supply chain measurement is the largest part of the contents, including the level of quality, product yield and productivity of workers, such as the measurement.Delivery: a lot of "insider" as "logistics", is to adjust the user's orders receipts, the establishment of the storage network, sending and delivery service delivery personnel to the hands of customers, the establishment of commodity pricing system, receiving payments.Return: This is the supply chain problems in the handling part. Networking customers receive the refund of surplus and defective products, and customer applications to provide support for the problem.Source70 in the late 20th century, Keith Oliver adoption and Skf, Heineken, Hoechst, Cadbury-Schweppes, Philips, and other contact with customers in the process of gradually formed its own point of view. And in 1982, "Financial Times" magazine in an article on the supply chain management (SCM) of the significance, Keith Oliver was that the word will soon disappear, but "SCM" not only not disappeared, and quickly entered the public domain , The concept of the managers of procurement, logistics, operations, sales and marketing activities sense a great deal.EvolutionSupply chain has never been a universally accepted definition, supply chain management in the development process, many experts and scholars have putforth a lot of definition, reflecting the different historical backgrounds, in different stages of development of the product can be broadly defined by these For the three stages:1, the early view was that supply chain is manufacturing enterprises in an internal process2, but the supply chain concept of the attention of the links with other firms 3, the last of the supply chain concept of pay more attention around the core of the network links between enterprises, such as core business with suppliers, vendors and suppliers, and even before all the relations, and a user, after all the users and to the relationship.ApplySupply chain management involves four main areas: supply, production planning, logistics, demand. Functional areas including product engineering, product assurance, procurement, production control, inventory control, warehouse management, distribution management. Ancillary areas including customer service, manufacturing, design engineering, accounting, human resources, marketing.Supply Chain Management implementation steps: 1, analysis of market competition environment, identify market opportunities, 2, analysis of customer value, 3, identified competitive strategy, 4, the analysis of the core competitiveness of enterprises, 5, assessment, selection of partners For the supply chain partners of choice, can follow the following principles:1, partners must have available the core of their competitiveness.2, enterprises have the same values and strategic thinking3, partners must Fewer but Better.CaseAs China's largest IT distributor, Digital China in China's supply chain management fields in the first place. In the IT distribution model generally questioned the circumstances, still maintained a good momentum of development, and CISCO, SUN, AMD, NEC, IBM, and other famous international brands to maintain good relations of cooperation. e-Bridge trading system in September 2000 opening, as at the end of March 2003, and 6.4 billion yuan in transaction volume. In fact, this is the Digital China from the traditional distribution supply chain services to best reflect the changes. In the "distribution of services is a" concept, Digital China through the implementation of change channels, expansion of product and service operations, increasing its supply chain in the value of scale and specialized operations, to meet customer demand on the lower reaches of the In the course of the supply chain system can provide more value-added services, with more and more "IT services" color.供应链管理所谓供应链,其实就是由供应商、制造商、仓库、配送中心和渠道商等构成的物流网络。

Perspectives in supply chain risk managementChristopher S. TangUCLA Anderson School, 110 Westwood Plaza, UCLA, Los Angeles, CA 90095,USAReceived 3 November 2005; accepted 16 December 2005Available online 2 March 2006AbstractTo gain cost advantage and market share, many firms implemented various initiatives such as outsourced manufacturing and product variety. These initiatives are effective in a stable environment, but they could make a supply chain more vulnerable to various types of disruptions caused by uncertain economic cycles, consumer demands, and natural and manmade disasters. In this paper, we review various quantitative models for managing supply chain risks. We also relate various supply chain risk management (SCRM) strategies examined in the research literature with actual practices. The intent of this paper is three-fold. First, we develop a unified framework for classifying SCRM articles. Second, we hope this review can serve as a practical guide for some researchers to navigate through the sea of research articles in this important area. Third, by highlighting the gap between theory and practice, we hope to motivate researchers to develop new models for mitigating supply chain disruptions.Keywords:Supply chain risk management; Quantitative models; Review1. IntroductionOver the last 10 years, earthquakes, economic crises,SARS, strikes, terrorist attacks have disrupted supply chain operations repeatedly. Supply chain disruptions can have significant impact on a firm’s short-term performance. For example, Ericsson lost 400 million Euros after their supplier’s semiconductor plant caught on fire in 2000, andApple lost many customer orders during a supply shortage of DRAM chips after an earthquake hit Taiwan in 1999. Supply chain disruptions can have long-term negative effects on a firm’s financial performance as well. For instance, Hendricks and Singhal (2005) report that companies suffering from supply chain disruptions experienced 33–40% lower stock returns relative to their industry benchmarks.To mitigate supply chain disruptions associated with various types of risks (uncertain economic cycles,uncertain consumer demands, and unpredictable natural andman-made disasters), many researchers have developed different strategies/models for managing supply chain risks. In this paper, we review primarily quantitative models that deal with supply chain risks. Also, we relate various supply chain risk management (SCRM) strategies examined in the literature with actual practices. The intent of this paper is threefold. First, we develop a unified framework for classifying SCRM articles. Second, we hope this review can serve as a practical guide for some researchers to navigate through the sea of research articles in this important area. Third, by highlighting the gap between theory and practice, we hope to motivate researchers to develop new models for mitigating supply chain disruptions.2. Supply managementTo gain cost advantage, many firms outsourced certain non-core functions so as to maintain a focus on their core competence (cf., Porter (1985)). Since the 1980s, we witnessed a sea change in which firms outsourced their supply chain operations including design, production, logistics, information services, etc. Essentially, supply management deal with five inter-related issues:1. supply network design,2. supplier relationship,3. supplier selection process (criteria and supplierselection),4. supplier order allocation,5. supply contract.3.Demand managementIn Section 2, we describe how manufacturers can use different supply management strategies to mitigate various supply chain operational risks However, these supply management strategies are ineffective when the underlying supply mechanism is inflexible. For instance, in the service industry or in the fashion goods manufacturing industry, the supply mechanism is inflexible because the capacity is usually fixed. When the supply capacity is fixed, many firms have attempted to use different demand management strategies so that they can manipulate uncertain demands dynamically so that the modified demand is better matched with the fixed supply.Due to space limitation, we are unable to review the dynamic pricing or clearance pricing literature. The reader is referred to Elmaghraby and Keskinocak (2003) for an extensive review of dynamic pricing models and clearance pricing models for selling a fixed number of units over a finite horizon. Also, we do not plan to review literature that deal with coordination of pricing and ordering decisions. The reader is referred to Yano and Gilbert (2004),Petruzzi and Dada (1999), Eliashberg and Steinberg (1993) for three comprehensive reviews in this area. Instead, we shall focus on articles that emphasize on the use of demand management strategies to‘‘shape’’ uncertain demand so that a firm can use an inflexible supply to meet the modified demand.4. Product managementTo compete for market share, many manufacturers expand their product lines. As reported in Quelch and Kenny (1984), the number of stock keeping units (SKUs) in consumer packaged goods has been increasing at a rate of 16% every year between 1985 and 1992. Marketing research shows that product variety is an effective strategy to increase increasing market share because it enables a firm to serve heterogeneous market segments and to satisfy consumer’s variety seeking behavior. However, while product variety may help a firm to increase market share and revenue, product variety can increase manufacturing cost due to an increasein manufacturing complexity. Moreover, product variety can increase inventory cost due to an increase in demand uncertainty. These twoconcerns have been illustrated in an empirical study conducted by MacDuffie et al. (1996). They show that the production and inventory costs tend to increase as product variety increases. Therefore, it is critical for a firm to determine an optimal product portfolio that maximizes the firm’s profit. The reader is referred to Ramdas (2003) for a comprehensive review of literature in the area of product variety.5. Information managementAs explained in Fisher (1997), most consumer products can be classified as fashion products or functional products. Basically, fashion products usually have shorter life cycles and higher levels of demand uncertainties than the functional products. Therefore, different information management strategies would be needed to manage for different typesof products especially in the presence of supply chain risks. For this reason, we shall classify the work in this section according to the product types: fashion products and functional products.6.Robust strategies for mitigating operational and disruption risksUpon examining the underlying assumptions of the models reviewed so far, it appears most of the quantitative models are designed for managing operational risks. Even though these quantitative models often provide cost effective solutions for managing operational risks, there do not address the issue of disruption risks in an explicit manner. Before we present some potential research ideas for managing supply chain disruption risk in the next section, we shall examine how disruptions risks are managed in practice and relate these practices to the models reviewed earlier. After reviewing some qualitative analyses presented in various risk management and SCRM articles, we can summarize the key findings as follows:1.Managers’attitude towards risks:Sharpira (1986) and March and Sharpira (1987) study managers’ attitude towards risks and they conclude that:(1)Managers are quite insensitive to estimates of the probabilities of possible outcomes.(2) Managers tend to focus on critical performance targets, which affect the way they manage risk.(3) Managers make a sharp distinction between taking risks and gambling.2.Managers’ attitude towards initiatives for managing supply chaindisruption risks.7. ConclusionsIn this paper, we have reviewed various quantitative models for managing supply chain risks. We found that these quantitative models are designed for managing operational risks primarily, not disruption risks. However, we argue that some of these strategies have been adopted by practitioners because these strategies can make a supply chain become more efficient in terms of handling operational risks and more resilient in terms of managing disruption risks. Since there are few supply chain management models for managing disruption risks, we would like to present six potential ideas for future research.1.Demand and supply process:Virtually, all models reviewed in this paper are based on the assumption that the demand or the supply process is stationary. To model various types of disruptions mathematically, one may need to extend the analysis to deal with non-stationary demand or supply process. For instance, one may consider modeling the demand or the supply process as a ‘‘jump’’ process to capture the characteristics of major disruptions.2.Objective function:The performance measures of the models reviewed in this paper are primarily based on the expected cost or profit. The expected cost or profit is an appropriate measure for evaluating different strategies for managing operational risks. When dealing with disruption risks that rarely happen, one may need to consider alternative objectives besides the expected cost/profit.3.Supply management strategies:When developing supply management strategies for managing disruption risks, both academics and practitioners suggest the idea of ‘‘back-up’’ suppliers.4.Demand management strategies: Among the demand management strategies presented in Section 3, it appears that dynamic pricing/ revenue management has great potential for managing disruption risks because a firm can deploy this strategy quickly after a disruption occurs. In addition, revenue management looks promising especially after successful implementations of different revenue management systems in the airline industry for managing operational risks.5. Product management strategies: When selling products on line, e-tailers can change their product assortments dynamically according to the supply and demand of different products. This idea can be extended to brick and mortar retailers for managing disruption risks.rmation management strategies: Among the information management strategies described in Section 6, we think the CPFR strategy is promising because it fosters a tighter coordination and stronger collaboration among supply chain partners.站在供应链风险管理的角度作者:Christopher S. Tang摘要:为了获得成本优势和抢占市场份额,很多企业采取了各种措施,比如外包生产制造和产品多样化生产。

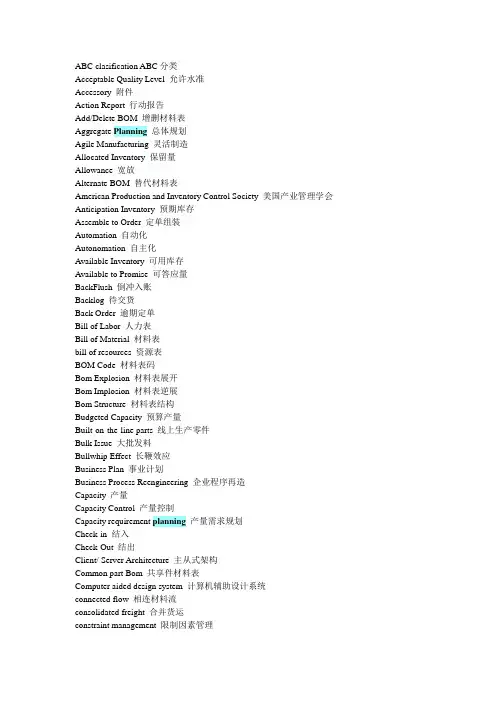

ABC clasification ABC分类Acceptable Quality Level 允许水准Accessory 附件Action Report 行动报告Add/Delete BOM 增删材料表Aggregate Planning总体规划Agile Manufacturing 灵活制造Allocated Inventory 保留量Allowance 宽放Alternate BOM 替代材料表American Production and Inventory Control Society 美国产业管理学会Anticipation Inventory 预期库存Assemble to Order 定单组装Automation 自动化Autonomation 自主化Available Inventory 可用库存Available to Promise 可答应量BackFlush 倒冲入账Backlog 待交货Back Order 逾期定单Bill of Labor 人力表Bill of Material 材料表bill of resources 资源表BOM Code 材料表码Bom Explosion 材料表展开Bom Implosion 材料表逆展Bom Structure 材料表结构Budgeted Capacity 预算产量Built-on-the-line parts 线上生产零件Bulk Issue 大批发料Bullwhip Effect 长鞭效应Business Plan 事业计划Business Process Reengineering 企业程序再造Capacity 产量Capacity Control 产量控制Capacity requirement planning产量需求规划Check-in 结入Check-Out 结出Client/ Server Architecture 主从式架构Common part Bom 共享件材料表Computer aided design system 计算机辅助设计系统connected flow 相连材料流consolidated freight 合并货运constraint management 限制因素管理continuous improvement 连续改善continuous production 连续式生产critical capacity 关键产量critical part 关键零件customer order 客户定单customization 客制化customer service level 顾客服务水准cycle count interval 周期盘点区间cycle counting 周期盘点cycle time 周期时间customer relationship management 客户关系管理data flow diagram 数据流程图de-coupling stock 反耦合库存Demand Management 需求管理Demand Rate 需求速率Demand time fence 需求时栅demonstrated capacity 验证产量dependent demand 依赖需求diagnostic test 诊断测试disconnected flow 分离材料流iscret manufacturing 装配式生产distribution center 配销中心distribution requirement planning配销需求规划drum-buffer-rope control DBR管制法earliest start date 最早开工日economic order quantity 经济订购量economic part period 经济量期elimination,combination,rearrangement,simplification ECRS改善法emergency kanban 紧急看板employee empowerment 员工授权employee involvement 员工参与end user computing 使用者自建系统engineering to order 定单设计engineering change 设计变更engineering product structure 工程用产品结构表exception report 企业资料规划enterprise resource planning例外报告executive information system 主管信息系统existence test 存在测试expeditor 催料人员final assembly schedule 最终组装排程finished goods 完成品firm planned order 固定计划定单first in first out 先进先出fixed order quantity 定量批量法flow shop 流程生产工厂forecast 预测forecast horizon预测期间fundamental data 基本资料gateway workstation 投料工作站graphic user interface 图形接口gross requirement 总需求group technology 群组技术hedge inventory 避险库存inbound queue control 输入端队列控制independent demand 独立需求input/output control 输入/输出控制intermittent production 间歇式生产inventory management 库存管理inventory status 库存状态inventory sub-type 库存副型态inventory type 库存型态item 材料(项目)item master 材料主档job 工件,工作job shop 工件生产工厂joint operation 联合作业just in time 及时供补kanban 看板kanban ceiling 看板界限latest start date 最晚开工日lead time 前置时间lead time offset 前置时间冲销least total cost 最低总成本批量法least unit cost 最低单位成本批量法level scheduling 平准化排程level production(linearity) 平准化生产linearity 定率生产load 负荷look ahead/look back 瞻前顾后法lot for lot 逐批批量法lot number 批号lot size 批量lot size inventory 批量库存lot sizing rule 批量法则low-level code 最低阶码maintenance, repair and operational supplies 间接物料make to order 定单生产make to stock 计划生产managerial product structure 管理用产品结构表manufacturing bom 制造单元manufacturing cell 制令单manufacturing order 制造规划与控制manufacturing planning and control 制造资源规划master production scheduling 主生产排程master scheduler 主生产排程员material service sheduling 主服务排程material handling 材料搬运material requirement planning材料需求规划(计划) mean absolute deviation 平均绝对差modular bom 模块材料表modular production 模块化生产mps item MPS 项目mrp crusades MRP 改革运动mrp nervousness MRP不安定性multilevel mps 多阶主生产排程net change 净变法net requirement 净需求offset time 冲销时间one less at a time 一次减一点on-hand inventory 在库量on-order inventory 在途量open system platform 开放系统平台operations planning and control 作业规划与管制operations process chart 作业程序图option 选用件optional bom 选用材料件order interval 订购区间order point 订购点original equipment manuafacturer 原设备制造商outbound queue control 输出端队列控制overflow stockroom 溢量仓parent/component 父件/子件part number 件号part periodic balancing 量期平衡批量法past due 逾期量peg file 溯源文件pegging 溯源period length 期长periodic order quantity 定期批量法periodic review system 定期评估法phantom 幽灵材料phantom bom 幽灵材料表phantom component 幽灵子件picking order 领料单pipeline stock 管路库存plan-do-check-action cycle 计划-执行-检查-行动循环planned order receipts 计划定单收料planned order releases 计划定单发出planning bom 计划材料表planning horizon计划期间planning time fence 计划时栅point of use 使用点primary stockroom 基本仓priority control 优先次序控制priority planning优先次序规划preventive maintenance 预防性维护process flow chart 制程流程图process manufacturing 流程式生产product configuration system 产品构造系统product family 产品族product line 产品线product load profile 产品负荷表product structure 产品结构表product sub-line 产品副线production activity control 生产活动管制production rate 生产速率production plan 生产计划production planning生产规划production run 生产连project-based production 项目式生产projected available balance 预计可用量projected on-hand 预计在库量pseuo bom 假材料表pull signal 拉式讯号pull system 拉式系统purchase order 订购单purchase reuisition 请购单quantity-per 单位用量quick response 快速反应rated capacity 评估产量raw material 原材料reasonableness test 合理测试receiving order 收料单refill kanban 补充看板regeneration 再生法re-order point 再订购点法repetitive manufacturing 重复性生产replacement part 替代件replenishment plan 补充计划replenishment time 补充时间resource profile 资源负荷表resource requirement planning资源需求规划rework kanban 重加工看板rolling kanban 滚动看板rolling schedule 滚动式排程rough-cut capacity planning粗略产量规划route 途程routing 途程表safety stock 安全存量safety time 安全时间safety order 销售定单scheduled receipts 在途量(已订未交量) scarp rate 报废率secondary stockroom 次级仓semi-finished goods 半成品serial number 序号setup 准备作业shop calendar 厂历shop floor 制造现场shop floor control 制造现场控制shop order 制令单significant numbering 显义编号standard coefficient 标准系数stock keeping unit 材料库存单位subsontract order 外包单super bom 超材料单supply chain management 供应链管理synchronized control 同步控制synchronized production 同步生产theoretical capacity 理论产量theory of constraints 限制理论three tier architecture 三层式架构throughtput 产出率time bucket 时段time phased order point 分期间订购点法transferring order 调拨单transportation inventory 运输库存total employee involvement 全员参与total preventive maintenance 全面预防性维护total productive maintenance 全面生产性维护total quality management 全面质量管理two bin system 双箱法two level mps 双阶主生产排程unit of measure 单位visual review system 目视评估法where-used report 用途表WIP inventory 在制品库存WIP tracking 在制品追踪work flow control system 工作流程控制系统work-in-process 在制品yield 良品率Common Terms in Newspapers :accredited journalist n. 特派记者advertisement n.广告.advance n.预发消息;预写消息affair n.桃色新闻;绯闻anecdote n.趣闻轶事assignment n.采写任务attribution n. 消息出处,消息来源back alley news n. 小道消息backgrounding n.新闻背景Bad news travels quickly. 坏事传千里。

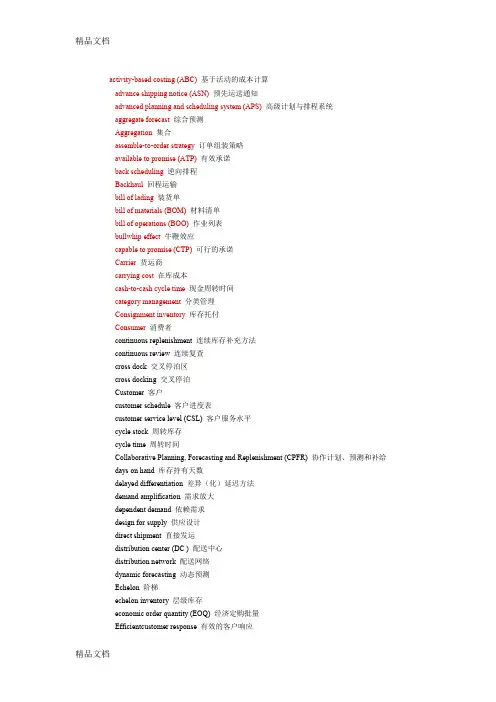

activity-based costing (ABC) 基于活动的成本计算advance shipping notice (ASN) 预先运送通知advanced planning and scheduling system (APS) 高级计划与排程系统aggregate forecast 综合预测Aggregation 集合assemble-to-order strategy 订单组装策略available to promise (ATP) 有效承诺back scheduling 逆向排程Backhaul 回程运输bill of lading 装货单bill of materials (BOM) 材料清单bill of operations (BOO) 作业列表bullwhip effect 牛鞭效应capable to promise (CTP) 可行的承诺Carrier 货运商carrying cost 在库成本cash-to-cash cycle time 现金周转时间category management 分类管理Consignment inventory 库存托付Consumer 消费者continuous replenishment 连续库存补充方法continuous review 连续复查cross dock 交叉停泊区cross docking 交叉停泊Customer 客户customer schedule 客户进度表customer service level (CSL) 客户服务水平cycle stock 周转库存cycle time 周转时间Collaborative Planning, Forecasting and Replenishment (CPFR) 协作计划、预测和补给days on hand 库存持有天数delayed differentiation 差异(化)延迟方法demand amplification 需求放大dependent demand 依赖需求design for supply 供应设计direct shipment 直接发运distribution center (DC ) 配送中心distribution network 配送网络dynamic forecasting 动态预测Echelon 阶梯echelon inventory 层级库存economic order quantity (EOQ) 经济定购批量Efficientcustomer response 有效的客户响应efficient frontier 效率曲线electronic data interchange (EDI) 电子数据交换enterprise resource planning system (ERP) 企业资源规划系统external supply chain 外部供应链extrinsic factor 外在因素finished goods inventory 产成品库存forecast horizon 预测范围forward buying 提前购买forward scheduling 正向排程fulfillment cycle 订单履行循环过程fulfillment lead time 订单完成时间Holding cost 持有成本independent demand 独立需求internal supply chain 内部供应链inventory turnover ratio 库存回报率inventory turns 库存回报inventory velocity 库存速率make-to-order strategy 订货型生产策略make-to-stock strategy 备货型生产策略mode of transportation 运输模式on-time delivery 准时交付率order cost 订购成本order fill rate 订单履行率packing slip 装箱单perfect order fulfillment 理想订单率periodic review 周期性复查point of sale system POSpositioning strategy 目标定位策略Postponement 延迟技术production facility 生产设施pull chain 拉动式供应链push chain 推动式供应链raw materials inventory 原材料库存reorder point (ROP) 再订购点replenishment cycle 补货循环过程replenishment lead time 补货完成时间replenishment policy 补货规则risk pooling 风险分担safety stock 安全库存static forecasting 静态预测Stockout 缺货storage facility 存储设施Supplier 供应商supply chain 供应链supply chain management (SCM) 供应链管理transport packaging 运输包装transportation lane 运输渠道Transshipment 货物转载vendor-managed inventory (VMI) 供应商管理库存vertical integration 纵向整合virtual Corporation 虚拟合作Warehouse 仓库work-in-process inventory (WIP) 在制品库存ABC ClassificationABC Inventory ControlABC ModelABC System。

供应链专业术语缩写及含义1. SCM -供应链管理(Supply Chain Management)供应链管理是指企业全球范围内的物流管理、采购管理、订单管理、库存管理等一系列与供应链相关的活动。

其目的是通过有效的资源配置和协调,以最低的成本满足顾客需求。

2. ERP -企业资源规划(Enterprise Resource Planning)ERP是集成化的商业管理系统,可以协调企业内部的各种活动,包括生产、库存、销售、人力资源等,从而提高整体的生产效率和管理水平。

3. MRP -物料需求计划(Material Requirements Planning)MRP是一种生产计划方法,通过对物料需求的计划和控制,帮助企业更好地管理生产进程,减少库存、提高交付率。

4. WMS -仓储管理系统(Warehouse Management System)WMS是一种用于管理仓库运营活动的信息系统,包括货物存储、货物流转、订单管理等,可以提高仓库的效率和准确性。

5. TMS -运输管理系统(Transportation Management System)TMS是一种用于管理运输活动的信息系统,包括运输计划、运输执行、运输优化等,可以提高运输效率和降低成本。

6. RFID -射频识别技术(Radio Frequency Identification)RFID是一种自动识别技术,可以实时跟踪物流运输中的货物位置和状态,提高物流的可见性和管理水平。

7. IoT -物联网(Internet of Things)IoT是一种通过互联网连接和传感器技术实现物品之间相互交流的技术,可以提高供应链运作的智能化和自动化水平。

8. KPI -关键绩效指标(Key Performance Indicator)KPI是衡量企业绩效的重要指标,可以帮助企业评估供应链的效率、成本和质量,从而进行管理与优化。

9. JIT -及时制造(Just-in-Time)JIT是一种生产管理理念,旨在通过减少库存、提高交付率和质量水平,从而降低成本、提高效率。

供应链管理外文翻译文献供应链管理外文翻译文献(文档含中英文对照即英文原文和中文翻译)Supply Chain ManagementThe so-called supply chain, in fact, from suppliers, manufacturers, warehouses, istribution centers and channels, and so constitute a logistics network. The same enterprise may constitute the different components of this network node, but the situation is different from a corporate network in different nodes. For example, in a supply chain, companies may not only in the same manufacturers, storage nodes, and in distribution centers, such as possession node location. In the more detailed division of labor, the higher the rofessional requirements of the supply chain, different nodes are basically composed by different enterprises. In the supply chain flows between the member units of raw materials, finished products, such as inventory and production constitutes the supply chain of goods flow.That is, to meet a certain level of customer service under the conditions, in order to make the whole supply chain to minimize costs and the suppliers, manufacturers, warehouses, distribution centers and channels, and so effectively organized together to carry out Product manufacturing, transport, distribution and sales management.From the above definition, we can be interpreted to include supply chain anagement of rich content.First of all, supply chain management products to meet customer demand in the process of the cost implications of various members of the unit are taken intoaccount, including from raw material suppliers, manufacturers to the warehouse distribution center to another channel. However, in practice in the supply chain analysis, it is necessary to consider the supplier's suppliers and customers of the customers, because their supply chain performance is also influential.Second, supply chain management is aimed at the pursuit of the whole supply chain's overall efficiency and cost effectiveness of the system as a whole, always trying to make the total system cost to a minimum. Therefore, the focus of supply chain management is not simply a supply chain so that members of the transportation costs to minimize or reduce inventory, but through the use of systems approach to coordinate the supply chain members so that the entire supply chain total cost of the minimum so that the whole supply chain System in the most fluent in the operation.Third, supply chain management is on the suppliers, manufacturers, warehouses, distribution centers and organically integrate the channel into one to start this problem, so many businesses, including its level of activities, including the strategic level, tactical and operational level Level, and so on.Although the actual logistics management, only through the organic supply chain integration, enterprises can significantly reduce costs and improve service levels, but in practice the supply chain integration is very difficult, it is because: First of all, in the supply chain There are different members of different and conflicting objectives. For example, providers generally want manufacturers to purchase large quantities of stable, and flexible delivery time can change; desire to the contrary with suppliers, although most manufacturers are willing toimplement long-term production operations, but they must take into account the needs of its customers and to make changes Positive response, which requires manufacturers choice and flexibility in procurement strategy. Therefore, suppliers and manufacturers to the goal of flexibility in the pursuit of the objectives inevitably exist between the contradictions.Secondly, the supply chain is a dynamic system, with time and constantly changing. In fact, customers not only demand and supply capacity to change over time, supply chain and the relationship between the members will change over time. For example, the increased purchasing power with customers, suppliers and manufacturers are facing greater pressure to produce more and more personalized varieties of high-quality products, then ultimately the production of customized products.Research shows that effective supply chain management can always make the supply chain of enterprises will be able to maintain stability and a lasting competitive advantage, thus increasing the overall supply chain competitiveness. Statistics show that, supply chain management will enable the effective implementation of enterprise total cost of about 20 per cent decline in the supply chain node on the enterprise-time delivery rate increased by 15 percent or more, orders to shorten the production cycle time 20 percent to 30 percent, supply chain Node on the enterprise value-added productivity increased by 15 percent or more. More and more enterprises have already recognized that the implementation of supply chain management of the great benefits, such as HP,IBM, DELL, such as supply chain management in the practice of the remarkable achievements made is proof.Supply chain management: it from a strategic level and grasp the overall perspective of the end-user demand, through effective cooperation between enterprises, access from the cost, time, efficiency, flexibility, and so the best results. From raw materials to end-users of all activities, the whole chain of process management.SCM (supply chain management) is to enable enterprises to better procurement of manufactured products and services required for raw materials, production of goods and services and their delivery to clients, the combination of art and science. Supply chain management, including the five basic elements.Plan: This is a strategic part of SCM. You need a strategy to manage all the resources to meet our customers for your products. Good plan is to build a series of methods to monitor the supply chain to enable it to effective, low-cost delivery of high quality for customers and high-value products or services.Procurement: you can choose the products and services to provide goods and services providers, and suppliers to establish a pricing, delivery and payment processes and create methods to monitor and improve the management, and the suppliers to provide goods and services Combined with management processes, including the delivery and verification of documentation, transfer of goods to your approval of the manufacturing sector and payments to suppliers and so on.Manufacturing: arrangements for the production, testing, packaged and ready for delivery, supply chain measurement is the largest part of the contents, including the level of quality, product yield and productivity of workers, such as the measurement.Delivery: a lot of "insider" as "logistics", is to adjust the user's orders receipts, the establishment of the storage network, sending and delivery service delivery personnel to the hands of customers, the establishment of commodity pricing system, receiving payments.Return: This is the supply chain problems in the handling part. Networking customers receive the refund of surplus and defective products, and customer applications to provide support for the problem.Source70 in the late 20th century, Keith Oliver adoption and Skf, Heineken, Hoechst, Cadbury-Schweppes, Philips, and other contact with customers in the process of gradually formed its own point of view. And in 1982, "Financial Times" magazine in an article on the supply chain management (SCM) of the significance, Keith Oliver was that the word will soon disappear, but "SCM" not only not disappeared, and quickly entered the public domain , The concept of the managers of procurement, logistics, operations, sales and marketing activities sense a great deal.EvolutionSupply chain has never been a universally accepted definition, supply chain management in the development process, many experts and scholars have putforth a lot of definition, reflecting the different historical backgrounds, in different stages of development of the product can be broadly defined by these For the three stages:1, the early view was that supply chain is manufacturing enterprises in an internal process2, but the supply chain concept of the attention of the links with other firms 3, the last of the supply chain concept of pay more attention around the core of the network links between enterprises, such as core business with suppliers, vendors and suppliers, and even before all the relations, and a user, after all the users and to the relationship.ApplySupply chain management involves four main areas: supply, production planning, logistics, demand. Functional areas including product engineering, product assurance, procurement, production control, inventory control, warehouse management, distribution management. Ancillary areas including customer service, manufacturing, design engineering, accounting, human resources, marketing.Supply Chain Management implementation steps: 1, analysis of market competition environment, identify market opportunities, 2, analysis of customer value, 3, identified competitive strategy, 4, the analysis of the core competitiveness of enterprises, 5, assessment, selection of partners For the supply chain partners of choice, can follow the following principles:1, partners must have available the core of their competitiveness.2, enterprises have the same values and strategic thinking3, partners must Fewer but Better.CaseAs China's largest IT distributor, Digital China in China's supply chain management fields in the first place. In the IT distribution model generally questioned the circumstances, still maintained a good momentum of development, and CISCO, SUN, AMD, NEC, IBM, and other famous international brands to maintain good relations of cooperation. e-Bridge trading system in September 2000 opening, as at the end of March 2003, and 6.4 billion yuan in transaction volume. In fact, this is the Digital China from the traditional distribution supply chain services to best reflect the changes. In the "distribution of services is a" concept, Digital China through the implementation of change channels, expansion of product and service operations, increasing its supply chain in the value of scale and specialized operations, to meet customer demand on the lower reaches of the In the course of the supply chain system can provide more value-added services, with more and more "IT services" color.供应链管理所谓供应链,其实就是由供应商、制造商、仓库、配送中心和渠道商等构成的物流网络。

SC专业术语解释Markdown是一种轻量级标记语言,常用于编写文档、网页和技术文档。

它简单易学,语法简洁明了,适合用于呈现技术性的信息。

本文将介绍SC专业术语,并用Markdown格式的文本进行解释,以提供清晰易读的文档。

术语解释1. Supply Chain (SC)SC是供应链的缩写,它涵盖了物流、采购、生产、分销等环节的协调和管理。

供应链的目标是将原材料转化为最终产品,并将其交付给最终客户。

供应链管理是以客户需求为导向的,旨在提高效率、减少成本、增加利润等。

2. 物流 (logistics)物流是供应链管理中的一个重要环节,其核心是将货物从供应商转移到最终客户的过程。

物流涉及到货运、仓储、包装、配送等多个方面,旨在优化运输和仓储过程,提高效率并减少成本。

3. 采购 (procurement)采购是指从供应商购买所需的物品或服务的过程。

在供应链管理中,采购是供应链的第一步,它涉及与供应商的协商、订单管理、交付等。

采购的目标是确保所需物品以适当的价格和质量及时交付。

4. 生产 (production)生产是指将原材料转化为最终产品的过程。

在供应链中,生产环节包括生产计划、原材料采购、生产线管理、质量控制等。

生产的目标是提高生产效率、减少生产成本,并确保产品质量。

5. 分销 (distribution)分销是将产品从生产商传递给最终客户的过程。

分销涉及到物流、库存管理、渠道管理等方面。

在供应链管理中,分销的目标是确保产品在最佳的时间和位置供应给客户,满足客户需求。

6. 供应商 (supplier)供应商是为企业提供所需产品或服务的公司或个人。

供应商在供应链中扮演着重要角色,其质量、交付和价格等方面的表现直接影响到整个供应链的运作。

7. 客户 (customer)客户是购买企业产品或服务的个人或组织。

在供应链中,客户的需求是主导供应链管理的关键因素,供应链的目标是满足客户需求,提供高质量的产品和优质的服务。

Leading a Supply Chain Turnaround领导供应链周转Five years ago, salespeople at Whirlpool said the company's supply chain staff were "sales disablers." Now, Whirlpool excels at getting the right product to the right place at the right time-while keeping inventory low. What made the difference?五年前,在Whirlpool的销售人员表示,该公司的供应链的工作人员“销售残疾人”。

但是现在,Whirlpool擅长将正确的产品销售在正确的地方在正确的时间,同时保持低库存。

是什么产生了这样的区别?Things would be very different today-for me, my colleagues, and my company- if the votes of Whirlpool's North American leadership team had swung in a different direction on May 3, 2001. It was a move I hadn't expected; Mike Todman, our executive vice president at the time, decided to go around the table and ask each member of his staff for a thumbs-up or thumbs-down on the investment that Paul Dittmann and I had just formally proposed. Did I look worried? I can't imagine I didn't, even though we'd spent hours in individual meetings with each of them, getting their ideas and buy-in. We thought we had everyone's support. But the facts remained: Our proposal had a bigger price tag than any supply chain investment in the company's history. We were asking for tens of millions during a period of general belt-tightening. Some of it was slated for new hires, even as cutbacks were taking place elsewhere in the company. And Paul and I, the people doing the asking, were coming from the supply chain organization.如果惠而浦在北美的领导团队在5月3日,2001年投票朝向不同的方向上,那么今天,对我来说,我的同事,我的公司,事情变得非常不同的。

这是我没想到的举动:我们当时的执行副总裁,迈克·托德曼,围着桌子要求他的每个工作人员的表决保罗和我提出了投资方案。

难道我当时看起来很担心?我想应该是的,即使我们花了时间与他们每个人单独会议去寻求他们的意见和补充。

我们认为我们得到了大家的支持。

但事实仍然是:我们的建议有比公司历史上任何供应链的投资有更大的价格标签。

在困难时期我们正在寻求上千万的资金。

其中一些给新员工,甚至削减了公司诸多方面的开支。

而申请资金的的保罗和我是公司供应链组织人员。

Let me be clear: The supply chain organization was the part of the business that Whirlpool's salespeople were in the habit of calling the "sales disablers" in 2000. We were perpetually behind the eight ball, tying up too much capital in finished goods inventory- yet failing to provide the product availability our customers needed. Our availability hovered around 87%. Our colleagues grimly joked that in surveys on the delivery performance of the four biggest appliance manufacturers in the U.S., we came in fifth.要明确指出:供应链组织业务是曾被惠尔浦的销售人员在2000年的习惯称为“销售残疾人”的。

我们永远捆绑太多资金在成品库存中,但未能提供一种使得产品能够有效满足客户需要可行性。

我们的可利用率徘徊在87%。

我们的同事们严肃地开玩笑说,在在美国四个最大的家电制造商的交货业绩调查中,我们排在第五。

And here, with all the credibility that track record conferred on us, we were proposing an ambitious new suite of IT solutions- something, too, for which the company had little appetite. It had been just 20 months since Whirlpool North America had flipped the switch on a massive new ERP system, with less than desired effect. Normally, Whirlpool ships close to 70,000 appliances a day to North American customers. The day after we went live with SAP, we were able to ship about 2,000. A barrage of bad press followed. Even though the situation was soon righted (SAP remains a valued partner), the experience of being treated as a sort of poster child for ERP folly had left scars.在这里,根据过去我们的信誉,我们雄心勃勃的提出了一项在公司没有什么兴趣的新套件It解决方案 .已经有20个月以来,惠而浦北美在翻转交换机上运用了一个巨大的新的ERP系统,但达不到不到预期的效果。

通常情况下,惠而浦产出70000器械供给北美客户。

与SAP合作后,我们能够出货约2,000。

负面报道的攻势接踵而至。

尽管这种情况很快就被纠正(SAP仍是一个有价值的合作伙伴),但是采用ERP系统的愚行为被视为典范愚蠢的经历给我们留下疤痕So imagine our relief when we heard the first voice say "yes" It was the executive who headed up sales to Sears. Paul and I looked anxiously to the next face, and the next. The heads of our KitchenAid, Whirlpool, and value brands followed suit-a watershed, given that the funding would have to come from their budgets. I could see that J.C. Anderson, my boss and senior vice president of operations, was happy, too. He had tried to voice his support at the beginning of the meeting, but Mike Todman had asked him to wait. Now that it was his turn to vote, he did it with a flourish: "I am fully committed" he said, "to moving our supply chain from a liability to a recognized competitive advantage." Only after Todman had heard from everyone in the room-brands, sales, finance, human resources, and operations- did he cast his vote.当我们听到第一个肯定的声音的时候那是一种解脱,就是执行官同意向Sears销售。

我们焦虑的期待剩下的人的同意。

我们KitchenAid惠而浦的领导人们,以及价值品牌的负责人纷纷效仿,因为资金必须来自自己的预算。

我看得出来,JC安德森,我的老板和运营的高级副总裁也是开心的。

他曾试图表达他支持的意见在会议的开始的时候,但是迈克·托德曼要求他等一等。

现在,轮到他投票,他做了一个成分肯定的表态说:“我完全致力于将我们的供应链从一个累赘变为公认有竞争力的优势。

”在托德曼听了在房间里品牌,销售,财务,人力资源和操作的发言后,他投了票。