ansys旋转经典命令流

- 格式:doc

- 大小:355.50 KB

- 文档页数:58

(完整版)ANSYS最常用命令流+中文注释(超级大全)ANSYS最常用命令流+中文注释VSBV, NV1, NV2, SEPO, KEEP1, KEEP2 —Subtracts volumes from volumes,用于2个solid相减操作,最终目的是要nv1-nv2=?通过后面的参数设置,可以得到很多种情况:sepo项是2个体的边界情况,当缺省的时候,是表示2个体相减后,其边界是公用的,当为sepo的时候,表示相减后,2个体有各自的独立边界。

keep1与keep2是询问相减后,保留哪个体?当第一个为keep时,保留nv1,都缺省的时候,操作结果最终只有一个体,比如:vsbv,1,2,sepo,,keep,表示执行1-2的操作,结果是保留体2,体1被删除,还有一个1-2的结果体,现在一共是2个体(即1-2与2),且都各自有自己的边界。

如vsbv,1,2,,keep,,则为1-2后,剩下体1和体1-2,且2个体在边界处公用。

同理,将v换成a 及l是对面和线进行减操作!mp,lab, mat, co, c1,…….c4 定义材料号及特性lab: 待定义的特性项目(ex,alpx,reft,prxy,nuxy,gxy,mu,dens)ex: 弹性模量nuxy: 小泊松比alpx: 热膨胀系数reft: 参考温度reft: 参考温度prxy: 主泊松比gxy: 剪切模量mu: 摩擦系数dens: 质量密度mat: 材料编号(缺省为当前材料号)co: 材料特性值,或材料之特性,温度曲线中的常数项c1-c4: 材料的特性-温度曲线中1次项,2次项,3次项,4次项的系数定义DP材料:首先要定义EX和泊松比:MP,EX,MA T,……MP,NUXY,MAT,……定义DP材料单元表(这里不考虑温度):TB,DP,MA T进入单元表并编辑添加单元表:TBDATA,1,CTBDATA,2,ψTBDATA,3,……如定义:EX=1E8,NUXY=0.3,C=27,ψ=45的命令如下:MP,EX,1,1E8MP,NUXY,1,0.3TB,DP,1TBDATA,1,27TBDATA,2,45这里要注意的是,在前处理的最初,要将角度单位转化到“度”,即命令:*afun,degVSEL, Type, Item, Comp, VMIN, VMAX, VINC, KSWP Type,是选择的方式,有选择(s),补选(a),不选(u),全选(all)、反选(inv)等,其余方式不常用Item, Comp 是选取的原则以及下面的子项如volu 就是根据实体编号选择,loc 就是根据坐标选取,它的comp就可以是实体的某方向坐标!其余还有材料类型、实常数等MIN, VMAX, VINC,这个就不必说了吧!,例:vsel,s,volu,,14vsel,a,volu,,17,23,2上面的命令选中了实体编号为14,17,19,21,23的五个实体VDELE, NV1, NV2, NINC, KSWP: 删除未分网格的体nv1:初始体号nv2:最终的体号ninc:体号之间的间隔kswp=0:只删除体kswp=1:删除体及组成关键点,线面如果nv1=all,则nv2,ninc不起作用其后面常常跟着一条显示命令VPLO,或aplo,nplo,这个湿没有参数的命令,输入后直接回车,就可以显示刚刚选择了的体、面或节点,很实用的哦!Nsel, type, item, comp, vmin, vmax, vinc, kabs 选择一组节点为下一步做准备Type: S: 选择一组新节点(缺省)R: 在当前组中再选择A: 再选一组附加于当前组U: 在当前组中不选一部分All: 恢复为选中所有None: 全不选Inve: 反向选择Stat: 显示当前选择状态Item: loc: 坐标node: 节点号Comp: 分量Vmin,vmax,vinc: ITEM范围Kabs: “0” 使用正负号“1”仅用绝对值下面是单元生死第一个载荷步中命令输入示例:!第一个载荷步TIME,... !设定时间值(静力分析选项)NLGEOM,ON !打开大位移效果NROPT,FULL !设定牛顿-拉夫森选项ESTIF,... !设定非缺省缩减因子(可选)ESEL,... !选择在本载荷步中将不激活的单元EKILL,... !不激活选择的单元ESEL,S,LIVE !选择所有活动单元NSLE,S !选择所有活动结点NSEL,INVE !选择所有非活动结点(不与活动单元相连的结点)D,ALL,ALL,0 !约束所有不活动的结点自由度(可选)NSEL,ALL !选择所有结点ESEL,ALL !选择所有单元D,... !施加合适的约束F,... !施加合适的活动结点自由度载荷SF,... !施加合适的单元载荷BF,... !施加合适的体载荷SA VESOLVE请参阅TIME,NLGEOM,NROPT,ESTIF,ESEL,EKILL,NSLE,NSEL,D, F,SF和BF命令得到更详细的解释。

1 旋转摩擦 (1)2. 电磁三d命令流实例(论坛看到) (21)3. 帮助感应加热例子induction heating of a solid cylinder billet (30)4. 感应加热温度场的数值模拟(论文)inducheat30命令流 (37)5. 如何施加恒定的角速度?Simwe仿真论坛 (47)6. 旋转一个已经生成好的物体 (52)7. 产生这样的磁力线 (53)8. 旋转摩擦生热简单例子(二维旋转) (62)8.1. 原版 (62)8.2. 部分gui操作 (67)9. VM229 Input Listing (75)10 轴承---耦合+接触分析 (90)11. 板的冲压仿真 (100)1 旋转摩擦FINISH/FILNAME,Exercise24 !定义隐式热分析文件名/PREP7 !进入前处理器ET,1,SOLID5 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7800 !定义材料1的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,206e9 !定义材料1的弹性模量MPDATA,PRXY,1,,0.3 !定义材料1的泊松比MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的比热MPTEMP,,,,,,,,MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松比CYLIND,0.7,0.5,0,0.2,0,180, !建立钢环的几何模型CYLIND,0.5,0.3,0,0.2,60,70, !建立铜滑块FLST,5,2,4,ORDE,2FITEM,5,8FITEM,5,12CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第8和第12号线并划分为4段FLST,5,2,4,ORDE,2FITEM,5,2CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YMSHAPE,1,3DMSHKEY,0FLST,5,2,4,ORDE,2FITEM,5,2FITEM,5,7CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,36, , , , ,1 !选择第2和第7号线并划分为36段FLST,5,1,4,ORDE,1FITEM,5,5CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,36, , , , ,1 !选择第5号线并划分为36段,. FLST,5,2,4,ORDE,2FITEM,5,17FITEM,5,19CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,2, , , , ,1 ! 选择第17和第19号线并划分为2段FLST,5,2,4,ORDE,2FITEM,5,20FITEM,5,24CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第20和第24号线并划分为4段TYPE, 1 !给钢环附单元类型MAT, 1 !给钢环附材料REAL, !给钢环附实常数ESYS, 0SECNUM,CM,_Y,VOLU,. VSEL, , , , 1CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块划分单元TYPE, 1 !给铜滑块附单元类型MAT, 2 !给铜滑块附材料REAL, !给铜滑块附实常数ESYS, 0SECNUM,CM,_Y,VOLUVSEL, , , , 2CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块附实常数/COM, CONTACT PAIR CREATION - START CM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLU/GSAV,cwz,gsav,,tempMP,MU,1,0.2MAT,1R,3REAL,3ET,2,170ET,3,174KEYOPT,3,9,0R,3,RMORE,RMORE,,0RMORE,0KEYOPT,3,1,3! Generate the target surfaceASEL,S,,,4CM,_TARGET,AREATYPE,2NSLA,S,1ESLN,S,0ESURF,ALLCMSEL,S,_ELEMCM! Generate the contact surface ASEL,S,,,9CM,_CONTACT,AREA TYPE,3NSLA,S,1ESLN,S,0ESURF,ALLALLSELESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3/PSYMB,ESYS,1/PNUM,TYPE,1/NUM,1EPLOTESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3CMSEL,A,_NODECMCMDEL,_NODECMCMSEL,A,_ELEMCMCMDEL,_ELEMCMCMSEL,S,_KPCMCMDEL,_KPCMCMSEL,S,_LINECMCMDEL,_LINECMCMSEL,S,_AREACMCMDEL,_AREACMCMSEL,S,_VOLUCMCMDEL,_VOLUCM/GRES,cwz,gsavCMDEL,_TARGETCMDEL,_CONTACT/COM, CONTACT PAIR CREATION - END !用接触向导建立铜滑块与钢环间的接触/GO*DIM,pre,TABLE,2,1,1,time,press, !定义压力载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 20e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 20e6FLST,2,1,5,ORDE,1FITEM,2,10/GOSFA,P51X,1,PRES, %PRE% !在铜滑块上表面施加压力载荷TUNIF,20, !施加初始温度FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UX, !在钢环的外表面施加UX向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UY, !在钢环的外表面施加UY向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UZ, !在钢环的外表面施加UZ向约束ESEL,S,MAT,,2 !选择铜滑块单元NSLE !选择铜滑块节点CSYS,1 !激活柱坐标系FLST,2,75,1,ORDE,2FITEM,2,876FITEM,2,-950NROTAT,P51X !旋转节点坐标系FLST,2,75,1,ORDE,2FITEM,2,876FITEM,2,-950/GOD,P51X, ,0.01, , , ,UY, , , , , ! 给铜滑块加Y向位移载荷(即切向位移)ALLSEL !选择所有的节点,单元,几何体FINISH/SOL !进入求解器ANTYPE,4 !设置为瞬态分析TRNOPT,FULL !选择瞬态全分析方法LUMPM,0 !关闭集中质量矩阵计算格式NLGEOM,1 !定义大变形NSUBST,100,200,100 !定义载荷步OUTRES,ALL,20 !定义结果输出子步间隔AUTOTS,1 !打开时间开关KBC,0 !设置为斜坡载荷TIME,10 !定义求解时间SSTIF,0 !关闭应力刚化影响NROPT,FULL, , !选择瞬态全分析方法EQSLV, , ,0,PRECISION,0 !定义双精度求解MSAVE,0TOFFST,273, !定义温度偏移量SOLVE !求解/POST1 !进入后处理器SET,LAST !读取最后子步结果PLNSOL,TEMP !显示温度分布云图PLNSOL,S,EQV,2 !显示等效应力分布云图FINISH/EXIT,NOSAV !退出ANSYS FINISH/FILNAME,Exercise23 ! 定义隐式热分析文件名/PREP7 !进入前处理器ET,1,PLANE13,4 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7800 !定义材料1的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,206e9 !定义材料1的弹性模量MPDATA,PRXY,1,,0.3 !定义材料1的泊松比MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松比RECTNG,0,5,0,1.25, !建立钢固定块的几何模型RECTNG,0,1.25,1.25,2.5, !建立铜滑块的几何模型TYPE, 1MAT, 1REAL, !给钢固定块附材料属性ESYS, 0SECNUM,ESIZE,0.25,0, !设置单元划分尺寸MSHAPE,0,2DMSHKEY,1CM,_Y,AREAASEL, , , , 1CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给钢固定块划分单元TYPE, 1MAT, 2REAL, !给铜滑块附材料属性ESYS, 0SECNUM,CM,_Y,AREAASEL, , , , 2CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块划分单元CM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLUMP,MU,1,0.2MAT,1MP,EMIS,1,R,3REAL,3ET,2,169ET,3,172R,3,,,1.0,0.1,0,RMORE,,,1.0E20,0.0,1.0,RMORE,0.0,0,1.0,,1.0,0.5RMORE,0,1.0,1.0,0.0,,1.0KEYOPT,3,3,0KEYOPT,3,4,0 KEYOPT,3,5,0 KEYOPT,3,7,0 KEYOPT,3,8,0 KEYOPT,3,9,1 KEYOPT,3,10,1 KEYOPT,3,11,0 KEYOPT,3,12,0 KEYOPT,3,2,0 KEYOPT,3,1,1 LSEL,S,,,3CM,_TARGET,LINE TYPE,2NSLL,S,1ESLN,S,0 ESURF,ALL CMSEL,S,_ELEMCM LSEL,S,,,5CM,_CONTACT,LINE TYPE,3NSLL,S,1ESLN,S,0ESURF,ALL ALLSELESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 ESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 CMSEL,A,_NODECM CMDEL,_NODECM CMSEL,A,_ELEMCM CMDEL,_ELEMCM CMSEL,S,_KPCM CMDEL,_KPCM CMSEL,S,_LINECM CMDEL,_LINECM CMSEL,S,_AREACM CMDEL,_AREACM CMSEL,S,_VOLUCM CMDEL,_VOLUCMCMDEL,_TARGETCMDEL,_CONTACTFLST,2,1,5,ORDE,1FITEM,2,1 !用接触向导建立滑块和固定块间的接触面/GODA,P51X,UX, !将下面的钢块施加X向约束FLST,2,1,5,ORDE,1FITEM,2,1/GODA,P51X,UY, !将下面的钢块施加Y向约束FLST,2,1,4,ORDE,1FITEM,2,6/GODL,P51X, ,UX,3.75 ! 给铜块右侧的线加X向位移载荷FINISH/SOL*DIM,pre,TABLE,2,1,1,time,press, !定义压力载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 10e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 10e6FLST,2,1,4,ORDE,1FITEM,2,7/GOSFL,P51X,PRES, %PRE% !在铜滑块上表面施加压力载荷TUNIF,30, !给铜块和钢块施加初始温度ALLSEL !选择所有的节点,单元,几何体ANTYPE,TRANS !设置为瞬态分析TIMINT,OFF,STRUC !关闭结构的动态惯性影响TINTP,,,,1.0 !定义瞬态积分参数NLGEOM,ON !定义大变形TIME,3.75E-3 !定义求解时间TOFFSET,273 !定义温度偏移量AUTO,ON !打开时间开关NSUB,100,10000,100 !定义载荷步OUTRES,ALL,-10 !定义结果输出子步间隔SOLVE !求解/POST1 !进入后处理器SET,LAST !读取最后子步结果PLNSOL,TEMP ! 显示温度分布云图PLNSOL,S,EQV,2 !显示等效应力分布云图FINISH/EXIT,NOSAV !退出ANSYS2. 电磁三d命令流实例(论坛看到)/BATCH/COM,ANSYS RELEASE 12.0.1 UP20090415 11:10:14 03/29/2011 /input,menust,tmp,'',,,,,,,,,,,,,,,,1/GRA,POWER/GST,ON/PLO,INFO,3/GRO,CURL,ON/CPLANE,1/REPLOT,RESIZEWPSTYLE,,,,,,,,0/TITLE, T est for EDGE-Formulation with SOLID117!! Parameters*SET,l,5e-6 ! length*SET,h,1e-6 ! height*SET,w,5e-6 ! width*SET,a,3e-6 ! 1st addition length of magnetic core*SET,b,5e-6 ! 2nd addition length of magnetic core!/PREP7 !!ET,1,117 !!MP,MURX,1,1MP,RSVX,1,17.2e-9 !MP,MURX,2,500MP,MURX,3,1BLOCK,-w,w,-h,h,-l,l !!BLOCK,-w-a,w+a,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h+a,h+2*a,-l,lBLOCK,-w-a,-w-a-b,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h,h+a,-l,lBLOCK,-w-a,-w-a-b,h,h+a,-l,l!BLOCK,-w-a,w+a,-(h+a),-(h+2*a),-l,l BLOCK,w+a,w+a+b,-(h+a),-(h+2*a),-l,l BLOCK,-w-a,-w-a-b,-(h+a),-(h+2*a),-l,l BLOCK,w+a,w+a+b,-h,-(h+a),-l,lBLOCK,-w-a,-w-a-b,-h,-(h+a),-l,l!BLOCK,-22e-6,22e-6,-15e-6,15e-6,-15e-6,15e-6 VOVLAP,ALLNUMCMP,VOLU VSEL,S,VOLU,,1 VATT,1VSEL,S,VOLU,,2,11,1 VATT,2VSEL,S,VOLU,,12 VATT,3VSEL,S,MAT,,1,2,1 ASLV,SLSLA,S LESIZE,ALL,3e-6 MSHKEY,1 MSHAPE,0,3D VMESH,ALL VSEL,S,MAT,,3 ASLV,SLSLA,S LESIZE,ALL,3e-6 MSHKEY,0 MSHAPE,1,3D VMESH,ALL ALLSEL,ALLFINISH/SOLUESEL,S,MAT,,1BFE,ALL,JS,1,,,-1e9ASEL,S,EXTDA,ALL,AZ,0ALLSEL,ALLANTYPE,0NROPT,AUTO,,EQSLV,SPAR,,0, PRECISION,0MSAVE,0PIVCHECK,1/STATUS,SOLUSOLVEFINISH/POST1! elements/VSCALE,1,1,0!!*PLVECT,B, , , ,VECT,ELEM,ON,0ESEL,U,MAT,,3/REPLOT[/color][/size][/b][/align][b][color=#0000ff][/color][/b][align=left][code]/BATCH,LIS T/TITLE, T est for EDGE-Formulation with SOLID117!! Parametersl=5e-6 ! lengthh=1e-6 ! heightw=5e-6 ! widtha=3e-6 ! 1st addition length of magnetic coreb=5e-6 ! 2nd addition length of magnetic core! *** Create Model!/PREP7 ! Enter ANSYS preprocessor to define problem!ET,1,117 ! Element type #1 is a magnetic edge element, 117.! (We use only one in this example)!MP,MURX,1,1 ! Define relative permeability of material #1.! Material #1 is the conductor made from copperMP,RSVX,1,17.2e-9 ! Define electric resistivity of material #1.!MP,MURX,2,500 ! Define relative permeability of material #2.! Material #2 is the magnetic core made from NiFe!MP,MURX,3,1 ! Define relative permeability of material #3.! Material #3 is the air ambient!! Define rectangular block of conductor volume! regionBLOCK,-w,w,-h,h,-l,l !!! Define rectangular block of upper magnetic core! volume regionBLOCK,-w-a,w+a,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h+a,h+2*a,-l,lBLOCK,-w-a,-w-a-b,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h,h+a,-l,lBLOCK,-w-a,-w-a-b,h,h+a,-l,l!! Define rectangular block of lower magnetic core ! volume regionBLOCK,-w-a,w+a,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-(h+a),-(h+2*a),-l,lBLOCK,-w-a,-w-a-b,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-h,-(h+a),-l,lBLOCK,-w-a,-w-a-b,-h,-(h+a),-l,l!! Define rectangular block of air ambientBLOCK,-22e-6,22e-6,-15e-6,15e-6,-15e-6,15e-6! Overlap volumesVOVLAP,ALLNUMCMP,VOLU! Assign attributes to the volumesVSEL,S,VOLU,,1VATT,1 ! conductorVSEL,S,VOLU,,2,11,1 ! magnetic coreVATT,2VSEL,S,VOLU,,12 ! air ambientVATT,3! Mesh volumesVSEL,S,MAT,,1,2,1 ! Conductor and magnetic core with hexaelements ASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,1 ! MAPPED VOLUME MESHMSHAPE,0,3D ! USING HEXVMESH,ALLVSEL,S,MAT,,3 ! Air ambientASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,0 ! FREE VOLUME MESHMSHAPE,1,3D ! USING TETVMESH,ALLALLSEL,ALLFINISH/SOLU!*** Apply current density on conductor ***ESEL,S,MAT,,1 ! Select coil elementBFE,ALL,JS,1,,,-1e9 ! Apply current density!*** Flux parallel boundary condition at all extern area of air ambient *** ASEL,S,EXTDA,ALL,AZ,0ALLSEL,ALL! Solution parametersANTYPE,0NROPT,AUTO,,EQSLV,SPAR,,0,PRECISION,0MSAVE,0PIVCHECK,1/STATUS,SOLUSOLVE/POST1!*** Vectorplot of magnetic flux (BSUM) for magnetic core's and conductor's elements ***/VSCALE,1,1,0!!*PLVECT,B, , , ,VECT,ELEM,ON,0ESEL,U,MAT,,3/REPLOTFINISH! /EXIT,MODEL[/code][/align][align=center][size=4][color=blue][b]===错因告诉你了,稍微改改就可以得到正确的解,来改着玩玩吧,奖分哦(+1技术分,+50贡献分)==[/b][/color][/size][/align]3. 帮助感应加热例子induction heating of a solid cylinder billet batch,list/filenam, induc/config,nres,100000 !将载荷步最大设置为100000 /prep7shpp,off/title, heating of a solid cylinder billet/com,et,1,13,,,1 ! PLANE13, axisymmetric, AZ dofet,2,13,,,1et,3,151,,,1,1,1 ! SURF151, thermal, radiationr,3,0 ! Real constant set for SURF151row=.015 ! outer radius of workpieceric=.0175 ! inner radius of coilroc=.0200 ! outer radius of coilro=.05 ! outer radius of modelt=.001 ! model thicknessfreq=150000 ! frequency (Hz.)pi=4*atan(1) ! picond=.392e7 ! maximum conductivitymuzero=4e-7*pi ! free-space permeabilitymur=200 ! maximum relative permeabilityskind=sqrt(1/(pi*freq*cond*muzero*mur)) ! skin depthftime=3 ! final timetinc=.05 ! time increment for harmonic analysistime=0 ! initialize timedelt=.01 ! maximum delta time stepemunit,mks ! set magnetic unitsmp,murx,1,1 ! air relative permeabilitymp,murx,3,1 ! coil relative permeabilitymptemp,1,25.5,160,291.5,477.6,635,698 ! temps for relative permeabilitymptemp,7,709,720.3,742,761,1000mpdata,murx,2,1,200,190,182,161,135,104 ! steel relative permeability mpdata,murx,2,7,84,35,17,1,1mptempmptemp,1,0,125,250,375,500,625 ! temps for resistivity mptemp,7,750,875,1000mpdata,rsvx,2,1,.184e-6,.272e-6,.384e-6,.512e-6,.656e-6,.824e-6 mpdata,rsvx,2,7,1.032e-6,1.152e-6,1.2e-6 ! steel resistivityrectng,0,row,0,t ! billetrectng,row,ric,0,t ! air-gaprectng,ric,roc,0,t ! coilrectng,roc,ro,0,t ! outer airaglue,allnumcmp,area !对面重新编号ksel,s,loc,x,row ! select keypoints at outer radius of workpiece kesize,all,skind/2 ! set meshing size to 1/2 skin depth(为什么是半个集肤深度)ksel,s,loc,x,0 ! select keypoints at centerkesize,all,40*skind ! set meshing sizelsel,s,loc,y,t/2 ! select vertical lineslesize,all,,,1 ! set 1 division through thicknesslsel,allasel,s,area,,1aatt,2,1,1 ! set attributes for billet regionasel,s,area,,3aatt,3,1,2 ! set attributes for coil regionasel,s,area,,2,4,2aatt,1,1,2 ! set attributes for air regionasel,allmshape,0,2dmshk,1amesh,1 ! mesh billet arealsel,s,loc,y,0lsel,a,loc,y,t !also selectlsel,u,loc,x,row/2lesize,all,.001lsel,allamesh,all ! mesh remaining areasn ! create space node for SURF151*get,nmax,node,,num,maxlsel,s,loc,x,rowtype,3real,3 ! REAL, NSET Sets the element real constant set attribute pointer. mat,2lmesh,all ! mesh billet outer radius with SURF151*get,emax,elem,,num,maxemodif,emax,3,nmax ! modify element to add space node for radiationet,3,0 ! reset type 3 to null elementnsel,s,loc,xd,all,az,0 ! apply flux-normal b.c. az向量磁位能nsel,allesel,s,mat,,3bfe,all,js,,,,15e6 ! apply current density to coil施加体力载荷esel,allfinishantyp,harmharfrq,150000physics,write,emag ! write emag physics filefinish/prep7lsclear,all ! clear all b.c.'s and optionset,1,55,,,1 ! PLANE55 thermal element, axisymmetric et,2,0 ! null element type for coil and air region et,3,151,,,1,1,1 ! SURF151 element for radiationkeyopt,3,9,1r,3,1,5.67e-8 ! form factor, Stefan-Boltzmann constant mptempmptemp,1,0,730,930,1000 ! temps for conductivity mpdata,kxx,2,1,60.64,29.5,28,28mptemp ! temps for enthalpy mptemp,1,0,27,127,327,527,727mptemp,7,765,765.001,927mpdata,enth,2,1,0,91609056,453285756,1.2748e9,2.2519e9,3.3396e9 mpdata,enth,2,7,3.548547e9,3.548556e9,4.3520e9mp,emis,2,.68 ! emissivityfinishantype,transtoffst,273tunif,100 ! initial uniform temperature d,nmax,temp,25 ! ambient temperature cnvtol,heat,1 ! convergence tolerance kbc,1 ! step loadstrnopt,fullautos,on ! auto time-stepping deltim,1e-5,1e-6,delt,on ! time step controloutres,basic,all ! save all load step information physics,write,thermal ! write thermal physics file finish*do,i,1,ftime/tinc ! solution *do looptime=time+tinc ! increment timephysics,read,emag ! read emag physics file/solu*if,i,eq,1,thentunif,100 ! initial temperature*elseldread,temp,last,,,,,rth ! read thermal analysis temperatures *endifsolve ! solve harmonic analysisfinishphysics,read,thermal ! read thermal physics file/assign,esav,therm,esav ! redirect files for use in thermal restart /assign,emat,therm,emat/solu*if,i,gt,1,thenantype,trans,rest ! thermal restart*endiftime,time ! time at end of thermal runesel,s,mat,,2 ! select billet regionldread,hgen,,,,2,,rmg ! apply coupled joule heating load from emagesel,allsolvefinish/assign,esav ! reassign files to default/assign,emat*enddo ! end of solution loopingfinishsave ! save database/post26 ! time-history postprocessor/shownsol,2,1,temp,,tempcl ! store temperature at billet centerline nsol,3,2,temp,,tempsurf ! store temperature at billet outer diameterplvar,2,3 ! plot temperature rise over time prvar,2,3 ! print temperature rise over time finishn 定义节点。

ansys命令流操作大全ansys——ANSYS命令流(Ⅰ)1. A,P1,P2,…,P17,P18(以点定义面)2. AADD,NA1,NA2,…NA8,NA9(面相加)3. AATT,MAT,REAL,TYPE,ESYS,SECN(指定面的单元属性)【注】ESYS为坐标系统号、SECN为截面类型号。

4. *ABBR,Abbr,String(定义一个缩略词)5. ABBRES,Lab,Fname,Ext(从文件中读取缩略词)6. ABBSAVE,Lab,Fname,Ext(将当前定义的缩略词写入文件)7. ABS,IR,IA,--,--,Name,--,--,FACTA(取绝对值)【注】*************8. ACCAT,NA1,NA2(连接面)9. ACEL,ACEX,ACEY,ACEZ(定义结构的线性加速度)10. ACLEAR,NA1,NA2,NINC(清除面单元网格)11. ADAMS,NMODES,KSTRESS,KSHELL【注】*************12. ADAPT, NSOLN, STARGT, TTARGT, FACMN, FACMX, KYKPS, KYMAC【注】*************13. ADD,IR, IA, IB, IC, Name, --,-- , FACTA, FACTB, FACTC(变量加运算)14. ADELE,NA1,NA2,NINC,KSWP(删除面)【注】KSWP =0删除面但保留面上关键点、1删除面及面上关键点。

15. ADRAG,NL1,NL2,…,NL6,NLP1,NLP2,…,NLP6(将既有线沿一定路径拖拉成面)16. AESIZE,ANUM,SIZE(指定面上划分单元大小)17. AFILLT,NA1,NA1,RAD(两面之间生成倒角面)18. AFSURF,SAREA,TLINE(在既有面单元上生成重叠的表面单元)19. *AFUN, Lab(指定参数表达式中角度单位)20. AGEN, ITIME, NA1, NA2, NINC, DX, DY, DZ, KINC, NOELEM, IMOVE(复制面)21. AGLUE,NA1,NA2,…,NA8,NA9(面间相互粘接)22. AINA,NA1,NA2,…,NA8,NA9(被选面的交集)23. AINP,NA1,NA2,…,NA8,NA9(面集两两相交)24. AINV,NA,NV(面体相交)25. AL,L1,L2,…,L9,L10(以线定义面)26. ALIST,NA1,NA2,NINC,Lab(列表显示面的信息)【注】Lab=HPT时,显示面上硬点信息,默认为空。

三生成关键点和线部分1.生成关键点K,关键点编号,X坐标,Y坐标,Z坐标例:K,1,0,0,02.在激活坐标系生成直线LSTR,关键点P1,关键点P2例LSTR,1,23.在两个关键点之间连线L,关键点P1,关键点P2例L,1,2注:此命令会随当前的激活坐标系不同而生成直线或弧线4.由三个关键点生成弧线LARC,关键点P1,关键点P2,关键点PC,半径RAD例LARC,1,3,2,0.05注:关键点PC是用来控制弧线的凹向5.通过圆心半径生成圆弧CIRCLE,关键点圆心,半径RAD,,,,圆弧段数NSEG例:CIRCLE,1,0.05,,,,46.通过关键点生成样条线BSPLIN,关键点P1,关键点P2,关键点P3,关键点P4,关键点P5,关键点P6例:BSPLIN,1,2,3,4,5,67.生成倒角线LFILLT,线NL1,线NL2,倒角半径RAD例LFILLT,1,2,0.0058.通过关键点生成面A,关键点P1,关键点P2,关键点P3,关键点P4,关键点P5,关键点P6,P7,P8...例:A,1,2,3,49.通过线生成面AL,线L1,线L2,线L3,线L4,线L5,线L6,线L7,线L8,线L9,线L10例:AL,5,6,7,810.通过线的滑移生成面ASKIN,线NL1,线NL2,线NL3,线NL4,线NL5,线NL6,线NL7,线NL8,线NL9例:ASKIN,1,4,5,6,7,8注:线1为滑移的导向线四目标:掌握常用的实体-面的生成生成矩形面1.通过矩形角上定位点生成面BLC4,定位点X方向坐标XCORNER,定位点Y方向坐标YCORNER,矩形宽度WIDTH,矩形高度HEIGHT,矩形深度DEPTH例:BLC4,0,0,5,3,02.通过矩形中心定位点生成面BLC5,定位点X方向坐标XCENTER,定位点Y方向坐标YCENTER,矩形宽度WIDTH,矩形高度HEIGHT,矩形深度DEPTH注:与上条命令的不同就在于矩形的定位点不一样例:BLC5,2.5,1.5,5,3,03.通过在工作平面定义矩形X.Y坐标生成面RECTNG,矩形左边界X坐标X1,矩形右边界X坐标X2,矩形下边界Y坐标Y1,矩形上边界Y坐标Y2例:RECTNG,0,5,0,3生成圆面4.通过中心定位点生成实心圆面CYL4,定位点X方向坐标XCENTER,定位点Y方向坐标YCENTER,圆面的内半径RAD1,内圆面旋转角度THETA1,圆面的外半径RAD2,外圆面旋转角度THETA2,圆面的深度DEPTH注:如要实心的圆面则不用RAD2,THETA2,DEPTH例:CYL4,0,0,5,3605.生成扇形圆面命令介绍如上例1实心扇形:CYL4,0,0,5,60例2扇形圆环:CYL4,0,0,5,60,10,60例3整的圆环:CYL4,0,0,5,360,10,360注:同时可通过定义圆面的深度以生成柱体6.通过在工作平面定义起始点生成圆面CYL5,开始点X坐标XEDGE1,开始点Y坐标YEDGE1,结束点X坐标XEDGE2,结束点Y坐标YEDGE2,圆面深度DEPTH例:CYL5,0,0,2,2,7.通过在工作平面定义内外半径和起始角度来生成圆面PCIRC,内半径RAD1,外半径RAD2,起始角度THETA1,结束角度THETA2例LCIRC,2,5,30,1808.生成面与面的倒角AFILLT,面1的编号NA1,面2的编号NA2,倒角半径RAD例:AFILLT,2,5,2下一讲:多边形面的生成。

ANSYS结构分析单元功能与特性/可以组成一一些命令,一般是一种总体命令(session),三十也有特殊,比如是处理/POST1! 是注释说明符号,,与其他软件的说明是一样的,ansys不作为命令读取,* 此符号一般是APDL的标识符,也就是ansys的参数化语言,如*do ,,,*enddo等等NSEL的意思是node select,即选择节点。

s就是select,选择。

DIM是定义数组的意思。

array 数组。

MP命令用来定义材料参数。

K是建立关键点命令。

K,关键点编号,x坐标,y坐标,z坐标。

K, NPT, X, Y, Z是定义关键点,K是命令,NPT是关键点编号,XYZ是坐标。

NUMMRG, keypoint 用这个命令,要保证关键点的位置完全一样,只是关键点号不一样的才行。

这个命令对于重复的线面都可以用。

这个很简单,压缩关键。

Ngen 复制节点e,节点号码:这个命令式通过节点来形成单元NUMCMP,ALL:压缩所有编号,这样你所有的线都会按次序重新编号~你要是需要固定的线固定的标号NSUBST,100,500,50:通过指定子步数来设置载荷步的子步LNSRCH线性搜索是求解非线性代数方程组的一种技巧,此法会在一段区间内,以一定的步长逐步搜索根,相比常用的牛顿迭代法所要耗费的计算量大得多,但它可以避免在一些情况下牛顿迭代法出现的跳跃现象。

LNSRCH激活线性搜索PRED 激活自由度求解预测NEQIT指定一个荷载步中的最大子步数AUTOTS 自动求解控制打开自动时间步长.KBC -指定阶段状或者用跳板装载里面一个负荷步骤。

SPLINE:P1,P2,P3,P4,P5,P6,XV1,YV1,ZV1,XV6,YV6,ZV6(生成分段样条曲线)*DIM,Par,Type,IMAX,JMAX,KMAX,Var1,Var2,Var3(定义载荷数组的名称)【注】Par: 数组名Type:array 数组,如同fortran,下标最小号为1,可以多达三维(缺省)char 字符串组(每个元素最多8个字符)tableIMAX,JMAX,KMAX各维的最大下标号Var1,Var2,Var3 各维变量名,缺省为row,column,plane(当type为table时)/config是设置ansys配置参数的命令格式为/CONFIG, Lab, V ALUELab为参数名称value为参数值例如:/config,MXEL,10000的意思是最大单元数为10000杆单元:LINK1、8、10、11、180梁单元:BEAM3、4、23、24,44,54,188,189管单元:PIPE16,17,18,20,59,602D实体元:PLANE2,25,42,82,83,145,146,182,1833D实体元:SOLID45,46,64,65,72,73,92,95,147,148,185,186,187,191壳单元:SHELL28,41,43,51,61,63,91,93,99,143,150,181,208,209弹簧单元:COMBIN7,14,37,39,40质量单元:MASS21接触单元:CONTAC12,52,TARGE169,170,CONTA171,172,173,174,175,178矩阵单元:MATRIX27,50表面效应元:SURF153,154粘弹实体元:VISCO88,89,106,107,108,超弹实体元:HYPER56,58,74,84,86,158耦合场单元:SOLID5,PLANE13,FLUID29,30,38,SOLID62,FLUID79,FLUID80,81,SOLID98,FLUID129,INFIN110,111,FLUID116,130界面单元:INTER192,193,194,195显式动力分析单元:LINK160,BEAM161,PLANE162,SHELL163,SOLID164,COMBI16杆单元单元名称简称节点数节点自由度特性备注LINK1 2D杆 2 Ux,Uy EPCSDGB常用杆元LINK8 3D杆Ux,Uy,Uz EPCSDGBLINK103D仅受拉或仅受压杆EDGB模拟缆索的松弛及间隙LINK11 3D线性调节器EGB模拟液压缸和大转动LINK180 3D有限应变杆EPCDFGB 另可考虑粘弹塑性E-弹性(Elasticity),P-塑性(Plasticity),C-蠕变(Creep),S-膨胀(Swelling),D-大变形或大挠度(Large deflection),F-大应变(Large strain)或有限应变(Finite strain),B-单元生死(Birth and dead),G-应力刚化(Stress stiffness)或几何刚度(Geometric stiffening),A-自适应下降(Adaptive descent)等。

1、A,P1,P2,P3,P4,P5,P6,P7,P8,P9此命令用已知的一组关键点点(P1~P9)来定义面(Area),最少使用三个点才能围成面,同时产生转围绕些面的线。

点要依次序输入,输入的顺序会决定面的法线方向。

如果超过四个点,则这些点必须在同一个平面上。

Menu Paths:Main Menu>Preprocessor>Create>Arbitrary>Through KPs2、*ABBR,Abbr,String--定义一个缩略语.Abbr:用来表示字符串"String"的缩略语,长度不超过8个字符.String:将由"Abbr"表示的字符串,长度不超过60个字符.3、ABBRES,Lab,Fname,Ext-从一个编码文件中读出缩略语.Lab:指定读操作的标题,NEW:用这些读出的缩略语重新取代当前的缩略语(默认)CHANGE:将读出的缩略语添加到当前缩略语阵列,并替代现存同名的缩略语.Ext:如果"Fname"是空的,则缺省的扩展命是"ABBR".4、ABBSA V,Lab,Fname,Ext-将当前的缩略语写入一个文本文件里Lab:指定写操作的标题,若为ALL,表示将所有的缩略语都写入文件(默认)5、add, ir, ia,ib,ic,name,--,--,facta, factb, factc将ia,ib,ic变量相加赋给ir变量ir, ia,ib,ic:变量号name: 变量的名称6、Adele,na1,na2,ninc,kswp !kswp=0时只删除掉面积本身,=1时低单元点一并删除。

7、Adrag, nl1,nl2,nl3,nl4,nl5,nl6, nlp1,nlp2,nlp3,nlp4,nlp5,nlp6 !面积的建立,沿某组线段路径,拉伸而成。

8、Afillt,na1,na2,rad !建立圆角面积,在两相交平面间产生曲面,rad为半径。

9、*AFUN,Lab在参数表达式中,为角度函数指定单位.Lab:指定将要使用的角度单位.有3个选项.RAD:在角度函数的输入与输出中使用弧度单位(默认)DEG:在角度函数的输入与输出中使用度单位.STAT:显示该命令当前的设置(即是度还是弧度).10、Agen, itime,na1,na2,ninc,dx,dy,dz,kinc,noelem,imove !面积复制命令。

ANSYS常用命令详解1、AA,P1,P2,........P18 连接点生成面P1-P18 生成面的点号(用键盘输入,最多18个),最少3个,如果p1=p,可以在图中拾取(仅在GUI中有效),注意: 点p1到p18一定按顺时针或逆时针方向沿面顺序输入,这个顺序也确定了面的法线正向(按右手法则)。

面包含相邻点间已生成的线,如果两点间不只存在一条线,将用最短的一条。

如果生成面的点大于4个,要求点和线在当前坐标系下坐标为常值(如面或柱)。

建议环形坐标系下实体建模不用此命令。

菜单:main>preprocessor>modeling>create>area>arbitrary>through KPs2、AADDAADD, NA1, NA2, NA3, NA4, NA5, NA6, NA7, NA8, NA9将分开的面相加生成一个面NA1, NA2,...为原来的面note:要相加的面要是共面的,相加后生成新面,原来的面将被删除,菜单:Main Menu>Preprocessor>Modeling>Operate>Booleans>Add>Areas3、AATTAATT, MAT, REAL, TYPE, ESYS, SECN指定所选的未划分网格的面的单元属性。

PREP7: MeshingMP ME ST DY <> PR EM <> FL PP EDMAT:指定给所选的未划分网格的面的材料号。

REAL:指定给所选的未划分网格的面的实常数号。

TYPE:指定给所选的未划分网格的面的单元类型号。

ESYS:指定给所选的未划分网格的面的坐标系号。

SECN:指定给所选的未划分网格的面的区域号。

注释:从所选的面中生成的面也将具有这些属性。

当面划分网格时将使用这些单元属性。

如果一个面在划分网格时,没有用此命令指定属性,那么该面的属性由当前的MAT,REAL,TYPE,ESYS,SECNUM命令的设置确定。

ANSYS结构分析单元功能与特性/可以组成一一些命令,一般是一种总体命令(session),三十也有特殊,比如是处理/POST1! 是注释说明符号,,与其他软件的说明是一样的,ansys不作为命令读取,* 此符号一般是APDL的标识符,也就是ansys的参数化语言,如*do ,,,*enddo等等NSEL的意思是node select,即选择节点。

s就是select,选择。

DIM是定义数组的意思。

array 数组。

MP命令用来定义材料参数。

K是建立关键点命令。

K,关键点编号,x坐标,y坐标,z坐标。

K, NPT, X, Y, Z是定义关键点,K是命令,NPT是关键点编号,XYZ是坐标。

NUMMRG, keypoint 用这个命令,要保证关键点的位置完全一样,只是关键点号不一样的才行。

这个命令对于重复的线面都可以用。

这个很简单,压缩关键。

Ngen 复制节点e,节点号码:这个命令式通过节点来形成单元NUMCMP,ALL:压缩所有编号,这样你所有的线都会按次序重新编号~你要是需要固定的线固定的标号NSUBST,100,500,50:通过指定子步数来设置载荷步的子步LNSRCH线性搜索是求解非线性代数方程组的一种技巧,此法会在一段区间内,以一定的步长逐步搜索根,相比常用的牛顿迭代法所要耗费的计算量大得多,但它可以避免在一些情况下牛顿迭代法出现的跳跃现象。

LNSRCH激活线性搜索PRED 激活自由度求解预测NEQIT指定一个荷载步中的最大子步数AUTOTS 自动求解控制打开自动时间步长.KBC -指定阶段状或者用跳板装载里面一个负荷步骤。

SPLINE:P1,P2,P3,P4,P5,P6,XV1,YV1,ZV1,XV6,YV6,ZV6(生成分段样条曲线)*DIM,Par,Type,IMAX,JMAX,KMAX,Var1,Var2,Var3(定义载荷数组的名称)【注】Par: 数组名Type:array 数组,如同fortran,下标最小号为1,可以多达三维(缺省)char 字符串组(每个元素最多8个字符)tableIMAX,JMAX,KMAX各维的最大下标号Var1,Var2,Var3 各维变量名,缺省为row,column,plane(当type为table时)/config是设置ansys配置参数的命令格式为/CONFIG, Lab, V ALUELab为参数名称value为参数值例如:/config,MXEL,10000的意思是最大单元数为10000杆单元:LINK1、8、10、11、180梁单元:BEAM3、4、23、24,44,54,188,189管单元:PIPE16,17,18,20,59,602D实体元:PLANE2,25,42,82,83,145,146,182,1833D实体元:SOLID45,46,64,65,72,73,92,95,147,148,185,186,187,191壳单元:SHELL28,41,43,51,61,63,91,93,99,143,150,181,208,209弹簧单元:COMBIN7,14,37,39,40质量单元:MASS21接触单元:CONTAC12,52,TARGE169,170,CONTA171,172,173,174,175,178矩阵单元:MATRIX27,50表面效应元:SURF153,154粘弹实体元:VISCO88,89,106,107,108, 超弹实体元:HYPER56,58,74,84,86,158耦合场单元:SOLID5,PLANE13,FLUID29,30,38,SOLID62,FLUID79,FLUID80,81, SOLID98,FLUID129,INFIN110,111,FLUID116,130 界面单元:INTER192,193,194,195 显式动力分析单元:LINK160,BEAM161,PLANE162,SHELL163,SOLID164,COMBI16杆单元(Large deflection),F-大应变(Large strain)或有限应变(Finite strain),B-单元生死(Birth and dead),G-应力刚化(Stress stiffness)或几何刚度(Geometric stiffening),A-自适应下降(Adaptive descent )等。

ansys旋转经典命令流1 旋转摩擦 (1)2. 电磁三d命令流实例(论坛看到) (11)3. 帮助感应加热例⼦induction heating of a solid cylinder billet (15)4. 感应加热温度场的数值模拟(论⽂)inducheat30命令流 (19)5. 如何施加恒定的⾓速度?Simwe仿真论坛 (24)6. 旋转⼀个已经⽣成好的物体 (27)7. 产⽣这样的磁⼒线 (28)8. 旋转摩擦⽣热简单例⼦(⼆维旋转) (32)8.1. 原版 (32)8.2. 部分gui操作 (35)9. VM229 Input Listing (39)10 轴承---耦合+接触分析 (47)11. 板的冲压仿真 (52)1 旋转摩擦FINISH/FILNAME,Exercise24 !定义隐式热分析⽂件名/PREP7 !进⼊前处理器ET,1,SOLID5 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7800 !定义材料1的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的⽐热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,, MPTEMP,1,0MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的⽐热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,, MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松⽐CYLIND,0.7,0.5,0,0.2,0,180, !建⽴钢环的⼏何模型CYLIND,0.5,0.3,0,0.2,60,70, !建⽴铜滑块FLST,5,2,4,ORDE,2FITEM,5,8FITEM,5,12CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第8和第12号线并划分为4段FLST,5,2,4,ORDE,2FITEM,5,2FITEM,5,7CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YMSHAPE,1,3DMSHKEY,0FLST,5,2,4,ORDE,2FITEM,5,2LSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,36, , , , ,1 !选择第2和第7号线并划分为36段FLST,5,1,4,ORDE,1 FITEM,5,5CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINELESIZE,_Y1, , ,36, , , , ,1 !选择第5号线并划分为36段FLST,5,2,4,ORDE,2FITEM,5,17FITEM,5,19CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,2, , , , ,1 ! 选择第17和第19号线并划分为2段FLST,5,2,4,ORDE,2 FITEM,5,20FITEM,5,24CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第20和第24号线并划分为4段TYPE, 1 !给钢环附单元类型MA T, 1 !给钢环附材料REAL, !给钢环附实常数ESYS, 0SECNUM,CM,_Y,VOLUVSEL, , , , 1CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_Y2 !给铜滑块划分单元TYPE, 1 !给铜滑块附单元类型MA T, 2 !给铜滑块附材料REAL, !给铜滑块附实常数ESYS, 0SECNUM,CM,_Y,VOLUVSEL, , , , 2CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_YCMDELE,_Y2 !给铜滑块附实常数/COM, CONTACT PAIR CREATION - START CM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLU/GSA V,cwz,gsav,,tempMP,MU,1,0.2MA T,1R,3REAL,3ET,2,170ET,3,174KEYOPT,3,9,0R,3,RMORE,RMORE,,0RMORE,0KEYOPT,3,1,3TYPE,2NSLA,S,1ESLN,S,0ESURF,ALLCMSEL,S,_ELEMCM! Generate the contact surface ASEL,S,,,9CM,_CONTACT,AREA TYPE,3NSLA,S,1ESLN,S,0ESURF,ALLALLSELESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3/PSYMB,ESYS,1/PNUM,TYPE,1/NUM,1EPLOTESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3 CMSEL,A,_NODECM CMDEL,_NODECM CMSEL,A,_ELEMCM CMDEL,_ELEMCM CMSEL,S,_KPCM CMDEL,_KPCM CMSEL,S,_LINECMCMSEL,S,_VOLUCMCMDEL,_VOLUCM/GRES,cwz,gsavCMDEL,_TARGETCMDEL,_CONTACT/COM, CONTACT PAIR CREATION - END !⽤接触向导建⽴铜滑块与钢环间的接触/GO *DIM,pre,TABLE,2,1,1,time,press, !定义压⼒载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 20e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 20e6FLST,2,1,5,ORDE,1FITEM,2,10/GOSFA,P51X,1,PRES, %PRE% !在铜滑块上表⾯施加压⼒载荷TUNIF,20, !施加初始温度FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UX, !在钢环的外表⾯施加UX向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UY, !在钢环的外表⾯施加UY向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UZ, !在钢环的外表⾯施加UZ向约束ESEL,S,MA T,,2 !选择铜滑块单元NSLE !选择铜滑块节点CSYS,1 !激活柱坐标系FLST,2,75,1,ORDE,2NROTA T,P51X !旋转节点坐标系FLST,2,75,1,ORDE,2FITEM,2,876FITEM,2,-950/GOD,P51X, ,0.01, , , ,UY, , , , , ! 给铜滑块加Y向位移载荷(即切向位移)ALLSEL !选择所有的节点,单元,⼏何体FINISH/SOL !进⼊求解器ANTYPE,4 !设置为瞬态分析TRNOPT,FULL !选择瞬态全分析⽅法LUMPM,0 !关闭集中质量矩阵计算格式NLGEOM,1 !定义⼤变形NSUBST,100,200,100 !定义载荷步OUTRES,ALL,20 !定义结果输出⼦步间隔AUTOTS,1 !打开时间开关KBC,0 !设置为斜坡载荷TIME,10 !定义求解时间SSTIF,0 !关闭应⼒刚化影响NROPT,FULL, , !选择瞬态全分析⽅法EQSLV, , ,0,PRECISION,0 !定义双精度求解MSA VE,0TOFFST,273, !定义温度偏移量SOLVE !求解/POST1 !进⼊后处理器SET,LAST !读取最后⼦步结果PLNSOL,TEMP !显⽰温度分布云图PLNSOL,S,EQV,2 !显⽰等效应⼒分布云图FINISH/EXIT,NOSAV !退出ANSYSFINISH/FILNAME,Exercise23 ! 定义隐式热分析⽂件名/PREP7 !进⼊前处理器ET,1,PLANE13,4 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的⽐热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,, MPTEMP,1,0MPDATA,EX,1,,206e9 !定义材料1的弹性模量MPDATA,PRXY,1,,0.3 !定义材料1的泊松⽐MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的⽐热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,, MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松⽐RECTNG,0,5,0,1.25, !建⽴钢固定块的⼏何模型RECTNG,0,1.25,1.25,2.5, !建⽴铜滑块的⼏何模型TYPE, 1MA T, 1REAL, !给钢固定块附材料属性ESYS, 0SECNUM,ESIZE,0.25,0, !设置单元划分尺⼨MSHAPE,0,2DMSHKEY,1CM,_Y,AREAASEL, , , , 1CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_Y2 !给钢固定块划分单元TYPE, 1MA T, 2REAL, !给铜滑块附材料属性ESYS, 0SECNUM,CM,_Y,AREAASEL, , , , 2CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块划分单元CM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLUMP,MU,1,0.2MA T,1MP,EMIS,1,R,3REAL,3ET,2,169ET,3,172R,3,,,1.0,0.1,0,RMORE,,,1.0E20,0.0,1.0,RMORE,0.0,0,1.0,,1.0,0.5RMORE,0,1.0,1.0,0.0,,1.0 KEYOPT,3,3,0 KEYOPT,3,4,0 KEYOPT,3,5,0 KEYOPT,3,7,0 KEYOPT,3,8,0 KEYOPT,3,9,1 KEYOPT,3,10,1 KEYOPT,3,11,0 KEYOPT,3,12,0 KEYOPT,3,2,0 KEYOPT,3,1,1LSEL,S,,,3CM,_TARGET,LINE TYPE,2NSLL,S,1ESLN,S,0CM,_CONTACT,LINE TYPE,3NSLL,S,1ESLN,S,0ESURF,ALLALLSELESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 ESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 CMSEL,A,_NODECM CMDEL,_NODECM CMSEL,A,_ELEMCM CMDEL,_ELEMCM CMSEL,S,_KPCM CMDEL,_KPCM CMSEL,S,_LINECM CMDEL,_LINECM CMSEL,S,_AREACM CMDEL,_AREACMCMSEL,S,_VOLUCMCMDEL,_VOLUCMCMDEL,_TARGETCMDEL,_CONTACTFLST,2,1,5,ORDE,1FITEM,2,1 !⽤接触向导建⽴滑块和固定块间的接触⾯/GODA,P51X,UX, !将下⾯的钢块施加X向约束FLST,2,1,5,ORDE,1FITEM,2,1/GODA,P51X,UY, !将下⾯的钢块施加Y向约束FLST,2,1,4,ORDE,1FITEM,2,6/GODL,P51X, ,UX,3.75 ! 给铜块右侧的线加X向位移载荷FINISH/SOL*DIM,pre,TABLE,2,1,1,time,press, !定义压⼒载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 10e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 10e6FLST,2,1,4,ORDE,1FITEM,2,7/GOSFL,P51X,PRES, %PRE% !在铜滑块上表⾯施加压⼒载荷TUNIF,30, !给铜块和钢块施加初始温度NLGEOM,ON !定义⼤变形TIME,3.75E-3 !定义求解时间TOFFSET,273 !定义温度偏移量AUTO,ON !打开时间开关NSUB,100,10000,100 !定义载荷步OUTRES,ALL,-10 !定义结果输出⼦步间隔SOLVE !求解/POST1 !进⼊后处理器SET,LAST !读取最后⼦步结果PLNSOL,TEMP ! 显⽰温度分布云图PLNSOL,S,EQV,2 !显⽰等效应⼒分布云图FINISH/EXIT,NOSAV !退出ANSYS2. 电磁三d命令流实例(论坛看到)/BATCH/COM,ANSYS RELEASE 12.0.1 UP20090415 11:10:14 03/29/2011 /input,menust,tmp,'',,,,,,,,,,,,,,,,1 /GRA,POWER/GST,ON/PLO,INFO,3/GRO,CURL,ON/CPLANE,1/REPLOT,RESIZEWPSTYLE,,,,,,,,0/TITLE, Test for EDGE-Formulation with SOLID117!! Parameters*SET,l,5e-6 ! length*SET,h,1e-6 ! height*SET,w,5e-6 ! width*SET,a,3e-6 ! 1st addition length of magnetic core*SET,b,5e-6 ! 2nd addition length of magnetic core!/PREP7 !!ET,1,117 !!MP,MURX,1,1MP,RSVX,1,17.2e-9 !MP,MURX,2,500MP,MURX,3,1BLOCK,-w,w,-h,h,-l,l !!BLOCK,-w-a,w+a,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h+a,h+2*a,-l,lBLOCK,-w-a,-w-a-b,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h,h+a,-l,lBLOCK,-w-a,-w-a-b,h,h+a,-l,l!BLOCK,-w-a,w+a,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-(h+a),-(h+2*a),-l,lBLOCK,-w-a,-w-a-b,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-h,-(h+a),-l,lBLOCK,-w-a,-w-a-b,-h,-(h+a),-l,l!BLOCK,-22e-6,22e-6,-15e-6,15e-6,-15e-6,15e-6 VOVLAP,ALL NUMCMP,VOLUVSEL,S,VOLU,,1V ATT,1VSEL,S,VOLU,,2,11,1V ATT,2VSEL,S,VOLU,,12V ATT,3VSEL,S,MA T,,1,2,1ASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,1MSHAPE,0,3DVMESH,ALLVSEL,S,MA T,,3ASLV,SLSLA,S LESIZE,ALL,3e-6 MSHKEY,0 MSHAPE,1,3D VMESH,ALL ALLSEL,ALL FINISH/SOLUESEL,S,MA T,,1 BFE,ALL,JS,1,,,-1e9 ASEL,S,EXT DA,ALL,AZ,0 ALLSEL,ALL ANTYPE,0 NROPT,AUTO,, EQSLV,SPAR,,0, PRECISION,0 MSA VE,0 PIVCHECK,1/STA TUS,SOLU SOLVEFINISH/POST1! elements/VSCALE,1,1,0!。

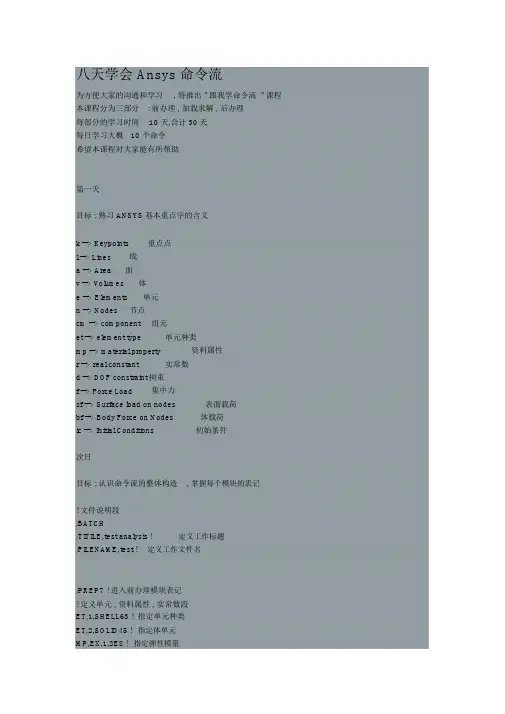

八天学会 Ansys 命令流为方便大家的沟通和学习, 特推出 " 跟我学命令流 " 课程本课程分为三部分: 前办理 , 加载求解 , 后办理每部分的学习时间:10 天,合计 30 天每日学习大概10 个命令希望本课程对大家能有所帮助第一天目标 : 熟习 ANSYS基本重点字的含义k --> Keypoints重点点l --> Lines线a --> Area面v --> Volumes体e --> Elements单元n --> Nodes节点cm --> component组元et --> element type单元种类mp --> material property资料属性r --> real constant实常数d --> DOF constraint拘束f --> Force Load集中力sf --> Surface load on nodes表面载荷bf --> Body Force on Nodes体载荷ic --> Initial Conditions初始条件次日目标 : 认识命令流的整体构造, 掌握每个模块的表记!文件说明段/BATCH/TITILE,test analysis !定义工作标题/FILENAME,test !定义工作文件名/PREP7 ! 进入前办理模块表记!定义单元 , 资料属性 , 实常数段ET,1,SHELL63 ! 指定单元种类ET,2,SOLID45 !指定体单元MP,EX,1,2E8 !指定弹性模量MP,PRXY,1,0.3 !输入泊松比MP,DENS,1,7.8E3 ! 输入资料密度R,1,0.001 !指定壳单元实常数- 厚度......!成立模型K,1,0,0,, !定义重点点K,2,50,0,,K,3,50,10,,K,4,10,10,,K,5,10,50,,K,6,0,50,,A,1,2,3,4,5,6, !由重点点生成面......!区分网格ESIZE,1,0,AMESH,1......FINISH ! 前办理结束表记/SOLU ! 进入求解模块表记!施加拘束和载荷DL,5,,ALLSFL,3,PRES,1000SFL,2,PRES,1000......SOLVE !求解表记FINISH ! 求解模块结束表记/POST1 ! 进入通用后办理器表记....../POST26 ! 进入时间历程后办理器/EXIT,SAVE ! 退出并存盘以下是日记文件中常出现的一些命令的表记说明, 希望能给大家在整理LOG文件时有所帮助/ANGLE ! 指定绕轴旋转视图/DIST !说明对视图进行缩放/DEVICE ! 设置图例的显示, 如: 风格 , 字体等/REPLOT ! 从头显示目前图例/RESET ! 恢复缺省的图形设置/VIEW ! 设置察看方向/ZOOM !对图形显示窗口的某一地区进行缩放第三天生成重点点和线部分1.生成重点点K, 重点点编号 ,X 坐标 ,Y 坐标 ,Z 坐标例:K,1,0,0,02.在激活坐标系生成直线LSTR,重点点 P1, 重点点 P2例 LSTR,1,23.在两个重点点之间连线L, 重点点 P1, 重点点 P2例 L,1,2注: 此命令会随目前的激活坐标系不同而生成直线或弧线4.由三个重点点生成弧线LARC,重点点 P1, 重点点 P2, 重点点 PC,半径 RAD例注: 重点点 PC是用来控制弧线的凹向5.经过圆心半径生成圆弧CIRCLE,重点点圆心 , 半径 RAD,,,, 圆弧段数NSEG例:CIRCLE,1,0.05,,,,46.经过重点点生成样条线BSPLIN,重点点 P1, 重点点 P2,重点点 P3, 重点点 P4, 重点点 P5, 重点点 P6例:BSPLIN,1,2,3,4,5,67.生成倒角线LFILLT, 线 NL1, 线 NL2,倒角半径RAD例8.经过重点点生成面A, 重点点 P1, 重点点 P2, 重点点 P3, 重点点 P4, 重点点 P5, 重点点 P6,P7,P8...例:A,1,2,3,49.经过线生成面AL, 线 L1, 线 L2, 线 L3, 线 L4, 线 L5, 线 L6, 线 L7, 线 L8, 线 L9, 线 L10例:AL,5,6,7,810.经过线的滑移生成面ASKIN, 线 NL1,线 NL2,线 NL3,线 NL4, 线 NL5, 线 NL6, 线 NL7,线 NL8, 线 NL9例:ASKIN,1,4,5,6,7,8注: 线 1 为滑移的导向线第四天目标 : 掌握常用的实体 - 面的生成生成矩形面1.经过矩形角上定位点生成面BLC4,定位点 X 方向坐标 XCORNER,定位点 Y 方向坐标 YCORNER,矩形宽度 WIDTH,矩形高度HEIGHT,矩形深度 DEPTH例:BLC4,0,0,5,3,02.经过矩形中心定位点生成面BLC5,定位点 X 方向坐标 XCENTER,定位点 Y 方向坐标 YCENTER,矩形宽度 WIDTH,矩形高度HEIGHT,矩形深度 DEPTH注: 与上条命令的不同就在于矩形的定位点不同样例:BLC5,2.5,1.5,5,3,03. 经过在工作平面定义矩形X.Y 坐标生成面RECTNG,矩形左界限 X 坐标 X1,矩形右界限X 坐标 X2, 矩形下界限Y坐标 Y1, 矩形上界限Y 坐标 Y2例:RECTNG,0,5,0,3生成圆面4.经过中心定位点生成实心圆面CYL4,定位点 X 方向坐标 XCENTER,定位点 Y 方向坐标 YCENTER,圆面的内半径 RAD1,内圆面旋转角度 THETA1,圆面的外半径 RAD2,外圆面旋转角度 THETA2,圆面的深度 DEPTH注: 如要实心的圆面则不用 RAD2,THETA2,DEPTH例:CYL4,0,0,5,3605.生成扇形圆面命令介绍如上例 1 实心扇形 :CYL4,0,0,5,60例 2 扇形圆环 :CYL4,0,0,5,60,10,60 例3 整的圆环 :CYL4,0,0,5,360,10,360注: 同时可经过定义圆面的深度以生成柱体6.经过在工作平面定义开端点生成圆面CYL5,开始点 X坐标 XEDGE1,开始点 Y坐标 YEDGE1,结束点 X坐标 XEDGE2,结束点 Y坐标YEDGE2, 圆面深度 DEPTH例:CYL5,0,0,2,2,7.经过在工作平面定义内外半径和开端角度来生成圆面PCIRC,内半径 RAD1,外半径 RAD2,开端角度THETA1,结束角度THETA2例 LCIRC,2,5,30,1808.生成面与面的倒角AFILLT, 面 1 的编号 NA1, 面 2 的编号 NA2,倒角半径RAD例:AFILLT,2,5,2下一讲 : 多边形面的生成第五天目标 : 掌握多边形面和体的生成1.生成多边形面命令 :RPR4, 多边形的边数NSIDES,中心定位点X 坐标 XCENTER,中心定位点Y 坐标 YCENTER,中心定位点距各边极点的距离RADIUS,多边形旋转角度THETA例:RPR4,4,0,0,0.15,30注: 这条命令可经过定义不同的NSIDES生成三边形 , 四边形 ,...,八边形2.生成多边形体命令 :RPR4, 多边形的边数NSIDES,中心定位点X 坐标 XCENTER,中心定位点Y 坐标 YCENTER,中心定位点距各边极点的距离RADIUS,多边形旋转角度THETA,多边形的深度DEPTH例注: 多边形体和面命令独一的不同就在于深度DEPTH的定义到此 , 重点点 , 线 , 面的生成解说已结束, 下一讲 : 体的生成第六天目标 : 掌握体的生成命令1.经过重点点生成体命令 :V, 重点点 P1, 重点点 P2, P3, P4, P5, P6, P7, P8例:V,4,5,6,7,15,24,252.经过面生成体命令 :VA, 面 A1, 面 A2, A3, A4, A5, A6, A7, A8, A9, A10例:VA,3,4,5,8,103.经过长方形角上定位点生成体命令 :BLC4该命令前方在讲生成面的时候已作介绍, 独一的不同在于深度DEPTH的定义 .4.经过长方形中心定位点生成面命令 :BLC55.经过定义长方体开端地点生成体命令 :BLOCK,开始点 X 坐标 X1,结束点 X 坐标 X2, Y1, Y2, Z1, Z2例:BLOCK,2,5,0,2,1,36.生成圆柱体基本命令通生成圆形面, 不同在于DEPTH的定义基本命令 :CYL4基本命令 :CYL5基本命令 :CYLIND7.生成棱柱基本命令通生成多边形, 不同在于DEPTH的定义基本命令 :RPR48.经过球心半径生成球体命令 :SPH4, 球心 X 坐标 XCENTER,球心 Y 坐标 YCENTER,半径 RAD1,半径 RAD2例:SPH4,1,1,2,59.经过直径上开端点坐标生成球体命令 :SPH5, 起点 X 坐标 XEDGE1,起点 Y坐标 YEDGE1,结束点 X 坐标 XEDGE2,结束点 Y 坐标YEDGE2例:SPH5,2,5,7,610.在工作平面起点经过半径和转动角度生成球体命令 :SPHERE,半径 RAD1,半径 RAD2,转动角度THETA1,转动角度THETA2例:SPHERE,2,5,0,6011.生成圆锥体命令 :CONE,底面半径 RBOT,顶面半径 RTOP,底面高 Z1, 顶面高 Z2, 转动角度 THETA1,转动角度THETA2例:CONE,10,20,0,50,0,180下一讲 : 布尔操作第七天目标 : 掌握常用的布尔操作命令1.沿法向延长面生成体命令 :VOFFST,面的编号NAREA,面拉伸的长度DIST, 重点点增量KINC例:VOFFST,1,2,,2.经过坐标的增量延长面生成体命令 :VEXT, 面 1 的编号 NA1,面 2 的编号 NA2,增量 NINC,X 方向的增量 DX,Y 方向的增量 DY,Z 方向的增量 DZ, RX, RY, RZ例:VEXT,1,5,1,1,2,2,3. 面绕轴旋转生成体命令 :VROTAT,面 1 的编号PAX1,定位轴重点点 2 编号NA1,面 2 的编号PAX2,旋转角度NA2,NA3, NA4, NA5, NA6,ARC,生成体的段数 NSEG定位轴重点点 1 编号例:VROTAT,1,2,,,,,4,5,360,44. 沿线延长面生成体命令 :VDRAG,面 1 的编号 NA1,面 2 的编号 NA2, NA3, NA4, NA5, NA6,导引线 2 的编号 NLP2, NLP3, NLP4, NLP5, NLP6例:VDRAG,2,3,,,,,8,导引线 1 的编号NLP1, 5. 线绕轴旋转生成面命令 :AROTAT,线 1 的编号 NL1, NL2, NL3, NL4, NL5, NL6,位轴重点点 2 的编号 PAX2,旋转角度ARC,生成面的段数例:AROTAT,3,4,,,,,6,8,360,4定位轴重点点NSEG1 的编号PAX1,定6.沿线延长线生成面命令 :ADRAG,线 1 的编号 NL1,NL2, NL3, NL4, NL5, NL6, 导引线 1 的编号 NLP1, NLP2, NLP3, NLP4, NLP5, NLP6例:ADRAG,3,,,,,,87.同理能够延长重点点 , 相应的命令以下 :LROTAT, NK1, NK2, NK3, NK4, NK5, NK6, PAX1, PAX2, ARC, NSEGLDRAG, NK1, NK2, NK3, NK4, NK5, NK6, NL1, NL2, NL3, NL4, NL5, NL6各选项的含义相同于上 .8.延长一条线命令 LEXTND,线的编号 NL1, 定位重点点编号 NK1,延长的距离 DIST, 原有线能否保存控制项KEEP例 LEXTND,5,2,1.5,09.布尔操作 : 加命令 LCOMB,线编号 NL1,线编号 NL2, 能否改正控制项KEEP例 LCOMB,2,5注: 对面和体的相应为:VADD,AADD.选项的含义都近似10.布尔操作 : 粘接和搭接搭接的中心重点字为:OVLAP,随实体的不同略有不同, 如 :对体为 VOVLAP对面为 AOVLAP对线为 LOVLAP粘接的中心重点字为:GLUE, 随实体的不同略有不同, 如 :对体为 VGLUE对面为 AGLUE对线为 LGLUE但其余的选项的含义是近似的, 这里就不再累述.下一讲 :挪动 ,复制 ,映照 , 删除 ...第八天目标 : 掌握体素的挪动, 复制 , 删除 , 映照一. 挪动重点点命令 :KMODIF,重点点编号NPT,挪动后的坐标X, 挪动后的坐标Y, 挪动后的坐标Z例:KMODIF,5,0,0,2二. 挪动复制重点点命令 :KGEN,复制次数选项 ITIME, 开端重点点编号 NP1,结束重点点编号 NP2,增量 NINC,偏移DX,偏移 DY,偏移 DZ,重点点编号增量 KINC, 生成节点单元控制项 NOELEM,原重点点能否被修改选项 IMOVE例:KGEN,2,1,10,1,2,2,2,,,,注:IMOVE 选项说明 , 设置为 0 时, 不改正原重点点 , 即为复制 , 设置为 1 时 , 改正原重点点 , 即为挪动 , 进而经过控制 IMOVE选项实现挪动或复制 .三. 挪动复制线命 LGEN,ITIME,NL1,NL2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上四. 挪动复制面命:AGEN,ITIME,NA1,NA2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上五. 挪动复制体命令 :VGEN,ITIME,NV1,NV2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上六. 改正面的法向方向命令 :ANORM,面的编号 ANUM,单元的法向方向能否改正选项NOEFLIP例:ANORM,2七.体素的删除基本的命令为 :*DELE组合不同的重点字形成不同的命令如:KDELE,LDELE,ADELE,VDELE基本的命令格式为 :*DELE, 开端体素编号 N*1, 结束体素编号 N*2, 增量 NINC,能否删除体素基层的元素选项 KSWP如 LDELE,2,5,1,1八.体素的映照基本的命令为 :*SYMM组合不同的重点字形成不同的命令如:KSYMM,LSYMM,ARSYM,VSYMM基本的命令格式为 :*SYMM,映照轴选项 NCOMP,开端体素编号 N*1, 结束体素编号 N*2, 增量NINC,重点点编号增量 KINC,NOELEM, IMOVE如:VSYMM,X,1,10,1,,,,。

ansys命令流中文说明展开全文KB、KE: 待划分线的定向关键点起始、终止号SECNUM: 截面类型号u SECPLOT,SECID,MESHKEY 画梁截面的几何形状及网格划分SECID:由SECTYPE命令分配的截面编号MESHKEY:0:不显示网格划分1:显示网格划分u /ESHAPE, SCALE 按看似固体化分的形式显示线、面单元SCALE: 0:简单显示线、面单元1:使用实常数显示单元形状u esurf, xnode, tlab, shape 在已存在的选中单元的自由表面覆盖产生单元xnode: 仅为产生surf151 或surf152单元时使用tlab: 仅用来生成接触元或目标元top 产生单元且法线方向与所覆盖的单元相同,仅对梁或壳有效,对实体单元无效Bottom产生单元且法线方向与所覆盖的单元相反,仅对梁或壳有效,对实体单元无效Reverse 将已产生单元反向Shape: 空与所覆盖单元形状相同Tri 产生三角形表面的目标元注意:选中的单元是由所选节点决定的,而不是选单元,如同将压力加在节点上而不是单元上u Nummrg,label,toler, Gtoler,action,switch 合并相同位置的itemlabel: 要合并的项目node: 节点, Elem,单元,kp: 关键点(也合并线,面及点)mat: 材料,type: 单元类型,Real: 实常数cp:耦合项,CE:约束项,CE: 约束方程,All:所有项toler: 公差Gtoler:实体公差Action: sele 仅选择不合并空合并switch: 较低号还是较高号被保留(low, high)注意:可以先选择一部分项目,再执行合并。

如果多次发生合并命令,一定要先合并节点,再合并关键点。

合并节点后,实体荷载不能转化到单元,此时可合并关键点解决问题。

u Lsel, type, item, comp, vmin, vmax, vinc, kswp 选择线type: s 从全部线中选一组线r 从当前选中线中选一组线a 再选一部线附加给当前选中组aunoneu(unselect)inve: 反向选择item: line 线号loc 坐标length 线长comp: x,y,zkswp: 0 只选线1 选择线及相关关键点、节点和单元u Nsel, type, item, comp, vmin, vmax, vinc, kabs 选择一组节点为下一步做准备Type: S: 选择一组新节点(缺省)R: 在当前组中再选择A: 再选一组附加于当前组U: 在当前组中不选一部分All: 恢复为选中所有None: 全不选Inve: 反向选择Stat: 显示当前选择状态Item: loc: 坐标node: 节点号Comp: 分量Vmin,vmax,vinc: ITEM范围Kabs: “0” 使用正负号“1”仅用绝对值u NSLL,type, nkey 选择与所选线相联系的节点u nsla, type, nkey: 选择与选中面相关的节点type:s 选一套新节点r 从已选节点中再选a 附加一部分节点到已选节点u 从已选节点中去除一部分nkey: 0 仅选面内的节点1 选所有和面相联系的节点(如面内线,关键点处的节点)u esel, type, item, comp, vmin, vmax, vinc, kabs 选择一组单元Type: S: 选择一组单元(缺省)R: 在当前组中再选一部分作为一组A: 为当前组附加单元U: 在当前组中不选一部分单元All: 选所有单元None: 全不选Inve: 反向选择当前组(?)Stat: 显示当前选择状态Item: Elem: 单元号Type: 单元类型号Mat: 材料号Real: 实常数号Esys: 单元坐标系号u ALLSEL, LABT, ENTITY 选中所有项目LABT: ALL: 选所有项目及其低级项目BELOW: 选指定项目的直接下属及更低级项目ENTITY: ALL: 所有项目(缺省)VOLU:体高级AREA:面LINE :线KP:关键点ELEM:单元NODE:节点低级u Tshap,shape 定义接触目标面为2D、3D的简单图形Shape: line:直线Arc:顺时针弧Tria:3点三角形Quad:4点四边形………….2.6 根据需要耦合某些节点自由度u cp, nset, lab,,node1,node2,……node17nset: 耦合组编号lab: ux,uy,uz,rotx,roty,rotznode1-node17: 待耦合的节点号。

一、定义材料号及特性mp,lab,mat,co,c1,…….c4lab:待定义的特性项目(ex,alpx,reft,prxy,nuxy,gxy,mu,dens)ex: 弹性模量nuxy:小泊松比alpx: 热膨胀系数reft:参考温度reft: 参考温度prxy: 主泊松比gxy: 剪切模量mu:摩擦系数dens:质量密度mat: 材料编号(缺省为当前材料号)c 材料特性值,或材料之特性,温度曲线中的常数项c1—c4:材料的特性—温度曲线中1次项,2次项,3次项,4次项的系数二、定义DP材料:首先要定义EX和泊松比:MP,EX,MAT,……MP,NUXY,MAT,……定义DP材料单元表(这里不考虑温度):TB,DP,MAT进入单元表并编辑添加单元表:TBDATA,1,CTBDATA,2,ψTBDATA,3,……如定义:EX=1E8,NUXY=0.3,C=27,ψ=45的命令如下:MP,EX,1,1E8MP,NUXY,1,0。

3TB,DP,1TBDATA,1,27TBDATA,2,45这里要注意的是,在前处理的最初,要将角度单位转化到“度”,即命令:*afun,deg 三、单元生死载荷步!第一个载荷步TIME,。

. !设定时间值(静力分析选项)NLGEOM,ON !打开大位移效果NROPT,FULL !设定牛顿-拉夫森选项ESTIF,。

.。

!设定非缺省缩减因子(可选)ESEL,。

!选择在本载荷步中将不激活的单元EKILL,... !不激活选择的单元ESEL,S,LIVE !选择所有活动单元NSLE,S !选择所有活动结点NSEL,INVE !选择所有非活动结点(不与活动单元相连的结点)D,ALL,ALL,0 !约束所有不活动的结点自由度(可选)NSEL,ALL !选择所有结点ESEL,ALL !选择所有单元D,.。

. !施加合适的约束F,。

. !施加合适的活动结点自由度载荷SF,。

. !施加合适的单元载荷BF,。

ansys命令流语法ANSYS命令流语法是使用ANSYS软件进行仿真分析的关键部分。

它是一种将命令以特定顺序组合在一起的方式,以实现特定的分析目标。

本文将介绍ANSYS命令流语法的基本语法规则和常用命令,以及如何使用它们进行仿真分析。

一、ANSYS命令流语法的基本语法规则1. 命令的基本格式:命令[选项] [参数1, 参数2, ...]2. 命令的执行顺序:ANSYS命令流是按照命令的顺序逐条执行的。

如果需要改变执行顺序,可以使用条件语句、循环语句等控制结构。

3. 注释:可以在命令流中添加注释,以"!"开头。

注释部分不会被执行,可以用于解释命令的用途或添加说明。

4. 变量和参数:可以使用变量和参数来存储和传递数据。

变量以"$"开头,参数以"%"开头。

二、常用命令1. Preprocessor命令:用于定义和准备分析模型的预处理操作。

- /PREP7:进入预处理器界面。

- ET,MP,REAL等:定义单元类型、材料属性、实数等。

- K,L,A等:创建节点、单元、区域等。

2. Solution命令:用于设置和运行分析求解器。

- /SOLU:进入求解器界面。

- SOLVE,ANTYPE等:设置分析类型、求解选项等。

- D,S等:定义边界条件、加载条件等。

3. Postprocessor命令:用于后处理和分析结果的可视化。

- /POST1:进入后处理器界面。

- PLOT,PDEF等:绘制图形、定义图形属性等。

- PRINT,*VWRITE等:输出结果数据。

三、使用ANSYS命令流语法进行仿真分析使用ANSYS命令流语法进行仿真分析的一般步骤如下:1. 导入几何模型:使用CAD软件创建几何模型,并将其导入ANSYS 中。

2. 定义材料属性:根据实际材料的物理特性,使用MP命令定义材料属性。

3. 网格划分:使用网格划分命令划分几何模型,生成有限元网格。

1 旋转摩擦 (1)2. 电磁三d命令流实例(论坛看到) (11)3. 帮助感应加热例子induction heating of a solid cylinder billet (15)4. 感应加热温度场的数值模拟(论文)inducheat30命令流 (19)5. 如何施加恒定的角速度?Simwe仿真论坛 (24)6. 旋转一个已经生成好的物体 (27)7. 产生这样的磁力线 (28)8. 旋转摩擦生热简单例子(二维旋转) (32)8.1. 原版 (32)8.2. 部分gui操作 (35)9. VM229 Input Listing (39)10 轴承---耦合+接触分析 (47)11. 板的冲压仿真 (52)1 旋转摩擦FINISH/FILNAME,Exercise24 !定义隐式热分析文件名/PREP7 !进入前处理器ET,1,SOLID5 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7800 !定义材料1的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,206e9 !定义材料1的弹性模量MPDATA,PRXY,1,,0.3 !定义材料1的泊松比MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松比CYLIND,0.7,0.5,0,0.2,0,180, !建立钢环的几何模型CYLIND,0.5,0.3,0,0.2,60,70, !建立铜滑块FLST,5,2,4,ORDE,2FITEM,5,8FITEM,5,12CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第8和第12号线并划分为4段FLST,5,2,4,ORDE,2FITEM,5,2FITEM,5,7CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YMSHAPE,1,3DMSHKEY,0FLST,5,2,4,ORDE,2FITEM,5,2FITEM,5,7CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,36, , , , ,1 !选择第2和第7号线并划分为36段FLST,5,1,4,ORDE,1FITEM,5,5CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINELESIZE,_Y1, , ,36, , , , ,1 !选择第5号线并划分为36段FLST,5,2,4,ORDE,2FITEM,5,17FITEM,5,19CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,2, , , , ,1 ! 选择第17和第19号线并划分为2段FLST,5,2,4,ORDE,2FITEM,5,20FITEM,5,24CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,4, , , , ,1 !选择第20和第24号线并划分为4段TYPE, 1 !给钢环附单元类型MAT, 1 !给钢环附材料REAL, !给钢环附实常数ESYS, 0SECNUM,CM,_Y,VOLUVSEL, , , , 1CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块划分单元TYPE, 1 !给铜滑块附单元类型MAT, 2 !给铜滑块附材料REAL, !给铜滑块附实常数ESYS, 0SECNUM,CM,_Y,VOLUVSEL, , , , 2CM,_Y1,VOLUCHKMSH,'VOLU'CMSEL,S,_YVSWEEP,_Y1CMDELE,_YCMDELE,_Y2 !给铜滑块附实常数/COM, CONTACT PAIR CREATION - STARTCM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLU/GSAV,cwz,gsav,,tempMP,MU,1,0.2MAT,1R,3REAL,3ET,2,170ET,3,174KEYOPT,3,9,0R,3,RMORE,RMORE,,0RMORE,0KEYOPT,3,1,3! Generate the target surfaceASEL,S,,,4CM,_TARGET,AREATYPE,2NSLA,S,1ESLN,S,0ESURF,ALLCMSEL,S,_ELEMCM! Generate the contact surfaceASEL,S,,,9CM,_CONTACT,AREATYPE,3NSLA,S,1ESLN,S,0ESURF,ALLALLSELESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3/PSYMB,ESYS,1/PNUM,TYPE,1/NUM,1EPLOTESEL,ALLESEL,S,TYPE,,2ESEL,A,TYPE,,3ESEL,R,REAL,,3CMSEL,A,_NODECMCMDEL,_NODECMCMSEL,A,_ELEMCMCMDEL,_ELEMCMCMSEL,S,_KPCMCMDEL,_KPCMCMSEL,S,_LINECMCMDEL,_LINECMCMSEL,S,_AREACMCMDEL,_AREACMCMSEL,S,_VOLUCMCMDEL,_VOLUCM/GRES,cwz,gsavCMDEL,_TARGETCMDEL,_CONTACT/COM, CONTACT PAIR CREATION - END !用接触向导建立铜滑块与钢环间的接触/GO*DIM,pre,TABLE,2,1,1,time,press, !定义压力载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 20e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 20e6FLST,2,1,5,ORDE,1FITEM,2,10/GOSFA,P51X,1,PRES, %PRE% !在铜滑块上表面施加压力载荷TUNIF,20, !施加初始温度FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UX, !在钢环的外表面施加UX向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UY, !在钢环的外表面施加UY向约束FLST,2,1,5,ORDE,1FITEM,2,3/GODA,P51X,UZ, !在钢环的外表面施加UZ向约束ESEL,S,MAT,,2 !选择铜滑块单元NSLE !选择铜滑块节点CSYS,1 !激活柱坐标系FLST,2,75,1,ORDE,2FITEM,2,876FITEM,2,-950NROTAT,P51X !旋转节点坐标系FLST,2,75,1,ORDE,2FITEM,2,876FITEM,2,-950/GOD,P51X, ,0.01, , , ,UY, , , , , ! 给铜滑块加Y向位移载荷(即切向位移)ALLSEL !选择所有的节点,单元,几何体FINISH/SOL !进入求解器ANTYPE,4 !设置为瞬态分析TRNOPT,FULL !选择瞬态全分析方法LUMPM,0 !关闭集中质量矩阵计算格式NLGEOM,1 !定义大变形NSUBST,100,200,100 !定义载荷步OUTRES,ALL,20 !定义结果输出子步间隔AUTOTS,1 !打开时间开关KBC,0 !设置为斜坡载荷TIME,10 !定义求解时间SSTIF,0 !关闭应力刚化影响NROPT,FULL, , !选择瞬态全分析方法EQSLV, , ,0,PRECISION,0 !定义双精度求解MSAVE,0TOFFST,273, !定义温度偏移量SOLVE !求解/POST1 !进入后处理器SET,LAST !读取最后子步结果PLNSOL,TEMP !显示温度分布云图PLNSOL,S,EQV,2 !显示等效应力分布云图FINISH/EXIT,NOSAV !退出ANSYSFINISH/FILNAME,Exercise23 ! 定义隐式热分析文件名/PREP7 !进入前处理器ET,1,PLANE13,4 !选择单元类型MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7800 !定义材料1的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,1,,460 !定义材料1的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,1,,66.6 !定义材料1的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,1,REFT,,,30 !定义材料1的热膨胀系数的参考温度MPDATA,ALPX,1,,1.06e-5 !定义材料1的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,206e9 !定义材料1的弹性模量MPDATA,PRXY,1,,0.3 !定义材料1的泊松比MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,2,,8900 !定义材料2的密度MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,C,2,,390 !定义材料2的比热MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,KXX,2,,383 !定义材料2的热传导系数MPTEMP,,,,,,,,MPTEMP,1,0UIMP,2,REFT,,,30 !定义材料2的热膨胀系数的参考温度MPDATA,ALPX,2,,1.75e-5 !定义材料2的热膨胀系数MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,2,,103e9 !定义材料2的弹性模量MPDATA,PRXY,2,,0.3 !定义材料2的泊松比RECTNG,0,5,0,1.25, !建立钢固定块的几何模型RECTNG,0,1.25,1.25,2.5, !建立铜滑块的几何模型TYPE, 1MAT, 1REAL, !给钢固定块附材料属性ESYS, 0SECNUM,ESIZE,0.25,0, !设置单元划分尺寸MSHAPE,0,2DMSHKEY,1CM,_Y,AREAASEL, , , , 1CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给钢固定块划分单元TYPE, 1MAT, 2REAL, !给铜滑块附材料属性ESYS, 0SECNUM,CM,_Y,AREAASEL, , , , 2CM,_Y1,AREACHKMSH,'AREA'CMSEL,S,_YAMESH,_Y1CMDELE,_YCMDELE,_Y1CMDELE,_Y2 !给铜滑块划分单元CM,_NODECM,NODECM,_ELEMCM,ELEMCM,_KPCM,KPCM,_LINECM,LINECM,_AREACM,AREACM,_VOLUCM,VOLUMP,MU,1,0.2MAT,1MP,EMIS,1,R,3REAL,3ET,2,169ET,3,172R,3,,,1.0,0.1,0,RMORE,,,1.0E20,0.0,1.0,RMORE,0.0,0,1.0,,1.0,0.5RMORE,0,1.0,1.0,0.0,,1.0 KEYOPT,3,3,0 KEYOPT,3,4,0 KEYOPT,3,5,0 KEYOPT,3,7,0 KEYOPT,3,8,0 KEYOPT,3,9,1 KEYOPT,3,10,1 KEYOPT,3,11,0 KEYOPT,3,12,0 KEYOPT,3,2,0 KEYOPT,3,1,1LSEL,S,,,3CM,_TARGET,LINE TYPE,2NSLL,S,1ESLN,S,0ESURF,ALL CMSEL,S,_ELEMCM LSEL,S,,,5CM,_CONTACT,LINE TYPE,3NSLL,S,1ESLN,S,0ESURF,ALL ALLSELESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 ESEL,ALLESEL,S,TYPE,,2 ESEL,A,TYPE,,3 ESEL,R,REAL,,3 CMSEL,A,_NODECM CMDEL,_NODECM CMSEL,A,_ELEMCM CMDEL,_ELEMCM CMSEL,S,_KPCM CMDEL,_KPCM CMSEL,S,_LINECM CMDEL,_LINECM CMSEL,S,_AREACM CMDEL,_AREACMCMSEL,S,_VOLUCMCMDEL,_VOLUCMCMDEL,_TARGETCMDEL,_CONTACTFLST,2,1,5,ORDE,1FITEM,2,1 !用接触向导建立滑块和固定块间的接触面/GODA,P51X,UX, !将下面的钢块施加X向约束FLST,2,1,5,ORDE,1FITEM,2,1/GODA,P51X,UY, !将下面的钢块施加Y向约束FLST,2,1,4,ORDE,1FITEM,2,6/GODL,P51X, ,UX,3.75 ! 给铜块右侧的线加X向位移载荷FINISH/SOL*DIM,pre,TABLE,2,1,1,time,press, !定义压力载荷随时间变化的TABLE表*SET,PRE(1,0,1) , 0*SET,PRE(1,1,1) , 10e6*SET,PRE(2,0,1) , 10*SET,PRE(2,1,1) , 10e6FLST,2,1,4,ORDE,1FITEM,2,7/GOSFL,P51X,PRES, %PRE% !在铜滑块上表面施加压力载荷TUNIF,30, !给铜块和钢块施加初始温度ALLSEL !选择所有的节点,单元,几何体ANTYPE,TRANS !设置为瞬态分析TIMINT,OFF,STRUC !关闭结构的动态惯性影响TINTP,,,,1.0 !定义瞬态积分参数NLGEOM,ON !定义大变形TIME,3.75E-3 !定义求解时间TOFFSET,273 !定义温度偏移量AUTO,ON !打开时间开关NSUB,100,10000,100 !定义载荷步OUTRES,ALL,-10 !定义结果输出子步间隔SOLVE !求解/POST1 !进入后处理器SET,LAST !读取最后子步结果PLNSOL,TEMP ! 显示温度分布云图PLNSOL,S,EQV,2 !显示等效应力分布云图FINISH/EXIT,NOSAV !退出ANSYS2. 电磁三d命令流实例(论坛看到)/BATCH/COM,ANSYS RELEASE 12.0.1 UP20090415 11:10:14 03/29/2011 /input,menust,tmp,'',,,,,,,,,,,,,,,,1/GRA,POWER/GST,ON/PLO,INFO,3/GRO,CURL,ON/CPLANE,1/REPLOT,RESIZEWPSTYLE,,,,,,,,0/TITLE, Test for EDGE-Formulation with SOLID117!! Parameters*SET,l,5e-6 ! length*SET,h,1e-6 ! height*SET,w,5e-6 ! width*SET,a,3e-6 ! 1st addition length of magnetic core*SET,b,5e-6 ! 2nd addition length of magnetic core!/PREP7 !!ET,1,117 !!MP,MURX,1,1MP,RSVX,1,17.2e-9 !MP,MURX,2,500MP,MURX,3,1BLOCK,-w,w,-h,h,-l,l !!BLOCK,-w-a,w+a,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h+a,h+2*a,-l,lBLOCK,-w-a,-w-a-b,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h,h+a,-l,lBLOCK,-w-a,-w-a-b,h,h+a,-l,l!BLOCK,-w-a,w+a,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-(h+a),-(h+2*a),-l,lBLOCK,-w-a,-w-a-b,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-h,-(h+a),-l,lBLOCK,-w-a,-w-a-b,-h,-(h+a),-l,l!BLOCK,-22e-6,22e-6,-15e-6,15e-6,-15e-6,15e-6 VOVLAP,ALLNUMCMP,VOLUVSEL,S,VOLU,,1VATT,1VSEL,S,VOLU,,2,11,1VATT,2VSEL,S,VOLU,,12VATT,3VSEL,S,MAT,,1,2,1ASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,1MSHAPE,0,3DVMESH,ALLVSEL,S,MAT,,3ASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,0MSHAPE,1,3DVMESH,ALLALLSEL,ALLFINISH/SOLUESEL,S,MAT,,1BFE,ALL,JS,1,,,-1e9ASEL,S,EXTDA,ALL,AZ,0ALLSEL,ALLANTYPE,0NROPT,AUTO,,EQSLV,SPAR,,0,PRECISION,0MSAVE,0PIVCHECK,1/STATUS,SOLUSOLVEFINISH/POST1! elements/VSCALE,1,1,0!!*PLVECT,B, , , ,VECT,ELEM,ON,0ESEL,U,MAT,,3/REPLOT[/color][/size][/b][/align][b][color=#0000ff][/color][/b][align=left][code]/BATCH,LIST /TITLE, Test for EDGE-Formulation with SOLID117!! Parametersl=5e-6 ! lengthh=1e-6 ! heightw=5e-6 ! widtha=3e-6 ! 1st addition length of magnetic coreb=5e-6 ! 2nd addition length of magnetic core! *** Create Model!/PREP7 ! Enter ANSYS preprocessor to define problem!ET,1,117 ! Element type #1 is a magnetic edge element, 117.! (We use only one in this example)!MP,MURX,1,1 ! Define relative permeability of material #1.! Material #1 is the conductor made from copperMP,RSVX,1,17.2e-9 ! Define electric resistivity of material #1.!MP,MURX,2,500 ! Define relative permeability of material #2.! Material #2 is the magnetic core made from NiFe!MP,MURX,3,1 ! Define relative permeability of material #3.! Material #3 is the air ambient!! Define rectangular block of conductor volume! regionBLOCK,-w,w,-h,h,-l,l !!! Define rectangular block of upper magnetic core! volume regionBLOCK,-w-a,w+a,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h+a,h+2*a,-l,lBLOCK,-w-a,-w-a-b,h+a,h+2*a,-l,lBLOCK,w+a,w+a+b,h,h+a,-l,lBLOCK,-w-a,-w-a-b,h,h+a,-l,l!! Define rectangular block of lower magnetic core ! volume region BLOCK,-w-a,w+a,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-(h+a),-(h+2*a),-l,lBLOCK,-w-a,-w-a-b,-(h+a),-(h+2*a),-l,lBLOCK,w+a,w+a+b,-h,-(h+a),-l,lBLOCK,-w-a,-w-a-b,-h,-(h+a),-l,l!! Define rectangular block of air ambientBLOCK,-22e-6,22e-6,-15e-6,15e-6,-15e-6,15e-6! Overlap volumesVOVLAP,ALLNUMCMP,VOLU! Assign attributes to the volumesVSEL,S,VOLU,,1VATT,1 ! conductorVSEL,S,VOLU,,2,11,1 ! magnetic coreVATT,2VSEL,S,VOLU,,12 ! air ambientVATT,3! Mesh volumesVSEL,S,MAT,,1,2,1 ! Conductor and magnetic core with hexaelements ASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,1 ! MAPPED VOLUME MESHMSHAPE,0,3D ! USING HEXVMESH,ALLVSEL,S,MAT,,3 ! Air ambientASLV,SLSLA,SLESIZE,ALL,3e-6MSHKEY,0 ! FREE VOLUME MESHMSHAPE,1,3D ! USING TETVMESH,ALLALLSEL,ALLFINISH/SOLU!*** Apply current density on conductor ***ESEL,S,MAT,,1 ! Select coil elementBFE,ALL,JS,1,,,-1e9 ! Apply current density!*** Flux parallel boundary condition at all extern area of air ambient *** ASEL,S,EXTDA,ALL,AZ,0ALLSEL,ALL! Solution parametersANTYPE,0NROPT,AUTO,,EQSLV,SPAR,,0,PRECISION,0MSAVE,0PIVCHECK,1/STATUS,SOLUSOLVE/POST1!*** Vectorplot of magnetic flux (BSUM) for magnetic core's and conductor'selements ***/VSCALE,1,1,0!!*PLVECT,B, , , ,VECT,ELEM,ON,0ESEL,U,MAT,,3/REPLOTFINISH! /EXIT,MODEL[/code][/align][align=center][size=4][color=blue][b]===错因告诉你了,稍微改改就可以得到正确的解,来改着玩玩吧,奖分哦(+1技术分,+50贡献分)==[/b][/color][/size][/align]3. 帮助感应加热例子induction heating of a solid cylinder billetbatch,list/filenam, induc/config,nres,100000 !将载荷步最大设置为100000/prep7shpp,off/title, heating of a solid cylinder billet/com,et,1,13,,,1 ! PLANE13, axisymmetric, AZ dofet,2,13,,,1et,3,151,,,1,1,1 ! SURF151, thermal, radiationr,3,0 ! Real constant set for SURF151row=.015 ! outer radius of workpieceric=.0175 ! inner radius of coilroc=.0200 ! outer radius of coilro=.05 ! outer radius of modelt=.001 ! model thicknessfreq=150000 ! frequency (Hz.)pi=4*atan(1) ! picond=.392e7 ! maximum conductivitymuzero=4e-7*pi ! free-space permeabilitymur=200 ! maximum relative permeabilityskind=sqrt(1/(pi*freq*cond*muzero*mur)) ! skin depthftime=3 ! final timetinc=.05 ! time increment for harmonic analysistime=0 ! initialize timedelt=.01 ! maximum delta time stepemunit,mks ! set magnetic unitsmp,murx,1,1 ! air relative permeabilitymp,murx,3,1 ! coil relative permeabilitymptemp,1,25.5,160,291.5,477.6,635,698 ! temps for relative permeabilitymptemp,7,709,720.3,742,761,1000mpdata,murx,2,1,200,190,182,161,135,104 ! steel relative permeability mpdata,murx,2,7,84,35,17,1,1mptempmptemp,1,0,125,250,375,500,625 ! temps for resistivity mptemp,7,750,875,1000mpdata,rsvx,2,1,.184e-6,.272e-6,.384e-6,.512e-6,.656e-6,.824e-6 mpdata,rsvx,2,7,1.032e-6,1.152e-6,1.2e-6 ! steel resistivityrectng,0,row,0,t ! billetrectng,row,ric,0,t ! air-gaprectng,ric,roc,0,t ! coilrectng,roc,ro,0,t ! outer airaglue,allnumcmp,area !对面重新编号ksel,s,loc,x,row ! select keypoints at outer radius of workpiece kesize,all,skind/2 ! set meshing size to 1/2 skin depth(为什么是半个集肤深度)ksel,s,loc,x,0 ! select keypoints at centerkesize,all,40*skind ! set meshing sizelsel,s,loc,y,t/2 ! select vertical lineslesize,all,,,1 ! set 1 division through thicknesslsel,allasel,s,area,,1aatt,2,1,1 ! set attributes for billet regionasel,s,area,,3aatt,3,1,2 ! set attributes for coil regionasel,s,area,,2,4,2aatt,1,1,2 ! set attributes for air regionasel,allmshape,0,2dmshk,1amesh,1 ! mesh billet arealsel,s,loc,y,0lsel,a,loc,y,t !also selectlsel,u,loc,x,row/2lesize,all,.001lsel,allamesh,all ! mesh remaining areasn ! create space node for SURF151*get,nmax,node,,num,maxlsel,s,loc,x,rowtype,3real,3 ! REAL, NSET Sets the element real constant set attribute pointer.mat,2lmesh,all ! mesh billet outer radius with SURF151*get,emax,elem,,num,maxemodif,emax,3,nmax ! modify element to add space node for radiation et,3,0 ! reset type 3 to null elementnsel,s,loc,xd,all,az,0 ! apply flux-normal b.c. az向量磁位能nsel,allesel,s,mat,,3bfe,all,js,,,,15e6 ! apply current density to coil施加体力载荷esel,allfinish/soluantyp,harmharfrq,150000physics,write,emag ! write emag physics filefinish/prep7lsclear,all ! clear all b.c.'s and optionset,1,55,,,1 ! PLANE55 thermal element, axisymmetricet,2,0 ! null element type for coil and air region et,3,151,,,1,1,1 ! SURF151 element for radiationkeyopt,3,9,1r,3,1,5.67e-8 ! form factor, Stefan-Boltzmann constant mptempmptemp,1,0,730,930,1000 ! temps for conductivitympdata,kxx,2,1,60.64,29.5,28,28mptemp ! temps for enthalpymptemp,1,0,27,127,327,527,727mptemp,7,765,765.001,927mpdata,enth,2,1,0,91609056,453285756,1.2748e9,2.2519e9,3.3396e9 mpdata,enth,2,7,3.548547e9,3.548556e9,4.3520e9mp,emis,2,.68 ! emissivityfinish/soluantype,transtoffst,273tunif,100 ! initial uniform temperatured,nmax,temp,25 ! ambient temperaturecnvtol,heat,1 ! convergence tolerancekbc,1 ! step loadstrnopt,fullautos,on ! auto time-steppingdeltim,1e-5,1e-6,delt,on ! time step controloutres,basic,all ! save all load step information physics,write,thermal ! write thermal physics filefinish*do,i,1,ftime/tinc ! solution *do looptime=time+tinc ! increment timephysics,read,emag ! read emag physics file/solu*if,i,eq,1,thentunif,100 ! initial temperature*elseldread,temp,last,,,,,rth ! read thermal analysis temperatures*endifsolve ! solve harmonic analysisfinishphysics,read,thermal ! read thermal physics file/assign,esav,therm,esav ! redirect files for use in thermal restart/assign,emat,therm,emat/solu*if,i,gt,1,thenantype,trans,rest ! thermal restart*endiftime,time ! time at end of thermal runesel,s,mat,,2 ! select billet regionldread,hgen,,,,2,,rmg ! apply coupled joule heating load from emagesel,allsolvefinish/assign,esav ! reassign files to default/assign,emat*enddo ! end of solution loopingfinishsave ! save database/post26 ! time-history postprocessor/shownsol,2,1,temp,,tempcl ! store temperature at billet centerline nsol,3,2,temp,,tempsurf ! store temperature at billet outer diameterplvar,2,3 ! plot temperature rise over time prvar,2,3 ! print temperature rise over time finishn 定义节点。

八天学会Ansys命令流为方便大家的交流和学习,特推出"跟我学命令流"课程本课程分为三部分:前处理,加载求解,后处理每部分的学习时间:10天,共计30天每天学习大约10个命令希望本课程对大家能有所帮助第一天目标:熟悉ANSYS基本关键字的含义k --> Keypoints 关键点l --> Lines 线a --> Area 面v --> Volumes 体e --> Elements 单元n --> Nodes 节点cm --> component 组元et --> element type 单元类型mp --> material property 材料属性r --> real constant 实常数d --> DOF constraint 约束f --> Force Load 集中力sf --> Surface load on nodes 表面载荷bf --> Body Force on Nodes 体载荷ic --> Initial Conditions 初始条件第二天目标:了解命令流的整体结构,掌握每个模块的标识!文件说明段/BATCH/TITILE,test analysis !定义工作标题/FILENAME,test !定义工作文件名/PREP7 !进入前处理模块标识!定义单元,材料属性,实常数段ET,1,SHELL63 !指定单元类型ET,2,SOLID45 !指定体单元MP,EX,1,2E8 !指定弹性模量MP,PRXY,1,0.3 !输入泊松比MP,DENS,1,7.8E3 !输入材料密度R,1,0.001 !指定壳单元实常数-厚度......!建立模型K,1,0,0,, !定义关键点K,2,50,0,,K,3,50,10,,K,4,10,10,,K,5,10,50,,K,6,0,50,,A,1,2,3,4,5,6, !由关键点生成面......!划分网格ESIZE,1,0,AMESH,1......FINISH !前处理结束标识/SOLU !进入求解模块标识!施加约束和载荷DL,5,,ALLSFL,3,PRES,1000SFL,2,PRES,1000......SOLVE !求解标识FINISH !求解模块结束标识/POST1 !进入通用后处理器标识....../POST26 !进入时间历程后处理器……/EXIT,SAVE !退出并存盘以下是日志文件中常出现的一些命令的标识说明,希望能给大家在整理LOG文件时有所帮助/ANGLE !指定绕轴旋转视图/DIST !说明对视图进行缩放/DEVICE !设置图例的显示,如:风格,字体等/REPLOT !重新显示当前图例/RESET !恢复缺省的图形设置/VIEW !设置观察方向/ZOOM !对图形显示窗口的某一区域进行缩放第三天生成关键点和线部分1.生成关键点K,关键点编号,X坐标,Y坐标,Z坐标例:K,1,0,0,02.在激活坐标系生成直线LSTR,关键点P1,关键点P2例LSTR,1,23.在两个关键点之间连线L,关键点P1,关键点P2例L,1,2注:此命令会随当前的激活坐标系不同而生成直线或弧线4.由三个关键点生成弧线LARC,关键点P1,关键点P2,关键点PC,半径RAD例LARC,1,3,2,0.05注:关键点PC是用来控制弧线的凹向5.通过圆心半径生成圆弧CIRCLE,关键点圆心,半径RAD,,,,圆弧段数NSEG例:CIRCLE,1,0.05,,,,46.通过关键点生成样条线BSPLIN,关键点P1,关键点P2,关键点P3,关键点P4,关键点P5,关键点P6 例:BSPLIN,1,2,3,4,5,67.生成倒角线LFILLT,线NL1,线NL2,倒角半径RAD例LFILLT,1,2,0.0058.通过关键点生成面A,关键点P1,关键点P2,关键点P3,关键点P4,关键点P5,关键点P6,P7,P8...例:A,1,2,3,49.通过线生成面AL,线L1,线L2,线L3,线L4,线L5,线L6,线L7,线L8,线L9,线L10例:AL,5,6,7,810.通过线的滑移生成面ASKIN,线NL1,线NL2,线NL3,线NL4,线NL5,线NL6,线NL7,线NL8,线NL9例:ASKIN,1,4,5,6,7,8注:线1为滑移的导向线第四天目标:掌握常用的实体-面的生成生成矩形面1.通过矩形角上定位点生成面BLC4,定位点X方向坐标XCORNER,定位点Y方向坐标YCORNER,矩形宽度WIDTH,矩形高度HEIGHT,矩形深度DEPTH例:BLC4,0,0,5,3,02.通过矩形中心定位点生成面BLC5,定位点X方向坐标XCENTER,定位点Y方向坐标YCENTER,矩形宽度WIDTH,矩形高度HEIGHT,矩形深度DEPTH注:与上条命令的不同就在于矩形的定位点不一样例:BLC5,2.5,1.5,5,3,03.通过在工作平面定义矩形X.Y坐标生成面RECTNG,矩形左边界X坐标X1,矩形右边界X坐标X2,矩形下边界Y坐标Y1,矩形上边界Y坐标Y2例:RECTNG,0,5,0,3生成圆面4.通过中心定位点生成实心圆面CYL4,定位点X方向坐标XCENTER,定位点Y方向坐标YCENTER,圆面的内半径RAD1,内圆面旋转角度THETA1,圆面的外半径RAD2,外圆面旋转角度THETA2,圆面的深度DEPTH注:如要实心的圆面则不用RAD2,THETA2,DEPTH例:CYL4,0,0,5,3605.生成扇形圆面命令介绍如上例1实心扇形:CYL4,0,0,5,60例2扇形圆环:CYL4,0,0,5,60,10,60例3整的圆环:CYL4,0,0,5,360,10,360注:同时可通过定义圆面的深度以生成柱体6.通过在工作平面定义起始点生成圆面CYL5,开始点X坐标XEDGE1,开始点Y坐标YEDGE1,结束点X坐标XEDGE2,结束点Y坐标YEDGE2,圆面深度DEPTH例:CYL5,0,0,2,2,7.通过在工作平面定义内外半径和起始角度来生成圆面PCIRC,内半径RAD1,外半径RAD2,起始角度THETA1,结束角度THETA2例LCIRC,2,5,30,1808.生成面与面的倒角AFILLT,面1的编号NA1,面2的编号NA2,倒角半径RAD例:AFILLT,2,5,2下一讲:多边形面的生成第五天目标:掌握多边形面和体的生成1.生成多边形面命令:RPR4,多边形的边数NSIDES,中心定位点X坐标XCENTER,中心定位点Y坐标YCENTER,中心定位点距各边顶点的距离RADIUS,多边形旋转角度THETA例:RPR4,4,0,0,0.15,30注:这条命令可通过定义不同的NSIDES生成三边形,四边形,...,八边形2.生成多边形体命令:RPR4,多边形的边数NSIDES,中心定位点X坐标XCENTER,中心定位点Y坐标YCENTER,中心定位点距各边顶点的距离RADIUS,多边形旋转角度THETA,多边形的深度DEPTH例:RPR4,4,0,0,0.15,30,0.1注:多边形体和面命令唯一的不同就在于深度DEPTH的定义到此,关键点,线,面的生成讲解已结束,下一讲:体的生成第六天目标:掌握体的生成命令1.通过关键点生成体命令:V,关键点P1,关键点P2, P3, P4, P5, P6, P7, P8例:V,4,5,6,7,15,24,252.通过面生成体命令:VA,面A1,面A2, A3, A4, A5, A6, A7, A8, A9, A10例:VA,3,4,5,8,103.通过长方形角上定位点生成体命令:BLC4该命令前面在讲生成面的时候已作介绍,唯一的不同在于深度DEPTH的定义.4.通过长方形中心定位点生成面命令:BLC55.通过定义长方体起始位置生成体命令:BLOCK,开始点X坐标X1,结束点X坐标X2, Y1, Y2, Z1, Z2例:BLOCK,2,5,0,2,1,36.生成圆柱体基本命令通生成圆形面,不同在于DEPTH的定义基本命令:CYL4基本命令:CYL5基本命令:CYLIND7.生成棱柱基本命令通生成多边形,不同在于DEPTH的定义基本命令:RPR48.通过球心半径生成球体命令:SPH4,球心X坐标XCENTER,球心Y坐标YCENTER,半径RAD1,半径RAD2例:SPH4,1,1,2,59.通过直径上起始点坐标生成球体命令:SPH5,起点X坐标XEDGE1,起点Y坐标YEDGE1,结束点X坐标XEDGE2,结束点Y坐标YEDGE2例:SPH5,2,5,7,610.在工作平面起点通过半径和转动角度生成球体命令:SPHERE,半径RAD1,半径RAD2,转动角度THETA1,转动角度THETA2例:SPHERE,2,5,0,6011.生成圆锥体命令:CONE,底面半径RBOT,顶面半径RTOP,底面高Z1,顶面高Z2,转动角度THETA1,转动角度THETA2例:CONE,10,20,0,50,0,180下一讲:布尔操作第七天目标:掌握常用的布尔操作命令1.沿法向延伸面生成体命令:VOFFST,面的编号NAREA,面拉伸的长度DIST,关键点增量KINC例:VOFFST,1,2,,2.通过坐标的增量延伸面生成体命令:VEXT,面1的编号NA1,面2的编号NA2,增量NINC,X方向的增量DX,Y方向的增量DY,Z 方向的增量DZ, RX, RY, RZ例:VEXT,1,5,1,1,2,2,3.面绕轴旋转生成体命令:VROTAT,面1的编号NA1,面2的编号NA2,NA3, NA4, NA5, NA6,定位轴关键点1编号PAX1,定位轴关键点2编号PAX2,旋转角度ARC,生成体的段数NSEG例:VROTAT,1,2,,,,,4,5,360,44.沿线延伸面生成体命令:VDRAG,面1的编号NA1,面2的编号NA2, NA3, NA4, NA5, NA6,导引线1的编号NLP1,导引线2的编号NLP2, NLP3, NLP4, NLP5, NLP6例:VDRAG,2,3,,,,,8,5.线绕轴旋转生成面命令:AROTAT,线1的编号NL1, NL2, NL3, NL4, NL5, NL6,定位轴关键点1的编号PAX1,定位轴关键点2的编号PAX2,旋转角度ARC,生成面的段数NSEG例:AROTAT,3,4,,,,,6,8,360,46.沿线延伸线生成面命令:ADRAG,线1的编号NL1,NL2, NL3, NL4, NL5, NL6,导引线1的编号NLP1, NLP2, NLP3, NLP4, NLP5, NLP6例:ADRAG,3,,,,,,87.同理可以延伸关键点,相应的命令如下:LROTAT, NK1, NK2, NK3, NK4, NK5, NK6, PAX1, PAX2, ARC, NSEGLDRAG, NK1, NK2, NK3, NK4, NK5, NK6, NL1, NL2, NL3, NL4, NL5, NL6各选项的含义雷同于上.8.延伸一条线命令LEXTND,线的编号NL1,定位关键点编号NK1,延伸的距离DIST,原有线是否保留控制项KEEP例LEXTND,5,2,1.5,09.布尔操作:加命令LCOMB,线编号NL1,线编号NL2,是否修改控制项KEEP例LCOMB,2,5注:对面和体的相应为:VADD,AADD.选项的含义都类似10.布尔操作:粘接和搭接搭接的核心关键字为:OVLAP,随实体的不同略有不同,如:对体为VOVLAP对面为AOVLAP对线为LOVLAP粘接的核心关键字为:GLUE,随实体的不同略有不同,如:对体为VGLUE对面为AGLUE对线为LGLUE但其他的选项的含义是类似的,这里就不再累述.下一讲:移动,复制,映射,删除...第八天目标:掌握体素的移动,复制,删除,映射一.移动关键点命令:KMODIF,关键点编号NPT,移动后的坐标X,移动后的坐标Y,移动后的坐标Z例:KMODIF,5,0,0,2二.移动复制关键点命令:KGEN,复制次数选项ITIME,起始关键点编号NP1,结束关键点编号NP2,增量NINC,偏移DX,偏移DY,偏移DZ,关键点编号增量KINC,生成节点单元控制项NOELEM,原关键点是否被修改选项IMOVE例:KGEN,2,1,10,1,2,2,2,,,,注:IMOVE选项说明,设置为0时,不修改原关键点,即为复制,设置为1时,修改原关键点,即为移动,从而通过控制IMOVE选项实现移动或复制.三.移动复制线命LGEN,ITIME,NL1,NL2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上四.移动复制面命:AGEN,ITIME,NA1,NA2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上五.移动复制体命令:VGEN,ITIME,NV1,NV2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上六.修改面的法向方向命令:ANORM,面的编号ANUM,单元的法向方向是否修改选项NOEFLIP例:ANORM,2七.体素的删除基本的命令为:*DELE组合不同的关键字形成不同的命令如:KDELE,LDELE,ADELE,VDELE基本的命令格式为:*DELE,起始体素编号N*1,结束体素编号N*2,增量NINC,是否删除体素下层的元素选项KSWP如LDELE,2,5,1,1八.体素的映射基本的命令为:*SYMM组合不同的关键字形成不同的命令如:KSYMM,LSYMM,ARSYM,VSYMM基本的命令格式为:*SYMM,映射轴选项NCOMP,起始体素编号N*1,结束体素编号N*2,增量NINC,关键点编号增量KINC,NOELEM, IMOVE如:VSYMM,X,1,10,1,,,,。

七目标:掌握常用的布尔操作命令1.沿法向延伸面生成体命令:VOFFST,面的编号NAREA,面拉伸的长度DIST,关键点增量KINC 例:VOFFST,1,2,,2.通过坐标的增量延伸面生成体命令:VEXT,面1的编号NA1,面2的编号NA2,增量NINC,X方向的增量DX,Y方向的增量DY,Z方向的增量DZ, RX, RY, RZ例:VEXT,1,5,1,1,2,2,3.面绕轴旋转生成体命令:VROTAT,面1的编号NA1,面2的编号NA2,NA3, NA4, NA5, NA6,定位轴关键点1编号PAX1,定位轴关键点2编号PAX2,旋转角度ARC,生成体的段数NSEG例:VROTAT,1,2,,,,,4,5,360,44.沿线延伸面生成体命令:VDRAG,面1的编号NA1,面2的编号NA2, NA3, NA4, NA5, NA6,导引线1的编号NLP1,导引线2的编号NLP2, NLP3, NLP4, NLP5, NLP6例:VDRAG,2,3,,,,,8,5.线绕轴旋转生成面命令:AROTAT,线1的编号NL1, NL2, NL3, NL4, NL5, NL6,定位轴关键点1的编号PAX1,定位轴关键点2的编号PAX2,旋转角度ARC,生成面的段数NSEG例:AROTAT,3,4,,,,,6,8,360,46.沿线延伸线生成面命令:ADRAG,线1的编号NL1,NL2, NL3, NL4, NL5, NL6,导引线1的编号NLP1, NLP2, NLP3, NLP4, NLP5, NLP6例:ADRAG,3,,,,,,87.同理可以延伸关键点,相应的命令如下:LROTAT, NK1, NK2, NK3, NK4, NK5, NK6, PAX1, PAX2, ARC, NSEG LDRAG, NK1, NK2, NK3, NK4, NK5, NK6, NL1, NL2, NL3, NL4, NL5, NL6各选项的含义雷同于上.8.延伸一条线命令LEXTND,线的编号NL1,定位关键点编号NK1,延伸的距离DIST,原有线是否保留控制项KEEP例LEXTND,5,2,1.5,09.布尔操作:加命令LCOMB,线编号NL1,线编号NL2,是否修改控制项KEEP 例LCOMB,2,5注:对面和体的相应为:VADD,AADD.选项的含义都类似10.布尔操作:粘接和搭接搭接的核心关键字为:OVLAP,随实体的不同略有不同,如:对体为VOVLAP对面为AOVLAP对线为LOVLAP粘接的核心关键字为:GLUE,随实体的不同略有不同,如:对体为VGLUE对面为AGLUE对线为LGLUE但其他的选项的含义是类似的,这里就不再累述.下一讲:移动,复制,映射,删除...八目标:掌握体素的移动,复制,删除,映射一.移动关键点命令:KMODIF,关键点编号NPT,移动后的坐标X,移动后的坐标Y,移动后的坐标Z例:KMODIF,5,0,0,2二.移动复制关键点命令:KGEN,复制次数选项ITIME,起始关键点编号NP1,结束关键点编号NP2,增量NINC,偏移DX,偏移DY,偏移DZ,关键点编号增量KINC,生成节点单元控制项NOELEM,原关键点是否被修改选项IMOVE 例:KGEN,2,1,10,1,2,2,2,,,,注:IMOVE选项说明,设置为0时,不修改原关键点,即为复制,设置为1时,修改原关键点,即为移动,从而通过控制IMOVE选项实现移动或复制.三.移动复制线命LGEN,ITIME,NL1,NL2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上四.移动复制面命:AGEN,ITIME,NA1,NA2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE各选项的含义同上五.移动复制体命令:VGEN,ITIME,NV1,NV2,NINC,DX,DY,DZ,KINC,NOELEM,IMOVE 各选项的含义同上六.修改面的法向方向命令:ANORM,面的编号ANUM,单元的法向方向是否修改选项NOEFLIP例:ANORM,2七.体素的删除基本的命令为:*DELE组合不同的关键字形成不同的命令如:KDELE,LDELE,ADELE,VDELE基本的命令格式为:*DELE,起始体素编号N*1,结束体素编号N*2,增量NINC,是否删除体素下层的元素选项KSWP如LDELE,2,5,1,1八.体素的映射基本的命令为:*SYMM组合不同的关键字形成不同的命令如:KSYMM,LSYMM,ARSYM,VSYMM基本的命令格式为:*SYMM,映射轴选项NCOMP,起始体素编号N*1,结束体素编号N*2,增量NINC,关键点编号增量KINC,NOELEM, IMOVE如:VSYMM,X,1,10,1,,,,。