流量计计算书

- 格式:pdf

- 大小:92.02 KB

- 文档页数:10

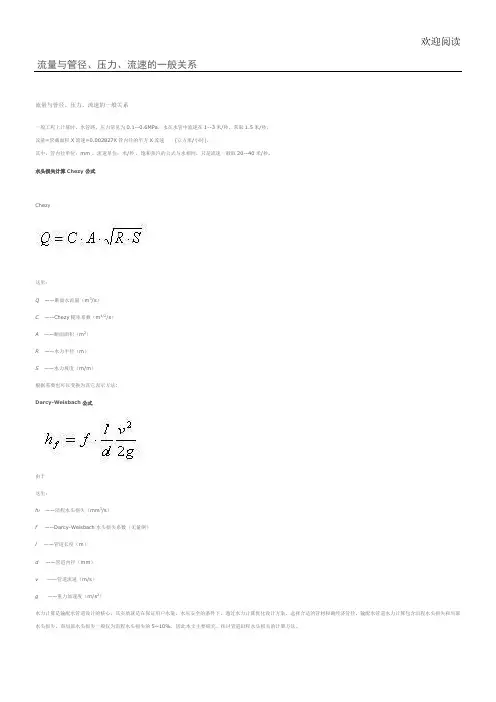

欢迎阅读流量与管径、压力、流速的一般关系流量与管径、压力、流速的一般关系一般工程上计算时,水管路,压力常见为0.1--0.6MPa,水在水管中流速在1--3米/秒,常取1.5米/秒。

流量=管截面积X流速=0.002827X管内径的平方X流速 (立方米/小时)。

其中,管内径单位:mm ,流速单位:米/秒,饱和蒸汽的公式与水相同,只是流速一般取20--40米/秒。

水头损失计算Chezy 公式Chezy这里:Q ——C ——ChezyA ——R ——S ——由于这里:h f——沿程水头损失(mm3/s)f ——Darcy-Weisbach水头损失系数(无量纲)l ——管道长度(m)d ——管道内径(mm)v ——管道流速(m/s)g ——重力加速度(m/s2)水力计算是输配水管道设计的核心,其实质就是在保证用户水量、水压安全的条件下,通过水力计算优化设计方案,选择合适的管材和确经济管径。

输配水管道水力计算包含沿程水头损失和局部水头损失,而局部水头损失一般仅为沿程水头损失的5~10%,因此本文主要研究、探讨管道沿程水头损失的计算方法。

管网建模之基本公式篇一、管渠沿程水头损失谢才公式h f——沿程水头损失(mm3/s)λ——Darcy-Weisbach水头损失系数(无量纲)l ——管道长度(m)d ——管道内径(mm)v ——管道流速(m/s)g ——重力加速度(m/s2)C、λ与水流流态有关,一般采用经验公式或半经验公式计算。

常用:1.舍维列夫公式(适用:旧铸铁管和旧钢管满管紊流,水温100C0(给水管道计算))2.海曾-威廉公式适用:较光滑圆管满流紊流(给水管道)34.适用:明渠流、非满流排水管道5.曼宁公式式中hm——局部水头损失,m;ξ——局部阻力系数。

给水排水管网中局部水头损失一般不超过沿程水头损失的5%,常忽略局部水头损失的影响,不会造成大的计算误差。

沿程水头损失计算公式的比较与选用∙∙∙∙∙∙巴甫洛夫斯基公式适用范围广,计算精度也较高,特别是对于较粗糙的管道,管道水流状态仍保持较准确的计算结果,最佳适用范围为1.0≤e≤5.0mm;∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙1.1 管道常用沿程水头损失计算公式及适用条件管道沿程水头损失是水流摩阻做功消耗的能量,不同的水流流态,遵循不同的规律,计算方法也不一样。

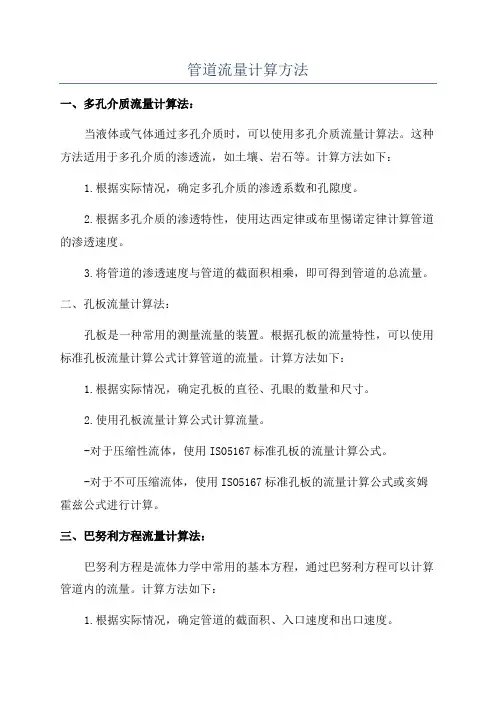

管道流量计算方法一、多孔介质流量计算法:当液体或气体通过多孔介质时,可以使用多孔介质流量计算法。

这种方法适用于多孔介质的渗透流,如土壤、岩石等。

计算方法如下:1.根据实际情况,确定多孔介质的渗透系数和孔隙度。

2.根据多孔介质的渗透特性,使用达西定律或布里惕诺定律计算管道的渗透速度。

3.将管道的渗透速度与管道的截面积相乘,即可得到管道的总流量。

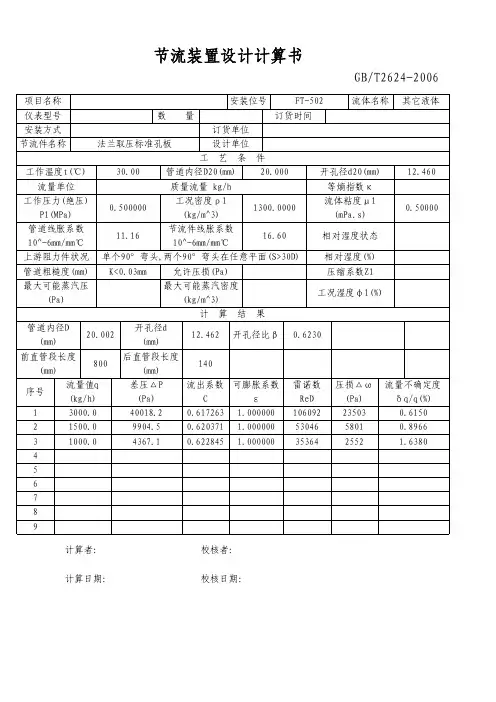

二、孔板流量计算法:孔板是一种常用的测量流量的装置。

根据孔板的流量特性,可以使用标准孔板流量计算公式计算管道的流量。

计算方法如下:1.根据实际情况,确定孔板的直径、孔眼的数量和尺寸。

2.使用孔板流量计算公式计算流量。

-对于压缩性流体,使用ISO5167标准孔板的流量计算公式。

-对于不可压缩流体,使用ISO5167标准孔板的流量计算公式或亥姆霍兹公式进行计算。

三、巴努利方程流量计算法:巴努利方程是流体力学中常用的基本方程,通过巴努利方程可以计算管道内的流量。

计算方法如下:1.根据实际情况,确定管道的截面积、入口速度和出口速度。

2.使用巴努利方程计算管道内的压力差。

3.根据压力差、管道的截面积和流体的密度,使用伯努利方程或卡门-科西格方程计算流量。

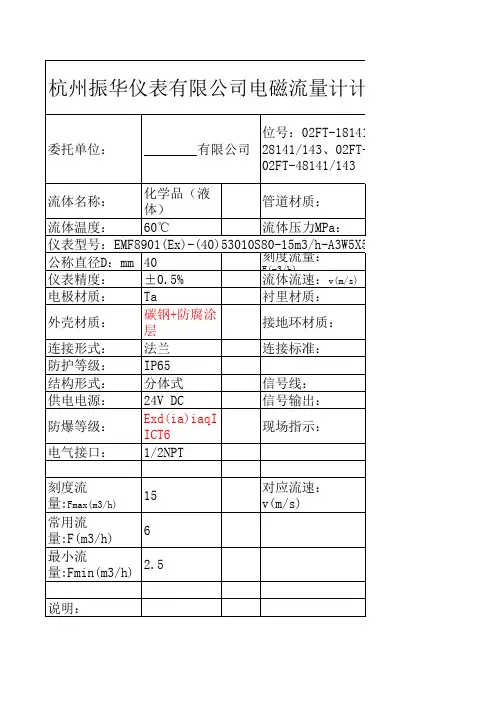

四、流量计测量法:流量计是常见的用于测量管道流量的装置。

根据流量计的原理和测量结果,可以计算管道的流量。

常见的流量计包括涡街流量计、电磁流量计、超声波流量计等。

1.根据实际情况,选择合适的流量计。

不同的流量计有不同的计算方法。

2.根据流量计的测量原理和测量结果,计算管道的流量。

需要注意的是,以上方法只是一些常见的管道流量计算方法,实际应用中可能还会涉及到其他因素和计算方法。

在进行管道流量计算时,需要根据实际情况选择合适的计算方法,并确保计算参数的准确性和一致性,以获得准确的流量计算结果。

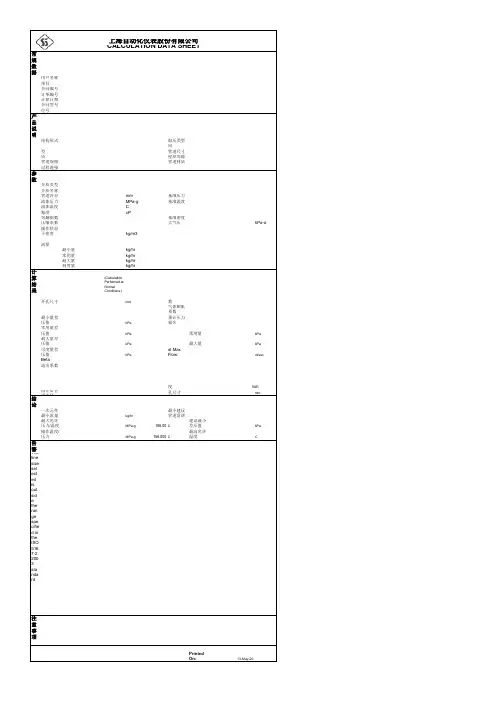

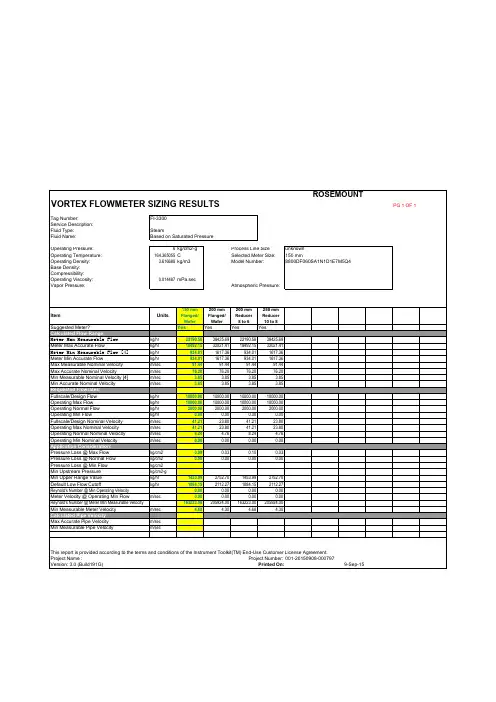

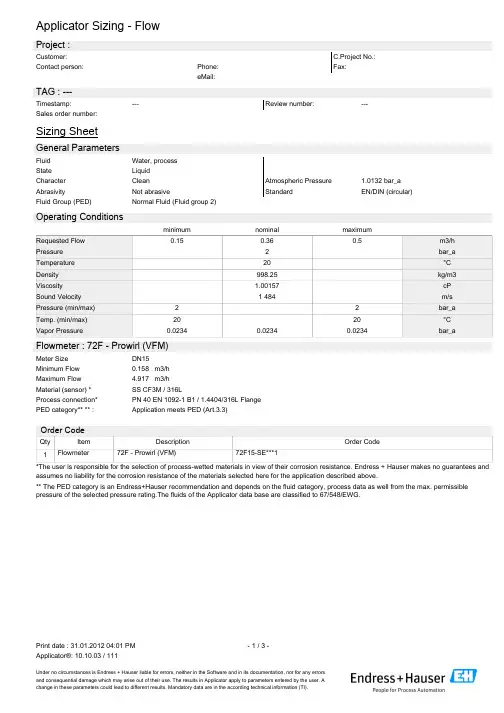

Sizing SheetGeneral ParametersFluid Water, processState LiquidCharacter Clean Atmospheric Pressure 1.0132 bar_aAbrasivity Not abrasive Standard EN/DIN (circular)Fluid Group (PED)Normal Fluid (Fluid group 2)Operating ConditionsFlowmeter : 72F - Prowirl (VFM)Meter Size DN15Minimum Flow0.158 m3/hMaximum Flow 4.917 m3/hMaterial (sensor) *SS CF3M / 316LProcess connection*PN 40 EN 1092-1 B1 / 1.4404/316L FlangePED category** ** :Application meets PED (Art.3.3)assumes no liability for the corrosion resistance of the materials selected here for the application described above.** The PED category is an Endress+Hauser recommendation and depends on the fluid category, process data as well from the max. permissible pressure of the selected pressure rating.The fluids of the Applicator data base are classified to 67/548/EWG.Sizing SheetSizing and Calculated Resultstechnical documentation.Attention for Flow! Device is used in non-ideal application conditions.Tri-size SheetGeneral ParametersFluid Water, processState LiquidCharacter Clean Atmospheric Pressure 1.0132 bar_aAbrasivity Not abrasive Standard EN/DIN (circular)Fluid Group (PED)Normal Fluid (Fluid group 2)Sizing and Calculated Resultsassumes no liability for the corrosion resistance of the materials selected here for the application described above.***For error calculation, the specified reference conditions for the calibration of the flowmeter according to ISO/IEC 17025 apply. Further information in technical documentation.。

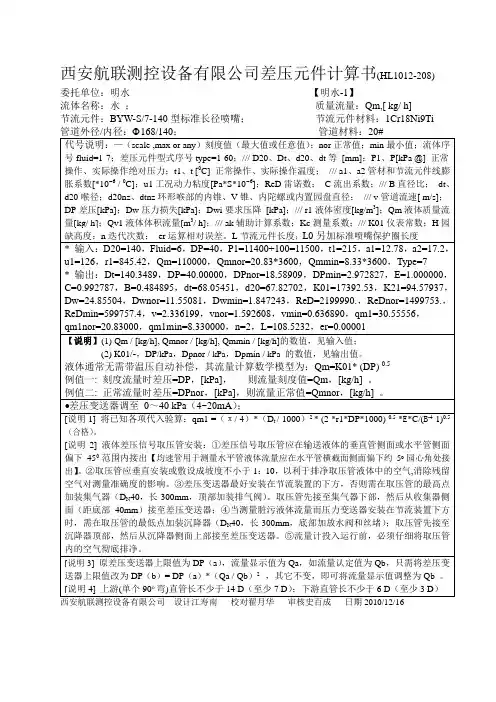

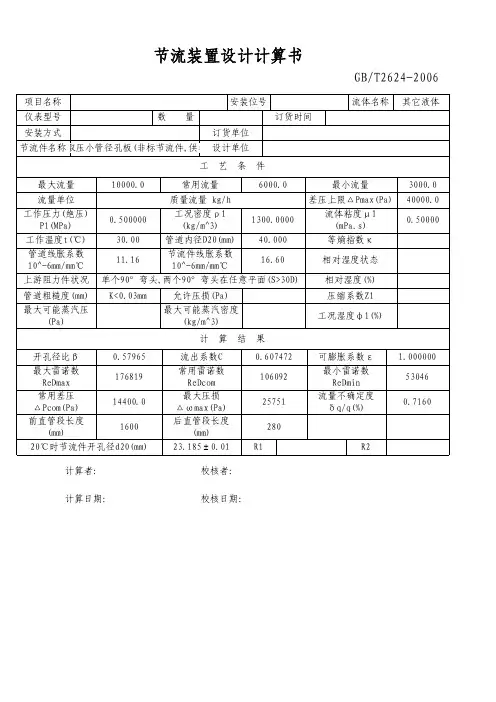

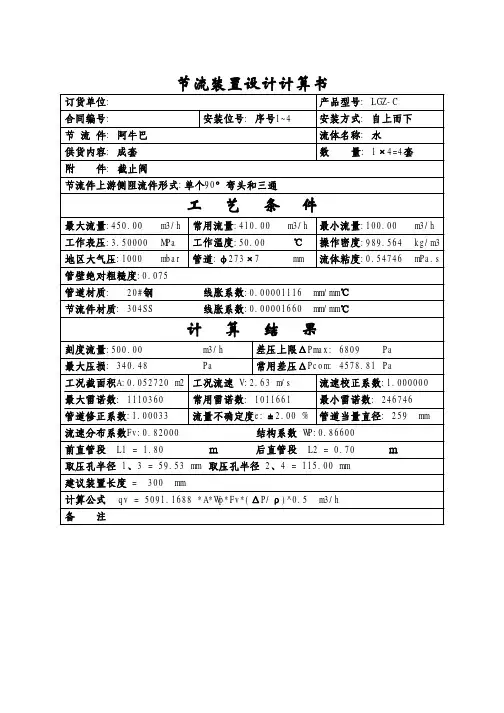

差压式流量计常用计算公式及计算实例差压式流量计维修中计算工作是仪表人不可缺少的, 在本文分享差压式流量计常用流量计算公式及计算实例,掌握这些干货技术,对用好差压式流量计有事半功倍效果。

流量计算公式1:差压式流量计的差压与流量关系的换算差压式流量计的差压与流量的平方成正比,或者说流量与差压的平方根成正比,用以下公式表示:流量仪表的刻度单位为流量百分数,差压的下限量程为0时,得以上公式中△P为任意差压;Q为任意流量;△P max为差压上限;Q max为流量上限;n为任意的流量百分数[计算实例1]某差压变送器的量程为0-40kPa,对应的流量为0-1603/h,输出信号为4-20mA,差压变送器输出电流为8mA时,流量应该是多少?差压又是多少?解:①根据流量计算公式计算差压式流量计的流量输出为8mA时,流量是80m3/h。

②已知差压变送器输出8mA时,流量是80m3/h,流量是满量程的50%,根据流量计算公式计算差压变送器差压值输出电流为8mA时,差压是10kPa。

流量计算公式2:标准状态和工作状态下的体积流量换算标准状态和工作状态的体积流量换算公式如下:公式中q v为工作状态下的体积流量,单位m3/h;q n为标准状态下的体积流量,单位m3/h;P为工作状态下的绝对压力,单位Pa;P n为标准状态下的绝对压力,单位Pa;T为工作状态下的热力学温度,单位K;T n为标准状态下的热力学温度,单位K;Z为工作状态下的气体压缩系数;Z n为标准状态下的气体压缩系数;[计算实例2]某空气流量计设计量程为0-2000m3/h(20℃,101.325kPa状态下),工作状态下的压力为0.5MPa,温度为60℃,求工作状态下的体积流量。

解:把数据代入公式计算工作状态下的体积流量本台流量计工作状态下的体积流量范围为0-460m3/h。

流量计算公式3:标准孔板改量程的计算在现场有时会遇到被测流量超过了孔板最大量程,或者流量太小仅能显示在最大量程的30%以下;可通过扩大或缩小差压量程来满足应急。

管道直管流量计计算公式管道直管流量计是一种常用的流量测量仪器,它可以用于测量液体、气体等在管道中的流量。

在工业生产中,流量的准确测量对于控制生产过程、保障产品质量至关重要。

因此,了解管道直管流量计的计算公式对于工程师和操作人员来说是非常重要的。

管道直管流量计的计算公式通常包括体积流量和质量流量两种计算方式。

下面将分别介绍这两种计算方式的公式及其应用。

一、体积流量计算公式。

体积流量是指单位时间内通过管道横截面的流体体积。

通常用单位时间内通过的标准体积来表示,单位通常为立方米/小时(m³/h)或立方英尺/小时(ft³/h)。

对于管道直管流量计来说,体积流量的计算公式为:Qv = A v。

其中,Qv为体积流量,单位为m³/h或ft³/h;A为管道横截面积,单位为平方米(m²)或平方英尺(ft²);v为流体在管道中的平均流速,单位为米/小时(m/h)或英尺/小时(ft/h)。

在实际应用中,通常会根据管道的形状和尺寸来计算管道横截面积A,然后通过流量计测得流体在管道中的平均流速v,就可以得到体积流量Qv的数值。

二、质量流量计算公式。

质量流量是指单位时间内通过管道横截面的流体质量。

通常用单位时间内通过的标准质量来表示,单位通常为千克/小时(kg/h)或磅/小时(lb/h)。

对于管道直管流量计来说,质量流量的计算公式为:Qm = A v ρ。

其中,Qm为质量流量,单位为kg/h或lb/h;A为管道横截面积,单位为m²或ft²;v为流体在管道中的平均流速,单位为m/h或ft/h;ρ为流体的密度,单位为千克/立方米(kg/m³)或磅/立方英尺(lb/ft³)。

在实际应用中,除了需要计算管道横截面积A和测得流体在管道中的平均流速v外,还需要测得流体的密度ρ,然后通过计算公式就可以得到质量流量Qm的数值。

在使用管道直管流量计进行流量测量时,需要注意以下几点:1. 确保管道直管流量计的安装位置正确,避免管道弯曲、收缩等对流体流动的影响;2. 定期对管道直管流量计进行校准,确保测量结果的准确性;3. 根据实际需要选择合适的管道直管流量计型号和规格,以满足流量测量的要求。

V锥流量计计算公式为:其中:K为仪表系数;Y为测量介质压缩系数;对于瓦斯气Y=0.998;ΔP为差压,单位pa;ρ为介质工况密度,单位kg/m3。

取0.96335 涡街流量计计算公式:一、孔板流量计1。

1 工作原理流体流经管道内的孔板,流速将在孔板处形成局部收缩因而流速增加,静压力降低,于是在孔板上、下游两侧产生静压力差.流体流量愈大,产生的压差愈大,通过压差来衡量流量的大小。

它是以流动连续性方程(质量守恒定律)和伯努利方程(能量守恒定律)为基础,在已知有关参数的条件下,根据流动连续性原理和伯努利方程可以推导出差压与流量之间的关系而求得流量。

其流量计算公式如下:上式中:ε——被测介质可膨胀性系数,对于液体ε=1;对气体等可压缩流体ε<1(0。

99192)Q工——流体的体积流量(单位:m3/min)d ——孔径(单位:m )△P——差压(单位:Pa)ρ1——工作状况下,节流件(前)上游处流体的密度,[㎏/m3];C —- 流出系数β-—直径比1.2 安装孔板流量计的安装要求:对直管段的要求一般是前10D后5D,因此在安装孔板流量计时一定要满足这个直管段距离要求,否则测量的流量误差大。

1。

3 测量误差分析1。

3.1 基本误差孔板在使用过程中,会由于煤气的侵蚀而产生变形,从而引起流量系数增大而产生测量误差;而且流量计工作时间越长,流体对节流件的冲刷越严重,也会引起流量系数增大而产生测量误差.1。

3。

2 附件误差孔板节流装置安装于现场严酷的工作场所,在长期运行后,无论管道或节流装置都会发生一些变化,如堵塞、结垢、磨损、腐蚀等等.检测件是依靠结构形状及尺寸保持信号的准确度,因此任何几何形状及尺寸的变化都会带来附加误差。

二、皮托管2。

1 技术参数L 型皮托管系数在0。

99~1。

01 之间;测量空气流速小于40m/s,测量水流速不超过25m/s .2.2 用途常用皮托管测量管道风速、炉窑烟道内的气流速度,经过换算来确定流量,也可测量管道内的水流速度。

欢迎阅读流量与管径、压力、流速的一般关系流量与管径、压力、流速的一般关系一般工程上计算时,水管路,压力常见为0.1--0.6MPa,水在水管中流速在1--3米/秒,常取1.5米/秒。

流量=管截面积X流速=0.002827X管内径的平方X流速 (立方米/小时)。

其中,管内径单位:mm ,流速单位:米/秒,饱和蒸汽的公式与水相同,只是流速一般取20--40米/秒。

水头损失计算Chezy 公式Chezy这里:Q ——C ——ChezyA ——R ——S ——由于这里:h f——沿程水头损失(mm3/s)f ——Darcy-Weisbach水头损失系数(无量纲)l ——管道长度(m)d ——管道内径(mm)v ——管道流速(m/s)g ——重力加速度(m/s2)水力计算是输配水管道设计的核心,其实质就是在保证用户水量、水压安全的条件下,通过水力计算优化设计方案,选择合适的管材和确经济管径。

输配水管道水力计算包含沿程水头损失和局部水头损失,而局部水头损失一般仅为沿程水头损失的5~10%,因此本文主要研究、探讨管道沿程水头损失的计算方法。

管网建模之基本公式篇一、管渠沿程水头损失谢才公式h f——沿程水头损失(mm3/s)λ——Darcy-Weisbach水头损失系数(无量纲)l ——管道长度(m)d ——管道内径(mm)v ——管道流速(m/s)g ——重力加速度(m/s2)C、λ与水流流态有关,一般采用经验公式或半经验公式计算。

常用:1.舍维列夫公式(适用:旧铸铁管和旧钢管满管紊流,水温100C0(给水管道计算))2.海曾-威廉公式适用:较光滑圆管满流紊流(给水管道)34.适用:明渠流、非满流排水管道5.曼宁公式式中hm——局部水头损失,m;ξ——局部阻力系数。

给水排水管网中局部水头损失一般不超过沿程水头损失的5%,常忽略局部水头损失的影响,不会造成大的计算误差。

沿程水头损失计算公式的比较与选用∙∙∙∙∙∙巴甫洛夫斯基公式适用范围广,计算精度也较高,特别是对于较粗糙的管道,管道水流状态仍保持较准确的计算结果,最佳适用范围为1.0≤e≤5.0mm;∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙1.1 管道常用沿程水头损失计算公式及适用条件管道沿程水头损失是水流摩阻做功消耗的能量,不同的水流流态,遵循不同的规律,计算方法也不一样。

GENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-600Tag No:FT401PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:24 inches (DN600)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:Gas Pipe I.D.:618.000mm Base Pressure:101.325kPa-a Pressure:15.000kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01700cPIsentropic Exponent: 1.100Base Density:1.1997kg/m3Compressibility at Flow: 1.0000Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.1309kg/m3Flow Rates:Minimum:2000.00Nm3/hr Normal:9000.00Nm3/hr Maximum:12000.00Nm3/hr Full Scale:15000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:380.441mm Pipe Reynolds Number (Normal):363485Gas Expansion Factor:0.9974DP at Min Flow:0.036kPa Permanent Pressure Loss DP at Normal Flow:0.720kPa at Normal Flow:0.44kPa DP at Max Flow:1.280kPa at Max Flow:0.78kPa URV (DP at Full Scale): 2.000kPaVelocity at Max Flow:11.79m/secBeta:0.6156Discharge Coefficient:0.6066Plate Thickness:Pipe ID (thermally corrected)618.000mm Bore Size (thermally corrected)380.453mm GUIDELINESPrimary Element Min Limit of Use 1691.15Nm3/hr Min Recommended Pipe Reynolds 39816.5Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:15.000kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-600Tag No:FT310PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:24 inches (DN600)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:618.000mm Base Pressure:101.325kPa-a Pressure:9.000kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01822cPIsentropic Exponent: 1.401Base Density:1.2925kg/m3Compressibility at Flow:0.9996Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.1468kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:7200.00Nm3/hr Maximum:11000.00Nm3/hr Full Scale:14000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:151.828mm Pipe Reynolds Number (Normal):292294Gas Expansion Factor:0.9987DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.406kPa at Normal Flow:0.23kPa DP at Max Flow:0.947kPa at Max Flow:0.54kPa URV (DP at Full Scale): 1.534kPaVelocity at Max Flow:11.48m/secBeta:0.6500Discharge Coefficient:0.6069Plate Thickness:Pipe ID (thermally corrected)618.000mm Bore Size (thermally corrected)401.700mm GUIDELINESPrimary Element Min Limit of Use 1799.99Nm3/hr Min Recommended Pipe Reynolds 44387.9Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:9.000kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 1799.9864 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-200Tag No:FT311~317PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:8 inches (DN200)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:207.000mm Base Pressure:101.325kPa-a Pressure:7.000kPa-g Base Temperature:0.00CTemperature at Flow:200.00C Absolute Viscosity:0.02582cPIsentropic Exponent: 1.391Base Density:1.2925kg/m3Compressibility at Flow: 1.0002Atmospheric Pressure:87.510kPa-aDensity at Flow:0.6954kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:1500.00Nm3/hr Maximum:2500.00Nm3/hr Full Scale:2500.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:58.679mm Pipe Reynolds Number (Normal):128025Gas Expansion Factor:0.9957DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow: 1.075kPa at Normal Flow:0.48kPa DP at Max Flow:2.987kPa at Max Flow:1.34kPa URV (DP at Full Scale):2.987kPaVelocity at Max Flow:38.35m/secBeta:0.7500Discharge Coefficient:0.6066Plate Thickness:Pipe ID (thermally corrected)207.449mm Bore Size (thermally corrected)155.728mm GUIDELINESPrimary Element Min Limit of Use 236.14Nm3/hr Min Recommended Pipe Reynolds 19873.3Max. Allow. Pressure @ Temp:4389.2kPa-g 200.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:7.000kPa-g200.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 236.136175 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-600Tag No:FT320PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:24 inches (DN600)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:618.000mm Base Pressure:101.325kPa-a Pressure:7.000kPa-g Base Temperature:0.00CTemperature at Flow:200.00C Absolute Viscosity:0.02582cPIsentropic Exponent: 1.391Base Density:1.2925kg/m3Compressibility at Flow: 1.0002Atmospheric Pressure:87.510kPa-aDensity at Flow:0.6954kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:6200.00Nm3/hr Maximum:8500.00Nm3/hr Full Scale:10000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:421.476mm Pipe Reynolds Number (Normal):177246Gas Expansion Factor:0.9987DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.384kPa at Normal Flow:0.20kPa DP at Max Flow:0.723kPa at Max Flow:0.39kPa URV (DP at Full Scale): 1.000kPaVelocity at Max Flow:14.63m/secBeta:0.6820Discharge Coefficient:0.6076Plate Thickness:Pipe ID (thermally corrected)619.342mm Bore Size (thermally corrected)422.759mm GUIDELINESPrimary Element Min Limit of Use 1716.00Nm3/hr Min Recommended Pipe Reynolds 49057.3Max. Allow. Pressure @ Temp:4389.2kPa-g 200.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:7.000kPa-g200.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 1716.003963 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-200Tag No:FT331~337PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:8 inches (DN200)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:207.000mm Base Pressure:101.325kPa-a Pressure:7.000kPa-g Base Temperature:0.00CTemperature at Flow:200.00C Absolute Viscosity:0.02582cPIsentropic Exponent: 1.391Base Density:1.2925kg/m3Compressibility at Flow: 1.0002Atmospheric Pressure:87.510kPa-aDensity at Flow:0.6954kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:1600.00Nm3/hr Maximum:2000.00Nm3/hr Full Scale:2000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:58.679mm Pipe Reynolds Number (Normal):136560Gas Expansion Factor:0.9951DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow: 1.226kPa at Normal Flow:0.55kPa DP at Max Flow:1.916kPa at Max Flow:0.86kPa URV (DP at Full Scale): 1.916kPaVelocity at Max Flow:30.68m/secBeta:0.7500Discharge Coefficient:0.6063Plate Thickness:Pipe ID (thermally corrected)207.449mm Bore Size (thermally corrected)155.728mm GUIDELINESPrimary Element Min Limit of Use 236.14Nm3/hr Min Recommended Pipe Reynolds 19873.3Max. Allow. Pressure @ Temp:4389.2kPa-g 200.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:7.000kPa-g200.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 236.136175 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-350Tag No:FT340PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:14 inches (DN350)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:369.000mm Base Pressure:101.325kPa-a Pressure:7.000kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01822cPIsentropic Exponent: 1.401Base Density:1.2925kg/m3Compressibility at Flow:0.9996Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.1231kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:3000.00Nm3/hr Maximum:4000.00Nm3/hr Full Scale:5000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:262.248mm Pipe Reynolds Number (Normal):203972Gas Expansion Factor:0.9987DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.360kPa at Normal Flow:0.18kPa DP at Max Flow:0.640kPa at Max Flow:0.32kPa URV (DP at Full Scale): 1.000kPaVelocity at Max Flow:11.96m/secBeta:0.7107Discharge Coefficient:0.6060Plate Thickness:Pipe ID (thermally corrected)369.000mm Bore Size (thermally corrected)262.246mm GUIDELINESPrimary Element Min Limit of Use 799.09Nm3/hr Min Recommended Pipe Reynolds 31684.1Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:7.000kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 799.08968 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-900Tag No:FT360PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:36 inches (DN900)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:908.000mm Base Pressure:101.325kPa-a Pressure:87.510kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01822cPIsentropic Exponent: 1.401Base Density:1.2925kg/m3Compressibility at Flow:0.9992Atmospheric Pressure:87.510kPa-aDensity at Flow: 2.0805kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:23000.00Nm3/hr Maximum:28000.00Nm3/hr Full Scale:36000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:535.448mm Pipe Reynolds Number (Normal):322007Gas Expansion Factor:0.9987DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.816kPa at Normal Flow:0.52kPa DP at Max Flow:1.210kPa at Max Flow:0.77kPa URV (DP at Full Scale): 2.000kPaVelocity at Max Flow:7.66m/secBeta:0.5897Discharge Coefficient:0.6066Plate Thickness:Pipe ID (thermally corrected)448.000mm Bore Size (thermally corrected)264.198mm GUIDELINESPrimary Element Min Limit of Use 1013.49Nm3/hr Min Recommended Pipe Reynolds 26486.8Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:87.510kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 1013.485941 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-150Tag No:FT411~417PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:6 inches (DN150)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:Gas Pipe I.D.:151.000mm Base Pressure:101.325kPa-a Pressure:15.000kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01700cPIsentropic Exponent: 1.100Base Density:1.1997kg/m3Compressibility at Flow: 1.0000Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.1309kg/m3Flow Rates:Minimum:Nm3/hr ←*See WarningsNormal:950.00Nm3/hr Maximum:1500.00Nm3/hr Full Scale:2000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:42.804mm Pipe Reynolds Number (Normal):157029Gas Expansion Factor:0.9962DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.816kPa at Normal Flow:0.36kPa DP at Max Flow:2.033kPa at Max Flow:0.91kPa URV (DP at Full Scale): 3.615kPaVelocity at Max Flow:24.68m/secBeta:0.7500Discharge Coefficient:0.6073Plate Thickness:Pipe ID (thermally corrected)151.000mm Bore Size (thermally corrected)113.250mm GUIDELINESPrimary Element Min Limit of Use 170.48Nm3/hr Min Recommended Pipe Reynolds 14439.4Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:15.000kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 170.480262 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-125Tag No:FT431~437PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:5 inches (DN125)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:Gas Pipe I.D.:125.000mm Base Pressure:101.325kPa-a Pressure:15.000kPa-g Base Temperature:0.00CTemperature at Flow:20.00C Absolute Viscosity:0.01700cPIsentropic Exponent: 1.100Base Density:1.1997kg/m3Compressibility at Flow: 1.0000Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.1309kg/m3Flow Rates:Minimum:Nm3/hr ←*See WarningsNormal:470.00Nm3/hr Maximum:700.00Nm3/hr Full Scale:1000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:35.434mm Pipe Reynolds Number (Normal):93847Gas Expansion Factor:0.9981DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.418kPa at Normal Flow:0.19kPa DP at Max Flow:0.926kPa at Max Flow:0.41kPa URV (DP at Full Scale): 1.890kPaVelocity at Max Flow:16.81m/secBeta:0.7500Discharge Coefficient:0.6116Plate Thickness:Pipe ID (thermally corrected)125.000mm Bore Size (thermally corrected)93.750mm GUIDELINESPrimary Element Min Limit of Use 117.53Nm3/hr Min Recommended Pipe Reynolds 11953.1Max. Allow. Pressure @ Temp:5102.1kPa-g 20.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:15.000kPa-g20.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 117.531369 Nm3/hr.0.250 InchNOTESGENERAL DATACustomer:Project:liuzailanS. O. No:P. O. No:Calc. Date:Model No:LGBK-510Tag No:FT510PRODUCT DESCRIPTIONBore Type:Concentric, Square Edged Tap Type:Flange tapping Tap Location:Upstream Plate Type:Paddle, Concentric, Spiral Finish Line Size:24 inches (DN600)Plate Material:304/304L Stainless SteelPipe Schedule:Meter Schedule:Pipe Material:Carbon SteelProcess Connection:INPUT DATAFluid Type:Gas Fluid Name:AIR Pipe I.D.:618.000mm Base Pressure:101.325kPa-a Pressure:45.000kPa-g Base Temperature:0.00CTemperature at Flow:60.00C Absolute Viscosity:0.02008cPIsentropic Exponent: 1.400Base Density:1.2925kg/m3Compressibility at Flow:0.9997Atmospheric Pressure:87.510kPa-aDensity at Flow: 1.3853kg/m3Flow Rates:Minimum:Nm3/hr←*See WarningsNormal:8000.00Nm3/hr Maximum:12000.00Nm3/hr Full Scale:15000.00Nm3/hrCALCULATED DATA(Calculation Performed at Normal Conditions.)Orifice Bore Size:375.508mm Pipe Reynolds Number (Normal):294574Gas Expansion Factor:0.9988DP at Min Flow:kPaPermanent Pressure Loss DP at Normal Flow:0.569kPa at Normal Flow:0.35kPa DP at Max Flow:1.280kPa at Max Flow:0.79kPa URV (DP at Full Scale): 2.000kPaVelocity at Max Flow:10.37m/secBeta:0.6076Discharge Coefficient:0.6070Plate Thickness:Pipe ID (thermally corrected)618.298mm Bore Size (thermally corrected)375.765mm GUIDELINESPrimary Element Min Limit of Use 1688.42Nm3/hr Min Recommended Pipe Reynolds 38822.6Max. Allow. Pressure @ Temp:4936.6kPa-g 60.00C Recommended Min DP 0.025kPa Design Pressure/Temperature:45.000kPa-g60.000C Max. Allow. Temp.:815.556CWARNINGS* Flowrate is below recommended minimum value of 1688.420772 Nm3/hr.0.250 InchNOTES。