光稳定剂 944

- 格式:doc

- 大小:63.00 KB

- 文档页数:1

产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用产品名称外观应用Chisorb 292无色或微黄色澄清液体适用于PU、汽车漆、工业涂料、木器漆、光固化涂料。

涂料体系可以应用于聚氨酯(一液型、二液型)、热固型丙烯酸树脂、聚酯、醇酸树脂、酚醛树脂、光固化丙烯酸酯。

不建议应用于酸催化体系的涂料体系。

Chisorb 523淡黄色澄清液体适用于PU、汽车漆、工业涂料、装饰涂料、光油。

涂料体系可以应用于高固含量的酸催化的汽车漆及工业漆、例如二液型金属热固化丙烯酸体系,一液型不透明丙烯酸涂料,聚酯涂料。

在以下应用中效果十分显著:醇酸/丙烯酸自干型汽车修补漆、醇酸氧化干燥型油漆及光油、二液型非异氰酸酯型油漆,也容易乳化应用于水性涂料体系。

Chisorb 622白色结晶颗粒或粉末适用于PE、PP注塑件、纤维或薄膜;聚苯乙烯树脂:对ABS, IPS,PS,SAN,ASA…等提供良好的光稳定效果;聚氨酯:可提供PU皮革、氨纶之耐候性;粉末涂料:对聚酯类效果更好。

Chisorb 718白色蜡状固体适用于聚烯烃、 ABS、聚酰胺、聚氨酯、工程塑料。

不宜和含有卤素的阻燃剂并用。

Chisorb 770白色结晶颗粒或粉末适用于聚烯烃、 ABS 和 PU。

对于PP厚制品的效果十分明显。

不宜和含有卤素的阻燃剂并用。

Chisorb 783淡黄色结晶性粉末适用于 PP, HDPE, LDPE, LLDPE, ABS。

它通过 FDA认证可以用在PP、PE包装袋中。

与紫外线吸收剂相比,对聚合物厚度没有限制,因此尤其适用于薄膜、纤维类制品。

Chisorb 788淡黄色结晶性粉末适用于 PP, HDPE, LDPE, LLDPE, ABS;耐老化效果比Chisorb 783更好。

它通过 FDA认证可以用在PP、PE包装袋中。

与紫外线吸收剂相比,对聚合物厚度没有限制,因此尤其适用于薄膜、纤维类制品。

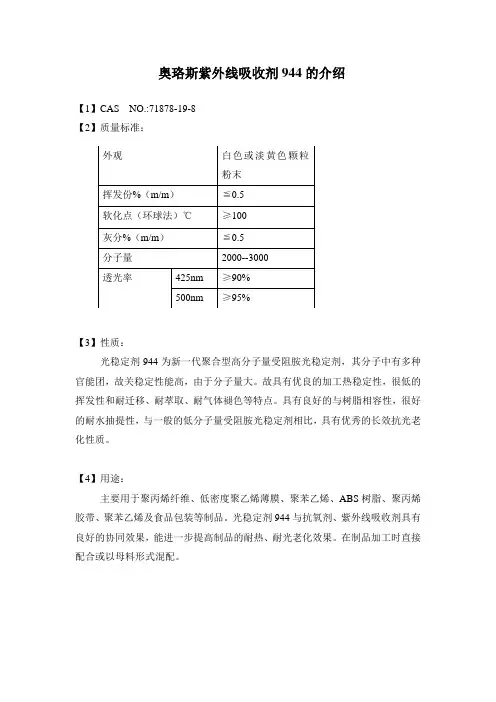

奥珞斯紫外线吸收剂944的介绍【1】CAS NO.:71878-19-8【2】质量标准:外观白色或淡黄色颗粒粉末挥发份%(m/m)≦0.5软化点(环球法)℃≥100灰分%(m/m)≦0.5分子量2000--3000透光率425nm ≥90%500nm ≥95%【3】性质:光稳定剂944为新一代聚合型高分子量受阻胺光稳定剂,其分子中有多种官能团,故关稳定性能高,由于分子量大。

故具有优良的加工热稳定性,很低的挥发性和耐迁移、耐萃取、耐气体褪色等特点。

具有良好的与树脂相容性,很好的耐水抽提性,与一般的低分子量受阻胺光稳定剂相比,具有优秀的长效抗光老化性质。

【4】用途:主要用于聚丙烯纤维、低密度聚乙烯薄膜、聚苯乙烯、ABS树脂、聚丙烯胶带、聚苯乙烯及食品包装等制品。

光稳定剂944与抗氧剂、紫外线吸收剂具有良好的协同效果,能进一步提高制品的耐热、耐光老化效果。

在制品加工时直接配合或以母料形式混配。

Ouroboros Ultraviolet Absorbent 9441. Chemical Name: Light stabilizer-9442. CAS NO.:71878-19-83. Specification:Appearance White or yellowish crystallinepowderV olatility ≦0.5Ring and ball softening point ≥100℃Ash content(m/m)≦0.5Molecular weight 2000--3000 Light transmittance 425nm ≥90%500nm ≥95%4. Product Property:It’s a new generation of hmw-polymeric hindered amine light stabilizer. Due to the large of molecular weight, it has excellent processing thermal stability and lower volatility that will be resist transference, extraction and being discolored by gases. With the good compatibility of resin, it is good at resisting water extraction. Ithas long-term photoaging resistance that compare with lmw-polymeric hindered amine light stabilizer.5. Purpose:It mainly works on the products of polypropylene fiber, low-density polyethylene, polystyrene, ABS resin, polypropylene tape, polystyreneand the food package. Its synergism both anti-oxygen and ultraviolet absorbent, that can improve the effect of the products’heat resistanceand photo-aging resistance. When processing, it can work in with other products or mix in master-batch form.。

受阻胺类光稳定剂的研究进展摘要:HALS具有捕获自由基和分解过氧化物的能力,其光稳定效果是传统吸收型光稳定剂的2到4倍。

HALS除了具有光稳定作用外,还具有抗氧化、吸收紫外线等多种功能,与紫外线吸收剂、抗氧化剂有很好的协同作用。

这种稳定剂不会使树脂着色,与多种树脂相容性好,低毒或无毒,可满足薄膜制品、纤维制品和食品包装材料的要求。

是目前发展最快、前景最广阔的一种新型光稳定剂。

关键词:受阻胺;光稳定剂;合成工艺;受阻胺光稳定剂是一种新型高效的光稳定剂,广泛应用于高分子材料中,其研发过程受到国内外关注。

介绍了受阻胺光稳定剂的作用机理,综述了其发展现状,并对其发展前景进行了展望。

1受阻胺光稳定剂的作用机理1.1 捕捉自由基。

受阻胺官能团属于脂环胺结构,在有氧状态下吸收光能后可转化为氮氧自由基NO。

这些氮氧自由基不仅能捕获高分子材料光氧化降解过程中产生的烷基活性自由基,而且在光稳定化过程中具有再生功能,从而抑制链式反应达到保护目的。

1.2 氢过氧化物的分解。

一般认为,氨基在与氢过氧化物中的氢结合后分解成氮氧自由基,然后与活性自由基反应,将其转化为稳定的醇和酮化合物。

结果也证实了受阻胺对氢过氧化物有浓度效应。

1.3 捕捉重金属。

HALS中的氮有一个与金属配位的孤对,能与高分子材料中的金属离子强烈配位,从而达到保护高分子材料的目的。

1.4 淬灭单线态氧。

HALS几乎不淬灭激发态,但其氧化产物NO显示出很高的淬灭效率。

受阻胺氮氧自由基可以通过转移能量使激发态的单线态氧回到基态,从而防止单线态氧引起聚合物降解反应,起到防止光老化的作用。

2受阻胺光稳定剂的发展现状2.1 高分子定量。

随着高分子材料应用范围的不断扩大,低分子量受阻胺光稳定剂由于易迁移、易挥发、耐萃取等特点,已经难以满足人们的需求。

因此,汽巴-嘉积公司推出了第一款高分子受阻胺光稳定剂Tinuvin622,后来又推出了另一款高分子产品Chimassorb944,性能更好,至今仍在广泛使用。

缚酸剂对合成光稳定剂944中间体4,6-二氯-2-叔辛基氨基-1,3,5-三嗪的影响姜泽;鲍芃丞;李效军;王嘉睿【摘要】以三聚氯氰和叔辛胺为主要原料合成了光稳定剂944中间体4,6--氯-2-叔辛基氨基-1,3,5-三嗪.实验考察了氢氧化钠、氢氧化钾、碳酸钠等无机碱和有机碱在上述合成过程中的缚酸作用,确定了较好的缚酸剂为二异丙基乙胺.与传统的氢氧化钠缚酸法相比,无水环境下使用二异丙基乙胺可杜绝三聚氯氰的水解.经实验优化,产物收率达97.0%以上,液相色谱纯度大于99.8%,以此为原料合成光稳定剂944,其收率较氢氧化钠缚酸法提高约5.0%.%The intermediate of HS-944 namely 4,6-dichloro-t-octylamine-1,3,5-triazine was prepared from cyanuric chloride and t-octylamine.The acid-binding behaviors of inorganic bases including sodium hydroxide,potassium hydroxide,sodium carbonate,potassium carbonate,and organic bases including t-octylamine,triethylamine and N,N-diisopropylethylamine were studied.The experimental results indicated that N,N-diisopropylethylamine showed better performance in the acid binding effect than other pared with the traditional method of using sodium hydroxide,N,N-diisopropy-lethylamine was used in anhydrous media and the hydrolysis of cyanuric chloride was eliminate completely.Upon the optimum condition the yield of the product was more than 97.0% with a purity of more than 99.8%measured by HPLC.The yield of HS-944 prepared from the triazineobtained by using N,N-diisopropylethylamine as acid-acceptor was about 5.0%higher than that by using sodium hydroxide.【期刊名称】《精细石油化工》【年(卷),期】2018(035)001【总页数】4页(P5-8)【关键词】光稳定剂944;4,6-二氯-2-叔辛基氨基-1,3,5-三嗪;三聚氯氰;叔辛胺;缚酸剂【作者】姜泽;鲍芃丞;李效军;王嘉睿【作者单位】河北工业大学化工学院,天津300130;河北工业大学化工学院,天津300130;河北工业大学化工学院,天津300130;东北育才外国语学校,辽宁沈阳110179【正文语种】中文【中图分类】TQ226.34,6-二氯-2-叔辛基氨基-1,3,5-三嗪(以下简称二氯三嗪)是制备光稳定剂944的重要中间体[1-2]。

塑料成型添加剂塑料成型加工添加剂一大类助剂,包括增塑剂、热稳定剂、抗氧剂、光稳定剂、阻燃剂、发泡剂、抗静电剂、防霉剂、着色剂和增白剂(见颜料)、填充剂、偶联剂、润滑剂、脱模剂等。

其中着色剂、增白剂和填充剂不是塑料专用化学品,而是泛用的协作材料。

塑料助剂是在聚氯乙烯工业化以后渐渐进展起来的。

20 世纪60 年月以后,由于石油化工的兴起,塑料工业进展甚快,塑料助剂已成为重要的化工行业。

依据各国塑料品种构成和塑料用途上的差异,塑料助剂消费量约为塑料产量的8%~10%。

目前,增塑剂、阻燃剂和填充剂是用量最大的塑料助剂。

增塑剂一类可以在确定程度上与聚合物混溶的低挥发性有机物,它们能够降低聚合物熔体的粘度以及产物的玻璃化温度和弹性模量。

其作用机理是基于增塑剂分子对聚合物分子链间引力的减弱。

增塑剂是最早使用的塑料助剂。

19 世纪下半叶,就曾承受樟脑和邻苯二甲酸酯作硝酸纤维素的增塑剂。

1935 年聚氯乙烯工业化后,增塑剂得到广泛应用。

目前,约80%用于聚氯乙烯和氯乙烯共聚物,其余用于纤维素衍生物、聚醋酸乙烯酯、聚乙烯醇、自然和合成橡胶。

软质聚氯乙烯平均外加45%~50%(质量,下同)增塑剂。

由于不需或仅少量添加增塑剂的硬质聚氯乙烯的快速进展,增塑剂在很多工业兴盛国家的增长率已低于聚氯乙烯。

中国聚氯乙烯软质制品仍占很大比例,故增塑剂仍将有较快的进展。

邻苯二甲酸酯类是增塑剂的主体,其产量约占增塑剂总产量的80%左右,其中邻苯二甲酸二辛酯(简称DOP)是最重要的品种。

生产规模较小的增塑剂有:己二酸和癸二酸的酯类〔具有良好耐寒性〕,磷酸酯类〔具有阻燃作用〕,环氧油和环氧酯类(与热稳定剂有协同作用),偏苯三酸酯和季戊四醇酯〔耐热性较好〕,氯化石蜡(关心增塑剂和阻燃增塑剂),烷基磺酸苯酯〔关心增塑剂〕。

热稳定剂主要功能是防止加工时的热降解,也有防止制品在长期使用过程中老化的作用。

用量较大的是聚氯乙烯和氯乙烯共聚物的热稳定剂。

光稳定剂的作用及分类光稳定剂定义Lightstabilizer,lightstabilityagent,photostabilizer,太阳辐射的电磁波在通过空间和臭氧层时,290nm以下和3000nm以上的射线几乎都被滤除,实际到达地面的为290nm-3000nm的电磁波,其中波长范围为400-800nm(约占40%)的是可见光,波长约为800-3000nm(约占55%)的是红外线,而波长约为290-400nm(仅占5%)的是紫外线。

光稳定剂作用机理光稳定剂的作用机理因自身结构和品种的不同而有所不同。

有的可以屏蔽、反射紫外线或吸收紫外线并将其转化为无害的热能;有的可猝灭被紫外线激发的分子或基团的激发态,使其回复到基态,排除或减缓了发生光氧化还原反应的可能性;有的因捕获因光氧化还原产生的自由基,从而阻止了导致制品老化的自由基反应,使制品免遭紫外线破坏。

工业上对光老化的有效防止阻缓,多以两种以上有不同作用机理的抗老化剂复配,因为各种抗老化剂特别是光吸收剂都有自身对紫外线不同的吸收波段。

复配配方如:二笨甲酮+苯并三唑类加受阻胺(HAL)类,可以起到单一光稳定剂所无法达到的最佳效果。

防晒化妆品中所加入的紫外线吸收剂,其防晒机理也是基于分散或吸收入射到皮肤表面上的紫外线,从而使皮肤避免或减少受到紫外线伤害。

光稳定剂分类一、按作用机理可分为1)光屏蔽剂、2)紫外线吸收剂(UVabsorber)、3)猝灭剂(quencher)、4)自由基捕获剂。

1)光屏蔽剂:它的作用就像在聚合物和光辐射之间设置了一道屏障,使光不能直接辐射到聚合物的内部,令聚合物内部不受紫外线的危害,从而有效地抑制光氧化降解。

2)紫外线吸收剂:它的作用机理在于能强烈地吸收聚合物敏感的紫外光,并能将能量转变为无害的热能形式放出。

3)猝灭剂:可以接受塑料中发色团所吸收的能量,并将这些能量以热量、荧光或磷光的形式发散出去,使其回到基料,从而保护聚合物免受紫外线的破坏。

收稿日期:682009-09-10光稳定剂在PVC 中的应用Application of Light Stabilizer in PVC王海鹰1,张玉杰2 Wang Haiying 1, Zhang Yujie 2 - 1. 大连塑料研究所有限公司,辽宁 大连 116033 2.北京极易伟业科技发展有限公司,北京102400 - 1. Dalian Plastics Research Institute Co., Ltd., Dalian 116033, China2. Beijing Jiyi Weiye Science&Technology Development Co., Ltd., Beijing 102400, China摘 要 : 论述了光稳定剂在PVC 中的应用情况。

重点介绍了受阻胺类光稳定剂和紫外线吸收剂在聚氯乙烯光降解中的作用和最新应用进展。

Abstract :The applications of light stabilizers in PVC were discussed. The effects of hindered amine light stabilizer and ultra-violet light stabilizer on the light degradation of PVC and their latest progress in applications were mainly introduced. 关键词 :聚氯乙烯;受阻胺光稳定剂;紫外线吸收剂;光稳定性Key words : Plolyvinyl chloride; Hindered amine light stabilizer; Ultraviolet light stabilizer; Light stability 文章编号:1005-3360(2009)12-0068-06涂料、塑料、橡胶、合成纤维等制品在日光或强的荧光下,因吸收紫外线而引发自动氧化,导致聚合物降解,使制品的外观和物理机械性能恶化,这一过程称为光氧化或光老化。

MATERIAL SAFETY DATA SHEETMSDS Number: 00407Effective Date:01/25/2006Page: 1 of 7 Product Name: Lowilite® 94 Granular and Lowilite® 94NDB™S ECTION I-C HEMICAL P RODUCT A ND C OMPANY I DENTIFICATIONProduct Name: Lowilite 94 Granular and Lowilite 94 NDB™Supplier: Chemtura USA CorporationAddress: 199 Benson Road City: MiddleburyState: Connecticut Zip: 06749Emergency Telephone Number: 1-800-949-5167Information Telephone Number: 1-765-497-6100 Fax:1-765-497-6123Chemtrec Phone: 1-800-424-9300; Internationally call 703-527-3887Effective Date: 01/25/2006 Supercede Date: 06/03/2004MSDS Prepared By: Chemtura Product Safety GroupSynonyms: Poly[[6-[(1,1,3,3-tetramethylbutyl)amino]-1,3,5-triazine-2,4-diyl][(2,2,6,6-tetramethyl-4-piperidinyl)imino]-1,6-hexanediyl[(2,2,6,6-tetramethyl-4-piperidinyl)imino]]Product Use: Polymer AdditiveChemical Name: 1,6-Hexanediamine, N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-, polymer with 2,4,6-trichloro-1,3,5-triazine, reaction products with 2,4,4-trimethyl-2Chemical Family: Polymeric hindered amineAdditional InformationManufacturer:Great Lakes Chemical Corporation, A Chemtura CompanyP.O. Box 2200West Lafayette, Indiana 47996-2200S ECTION II-C OMPOSITION/I NFORMATION ON I NGREDIENTSI NGREDIENT N AME CAS N O. % E XPOSURE L IMITSLowilite 94 70624189 100 Y (Hazardous)15 mg/m3 (PNOR) (OSHA PEL TWA)Not established (OSHA PEL STEL)Not established (OSHA PEL CEIL)10 mg/m3 (PNOS) (ACGIH TLV TWA)Not established (ACGIH TLV STEL)Not established (ACGIH TLV CEIL)*Indented chemicals are components of previous ingredient.Additional InformationCAS REG. NO. 70624-18-9 is chemically equivalent to CAS REG. NO. 71878-19-8.5 mg/m3 Respirable Dust Level (OSHA)3 mg/m3 Respirable Dust Level (ACGIH)PNOR = Particulates Not Otherwise RegulatedPNOS = Particulates Not Otherwise SpecifiedS ECTION III-H AZARDS I DENTIFICATIONEmergency Overview:White to light yellow granules or pelletsNo odorMay cause eye irritation.May cause respiratory tract irritation.Dusts can form an explosive mixture with air.S ECTION III-H AZARDS I DENTIFICATIONRelevant Routes of Exposure: Ingestion, inhalation and skin absorptionSigns and Symptoms of Overexposure:General reddening and irritation to the skin and eyes, mucous membraneirritation, upper respiratory tract irritation.Medical Conditions GenerallyAggravated By Exposure: None reportedPotential Health Effects: See Section XI for additional information.Eyes: May cause eye irritation.Skin: Not expected to be a hazard in normal industrial use.As with any dust, mechanical irritation is possible to the skin.May cause skin irritation after repeated exposure.Ingestion: Not expected to be a hazard in normal industrial use.Long term oral exposure may result in liver damage.Long term overexposure may result in spleen effects.Long term overexposure may produce blood effects.Long term overexposure may produce lymph node effects.Long term oral exposure may cause developmental effects.Inhalation: May cause respiratory tract irritation.Chronic Health Effects: May cause liver, lymph node, blood, spleen and developmental effects based onanimal data.Carcinogenicity:NoNTP: No ACGIH:NoIARC: No OTHER:OSHA: NoAdditional InformationNo information availableS ECTION IV-F IRST A ID M EASURESEyes:Flush with large volumes of water for at least 15 minutes. Get medical attention. Skin: Wash with large volumes of soap and water for at least 15 minutes. If irritationdevelops, get medical attention.Ingestion: If conscious, give person 1 to 2 glasses of water. Get medical attentionimmediately.Inhalation: Remove person to fresh air. Get medical attention.Antidotes: No information availableNotes to Physicians and/or Protectionfor First-Aiders: No information availableAdditional InformationNo information availableS ECTION V-F IRE F IGHTING M EASURESFlammable Limits in Air (% byVolume):Not availableFlash Point: >160 degrees CAutoignition Temperature: 390 degrees C BAMExtinguishing Media: All conventional media are suitable.Fire Fighting Instructions: Wear a self-contained breathing apparatus and protective clothing to prevent skinand eye contact in fire situations.Unusual Fire and Explosion Hazards:Under fire conditions, toxic and irritating fumes may be emitted.Dusts can form an explosive mixture with air.Flammability Classification: Combustible dustS ECTION V-F IRE F IGHTING M EASURESKnown or Anticipated HazardousProducts of Combustion: Oxides of nitrogenCarbon monoxide and carbon dioxideAdditional InformationNo information availableS ECTION VI-A CCIDENTAL R ELEASE M EASURESAccidental Release Measures:Shut off all sources of ignition.Wearing appropriate personal protective equipment, carefully sweep up materialand place in suitable labeled containers for disposal.Use only non-sparking tools.Avoid creating a dusting condition.Personal Precautions: See Section VIII.Environmental Precautions: Avoid releasing to the environment.Additional InformationNo information availableS ECTION VII-H ANDLING AND S TORAGEHandling:Use appropriate personal protection equipment.Avoid eye, skin and clothing contact.Avoid breathing dust.Avoid repeated and prolonged contact.Prevent buildup of static electricity.Keep away from heat, sparks and flame.All equipment should be properly grounded.Avoid creating a dusting situation.Storage: Store in a cool, dry, well-ventilated area away from incompatible materials.Store away from heat, sparks, and flame.Keep container tightly closed.Recommend plastic (polyethylene) packaging.Other Precautions: No information availableAdditional InformationNo information availableS ECTION VIII-E XPOSURE C ONTROLS/P ERSONAL P ROTECTIONEngineering Controls:No information availableVentilation Requirements: Use local exhaust to minimize dusting.Use mechanical ventilation for general area control.Personal Protective Equipment:Eye/Face Protection: Chemical safety glasses with side shields or chemical safety gogglesSkin Protection: Chemical resistant glovesClothing designed to minimize skin contactRespiratory Protection: Wear a NIOSH/MSHA approved dust respirator if dusting occurs, or there ispotential for airborne exposures to exceed established threshold values.Consult the OSHA respiratory protection information located at 29CFR 1910.134and the American National Standard Institute's Practices of RespiratoryProtection Z88.2.Other Protective Clothing orEquipment: No information availableExposure Guidelines: See Section II.S ECTION VIII-E XPOSURE C ONTROLS/P ERSONAL P ROTECTIONWork Hygienic Practices: Wash thoroughly after handling.Wash contaminated clothing before reuse.Additional InformationNo information availableS ECTION IX-P HYSICAL &C HEMICAL P ROPERTIESAppearance:White to light yellowPercent Volatile: Not availablegranules or pelletsBoiling Point: Not available pH Value: 6.8 (Aqueous dispersion at1%)Bulk Density: Not available pH Concentration: Not availableColor: White to light yellow Physical State: SolidDecomposition Temperature: >350 degrees C Reactivity in Water: Not water reactive Evaporation Rate: Not available Saturated VaporConcentration: Not availableFreezing Point: Not available Softening Point: Not availableHeat Value: Not available Solubility in Water: <0.001 g/L at 20 degrees C Melting Point: 100 - 135 degrees C Specific Gravity orDensity (Water=1): 1.01 at 20 degrees C Molecular/Chemical Formula: Polymer Vapor Density: Not availableMolecular Weight: 2000-3300 Vapor Pressure: ~5E-12 mmHg at 25degrees COctanol/Water Partition Coefficient: 2.44 (log Pow) Viscosity: Not availableOdor: None Volatile OrganicCompounds: Not availableOdor Threshold: Not available Water/Oil DistributionCoefficient: Not availableParticle Size: Not available Weight Per Gallon: Not availableAdditional InformationNo information availableS ECTION X-S TABILITY AND R EACTIVITYStability:Stable under normal conditions of handling and use.Conditions to Avoid: High temperatures, heat, open flames, static electricity and other sources ofignitionDecomposes at temperatures >350 degrees C.Incompatibility With Other Materials:Strong oxidizersStrong acidsStrong basesHazardous Decomposition Products:Thermal decomposition may produce the following:Oxides of nitrogenCarbon monoxide and carbon dioxideHazardous Polymerization: Will not occurConditions to Avoid: NoneAdditional InformationNo information availableS ECTION XI-T OXICOLOGICAL I NFORMATIONV ALUE (LD50 OR LC50) A NIMAL R OUTES C OMPONENTS>2,000 mg/kg Rat Acute Oral Lowilite 94>3,000 mg/kg Rat Acute Dermal Lowilite 94Toxicological Information:The toxicological properties of this material have not been fully determined.This material was found to be an eye irritant, but not a skin irritant, in rabbits. In hairless mice, no skin photo-irritant potency was found with a 3% solution. In a guinea pig maximization study, sensitization was not observed; and in a guinea pig photosensitivity test, no skin photo-sensitization was observed with a 0.1% solution.In various 1 to 4 hour inhalation exposures in rats, it was found that respiratory irritation can occur in the range of 0.2 - 0.6 mg/L. Deaths have occurred >2 mg/L.In a teratology study, pregnant rats were dosed by gavage from day 6 to day 15 of pregnancy at 0, 200, 600 and 1,200 mg/kg. Offspring in the high dose group displayed a delay of skeletal maturation. No other significant effects were seen.In a two generation reproduction study, rats were dosed at 400, 2,000 and 4,000 ppm in the diet. No study related effects were noted in the offspring. However, toxic effects at the 2,000 and 4,000 ppm levels observed in parents included immuno-response related effects such as reddened and/or swollen ears, and/or extremities, enlarged lymph nodes, and/or findings in the kidneys, spleen and/or liver. The no observable effect level (NOEL) for effects on the offspring was 4,000 ppm and 400 ppm for parental toxicity.This material was not found to be mutagenic in the Ames test, a nucleus anomaly test or sister chromatid exchange studies on somatic cells.Feeding studies involving rats and dogs at dietary levels up to 10,000 ppm for up to a 6 month period produced liver, mesenteric lymph node, spleen and blood effects.In a 24 month study in rats, no evidence of carcinogenicity was observed at dose levels of 5, 30, and 200 mg/kg.Other acute and chronic health hazards, as well as target organs, are unknown.As with all dusts, inhalation of air concentration levels above the PNOR may cause irritation and adverse lung effects.Additional InformationNo information availableS ECTION XII-E COLOGICAL I NFORMATIONEcological Information:The following ecological information is offered:LC50 in rainbow trout (96H) = 0.35 ppmLC50 in bluegill (96H) = 0.59 ppmEC50 in Daphnia magna (24H) = 55 ppmEC50 in green algae (0 - 72 ) >100 mg/LIC20, 50, 80 on respiration of aerobic waste bacteria >100 mg/LThis product is not biodegradable in the modified Sturm test with 0 - 1% in 28daysAvoid releasing to the environment.Additional InformationNo information availableS ECTION XIII-D ISPOSAL C ONSIDERATIONSDisposal Considerations:Dispose of waste at an approved chemical disposal facility in compliance with allcurrent Local, State/Province, Federal/Canadian laws and regulations.Additional InformationNo information availableS ECTION XIV-T RANSPORT I NFORMATIONU.S. DOTProper Shipping Name:Not regulatedHazard Class: N/A ID Number: N/APacking Group: N/A Labels: N/ASpecial Provisions: N/A Packaging Exceptions: N/ANon-Bulk Packaging: N/A Bulk Packaging:N/APassenger Air/Rail Limit:N/A Air Cargo Limit: N/AVessel Stowage: N/A Other Stowage: N/AReportable Quantity: N/AAIR - ICAO OR IATAProper Shipping Name:Not regulatedHazard Class: N/A ID Number: N/ASubsidiary Risk: N/A Packing Group: N/AHazard Labels: N/A Packing Instructions: N/AAir Passenger Limit Per Package: N/A Packing Instruction -Cargo: N/AAir Cargo Limit Per Package: N/A Special Provisions Code: N/AWATER - IMDGProper Shipping Name: Not regulatedHazard Class: N/A ID Number: N/APacking Group: N/A Subsidiary Risk: N/AMedical First Aid Guide Code: N/AAdditional InformationNo information availableS ECTION XV-R EGULATORY I NFORMATIONU.S. Federal Regulations:The components of this product are either on the TSCA Inventory or exempt (i.e. impurities, a polymer complying with the exemption rule at 40 CFR 723.250) from the Inventory.CAS REG. NO. 70624-18-9 is chemically equivalent to CAS REG. NO. 71878-19-8.State Regulations:None knownInternational Regulations:This material (or each component) is listed on the following inventories:Canada - DSLEU- EINECS (Monomers Listed)Australia - AICSKorea - ECLPhilippines - PICCSChina - List ICAS REG. NO. 70624-18-9 is chemically equivalent to CAS REG. NO. 71878-19-8.Canadian WHMIS Hazard Class and Division = D.2.bS ECTION XV-R EGULATORY I NFORMATIONSARA Hazards:Acute: Yes Chronic: YesReactive: No Fire: NoPressure: NoAdditional InformationThe above regulatory information represents only selected regulations and is not meant to be a complete list.S ECTION XVI-O THER I NFORMATIONNFPA Codes:Health:NR Flammability: NRReactivity: NR Other: NRHMIS Codes: * indicates chronic health hazard.Health:NR Flammability: NRReactivity: NR Protection: NRLabel Statements: Not availableOther Information: Abbreviations:(L) = Loose bulk density in g/mlLOEC = Lowest observed effect concentrationMATC = Maximum acceptable toxicant concentrationNA = Not availableN/A = Not applicableNL = Not limitedNOAEL = No observable adverse effect levelNOEC = No observed effect concentrationNOEL = No observable effect levelNR = Not rated(P) = Packed bulk density in g/mlPNOR = Particulates Not Otherwise RegulatedPNOS = Particulates Not Otherwise SpecifiedREL = Recommended exposure limitTS = Trade secretAdditional InformationInformation on this form is furnished solely for the purpose of compliance with OSHA's Hazard Communication Standard, 29CFR 1910.1200 and the Canadian Hazardous Products Act and associated Controlled Products Regulations and shall not be used for any other purpose.。

光稳定剂944在PVC中的应用聚氯乙稀(PVC)全球产能2005年已达3717万t/a,预计2010年将增至4196万t/a,PVC作为五大通用合成树脂之一,其消费量约占合成树脂消费总量29%。

2005年,中国PVC需求量超过美国,成为世界最大的PVC 消费国。

2006年中国PVC树脂产量824万吨,表现消费量919万吨。

PVC制品在户外应用越来越多,例如塑料门窗、管道、墙板、农膜、车用塑料等,改进其光稳定性,延长PVC制品使用寿命,被认定是节约资源和能源,以及保护环境的举措。

一般认为,PVC热降解和光降解产生的HCl和HALS哌啶环的氨基会产生化学反应,因此妨碍了HALS转化为氮氧自由基和捕获高聚物降解所产生自由基的能力,使得HALS的活性降低甚至完全失去作用。

最近发现,随着PVC聚合工艺技术的发展和PVC质量的改善,以及PVC稳定剂效能的提高,PVC树脂因分解而产生的HCl已不足以抑制HALS的作用了,HALS在PVC中应用的实例越来越多,而且取得了令人满意的效果。

将HALS用于PVC压延农膜,试验中用HALS两个品种Tiangang® HS-770和GW-540与TIANGANG® UV-9做对比,结论认为HALS对PVC具有光稳定作用,其效果优于二苯甲酮类光稳定剂,提高了PVC耐光老化作用。

研究认为紫外线吸收剂TIANGANG® UV-531和TIANGANG® UV-9和HALS在PVC棚膜中有协同作用;受阻胺光稳定剂具有防止PVC棚膜发生“背板效应”,因此认为HALS完全可以应用于PVC棚膜中。

表177数据说明,增塑PVC透明膜中单独使用HALS的光稳定效果,与单独使用苯并三唑类TIANGANG® UV-326或二苯甲酮类TIANGANG® UV-531效果相当,然而复合应用效果优于单独应用;无论是单独应用或与紫外线吸收剂TIANGANG® UV-531复合应用,TIANGANG® HS-944光稳定效果均比TIANGANG® HS-770和TIANGANG® BW-10LD(622)优秀。

光稳定剂 944

产品说明:

光稳定剂944是一种用于塑料制品的聚合型高分子量受阻胺类光稳定剂。

它可应用在聚烯烃塑料(如PP 、PE),烯烃共聚物(如EVA 和丙烯与橡胶的混合体等)。

应用在交联聚乙烯中更能显出其卓越的功效。

除聚烯烃塑料外,它还可用于聚苯醚复合物(PPE),聚甲醛(polyacetals),聚酰胺(polyamides),聚氨酯(polyurethanes),软硬PVC 及PVC 共混物等。

另外,光稳定剂944对苯乙烯类, 橡胶和胶粘体也有良好的功效。

光稳定剂 944与紫外线吸收剂合用具有协调效果。

由于聚合体的特殊结构,其平均分子量可达3000,它可用于要求低挥发及少量迁移的系统中, 特别适用于薄膜与纤维中。

光稳定剂 944有抗氧剂的效果,同时对聚合物有长期热稳定效果。

CAS NO :70624-18-9

结 构 式: N (CH 2)6N

HN

C CH 2CH 3

CH 2CH 2CH 3H 3CH 2C n

主要指标:

特性及用途:

硫或含卤素类可能会影响光稳定剂 944的效果。

如有些稳定剂,杀虫剂及阻燃剂,可能会与光稳定剂 944产生付反应。

如需与此类物质共用,为保证效果,建议先进行小试。

贮运及包装:

光稳定剂944性质稳定,无特殊的贮存要求,存放时避免高温及潮湿。

用纸板桶内衬塑袋包装,净重25kg /桶,也可根据客户要求设计。