Chapter 1 Introduction 材料概论

- 格式:ppt

- 大小:9.78 MB

- 文档页数:22

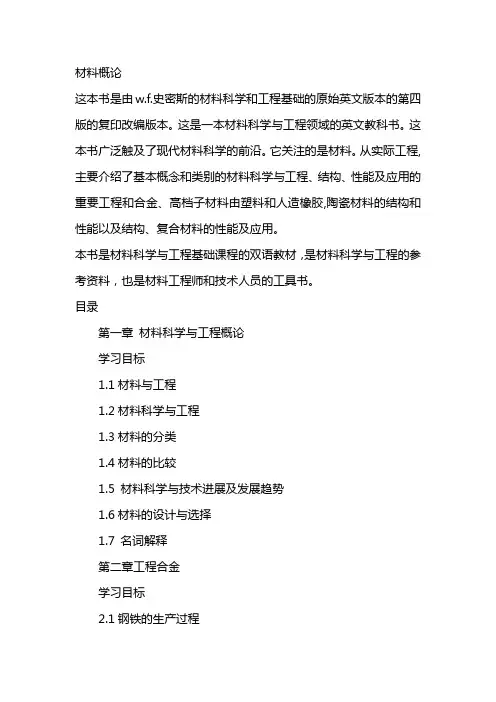

材料概论这本书是由w.f.史密斯的材料科学和工程基础的原始英文版本的第四版的复印改编版本。

这是一本材料科学与工程领域的英文教科书。

这本书广泛触及了现代材料科学的前沿。

它关注的是材料。

从实际工程,主要介绍了基本概念和类别的材料科学与工程、结构、性能及应用的重要工程和合金、高档子材料由塑料和人造橡胶,陶瓷材料的结构和性能以及结构、复合材料的性能及应用。

本书是材料科学与工程基础课程的双语教材,是材料科学与工程的参考资料,也是材料工程师和技术人员的工具书。

目录第一章材料科学与工程概论学习目标1.1材料与工程1.2材料科学与工程1.3材料的分类1.4材料的比较1.5 材料科学与技术进展及发展趋势1.6材料的设计与选择1.7 名词解释第二章工程合金学习目标2.1钢铁的生产过程2.2铁- 渗碳体体系2.3 碳素钢的热处理2.4低合金钢2.5铝合金2.6 铜合金2.7不锈钢2.8铸铁2.9 镁合金、钛合金和镍合金2.10名词解释第三章高分子材料学习目标3.1概况3.2 聚合反应3.3工业生产中的聚合反应方法3.4某些热塑性塑料的结晶度和立体异构现象3.5塑料的加工过程3.6常用的热塑性塑料3.7工程热塑性塑料3.8 热固性塑料(热固树脂)3.9高弹体(橡胶)3.10 塑料材料的成型和强化3.11名词解释第四章陶瓷学习目标4.1概况4.2陶瓷晶体结构4.3 硅酸盐的结构4.4陶瓷的加工过程4.5 传统陶瓷和工程陶瓷4.6陶瓷的机械性能4.7陶瓷的热学性能4.8玻璃4.9陶瓷涂层与表面工程4.10陶瓷在生物医学上的应用4.11名词解释第五章复合材料学习目标5.1概况5.2 增强塑料复合材料的纤维5.3 纤维增强塑料复合材料5.4纤维增强塑料复合材料的明模浇注加工过程5.5纤维增强塑料复合材料的闭模浇注加工过程5.6混凝土5.7 三明治结构5.8金属基体和陶瓷基体的复合材料5.9骨:一种天然的复合材料5.10名词解释序言“材料概论”是材料类专业开设的一门必修课,属于材料类相关专业的技术基础课,通常安排在大一或大二讲授。

Chapter 1General Introduction1.1 Background of this Thesis“A diamond is forever”. Diamond is known as the ultimate gemstone of perfect clarity, brilliance, hardness, and permanence. Diamond has long been the king of all jewels, and it is also a very attractive material for many industrial applications because of its unique combination of optical, thermal, mechanical, chemical and semiconductor properties. These include the highest hardness and the highest thermal conductivity of any known material, high electrical resistance, large optical band gap, high transmission from ultraviolet to infrared regions, chemical inertness to most corrosive environments, and low adhesion and friction, extremely low thermal expansion coefficient [Field, 1979, 1992, Nazaré and Neves, 2001, Pierson, 1993, Prelas et al., 1998, Sung, 2003, Valentinas, 1997, Wilks, J. and Wilks, E., 1991]. For example, diamond is an ideal material for cutting tools and wear resistant components because of its extreme hardness and low coefficient of friction. Further, diamond is highly resistant towards chemicals, making it an ideal material for protection of components in harsh environments. Another important application is as substrate material for integrated circuits, non-memory semiconductors, and laser diodes due to its combination of high thermalconductivity, high electrical resistance, high mechanical strength, low dielectric constant, and low coefficient of thermal expansion.However, the full industrial exploitation of this unique combination of properties has been limited by the scarcity and expense of natural diamond. In 1954, General Electric first synthesized diamond grits under high pressure and high temperature and then commercialized synthesized diamond [Bundy et al., 1955, Hall, 1955, 1960, 1961]. But their small sizes had restricted applications, e.g., only for making grinding wheels. Many useful applications require a surface larger than a grit. In early 1960s both General Electric and Megadiamond began to develop polycrystalline diamond (PCD) by sintering diamond grits together [De Lai, 1964, Hall, 1970, Horton et al., 1974, Pope et al., 1974]. This is a short cut to get a larger diamond because the sintering process avoids the problem involved in growing large single crystals, and PCD is a much tougher material than diamond, because the crystallites of PCD are oriented in random directions so the passage of a crack tends to be held up when passing from one crystallite to another, and PCD will be worn uniformly in all direction [Sung, 2000, Wilks, E. and Wilks, J., 1991].However, these PCD compacts which contain significant amounts of bonding metals (e.g cobalt, nickel) are thermally unstable. First they are made under very high pressures and temperatures and thus require highly specialised and expensive apparatus. Moreover, the sizes of PCD compacts are relatively small. If the compacts are subjected to high temperatures (e.g. >800 °C.) as can be produced during drilling of hard rocks or machining hard ceramics, the metallic inclusions can catalyze the retrogressive transformation of diamond to graphite, which results in a reduction in strength and/orcomplete degradation of the material. The solvent/catalyst is also responsible for a second undesirable effect: because diamond has a very low coefficient of thermal expansions, much lower than that of bonding metals, heating the PCD produces differential expansions and internal stresses, additional to those caused by the volume changes associated with any graphitization.Therefore, a new class of thermally stable PCD composite systems has been developed by the industrial partner of this project, Ringwood Diamond Material Technologies (DMT) Pty. Ltd. These compacts use silicon carbide (SiC) and related materials to form strong inter-particle bonds among diamond grains at intermediate high pressures [Ringwood, 1986, 1991, 1992]. They are very attractive cutting tool materials because of their properties, such as ultra high hardness and thermal conductivity and strength, low coefficient of friction, excellent wear resistance, and chemical inertness to most corrosive environments. Moreover, since these PCD composites are made under intermediate high pressure, they can be made significantly thicker with lower cost equipment. The electrically conductive silicon carbide binder further stabilizes the diamond composites and allows them to be shaped into virtually required shapes by Electrical Discharge Machining (EDM).To conduct quality precision machining, the cutting tool must have an excellent surface finish and cutting edge sharpness. The shaped PCD composite surface must be polished to meet the required precision, for example, the surface roughness Ra values of commercial PCD cutting tools were found to be 0.06 µm. However, because of the ultra high hardness and chemical inertness of diamond and ceramic bond SiC, effective polishing of the cutting tools has been very difficult. In addition, the two phases in acompact (diamond and SiC) have very different properties, such as, hardness, chemical reactivity, etc., thus the material removal rates for diamond and SiC would be different during polishing.The polishing technique employed at Ringwood DMT for PCD compacts is traditional mechanical abrasive polishing, which uses a diamond wheel to polish PCD compacts. The polishing rate is extremely low, it takes about 3 hours to polish a 12.7 mm diameter PCD surface, and therefore is time consuming and costly, and greatly contributes to the high cost of PCD tools. Moreover, if a high force is applied to the workpiece to effect polishing, it would cause subsurface micro-cracking. Thus an effective PCD polishing method needs to be developed.1.2 Aim of this ThesisThis present work aims to develop an effective (efficient and economical) PCD polishing technique to improve the quality of PCD cutting tools, raise the surface integrity of a machined component to the highest possible level and reduce the tool production cost. There are five issues to be addressed:•Development of an effective polishing technology for cutting tools made of sintered, thermally stable composites of diamond•Design and manufacture of a new machine for polishing PCD composite •Experimental and theoretical investigation of the material removal mechanisms in PCD polishing to gain a better understanding of the process•Modelling of the polishing process•Control and optimization of the polishing parameters and conditions by establishing relationships between surface integrity and processing parameters to find out the most suitable parameters to obtain the required surface finish efficiently.1.3 Thesis OrganizationThis thesis consists of nine chapters. Following this introduction, Chapter 2 reviews the diamond polishing techniques and the material removal mechanisms involved. By comparison of the various polishing techniques and based on the project application, an effective PCD polishing technique is developed in the thesis work.Chapter 3 describes the characterization methods used in our experiment for examination of the surface integrity, and investigation of the PCD polishing mechanisms by micro-structural and chemical structure analyses and temperature measurement.The design of a new polishing machine for PCD and its manufacture, fabrication and calibration are presented in Chapter 4.Chapter 5 presents the polishing experiments and experimental study of the material removal mechanisms by investigating the PCD specimen surface and polishing debris using microscopy, spectroscopy and diffraction analyses.A theoretical model to predict temperature rise at the interface during polishing is presented in Chapter 6. Additionally the temperatures at subsurface are measured experimentally and compared with the theoretical predictions.In Chapter 7, the material removal mechanisms of PCD are analysed based on the theoretical and experimental results, including reaction of carbon with metal, carbon phase transformation, diffusion and chemical reactions at elevated temperatures.Chapter 8 presents the optimization process by investigating the effect of polishing parameters on material removal rate and surface characteristics of polished specimens to obtain the required good quality surface at a very high polishing rate.In the last Chapter 9, conclusions drawn from the present work and suggestions for future work are given.Overall, the work conducted in present project seeks to develop a sound scientific methodology for the effective and efficient polishing of thermally stable PCD composite, and to optimize the processing conditions to obtain the cutting tool application requirement with surface roughness less than 0.06 µm Ra. It includes development of a new polishing machine, extensive investigation of the material removal mechanism, presentation of a theoretical model and optimization of the polishing process.。

1 Introduction教学目的: List six different property classifications of materials that determine their applicability. Cite the four components that are involved in the design, production and utilization of materials, and briefly describe the interrelationship between these components.教学重点: The four components that are involved in the design, production and utilization of materials教学难点: The discipline of materials science involves investigating the relationships that exist between the structure and properties of materials.教学方法:Multimedia学时分配1.1Historical Perspective10 min1.2Materials science and engineering 25 min1.3Why Study Materials Science and Engineering 10 min1.4Classification of Materials 35 min1.5 Modern Material‟s Needs 10 min教学过程及主要内容:1. Historical PerspectiveWebster编者“New International Dictionary(1971年)”中关于材料(Materials)的定义为:材料是指用来制造某些有形物体(如:机械、工具、建材、织物等的整体或部分)的基本物质(如金属、木料、塑料、纤维等)迈尔《新百科全书》中材料的含义:材料是从原材料中取得的,为生产半成品、工件、部件和成品的初始物料,如金属、石块、木料、皮革、塑料、纸、天然纤维和化学纤维等等。

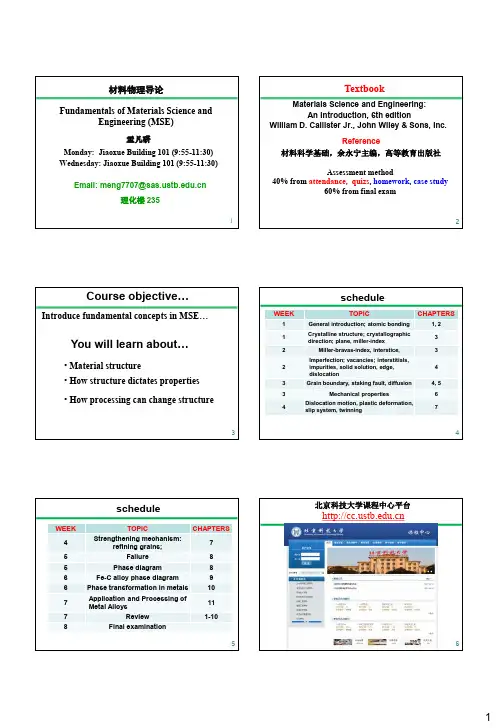

材料物理导论Fundamentals of Materials Science andEngineering (MSE)孟凡研Monday: Jiaoxue Building 101 (9:55-11:30) Wednesday: Jiaoxue Building 101 (9:55-11:30)Email: meng7707@理化楼 2351Materials Science and Engineering:An Introduction, 6th editionWilliam D. Callister Jr., John Wiley & Sons, Inc. Reference材料科学基础,余永宁主编,高等教育出版社 Assessment method40% from attendance, quizs , homework, case study60% from final examTextbook2Course objective…Introduce fundamental concepts in MSE…You will learn about…• Material structure• How structure dictates properties • How processing can change structure3 scheduleWEEKTOPICCHAPTERS1 General introduction; atomic bonding 1,2 1 Crystalline structure; crystallographic direction; plane, miller-index3 2 Miller-bravas-index, interstice, 3 2 Imperfection; vacancies; interstitials, impurities, solid solution, edge, dislocation4 3 Grain boundary, staking fault, diffusion4, 5 3 Mechanical properties6 4Dislocation motion, plastic deformation, slip system, twinning74scheduleWEEK TOPICCHAPTERS4 Strengthening mechanism:refining grains;7 5Failure85Phase diagram86 Fe-C alloy phase diagram 9 6 Phase transformation in metals 107 Application and Processing of Metal Alloys11 7 Review 1-108Final examination5 6北京科技大学课程中心平台7 Chapter 1Introduction89MetalGlassPlasticsBeverage containerIntroductionHistorical perspective Stage 1: materials that exist naturally, such as stone, wood, clay, and skin.Stage 3: materials that are modified by heat treatment and addition of other substances, such as steel and AlCu (bronze). Stage 2: materials that are produced by humans, such as pottery and metals.Stage 4: advanced materials that are made based on knowledge of processing - structure - property - performance relationship, such as metals, plastics, glasses, and fibers.10IntroductionMaterials Science and Engineering•Materials science involves investigation of relationship between structures and properties of materials•Materials engineering involves designing and engineering the structure of materials to produce desired properties11IntroductionWhat is structure?On an atomic level, structure encompasses the organization of atoms or molecules relative to one another.Subatomic structure is arrangement of electrons within each individual atoms, and their interactions with nuclei 12IntroductionIn brief, the structure of a material usually relates to the arrangement of its internal components.Microscopic : larger structural realm is subject to direct observation using some type of microscope.Macroscopic : structural elements may be viewed with the naked eye.Structure has many dimensions13 IntroductionWhat is properties?•Property is a trait in terms of the kind and magnitude of response to a specific imposed stimulus.• 6 groups mechanical, electrical, thermal, magnetic, optical, deteriorative14IntroductionprocessingperformanceWhat determines structure ?What does property affect ?15Introductionfour basic elementsSynthesis-Processing Composition-StructurepropertiesPerformance/Application16IntroductionThe material selection process1. Pick Application (performance) Determine required properties (6)2. Properties3. MaterialIdentify candidate materialMaterial: structure, compositionIdentify required processingProcessing: changes structure and overall shape Ex: casting, sintering, vapor deposition, doping , forming, joining, annealing17IntroductionStructure, processing, properties184wt%C compositionexample: hardness vs. structure of steelProperties dependon structureProcessing can change structureexample: structure vs. cooling rate of steelIntroduction19 Introduction 20Introduction21 Introduction 22Introduction23 IntroductionWhy study MSE?How does one select “proper” materials ?How can one know the selection criteria?An engineer has to select materials at various stages of his/her engineering24IntroductionHow does one select ‘proper’ materials? •Fit the in-service condition•resist deterioration•Economical•Recycling, without pollutionPerformance ApplicationDurability, reliability, environmental compliance costecomaterial25A reasonable compromise may be necessary! Introduction four basic elementsSynthesis-Processing Composition-StructurepropertiesPerformance/Application26Introductionknowledgeable in materials science and engineeringHow can one know the selection criteria?five basic elements propertiescompositionstructuretheory, modeling,material andtechnology designsynthesis/processing performanceenvironment (T, pressure, ambient, medium) 27IntroductionBasic classification of Materials (3) contain large numbers of nonlocalized electrons, good conductors of electricity and heat, not transparent to light, lustrous appearance, strong yet deformable. CeramicsCompounds between metallic and nonmetallic elements, oxides, nitrides, and carbides, insulative to electricity and heat, resistant to high T and harsh environments, hard but brittle.PolymersOrganic compounds that are chemically based on C, H, and other nonmetallic elements, with large molecular structure. Low density, extremely flexible. steelglass, cement, clay mineralsrubber, plasticMetals28IntroductionOther groups of important engineering materials (3) composites semiconductors biomaterials Combination of materials, designed to display a combination of the bestcharacteristics of each of the componentmaterialsfiberglass: glass fibers (strength) embedded in polymer (flexibility)electrical properties sensitive to smallamount of impurity, key elements ofintegrated circuitry.silicon, carbonEmpolyed in components implanted intothe human body for replacement ofdiseased or damaged body parts, notproduce toxic substances, compatible with body tissuesmetal, ceramics, polymers, composites, semiconductors29IntroductionAdvanced Material•electronic equipment (VCR, CD players, LCDs) •computers•fiber-optic systems•spacecraft •aircraft •military rocketryUtilized in high-tech applications expensivecomplicate to make 30IntroductionShape memory alloys (SMA): shape changes in response to temperature changes;Piezoelectric ceramics: shape changes in response to an applied electrical field (or voltage);Magnetostrictive materials : shape changes in response to an applied magnetic field;Electrorheological/magnetorheological fluids: viscosity changes in response to changes in electric or magnetic field.Future materials (1)“Smart Materials”: sense and respond to changes in environment.31IntroductionFuture materials (2) NanotechnologyThe general procedure has been to begin by studying large and complex structures, and then to investigate the fundamental building blocks of these structures that are smaller and simpler.32Introduction“Top down” Science“Bottom -up” approachIt has been possible to manipulate and move atoms and molecules to form new structures and, thus, design new materials that are built from simple atomic level constituents. This ability to carefully arrange atoms provides opportunities to develop mechanical, electrical, magnetic, and other properties that are not otherwise possible.CoalGraphiteDiamonds33 Introduction34Is it possibleto handle atoms ? Yes !NanotechnologyIntroduction35•What have been done… Micro-chipsMicro-motorsNanotechnologyIntroductionEngr Mater: 0136Dreams…Nano-pumpNano-bearingsNano-armNano-chips ?NanotechnologyIntroduction37 •Reading: Richard P. Feynman’ s talk: “There's Plenty of Room at the Bottom”at /nanotech/feynman.htmlAnother very fun book to read: 'Surely You're Joking, Mr. Feynman!‘NanotechnologyIntroductionFuture materials (3)BiotechnologyApply mechanical/physical/chemical principles to biotechnology38Introduction39 BiotechnologyWhy can gecko walk on the wall without difficulties? Introduction40BiotechnologyWhy can gecko walk on the wall without difficulties?Introduction41 BiotechnologyWhy can water skipper walk on the water?Introduction42BiotechnologyShoes for mountain climbing, adhensive tape, adhensive paper, recycling.They are masters majored in applied physics! Nanostructure!Van Der Waals ForceIntroduction43 壁虎脚底的粘着力究竟是怎样产生的呢?美国加利福尼亚大学伯克利分校的科学家罗伯特·福尔等人经过研究发现看上去不起眼的壁虎,居然是自然界数一数二的“应用物理大师”。