海尔洗衣机XQB100-BZ826说明书

- 格式:pdf

- 大小:8.35 MB

- 文档页数:2

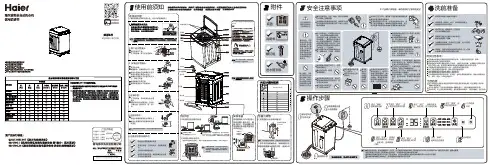

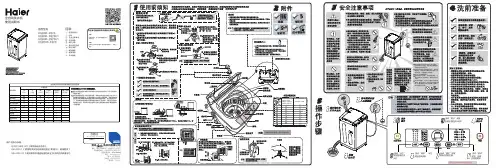

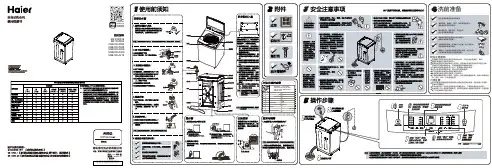

适用型号XQB80-F826XQB90-F826U1XQB90-Z826U1XQB100-F826版次:2017年第2版专用号:0030509626Q厂家代码:V14252地址:青岛市高科技工业园海尔工业园内在线报修地址:售后服务热线:4006 999 999网址:青岛 洗衣机有限公司该产品执行标准:Q/0212HRE 007《家用电动洗衣机》GB 4706.1 《家用和类似用途电器的安全 第1部分:通用要求》GB 4706.24 《家用和类似用途电器的安全 洗衣机的特殊要求》全自动洗衣机使用说明书一、使用前须知 二、附件 三、安全注意事项 四、洗前准备 五、操作步骤 六、操作按钮说明 七、清洁/维护 八、疑问解答 目录:九、保修说明 十、技术数据 关注海尔智能洗衣机微信公共账号方法一方法二在微信公共账户中搜索“海尔智能洗衣机”,并进行关注扫描二维码,对“海尔智能洗衣机”进行关注尊敬的海尔用户:感谢您使用海尔家用洗衣机,我公司将按照《中华人民共和国消费者权益保护法》的有关规定,凭电子保修卡(扫描封面二维码选择电子保修卡下载、安装后,录入发票注册产品,保修无忧,一键家电管理,报装、报修,方便快捷)或发票,为您提供下列服务:一、家庭用洗衣机的整机免费保修三年。

二、下列情况不属于免费保修范围:1.用户因运、装、用、管不当而损坏的;2.自行拆卸产品的;3.涂改发票或无购机发票的;4.因异常电压、火灾等外部原因损坏的;5.未按说明书、洗衣机主体注意标牌等注意事项要求使用的。

家庭用以外的洗衣机使用提示:该产品为家用,除家庭以外(如:学校、公寓、部队、企业、医院、洗衣房、洗浴中心、酒店、宾馆、招待所等团体)使用的洗衣机,不属于免费保修范围。

为了您更好的使用,请定期与海尔售后服务联系维护保养,以免使用不当造成损失。

备注:1、本产品有结构变化,数据变化,恕不另行通知。

2、根据需要,以下零件可供选购: 进水管加长管 排水管加长管。

洗衣机使用说明书型号EB100M32NOVA2• 本说明书为通用手册• 本公司保留说明书解释权• 产品外观请以实物为准• 阅后请与发票一并妥善保存• 如遇产品技术或软件升级,恕不另行通知• 本产品只适合在中国大陆销售和使用1. 产品介绍1 1.1. 产品部件1 1.1.1. 部件介绍1 1.2. 技术规格21.2.1. 参数介绍22. 使用说明4 2.1. 安全注意事项4 2.1.1. 图示说明4 2.1.2. 警告类4 2.1.3. 注意类4 2.2. 洗衣机的安装5 2.2.1. 拆除包装5 2.2.2. 洗衣机的放置6 2.2.3. 洗衣机的调平6 2.2.4. 排水管7 2.2.5. 进水管8 2.3. 洗涤注意事项12 2.3.1. 不可洗涤衣物12 2.3.2. 检查衣物12 2.3.3. 衣物分类洗涤16 2.3.4. 重污衣物预处理17 2.3.5. 衣物放入方法19 2.3.6. 衣物洗涤重量参考20 2.4. 洗衣操作20 2.4.1. 洗衣步骤20 2.4.2. 操控界面21 2.4.3. 开机21 2.4.4. 程序21 2.4.5. 参数22 2.4.6. 洗涤剂投放24 2.5. 清洁保养25 2.5.1. 线屑过滤器25 2.5.2. 进水阀过滤网262.5.3. 箱体和内桶293. 售后服务31 3.1. 疑问解答31 3.1.1. 问题解答31 3.1.2. 显示代码及处理方法333.2. 有害物质33 3.2.1. 有害物质名称及含量33 3.3. 保修说明34 3.3.1. 洗衣机保修说明341. 产品介绍1.1. 产品部件1.1.1. 部件介绍本电子说明书使用的配图均为示意图,由于产品改进及系列化扩展,您所得到的产品外观、颜色及功能部件可能与此图片不一致,请以实际产品为准。

附件1.2. 技术规格1.2.1. 参数介绍技术数据注:本产品技术数据如有变更,恕不另行通知,请以产品实物为准。

“预约”程序根据需要,可选择洗涤温度、甩干速度 、选择所需的程序

使用前请仔细阅读说明书请妥善保存,以备参阅

本产品只适合在中国大陆销售和使用

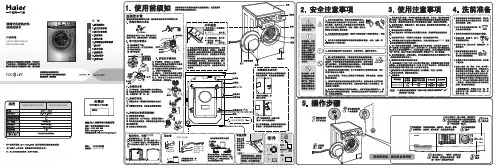

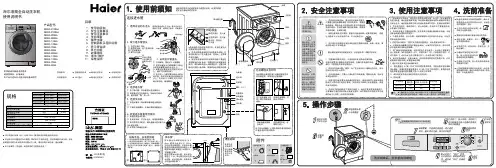

海尔滚筒全自动洗衣机使用说明书

XQG50-B12866

XQG50-B10866XQG50-B9866XQG50-B8866XQG50-12866XQG50-10866XQG50-9866XQG50-8866XQG50-8866A XQG56-12866XQG56-10866XQG56-9866XQG56-8866

产品型号:

使用前须知安全注意事项使用注意事项洗前准备操作步骤

控制面板及程序说明显示屏说明其它功能故障排除清洁/维护保修说明

1.2.3.4.5.6.7.8.9.10.11.● 该产品执行标准:GB/T 4288-2008 《家用和类似用途电动洗衣机》

● 本产品属于I 类电器,请您使用时注意用电安全!

规格

电源

额定洗涤容量额定脱水容量洗涤噪声脱水噪声外形尺寸(高×深能效等级

甩干转速0020505501

2009年第1版6

9

● 本说明书中的图形均为示意图,同时由于产品的改进,您所得到的产品外观、颜色及其配件可能与本说明书中的图示不一致,请以实际产品为准,谨此致歉。

●●●●电源

预洗

棉麻

化纤

羊毛

内衣

快洗

启动/暂停

单甩

单洗

单漂

XQG50-B12866

S-D 芯变频

目录

自动档技术变频驱动技术断电记忆技术变频系列非变频系列

LED 显示

●断电记忆技术

●自选档技术。

海尔洗衣机参数详解为便利广大用户认识选购海尔洗衣机,海尔洗衣机按照国内统一标准给产品分了类型。

海尔滚筒洗衣机类型的字母代表意思如下:第1位符号“X”代表洗衣机;“T”则是脱水机。

第2位符号“P”表明普通型;“B”半自动型;“Q”全自动型。

第3位符号“B”代表波轮式;“G”滚筒式;“D”搅拌式。

第4位代表洗涤容量。

第5位是厂家规划序号。

第6位是结构型式代号,“S”表明双桶机,单桶机则不标明。

以XQB72-M12688这个类型为例详细解说:一般的洗衣机是以X开头,代表的洗衣机的意思。

如上文的X就代表洗衣机的意思,基本上一切洗衣机都是这么标的;Q代表的是全自动的意思(拼音是quan),此外XPB65-187BSAM这儿X后边的P代表是半自动的意思;B的意思波轮的意思(拼音bo),例如XQB意思就是全自动波轮洗衣机。

相对应的就是滚筒,滚筒的字母是G(拼音gun),例如XQG70-BS1228A代表的就是全自动滚筒洗衣机。

例如XQS70-Z118至爱,这一款机子的S就代表是双动力的意思(拼音shuang)。

此外,十分知名的波轮技术,匀动力技术是海尔的专利。

例如XQY70-BZ228这一款机子的Y就代表了匀动力的意思(拼音yun)。

还有一些特别的滚筒洗衣机在公斤前面还有一些字母,那详细代表的是什么意思?例如XQGH70-B1266这一款海尔卡萨帝滚筒就有一个H在后边,这个H的意思是高的意思(英文high),这款滚筒高度到达1.2米。

再就是要介绍海尔洗衣机的第二部分数字解说例如XQGH70-B1266,咱们知道前面的数字代表的是全自动滚筒高洗衣机,后边的70就代表的是7公斤的意思,买过洗衣机的人们都知道,洗衣机最小的是3公斤的MINI洗衣机,最大的是12.5公斤的半自动洗衣机(我指的都是家用)。

再例如XQS60-Z118至爱,咱们知道前面代表的是全自动双动力波轮洗衣机,60就代表了6公斤的意思。

下一步咱们就要详细了解海尔洗衣机最杂乱也是最有学识的一块,功能字母为了便利了解,我会悉数以实例的方式给我们解说。

洗衣机使用说明书(总9页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--1.使用前须知连接进水管1.选择适合的水龙头(前段长度必须大于10mm,若水龙头出口端面不平整,请用锉刀锉平,以免漏水)2.取下进水管接头①②③④①按住锁紧杆下端;②握住进水管,向下压滑动器,取下进水管接头;③接下标记牌。

3.安装进水管接头①拧动螺母,露出3至4圈螺纹;②将进水管接头的四颗螺钉拧松至可将进水管接头套在水龙头上;③如果进水管水龙头无法套在水龙头上,请取下衬套在安装;④将其中一个螺钉事先旋到大致适合位置,在将进水管套在水龙头上,将其余三颗螺钉均匀拧紧,确认到位后,旋紧螺母。

4.连接进水管①压下滑动器,将水管插入进水管接头;②用锁紧杆挂住水管接头,然后松开滑动器,直到听到“啪”的一声。

5.连接洗衣机①将进水管另一端的螺母套到进水阀接头上;②拧紧进水管螺母并确认螺母紧固到位。

6.检查进水管是否连接好①检查连接是否牢固;②安装完毕后,打开水龙头,检查是否漏水;③每次使用洗衣机前,请检查确认进水管与水龙头连接牢靠④切勿强力弯曲进水管。

粘贴毛毡,安装降噪板1.将毛毡粘贴在降噪板的一侧。

2.将洗衣机向后倾斜,卸下四个底脚。

3.降噪板附有毛毡的一面朝内,将将底脚螺栓穿过四个孔装在壳体上旋紧,重新放平机器。

排水管排水管出水端高度必须大于80cm,最高点必须小于100cm,为防止排水管脱落,可将排水管固定在机器后的排水管卡上或使用排水支架固定,建议不要加长排水管,加长部分若超过,易出现边进水边排水现象。

延长排水管,请联系本公司售后服务部门。

调整底脚使用之前应先调节四个底脚,使洗衣机处于平衡状态。

底脚调节完毕后,要把底脚支撑螺母旋至紧贴壳体位置处,以支撑洗衣机。

分配器盒(每次只放入一次洗涤所需的洗涤剂)预洗洗涤剂投入室主洗洗涤剂投入室软化剂,漂白剂投入室选择预洗的功能时,在预洗室投入洗涤剂预先洗涤衣物;洗涤剂的用量请参照洗涤剂的使用说明,过量的洗涤剂会产生大量泡沫,易溢出,且影响洗涤剂的溶解;应使用滚筒洗衣机专用低泡洗涤剂,若洗涤合成或羊毛织物时,则应该用为其特制得洗涤剂软化剂或漂白剂的最高液面不要超过分配器盒的MAX标识。

1Hood2Tank3Wash and rinse arms 4Wash5Water softener6Pump7Control box8Rinse aid injector9Drain pump10Detergent dispenser 11Wash and rinse armsCode Description150819CABLE HOLDER PG16 WITH HOLE 160772PLUG FOR DOOR (BR-BC-FC)160804GASKET D.6160838SLIDING WASHER TIE ROD FC 160840WASHER160905SLIDING PLATE F. TIE ROD180506DOOR CATCH BR-BC-FC190619DOOR CATCH B-F-R200923DOOR GASKET260223M5X12 MSH/HD SCREW SPECIAL S/S 260238M4 X 10 MUSH/HD SCREW260247SCREW TCB 5X16260250SCREW TB 5X20260414SELF-LOCKING NUT M5260503STAINL.STEEL FLAT WASHER D5 UN 260512ST/ST GROWER WASHER D6260542WASHER D.5320395TOP PANEL FC321807DOOR HINGE FC MACHINES322417RIGHT GUIDE FC322418LEFT GUIDE FC322941DOOR FC54-543-544-HR330233FC DOOR TIE ROD331764FIXING PLATE FOR B-F DOOR GASK 341218HINGE PIN B-F-G341482HOOD FC54-543-544-HR342010PIN FOR TIE ROD DOOR FC351351LEFT PANEL FC54-544-543-HR 351352RIGHT PANEL FC54-543-544-HR 351353FRONT PANEL FC351526LOWER FRONT PANEL390150LOWER BACK PANEL FC390159BACK PANEL FC54A440201RUBBER FOOT D.60X10450821SPRING CLIP FASTENER SNU 3634 461258PLATE FC54E/A463018FC54 NAMECode Description110263TANK HEATER 2000W 230V160121HOSE EPDM D. 5 X 9160203ELBOW 1"1/2 N-S-F-C /DRAIN 160301DRAIN OUTLET 1"1/2 C-S-N160308PUMP INLET HOSE FC160727PLUG 1/2 NTP CAP160755PLUG FOR MACHINES WITHOUT SOFT 161305AIR CHAMBER F45-F80161306HOSE FOR AIR CHAMBER F45-80 170711OVERFLOW PIPE FC180102DRAIN PIPE NUT 1"1/2 F45-55 180109LOCK NUT 1 1/2"180818STRAINER FOR FC200410DRAIN OUTL.WASH.1 1/2"65X47X2 200412GASKET DRAIN 11/2" 45X33X3 200415AIR TRAP GASKET -F2 18,5X10X3 200467DUTRAL GASKET F. AIR TRAP200469STAND PIPE O RING 45X35,5X7 200489GASKET 81X68X3200721DRAIN HOSE 28X35 3MT.200810O-RING 2,62X9,92X15,6 F.GLASSW 200919GASKET FOR SUCTION BASIN FC 260408S/S NUTS D.12260506STAINL.STEEL FLAT WASHER D10 270101HEXAGON LOCK NUT 1/2"290105BRASS-TE-PLUG 1/2"320166VORTEX BREAKER FOR FC MACHINES 450107CLAMP FE ZN 38-50 H=12,2450115ELASTIC CLAMP D.8,3/7,8450519TANK THERMOSTAT SHIELD C-F 460502GASKET 30X21X2Code Description140108PLATE FOR WASH ARM160734END PLUGS RINSE ARM160736WASH ARM PLUG F45160804GASKET D.6170946RINSE JET/RINSE ARM B-F170947WASH JET/WASH ARM F45-80 190203LOWER TEE WASH-RINSE F2-45-55-190218UPPER ARM SUPPORT190624BUSH FOR PLASTIC ARM F45190645LOWER BUSH FOR WASH ARM F 191077LOWER WASH ARM SUPPORT FC54E 200415AIR TRAP GASKET -F2 18,5X10X3 200806O-RING 2,62X13,10X18,34200812O-RING 1,78X17,17X20,73200820O-RING151 46,99X5,33X57,6 200824O-RING 1,78X12,42X15,98200829O-RING 81,92X92,58X5,33200843O RING 2X13X17200844O RING 2X9,5X13,5200845O RING 109 2,62X9,13X14,37 260106SCREW TE 6X25260404STAINLESS STEEL NUTS D6 UNI 55 260504ST/ST FLAT WASHER D6260512ST/ST GROWER WASHER D6260711SCREW 4,2X13 A2 DIN7972261005SCREW F. TEE UP.WASH F2-B41 261009RETAIN.SCREW FOR WASH-RINSE AR 320161UPPER WASH ARM PROTECTION 420552ARM FC-ECONOMYCode Description190203LOWER TEE WASH-RINSE F2-45-55-190218UPPER ARM SUPPORT200787INLET HOSE FC53-FC544-FCHR 200789OUTLET HOSE FC200792HOSE FOR UPPER/LOWER WASH FC54 260103SCREW TE 6X12260126SCREW TE 5X12260404STAINLESS STEEL NUTS D6 UNI 55 260511GROWER WASHER D.5260512ST/ST GROWER WASHER D6260538WASHER 18X6X1,5 ST/ST331922BRACKET F. PUMP "F"450105CLAMP FE ZN. 26-38 H=12,2450107CLAMP FE ZN 38-50 H=12,2450135CLAMP FE ZN. 44-56 H=12,2Code Description110363HEATING ELEMENT 3000W 230V 120144SOLENOID VALVE FCA 20 LT TYPE 120522TANK THERMOSTAT 90?120523SAFETY THERMOSTAT 110?120525BOOSTER THERMOSTAT 2 TEMPERAT. 160105INJECT.INLET HOSE D.6X4160117HOSE 6,3X1,1 WITHE160805GASKET D.8161123HEAT.ELEMENT COVER H42 SNL 180130CONNECTION NUT FOR BY PASS (1/ 180408TEE-NIPPLE F.INJECT.W/CENTR.RE 180411TEE-NIPPLE FOR BY PASS "BTM" 180415TEE NIPPLE DOUBLE "T"190330TEE FOR VAACUM BREAKER191040FRAME F.THERMOSTAT KNOB200113RUBBER HOSE 12 X 22200117RUBBER HOSE 7X16200122HOSE 11X19200416GASKET D. 3/4"200454GASKET F. SALT CONT.200714GLASSWASHER INLET HOSE200800HOSE FOR SALT CONTAINER200815O-RING F. HEAT. ELEM.200822PLUG GASKET OF SALT CONTAINER 201002HOSE260112STAINLESS STEEL TE-SCREW 8X16 280121ELL FOR VAACUM BREAKER330342BOILER C1000/1300-FC-LC330725STANDARD BRACKET F.SOLEN.VALV 331726BRACKET FOR 3 THERMOSTATS 331839BRACKET FOR WATER SOFTENER 450102CLAMP FE ZN 11-17 H=9450103CLAMP FE ZN. 13-20 H=9450114CLAMP FE ZN.22-32 H=12,2450115ELASTIC CLAMP D.8,3/7,8450315KNOB F. THERMOSTAT 90?460502GASKET 30X21X2620120RINSE AID INJECTOR620243VACUUM BREAKER (WITHOUT KIT) 630969COIL S4216 220/50HZ631302SALT CONTAINER640209WATER SOFTENER (4 COLUMNS)Code Description100399PUMP HP0,6 220-50HZ (100740) 100740PUMP 0,6HP 220/240V 4247 100744PUMP HP 0,6 200-220-60HZ 630116-NO MORE AVAILABLE630129VOLUTE PUMP 0,5HP 2247 630222COVER PUMP IB HP 0,4630240PUMP FLANGE 0,6HP-4247 FIR 630413-NO MORE AVAILABLE630419PUMP GASKET 2247 0,5HP 630501SEAL FOR PUMP HP 2-3-3,2 631206CONDENSER 10MF. 450V 85C 631652-NO MORE AVAILABLE631683PUMP IMPELLER 50HZ FIR 4247 631684IMPELLER FOR PUMP 60 HZCode Description110478FLAT CABLE FOR FC54E PCB120356DOOR MAGN.SWITCH120444CONTACTOR 9A 220V 50HZ120460RELAY 16A 220V121277CONTROL PANEL121279ELECTRONIC TIMER130264FUSE 5X20 1A130311TERMINAL BLOCK130605PRESSURE SWITCH 50-30 1 LEVEL 150622FUSE HOLDER SIEMENS 1,5MM-6,3A 150833CABLE HOLDER BC/BR160121HOSE EPDM D. 5 X 9260201SCREW TCP 3X10260205SCREW TCP 4X16260248SPECIAL SCREW TB 5X12260402STAINLESS STEEL NUT D4 UNI 55 260404STAINLESS STEEL NUTS D6 UNI 55 260502S/S FLAT WASHER D.4260510GROWER WASHER D.4260534WASHER260538WASHER 18X6X1,5 ST/ST260542WASHER D.5331892BRACKET332125351816SUPPORT390206450115ELASTIC CLAMP D.8,3/7,8450137COLLAR CONNECTION WITH BASE 31 450221SPRING FOR ELECTRONIC TIMER 461254PLATE FC54E461258PLATE FC54E/A631209ANTI-NOISE FILTERCode Description160714PLUG FOR RINSE AID INJECTOR MO 170701LOCK NUT 1/2" F.INJECTOR180306NIPPLE F.RINSE AID INJECTOR 190107COVER FOR RINSE AID DISPENSER 190108VOLUTE FOR RINSE AID DISPENSER 190803GASKET SUPPORT RING F.INJECT 191018FILTER SUPPORT RINSE AID INJEC 200444SUCTION VALVE RINSE INJECTOR 200816O-RING 2,5X59,2X64,2 RINSE INJ 200825O-RING 3X5X11 RINSE INJECTOR 200861O-RING 14X18X2260142SCREW TE 4X16260213SCREW TCP 5X25260402STAINLESS STEEL NUT D4 UNI 55 260404STAINLESS STEEL NUTS D6 UNI 55 260512ST/ST GROWER WASHER D6 330543FILTER RINSE AID INJECTOR D.17 340483PISTON FOR RINSE AID DISPENSER 381105DIAPHRAGME DISC440405GASKET FOR RINSE AID INJ. 450214SPRING RINSE AID INJECTOR 620120RINSE AID INJECTOR630614DIAPHRAGM RINSE INJECTORCode Description100342DRAIN PUMP 100 W 220V160307DRAIN OUTLET FC170712OVERFLOW PIPE FOR DRAIN PUMP 200346DRAIN HOSE GLASSWASHER 200469STAND PIPE O RING 45X35,5X7 200793DRAIN PUMP INLET HOSE FC 332333BRACKET FOR DRAIN PUMP 450106CLAMP FE ZN 32-44 H=12,2 450114CLAMP FE ZN.22-32 H=12,2 450135CLAMP FE ZN. 44-56 H=12,2Code Description180719DETERGENT DISPENSER SUCTION HO 200467DUTRAL GASKET F. AIR TRAP200607DETERGENT DISPENSER HOSE 251213INJECTOR S/S FOR DETERGENT IN 260408S/S NUTS D.12620242DETERGENT INJECTOR (KIT)Code Description160804GASKET D.6170963RINSE JET X FC190203LOWER TEE WASH-RINSE F2-45-55-190215UPPER WASH/RINSE ARM SUPPORT F 190617BUSH190663BUSH191068LOWER WASH ARM SUPPORT FC-MACH 191069WASH ARM CENTER (FC - MACHINES 191070LOCK NUT FOR WASH ARM CENTER ( 200415AIR TRAP GASKET -F2 18,5X10X3 200806O-RING 2,62X13,10X18,34200820O-RING151 46,99X5,33X57,6200824O-RING 1,78X12,42X15,98200829O-RING 81,92X92,58X5,33200850O-RING260106SCREW TE 6X25260404STAINLESS STEEL NUTS D6 UNI 55 260504ST/ST FLAT WASHER D6260512ST/ST GROWER WASHER D6261005SCREW F. TEE UP.WASH F2-B41 280413RETAIN.LOCK NUT FOR FC RINSE A 320161UPPER WASH ARM PROTECTION 342706SHAFT420548FC WASH ARM (ST/ST)430332RINSE ARM FC 01/00450236SPRING FOR WASHER 170963。

SuperPole™SuperBar™SuperTrapeze™SP-S SP-HDSPB-SSPB-HDSPB-AK(DC100 - RevE)STP-SSTP-AK89111012131457346212HW318HW323HW302202122232829301724252726182315181917163HW100SP102HW320HW300HW320HW112+++SP-SSPB-SSTP-SSP-SSPB-SSTP-SSP-HDSPB-HD12345 678910 42"/51mm6"/154mm3"/76mm10"/254mm ABC D EABCEDFACEBD45612351234 56 6HW318HW323HW30278910+(2-5)111271234HW100 56889101112HW100984"2134mm3+4567101289101111Ø 5" / 127mm 20"508mm93-99"2362-2515mm2.50" / 64mm1.0625" / 27mm8"203mm20"508mmØ 1.50" / 38.1mmFE / PVC / UHMW SP-P 13lbs / 5.9kgFE / NBR SP4034lbs / 1.8kgFE / NBR SP4021lbs / 0.4kg1216"406mm8"203mmØ 2.50"64mmØ 2"51mmØ 1.50"38.1mm3.875"98mm17"432mm8"203mm3-29"76-737mm12.25"311mm13.5"343mmPOMFEFE / PA / LDPE FE / PVC SP102.05lbs / .02kgFE / PVC SP4044.20lbs / 1.91kgSP4085.25lbs / 2.38kgSP411.85lbs / .39kgSP4092.05lbs / .93kgSUPERPOLE (SP-S)93-99"2362-2515mm 93-99"2362-2515mm 100-120"2540-3048mm 121-140"3073-3556mm < 93"2362mmSUPERBAR300lbs / 136kg450lbs / 205kg 300lbs / 136kg 300lbs / 136kg 300lbs / 136kgMAXANGLED CEILING PLATEUNI-FIT EXTENDERCEILING PLATE EXTENDERSUPER-TRAPEZESUPERPOLE HEAVY DUTY (SP-HD)UNI-FITEXTENDER (SP-UF)SUPERPOLEULTRA (SP-ULTRA)SUPERPOLE CUSTOM (SP-CUSTOM)SUPERPOLE CEILING PLATE EXTENDER (SP-CPE)SUPERPOLE ANGLED CEILING PLATE (SP-ACP)13OVERVIEWThank you for choosing the SuperPole System from HealthCraft. Please read and understand the instructions in this manual; keep manual for future reference. It is your responsibility to see that your SuperPole System is properly assembled, installed, and cared for. Failure to follow instructions in this manual could result in serious injury or death. If you are not equipped to undertake the outlined work, we would recommend that you have your SuperPole System installed by a qualified contractor.The SuperPole System is intended for moderate vertical load bearing to provide sitting and standing support for people with reduced mobility. The floor to ceiling range and maximum user weight dependent on model (see Page 13 for details and product / accessory compatibility chart). Product is not intended to support full body weight. The SuperPole System is not to be used in any other way than described above.The SuperPole is a high quality, commercial grade floor to ceiling safety pole. The SuperPole must be installed between a structural floor and ceiling by turning a jackscrew at the bottom of the pole. The pressure created by the jackscrew is strong enough for the SuperPole to support the user, yet it does not require drilling holes into the floor or ceiling. This is ideal for relocating or removing the pole. NOTE: The top plate has two holes that may be used to fix the plate directly to the ceiling joist if necessary. See Page 4 for details.The SuperBar is a high quality, commercial grade pivoting and locking horizontal bar that connects to the SuperPole (floor to ceiling safety pole). The horizontal bar can be lifted, pivoted and lowered to the next locking position around the SuperPole. In any of the 8 lowered position (every 45 degrees) the SuperBar can be used to support the user. It is important to set proper height and orientation of the SuperBar to optimize the user’s range of motion.The SuperTrapeze is a high quality, commercial grade over-bed trapeze that connects to the SuperPole (floor to ceiling safety pole). The SuperTrapeze handle features two offset ladder rungs to allow for improved use of arm strength and increased comfort. Additionally, it can hook around the pole to store out of the way when not in use. The support arm has an adjustable strap that attaches to the trapeze handle. It is important to set proper height and orientation of the SuperTrapeze to optimize the user’s range of motion.WARNING - PATIENT ENTRAPMENT (see additional guidelines)The potential risk of entrapment (limb, neck, head, torso) between the pole and adjacent item (i.e. bed, toilet, etc.) can be reduced or avoided by the following strategies:1. Situate the pole at a distance that is considerably smaller or larger than that which could result in entrapment.2. Consider situations that could change with time or usage such as mattress compression, patient movement, bed position changes due to electrically powered beds, etc.3. Realize that this product is not intended as a physical constraint or barrier to exiting the bed.LIMITED LIFETIME WARRANTYProducts are covered by a limited lifetime warranty against defects in materials and workmanship for the original purchaser. Warranty excludes products that have been damaged through misuse, accidental damage, alteration, normal wear and tear, wood material and stain, or the use of corrosive or abrasive cleaning products.Buyer hereby indemnifies, agrees to hold harmless and defend HealthCraft Products Inc. from and against any and all liabilities, claims, (founded and unfounded), losses, damages, costs and expenses (including without limitation consequential damages and reasonable professional fees) resulting from buyers specification, application, or improper use of goods described hereon; buyers omission or neglect. HealthCraft Products Inc. does not assume any liability for damage resulting from services performed by others or faulty installation, misuse or misapplication of goods sold by HealthCraft Products Inc. HealthCraft Products Inc. shall not be liable for prospective profits or special, indirect, or consequential damages, or for the cost of any corrective work done without HealthCraft Products Inc. prior approval. HealthCraft Products Inc. total liability hereunder shall in no event exceed the purchase price of the goods specified hereon. Specifications subject to change without notice.DELIVERY CONTENTS - SUPERPOLE FIGURE A.SP400 - POLE ASSEMBLY1. Pole2. Pole Grip, 20" length3. Cover Sleeve (with warning label)4. Threaded Collar5. Jam Nut6. Extension Screw7. Plastic WasherDELIVERY CONTENTS - SUPERBAR FIGURE B.SP404 - T-BAR ASSEMBLY15. T-Bar Weldment16. GripSP411 - COLLAR ASSEMBLY17. Spring Ring (with warning label)18. 5/16-24 Set Screw (x3)19. Castellated CollarSP403 - TOP PLATE ASSEMBLY8. Top Plate Rubber9. Top Plate10. Nylon Washer11. Cotter Pin12. Clevis PinSP402 - BASE PLATE ASSEMBLY13. Base Plate14. Base Plate RubberHARDWARE20. #8-32 Set Screw (x2)21. Pivot Bushing (x2)22. 3/32"Hex Key23. 5/32" Hex Key14DELIVERY CONTENTS - SUPERTRAPEZE FIGURE C. SP408 - SUPPORT ARM24. Support Arm Weldment25. Rectangular Plug26. Plastic Buckle27. Safety StrapSP409 - TRAPEZE ASSEMBLY28. Trapeze Handle29. Top Grip, 6" length30. Bottom Grip, 10" lengthINSTALLATION WARNINGS FIGURE D.1. Use caution while maneuvering pole during installation.2. Standard pole can be installed directly under 1 ceiling joist.3. Standard pole can be installed directly under 2 ceiling joists.4. Heavy Duty (HD) pole must be secured to ceiling joist (s).5. If subject to heavy usage, pole must be secured to ceiling joist (s).6. CAUTION - Damage may occur if extension screw is overtightened.7. CAUTION - Do not install if the structure above ceiling is unknown.8.CAUTION - Do not install on loose floor coverings.9. CAUTION - Do not install in rooms with radiant ceiling heat.10. CAUTION - Do not install on angled ceilings.SUPERPOLE PLACEMENT FIGURE E. 1. BEDROOM - Locate pole adjacent to waistline, and as close to bed as possible while allowing clearance for bed coverings.2. BATHTUB ONLY - Locate pole base against tub, approximately half way along its length3. SEATING (TOILET or CHAIR) - To provide clearance when standing, locate pole 3-10" / 76mm-254mm forward of the knees, and 2-6" /51mm-154mm to the side of knees when sitting.SUGGESTED SUPERBAR POSITIONS FIGURE E.4. BEDROOMA = side support / out of the wayB = in-bed supportC = sitting supportD = standing supportE = transfer support towalker / wheelchairSUPERPOLE INSTALLATION INSTRUCTIONS FIGURE F.1. On a flat horizontal surface, place top plate onto pole.2. Align holes and install clevis pin with washer on opposite side.3. Install cotter pin into clevis pin.4. Place base plate on floor at intended location, and tilt pole.5. When upright, install the pole into the base plate hole.6. Insert shaft of screwdriver thru drive hole of extension screw.7. Hold pole and turn screwdriver clockwise to raise pole.8. Top plate must contact ceiling squarely.9. Continue turning extension screw approx 2-5 turns until pole is secure.10. Turn jam nut until it is tight against bottom of pole.11. Turn both jam nut and extension screw together to jam tight.12. Remove screwdriver and lower cover sleeve to conceal screw.SUPERBAR INSTALLATION INSTRUCTIONS FIGURE G.1. Slide spring ring upwards on castellated collar to expose 3 set screws.2. Back off 3 cone point set screws with hex key so castellated collar canslide onto pole without set screws contacting pole.3. Install pivot bushing into T-bar assembly.4. Align hole and install screw with hex key.5. Remove cover sleeve from bottom of pole.6. Slide items onto bottom of pole (note order and orientation): T-Barassembly with installed pivot bushing top/first, spring ring withcastellated collar, pivot bushing and cover sleeve.7. Install SuperPole as per instructions Page 6-7.8. Install castellated collar to pole by tightening 3 set screws with hex key.The set screws MUST be tightened until the back of the screw is flushwith the collar or injury may result.9. Slide spring ring downwards on the castellated collar to retain set screws.10. Lower T-bar assembly onto castellated collar.11. Install bottom pivot bushing into T-bar assembly.12. Align hole and install screw with hex key.SUPERTRAPEZE INSTALLATION INSTRUCTIONS FIGURE H.1. Slide support arm onto top of pole with strap hook facing towards grip.Rest support arm on top of grip.2. Install SuperPole as per instructions Page 6-7.3. Rotate support arm over bed.4. Hold the trapeze handle under the support arm, such that the shorter rail of the handle is closest to the head of the bed.5. Rotate the strap 180° and slide onto the shorter rail of the trapezehandle until it reaches the top bend of the trapeze.6. Position support arm such that the trapeze handle hangs directly overthe user’s hands (on thighs) when they lay on the bed.7. Raise support arm approx 84"/2134mm from floor to top of support arm.8. Slide spring ring upwards on support arm to expose threaded holes.9. Install support arm to pole by tightening 3 set screws with hex key. Theset screws MUST be tightened until the back of the screw is flush withthe collar or injury may result.10. Slide spring ring downwards on the castellated collar to retain set screws.11. Adjust length of strap such that the user can comfortably grasp thebottom rail of the trapeze handle when laying down.TECHNICAL DATASee Figure I.PRODUCT COMPATIBILITY CHARTSee Figure J.PRODUCT USAGESee Figure I.HARDWARE18. 5/16-24 Set Screw (x4)23. 5/32" Hex Key5.BATHROOM or6.SITTINGA = side support / out of the wayB = standing or transfer supportC = standing supportD = standing or transfer supportE = standing or transfer supportF = transfer support in/out of bathtub1520。

全自动洗衣机智能家电操控智慧场景定制智家商城购物家电报装报修Q/0212HRE 007《家用电动洗衣机》GB 4706.1《家用和类似用途电器的安全 第1部分:通用要求》GB 4706.24《家用和类似用途电器的安全 洗衣机的特殊要求》表示该有害物质在该部件所有均质材料中的含量在GB/T26572规定的限量要求以下。

表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T26572使用规定的限量要求。

但符合欧盟ROHS指令环保要求。

本表提供的信息是基于供应商提供的数据及海尔洗衣机的检测结果。

在当前技术水平下,所有有毒有害物质或元素的使用控制到了最底线,目前业界没有成熟的替代方案,海尔洗衣机会继续努力通过改善技术来减少有害物质和元素的使用。

电脑板类○○○○排水电机○○○○○泵、浊度传感器○○○○○停止开关部件○○○○○加热元件类○○○○○外壳、桶○○○○○○减速离合器○○○○○电容器○○○○○○电源线、线束○○○○○○包装印刷件○○○○○○其他○○○○○○全自动洗衣机有害物质的名称与含量部件名称有害物质六价铬(C r(Ⅵ))多溴联苯(P B B )多溴二苯醚(P B D E )铅(P b )汞(H g )镉(C d )○12021专用号对应的条形码使用说明书·使用前请仔细阅读本说明书·本公司保留说明书解释权·产品外观请以实物为准·阅后请与发票一并妥善保存·如遇产品技术或软件升级,恕不另行通知·本产品只适合在中国大陆销售和使用XQB100-BZ8260030515735青岛海尔洗衣机有限公司XQB100-BZ218选择童锁功能,洗衣机开始启动后,所有按键将被锁定。

锁定后,按键不可操作,不能改变程序设定若在洗涤时上盖被强制打开后,本机将E2报警,停止运行并会在10秒钟后自动进行排水。

若确认安全后,请合上上盖,并按“启动/暂停”按键,洗衣机将继续运行。

适用型号全自动洗衣机使用说明书

·使用前请仔细阅读本说明书·本公司保留说明书解释权·产品外观请以实物为准·阅后请与发票一并妥善保存

·如遇产品技术或软件升级,恕不另行通知·本产品只适合在中国大陆销售和使用

扫描二维码 智享科技魅力

XQB100-BZ826

版次:2019年 第1版 专用号:0030515735厂家代码:

在线报修地址:

售后服务热线:4006 999 999

网址:

Q/0212HRE 007《家用电动洗衣机》GB 4706.1《家用和类似用途电器的安全 第1部分:通用要求》GB 4706.24《家用和类似用途电器的安全 洗衣机的特殊要求》

选择童锁功能,洗衣机开始启动后,所有按键将被锁定。

锁定后,按键不可操作,不能改变程序设定

若在洗涤时上盖被强制打开后,本机将E2报警,停止运行并会在10秒钟后自动进行排水。

若确认安全后,请合上上盖,并按“启动/暂停”按键,洗衣机将继续运行。

若10分钟内未进行上述操作,洗衣机将自动关机。

按动“启动/暂停”按键,启动洗衣机

如果在洗衣机工作时按下该按键,则洗衣机将暂停。