YLT公司与SMJ设计院战略合作框架协议

- 格式:docx

- 大小:24.21 KB

- 文档页数:21

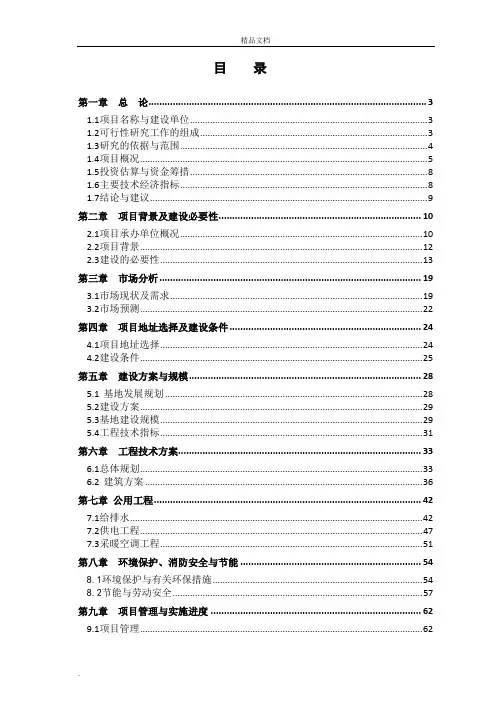

目录第一章总论 (3)1.1项目名称与建设单位 (3)1.2可行性研究工作的组成 (3)1.3研究的依据与范围 (4)1.4项目概况 (5)1.5投资估算与资金筹措 (8)1.6主要技术经济指标 (8)1.7结论与建议 (9)第二章项目背景及建设必要性 (10)2.1项目承办单位概况 (10)2.2项目背景 (12)2.3建设的必要性 (13)第三章市场分析 (19)3.1市场现状及需求 (19)3.2市场预测 (22)第四章项目地址选择及建设条件 (24)4.1项目地址选择 (24)4.2建设条件 (25)第五章建设方案与规模 (28)5.1基地发展规划 (28)5.2建设方案 (29)5.3基地建设规模 (29)5.4工程技术指标 (31)第六章工程技术方案 (33)6.1总体规划 (33)6.2建筑方案 (36)第七章公用工程 (42)7.1给排水 (42)7.2供电工程 (47)7.3采暖空调工程 (51)第八章环境保护、消防安全与节能 (54)8.1环境保护与有关环保措施 (54)8.2节能与劳动安全 (57)第九章项目管理与实施进度 (62)9.1项目管理 (62)9.2项目实施进度 (62)第十章组织机构与定员 (64)10.1组织机构 (64)10.2定员 (64)第十一章项目招投标方案 (65)11.1基础设施建设项目招标范围及招标组织形式 (65)11.2投标、开标、评标和中标程序 (65)11.3评标委员会的人员组成和资质要求 (66)第十二章投资估算与资金筹措 (67)12.1投资估算 (67)12.2资金筹措 (69)第十三章项目财务分析与评估 (70)13.1分析评估依据 (70)13.2总成本费用估算 (70)13.3收入估算 (71)13.4不确定性和风险 (71)第十四章社会效益分析 (72)14.1外部效果分析 (72)14.2社会效益分析 (73)第十五章结论与建议 (74)附图:1、规划总平面方案一(推荐方案)2、规划总平面方案二附件:1、《xxxx区鼓励创业带动就业工作的若干意见》;2、《关于成立xxxx区公共实训基地的通知》(克区政办发【2011】12号);第一章总论1.1项目名称与建设单位1.1.1项目名称xxxx区人才创新创业基地(人才公共实训基地)1.1.2项目承办单位项目承办单位:xxxx区人事劳动和社会保障局1.1.3项目拟建设地点xxxx区原九小院内1.1.4可行性研究编制单位编制单位:xxxx城市设计研究(院)有限公司1.2可行性研究工作的组成xxxx城市设计研究院接受xxxx区人事劳动和社会保障局xxxx区人才创新创业基地(人才公共实训基地)建设项目可行性研究工作的委托,进行了现场勘察,收集相关资料,并依据国家及自治区、市、区有关文件、规范、协议,对该项目进行可行性研究论证后,形成此报告。

PL20876A Manufacturing Cad Environment; Admin StyleKevin SmedleyEngineering Systems Managers FS-Elliott Co., LLCDescriptionWhat does it take to strategize and implement an efficient Cad and Vault environment?“Standards, Communications, and Consistency”, the three keys to an efficient Cad and Vault environment. This lecture is about how to build, implement and run a highly technical Cad arena to produce and sustain small to large Caddesigns. This discussion pertains to Vault start-ups, small, medium or large companies andthose that have been using Vault for some time. This session features Vault Professional, Vault Office, and Vault WorkgroupYour AU ExpertKevin has been an Autodesk product user since 1987 and Autocad 2.61. Currently Kevin is an Engineering Systems Manager and performs an array of administration strategy, planning,configurations and deployments of Engineering Business software(s) and processes. FS-Elliott Co., LLC engineering software(s) includes Cad programs, Vault product documentmanagement, CNC, ERP (Epicor), an array of SQL databases, Lotus Notes, etc. Future strategies are researched, tested and presented relating to continued global progress for FS-Elliott Co., LLC. The overall concepts and considerations are to allow for improved company (global) processes utilizing current and future technologies. Previously Kevin was an AutodeskSr. Mechanical AE for an Autodesk Reseller in Roanoke, Va. Kevin has also been involved with the Manufacturing software since beta Mechanical Desktop and then beta Inventor (Rubicon) in 1998. Kevin has taught lectures, labs and virtual lectures at AU since 1995. ***********************2OverviewThe basic values and ideas brought to this lecture are two and a half decades of Autodeskimplementation strategy and successes, both personally and professionally. This paper is about building a strong sustainable Cad design/engineering environment that constantly stays on the forefront of technology. Over the years, there have been challenges to overcome and failures to rise above.Business PracticesDefinition:“A method, procedure, process, or rule employed or followed by acompany in the pursuit of its objectives. Business practice may also refer to these collectively.”Standards, Communications, and Consistency; this has been the business mindset of mine for years and has been successful for others to follow. The strategies created depend on a number of factors; such as the size of the company, single or multiple sites, number of applications that are used for design, data storage and standards.Best business practices involve multiple strategic thinking and collaboration between varying factions of the company. There are two important statements for a company to follow:Mission Statement & Quality Policy; A company’s direction…3What does it take to strategize and implement an efficient Cad and Vault Environment?One of the first strategic moves you make ispreparing a paper for uppermanagement and executives. To be successful there must be buy in from the executive level. Prepareyour first document for the executives to read over and understand theinvestment(s) that you are looking to implement. This should be a 10,000-foot overview with positive direction and a long-term outcome towards efficiency of the engineering/Caddepartment, along with an understanding of growth to other departments. Present your strategy with short and long-term goals.You have a vision, as a leader, to implement and/or improve the workflows,procedures and standards that will create a more efficient cycle of work. You also have the ideas to include otherareas of the company in order to collaborate better.You are in a position to administer a design andproduction environment for a manufacturing company. The design applications are Autodesk Product Design Suites and/or Manufacturing Collections, along withAutodesk Vault Professional.Your main tools are 3D Inventor and 2D Autocad. The software’s span reaches areas from New Product Design (NPD), to 3D Project designs, to Electrical, shop floor deliverables and/or the customer.Think steps ahead of the current process:The starting gate begins with Strategy. The strategic ideas are to implement the newest version of software and database technology to the manufacturing facility(s). All of the Cad and database standards along with configurations need to be uniformly instituted. Product Document Management (PDM) formulas are to be created on a global level of Collaborating by means of SQL replication.Strategic pieces include:Servers Software Databases Security Workstations Common folder structureDeploymentsTeam(s)UsersTrainingEngineering/ManagementProcurement/PurchasingShop and fabricationMarketingInventoryStart with a document just like the executive paper, even incorporate the executive document into the overall documentation. This Document contains more details and specifics and should include an Introduction/overview, main body, instructions and conclusion. This document can also be the fundamental Cad document for IT to follow after the initial implementation. As IT should be part of the strategic discussions, this document will also be the bible for new server and workstation configurations.ServersThe server(s) play a major role in the PDM and Collaboration with other global facilities. If there is more than one facility and you are looking to replicate the Vault, then all Windows Servers and SQL databases, MUST be the same version and build. The build number is a “gotcha” and can throw you for a loop.SoftwareAutodesk Suite and/or Collections comes with an array of applications. You will need to make decisions on what actually is used in the design work and production output.DatabasesAutodesk Vault PDM is necessary for using Inventor 3D and works in conjunction with a SQL database. The Vault PDM is the database that controls the security and lifecycles for files and folders. The SQL database and Vault are the collaboration tools for replication to other facilities allowing, for live data sharing around design(s) and projects.SecurityThe security of your engineering assets (Drawings, Parts, Assembly’s) and proprietary information is rooted in the Vault. Security methodologies will drive some of the processes and workflows in engineering and Cad design.WorkstationsEach user has either a desktop or laptop. The makeup and rotation of these systems is important for efficient workflows and speed to completion. A decision on the type of hardware depends on the category of work that takes place.4Common folder structureRepetitive folder structure is important in maintaining both local files and server files. When using Vault, both are imperative to sustaining efficiency.DeploymentsThe creation of deployments is for strategic installations maintaining consistency and speed throughout. Deployments are also a critical placeholder for the distribution of software builds per allocated user(s).Team(s)Put together a small team that consists of users and IT. This will allow the bouncing of ideas and the ability to make decisions with other inputs. The team will support your actions and decisions along with being part of the successful implementation.UsersUsers are your customers, their production with the tools that you implement is most critical, and therefore you must listen and keep them engaged. Every user customizes the UI in some manner that they choose, but the results need to be similar.TrainingIn order for all the tools, workflows and processes to work; users, managers and administrators must be trained on those specific applications. Training is one of the key strategic components to a successful Engineering Cad environment.Project Engineering/ManagementProject Engineering and Management staff most likely will not produce the designs with the Cad applications; they could be instrumental in the design lifecycles from cradle to grave.Procurement/PurchasingThis area can see potential limiting of human errors. This group of people generally maintain an ERP system. To limit human errors, you need to automate as much as possible. There are ways to take away the manual inputting of data and use digital processes to keep the ERP consistent.InventoryWhere can the engineering BOM (Bill of Material) help drive the pick lists from inventory?Shop and fabricationThe shop area is an area with a high potential for cost savings. How can you streamline the delivery of drawings from engineering/Cad to the shop floor? Is printing an issue? MarketingHow can your plans assist in marketing, sharing the manufacturer’s story to the customer, both current and new? Where could additive manufacturing help marketing at events?56Build: a pictureThe strategic area is where you build the picture of time, cost and impact. This part isimperative in the sense of executives understanding the business incentives and investments to drive future improvements. As stated previously, it also is a major document for the IT department.The strategic document will incorporate all the definitions above and sync to a schedule that begins with a test server and setting up configurations along with standards. An example is a full strategic document that I have as a company Cad bible and it is 40 pages in length.TIMECOST IMPACT7Incorporate equations into the planBuild: the landscapeWith Product Design Suites or Manufacturing Collections there are an array of softwareapplications to use for your design work and deliverables. We know for this conversation that Inventor, Autocad and Vault are the main applications that are going to be utilized. What else may be used that only a few may benefit from? When using other applications, what areas of growth can be expected during the upcoming year?So, where do you start to coordinate all of these softwareapplications into a deployment?How many designers / engineers use Inventor or Autocad? Are there controls engineers / designers that could access Autocad Electrical?We do know that everyone uses Vault, but to what level?Creating deployments for installations and standardizing configurations are essential toupgrades/updates, service packs, new hires, maintaining company standards, etc. (IT love)When creating deployments think of the users and who will run the Cad software applications. Think of this situation in a perspective of groups and work to keep the installation packages lean. Not every user needs to have all applications installed on their systems from the Design Suite and/or Collection.Group DeploymentsDesign 1. Inventor 2. Autocad Mechanical 3. Autocad 4. Fusion 360 5. Vault Professional Controls 1. Autocad Electrical 2. Vault Professional Engineering 1. Autocad P&ID 2. Vault ProfessionalMisc. 1. Autocad Mechanical 2. 3D Max 3. Showcase 4. Vault ProfessionalUtilize higher level tools and featuresBuild: the tools“Back in the day”, drafting tools included suchthings as pencils, erasers (Manual and/or Electric),T-Squares, French Curves, Paper, Vellum andsome symbol templates to use for tracing.For the past 30 years (mainly the last 20), our toolsare based on programs and commands that allowusers to create designs that were never imaginablebefore. We have emerged from a flat 2D table to avast world of 3D and even 4D.•Efficiency; Where do we look for this in our working environment? Some look at it through an hourglass or time cards•Some analyze efficiency through product completion•Some look at efficiency in a longer span of time, from estimating an idea to the completion of the idea.No matter which way you look at efficiency it still comes down to time vs. quality.The tools and skills of the Cad designer or Controlsdesigner vastly varies as in any job, but the ability tolearn and grow using the Cad tools is endless. To beoutstanding at your design position, it takes more thandrawing lines, arcs and circles. Cad developers andprogrammers do not do the design work; they createthe tools that allow us to master better ways to design.With all the Cad software applications there are intelligent ways to design and shortening the editing cycle is a key to design longevity. Using Inventor, it has more advanced tools than Autocad, but you must learn those and incorporate the intelligence into company methodologies. In order to be successful, these methods must keep growing.From an Administrators position, efficiency comes from getting started with a design quicker and maybe having template scenarios to assist with completing 2D deliverable drawings. Efficiency of an upgrade is key in achieving proper deployment configurationsQuestions:1. Does the Cad administrator/manager implement 1 template per file type or multiply that byunits of measure?2. Are there company standards for drawings, parts, assemblies and/or presentation files?3. What are the basics for extracting BOM’s (Bills of Material)?4. How does all the preparation affect the designer’s workflow?5. Where can a Cad Administrator impact efficiency the most?910Formalize processes to stave off potential problemsBuild: the StandardsWithout proper workflows, processes and company standards, chaos emerges quickly.The Cad Administrator is responsible for implementing standards into the design environment which allows for the designers to focus on their work, and not the Cad systems abilities.Create standard SOPs (Company Standard Operating Procedures). The Cad drawing output is the most noticeable SOP, but other standards play a large role in smart design and document control.Standards for:Inventor Drawings 1. Properties 2. Title Block 3. Border4. Views5. Numbering6. Units7. Styles8. Sheet size9. Dimension/Text Inventor Parts/Assembly 1. Materials/Color 2. iProperties 3. SimplificationAutocad Drawings 1. Attributes 2. Title Block3. Border4. Units5. Sheet size6. Dimension/Text Vault storage and revision control1. Configurations2. Lifecycle Revisions3. Change Orderworkflows4. Item Mater workflows5. Folder layout6. Security7. User’s login8. GroupsBuild: the Cad StandardsStandards are essential and includes key information for the user to follow. There are large differences between 2D and 3D standards per software application. Be sure to centralize all templates, design data, library data on a server centrally located which makes for linking everyone to a common area. The administrator can easily control this area.•2D Autocad standards would include, but not limited to, borders, title blocks, attributes, options for dimensions, text, etc.•3D Inventor standards are more involved as there is more intelligence within the file makeup. Inventor standards also include borders and title blocks, but span muchdeeper into iProperties, Styles (Part, Assembly, Drawing), materials, BOM’s, etc.Build: the Vault Standards Array The most complicated aspect of acompanywide success story is the VaultConfigurations and workflows. Whetheryou are instituting file lifecycle revisions,Engineering Change Orders, ItemMasters and/or even structurally layingout organizational folders, there is a lotto capture.Vault is built on rules and a startingposition would be with Categories.Setting up rules and security will set thetone for the structure that you arelooking to implement.Common path locations across the board are important and a consistency that keeps the individual mayhem under control. An example would be to set the Project Explorer ($) to0_Workspace folder local to the C:\drive. Inventor Content Center library can be pathed to a server folder similar to Cad standards location.Setting up your team, can be; either manually created or imported from the server domain. Either way, controlling all the users with groups harnesses specific users and can control rightswithin the Vault.11Limit human errorBuild: a limitless environmentHuman error is inescapable, but can be limited. These are all manageable by incorporating Standards – Communications – Consistencies into your environment.Allow your admin group to have a select number of persons that will be the guardians of the Standards and assist in the implementation and consistent effectiveness of the environment. Start using iLogic or API to automate redundancies. Efficient processes can be formulized using Copy/Design.ConclusionBuild: the finaleIn conclusion, administrating Cad and Data Management within a manufacturing environment is a challenge and the successes are rewarding. The time allocated to the whole process can span anywhere from a month to three or four months.The final document should have all the steps that are in place now for IT to be able to install and configure a new user workstation.Remember that there are periodic Autodesk software service packs and/or updates which should be part of instruction(s) documented that allow for you, your admin team and IT to follow. Inventor, Autocad, Autocad Electrical, Autocad P&ID can be updated individually trough the user system “Autodesk Desktop App” or a scheduled routine through a script. Vault updates are more critical and must be updated from the server first, then the clients. All Vault servers MUST be updated at the same time.are critical and should be taskscheduled through the server.Backup strategies are either a fullback up every night or one full backup on the weekend and Incrementalbackups during the week.12Appendix A Array 1. Strategy1. Executive & Complete2. Server(s)1. Sans2. Virtual3. Windows Server 201?4. SQL Database5. SQL Server 201?6. For Vault Replication3. Software1. Autodesk1. Product DesignSuite/Manufacturing Collections2. Inventor3. Fusion4. Autocad Mechanical5. Autocad Electrical6. Autocad LT7. Autocad P&ID8. Viewers4. Vault Professional1. Vault Server2. Vault Client3. A3605. Build1. Servers1. Deployments2. Standards2. Inventor1. Templates2. Styles3. Options6. Autocad1. Templates2. Options7. Vault1. Users/Groups2. ECN3. Item Master4. Folder Structure8. Workflows1. Revision Lifecycle Management2. ECN (Engineering Change Orders)3. Item Master4. Local Workspace139. Library / Libraries1. Content Center Files1. Custom Library Files1. Processes1. Uninstall software(s)2. Install1. Run Deployments2. Configure user stations3. Distribute Configurations2. Read Strategy Document3. SOP1. Create Standard Operating Procedures2. ISO Certification3. Persons to understand methods4. Skills1. Cad and non-Cad training2. 3D methodology with Inventor3. 2D drawings with Autocad4. Vault training5. Folder Structure for file storage6. ECN Training1. Updates1. Manage and incorporate future updates and new versions1. SQL2. Server O/S3. Cad Software4. Vault DatabaseNew Users5.14。

九、承包人实施方案(一)概述1、项目简要介绍:2、项目围:3、项目特点:(二)总体实施方案1、项目目标(质量、工期、造价)1.1质量目标1.1.1勘察质量目标:满足现行相关工程建设标准、勘察规(规程)、相应勘察文件编制深度要求;1.1.2设计质量目标:满足现行相关工程建设标准、设计规(规程)、相应设计文件编制深度要求;1.1.3施工质量目标:符合现行国家有关工程施工验收规和标准的要求合格。

1.1.4工期目标在总工期日历天依序施工,争取提前完成全部工程项目。

1.1.5造价目标我公司始终站在为业主优质服务、为业主着想的角度,树立工程管理全局观念,通过优秀的人才、科学的管理、先进的技术、充分的设备投入、经济合理的施工方案、大量新技术新工艺的运用、全部系统的策划和部署、有效的组织、管理、协调和控制,使本工程成本和造价得到最为有效的控制。

①在工程(经批准的)投资总额围,采取限额设计、优化设计的方法,控制工程造价。

②实行招标采购制度,引进市场价格竞争,降低工程造价③严格控制工程变更,降低变更费用。

1.1.6安全目标杜绝重大安全事故发生,安全率100%。

1.1.7环境保护和文明施工目标我公司将严格按照国家标准及省建设工地施工扬尘整治法规等管理规定执行,使该工程成为我公司“企业形象示工程”,并使本工程在文明施工、安全生产等方面成为我公司新的样板和代表性工程。

2、项目实施组织形式我公司中标该项目后,将与勘察、设计单位在联合体协议书的框架下,根据招标文件的要求和现场建设实施的实际需要,联合组建“省格尔木昆仑经济技术开发区2016年重金属污染防治项目EPC总承包项目部”,由总承包方派人担任该项目的项目经理和技术负责人,下设总承包部和勘察设计部,分别负责该项目的施工建设和工程设计,总承包部下设工程部、质安部、计划材料部、财务部和办公室共五个部门,其中工程部下设测量队和试验室,勘察设计部下设勘察室和设计室。

全面负责施工过程中的生产、经营、技术、质量、安全、材料、设备、资金、生活服务等管理工作,并直接组织、调度、协调作业层施工。

加油站消防设计规范篇一:加油站设计防火规范第三章汽车加油站第一节加油站的分级及站址选择第3.1.1条汽车加油站的等级划分,应符合表3.1.1的规定。

表3.1.1 加油站的等级划分注:①本表油罐总容量系指汽油储量。

当兼营柴油时,汽油、柴油的储量,可按1∶2的比例折算。

②城市市区内不宜建设一级加油站,且宜采用直埋地下卧式油罐。

第3.1.2条汽车加油站的站址选择,应符合城镇规划、环境保护和防火安全的要求,并应选在交通便利的地方。

城市市区的汽车加油站,应靠近城市交通干道或设在出入方便的次要干道上。

郊区汽车加油站,应靠近公路或设在靠近市区的交通出入口附近。

企业附属汽车加油站由企业统一规划,宜靠近车库或车辆进出口。

第3.1.3条当汽车加油站选在城市市区的交叉路口附近时,不应影响交叉路口的通行能力。

第3.1.4条汽车加油站的加油机、油罐与周围建筑物、构筑物、交通线等的安全距离,不应小于表3.1.4的规定。

表3.1.4 汽车加油站的加油机、油罐与周围建筑物、构筑物、交通线等的安全距离(m)注:①三级汽车加油站相邻的民用或其它建筑为一、二级耐火等级,且与加油站相邻一面无门窗时,其与加油站的安全距离可不限。

②设有油气回收系统的加油站,与周围建筑物、交通线的安全距离,可按本表减少50%。

第二节总平面布置第3.2.1条汽车加油站的布置,应符合下列要求:一、加油站的进、出口,应分开设置。

二、加油站进、出口道路的坡度,不得大于6%。

三、当油泵房、消防器材间与站房合建时,应单独设门,且应向外开启。

第3.2.2条汽车加油站内的各主要建筑物、构筑物之间的安全距离,不应小于表3.2.2的规定。

表3.2.2 汽车加油站内的各建筑物、构筑物之间的安全距离(m)注:①站房包括:营业室、值班休息室、卫生间、储藏间等。

②其它建筑物、构筑物系指根据需要设置的汽车洗车房、加润滑油间和零售油品间等。

③直埋地下卧式油罐与站房无门窗的实体墙一侧的安全距离,可不限。

目录前言 (1)1 总论 (3)1.1编制依据 (3)1.2评价因子 (6)1.3评价标准 (7)1.4评价工作等级及评价重点 (9)1.5评价范围及环境保护目标 (11)1.6评价原则 (15)1.7评价工作程序 (15)2 建设项目概况 (17)2.1建设项目名称、性质及地点 (17)2.2建设项目规模、投资、占地面积及平面布置 (17)2.3建设项目工程建设进度 (18)2.4劳动生产定员及工作制度 (18)2.5主要技术经济指标 (19)3 工程分析 (20)3.1项目建设内容及组成 (20)3.2原、辅材料耗用情况 (23)3.3物料储运方式 (25)3.4设备清单 (26)3.5物料平衡分析 (26)3.6生产原理及工艺流程 (30)3.7主要污染物的排放 (31)4 建设项目周围环境概况 (42)4.1自然环境 (42)4.2社会环境简况 (44)4.3环境质量现状 (48)5 环境影响预测及评价 (57)5.1施工期影响分析 (57)5.2营运期环境影响预测与分析 (59)6 环境风险评价 (74)6.1风险识别 (74)6.3风险分析 (80)6.4风险防范措施 (84)6.5应急预案 (85)7 产业政策和项目选址分析 (94)7.1产业政策符合性分析 (94)7.2与区域规划符合性分析 (94)7.3选址合理性分析 (94)8 清洁生产 (96)8.1清洁生产水平评述 (96)8.2清洁生产的对策 (100)9 公众参与 (102)9.1调查目的及要求 (102)9.2环境信息公开方式与内容 (102)9.3公众意见征询 (104)9.4结论 (109)10 拟建工程污染防治措施分析 (111)10.1施工期污染防治对策措施 (111)10.2营运期污染防治对策措施 (111)11 环境经济损益分析 (117)11.1环保投资 (117)11.2经济效益简析 (118)11.3社会效益分析 (118)11.4环境经济损益分析 (118)11.5三效统一 (119)12 环境监测与管理计划 (120)12.1环境管理 (120)12.2环境监理 (122)12.3环境监测 (122)12.4竣工环境保护验收 (123)13 污染物总量控制 (125)13.1总量控制的原则 (125)13.2总量控制指标建议 (125)14.1工程分析结论 (127)14.2环境质量现状结论 (127)14.3环境影响分析结论 (128)14.4产业政策符合性分析结论 (129)14.5规划符合性分析结论 (129)14.6选址合理性分析结论 (129)14.7环境风险评价结论 (129)14.8清洁生产结论 (129)14.9公众参与及“三效”分析结论 (130)14.10总结论 (130)附件:1.会议纪要及修改清单。

目录1设计依据 (1)2工程概述 (1)2.1公司概况 (1)2.2设计承担的范围 (1)2.3工程概况 (1)2.4工艺流程 (2)2.5主要设备 (3)2.6项目生产过程中火灾爆炸危险分析 (3)2.7项目涉及化学品数量及状况 (10)3消防设计 (11)3.1消防设计规划 (12)3.2总平面设计 (12)3.3建筑防火及安全疏散 (13)3.4工艺及电气防火措施 (15)3.5消防给水 (17)3.5消防电源及其配电 (18)3.6火灾应急照明和疏散指示标志 (18)4消防设施设计结论和建议 (19)4.1消防设施设计结论 (19)4.2消防设施设计建议 (19)1设计依据1、《中华人民共和国消防法》(国家主席令【2008】第6号)2、《建筑设计防火规范》GB50016-20063、《建筑灭火器配置设计规范》GB50140-20054、《汽车加油加气站设计与施工规范》GB 50156-2002(2006版)5、《建筑防雷设计规范》 GB 50057-94(2000年版)6、《山东省消防条例》山东省人民代表大会常务委员会公告(第18号)7、国家及地方有关部门的其他相关规范、规定2工程概述2.1公司概况成武县汇丰加油站位于成武县南鲁镇政府驻地李元村路北,本项目为新建项目,使用性质为易燃易爆液体的供应站。

共设6台埋地储罐,其中设柴油罐3台,每台25m3,汽油罐3台,每台25m3,折合后的总容量为112.5m3,属于二级加油站。

2.2设计承担的范围成武县汇丰加油站委托济宁化工设计院对加油站新建项目进行消防设施设计,双方协商的本次设计范围为加油站消防平面布置图,站房以及油罐区的消防设施设计。

2.3 工程概况2.3.1工程性质项目名称:加油站新建项目建设单位:成武县汇丰加油站建设地点:成武县南鲁镇政府驻地李元村路北建设性质:本项目涉及到的危险化学品有汽油、柴油,属于危险化学品储存项目。

2.3.2地理位置成武县汇丰加油站位于成武县南鲁镇政府驻地李元村路北,本站北侧为耕地,东侧为空地,西南两侧为公路。

YLT管理咨询有限公司与SMJ设计院战略合作框架协议日期:2016年 1月 10日目录1.0 合作纲领 ................................................................................................................ . (4)1.1 合作宗旨 (4)1.2 合作目标 (4)1.3 合作内容 (4)1.3.1广告灯箱设计 (4)1.3.2商业区深化设计 (5)1.3.3商业区整体布局及商户施工 (5)1.3.4衍生服务 (5)1.4 合作范围 (6)1.5 合作期限 (6)2.0 乙方与甲方在战略层面的合作与配合 (6)2.1 组织架构 (6)2.2 工作流程 (8)2.3 收费模式 (8)2.3.1报酬及支付方式 (8)2.3.2对应付款项的争议 (8)3.0 合作双方的权利与义务 (8)3.1 甲方的权利与义务 (8)3.2 乙方的权利与义务 (9)4.0 协议附件 ................................................................................................................ . (9)5.0 不可抗力 ................................................................................................................ .. 106.0 声明与保证 ..............................................................................................................106.1 乙方向甲方声明与保证 (10)6.2 甲方向乙方声明与保证 (10)7.0 通知 ................................................................................................................ (10)8.0 保密条款 ................................................................................................................ .. 119.0 知识产权条款 (11)10.0 语言 ................................................................................................................ . (12)11.0 期限 ................................................................................................................ .. (12)12.0 争议解决 .................................................................................................................12甲方:YLT管理咨询有限公司(以下简称“甲方” )地址:联系人:乙方: SMJ设计院(以下简称“乙方” )地址:联系人:24033 5DE1 巡40384 9DC0 鷀/f36004 8CA4 貤+38683 971B 霛20376 4F98 侘YLT管理咨询有限公司(以下简称“甲方”)与SMJ设计院(以下简称“乙方”)本着平等互利原则,经友好协商,就YBH交通枢纽站广告及商业区相关深化设计、装饰机电等施工、工程监理和咨询等领域的合作关系达成共识。

20XX 专业合同封面COUNTRACT COVER甲方:XXX乙方:XXX2024年塔材物流合作协议本合同目录一览第一条合作协议的概述1.1 合作双方的名称和地址1.2 合作范围和目标1.3 合作期限第二条货物交付2.1 货物描述2.2 交付时间和地点2.3 交付方式和流程第三条质量保证3.1 货物质量标准3.2 质量检验和验收3.3 质量问题处理第四条物流服务4.1 物流渠道和路线4.2 运输方式和时间4.3 物流成本和费用第五条价格和支付5.1 货物价格和定价机制5.2 支付方式和时间5.3 支付条件和违约金第六条违约责任6.1 合作双方的违约行为6.2 违约责任和赔偿方式第七条争议解决7.1 争议解决方式7.2 仲裁地点和机构7.3 法律适用第八条合同的变更和终止8.1 合同变更的条件和程序8.2 合同终止的条件和程序8.3 合同终止后的处理事项第九条保密条款9.1 保密信息的范围和内容9.2 保密责任和期限第十条合作宣传和推广10.1 宣传方式和范围10.2 推广材料的使用和归属第十一条合同的生效和解除11.1 合同生效的条件和时间11.2 合同解除的条件和程序第十二条合同的附件12.1 附件一:货物交付时间表12.2 附件二:质量标准和要求12.3 附件三:物流服务协议第十三条其他条款13.1 合作双方的协调和沟通机制13.2 合同的翻译和解释第十四条签署和盖章14.1 合同签署的时间和地点14.2 合作双方的盖章和代表签字第一部分:合同如下:第一条合作协议的概述1.1 合作双方的名称和地址甲方:X塔材有限公司地址:省市区路号乙方:X物流有限公司地址:省市区路号1.2 合作范围和目标双方约定在2024年内,乙方负责甲方塔材产品的国内物流运输服务。

目标是实现高效、安全、低成本的物流服务,满足甲方的业务需求。

1.3 合作期限本合作协议自双方签署之日起生效,有效期为2024年1月1日至2024年12月31日。

实现企业技术创新的主要途径——信息化与引资

金奇宪

【期刊名称】《情报学报》

【年(卷),期】1999()S1

【摘要】本文叙述了技术创新与加快信息化建设的意义、相互关系,论述了企业提高创新能力的关键途径是信息化、重要途径是引进外资,阐述了信息化、引进外资对技术创新的重要作用。

【总页数】5页(P289-293)

【关键词】技术创新;信息化;引进外资;企业

【作者】金奇宪

【作者单位】吉林省延吉市科技情报研究所

【正文语种】中文

【中图分类】F273.1

【相关文献】

1.再论实现企业技术创新的主要途径 [J], 叶枫;;

2.技术创新提高企业国际竞争力的主要途径 [J], 姜鹤;唐志丹

3.浅谈企业管理信息化及其主要实现途径 [J], 江旎旎

4.浅谈企业管理信息化及其主要实现途径 [J], 江旎旎

5.信息化是带动企业技术创新实现经济增长的主要源泉 [J], 吴宏伟

因版权原因,仅展示原文概要,查看原文内容请购买。