阿尔西空调样本-DATACOOL-C1301V01.3

- 格式:pdf

- 大小:2.10 MB

- 文档页数:15

air-sys阿尔西机房专用恒温恒湿精密空调故障报警维护维修说明当air-sys阿尔西机房专用恒温恒湿精密空调机组发生故障时,报警信号将通过声光报警由电脑显示板显示出来。

下面将对各项报警作出详细说明,可帮助用户分析查找故障原因。

以指导维修。

1 EXT. ENABLE OFF:外部有效关(空调机组禁止启动),阿尔西300x卡,A1输入口,CnB接头,该故障出现时,除冷凝风扇可继续工作外,禁止所有控制和比例信号输出。

此报警不启动音响报警、报警继电器和红色LED灯指示。

此报警不存储在最后10个报警内。

当air-sys阿尔西机房精密空调机组处于该报警情况下时,除HI/LO TEMP 和HI/LO HUMID之外的任何其他报警将被记录及显示。

空调维护报警维修后自动复位。

2 SUPPLY FAN FAIL (主风机热保护):阿尔西300x卡,A2输入口,CnB接头此报警停止air-sys阿尔西空调机组,直到热保护复位,如果在30分钟内,此报警重新发生,除冷凝风扇外,air-sys阿尔西机房恒温恒湿精密空调整机被子锁住,即使在备用状态下,此报警也可能发生,维护维修后键盘手动复位。

3 AIR FLOW LOSS(风量损失):阿尔西3100-A卡,A8输入口,CnR接头,此报警停止机组的其它功能,除送风机与冷凝风机继电器之外,此报警有10秒的延时,维护维修后自动复位。

4 CLOGGED FILTER(过滤器堵塞):阿尔西3100-A卡,A9输入口,CnR接头。

此报警不停止air-sys阿尔西机房专用恒温恒湿精密空调机组并有此报警有5秒的延时。

维护维修后自动复位。

5 COND. FAN 1 FAIL冷凝风机1故障-仅用于DXA机组:5 LIMIT THERM 1 极限温度控制1-DXW机组:阿尔西300x卡,A3输入口,CnB接头。

此报警停止压缩机2的工作及冷凝风机1(DXA机组)工作,停止向P5输出口输出信号,直到热保护复位。

Oil-free rotary screw compressorsZR/ZT 110-275 (FF) & ZR/ZT 132-315 VSD (FF)Setting the standard in energy efficiency, safety and reliability The shortest route to superior productivity is to minimize operational cost while maintaining an uninterrupted supply of the right quality of air. The Atlas Copco Z compressor series is focused on effectively saving energy, ensuring product safety –only oil-free machines exclude contamination risks for 100% – and guaranteeing the utmost reliability around the clock. And not just today, but day after day, year after year,with minimal maintenance cost, few service interventions and long overhaul intervals.Highest reliabilityFor 60 years, Atlas Copco Z compressors have set the benchmark for durability. T hey are built using long-standing internal engineering practices, and are designed and manufactured according to ISO 9001, ISO 14001, ISO 22000& OHSAS 18001. T he high-end ZR/ZT uses time-provenstate-of-the-art screw technology, cooling and pulsation dampers and provides you with the highest reliability. 100% oil-free compressed airThe ZR/ZT offers you 100% pure, clean air that complies with ISO 8573-1 CLASS 0 (2010) certification. T his means zero riskof contamination; zero risk of damaged products; zero risk of losses from operational downtime; and zero risk of damaging your company’s hard-won professional reputation. Maximum energy efficiencyThe ZR/ZT’s superior oil-free screw elements provide the optimum combination of high Free Air Delivery (FAD) with the lowest energy consumption. Ample sized cooling, low pressure drops and an extremely efficient drive train result in the highest compressor package efficiency.The most complete packageWith the ZR/ZT compressor, Atlas Copco provides a superior solution without hidden costs. T he totally integrated,ready-to-use package includes internal piping, coolers, motor, lubrication and control system. T he Full Feature version even integrates an IMD adsorption dryer for an impeccable end product. Installation is fault-free, commissioning time is low and no external instrument air is required. Y ou simply plug and run. Global presence - local serviceOur aftermarket product portfolio is designed to add maximum value for our customers by ensuring the optimum availability and reliability of their compressed air equipment with the lowest possible operating costs. We deliver this complete service guarantee through our extensive service organization,maintaining our position as leader in compressed air.100% certified oil-free airAtlas Copco is renowned for designing and manufacturing some of the most durable oil-free screw compressors. T he ZR/ZT high-end rotary screw compressor comes out of this strong tradition.Ideal for industries where high-quality oil-free air is key, the ZR/ZT offers the highest reliability and safety in combination with low energy costs.Food & beverage• 100% pure, clean, oil-free air for all kinds of applications(e.g. fermentation, packaging, aeration, transportation,filling & capping, cleaning, instrument air).• ISO 8573-1 CLASS 0 (2010) certification to avoidcompromising the purity of your end productand ensure zero risk of contamination.T extiles• Easy and quick installation.• A completely, fully integrated, ready-to-use solution.Oil & gas• Years of experience in providing compressed airfor the oil & gas industry.• 100% oil-free compressed air for control/instrumentair or buffer air.• Strong global support network to provide 24/7 assistance.Power plants• Ideal for applications such as flue gas desulphurization,oxidation air, and fluidized beds.• Continuous operation.Class 0:the industry standardOil-free air is used in all kinds of industries whereair quality is paramount for the end product and production process. T hese applications includefood and beverage, pharmaceutical, chemical and petrochemical, semiconductor and electronics,the medical sector, automotive paint spraying, textile and many more. In these critical environments, contamination by even the smallest quantities of oil can result in costly production downtime and product spoilage.First in oil-free air technologyOver the past sixty years Atlas Copco has pioneered the development of oil-free air technology, resulting in a rangeof air compressors and blowers that provide 100% pure, clean air. Through continuous research and development, Atlas Copco achieved a new milestone, setting the standard for air purityas the first manufacturer to be awarded CLASS 0 certification. Eliminating any riskAs the industry leader committed to meeting the needs of the most demanding customers, Atlas Copco requested the renownedTÜV institute to type-test its range of oil-free compressors and blowers. Using the most rigorous testing methodologies available, all possible oil forms were measured across a range of temperatures and pressures. T he TÜV found no traces of oil at all in the outputair stream.concentration in total oil content).321High efficiency coolers and water separator• Corrosion resistant stainless steel tubing*.• Highly reliable robot welding; no leakages*.• Aluminium star insert increases heat transfer*.• Water separator with labyrinth design to efficiently separate the condensate from the compressed air.• Low moisture carry-over protects downstream equipment.3World-class oil-free compression element• Unique Z seal design guarantees 100% certified oil-free air.• Atlas Copco superior rotor coating for high efficiency and durability.• Cooling jackets.2Throttle valve with load/unload regulation• No external air supply required.• Mechanical interlock of inlet and blow-off valve.• Low unload power.1* Only for ZR water-cooled versions.45AirWaterOilMotor• IP55 T EFC protection against dust and humidity.• High efficiency fixed speed IE3 motor (equal to NEMA Premium).4Advanced Elektronikon ®• Large 5.7” sized color display available in 31 languages for optimal ease of use.• Controls the main drive motor and regulates system pressure to maximize energy efficiency.5Water-cooled ZR Pack123Silenced canopy• Base frame with forklift slot.• Fully packaged, easy to install.• Easy ducting.1Efficient intake air filtration• 2-stage dust removal system (99.9% for 3 micron).• Low pressure drop.• Efficient protection of the compressor.• Minimum intake losses.2High-efficiency motor + VSD• TEFC IP55 motor protects against dust and chemicals.• Continuous operation under severe ambient temperature conditions.• Full regulation between 30 to 100% of the maximum capacity.34Full Feature: IMD adsorption dryer• Eliminates the moisture before it enters the air net.• Ensuring a reliable process and a top quality end product.• No external energy is needed to dry the air, resulting in high energy savings and no compressed air losses.• Minimal pressure drop.4Air outAir-cooled ZT Full FeatureAirWaterOilVSD: driving down energy costsOver 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. T o cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. T hanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressorson the market.EnergyEnergy savings with VSD Investment MaintenanceEnergy savings of up to 35%Atlas Copco's VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD minimizes energy use across your production dramatically.T otal compressor lifecycle costVSD?1The Elektronikon® controls both the compressor and the integrated converter, ensuring maximum machine safety within parameters.2Flexible pressure selection from 4 to 10.4 bar with VSD reduces electricity costs.3Specific converter and motor design (with protected bearings) for the highest efficiency acrossthe speed range.4Electric motor specifically designed for low operating speeds with clear attention to motor cooling andcompressor cooling requirements.5All Atlas Copco VSD compressors are EMC tested and certified. Compressor operation does notinfluence external sources and vice versa.6Mechanical enhancements ensure that all components operate below critical vibration levels throughout theentire compressor speed range.7 A highly efficient frequency converter in a cubicleensures stable operation in high ambient temperatures up to 50°C/122°F (standard up to 40°C/104°F).8No ‘speed windows’ that can jeopardize the energy savings and the stable net pressure. T urndown capability of the compressor is maximized to 70-75%.9Net pressure band is maintained within 0.10 bar, 1.5 psi.Monitoring and control:how to get the most from the leastThe Elektronikon ® unit controller is specially designed to maximize the performance of your compressors and air treatment equipment under a variety of conditions. Our solutions provide you with key benefits such as increased energy efficiency, lower energy consumption, reduced maintenance times and less stress… less stress for both you and your entire air system.Intelligence is part of the package• High resolution color display gives you an easy to understand readout of the equipment’s running conditions. • Clear icons and intuitive navigation provides you fast access to all of the important settings and data. • Monitoring of the equipment running conditions and maintenance status; bringing this information to your attention when needed.• Operation of the equipment to deliver specifically and reliably to your compressed air needs.• Built-in remote control and notifications functions provided as standard, including simple to use Ethernet based communication.• Support for 31 different languages, including character based languages.Online & mobile monitoringMonitor your compressors over the Ethernet with the new Elektronikon ® controller. Monitoring features include warning indications, compressor shut-down andmaintenance scheduling. An Atlas Copco App is available for iPhone/Android phones as well as iPad and Android tablets. It allows fingertip monitoring of your compressed air system through your own secured network.• A remote monitoring system that helps you optimize your compressed air system and save you energy and cost.• It offers you a complete insight in your compressed air network and anticipates on potential problems by warning you up-front.*Please contact your local sales representative for more information.SMART LINK *:Data monitoring programProtecting your productionUntreated compressed air contains moisture and possibly dirt particles that can damage your air system and contaminate your end product. T he resulting maintenance costs far exceed air treatment costs. Atlas Copco believes in effective prevention and provides a complete range of air treatment solutions to protect investments, equipment, production processes and end products.Increase production reliabilityLow quality air heightens the risk of corrosion, which can lower the life span of production equipment. T he air treatment solutions produce clean air that enhances your system’s reliability, avoiding costly downtime and production delays.Safeguard production qualityCompressed air coming into contact with your final products should not affect their quality. Atlas Copco provides clean,dry air to protect your production and reputation in the market.Supreme energy and cost savingsAtlas Copco’s quality air solutions stand for substantial energy savings all day, every day. T aking technology to a new level,these products achieve maximum cost savings.Proven peace of mindBuilding on know-how and years of experience, the entire Atlas Copco quality air range is produced in-house and tested using the most stringent methods in the industry.A dryer solution for every needUntreated compressed air contains moisture and possibly dirt particles that can damage your air system and contaminate your end product. T he resulting maintenance costs far exceed air treatment costs. Atlas Copco believes in effective prevention and provides a complete range of air treatment solutions to protect investments, equipment, production processes and end products.BD/BD +-70°C/-40°C/-20°C -94°F/-40°F/-4°FHeat reactivated adsorption dryer• Use of electrical heaters for regenerating the desiccant• Limited pressure drop• Variants without loss of compressed airFD/FD +(VSD)+3°C/+20°C +37°F/+68°FRefrigerant dryer• Use of cooling circuit for cooling down compressed air • Guaranteed pressure dew points• Lowest energy consumption in all operating conditions • Air and water cooled variantsMD-20°C/+3°C -4°F/+37°FMDG-40°C/-20°C -40°F/-4°FRotary drum heat of compression dryers• Use of freely available heat of compression • Negligible power consumption• Variants with extra heat augmentation for lower dew pointsND-40°C/-20°C -40°F/-4°FDryers overviewD e w p o i n t (°C )D e w p o i n t (°F )Flow (l/s)Flow (cfm)+3+37-20-4-40-40-70-94To further protect your investment, equipment and processes, Atlas Copco presents a full line-up of innovative quality air solutions to suit the high quality requirements of your specific application.45213A complete Full Feature packageAtlas Copco’s Full Feature concept stands for a compact, all-in-one quality air solution. Integrating the IMD dryer and its Variable Speed Drive on VSD models, this integrated package offers the highest quality air at the lowest possible cost.Protect your compressed air systemA dry compressed air system is essential to maintain the reliability of production processes and the quality of the end products. Untreated air can cause corrosion in the pipe work, premature failure of pneumatic equipment and product spoilage.IMD adsorption dryerThe IMD adsorption dryer eliminates the moisture before it enters the air net,ensuring a reliable process and an impeccable end product. As no external energy is needed to dry the air, large savings are obtained. T he pressure drop through the dryer is minimal, which again cuts down the operating cost.The IMD drying principle1 Hot unsaturated air2 Hot saturated air3 Cold saturated air4 Dry air5 Drying sectionOptimize your systemWith the ZR/ZT , Atlas Copco provides an all-in-one standard package incorporating the latest technology in a built-to-last design. T o further optimize your ZR/ZT’s performance or to simply tailor it to your specific production environment, optional features are available.Engineered solutionsAtlas Copco recognizes the need to combine our serially produced compressors and dryers with thespecifications and standards applied by major companies for equipment purchases. Strategically located departments within the Atlas Copco Group take care of the design and manufacturing of customized equipment to operate at extreme temperatures, often in remote locations.Innovative technologyAll equipment is covered by our manufacturer warranty.The reliability, longevity and performance of our equipment will not be compromised. A global aftermarket operation employing 360 field service engineers in 160 countries ensures reliablemaintenance by Atlas Copco as part of a local service operation.Innovative engineeringEach project is unique and by entering into partnership with our customers, we can appreciate the challenge at hand, ask the relevant questions and design the best engineered solutionfor all your needs.Options• : Optional- : Not available(*) Maximum intake/cooling air temperature is 50°C/122 °F for HAT versions.Please note the availability of the option depends on the chosen configuration.ZR 110-275 (FF)(1) Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009).Reference conditions:- Relative humidity 0%.- Absolute inlet pressure: 1 bar (14.5 psi).- Intake air temperature: 20°C/68°F.FAD is measured at the following working pressures: Fixed speed:- 7/7.5/8.6 bar versions at 7 bar.- 10/10.4 bar versions at 9 bar.- 13 bar version at 12 bar.For VSD: at their maximum working pressure.(2) A-weighted emission sound pressure level at the work station (LpWSAd).Measured according to ISO 2151: 2004 using ISO 9614/2 (sound intensity scanning method).The added correction factor (+/- 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.(3) Not available as FF variant.CABZT 110-275 (FF)(1) Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009).Reference conditions: - Relative humidity 0%.- Absolute inlet pressure: 1 bar (14.5 psi). - Intake air temperature: 20°C/68°F .FAD is measured at the following working pressures:Fixed speed:- 7/7.5/8.6 bar versions at 7 bar. - 10/10.4 bar versions at 9 bar. - 13 bar version at 12 bar.For VSD: at their maximum working pressure.(2) A-weighted emission sound pressure level at the work station (LpWSAd).Measured according to ISO 2151: 2004 using ISO 9614/2 (sound intensity scanning method).The added correction factor (+/- 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.(1) For the working pressure of the FF variant, please consult Atlas Copco.(2) Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009).Reference conditions:- Relative humidity 0%.- Absolute inlet pressure: 1 bar (14.5 psi).- Intake air temperature: 20°C/68°F.FAD is measured at the following working pressures: Fixed speed:- 7/7.5/8.6 bar versions at 7 bar.- 10/10.4 bar versions at 9 bar.- 13 bar version at 12 bar.For VSD: at their maximum working pressure.(3) A-weighted emission sound pressure level at the work station (LpWSAd).Measured according to ISO 2151: 2004 using ISO 9614/2 (sound intensity scanning method).The added correction factor (+/- 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.ZR 132-315 VSD (FF) (50/60 Hz)(1) For the working pressure of the FF variant, pleaseconsult Atlas Copco.(2) Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009).Reference conditions: - Relative humidity 0%.- Absolute inlet pressure: 1 bar (14.5 psi). - Intake air temperature: 20°C/68°F .FAD is measured at the following working pressures:Fixed speed:- 7/7.5/8.6 bar versions at 7 bar. - 10/10.4 bar versions at 9 bar. - 13 bar version at 12 bar.For VSD: at their maximum working pressure.(3) A-weighted emission sound pressure level at the work station (LpWSAd).Measured according to ISO 2151: 2004 using ISO 9614/2 (sound intensity scanning method).The added correction factor (+/- 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.ZT 132-315 VSD (FF) (50/60 Hz)DimensionsCABCOMMITTED TO SUSTAINABLE PRODUCTIVITY2935 0538 14 © 2017, A t l a s C o p c o , B e l g i u m . A l l r i g h t s r e s e r v e d . D e s i g n s a n d s p e c i fi c a t i We stand by our responsibilities towards our customers, towards the environment and the people around us. We make performance stand the test of time. T his is what we call – Sustainable Productivity.。

数据中心专用空调系统解决方案阿尔西集团2010年12月目 录一、前言 (2)二、数据中心空调制冷解决方案 (4)2.1、数据中心空调系统的重要性 (4)2.2、数据中心空调系统的关键环节 (4)2.3、数据中心空调系统全面解决方案 (4)2.4、中央冷源解决方案 (6)2.5、单元式空调系统解决方案 (12)2.6、高热流密度解决方案 (17)2.7、集装箱数据中心解决方案 (19)2.8、局部热点解决方案 (21)2.9、节能改造解决方案 (22)三、附录 (26)3.1、集团简介 (26)3.2、设备介绍 (26)3.3、成功案例 (27)一、前言随着新一代数据中心的建设,供电能耗问题,已经成为了所有的数据中心无法回避的问题。

通常,一个投资几百万元的数据中心,每年运营所产生的能耗成本就高达几十万元。

CIO把数据中心评价为“建得起而用不起”。

在能源日趋稀缺的状态下,利用各种新技术和管理手段,获得“增容不增耗”的绿色数据中心解决方案已成为行业发展的当务之急。

事实上,比起前几年来,企业在数据中心建设中已经更加注意能耗问题,但是,数据中心仍然和高额的电力和散热成本相伴随。

主要原因在于,随着新一代数据中心的建设,网络、服务器、存储等设备进一步集中,这就对数据中心的环境管理提出了新的要求。

就拿刀片服务器来说,它的设计特点是在狭小的空间内安装大量的服务器,每平米的功耗大量增加,企业对IT系统的要求愈加提高,电力供应系统密度加大,生产的热量更加集中和庞大,问题也就变得愈发严重。

据统计,维护一个数据中心的能耗中,真实用于IT设备的电力,大约30%~50%,剩余维护费用中冷却费用占到了40%~50%,甚至更高。

能耗的增加带来了热量,热量的增长也扩大了能耗。

而另外,更大的热量密度会增加这些影响。

作为如今业界的热点,建设新一代数据中心,除了资源整合等之外,实现绿色节能也是时代对企业提出的新的要求。

不仅是保护环境的需要,同时,高额的维护和能耗费用也让这成为企业不得不考虑的问题。

AUTO-purge IIIProven solutions for the power industryPrecision Airflow MeasurementAn ON I CON BrandAir Monitor’s AUTO-purge III is designed for applications where the continuous exposure to airborne particulate might impair the measurement accuracy of Air Monitor’s Combustion Air (CA) Station or VOLU-probe/SS array. When activated by an Air Monitor flow transmitter (such as the VELTRON II, MASS-tron II or VELTRON DPT-plus ) or a distributed control system, a combination of valves are operated to introduce highpressure/high volume air to the flow measurement device’s sensing ports for a short duration while simultaneously isolating the transmitter from over-pressurization. This periodic purging assists in maintaining the sensing ports of the total and static pressure manifolds in a clear, unobstructed condition.Product Description• NEMA 4X Stainless Steel Enclosure• Vortex Cooler. Requires 80-100 psi air supply • Enclosure Heater. Requires 120VAC power supply •Viewing WindowPower Capacity • 24VAC • Standard• 24VDC • Low – Model SP • 120VAC • High – Model HCOptional ConstructionDimensional SpecificationsBrass and Copper Construction • All wetted tubing, fittings, and valves constructed of copper and/or brass.• Enclosure is NEMA 4 painted steel.• External connection fittings are stainless steel FPT.Stainless Steel Construction • All wetted tubing, fittings, and valves constructed of 316 stainless steel.• Enclosure is NEMA 4 painted steel.• External connection fittings are stainless steel FPT.Standard ConstructionSequence of OperationAutomatic purging at regular field selectable intervals utilizes short duration, high pressure (up to 125 psig) air to maintain signal lines and the sensing ports of the total and static press ure manifolds in a clean, unobstructed condition. If accompanied with a VELTRON II, MASS-tron II or VELTRON DPT-plus transmitter, the last transmitted process outputs are maintained for the purge cycle. At the start of the purge cycle solenoid piloted spool valves are activated to isolate the transmitter from the process signal lines, followed by the energizing of a separate purge air solenoid valve thatallows high pressure purge air to flow to the measurement station or probe array, forcefully flushing out all particulate contaminants.At the end of the timed purge cycle the purge air valve is de-energized to shut off the supply of compressed air. After a short period to allow the pressures in the signal lines to bleed down to process levels, the spool valves are shuttled to reconnect process signal lines to the attached transmitter and active process measurement resumes.Installation GuideAccumulator Tank (strongly recommended)• Requires coalescing filter, pressure regulator, and checkvalve at the tank inlet. 120 gallons – All CA stations.120 gallons – Multiple VOLU-probes having a combinedlength greater than 10'. 80 gallons – One or more VOLU-probes having acombined length less than 10'.Line from Accumulator Tank to AUTO-purge Panel• 25' maximum length, 1/2" pipe (minimum).• Recommend locating accumulator tank as close aspossible to AUTO-purge Panel.Electrical Power Requirement• 74VA at 24VAC; 28W at 24VDC; 77VA at 120VAC.• 120VAC, 5 amp when an optional enclosure heater isinstalled.Air Requirement• 80 to 175 psig at 20 ACFM, oil and dirt free.Line Size• If the distance from the AUTO-purge Panel to the airflow measuring station or probe array is less than 25', tube size to be 1/2" O.D. with a wall thickness no greater than 0.065".• If the distance from the AUTO-purge Panel to the airflow measuring station or probe array is 25' to 50', tube size to be 3/4" O.D. with a wall thickness no greater than 0.065".• If the distance from the AUTO-purge Panel to the airflowmeasuring station or probe array is greater than 50', tube size to be 1.0" O.D. with a wall thickness no greater than 0.065".Ambient Temperature • 40ºF to 140ºF. For ranges above or below this ambienttemperature, the use of an enclosure heater and/or cooler is required.The VELTRON II ultra-low differential pressure and flow transmitter, with its 0.1% of Natural Span accuracy, is intended for the most critical and demanding industrial applications that require the utmost accuracy and long-term stability. The VELTRON II’s long list of features include: AUTO-purge management; microprocessor based configuration and calibration; four lines of process data display via the graphical LCD; four analog outputs individually configurable for 0-10VDC or 4-20mA; AUTO-zero capability; electronic re-spanning; adjustable digital low pass filter; membrane keypad interface; 10:1 turndown capability; and nine different standard and bi-polar natural spans covering a range of 25.0 to 0.05 Inches w.c.Via the addition of process temperature and pressure compensation, the ultra high accuracy VELTRON II becomes the MASS-tron II multi-variable flow transmitter. For process temperature the input is an analog signal from a remote 4-wire or loop powered tempe rature transmitter with the MASS-tron II having the capability of performing the linearization. The process pressure is measured by means of an internal absolute pressure transducer connected to the transmitter’s static pressure signal input.The CAMM is an ultra-low differential pressure mass flow transmitter designed to convert the low magnitude pressure signals generated by airflow stations or probes - plus process temperature and static pressure inputs - into multiple output signals (4-20mA, 0-5VDC or 0-10VDC) linear to mass flow, temperature, and pressure.When combined with the AUTO-purge III, the CAMM multivariable transmitter becomes theCAMS. Please refer to the CAMS brochure for additional detail on this product.P.O. Box 6358 • Santa Rosa, CA 95406 • P: 800-airflow • F: 707-526-9970 •***********************IBAM TM – Individual Burner Airflow MeasurementThe IBAM TM – Individual Burner Airflow Measurement probe is ideally suited for new or retrofit applications where a reduction in plant emissions and improvement in efficiency can be obtained through accurate measurement of burner secondary airflow. The IBAM TM probe has been designed to accurately measure in the particulate laden, high operating temperature conditions found in burner air passages.CEMS TM – Continuous Emissions Monitoring SystemAir Monitor's CEMS TM – Continuous Emissions Monitoring Systems assist in complying with the Clean Air Act’s stringent emission measurement standards and the requirements of 40 CFR 75. Air Monitor has assembled a cost effective integrated system consisting of in-stack flow measurement equipment and companion instrumentation to provide continuous, accurate,and reliable volumetric airflow monitoring of stacks and ducts of any size and configuration.CA TM – Combustion Airflow Measuring Station & VOLU-probe/SS TM Traverse Probes . Air Monitor's duct mounted airflow measurement devices have beendesigned to accurately and repeatedly measure air mass flow in power plants. The Combustion Air (CA) Station TM includes honeycomb air straightener to accurately measure in shorter straight duct runs than any other flow measurement device. The VOLU-probe/SS TM delivers accurate airflow measurement performance in the form of an insertion probe. Both devices feature Type 316 stainless steel flow sensing arrays.Engineering & Testing Services. Air Monitor offers complete engineering and testing to analyze air and coal deliverysystems. Air Monitor's field testing services use 3D airflow traversing and flow measurement systems for the highest possible accuracy. To ensure cost effective and accurate solutions, Air Monitor Power has full scale model fabrication and certified windtunnel testing is used to develop application specific products that will measure accurately where no standard flow measurement can.VOLU-probe/SS TM Stainless Steel Airflow Traverse ProbesMulti-point, self-averaging, Pitot-Fechheimer airflow traverse probes with integral airflow direction correcting design. Constructed of Type 316 stainless steel and available in externally and internally mounted versions for harsh, corrosive or high temperature applications such as fume hood, laboratory exhaust, pharmaceutical, and clean room production and dirty industrial process applications.125-501-10 (03/20)Precision Airflow MeasurementAn ON I CON BrandCAMS TM – Combustion Airflow Management Systems .The CAMS TM – Combustion Airflow Management System has been designed to reliably and accurately measure airflow in combustion airflow applications. The CAMS TM contains the microprocessor based instrumentation to measure the airflow and manage the AUTO-purge. The AUTO-purge is a high pressure air blowback system that protects the duct mounted flow measurement device from any degradation in performance due to the presence of airborneparticulate (flyash).。

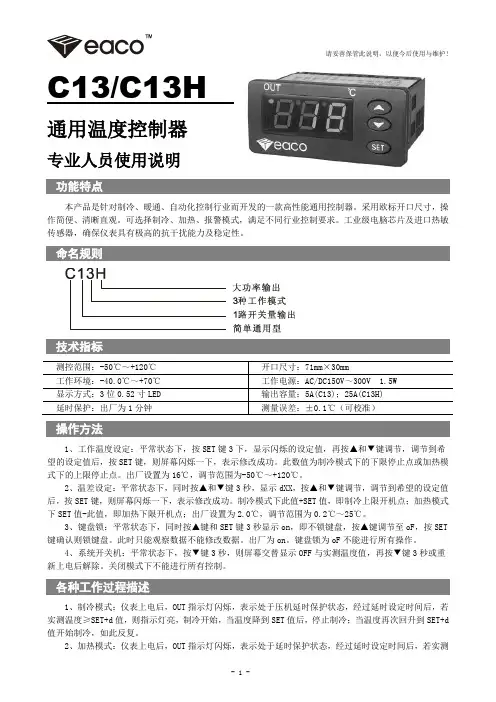

请妥善保管此说明,以便今后使用与维护! C13/C13H通用温度控制器专业人员使用说明功能特点本产品是针对制冷、暖通、自动化控制行业而开发的一款高性能通用控制器。

采用欧标开口尺寸,操作简便、清晰直观。

可选择制冷、加热、报警模式,满足不同行业控制要求。

工业级电脑芯片及进口热敏传感器,确保仪表具有极高的抗干扰能力及稳定性。

命名规则技术指标测控范围:-50℃~+120℃开口尺寸:71mm×30mm工作环境:-40.0℃~+70℃工作电源:AC/DC150V~300V 1.5W显示方式:3位0.52寸LED 输出容量:5A(C13);25A(C13H)延时保护:出厂为1分钟测量误差:±0.1℃(可校准)操作方法1、工作温度设定:平常状态下,按SET键3下,显示闪烁的设定值,再按▲和▼键调节,调节到希望的设定值后,按SET键,则屏幕闪烁一下,表示修改成功。

此数值为制冷模式下的下限停止点或加热模式下的上限停止点。

出厂设置为16℃,调节范围为-50℃~+120℃。

2、温差设定:平常状态下,同时按▲和▼键3秒,显示dXX,按▲和▼键调节,调节到希望的设定值后,按SET键,则屏幕闪烁一下,表示修改成功。

制冷模式下此值+SET值,即制冷上限开机点;加热模式下SET值-此值,即加热下限开机点;出厂设置为2.0℃,调节范围为0.2℃~25℃。

3、键盘锁:平常状态下,同时按▲键和SET键3秒显示on,即不锁键盘,按▲键调节至oF,按SET 键确认则锁键盘。

此时只能观察数据不能修改数据。

出厂为on。

键盘锁为oF不能进行所有操作。

4、系统开关机:平常状态下,按▼键3秒,则屏幕交替显示OFF与实测温度值,再按▼键3秒或重新上电后解除。

关闭模式下不能进行所有控制。

各种工作过程描述1、制冷模式:仪表上电后,OUT指示灯闪烁,表示处于压机延时保护状态,经过延时设定时间后,若实测温度≥SET+d值,则指示灯亮,制冷开始,当温度降到SET值后,停止制冷;当温度再次回升到SET+d 值开始制冷,如此反复。

1. 阿尔西 CYBERCOOL系列精密空调特点:CYBERCOOL DAX U 系列产品特点:1.1、产品简介:CYBERCOOL 系列精密空调是阿尔西集团将多年的机房空调生产技术,结合中国精密空调特性设计、开发、生产的精密机房专用空调机组。

此系列产品服务于对温度、湿度有严格要求的空调场合,这种场合要求设备一年365天,每天24小时全天候运行,因此该系列产品具有极高法人可靠性和稳定性及经济性。

CYBERCOOL 精密机房专用空调机组从设计、开发、制造、安装及售后服务完全依照ISO9001质量认证体系进行,全部符合质量标准。

CYBERCOOL 精密机房专用空调机组在出厂前已完成全部的装配、测试,每一个制冷及安全部件都经过严格的检验与测试,并已加注制冷剂及冷冻油,用户只需连接管路、通水通电即可使用,减少现场安装及调试的时间。

CYBERCOOL 精密机房专用空调机组只需更换少量部件后,即可使用R134a或R407C制冷剂。

如需要详细的资料,请与本公司技术部门联系。

CYBERCOOL与舒适性空调机的对比目前中小型机房应用的空调系统主要有两大类:一类为舒适性空调,另一类为机房专用空调机组。

舒适性空调是以满足人体舒适性要求而设计的,其特点是小风量,大焓差,低显热比,而机房专用空调以满足机房环境的温湿度要求为设计标准,特点为大风量、小焓差、高显热比。

舒适性空调的出风温度低,使机房设备造成凝露现象,危害设备的正常运行,而机房专用空调的出风温度高则避免凝露发生。

另外,舒适性空调只有除湿功能,而机房专用空调可以根据机房的具体需求对其进行加湿和除湿。

舒适性空调在机房中使用会产生一系列的问题,如电子设备故障多、舒适性空调设备本身的维护量大等。

主要原因在于舒适性空调的设计标准不适合机房环境对温湿度的严格要求。

由此可见,使用舒适性空调机组虽然减少了初投资,但其使用寿命短,远远不及机房专用空调,并且无法保证机房环境的温湿度要求,致使空调本身和电子设备故障率提高,TCO(全生命周期成本)反而远远高于机房专用空调。

NO.1机房专用空调机组 产品价格表2009年第01版NO.1DATACOOL 机房专用空调机组价格表07C1 价格送风方式 机组类型 型号编码 普通 EC风机 单冷机组 DATACOOL/A O DXA 7 E1 C1 64,667 69,363 上送风冷暖机组 DATACOOL/B O DXA 7 E1 C1 66,490 71,187恒温恒湿机组 DATACOOL/C O DXA 7 E1 C1 72,063 76,760单冷机组 DATACOOL/A U DXA 7 E1 C1 63,399 68,003 下送风冷暖机组 DATACOOL/B U DXA 7 E1 C1 65,187 69,791恒温恒湿机组 DATACOOL/C U DXA 7 E1 C1 70,650 75,254单冷机组 DATACOOL/A DL DXA 7 E1 C1 63,399 68,003 置换送风冷暖机组 DATACOOL/B DL DXA 7 E1 C1 65,187 69,791恒温恒湿机组 DATACOOL/C DL DXA 7 E1 C1 70,650 75,25413C1 价格送风方式 机组类型 型号编码 普通 EC风机 单冷机组 DATACOOL/A O DXA 13 E1 C1 71,203 75,899 上送风冷暖机组 DATACOOL/B O DXA 13 E1 C1 74,297 78,993恒温恒湿机组 DATACOOL/C O DXA 13 E1 C1 80,594 85,290单冷机组 DATACOOL/A U DXA 13 E1 C1 69,806 74,411 下送风冷暖机组 DATACOOL/B U DXA 13 E1 C1 72,840 77,444恒温恒湿机组 DATACOOL/C U DXA 13 E1 C1 79,014 83,618单冷机组 DATACOOL/A DL DXA 13 E1 C1 69,806 74,411 置换送风冷暖机组 DATACOOL/B DL DXA 13 E1 C1 72,840 77,444恒温恒湿机组 DATACOOL/C DL DXA 13 E1 C1 79,014 83,61820C2 价格送风方式 机组类型 型号编码 普通 EC风机 单冷机组 DATACOOL/A O DXA 20 E1 C2 121,518 151,906 上送风冷暖机组 DATACOOL/B O DXA 20 E1 C2 126,367 156,754恒温恒湿机组 DATACOOL/C O DXA 20 E1 C2 131,584 161,972单冷机组 DATACOOL/A U DXA 20 E1 C2 119,136 148,928 下送风冷暖机组 DATACOOL/B U DXA 20 E1 C2 123,889 153,680恒温恒湿机组 DATACOOL/C U DXA 20 E1 C2 129,004 158,796单冷机组 DATACOOL/A DL DXA 20 E1 C2 119,136 148,928 置换送风冷暖机组 DATACOOL/B DL DXA 20 E1 C2 123,889 153,680恒温恒湿机组 DATACOOL/C DL DXA 20 E1 C2 129,004 158,79626C2 价格送风方式 机组类型 型号编码 普通 EC风机 单冷机组 DATACOOL/A O DXA 26 E1 C2 130,801 161,189 上送风冷暖机组 DATACOOL/B O DXA 26 E1 C2 135,649 166,037恒温恒湿机组 DATACOOL/C O DXA 26 E1 C2 140,867 171,254单冷机组 DATACOOL/A U DXA 26 E1 C2 128,237 158,028 下送风冷暖机组 DATACOOL/B U DXA 26 E1 C2 132,990 162,781恒温恒湿机组 DATACOOL/C U DXA 26 E1 C2 138,105 167,897单冷机组 DATACOOL/A DL DXA 26 E1 C2 128,237 158,028 置换送风冷暖机组 DATACOOL/B DL DXA 26 E1 C2 132,990 162,781恒温恒湿机组 DATACOOL/C DL DXA 26 E1 C2 138,105 167,897NO.1CYBERCOOL DXA 系列机房专用机组价格表产品型号 7E1 10E2 15E1 10E115E1 22E1 24E1 30E1 36E1 40E1 24E2 30E2 36E2 机柜规格 S0 S0 S1 S2 S3 S4 S5 S6 S6 S7 S5 S6 S6 制冷量(kw) 7 9 16 12 17 22 26 32 37 46 26 31 37 风量(m3/h) 1,580 1,580 3,150 3,6405,5007,0007,5009,5009,50013,000 7,500 9,500 9,500 40℃标准机组价格单冷型 64,701 83,022 85,370 0 85,141122,290136,349147,934161,864175,037 144,816 154,966171,259 冷热型 67,480 85,801 89,703 0 89,989127,139141,198153,322167,251180,425 150,204 160,354176,647 恒温恒湿型 75,325 93,646 97,548 0 97,834135,691149,749161,958175,888189,061 158,755 168,990185,283 冷凝器配置 CME2 CME4 CME5 CME5 CME8 CME10CME10CME15CME15 CME4×2 CME5×2CME8×2 45℃高温机组价格单冷型 65,484 85,217 91,347 0 91,117124,128158,055169,639177,236190,409 149,205 166,919171,259 冷热型 68,263 87,996 95,680 0 95,965128,976162,903175,027182,623195,797 154,593 172,307176,647 恒温恒湿型 76,107 95,840 103,525 0 103,810137,528171,455183,664191,260204,433 163,144 180,943185,283 冷凝器配置 CME4 CME5 CME8 CME8 CME10CME15CME15CME20CME20 CME5×2 CME8×2CME8×2 48℃高温机组价格单冷型 67,678 91,193 93,184 0 92,954145,833173,427185,011186,604199,777 161,157 170,593174,933 冷热型 70,457 93,972 97,517 0 97,803150,682178,275190,399191,991205,165 166,545 175,981180,321 恒温恒湿型 78,302 101,817 105,361 0 105,648159,234186,827199,036200,629213,802 175,096 184,618188,958 冷凝器配置 CME5 CME8 CME10 CME10CME15CME20CME20CME25CME25 CME8×2 CME10×2CME10×2 CYBERCOOL DXW 系列机房专用机组价格表产品型号 DXW15E1DXW22E1DXW24E1DXW30E1DXW36E1DXW40E1 DXW24E2 DXW30E2DXW36E2 机柜规格 S3 S4 S5 S6 S6 S7 S5 S6 S6 制冷量 18 25 27 33 38 48 27 33 38 风量 5,5007,0007,5009,5009,50013,000 7,500 9,500 9,500 单冷型 93,371125,782128,347144,480150,338166,594 126,901 146,581153,821 冷热型 98,220130,631133,195149,867155,726171,982 132,289 151,969159,209 恒温恒湿型 106,064139,182141,747158,504164,362180,619 140,840 160,605167,845NO.1CYBERCOOL DXA 系列机房专用机组价格表产品型号 40E2 40E2 50E2 52E2 74E2 88E2 45E2 51E2 63E2 73E2 79E2 92E2 机柜规格 S7 S8 S8 S9 S9 S10 S4×2S5×2 S5+S6 S6×2 S6+S7 S7×2 制冷量(kw) 42 45 52 60 79 94 45 52 63 74 83 92 风量(m3/h) 13,000 15,750 15,750 17,800 22,50028,00014,00015,00017,00019,000 22,50026,000 40℃标准机组价格单冷型 187,329 196,305 208,613 212,420 282,555353,493216,583236,719270,785304,851 324,865344,880冷热型 192,716 201,692 215,488 219,295 289,431360,368226,281246,417281,021315,626 335,640355,655 201,353 210,330 224,124 231,656 301,836373,344243,384263,520298,210332,900 352,914372,929恒温恒湿型冷凝器配CME8×2 CME8×2 CME10×2 CME10×2 CME15×2CME20×2CME8×2CME10×2CME10+15 CME15×2 CME15×2CME15×2置45℃高温机组价格单冷型 191,003 199,979 252,024 255,831 313,299372,230220,258280,130292,490335,595 355,609375,624冷热型 196,390 205,367 258,899 262,706 320,174379,106229,955289,828302,727346,370 366,385386,399恒温恒湿205,027 214,004 267,535 275,067 332,580392,081247,058306,931319,915363,644 383,658403,673型CME10×2 CME10×2 CME15×2 CME15×2 CME20×2CME25×2CME10×2CME15×2CME15×2 CME20×2 CME20×2CME20×2冷凝器配置48℃高温机组价格单冷型 234,414 243,390 282,767 286,575 332,036418,670263,669310,874323,234354,332 374,347394,361冷热型 239,801 248,778 289,642 293,450 338,912425,545273,366320,571333,471365,107 385,122405,137恒温恒湿248,438 257,415 298,279 305,810 351,317438,520290,469337,674350,659382,381 402,396422,410型CME15×2 CME15×2 CME20×2 CME20×2 CME25×2CME35×2CME15×2CME20×2CME20×2 CME25×2 CME25×2CME25×2冷凝器配置CYBERCOOL DXW 系列机房专用机组价格表产品型号 DXW40E2 DXW40E2 DXW50E2 DXW52E2 DXW74E2DXW88E2DXW'45E2DXW51E2 DXW63E2 DXW73E2 DXW79E2 DXW92E2机柜规格 S7 S8 S8 S9 S9 S10 S4×2S5×2 S5+S6 S6×2 S6+S7 S7×2 制冷量 44 48 55 62 81 98 49 54 65 76 86 96 风量 13,000 15,750 15,750 17,800 22,50028,00014,00015,00017,00019,000 22,50026,000单冷型 177,016 197,105 211,426 219,527 251,839311,883232,689237,817259,809281,800 298,057314,313冷热型 182,403 202,493 218,301 226,402 258,714318,759242,386247,515270,045292,575 308,831325,087恒温恒湿191,041 211,130 226,938 238,762 271,119331,734259,490264,617287,233309,849 326,106342,362型NO.1 室外风冷冷凝器价格说明: 产品型号 换热能力(kW) 价格 CMD4 17 13,892 CMD5 25 16,547 CME2 9.6 11,206 CME4 16.4 14,255 CME5 21.6 16,330 CME8 31.2 22,961 CME10 37.3 24,333 CME15 50.1 36,583 CME20 70.9 38,425 CME25 76.9 56,042 CME30 84.8 65,850 CME35 109.2 69,165 CME40 115.4 81,483 CME50 145.7 100,706 CME60 154.3 110,776以上报价为单独购买室外冷凝器时的报价标准包装方式:CME15以上为木箱包装,以下为纸箱价格说明该手册中的价格均为产品在工厂交货的人民币交货价,即出厂价。

CYBERCOOL系列精密机房专用空调产品介绍一、概述CYBERCOOL系列精密空调是阿尔西集团将多年的机房空调生产技术,结合中国精密空调市场特性、开发、生产的精密机房专用空调机组。

此系列产品服务于对温度、湿度有严格要求的空调场合,这种场合要求设备一年365天,每天24小时全天候运行,因此该系列产品具有极高的可靠性、稳定性和经济性。

二、产品技术说明CYBERCOOL精密机房专用空调机组,可适用于电信、通讯、卫星、计算机房、数据中心、INTERNET、CT及核磁共振机房等需要恒定温度和湿度、并需对工作环境进行精密控制的高科技场所。

CYBERCOOL精密机房专用空调机组从设计、开发、制造、安装及售后服务完全依照ISO9001质量认证体系进行,全部符合质量标准。

出厂前已完成全部的装配、测试,每一个制冷及安全部件都经过严格的检验与测试,并已加注制冷剂及冷冻油,用户只需连接管路、通水通电即可使用,减少现场安装及调试的时间。

三大系列机型:1、自含冷源:◆自含冷源—风冷直接蒸发式机组DXA系列(分体风冷冷凝器)。

安装方便快捷,适用于水源缺乏的地区和无冷却水系统的场所。

◆自含冷源—水冷直接蒸发式机组DXW系列(内置水冷冷凝器)。

适用于有集中冷却水系统的场所。

机组能效比比风冷机组高,因此更加节能;机组安装不受室外场地限制。

2、不含冷源:不含冷源—冷冻水型机组CW系列。

该系列机组适用于有中央空调冷冻水系统的场所,利用用户冷冻水进行制冷,机组制冷运行时除了送风机外没有任何功率消耗,因此非常节能。

3、双冷源型:对于较大规格的机组(如:S5以上机组,S5以上机组均具备两级制冷系统。

)将自含冷源的直接蒸发式机组和不含冷源的冷冻水型机组组合在一起可以形成双冷源型空调机组。

即:DXA+CW 或DXW+CW。

双冷源机组具有直接蒸发式和冷冻水机组的双重优点外,同时还具有冷源相互备份的特点:当使用用户冷冻水资源时,只有冷冻水盘管换热,压缩机停止运行,利于节能;当用户停止中央空调冷冻水系统时,机组启动压缩机进行制冷。