外文翻译译文汇总

- 格式:docx

- 大小:944.90 KB

- 文档页数:18

Strengths优势All these private sector banks hold strong position on CRM part, they have professional, dedicated and well-trained employees.所以这些私人银行在客户管理部分都持支持态度,他们拥有专业的、细致的、训练有素的员工。

Private sector banks offer a wide range of banking and financial products and financial services to corporate and retail customers through a variety of delivery channels such as ATMs, Internet-banking, mobile-banking, etc. 私有银行通过许多传递通道(如自动取款机、网上银行、手机银行等)提供大范围的银行和金融产品、金融服务进行合作并向客户零售。

The area could be Investment management banking, life and non-life insurance, venture capital and asset management, retail loans such as home loans, personal loans, educational loans, car loans, consumer durable loans, credit cards, etc. 涉及的领域包括投资管理银行、生命和非生命保险、风险投资与资产管理、零售贷款(如家庭贷款、个人贷款、教育贷款、汽车贷款、耐用消费品贷款、信用卡等)。

Private sector banks focus on customization of products that are designed to meet the specific needs of customers. 私人银行主要致力于为一些特殊需求的客户进行设计和产品定制。

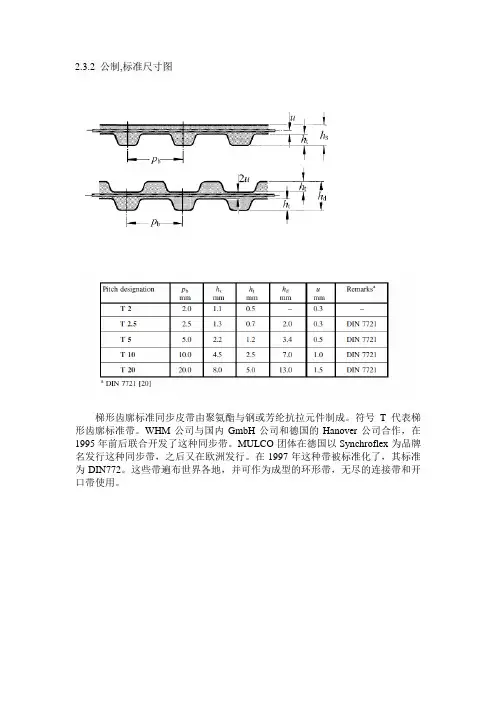

2.3.2 公制,标准尺寸图梯形齿廓标准同步皮带由聚氨酯与钢或芳纶抗拉元件制成。

符号T代表梯形齿廓标准带。

WHM公司与国内GmbH公司和德国的Hanover公司合作,在1995年前后联合开发了这种同步带。

MULCO团体在德国以Synchroflex为品牌名发行这种同步带,之后又在欧洲发行。

在1997年这种带被标准化了,其标准为DIN772。

这些带遍布世界各地,并可作为成型的环形带,无尽的连接带和开口带使用。

具有梯形齿廓和公制标准尺寸,AT同步带是T型同步带的一个发展。

它们由由聚氨酯与钢或芳纶抗拉元件制成。

与T型同步带先比,AT型同步带有更宽的齿形截面和更强的抗拉构件。

AT型同步带一个特殊的特点是带齿齿隙紧靠带轮槽底座。

德国的MULCO和Hanover公司开发了这种类型的同步带,并在1980年左右以Synchroflex为品牌发行了这种带。

这些带遍布世界各地,并可作为成型的环形带,无尽的连接带和开口带使用。

这些带ISO 13050 标准用符号H表示,也被称为HTD同步带。

HTD代表大扭矩驱动。

这种同步带是由氯丁橡胶与玻璃纤维抗拉元件和聚酰胺纤维织物制成,并由在1973年引领美国市场的Gates公司开发。

曲齿的几何形状是圆形,较大的齿高显然增加了齿承载能力和抗牙跳能力。

这种带在世界各地都可以看到,许多制造商都参与它的生产。

它们也用聚氨酯,任选与钢丝帘线或芳纶抗拉元件制造。

用户可以从无尽的成型带,开口带和连续挤压环形带中选择使用。

这些带ISO 13050 标准用符号R表示,也被称为RPP同步带。

RPP代表橡胶抛物线。

1985年意大利的公司开发了这种双抛物线齿廓的同步带,他们是由氯丁橡胶与玻璃纤维抗拉元件和聚酰胺纤维织物制成。

这种类型的同步带主要发行在欧洲南部,许多制造商都参与它们的生产。

它们也用聚氨酯,任选钢丝帘线或芳纶抗拉元件制造。

用户可以从无尽的成型带,开口带和连续挤压环形带中选择使用。

这些带ISO 13050 标准用符号S表示,也被称为STD同步带。

中英互译文章什么是好的译文很难定,但良好的中英互译得好受到很多因素影响。

下面就是店铺给大家整理的中英互译文章,希望大家喜欢。

中英互译文章篇1:玫瑰色的月亮The Rosy Moon李秀鲁Li Xiulu就像半天空里掉下个金元宝一样,罗君的一幅条幅竟然在全省书法比赛中得了奖,整个世界立刻在23岁的罗君眼里变成了令人心荡神驰的玫瑰色。

此刻,他吸着烟,以一个书法家的眼光望着镜框里的B 姑娘,这个差点成为自己妻子的她,原来一点也不漂亮,瞧那嘴唇,厚得多厉害,简直可以说,丑死了。

以后人家会说--年轻的书法家,怎么找一个卖冷饮的?配得上吗?……哎,幸亏这奖状来得是时候,不然等结了婚可就不好办了。

When he won a prize in the Province's calligraphy contest, Mr. Luo feltelated as if a gold ingothad fallen on him from the sky. The world instantlybecame ecstatically rosy in the eyes of the23-year-old winner. At the moment,he was smoking a cigarette while judging Miss B'sphotograph in a glassframe with a calligrapher's eye. He found that she was by no means prettyand she was the one who almost became his wife! Look at her lips, he thought. How thick theyare! Ugly beyond words! People would ask, then, how come a young calligrapher should chooseto marry a cold drink peddler? It isn't a good match! Well, fortunately, the prue camein time, orit would be too late if we had gotten married.把她扔掉!不过肯定会有人指责这件事儿,有人就爱管闲事儿!罗君可不怕这个:虽然自己曾和她信誓旦旦,但此一时彼一时也,现在我已是书法家了,搞艺术的,一个卖冷饮的懂什么艺术?再说……比如有一个粗瓷盘子,本来一直和许多普通盘子混在一起当餐具,可有一天考古学家发它竟是一件珍贵文物,那么以后呢,当梦就跟那些珍贵文物摆到一起去啦。

车床用于车外圆、端面和镗孔等加工的机床称作车床。

车削很少在其他种类的机床上进行,因为其他机床都不能像车床那样方便地进行车削加工。

由于车床除了用于车外圆还能用于镗孔、车端面、钻孔和铰孔,车床的多功能性可以使工件在一次定位安装中完成多种加工。

这就是在生产中普遍使用各种车床比其他种类的机床都要多的原因。

两千多年前就已经有了车床。

现代车床可以追溯到大约1797年,那时亨利•莫德斯利发明了一种具有把主轴和丝杆的车床。

这种车床可以控制工具的机械进给。

这位聪明的英国人还发明了一种把主轴和丝杆相连接的变速装置,这样就可以切削螺纹。

车床的主要部件:床身、主轴箱组件、尾架组件、拖板组、变速齿轮箱、丝杆和光杆。

床身是车床的基础件。

它通常是由经过充分正火或时效处理的灰铸铁或者球墨铸铁制成,它是一个坚固的刚性框架,所有其他主要部件都安装在床身上。

通常在球墨铸铁制成,它是一个坚固的刚性框架,所有其他主要部件都安装在床身上。

通常在床身上面有内外两组平行的导轨。

一些制造厂生产的四个导轨都采用倒“V”,而另一些制造厂则将倒“V”形导轨和平面导轨结合。

由于其他的部件要安装在导轨上并(或)在导轨上移动,导轨要经过精密加工,以保证其装配精度。

同样地,在操作中应该小心,以避免损伤导轨。

导轨上的任何误差,常常会使整个机床的精度遭到破坏。

大多数现代车床的导轨要进行表面淬火处理。

以减少磨损和擦伤,具有更大的耐磨性。

主轴箱安装在床身一端内导轨的固定位置上。

它提供动力。

使工件在各种速度下旋转。

它基本上由一个安装在精密轴承中的空心轴和一系列变速齿轮---类似于卡车变速箱所组成,通过变速齿轮,主轴可以在许多中转速的旋转。

大多数车床有8~18中转速,一般按等比级数排列。

在现代车床上只需扳动2~4个手柄,就能得到全部挡位的转速。

目前发展的趋势是通过电气的或机械的装置进行无级变速。

由于车床的精度在很大程度上取决于主轴,因此主轴的结构尺寸较大,通常安装在紧密配合的重型圆锤滚子轴承或球轴承中。

中英文对照翻译文章不少英文文章都是带有翻译的,为的就是方便读者在不理解文章的时候能够找到对照的意思。

下面就是店铺给大家整理的中英文对照翻译文章,希望大家喜欢。

中英文对照翻译文章篇1:A Sailor's Christmas Gift一个水手的圣诞礼物William J·Lederer威廉·J·莱德勒Last year at Christmas time my wife,three boys,and I were in France,on our way from Paristo Nice.For five wretched days ererything had gone wrong.Our hotels were“touristtraps”;our rented car broke down;we were all restless and irritable in the crowded car.OnChristmas Eve,when we checked into a dingy hotel in Nice,there was no Christmas spirit inour hearts.去年,在圣诞节期间,我和我的妻子以及我们的三个孩子,从法国踏上由巴黎到尼斯的旅途。

由于接连五天的恶劣天气,旅途上一切很不顺心。

我们下榻的旅馆尽是些敲诈勒索旅客的“陷阱”;我们租用的那辆汽车老是发生故障,在拥挤不堪的车子上大家个个显得烦躁不安。

圣诞节前夕,我们住进了尼斯的一家旅店,这家旅店又脏又暗,我们打心眼里感觉不到丝毫的节日气氛。

It was raining and cold when we went out to eat.We found a drab littlejoint shoddily decoratedfor the holiday.It smelled greasy.Only five tables in the restaurant were occupied.Therewere two German couples,two French families,and an American sailor,by himself.In thecorner a piano player listlessly played Christmas music.我们外出就餐时,天正下着小雨,天气寒冷。

1Lexicography1)Lexicography provides at its best a joyful sense of busyness with language2) One isimmersed in the details of language as in no other field. 3) Sometimes the details are so overwhelming and endless they sap the spirit and depress the mind4) Often at the end of a hard day’s work one realizes with dismay that the meager stack of finished work one has accomplished has an immeasurably slight impact on the work as a whole 5) As I hope the readers of this work will come to understand dictionaries do not sprint into being 6)People must plan them collect information and write them.7 )Writing takes time and it is often frustrating and even infuriating.8 )No other form of writing is at once so quixotic and so intensely practical.9) Dictionary making does not require brilliance or originality of mind.10) It does require high intelligence mastery of the craft and dedication to hard work.11) If one has produced a dictionary one has the satisfaction of having produced a work of enduring value.2.Pollution1) Pollution is a problem because man in an increasingly populated and industrialized world is upsetting the environment in which he lives.2) Many scientists maintain that one of man’s greatest errors has been to equate growth with advancement. 3) Now ―growth‖ industries are being looked on with suspicion in case their side effects damage the environment and disrupt the relationship of different forms of life.4) The growing population makes increasing demands on the world’s fixed supply of air water and land.5) This rise in population is accompanied by the desire of more and more people for a better standard of living, in an ever increasing amount of waste material to be disposed of.6) The problem has been causing increasing concern to living things and their environment.7) Many believe that man is not solving these problems quickly enough and that his selfish pursuit of possessions takes him past the point of no return before he fully appreciates the damage.1参考译文词典编纂的绝妙之处是给人一种与语言打交道的快乐感。

经典中文的英译但愿人长久,千里共婵娟。

We wish each other a long life so as to share the beauty of this graceful moonlight, even though miles apart.独在异乡为异客,每逢佳节倍思亲。

A lonely stranger in a strange land I am cast, I miss my family all the more on every festive day.大江东去,浪淘尽,千古风流人物。

The endless river eastward flows; with its huge waves are gone all those gallant heroes of bygone years.二人同心,其利断金。

If two people are of the same mind, their sharpness can cut through metal.富贵不能淫,贫贱不能移,威武不能曲,此之谓大丈夫。

It is a true great man whom no money and rank can confuse, no poverty and hardship can shake, and no power and force can suffocate.海内存知己,天涯若比邻。

A bosom friend afar brings distance near.合抱之木,生于毫末,九层之台,起于累土;千里之行始于足下。

A huge tree that fills one’s arms grows f rom a tiny seedling; a nine-storied tower rises from a heap of earth; a thousand li journey starts with the first step.祸兮,福之所依;福兮,祸之所伏。

译文翻译大全 Translation DictionaryAAccount 账户;账号Accurate 准确的Achievement 成就;成绩Action 行动;作用Adapt 适应;改编Address 地址Advantage 优势Advertising 广告BBalance 平衡;余额Beauty 美丽;美妙Behavior 行为;举止Bold 大胆的;勇敢的Book 书籍;本子CCareful 仔细的Challenge 挑战;难题Championship 冠军赛Character 字符;角色Church 教堂DData 数据;资料Debt 债务Decision 决定;抉择Description 描述;描写 Design 设计;布置EEducation 教育Electricity 电Employment 雇佣;就业 Energy 能量;力量Engineer 工程师FFamiliar 熟悉的Fashion 时尚;潮流Finance 金融;财政Forgive 宽恕;饶恕Freedom 自由;自主GGift 礼物Goal 目标;目的Golf 高尔夫Government 政府;行政 HHabit 习惯;习性Hall 大厅;厅堂Harmful 有害的Healthy 健康的History 历史IIdentity 身份;本质 Income 收入;收益Interest 兴趣;利息 Interview 面试;会谈 Involve 包含;牵扯JJob 工作;职务Judge 审判;裁定KKitchen 厨房;厨具Knowledge 知识;学问 LLanguage 语言Liberty 自由;豁达Lifestyle 生活方式Logic 逻辑;推理MMajor 专业;主要Mark 标志;印记Material 物质;材料Mile 英里;里程NNature 自然;本质Negative 负面的;消极的 Notice 通告;注意OObject 物体;目标Opinion 意见;看法Organization 组织;机构 PPayment 付款;费用Performance 表演;表现 Pollution 污染;环境污染 Position 位置;姿势QQuantity 数量;量Question 问题;疑问RRace 种族;人种Religion 宗教;信仰Response 回应;答复Reward 奖励;报酬SService 服务;业务Skill 技能;技巧Social 社会的;社交的 Solution 解决方案;溶液 TTeacher 老师;教师Technique 技术;方法Team 团队;组织Technology 技术;科技 Thought 思想;想法UUnit 单位;部门University 大学VValuable 有价值的Victory 胜利;成功 Vision 视觉;远见WWorth 价值;可取之处 XX-ray X光YYard 码;院子Year 年;一年ZZone 区域;地带。

英汉对照全译大全全文共四篇示例,供读者参考第一篇示例:英汉对照全译是指将英语原文逐字逐句地翻译成中文,以保留原文的语言风格和表达方式,同时也让读者更容易理解原文的含义。

英汉对照全译不仅可以帮助中文读者学习英语,还可以让熟练掌握英语的读者更加深入地理解原文的含义和细节。

下面将为大家制作一份关于【英汉对照全译大全】的文章,通过英汉对照的方式,为大家提供更多学习和阅读的机会。

1. Hello, how are you? 你好,你好吗?2. I’m fine, thank you. 我很好,谢谢你。

3. What’s your name? 你叫什么名字?4. My name is Lisa. 我的名字是丽莎。

6. I am from China. 我来自中国。

8. Yes, I like reading very much. 是的,我非常喜欢读书。

10. My favorite book is "Pride and Prejudice" by Jane Austen. 我最喜欢的书是简·奥斯汀的《傲慢与偏见》。

12. I am twenty years old. 我二十岁了。

13. What do you do for a living? 你是做什么工作的?14. I am a teacher. 我是一名教师。

16. I enjoy listening to music and watching movies. 我喜欢听音乐和看电影。

17. Have you ever traveled abroad? 你有没有去过国外旅行?21. Do you have any siblings? 你有兄弟姐妹吗?22. Yes, I have one brother and one sister. 是的,我有一个哥哥和一个妹妹。

23. Are you married? 你结婚了吗?26. I plan to further my education and travel around the world. 我计划继续教育并环游世界。

2. I did not remember a single point discussed at the meeting.会上讲了什么,我一点没记住。

1. Even if the monk can run away, his temple cannot run with him. 跑得了和尚,跑不了庙。

2. Even if I were to be beaten to death, I will not tell.打死我也不说。

3. Modesty helps one go forward, whereas conceit makes one lag behind. 谦虚使人进步,骄傲使人落后。

5. We will not attack unless we are attacked. 人不犯我,我不犯人。

6. 吃苦在前,享乐在后。

Be the first to bear hardships and the last to enjoy comforts.8. 不知苦中苦,哪知甜中甜?If you have never tasted the bitterness of gall, how can you know the sweetness of honey?东边闪电出日头,西边闪电必有雨,南边闪电天气热,北边闪电有雷雨。

If it lightens in the east, it will be sunny; if it lightens in the west, it will be rainy; if it lightens in the south, it will be sultry; if it lightens in the north, it will be stormy.有饭大家吃。

(= 如果有饭的话,那就让大家吃吧)Let everybody share the food if there is any.不到黄河心不死。

外文文献原稿和译文原稿IntroductionROM. Marie dvali, Moore mandela • Ralph are mainly introduced in storage, storage system plays in logistics system 。

The buffer, and regulate and the effect of the balance in the low-cost, provide satisfactory customer service has a pivotal role. In enterprise warehouse management decision-making, is self-supporting storage or public storage, become logistics managers often face problems of two kinds of storage, the disadvantages. The contrast analysis of.Enterprise warehouse management decision analysisStorage system is a subsystem of logistics system in logistics system, plays a buffer, regulation and the effect of the balance. Through the storage, can make the goods at the most effective During the periods of play a role, create the "time value of goods" and "use value"; Can make the raw materials, fuel and semi-finished products in need of the production links form right amount Inventory to ensure continuous production; Also can adjust production and consumption imbalances. So said left storage is impossible to have high efficiency low cost of logistics Service. So how to arrange storage space for inventory, warehouse or public warehouse self-support, has become the enterprise warehouse management of an important decision.a the advantages and disadvantages of self-management storageSelf-supporting storage refers to the manufacturing or distribution enterprises business built the need for the enterprise subsidiary warehouse, logistics system of providing services.1. Self-supporting storage advantages(1) adaptability stronger. Proprietary stock of enterprise is the owner, can according towarehouse enterprise itself requirements and characteristics of the products to warehouse designed and clothInnings. A highly specialized product often need professional storage and handling technology, and according to the popularization of public storage mostly, to meet the design requirement for enterprise Personalized requirements, self-supporting storage enterprise in the design and management of the warehouse can better satisfy enterprise needs.(2) enterprise warehouse control bigger. Because enterprise for implementing the warehouse ownership, so enterprises as shippers to storage implementation to a greater degree of control System. In finished goods over to the customer before, enterprise can directly control and responsible for product. This control make the enterprise will be integrated into the warehouse functions to logistics system.(3) long-term storage costs less. If self-owned warehouse full use of, get long-term storage costs considerably below has its own public storage costs. This is by In long-term use their own warehousing large shipments will reduce the storage unit cost of goods, which is a form of economies of scale. If the enterprise self-owned warehouse Lower utilization rate, explain own warehousing produce the scale economy can't compensate the cost of private storage, should consider to public storage.(4) to set up the business enterprise image. Enterprises have their own warehouses will bring many intangible benefits, will give customers an enterprise sustainable business and continuous operation A good impression, the customer will think enterprise operation is stable, reliable, this will help enhance the enterprise the competitive advantage, setting up the enterprise image.2. Self-supporting storage shortcomings(1) investment risk is big. Self-supporting storage, as warehouse construction or buy need large amounts of funds, warehouse construction cycle is long, the investment risk bigger, another Outside the hiring and training staff costs and material handling equipment investment will increase, and the enterprise funds can invest in other projects. Therefore, investment Build proprietary warehousing decisions should be very careful.(2) flexibility is low. Self-supporting storage warehouse capacity is relatively fixed, regardless of storage space requirements of enterprises, can with how to increased demand Or reduce and expand or reduced. When enterprise to the warehouse space, still less demand must assume self-owned warehouse unused portion of the costs; And when the enterprise to the warehouse The space has the extra demand, but can not satisfy own warehouse. Another market size, market position and customer preferences often changes, if the enterprise warehouse in knots Compose and services can't adapt to these changes, the enterprise will lose many business opportunitiesSecond, the advantages and disadvantages of public storage Public storage is to show enterprise renting do not belong to his warehouse or a certain quantity of location, the storage service to satisfy his needs.1. The advantages of public storage(1) reduces the risk of investment. Use of public storage, enterprise can avoid warehouse construction capital investment and financial risk. Public storage does not require users to anyInvestment and enterprise to pay the rent relatively few can get storage service. Thus avoiding the enterprise in land, houses, material handling equipment, hiring and training Staff etc investment.(2) adaptability. If the management of the enterprise has seasonal, so public storage will satisfy enterprise in sales blitz need storage space. While a dedicated warehouse Store will be restricted by warehouse capacity, and at times, warehouse may idle. Most enterprise as products of seasonal, promotions or other reasons And cause stock levels change, use public storage, then there is no limit to the capacity of the warehouse, to meet in different periods of enterprise warehouse space requirement, especially Is stock of extra inventory of peak demand.(3) flexible degree is high. When use public storage business activities more flexible, if the enterprise, and then when building itself warehouse to meet the needs of the market and change The location of the warehouse, the original warehouse became enterprise burden. Because the public storage contract is short, when the market, transportation, sales or enterprises Industry financial conditions change, public storage mode enterprise can flexibility to change the position of the warehouse. (4) produce scale economic benefit. Public storage will produce self-owned storagedifficult to achieve economies of scale, because public storage for many enterprises of keeping library Memory, and hence compared with self-owned storage, which greatly improved the utilization ratio and the storage warehouse utilization ratio, reduced inventory costs; unit of storage In addition, scale economy still makePublic storage can adopt more effective material handling equipment, so as to provide more professional warehousing services; Finally, public storage economies of scale and thus LCL Homework and mass transportation, thereby reducing the shipper's storage costs.2. Public storage shortcomings(1) increase the packaging cost. Public warehouse storage the various kinds of goods, and various different kinds of goods may influence each other, therefore, the enterprise Use public storage of goods must be protective packaging, thus increasing the packaging cost.(2) increase inventory control difficulty. Enterprise and warehouse operator has to perform the contract obligations, but theft, etc the damage caused to the losses will be far owner More than to be compensated for. So in control, use public warehouse inventory than use their own warehouse to take greater risks. In addition, enterprise and will thus The commercial confidential information disclosure about.Three, enterprise warehouse decision analysis1. Decision-making factor analysisSelf-supporting storage, public storage has its advantages and disadvantages, the enterprise is in storage decision analysis, is self-supporting storage or public warehouse, enterprise's decision was based on The premise of satisfying the needs of customers the lowest total cost of logistics. Generally speaking, the enterprise is self-supporting storage or to use the public storage should focus on considers the following factors:(1) turnover. The cost of self-management storage structure including variable cost and fixed cost two parts, fixed cost relatively high, and has nothing to do with use degree, because This must have enough stock to share these costs, unit variable costs generally lower than public storage unit variable costs. Public storage costs contains only can Into this, along with the increase in the number of inventory, the lease spacewill increase, because public warehouse according to take up the space is general to collect fees, such costs and total turnover Is proportional to the amount of the cost function is linear. Therefore enterprise turnover is low public storage is the best choice, with the increasing turnover, when turnover To achieve a certain scale to consider choose self-conducting storage.(2) market density. Market density, relative concentration of the larger or supplier to build own warehouse. This is because less-than-one carload transport rate is relative taller, via since After a warehouse LCL shipments, vehicle transport rate will be greatly reduced. Instead, the market, the low density in different place to use than a few public warehouse since A warehouse services a large district is more economical.(3) needs stability. Demand of the stability of self-management storage is a key factor. Many manufacturers have various product lines, make the warehouse has the stable weeks Turn quantity, so more economic operation of self-management storage.2. Self-supporting storage and public storage decision analysis(1) self-supporting warehouse if can rent, self-conducting storage can reduce storage costs. Enterprise if can easily find warehouse in the use of logistics market The enterprise need bigger storage space, their use in lower utilization rate, when will the remaining space rent to other enterprise, make up costs, which can Overcome because utilization rate is not stable, thus make the malpractices of self-supporting warehousing costs low.(2) in demand fluctuation is bigger, use the public storage can reduce storage costs. For storage demand fluctuation larger enterprise, according to choose self-conducting storage will be Demand to construction in the rush hour, warehouse, warehouse will be large number of idle, speaking of the enterprise is a kind of waste. If using public warehouse, on loan at peak hours can more Many public storage space to meet demand, it will lower overall storage costs.(3) for the new development of the market, to use the public storage is more suitable for the need of market volatility. There are many new developing market uncertainty and uncertainty. If the blind investment construction self-supporting storage, may bring huge risks, to use the public storage, can reduce risk benefit, but also on the accumulation of storage Information for enterprise decision to provide the reference.(4) self-conducting warehousing and public storage organic union. Most enterprise market demand is the fluctuation in design and planning, enterprise has its own warehouse, press Meet the demand low storage quantity in the size of the warehouse, designed by public storage sales season to increase storage space, so, not only ensure the self-supporting storage utilization Rate, have satisfied the demand of enterprise peak, make full use of the advantages of the two kinds of storage for enterprise service. In short, the enterprise warehouse decision no fixed pattern, the enterprise should need to its own characteristics and conditions, to cost and customer service on the basis of comprehensive analysis to make reasonable choice译文介绍罗玛丽•瓦利,莫尔曼德•拉夫主要介绍的是仓储,仓储系统在物流系统中起着缓冲、调节和平衡的作用,其在以低成本提供令人满意的客户服务方面具有举足轻重的作用。

本科毕业设计(论文)外文参考文献译文及原文学院材料与能源学院专业微电子学年级班别2009级(01)班学号3109007456学生姓名谭文海指导教师刘振2013 年06 月08日目录外文参考文献译文 (1)角多样性无向无线红外通信 (1)摘要 (1)介绍 (1)总结 (9)外文参考文献译文角多样性无向无线红外通信摘要我们提纲的是使用射角分集无向无线红外通信系统的好处和机遇。

多个发射机束和多个窄视场接收器减少的信道路径损耗、多路径失真,和背景噪声,从而导致改进范围。

我们也讨论对多元素角多样性系统,包括信道特性和次优的检测技术的实际问题。

也考虑了最大比结合度提供角多样性系统近最优性能高达100 Mb / s。

一个原型角多样性的红外通信系统的设计和性能也讨论了。

这个原型可以超过一个4米的范围保持70Mb/s每Pe.索引词-光通信,无线局域网。

介绍高速无线通信内部建筑可以通过使用非向性红外线连接器来获取。

非向性连接器,每个点由宽光束发射器和宽视场(FOV)接收器,需要消除个点的发射机和接收器组成的。

如果他们被设计成使用非视距(LOS)路径(通过照明天花板或者墙壁)代替,或者除了,los 路径,这样的连接会变得更加稳健。

如附图1(a)描述非向性红外连接的传统方法。

一个探测器在宽视场里收集不必要的环境光度以及所需的信号。

稳定的光源,如太阳和白炽灯,导致白色,近似于高斯散粒噪声;调制光源,如荧光灯,引起周期平稳的噪声。

同样,一个宽视场接收机不仅收集主要照明点,还包括已经经历了两个或两个以上或因此延迟的反射的信号。

这个过程,同时增加收集信号能力,介绍了多路径失真。

我们考虑多波束发射机和多个非成象的接收器的使用,如附图1(b),一个探测阵列窄视拨的探测器,跟同样的视场结合起来作为单个的宽视场探测器,它能拒档周围的不能组成单个的光。

更多的是,因为位于同一个视场作为主要的信号更小的一部分的光被耽搁,会降低多路径失真。

相对于单一的宽束发射机和特别有效结合窄视场接收器,使用多个光束会减少路径损耗,因为这些接收器能收集集中信号而拒挡更多的漫射噪声来源。

附录C:外文翻译资料Article Source:Business & Commercial Aviation, Nov 20, 2000. 5-87-88 Interactive Electronic Technical Manuals Electronic publications can increase the efficiency of your digital aircraft and analogtechnicians.Benoff, DaveComputerized technical manuals are silently revolutionizing the aircraft maintenance industry by helping the technician isolate problems quickly, and in the process reduce downtime and costs by more than 10 percent.These electronic publications can reduce the numerous volumes of maintenance manuals, microfiche and work cards that are used to maintain engines, airframes, avionics and their associated components."As compared with the paper manuals, electronic publications give us greater detail and reduced research times," said Chuck Fredrickson, general manager of Mercury Air Center in Fort Wayne, Ind.With all the advances in computer hardware and software technologies, such as high quality digital multimedia, hypertext and the capability to store and transmit digital multimedia via CD-ROMs/ networks, technical publication companies have found an effective, cost-efficient method to disseminate data to technicians.The solution for many operators and OEMs is to take advantage of today's technology in the form of Electronic Technical Manuals (ETM) or Interactive Technical Manuals (IETM). An ETM is any technical manual prepared in digital format that has the ability to be displayed using any electronic hardware media. The difference between the types of ETM/IETMs is the embedded functionality and implementation of the data."The only drawback we had to using ETMs was getting enough computers to meet our technicians' demand," said Walter Berchtold, vice president of maintenance at Jet Aviation's West Palm Beach, Fla., facility.A growing concern is the cost to print paper publications. In an effort to reduce costs, some aircraft manufacturers are offering incentives for owners to switch from paper to electronic publications. With an average printing cost of around 10 cents per page, a typical volume of a paper technical manual can cost the manufacturer over $800 for each copy. When producing a publication electronically, average production costs for a complete set of aircraft manuals are approximately $20 per copy. It is not hard to see the cost advantages of electronic publications.Another advantage of ETMs is the ease of updating information. With a paper copy, the manufacturer has to reprint the revised pages and mail copies to all the owners. When updates are necessary for an electronic manual, changes can either be e-mailed to theowners or downloaded from the manufacturer's Web site.So why haven't more flight departments converted their publications to ETM/IETMs? The answer lies in convincing technicians that electronic publications can increase their efficiency."We had an initial learning curve when the technicians switched over, but now that they are familiar with the software they never want to go back to paper," said Fredrickson.A large majority of corporate technicians also said that while they like the concept of having a tool that aids the troubleshooting process, they are fearful to give up all of their marked-up paper manuals.In 1987, a human factors study was conducted by the U.S. government to compare technician troubleshooting effectiveness, between paper and electronic methodology, and included expert troubleshooting procedures with guidance through the events. Results of the project indicated that technicians using electronic media took less than half the time to complete their tasks than those using the paper method, and technicians using the electronic method accomplished 65 percent more in that reduced time.The report also noted that new technicians using the electronic technical manuals were 12-percent more efficient than the older, more experienced technicians. (Novices using paper took 15 percent longer than the experts.)It is interesting that 90 percent of the technicians who used the electronic manuals said they preferred them to the paper versions. This proved to the industry that with proper training, the older technicians could easily transition from paper to electronic media.Electronic publications are not a new concept, although how they are applied today is. "Research over the last 20 years has provided a solid foundation for today's IETM implementation," said Joseph Fuller of the U.S. Naval Surface Warfare Center. "IETMs such as those for the Apache, Comanche, F-22, JSTAR and V-22 have progressed from concept to military and commercial implementation."In the late 1970s, the U.S. military investigated the feasibility of converting existing paper and microfilm. The Navy Technical Information Presentation System (NTIPS) and the Air Force Computer- based Maintenance Aid System (CMAS) were implemented with significant cost savings.The report stated that transition to electronic publications resulted in reductions in corrective maintenance time, fewer false removals of good components, more accurate and complete maintenance data collection reports, reduction in training requirements and reduced system downtime.The problem that the military encountered was ETMs were created in multiple levels of complexity with little to no standardization. Options for publications range from simple page-turning programs to full-functioning automated databases.This resulted in the classification of ETMs so that the best type of electronic publication could be selected for the proper application.Choosing a LevelWith all of the OEM and second- and third-party electronic publications that are available it is important that you choose the application level that is appropriate for your operation.John J. Miller, BAE Systems' manager of electronic publications, told B/CAthat "When choosing the level of an ETM/IETM, things like complexity of the aircraft and its systems, ease of use, currency of data and commonality of data should be the deciding factors; and, of course, price. If operational and support costs are reduced when you purchase a full-functioning IETM, then you should purchase the better system."Miller is an expert on the production, sustainment and emerging technologies associated with electronic publications, and was the manager of publications for Boeing in Philadelphia.Electronic publications are classified in one of five categories. A Class 1 publication is a basic electronic "page turner" that allows you to view the maintenance manual as it was printed. With a Class 2 publication all the original text of the manual is viewed as one continuous page with no page breaks. In Class 3, 4 and 5 publications the maintenance manual is viewed on a computer in a frame-based environment with increasing options as the class changes. (See sidebar.)Choosing the appropriate ETM for your operation is typically limited to whatever is being offered on the market, but since 1991 human factors reports state the demand has increased and, therefore, options are expected to follow.ETM/IETM ProvidersCompanies that create ETM/IETMs are classified as either OEM or second party provider. Class 1, 3 and 4 ETM/IETMs are the most commonly used electronic publications for business and commercial operators and costs can range anywhere from $100 to $3,000 for each ETM/ IETM. The following are just a few examples ofETM/IETMs that are available on the market.Dassault Falcon Jet offers operatorsof the Falcon 50/50EX, 900/900EX and 2000 a Class 4 IETM called the Falcon Integrated Electronic Library by Dassault (FIELD). Produced in conjunction with Sogitec Industries in Suresnes Cedex, France, the electronic publication contains service documentation, basic wiring, recommended maintenance and TBO schedules, maintenance manual, tools manual, service bulletins, maintenance and repair manual, and avionics manual.The FIELD software allows the user to view the procedures and hot- link directly to the Illustrated parts catalog. The software also enables the user to generate discrepancy forms, quotation sheets, annotations in the manual and specific preferences for each user.BAE's Miller said most of the IETM presentation systems have features called "Technical Notes." If a user of the electronic publication notices a discrepancy or needs to annotate the manual for future troubleshooting, the user can add a Tech Note (an electronic mark-up) to the step or procedure and save it to the base document. The next time that or another user is in the procedure, clicking on the tech note icon launches a pop-up screen displaying the previous technician's comments. The same electronic transfer of tech notes can be sent to other devices by using either a docking station or through a network server. In addition, systems also can use "personal notes" similar to technical notes that are assigned ID codes that only the authoring technician can access.Requirements for the FIELD software include the minimum of a 16X CD-ROM drive,Pentium II 200 MHz computer, Windows 95, Internet Explorer 4 SP 1 and Database Access V3.5 or higher.Raytheon offers owners of Beech and Hawker aircraft a Class 4 IETM called Raytheon Electronic Publication Systems (REPS). The REPS software links the frame-based procedures with the parts catalog using a single CD-ROM.Raytheon Aircraft Technical Publications said other in- production Raytheon aircraft manual sets will be converted to the REPS format, with the goal of having all of them available by 2001. In addition Raytheon offers select Component Maintenance Manuals (CMM). The Class 1 ETM is a stand-alone "page-turner" electronic manual that utilizes the PDF format of Adobe Acrobat.Other manufacturers including Bombardier, Cessna and Gulfstream offer operators similar online and PDF documentation using a customer- accessed Web account.Boeing is one manufacturer that has developed an onboard Class 5 IETM. Called the Computerized Fault Reporting System (CFRS), it has replaced the F-15 U.S. Air Force Fault Reporting Manuals. Technologies that are currently being applied to Boeing's military system are expected to eventually become a part of the corporate environment.The CFRS system determines re-portable faults by analyzing information entered during a comprehensive aircrew debrief along with electronically recovered maintenance data from the Data Transfer Module (DTM). After debrief the technicians can review aircraft faults and schedule maintenance work to be performed. The maintenance task is assigned a Job Control Number (JCN) and is forwarded electronically to the correct work center or shop. Appropriate information is provided to the Air Force's Core Automated Maintenance System (CAMS).When a fault is reported by pilot debrief, certain aircraft systems have the fault isolation procedural data on a Portable Maintenance Aid (PMA). The JCN is selected on a hardened laptop with a wireless Local Area Network (LAN) connection to the CFRS LAN infrastructure. The Digital Wiring Data System (DWDS) displays aircraft wiring diagrams to the maintenance technician for wiring fault isolation. On completion of maintenance, the data collected is provided to the Air Force, Boeing and vendors for system analysis.Third party IETM developers such as BAE Systems and Dayton T. Brown offer OEMs the ability to subcontract out the development of Class 1 through 5 ETM/IETMs. For example, Advantext, Inc. offers PDF and IPDF Class 1 ETMs for manufacturers such as Piper and Bell Helicopters. Technical publications that are available include maintenance manuals, parts catalogs, service bulletins, wiring diagrams, service letters and interactive parts ordering forms.The difference between the PDF and IPDF version is that the IPDF version has the ability to search for text and include hyperlinks. A Class 1 ETM, when printed, is an exact reproduction of the OEM manuals, including any misspellings or errors. Minimum requirements for the Advantext technical publications is a 486 processor, 16 MB RAM with 14 MB of free hard disk space and a 4X CD-ROM or better.Aircraft Technical Publishers (ATP) offers Class 1, 2 and 3 ETM/ IETMsfor the Beechjet 400/400A; King Air 300/ 350, 200 and 90; Learjet 23/24/25/28/29/35/36/55; Socata TB9/10/20/21 and TBM 700A; Sabreliner 265-65, -70 and -80; andBeech 1900. The libraries can include maintenance manuals, Illustrated parts bulletins, wiring manuals, Airworthiness Directives, Service Bulletins, component maintenance manuals and structural maintenance manuals. System minimum requirements are Pentium 133 MHz, Windows 95 with 16 MB RAM, 25 MB free hard disk space and a 4X CD-ROM or better.Additional providers such as Galaxy Scientific are providing ETM/ IETMs to the FAA. This Class 2, 3 and 4 publication browser is used to store, display and edit documentation for the Human Factors Section of the administration."Clearly IETMs have moved from research to reality," said Fuller, and the future looks to hold more promise.The Future of Tech PubsThe use of ETM/IETMs on laptop and desktop computers has led research and development corporations to investigate the human interface options to the computer. Elements that affect how a technician can interface with a computer are the work environment, economics and ease of use. Organizations such as the Office of Naval Research have focused their efforts on the following needs of technicians: -- Adaptability to the environment.-- Ease of use.-- Improved presentation of complex system relationship.-- Maximum reuse and distribution of engineering data.-- Intelligent data access.With these factors in mind, exploratory development has begun in the areas of computer vision, augmented reality display and speech recognition.Computer vision can be created using visual feedback from a head- mounted camera. The camera identifies the relative position and orientation of an object in an observed scene, and the object is used to correlate the object with a three-dimensional model. In order for a computer vision scenario to work, engineering data has to be provided through visually compatible software.When systems such as Sogitech's View Tech electronic publication browser and Dassault Systemes SA's Enovia are combined, a virtual 3D model is generated.The digital mockup allows the engineering information to directly update the technical publication information. If a system such as CATIA could be integrated into a Video Reference System (VRS), then it could be possible that a technician would point the camera to the aircraft component, the digital model identifies the component and the IETM automatically displays the appropriate information.This example of artificial intelligence is already under development at companies like Boeing and Dassault. An augmented reality display is a concept where visual cues are presented to users on a head-mounted, see-through display system.The cues are presented to the technician based on the identification of components on a 3D model and correlation with the observed screen. The cues are then presented as stereoscopic images projected onto the object in the observed scene.In addition a "Private Eye" system could provide a miniature display of the maintenance procedure that is provided from a palm- size computer. Limited success hascurrently been seen in similar systems for the disabled. The user of a Private Eye system can look at the object selected and navigate without ever having to touch the computer. Drawbacks from this type of system are mental and eye fatigue, and spatial disorientation.Out of all the technologies, speech recognition has developed into an almost usable and effective system. The progression through maintenance procedures is driven by speaker-independent recognition. A state engine controls navigation, and launches audio responses and visual cues to the user. Voice recognition software is available, although set up and use has not been extremely successful.Looking at other industries, industrial manufacturing has already started using "Palm Pilot" personal digital assistants (PDAs) to aid technicians in troubleshooting. These devices allow the technician to have the complete publication beside them when they are in tight spaces. "It would be nice to take the electronic publications into the aircraft, so we are not constantly going back to the work station to print out additional information," said Jet Aviation's Berchtold.With all the advantages that a ETM/ IETM offers it should be noted that electronic publications are not the right solution all of the time, just as CBT is not the right solution for training in every situation. Only you can determine if electronic publications meet your needs, and most technical publication providers offer demo copies for your review. B/CA IllustrationPhoto: Photograph: BAE Systems' Christine Gill prepares a maintenance manual for SGML conversion BAE Systems; Photograph: Galaxy Scientific provides the FAA's human factors group with online IETM support.; Photograph: Raytheon's Class 4 IETM "REPS" allows a user to see text and diagrams simultaneously with hotlinks to illustrated parts catalogs.外文翻译资料译文部分文章出处:民航商业杂志,2000-11-20,5-87-88交互式电子技术手册的电子出版物可以提高数字飞机和模拟技术的效率。

外文文献翻译(附原文)外文译文一:产业集群的竞争优势——以中国大连软件工业园为例Weilin Zhao,Chihiro Watanabe,Charla-Griffy-Brown[J]. Marketing Science,2009(2):123-125.摘要:本文本着为促进工业的发展的初衷探讨了中国软件公园的竞争优势。

产业集群深植于当地的制度系统,因此拥有特殊的竞争优势。

根据波特的“钻石”模型、SWOT模型的测试结果对中国大连软件园的案例进行了定性的分析。

产业集群是包括一系列在指定地理上集聚的公司,它扎根于当地政府、行业和学术的当地制度系统,以此获得大量的资源,从而获得产业经济发展的竞争优势。

为了成功驾驭中国经济范式从批量生产到开发新产品的转换,持续加强产业集群的竞争优势,促进工业和区域的经济发展是非常有必要的。

关键词:竞争优势;产业集群;当地制度系统;大连软件工业园;中国;科技园区;创新;区域发展产业集群产业集群是波特[1]也推而广之的一个经济发展的前沿概念。

作为一个在全球经济战略公认的专家,他指出了产业集群在促进区域经济发展中的作用。

他写道:集群的概念,“或出现在特定的地理位置与产业相关联的公司、供应商和机构,已成为了公司和政府思考和评估当地竞争优势和制定公共决策的一种新的要素。

但是,他至今也没有对产业集群做出准确的定义。

最近根据德瑞克、泰克拉[2]和李维[3]检查的关于产业集群和识别为“地理浓度的行业优势的文献取得了进展”。

“地理集中”定义了产业集群的一个关键而鲜明的基本性质。

产业由地区上特定的众多公司集聚而成,他们通常有共同市场、,有着共同的供应商,交易对象,教育机构和其它像知识及信息一样无形的东西,同样地,他们也面临相似的机会和威胁。

在全球产业集群有许多种发展模式。

比如美国加州的硅谷和马萨诸塞州的128鲁特都是知名的产业集群。

前者以微电子、生物技术、和风险资本市场而闻名,而后者则是以软件、计算机和通讯硬件享誉天下[4]。

Business process re-engineering –saviour or just another fad?One UK health care perspectiveAnjali PatwardhanHealth Service Management Centre,Birmingham,UK,and Dhruv Patwardhan University of Newcastle,Newcastle upon Tyne,UKAbstractPurpose –Pressure to change is politically driven owing to escalating healthcare costs and an emphasis on efficiency gains,value for money and improved performance proof in terms of productivity and recently to some extent by demands from less satisfied patients and stakeholders.In a background of newly immerging expensive techniques and drugs,there is an increasing consumer expectation,i.e.quality services.At the same time,health system managers and practitioners are finding it difficult to cope with demand and quality expectations.Clinicians are frustrated because they are not recognised for their contribution.Managers are frustrated because meaningful dialogue with clinicians is lacking,which has intensified the need for change to a more efficient system that satisfies all arguments about cost effectiveness and sustainable quality services.Various strategies,originally developed by management quality “gurus”for engineering industries,have been applied to health industries with variable success,which largely depends on the type of health care system to which they are applied.Design/methodology/approach –Business process re-engineering is examined as a quality management tool using past and recent publications.Findings –The paper finds that applying business process re-engineering in the right circumstances and selected settings for quality improvement is critical for its success.It is certainly “not for everybody”.Originality/value –The paper provides a critical appraisal of business process re-engineering experiences in UK healthcare.Lessons learned regarding selecting organisations and agreeing realistic expectations are addressed.Business process re-engineering has been evaluated and reviewed since 1987in US managed health care,with no clear lessons learned possibly because unit selection and simultaneous comparison between two units virtually performing at opposite ends has never been done before.Two UK pilot studies,however,add useful insights.Keywords Business process re-engineering,Total quality management,Continuous improvement,Medical management,Health services,United KingdomPaper type ViewpointHistory of quality management in health careTo know how health care organisations became interested in industrial quality development tools and how business process re-engineering (BPR)emerged as an option,we have to go back to 1987when the Quality Improvement in Health Care National Demonstration Project (NDP)was launched as an experiment (Godfrey,n.d.).A total of 21health-care organisations participated and promised to support this study lasting eight-months.The aim was to look at the applicability of industrial quality-improvement methods to health care.Support included free consulting,The current issue and full text archive of this journal is available at/0952-6862.htmBPR –saviour or just a fad?289Received 29November 2006Revised 10February 2007Accepted 25May 2007International Journal of Health Care Quality Assurance Vol.21No.3,2008pp.289-296q Emerald Group Publishing Limited 0952-6862DOI 10.1108/09526860810868229materials,access to training courses and reviews.The funding companies included many of the USA’s leading organisations such as Corning,Ford,Hewlett-Packard,IBM and Xerox.At the final stages of the project evaluations it was clear that out of 21organisations,15health care organisations made significant progress –mainly financial and patient satisfaction gains,target and project time keeping and investment in research and development.The NDP was extended for three years,which eventuallyevolved into the Institute for Healthcare Improvement,a not-for-profit organisation –dedicated to providing health-care quality management ter,BPR emerged as an alternative for managers in organisations frustrated with slow improvements,not encompassing the whole organisation experiencing total quality management (TQM).The TQM key target was to convert an organisation’s structure,culture and services to patient/consumer rather than organisation-focused goals (Harvey and Millett,1999).Why change?Traditionally health care systems were mostly “governed”by clinicians (Shutt,2003)because patient outcomes;that is,recovery from illness,were the sole responsibility of all professionals directly involved in patient plexity and variance in health care studies reveal that outcome has many determinants;i.e.pharmacy,pathology,technical support and information technology.It was also realised that cost containment and good quality care needed teamwork,communication,time management,etc.(Shutt,2003).Sir Roy Griffiths,in the early 1980s,developed hospital general management and the greater involvement of clinicians in resource management initiatives (DHSS,1984).Today,apart from political motives,change is driven by escalating health care costs,increased demands for quality care,value for money services,patient expectation and third-party payers in managed health care systems.These intensified the need for change to more efficient health care systems.What is BPR?BPR,also known business transformation and process change management,was introduced to the business world by Frederick Taylor in his article The Principles of Scientific Management in the 1900s (wikipedia,2006).In the 1990s,Hammer and Champy (1993)introduced Reengineering the Corporation ,which gave birth to BPR.BPR is “the analysis and design of workflows and processes within and between organizations”(Devenport and Short,1990,p.11).Teng et al.(1994)on the other hand,defined BPR as critical analysis and radical redesign of existing business processes to achieve breakthrough improvements in performance measures.Hammer and Champy (1993),similarly,defined BPR as fundamentally rethinking and radically redesigning business processes to achieve dramatic improvements in critical contemporary performance measures such as cost,quality,service and speed.From a health care viewpoint,BPR is a management approach that rethinks present practices and processes in business and its interactions.It attempts to improve underlying process efficiency by applying fundamental and radical approaches by either modifying or eliminating non-value adding activities and redeveloping the process/structure/culture (McNulty and Ferlie,2000).However,in the health sector,a wide variety of patient groups make the health care service a complex project to redesign along these lines,thereby rendering changes context and time sensitive.IJHCQA 21,3290BPR key featuresHealth care’s BPR approach means starting with clean slate and rethinking services using a patient-focused approach.With the benefit of hindsight BPR identifies delays caused by unnecessary steps or potential errors that are built into processes.It is presumed that redesigning processes by removing these errors dramatically improves care quality.The BPR approach,therefore,raises expectations about dramatic results. Consequently,high returns on investment are anticipated.The process,planned strategically,is explained in Taylor’s BPR framework(wikipedia,2006): .defining BPR’s purpose and goal;.identifying requirements that meet clients’needs;.defining project scope,including appropriate activities such as process mapping;.assessing the environment using,for example,force-field analyses;.re-engineering business processes and activities;.implementing redesigned processes;and.monitoring redesign success and failure.BPR vs TQMComparing BPR with other popular quality management methods helps us to appreciate and highlight key features in a health care context(Harvey and Millett,1999).TQM or continuous quality improvement(CQI)refers to programmes and initiatives that emphasise incremental improvement in work processes and outputs over an open-ended time period.In contrast,BPR refers to discrete initiatives intended to radically redesign and improve work processes within a time frame.Some people think TQM is best suited to quality in health care improvement though it is an incremental stepwise,slow but holistic approach.In practice,TQM and BPR are customer-oriented and both encourage managers and practitioners to take a customer view point.Both are team approaches that involve process control.The TQM protagonists assume that existing health care practices and systems are principally right but improvements are needed.The BPR supporters,on the other hand,assume that health care systems and practices areflawed and need replacing.Those using TQM expect and believe in stepwise increments in performance as opposed to BPR experts who look for dramatic results.TQM aims to improve all levels for all stakeholders and at all steps,while BPR aims at specified areas only.Standardisation and supporting documentation is a TQM key point.Believing in consistent and cost-effective performance and minimising process or system defects, prevents rather than corrects problems(Field and Swift,1996).Those that use the BPR approach,on the other hand,areflexible and assume that standardisation increases process complexity(Harvey and Millett,1999).Nevertheless,BPR is a drastic change leading to staff resistance.Moreover,it is a top-down approach,so management support and commitment is vital to success.Innovation,therefore,is a risky process when used for“sick organisations”.The TQM incremental method,on the other hand,follows a gradual approach that is mostly bottom-up.It involves employees and often based on Deming’s principles that direct improvements through plan-do-study-act(PDSA)cycle.TQM,therefore,is suitable for improving quality in any organisation,although some amendments to suit context may be needed.Application in managed health care generated different results BPR–saviour or just a fad?291when dissimilar processes were applied in different scenarios.Business process re-engineering,therefore,may not suite everyone because it works better when applied to sick organisations or in fundamentally defective systems (Bashein et al.,1994).The TQM approach is about a cultural change as it is built into practices hooked on daily routines.The BPR method is a target-oriented process that is time sensitive because if not completed as planned then success may be jeopardised.The TQM primary enableris statistical process control,while in BPR it is information and technology (Harvey and Millett,1999).Advantages of applying BPR to health service quality improvementUsing BPR in the health sector was a response to frustrations amongst managers in organisations who perceived TQM’s incrementalism and ability to achieve organisation-wide change had failed.King’s College Hospital experience (Grimes,2000;Harrison et al.,1992)suggests that BPR could be best tried to achieve previously unachieved levels of efficiency in scenarios when other efforts/methods had been unsuccessful.The driving forces for change were aspirations to develop a more efficient system that satisfies consumers’demands for service quality and value for money (Bowns and McNulty,1999).At the same time,BPR makes it possible to sustain such quality without necessarily costing more,even though we know that health care costs are rising steeply.The third and most important aspiration in the King’s project was to improve professionals’job satisfaction,what they felt they always deserved.The aim was to orient health care towards and focus on patients rather than organisation needs.The BPR approach focuses on rethinking and redesigning processes from scratch,giving staff opportunities to revisit services in detail,thereby pointing out improvement areas.It strips all non-value adding and unnecessary steps from the process to make services more efficient.Although it is managed top-down and dominated by managers and leaders,decision making is done at the coal-face,thereby empowering the team.The BPR approach provides a flexible work environment,culture and work practices.It can be valuable for organisations in deep difficulties and performing poorly.In such a crisis,re-engineering may be the only way organisations can survive (Harvey and Millett,1999).Where major structural and cultural deficiencies are identified or are obvious as a poor performance cause,BPR is the best way to handle that scenario –evident from King’s College Hospital experiences (Bowns and McNulty,1999).BPR limitations in health care quality improvementWe know that BPR is a top-down approach that staff may resist.It is cited by autonomous clinical professionals as “a brutal and inappropriate technique”(Jones,1996,p.4284).Implementing BPR in health care scenarios,where clinicians are key players,therefore,is not only difficult but also unsafe (McNulty and Ferlie,2000).Thus,BPR may lead to ownership loss and employee de-motivation because they are not involved in planning and change management.Generally,change processes are less-well understood by employees (Jones,1996,p.4284):Quality would seem unlikely to be forthcoming if re-engineering is imposed from the top down in a rigid and mechanistic fashion ...If organizational change is to be effective and sustainable,this will also require the active engagement of,and learning by,employees rather than grudging compliance with management diktat.IJHCQA 21,3292Quality improvement in European public services elaborated health care TQM and BPR as quality improvement tools.It was acknowledged that many business approaches to quality improvement,including TQM and re-engineering,failed to take account of health care’s complexity and the nature of professionalised knowledge.The language and values used in most of these projects were alien to clinicians and so were rejected as management fads.It seems that BPR requires massive culture and structure change if it is to improve quality of the same magnitude.It may be that radical overnight transformation may sound impressive but unrealistic.Structural and cultural change needs time to develop,be accepted and absorbed at all levels, particularly in health care settings.In short,BPR is a high-cost and high-risk project. Seventy-percent of all industries could not achieve their targets–a BPR success rate around30per cent.In the health care sector,on the other hand,from the literature we reviewed,there is no successfigure available.BPR carries an unrealistic scope and expectation most of the time,which may be a reason for its70per cent failure rate.Its top-down nature and success depends on sustained management commitment and inspirational leadership,which is not easily measured and may not be available up to the threshold needed.BPR may make only a unit change in time.To be meaningful,it needs to be followed by a CQI exercise.Once changes are brought about,BPR-based change needs CQI projects to have sustained results.It is always contested that BPR does not take account of human processes–evident from Jones’(1996,p.4284) quotation:Such a perspective is seen as promoting the idea that you can design a perfect process, implement it exactly as you planned and the organizational machine will carry it out faultlessly.Setting on one side questions about the reliability of this whole process,it is evident that BPR neglects the important role of human creativity in making process work. As we raised earlier,BPR usually innovates one process at a time rather than a whole organisation approach.The process that is changed,therefore,might not have an effect on overall organisational performance that can be measured especially those perceived by consumers.In other words,BPR may have a drastic effect on one specific process but none or very little on total organisational performance.A simple illustration for improving inpatient admissions shows that BPR alone cannot improve services.There will be need also to improve day care,outpatient,primary care and emergency services. All have an effect on an organisation’s inpatient services because they are interlinked and interdependent.Moreover,BPR’s effect can be difficult to assess in this context since NHS organisations lack specific measures(Bowns and McNulty,1999).The extent to which BPR is applicable to health care systemsThe UK BPR health care experience comes from two centrally funded pilot studies:(1)King’s College Hospital,London(KCH);and(2)Leicester Royal Infirmary(LRI).The KCH project was evaluated by a Brunel team(Packwood et al.,1998;Grimes,2000) and the LRI scheme by Sheffield and Warwick(Bowns and McNulty,1999).Employees in these organisations shared their BPR experiences during evaluation.Consequently, both studies generated interesting and valuablefindings as they highlighted to what extent BPR could be applied to health care systems.However,the two hospitals were BPR–saviour or just a fad?293extremes,i.e.KCH was a “sick”unit at the time of the study.LRI,on the other hand,was one of the best teaching hospitals (McNulty and Ferlie,2000)with little scope to improve.At the end of the pilot studies it was evident from reports that both hospitals could not reach expectations especially the drastic changes and improvements anticipated at the beginning of the BPR projects.Both reduced waiting times and length of stay along with faster diagnostic processes.King’s,over and above theseimprovements,also made £1million savings (Grimes,2000)–attributed to “waste reduction”by process mapping followed by removing non-value adding activities and by increasing efficiency in the renewed system (Packwood et al.1998).This suggests that BPR is not for everybody and that selecting units to which BPR can be applied is important to achieve desired results.When the two trusts ran the pilot,they also continued to work on their generic and core improvement initiatives at different levels in the process and so it was difficult to attribute success to BPR alone or to assess its relative contribution to overall improvements.One approach to identify suitable sub processes for applying BPR is process mapping from “door to door”,which helps capture all the process components and applying a lean approach (Jones and Mitchell,2006,p.23).Identifying value-added activities highlights the non-value-added ones.Each non-value-added activity can be measured and analysed to assess its impact and ways to eliminate activity.Resource availability,deadline,cost,generic skills and above all,urgency to change help users select the right improvement tool.Also,as raised earlier,change management success is closely related to team morale,ownership and motivation.To achieve quality in health care services,therefore,two key staff groups –managers and clinicians,who come from different cultural backgrounds and are knowledgeable in different ways,need to work as a team.Understanding and cooperation are crucial if difficult tasks are to be accomplished (Shortell et al.1998).However,BPR’s failure to consider the human aspects of processes may make it difficult to integrate BPR into health care services.The BPR approach sounds impressive but unrealistic because soft structural and cultural change need time to develop particularly in health care settings.We believe that BPR can help to improve health services if it is meticulously planned and applied diligently.In short,even with all BPR’s limitations,it is still capable of delivering dramatic results not least because it forces staff to think from outside the scenario or process as a whole and work to deadlines (Bowns and McNulty,1999).Conclusions and recommendationsHealth care is a more complex system than any manufacturing industry.As a service provider with a major human component there are safety and efficiency issues rather than cost and efficacy,which separates health care from industry.BPR,like other single approaches to improve service quality,are likely to be unsuitable for health care (Shortell and Ferlie,2001),which is comprised of a number of sub processes.It has many stakeholders at different levels and there is wide variation in its internal customer (e.g.,fellow professionals)and external customer (i.e.patients)needs.We accept that BPR can be used as a tool for improving some sub-process or sub-unit activity.An example could be what happened in the LRI where BPR was tried as a quality improvement tool in bed management,pathology and OPD service innovation,etc.;but not applied in areas where clinician’s precision was paramount or where BPR was accepted less-well.In these areas,therefore,views on the methods’suitability forIJHCQA 21,3294quality improvements were mixed.That is,TQM and BPR ideally should always be followed by CQI methods for service improvement to be sustainable and effective.In short,quality management tools designed for industry should be applied to health services with proper selection,caution and care.ReferencesBashein,B.J.,Markus,M.L.and Riley,P.(1994),“Preconditions for BPR success:and how to prevent failures”,Information Systems Management,Vol.11No.2,pp.7-13.Bowns,I.R.and McNulty,T.(1999),Re-engineering Leicester Royal Infirmary–Executive Summary,School of Health and Related Research,University of Sheffield,Sheffield. Devenport,T.and Short,J.(1990),“The new industrial engineering information technology and BPR”,Sloan Management Review,Summer,pp.11-27.DHSS(1984),Health Services Management:Implementation of the NHS Management Inquiry, DHSS Circular HC(84)13,DHSS,London.Field,S.W.and Swift,K.G.(1996),Effecting a Quality Change:An Engineering Approach,Arnold, London.Godfrey,B.(n.d.),“Quality health care”,Quality Digest,available at:/ sep96/health.htm(accessed on15October2006).Grimes,K.(2000),Changing the Change Team,King’s College Hospital,London.Hammer,M.and Champy,J.(1993),Reengineering the Corporation:A Manifesto for Business Revolution,Harper Business Books,New York,NY.Harrison,S.,Hunter,D.,Marnoch,G.and Pollitt,C.(1992),Just Managing:Power and Culture in the NHS,Macmillan,Basingstoke.Harvey,S.and Millett,B.(1999),“OD,TQM and BPR:a comparative approach”,Australian Journal of Management and Organizational Behavior,Vol.2No.3,pp.30-42.Jones,D.and Mitchell,A.(2006),Lean Thinking for the NHS:A Report Commissioned by the NHS Confederation,pamphlet RA395.G7,NHS Confederation,London.Jones,M.(1996),“Re-engineering”,in Warner,M.(Ed.),International Encyclopedia of Business and Management,Routledge,London.McNulty,T.and Ferlie,E.(2000),Reengineering Health Care:The Complexities of Organisational Transformation,Oxford University Press,Oxford.Packwood,T.,Pollitt,C.and Roberts,S.(1998),“Good medicine?A case study of business process reengineering in a hospital”,Policy and Politics,Vol.26No.4,pp.401-15. Shortell,S.and Ferlie,E.(2001),“Improving quality of healthcare in the United Kingdom and the United States:a framework for change”,The Milbank Quarterly,Vol.79No.2,May, pp.281-315.Shortell,S.M.,Waters,T.M.and Clarke,K.W.B.(1998),“Physicians as double agents: maintaining trust in an era of multiple accountabilities”,Journal of the American Medical Association,Vol.280No.12,pp.1102-8.Shutt,J.A.(2003),“Balancing the health care scorecard”,Managed Care,September,pp.42-6. Teng,J.T.C.,Grover,V.and Fiedler,K.(1994),“Business process reengineering:charting a strategic path for the information age”,California Management Review,Vol.36No.3, pp.9-31.wikipedia(2006),“Frederick Winslow Taylor”,available at:/wiki/ Frederick_Winslow_Taylor(accessed2December2006).BPR–saviour or just a fad?295Further reading Davies,H.T.O.(2000),“Organizational culture and quality of health care”,Quality in Health Care ,Vol.9No.2,pp.111-9.Malhotra,Y.(1998),“Business process redesign:an overview”,IEEE Engineering Management Review ,Vol.26No.3,pp.214-25.Pollitt,C.(1996),“Business approaches to quality improvement:why are they hard for the NHS toswallow?”,Quality in Health Care ,Vol.5No.2,pp.104-10.Raymond,L.,Bergeron, F.and Rivard,S.(1980),“Determinants of business processreengineering success in small and large enterprises:an empirical study in the Canadian context”,Journal of Small Business Management ,Vol.36,pp.72-85.Corresponding authorAnjali Patwardhan can be contacted at:doctoranjali@IJHCQA 21,3296To purchase reprints of this article please e-mail:reprints@ Or visit our web site for further details:/reprints。