Caterpillarchina-QCLDM

- 格式:ppt

- 大小:356.00 KB

- 文档页数:8

Caterpillar (卡特彼勒公司):如何在全球竞争激烈的制造业市场中获得成功上海普华科技发展有限公司宋珊珊企业级项目管理为我们带来了统一的产品开发理念,还为我们带来了在不断变化的商业需求中随机应变的能力。

黄得耀眼的大型设备遍布世界各地,如履带式拖拉机,重型施工设备和采矿设备,发电机组和发动机。

鲜艳的黄色--这个全球最大的制造商之一的象征,它的名字就是“Caterpillar”。

卡特彼勒公司是一家多元化的国际公司,总部设在美国伊利诺州中北部的皮奥利亚,是建筑机械、矿用设备、柴油和天然气发动机以及工业用燃气轮机领域的技术领导者和全球领先制造商。

这个多元化的国际公司2005 年销售和收入达到 363.4 亿美元,在财富500强企业中排名第57位,Caterpillar在全球范围内制造了300多种用于工厂的产品,在世界各地的3200个网点,有200多家经销商在销售Caterpillar的产品。

整体小于部分之和Caterpillar将企业策略的重点放在追求完美的服务,而不是一味地扩展它的版图。

Caterpillar 的主要任务之一就是在机械制造、发动机和维护服务方面为客户发挥最大的价值。

在Caterpillar的30个部门中,决大多数都是产品部门,因此Caterpillar公司面对的主要挑战是如何在全球范围内利用自身的设施有效地管理复杂而广泛的公司内部资源。

如产品设计和开发,Caterpillar公司的许多产品都是由不同部门的开发小组工程师设计的。

因为产品的关系,很多不同的部门都参与到产品的设计、开发和生产过程中。

按照惯例, 每一个部门都会为产品制定部门特有的项目计划,到目前为止,部门和其它事业部之间都还没有实现计划的共享、集成和同步。

Fawn M.Briggerman是Caterpillar公司项目管理主管,她通过了项目管理专业人员资格认证,她说:“每一个事业部都有各自的项目管理强度,但是由于计划交流和计划共享受到限制,组织机构内部对产品的设计和开发方面的前瞻性不强。

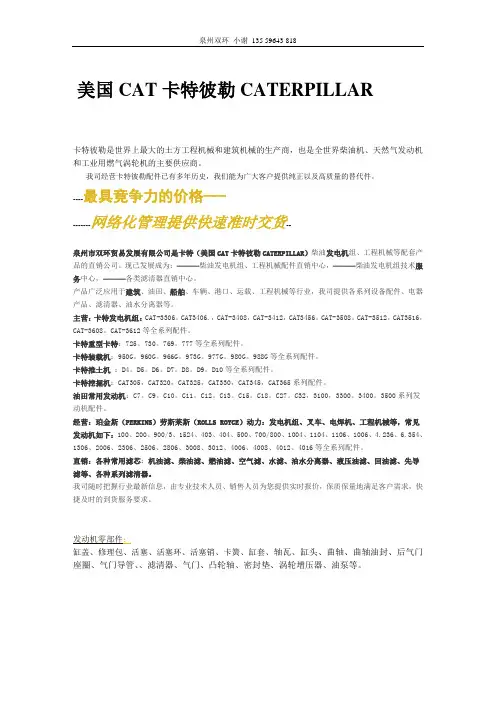

美国CAT卡特彼勒CATERPILLAR卡特彼勒是世界上最大的土方工程机械和建筑机械的生产商,也是全世界柴油机、天然气发动机和工业用燃气涡轮机的主要供应商。

我司经营卡特彼勒配件已有多年历史,我们能为广大客户提供纯正以及高质量的替代件。

----最具竞争力的价格----------网络化管理提供快速准时交货--泉州市双环贸易发展有限公司是卡特(美国CAT卡特彼勒CATERPILLAR)柴油发电机组、工程机械等配套产品的直销公司。

现已发展成为:———柴油发电机组、工程机械配件直销中心,———柴油发电机组技术服务中心,———各类滤清器直销中心。

产品广泛应用于建筑、油田、船舶、车辆、港口、运载、工程机械等行业,我司提供各系列设备配件、电器产品、滤清器、油水分离器等。

主营:卡特发电机组:CAT-3306。

CAT3406.,CAT-3408,CAT-3412,CAT3456。

CAT-3508。

CAT-3512,CAT3516,CAT-3608。

CAT-3612等全系列配件。

卡特重型卡特:725。

730。

769。

777等全系列配件。

卡特装载机:950G。

960G。

966G。

973G。

977G。

980G。

988G等全系列配件。

卡特推土机:D4。

D5。

D6。

D7。

D8。

D9。

D10等全系列配件。

卡特挖掘机:CAT305,CAT320,CAT325,CAT330,CAT345,CAT365系列配件。

油田常用发动机:C7。

C9。

C10。

C11。

C12。

C13。

C15。

C18。

C27。

C32,3100,3300。

3400。

3500系列发动机配件。

经营:珀金斯(PERKINS)劳斯莱斯(ROLLS ROYCE)动力:发电机组、叉车、电焊机、工程机械等,常见发动机如下:100、200、900/3、1524、403、404、500、700/800、1004、1104、1106、1006、4.236、6.354、1306、2006、2306、2506、2806、3008、3012、4006、4008、4012、4016等全系列配件。

MARINE FILTRATIONWORKING AS HARD AS YOU DOIT’S IN OUR BLOODCATERPILLARBALDWIN OEAIRPA618-S4L9852PA1620-S4L9851PA1629-S4L9853PA1631-S5L1203WPA16496L3313PA17656L4714PA1765 FOAM2N7003PA23847W5313, 8N5313PA25544N0015PA26538N6309PA2653 FOAM8N2555PA28488N2556PA36331059741, 1059742PA39044P0710PA39054P0711PA39321131578PA300692076870FUELBF6141R0712, 4N5823PF823-E5L7564, 6H5932PF9358H4681, 9M2342BF9701P2299, 1R0740, 6L7440 BF75871R0749BF76321R0751, 6I4783BF76331R0750BF76391R0755PF76551R0718, 1R0756, 8N9850 BF7677-D1454501PF77991R0725, 1R0766PF78904P7384CATERPILLAR (CONT’D)BALDWIN OEF/W SEPARATORPF3168N0205BF9126N7617, 8N9803BF12831290373BF1283-SP1290372BF1395-O1335673BF7674-D2053043PF7890-301346307LUBEB751R0714PT88-HD5S0485, 6H9937, 6H9999, 8F1151B991R0716, 2P4005BT2167W2327BT2301R0713BT3649L9200PT670 (Paper)1R0659, 1W7399, 4W4840, 5S0484, 9F6426, 9F6430, 9F6700 B14052201523P70031R0726, 7N7500, 4P2839P70121791502, 1W4136B72991R1808PT7332 (Metal)1R0659, 1W7399, 4W4840, 5S0484, 9F6426, 9F6430, 9F6700 B76001R0739B77001R1807OTHERPT88-HD5S0485PT275-109G6420BW51379N3368BW51381112371BW51399N3367BT8840-MPG 1446691YOU MUSTTHINK RULESARE MADETO BEBROKENIt’s a tough life. It forces you to push your limits.Baldwin pushes limits too. There’s no stopping uswhen it comes to protecting your engine. We have thecoverage, quality, service and availability you need.Baldwin has what it takes to be your one-source filterprovider, keeping your engine running and ensuringyou return home safe.YOUR SINGLE, RELIABLE FILTER PARTNERCUMMINSPA602AF274, 1401089PA1667-FN AF437K, 1401204BF596FF202BF788FF5052BF957-D FF105DBF7879FF5285, 3890017BF46002FF5644, 2881458BF855FF5051, 1491758BF1212FS1212BF1216FS1216BF1226FS1251BF1262FS1013BF1280FS1280BD103LF3000B196LF670B205LF734B281LF3473, 1220550BT339LF3349BT427LF3345C704-L LF500C750-E LF750DB7396LF3325B7577LF777BW5071WF2071BW5073WF2073DETROIT DIESELBF59223518527BF59323518526, 23530640BF78423518528, 23530642BF78523530643PF9025574508BF580023518481, 23530706BF581023530707BF581523518530, 23530645BF7639-D2*******BF769723518529, 23530644BF980020922801PF9924 KIT A0000903451, A0000903551, A0000904251BF581223516189BF581323512317PF768023514049PF774823533816B6-HPG23518668B9523530407B49523530573B703023529744B71355241800310B71805361840001B72295241840301P5092A4722030255DEUTZRS3517P532966RS3717P533781BF5872133943BF587-D1174482PF594W2H4115BF7901174424, WK7123BF900WK94019BF9881160243, 1181917, Q1H4117, WK723 BF1292-O4291642BF7883WK9305BF79151174696BF79971182672P41E1214P52P3H4120B2181174420B2281174416B2361160025, 1174421, A15H4123, W9626 BT2921174418, A1H4123P7145HU9472XP7188HU9453XP7199HU9316XB727612850312JOHN DEERE (6068, 6076, 6081 SERIES)BF959AR86745, RE27091BF7673-D RE50455BF7674-D RE52987BF7677-D RE62420BF7717RE506428BF7853RE522688BF7949-D RE522878BF7949-DM RE521538BF1285-SP RE519608BF1353-SPS RE522372BF1354-SPS RE522687BF7682-D RE508633BF7950-D RE529643BF7971-D RE522966BF9921-O RE503676BT259T19044BT486RE46380, RE57394B7125RE59754P7233RE509672B7322RE504836KOHLERPA602271276PA1712231847PA20674508302, 3508302PA20684708301PA20694708303PA3890253107PA39012408303P40A271271B43-S GM28351BT2235205002B243277233T300-M270197B14101205001B1438GM16703DON’T BE LEFTSTRANDEDThe engine is the heart and soul of your boat and abreakdown is not only costly, it can be dangerous.With Baldwin on board, you can be sure your enginehas protection you can rely on.WORKING AS HARD AS YOU DOIT’S IN OUR BLOODLUGGERBF5962455001BF9542452020BF9592452259BF75462454808BF7673-D2451003, 2451005B22405401B1962404801BT2592400000B71252401002B72232405701BW51392414802, AR87112BW51402415001NORTHERN LIGHTSBF5962455001BF9542452020BF9592452259BF75462454808BF7673-D2451003, 2451005B22405401B372408001B1632403100B1962404801BT2592400000B71252401002BW51392414802BW51402415001PERKINSBF82526560017, 26561117, 2656621, 7111296 BF8847111796BF954130366020BF7674-D2*******BF7681-D2*******PT10832527, 26540132BT2162654403BT2372654407VOLVO-PENTAPA2181876185PA2771823701PA3483842280RS543221377909PA5664858488RS569321196919BF5878385932BF790829913BF825236628, 3581078, 7111296PF950233897BF954861477PF986870065, 876554BF988243004, 3825133, 4669875, 8299132 BF79693852413, 3862228BF4603421879886PF5981147147PF598-10861014BF791855686, 8556862BF1386-O21380475PF7890-103838854BF46101-O3817517VOLVO-PENTA (CONT’D)B2430143B63850559B27835440, 8354409B35-S841750B43-S3827069B75847741B76466634, 4666343, 21707133B76-SS478736B163266286, 418432, 897321, 1266286, 12662862B2363831236BT2516612598B7165834337B740921707132B7685477556WAUKESHAPA1637-FN350123BPA1676-FN208226PA2360-FN207965PA2426-FN208227PA2691169180CPA2693169180GPF116153188PF821-S F1106PLPF902DDED8PF906117900, FBM1124APB, FBM1124APBPF7550F1104B2164830B50176554, 199269B99199395C133-W168660V1656-T167602V1874-T172607AWESTERBEKEBF82514776, 7111296BF88419397B216655B17930220, 36918B20235828YANMARPF71712910055650PF93710450055710BF94012947055701BF753511977355510BF783812957455711PF98612032455760BF753412185755710B161-S11900535100, 12408535111B22711966035150B140011930535151BD702911977090620B748712915035153800.822.5394 | Designed and manufactured in the USA.Form 602 (R 9/21) © 2021 Baldwin Filters, a Parker Hannifin CompanyWARNING: These products can expose you to chemicals, including Diisononyl Phthalate, Carbon black extracts, Nickel, 1,3 Butadiene, Ethylene Oxide, Epichlorohydrin, which are known to the State of California to cause cancer, and Bisphenol-A, Ethylene Glycol, Ethylene Oxide, 1,3 Butadiene, Epichlorohydrin, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to .。

Catalog 0730-2Hi-Flow F602 SeriesHi-Flow Filters2 & 2-1/2 Inch PortsFeatures• Excellent water removal efficiency • For heavy duty applications with minimum pressure drop requirement • Unique deflector plate that creates swirling of the air stream ensuring maximum water and dirt separation • Large filter element surface guarantees low pressure drop and increased element life• 40 micron filter element standard • Metal bowl with sight gauge standard • Twist drain as standard, optional auto drain• Large bowl capacity• Optional high capacity bowl(s) available • High flow: 2 & 2-1/2" – 1200 SCFM §Drains and Options Blank Manual Twist Drain Q External Heavy Duty Auto Drain R Internal Auto DrainOrdering InformationF 602 — 16 W J /**BowlE 32 oz. Large Capacity Metal without Sight GaugeW 16 oz. Metal with Sight GaugeElement J 40 MicronPort Size 16 2 Inch 20 2-1/2 InchPort Threads — NPT G BSPPEngineeringLevel * Will be Entered at Factory.Standard part numbers shown bold.For other models refer to ordering information below.§SCFM = Standard cubic feet per minute at 90 PSIG inlet and 5 PSIG pressure drop.Port Size NPTTwist DrainAutomatic Pulse DrainMetal Bowl / Sight Gauge - 16 oz.2"F602-16WJ F602-16WJR 2-1/2"F602-20WJ F602-20WJR Metal Bowl without Sight Gauge - 32 oz.2"F602-16EJ F602-16EJR 2-1/2"F602-20EJF602-20EJRAutomaticDrainManual DrainF602 Filter Dimensions A BCD E F F602-16W, F602-20W4.90(124)11.08 (281)13.00 (330) 6.30 (160) 1.92 (48.7) 2.45(62.2)F602-16E, F602-20E4.90(124)14.31(364)16.23(412)6.30 (160)1.92 (48.7)2.45(62.2)inches (mm)BOLD ITEMS ARE MOST POPULAR.Catalog 0730-2Technical Specifications – F602F602 Series, 2 & 2-1/2 Inch Ports Hi-Flow FiltersTechnical InformationF602 Filter Kits & AccessoriesBowl Kits –Aluminum (E) .....................................................................BK603B Zinc with Sight Gauge (W) ..............................................BK605WB Drain Kits –External Auto (E) .................................................................SA603D External Auto (W) ................................................................SA602D Internal Auto (All) ............................................................SA602MD Manual (All) ...................................................................SA600Y7-1Semi-Automatic “Overnight” Drain ...................................SA602A7 (Drains automatically under zero pressure)Filter Element Kits – 40 Micron (All) .....................................................................EK602B Repair Kits –Deflector, Baffle Assembly, and Retaining Rod (All) ..........RK602C External Auto Drain (All) .....................................................RK602D Internal Auto Drain (All) ...................................................RK602MD Metal Bowl Sight Gauge (W) ........................................RKB605WBSpecificationsBowl Capacity –Aluminum (E) .................................................................32 Ounces Zinc (W) ..........................................................................16 Ounces Port Threads .................................................................2, 2-1/2 Inch( ) = Bowl TypeFloat (Inside Bowl) Manual Push ButtonDrain(Outside Bowl)Drain (1/4" NPTF)Connection Through Bowl (1/8" NPSM)“Q” Option External Heavy Duty Auto Drain SA602D / SA603DFor heavy duty applications where the filter is being used to remove large volumes of liquid and/or particulate matter from the airstream, the external automatic drain (“Q” option) should be used.Pressure & Temperature Ratings –Aluminum Bowl (E) ............................0 to 300 PSIG (0 to 20.4 bar) 40°F to 150°F (4.4°C to 65.6°C) Zinc (W) ..............................................0 to 250 PSIG (0 to 17.2 bar) 40°F to 150°F (4.4°C to 65.6°C) With Internal Auto Drain (R) ..........20 to 175 PSIG (1.4 to 11.9 bar) 40°F to 125°F (4.4°C to 52°C) With External Auto Drain (Q) ............30 to 250 PSIG (0 to 17.2 bar) 40°F to 150°F (4.4°C to 65.6°C)Weight –Aluminum Bowl (E) .................................... 10.3 lb. (4.67 kg) / Unit 11 lb. (4.99 kg) / 1-Unit Master Pack Zinc Bowl (W) .............................................. 9.8 lb. (4.45 kg) / Unit 39 lb. (17.69 kg) / 4-Unit Master PackMaterials of ConstructionBody ....................................................................................Aluminum Bowls –(E) ...................................................Aluminum without Sight Gauge (W) ................................................................Zinc with Sight Gauge Drain –Manual Twist & Overnight .......................................................Brass Housing “R” ............................................................................Acetal Housing “Q” .........................................................................Bronze Filter Elements –40 Micron (Standard) ................................................Polypropylene Seals ........................................................................................Buna N Sight Gauge ...............................................................................Nylon2505007501000125012345Flow - SCFMP r e s s u r e D r o p - P S I GP r e s s u r e D r o p - b a r.1.2.3Primary Pressure - PSIG1.7 3.4 5.2 6.9Primary Pressure - bar 0240360480120Flow - dm n 3/s。

320Hydraulic Excavator Technical SpecificationsEngine TrackEngine Model Cat® C4.4 ACERT™ Standard with Long Undercarriage 790 mm 31 inNet Power (ISO 9249) 121 kW 162 hp Number of Shoes (each side) – 49Long UndercarriageNet Power (SAE J1349) 121 kW 162 hpNumber of Track Rollers (each side) – 8Gross Power (ISO 14396/SAE J1995) 122 kW 164 hpLong UndercarriageBore 105 mm 4 inNumber of Carrier Rollers (each side) 2Stroke 127 mm 5 inDisplacement 4.4 L 269 in3 Drive• The 320 meets U.S. EPA Tier 4 Final emission standards.Maximum Gradeability 35°/70%• Recommended for use up to 4500 m altitude (14,764 ft) withengine power derate above 3000 m (9,842.5 ft). Maximum Travel Speed 5.7 km/h 3.5 mph • Net power advertised is the power available at the fl ywheel when Maximum Drawbar Pull – 205 kN 45,996 lbf the engine is equipped with fan, air cleaner, muffler and alternator. Long Undercarriage• Rating at 1,800 rpm.Hydraulic SystemEngine rpmMain System – Maximum Flow 429 L/min 113 gal/min Operation 1,650 rpm (Implement) (214.5 × (56.5 × Travel 1,800 rpm 2 pumps) 2 pumps)Swing System – Maximum Flow No swing pump Swing Mechanism Maximum Pressure – Equipment – 35 000 kPa 5,075 psiNormalSwing Speed 11.25 rpmMaximum Pressure – Equipment – 38 000 kPa 5,510 psi Maximum Swing Torque 74 kN·m 54,440 lbf-ftLift ModeWeights Maximum Pressure – Travel 34 300 kPa 4,974 psiMaximum Pressure – Swing 26 800 kPa 3,886 psi Operating Weight 22 700 kg 50,100 lbBoom Cylinder – Bore 120 mm 5 in• Long undercarriage, Reach boom, R2.9 (9'6") stick, HD 1.19 m3 Boom Cylinder – Stroke 1260 mm 50 in(1.56 yd3) bucket and 790 mm (31 in) triple grouser shoes, 4.2 mtStick Cylinder – Bore 140 mm 6 in(9,300 lb) counterweight.Stick Cylinder – Stroke 1504 mm 59 inBucket Cylinder – Bore 120 mm 5 inBucket Cylinder – Stroke 1104 mm 43 in320 Hydraulic Excavator SpecificationsService Refill CapacitiesFuel Tank Capacity 345 L 86.6 galCooling System 35 L 9.2 galEngine OilSwing Drive (each) 15 L7 L4.0 gal1.8 galFinal Drive (each) 6 L 1.6 gal Hydraulic System (including tank) 240 L 63.4 gal Hydraulic Tank 128 L 33.8 gal DEF Tank 40 L 10.6 galStandardsBrakes ISO 10265:2008Cab/FOGS ISO 10262:1998Cab/ROPS ISO 12117-2:2008Sound PerformanceISO 6395 (external) 97 dB(A)ISO 6396 (inside cab) 70 dB(A)• When properly installed and maintained, the cab offered by Caterpillar, when tested with doors and windows closed according to ANSI/SAE J1166 OCT98, meets OSHA and MSHA requirements for operator sound exposure limits in effect at time of manufacture. • Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/ windows open) for extended periods or in a noisy environment.Operating Weight and Ground Pressure4.2 mt (9,300 lb) Counterweight + Long Undercarriage Base Machine790 mm (31 in)Triple Grouser ShoesWeight Ground PressureReach Boom + R2.9 (9'6") Stick + 1.19 m3 (1.56 yd3) HD Bucket 22 700 kg 50,100 lb 35.9 kPa 5.2 psi All operating weights include a 90% fuel tank with 75 kg (165 lb) operator.2Major Component Weights320 Hydraulic Excavator Specificationskg lb Base Machine (with 4.2 mt [9,300 lb] counterweight, semi-HD swing frame, standard base frame with14 80032,600HD track rollers and standard carrier rollers for long undercarriage, with boom cylinder – does not include 90% fuel and 75 kg [165 lb] operator) Track Shoes:790 mm (31 in) Width, 10 mm (0.39 in) Thick Triple Grouser Track Shoes for Long Undercarriage 3370 7,400 with Step Extension for ISO 2867 Two Boom Cylinders340 700 Weight of 90% Fuel Tank and 75 kg (165 lb) Operator 310 Counterweights:4.2 mt (9,300 lb) Counterweight4200 9,300 4.7 mt (10,400 lb) Counterweight (only for Super Long Reach) 4700 10,400 Swing Frame:Semi-HD Swing Frame, for C4.4 ACERT 1910 4,210 Standard and Long Undercarriage:Standard Base Frame with HD Track Rollers and Standard Carrier Rollers for Long Undercarriage 4390 9,700 Booms (including lines, pins, stick cylinder): Reach Boom (5.7 m/18'8")1710 3,800 Super Long Reach Boom (8.85 m/29'0")2170 4,800 Sticks (including lines, pins, bucket cylinder, bucket linkage): Reach Stick (R2.9B1/9'6")1300 2,900 Super Long Reach Stick (6.28A/20'7") 1340 3,000 Buckets (without linkage): 1.19 m3 (1.56 yd3) HD 880 1,940 1.0 m3 (1.31 yd3) HD8501,8700.57 m3 (0.75 yd3) Ditch Cleaning 390 850 Quick Couplers: Pin Grabber QC3903700 850320 Hydraulic Excavator SpecificationsDimensionsAll dimensions are approximate and may vary depending on bucket selection.Boom Options Reach Boom SLR Boom5.7 m (18'8") 8.85 m (29'0")Stick Options Reach Stick SLR StickR2.9B1 (9'6") 6.28A (20'7") 6.28A (20'7")1 Machine Height:Top of Cab Height 2960 mm 9'9" 2960 mm 9'9" 2960 mm 9'9"Top of FOGS Height 3100 mm 10'2" 3100 mm 10'2" 3100 mm 10'2"Handrails Height 2950 mm 9'8" 2950 mm 9'8" 2950 mm 9'8"With Boom/Stick/Bucket Installed 3160 mm 10'4" 3190 mm 10'6" 3190 mm 10'6"With Boom/Stick Installed 2910 mm 9'7" 3070 mm 10'1" 3070 mm 10'1"With Boom Installed 2480 mm 8'2" 2650 mm 8'8" 2650 mm 8'8"2 Machine Length:With Boom/Stick/Bucket Installed 9530 mm 31'3" 12 750 mm 41'9" 12 750 mm 41'9"With Boom/Stick Installed 9500 mm 31'2" 12 760 mm 41'9" 12 760 mm 41'9"With Boom Installed 8450 mm 27'9" 8920 mm 29'3" 8920 mm 29'3"3 Upperframe Width without Walkways 2780 mm 9'1" 2780 mm 9'1" 2780 mm 9'1"4 Tail Swing Radius 2830 mm 9'3" 2830 mm 9'3" 2830 mm 9'3"5 Counterweight Clearance 1050 mm 3'5" 1050 mm 3'5" 1050 mm 3'5"6 Ground Clearance 470 mm 1'7" 470 mm 1'7" 470 mm 1'7"7 Track Length – Length to Center of Rollers 3650 mm 12'0" 3650 mm 12'0" 3650 mm 12'0"8 Track Gauge – Extended 2380 mm 7'9" 2380 mm 7'9" 2380 mm 7'9"9 Track Width:790 mm (31 in) Shoes 3170 mm 10'5" 3170 mm 10'5" 3170 mm 10'5"10 Undercarriage Width (with steps/without steps):790 mm (31 in) Shoes 3170 mm 10'5" 3170 mm 10'5" 3170 mm 10'5" Bucket Type HD Ditch Cleaning (DC) GD Bucket Capacity 1.19 m3 1.56 yd3 0.57 m3 0.75 yd3 0.53 m3 0.69 yd3 Bucket Tip Radius 1570 mm 5'2" 1070 mm 3'6" 1230 mm 4'0"4320 Hydraulic Excavator SpecificationsWorking RangesAll dimensions are approximate and may vary depending on bucket selection.35Feet 10 11 Meters30 9 25 7 8 20 6 154 510 3 5 1 215 10 5 0 0 5 4 3 2 1 206 7 1110 9 8 7 6 5 4 3 2 1 0 –1 Meters 3530252015105FeetBoom Option Stick Option1 Maximum Digging DepthReach Boom 5.7 m (18'8")Reach Stick R2.9B1 (9'6")6720 mm 22'1" 2 Maximum Reach at Ground Line 9860 mm 32'4" 3 Maximum Cutting Height 9370 mm 30'9" 4 Maximum Loading Height6490 mm 21'4" 5 Minimum Loading Height2170 mm 7'1" 6 Maximum Depth Cut for 2440 mm (8'0") Level Bottom 6550 mm 21'6" 7 Maximum Vertical Wall Digging Depth 5190 mm 17'0" Bucket Digging Force (SAE) 134 kN 295 lbf Bucket Digging Force (ISO) 150 kN 332 lbf Stick Digging Force (SAE) 103 kN 228 lbf Stick Digging Force (ISO) 106 kN235 lbfBucket Type HDBucket Capacity 1.19 m3 1.56 yd3 Bucket Tip Radius1570 mm5'2" 5320 Hydraulic Excavator SpecificationsWorking RangesAll dimensions are approximate and may vary depending on bucket selection.Feet Meters 1445 13 40 12 11 35 10 30 9 8 25 7 20 6 5 15 4 10 3 2 5 1 0 0 5 1 2 10 3 4 15 5 20 6 7 25 8 30 9 10 35 11 401220 19 18 17 16 15 14 13 12 11 10 9 876 5 43 2 10 –1 –2 –3 Meters 656055504540353025 2015 105 0–5Feet Boom Option SLR Boom8.85 m (29'0") Stick OptionSLR Stick6.28A (20'7")6.28A (20'7")1 Maximum Digging Depth11 540 mm 38'0" 11 690 mm 38'4" 2 Maximum Reach at Ground Line 15 570 mm 51'1" 15 730 mm 51'7" 3 Maximum Cutting Height 13 540 mm 44'5" 13 610 mm 44'8" 4 Maximum Loading Height11 440 mm 37'6" 11 290 mm 37'0" 5 Minimum Loading Height2240 mm 7'4" 2080 mm 6'9" 6 Maximum Depth Cut for 2440 mm (8'0") Level Bottom 11 440 mm 37'6" 11 590 mm 38'0" 7 Maximum Vertical Wall Digging Depth 11 020 mm36'2"10 560 mm 34'8" Bucket Digging Force (SAE) 62 kN 136 lbf 54 kN 119 lbf Bucket Digging Force (ISO) 62 kN 136 lbf 60 kN 133 lbf Stick Digging Force (SAE) 49 kN 108 lbf 48 kN 106 lbf Stick Digging Force (ISO) 49 kN 108 lbf 49 kN107 lbfBucket Type Ditch Cleaning (DC) GDBucket Capacity 0.57 m3 0.75 yd3 0.53 m3 0.69 yd3 Bucket Tip Radius 1070 mm 3'6"1230 mm4'0" 6320 Hydraulic Excavator Specifications Reach Boom Lift Capacities – Counterweight: 4.2 mt (9,300 lb) – without Bucket5.7 m (18'8")ISO 10567*Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to handle/lift objects, could affect the machine lift performance.Lift capacity stays with ±5% for all available track shoes.Always refer to the appropriate Operation and Maintenance Manual for specific product information.7320 Hydraulic Excavator SpecificationsSuper Long Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) – without Bucket8.85 m (29'0")ISO 10567*Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to handle/lift objects, could affect the machine lift performance.Lift capacity stays with ±5% for all available track shoes.Always refer to the appropriate Operation and Maintenance Manual for specific product information.(continued on next page) 8320 Hydraulic Excavator Specifications Super Long Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) – without Bucket (continued)8.85 m (29'0")ISO 10567*Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to handle/lift objects, could affect the machine lift performance.Lift capacity stays with ±5% for all available track shoes.Always refer to the appropriate Operation and Maintenance Manual for specific product information.9320 Hydraulic Excavator SpecificationsThe above loads are in compliance with hydraulic excavator standard EN474, they do not exceed Maximum Material Density:87% of hydraulic lifting capacity or 75% of tipping capacity with front linkage fully extended at 2100 kg/m3 (3,500 lb/yd3)ground line with bucket curled. 1800 kg/m3 (3,000 lb/yd3)Capacity based on ISO 7451. 1500 kg/m3 (2,500 lb/yd3)Bucket weight with General Duty tips. 1200 kg/m3 (2,000 lb/yd3)900 kg/m3 (1,500 lb/yd3)X Not RecommendedCaterpillar recommends using appropriate work tools to maximize the value customers receive from our products. Use of work tools, including buckets, which are outside of Caterpillar’s recommendations or specifications for weight, dimensions, flows, pressures, etc. may result in less-than-optimal performance, including but not limited to reductions in production, stability, reliability, and component durability. Improper use of a work tool resulting in sweeping, prying, twisting and/or catching of heavy loads will reduce the life of the boom and stick.10320 Hydraulic Excavator SpecificationsThe above loads are in compliance with hydraulic excavator standard EN474, they do not exceed Maximum Material Density:87% of hydraulic lifting capacity or 75% of tipping capacity with front linkage fully extended at 2100 kg/m3 (3,500 lb/yd3)ground line with bucket curled. 1800 kg/m3 (3,000 lb/yd3)Capacity based on ISO 7451. 1500 kg/m3 (2,500 lb/yd3)Bucket weight with General Duty tips. 1200 kg/m3 (2,000 lb/yd3)900 kg/m3 (1,500 lb/yd3)Caterpillar recommends using appropriate work tools to maximize the value customers receive from our products. Use of work tools, including buckets, which are outside of Caterpillar’s recommendations or specifications for weight, dimensions, flows, pressures, etc. may result in less-than-optimal performance, includingbut not limited to reductions in production, stability, reliability, and component durability. Improper use of a work tool resulting in sweeping, prying, twisting and/or catching of heavy loads will reduce the life of the boom and stick.11320 Hydraulic Excavator SpecificationsWork Tool Offering Guide*Boom Type Reach BoomTrash GrappleThese work tools are available for the 320. ThumbsConsult your Cat dealer for proper match. RakesPin Grabber Coupler Cat PG*Offerings not available in all areas. Matches are dependent on excavator configurations. Consult your Cat dealer to determine what is offered in your area and for proper work tool match.Match** Match; Pin-On only# Match; Boom Mount## Work over the front only^ Work over the front only with Cat PG (match; Pin-On and Cat PG)50% P Allowed usage with Pin-On and Coupler on machine less than 50%50% C Allowed usage with Coupler on machine less than 50%Demolition and Sorting Grapple: D – Demolition shells, R – Recycling shells, WH – Waste Handling shells12320 Standard and Optional Equipment Standard and Optional EquipmentStandard and optional equipment may vary. Consult your Cat dealer for details.Standard OptionalENGINECat C4.4 ACERT Twin Turbo 9Tier 4 Final diesel engineThree selectable power modes 9One-touch low idle with automatic 9engine speed controlAutomatic engine idle shutdown 9Work up to 3000 m (9,842.5 ft) above sea 9level without engine power de-rating46° C (115° F) high-ambient cooling 9capacity52° C (125° F) high-ambient cooling 9capacityCold starting capability for 9–32° C (–25° F)Double element air fi lter 9with integrated precleanerElectric fuel priming pump 9Reversible electric cooling fans 9Biodiesel capability up to B20 9HYDRAULIC SYSTEMBoom and stick regeneration circuits 9Electronic main control valve 9Auto hydraulic oil warm up 9Automatic two-speed travel 9Boom and stick drift reduction valve 9Element type main hydraulic fi lter 9Slider joysticks 9Tandem type electronic main pump 9Hammer return fi lter circuit 9Combined fl ow/high pressure auxiliary circuitMedium pressure auxiliary circuit 9 9Quick coupler circuit for Cat Pin Grabber 9 Fine swing control 9UNDERCARRIAGE AND STRUCTURESStandard OptionalTie-down points on base frame(ISO 15818 compliant)Center track guiding guardStandard bottom guardsStandard swivel guardStandard travel motor guardsGrease lubricated track links9999994200 kg (9,300 lb) counterweight4700 kg (10,400 lb) counterweightfor Super Long ReachSemi-HD swing frame for C4.4 ACERTStandard swing bearingBase frame with HD track rollersand standard carrier rollers99999Final drive with standard travel motor 9BOOM, STICKS AND LINKAGES790 mm (31 in) triple grouser track shoes 95.7 m (18'8") Reach boom 92.9 m (9'6") stick 9Super Long Reach 8.85 m (29'0") boom 9 Super Long Reach 6.28 m (20'7") stick 9 Bucket linkage, B1-family without 9lifting eye, Cat GRADEBucket linkage, A-family without 9 lifting eye, SLR(continued on next page)13320 Standard and Optional EquipmentStandard and Optional Equipment (continued)Standard and optional equipment may vary. Consult your Cat dealer for details.Standard Optional Standard OptionalELECTRICAL SYSTEMMachine electronic control module (×2) 91,000 CCA maintenance-free 9batteries (×2)Centralized electrical disconnect switch 9 Programmable time-delay LED 9working lightsLED chassis light, LH and RH boom 9lights for Reach and SLR, cab lightsCAT CONNECT TECHNOLOGYCat Product Link™ 9Cat GRADE with 2D 9(not available on SLR)Cat GRADE with Advanced 2D 9 (not available on SLR)Cat GRADE with 3D 9 (not available on SLR)Cat Assist: 9– Boom Assist– Bucket Assist– Swing Assist– Grade AssistCat Payload: 9– Payload Information– Static Weigh– Auto Calibration320 AttachmentsDealer Installed Kit and Attachments SERVICE AND MAINTENANCESampling ports for Scheduled Oil 9 Sampling (S·O·S SM)Preventative Maintenance ready 9 (QuickEvac™)Grouped location for engine oil 9and fuel fi ltersGround level second dipstick for engine oil 9Remote fl ash 9SAFETY AND SECURITYRearview camera and side RH mirror 9360° visibility 9 Neutral lever (lock out) for all controls 9Anti-skid plate and countersunk bolts 9on service platformGround-level accessible secondary engine 9shutoff switch in cabRadiator screen 9 Bluetooth® receiver 9RH handrail and hand hold 9(ISO 2867 compliant)Travel alarm 9Attachments may vary. Consult your Cat dealer for details.CAB SAFETY AND SECURITY GUARDS• Radial lower wiper for 70/30 with washer • Bluetooth key fob • Standard swivel guard• LH/RH electrical pedal for tool control • Side rubber bumper• Dual exit rear window kit ELECTRICAL • FOGS (not compatible with cab light cover, • Rain protector plus cab light cover • Jump start wiring rain protector)• Seat belt, retractable (75 mm/3 in width) • LED premium lighting package • Mesh guard full front (not compatible withcab light cover, rain protector)• Mesh guard lower half front• Full protecting vandalism guard14320 Cab Options Cab OptionsStandardOptional15For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at © 2017 CaterpillarAll rights reservedMaterials and specifications are subject to change without notice. Featured machines in photos may include additional equipment. See your Cat dealer for available options.CAT, CATERPILLAR, , their respective logos, “Caterpillar Yellow” and the “Power Edge” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may AEXQ2161 (06-2017) Build Number: 07A(North America)not be used without permission.。

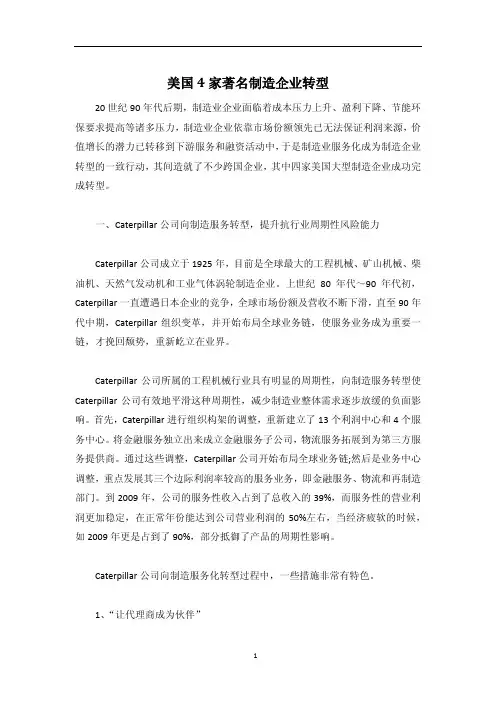

美国4家著名制造企业转型20世纪90年代后期,制造业企业面临着成本压力上升、盈利下降、节能环保要求提高等诸多压力,制造业企业依靠市场份额领先已无法保证利润来源,价值增长的潜力已转移到下游服务和融资活动中,于是制造业服务化成为制造企业转型的一致行动,其间造就了不少跨国企业,其中四家美国大型制造企业成功完成转型。

一、Caterpillar公司向制造服务转型,提升抗行业周期性风险能力Caterpillar公司成立于1925年,目前是全球最大的工程机械、矿山机械、柴油机、天然气发动机和工业气体涡轮制造企业。

上世纪80年代~90年代初,Caterpillar一直遭遇日本企业的竞争,全球市场份额及营收不断下滑,直至90年代中期,Caterpillar组织变革,并开始布局全球业务链,使服务业务成为重要一链,才挽回颓势,重新屹立在业界。

Caterpillar公司所属的工程机械行业具有明显的周期性,向制造服务转型使Caterpillar公司有效地平滑这种周期性,减少制造业整体需求逐步放缓的负面影响。

首先,Caterpillar进行组织构架的调整,重新建立了13个利润中心和4个服务中心。

将金融服务独立出来成立金融服务子公司,物流服务拓展到为第三方服务提供商。

通过这些调整,Caterpillar公司开始布局全球业务链;然后是业务中心调整,重点发展其三个边际利润率较高的服务业务,即金融服务、物流和再制造部门。

到2009年,公司的服务性收入占到了总收入的39%,而服务性的营业利润更加稳定,在正常年份能达到公司营业利润的50%左右,当经济疲软的时候,如2009年更是占到了90%,部分抵御了产品的周期性影响。

Caterpillar公司向制造服务化转型过程中,一些措施非常有特色。

1、“让代理商成为伙伴”Caterpillar公司将分销系统视为客户需求信息的反馈渠道,能够促使公司推出新产品和改进服务,因此,Caterpillar公司严格挑选代理商,与那些熟悉当地情况,接近客户并掌握需求状况,能够提供快捷地服务的代理商建立了一种长期、稳定的关系,并将不对代理商进行压榨作为其最主要的原则。

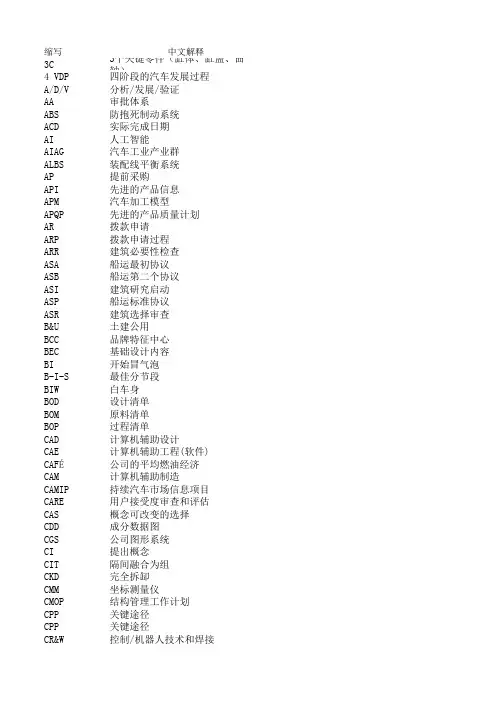

缩写中文解释3C3个关键零件(缸体、缸盖、曲轴)4 VDP四阶段的汽车发展过程A/D/V分析/发展/验证AA审批体系ABS防抱死制动系统ACD实际完成日期AI人工智能AIAG汽车工业产业群ALBS装配线平衡系统AP提前采购API先进的产品信息APM汽车加工模型APQP先进的产品质量计划AR拨款申请ARP拨款申请过程ARR建筑必要性检查ASA船运最初协议ASB船运第二个协议ASI建筑研究启动ASP船运标准协议ASR建筑选择审查B&U土建公用BCC品牌特征中心BEC基础设计内容BI开始冒气泡B-I-S最佳分节段BIW白车身BOD设计清单BOM原料清单BOP过程清单CAD计算机辅助设计CAE计算机辅助工程(软件)CAFÉ公司的平均燃油经济CAM计算机辅助制造CAMIP持续汽车市场信息项目CARE用户接受度审查和评估CAS概念可改变的选择CDD成分数据图CGS公司图形系统CI提出概念CIT隔间融合为组CKD完全拆缷CMM坐标测量仪CMOP结构管理工作计划CPP关键途径CPP关键途径CR&W 控制/机器人技术和焊接CRIT中心新产品展示执行组CS合同签订CTS零件技术规格D/EC设计工程学会DAP设计分析过程DCAR设计中心工作申请DDP决策讨论步骤DES设计中心DFA装配设计DFM装配设计DLT设计领导技术DMA经销商市场协会DMG模具管理小组DOE试验设计DOL冲模业务排行DQV设计质量验证DRE设计发布工程师DSC决策支持中心DVM三维变化管理DVT动态汽车实验E/M进化的EAR工程行为要求ECD计划完成日期EGM工程组经理ELPO电极底漆ENG工程技术、工程学EOA停止加速EPC&L工程生产控制和后勤EPL工程零件清单ETSD对外的技术说明图EWO工程工作次序FA最终认可FE功能评估FEDR功能评估部署报告FFF自由形态制造FIN金融的FMEA失效形式及结果分析FTP文件传送协议GA总装GD&T几何尺寸及精度GM通用汽车GME通用汽车欧洲GMIO通用汽车国际运作GMIQ通用汽车初始质量GMPTG通用汽车动力组GP通用程序GSB全球战略部HVAC加热、通风及空调I/P仪表板IC初始租约ICD界面控制文件IE工业工程IEMA国际出口市场分析ILRS间接劳动报告系统IO国际业务IPC国际产品中心IPTV每千辆车的故障率IQS初始质量调查IR事故报告ISP综合计划ITP综合培训方法ITSD内部技术规范图IUVA国际统一车辆审核KCC关键控制特性KCDS关键特性标识系统KO Meeting启动会议KPC关键产品特性LLPRLOI意向书M&E机器设备MDD成熟的数据图MFD金属预制件区MFG制造过程MIC市场信息中心MIE制造综合工程师MKT营销MLBS物化劳动平衡系统MMSTS制造重要子系统技术说明书MNG制造工程MPG试验场MPI主程序索引MPL主零件列表MPS原料计划系统MRD物料需求日期MRD物料需求时间MSDSMSE制造系统工程MSS市场分割规范MTBF平均故障时间MTS生产技术规范MVSS汽车发动机安全标准NAMA北美市场分析NAO北美业务NAOC NAO货柜运输NC用数字控制NGMBP新一代基于数学的方法NOA授权书NSB北美业务部OED组织和员工发展P.O采购订单PA生产结果PAA产品行动授权PAC绩效评估委员会PACE项目评估和控制条件PAD产品装配文件PARTS零件准备跟踪系统PC问题信息PCL生产控制和支持PDC证券发展中心PDM产品资料管理PDS产品说明系统PDT产品发展小组PED产品工程部PEP产品评估程序PER人员PET项目执行小组PGM项目管理PIMREP事故方案跟踪和解决过程PLP生产启动程序PMI加工建模一体化PMM项目制造经理PMR产品制造能要求PMT产品车管理小组POMS产品指令管理小组POP采购点PPAP生产零部件批准程序PPAP生产件批准程序PPH百分之PPM百万分之PR绩效评估PR采购需求PR/R问题报告和解决PSA潜在供应商评估PSC部长职务策略委员会PTO第一次试验PUR采购PVM可设计的汽车模型PVT生产汽车发展QAP质量评估过程QBC质量体系构建关系QC质量特性QFD质量功能配置QRD质量、可靠性和耐久力QS质量体系QUA质量RC评估特许RCD必须完成日期RFQ报价请求RFQ报价要求书RONA净资产评估RPO正式产品选项RQA程序安排质量评定RT&TM严格跟踪和全程管理SDC战略决策中心SF造型冻结SIU电子求和结束SL系统规划SMBP理论同步过程SMT系统管理小组SOP生产启动,正式生产SOR要求陈述SOR要求说明书SOW工作说明SPE表面及原型工程SPO配件组织SPT专一任务小组SQC供方质量控制SQIP供应商质量改进程序SSF开始系统供应SSLT子系统领导组SSTS技术参数子系统STO二级试验SUW标准工作单位TA 技术评估TAG定时分析组TBD下决定TCS牵引控制系统TDMF文本数据管理设备TIMS试验事件管理系统TIR试验事件报告TLA 技术转让协议TMIE总的制造综合工程TOE总的物主体验TSM贸易研究方法TVDE整车外型尺寸工程师TVIE整车综合工程师TWS轮胎和车轮系统UAW班组UCL统一的标准表UDR未经核对的资料发布UPC统一零件分级VAPIR汽车发展综合评审小组VASTD汽车数据标准时间数据VCD汽车首席设计师VCE汽车总工程师VCRI确认交叉引用索引VDP汽车发展过程VDPP汽车发展生产过程VDR核实数据发布VDS汽车描述概要VDT汽车发展组VDTO汽车发展技术工作VEC汽车工程中心VIE汽车综合工程师VIS汽车信息系统VLE总装线主管,平台工程师VLM汽车创办经理VMRR汽车制造必要条件评审VOC顾客的意见VOD设计意见VSAS汽车综合、分析和仿真VSE汽车系统工程师VTS汽车技术说明书WBBA全球基准和商业分析WOT压制广泛开放WWP全球采购PC项目启动CA方案批准PA项目批准ER工程发布PPV产品和工艺验证PP预试生产P试生产EP工程样车Descriptions3 Critical Parts(Cylinder-block, Cylinder-head, Crankshaft) Four Phase Vehicle Development ProcessAnalysis/Development/ValidationApprove ArchitectureAnti-lock Braking SystemActual Completion DateArtificial IntelligenceAutomotive Industry Action GroupAssembly Line Balance SystemAdvanced PurchasingAdvanced Product InformationAutomotive Process ModelAdvanced Product Quality PlanningAppropriation RequestAppropriation Request ProcessArchitectural Requirements ReviewAgreement to Ship AlphaAgreement to Ship BetaArchitecture Studies InitiationAgreement to Ship PrototypeArchitecture Selection ReviewBuilding & UtilityBrand Character CenterBase Engineered ContentBubble Up InitiationBest-In-SegmentBody In WhiteBill of DesignBill of MaterialBill of ProcessComputer-Aided DesignComputer-Aided EngineeringCorporate Average Fuel EconomyComputer-Aided ManufacturingContinuous Automotive Marketing Information Program Customer Acceptance Review and EvaluationConcept Alternative SelectionComponent Datum DrawingsCorporate Graphic SystemConcept InitiationCompartment Integration TeamComplete KnockdownCoordinate Measuring MachinesConfiguration Management Operating PlanCorporate Product PorefolioCritical Path PlanControls/Robotics & WeldingCenter Rollout Implementation Team Contract SigningComponent Technical SpecificationDesign and Engineering CouncilDesign Analysis ProcessDesign Center Action RequestDecision Dialog ProcessDesign CenterDesign for AssemblyDesign For ManufacturabilityDesign leader TechnicalDealer Market AssociationDie Management GroupDesign Of ExperimentsDie Operation Line-UpDesign Quality VerificationDesign Release EngineerDecision Support CenterDimensional Variation ManagementDynamic Vehicle TestEvolutionary/MajorEngineering Action RequestEstimated Completion DateEngineering Group ManagerElectrode position PrimerEngineeringEnd of AccelerationEngineering Production Cntrol &Logistics Engineering Parts ListExterior Technical Specification Drawing Engineering Work OrderFinal ApprovalFunctional EvaluationFunctional Evaluation Disposition Report Free Form FabricationFinancialFailure Mode and Effects AnalysisFile Transfer ProtocolGeneral AssemblyGeometric Dimensioning & Tolerancing General MotorsGeneral Motors EuropeGeneral Motors International Operations General Motors Initial QualityGeneral Motors Powertrain GroupGeneral ProcedureGlobal Strategy BoardHeating, Ventilation ,and Air ConditioningInstrument PanelInitiate CharterInterface Control DocumentIndustrial EngineeringInternational Export Market AnalysisIndirect Labor Reporting SystemInternational OperationsInternational Product CenterIncidents Per Thousand VehiclesInitial Quality SurveyIncident ReportIntegrated Scheduling ProjectIntegrated Training ProcessInterior Technical Specification DrawingInternational Uniform Vehicle AuditKey Control CharacteristicsKey Characteristics Designation SystemKick-off MeetingKey product CharacteristicLing Lead P ReleaseLetter of IntentMachine & EquipmentMaster Datum DrawingsMetal Fabrication DivisionManufacturing OperationsMarketing Information CenterManufacturing Integration EngineerMarketingMaterial Labor Balance SystemManufacturing Major Subsystem Technical Specifications Manufacturing EngineeringMilford Proving GroundMaster Process IndexMaster Parts ListMaterial Planning SystemMaterial Required DateMaterial Required DateMaterial Safery Data SheetsManufacturing System EngineerMarket Segment SpecificationMean Time Between FailuresManufacturing Technical SpecificationMotor Vehicle Safety StandardsNorth American Market AnalysisNorth American OperationsNAO ContainerizationNumerically ControlledNext Generation Math-Based ProcessNotice of AuthorizationNAO Strategy BoardOrganization and Employee DevelopmentPurchasing OrderProduction AchievementProduction Action AuthorizationPerformance Assessment CommitteeProgram Assessment and Control EnvironmentProduct Assembly DocumentPart Readiness Tracking SystemProblem CommunicationProduction Control and LogisticsPortfolio Development CenterProduct Data ManagementProduct Description SystemProduct Development TeamProduction Engineering DepartmentProduct Evaluation ProgramPersonnelProgram Execution TeamProgram ManagementProject Incident Monitoring and Resolution Process Production Launch ProcessProcess Modeling IntegrationProgram Manufacturing ManagerProduct Manufacturability RequirementsProduct Management TeamProduction Order Management SystemPoint of PurchaseProduction Part Approval ProcessProduction Parts Approval ProcessProblems Per HundredProblems Per MillionPerformance ReviewPurchase RequirementProblem Reporting and ResolutionPotential Supplier AssessmentPortfolio Strategy CouncilPrimary TryoutPurchasingProgrammable Vehicle ModelProduction Vehicle DevelopmentQuality Assessment ProcessQuality Build ConcernQuality CharacteristicQuality Function DeploymentQuality, Reliability,andDurabilityQuality SystemQualityReview CharterRequired Completion DateRequest For QuotationRequirement for QuotationReturn on Net AssetsRegular Production OptionRouting Quality AssessmentRigorous Tracking and Throughout Managment Strategic Decision CenterStyling FreezeSumming It All UpSystem LayoutsSynchronous Math-Based ProcessSystems Management TeamStart of ProductionStatement of RequirementsStatement of RequirementsStatement of WorkSurface and Prototype EngineeringService Parts OperationsSingle Point TeamStatistical Quality ControlSupplier Quality Improvement ProcessStart of System FillSubsystem Leadership TeamSubsystem Technical Specification Secondary TryoutStandard Unit of WorkTechnology AssessmentTiming Analysis GroupTo Be DeterminedTraction Control SystemText Data Management FacilityTest Incident Management SystemTest Incident ReportTechnology License AgreementTotal Manufacturing Integration Engineer Total Ownership ExperienceTrade Study MethodologyTotal Vehicle Dimensional EngineerTotal Vehicle Integration EngineerTire and Wheel SystemUnited Auto WorkersUniform Criteria ListUnverified Data ReleaseUniform Parts ClassificationVehicle & Progress Integration Review TeamVehicle Assembly Standard Time DataVehicle Chief DesignerVehicle Chief EngineerValidation Cross-Reference IndexVehicle Development ProcessVehicle Development Production Process Verified Data ReleaseVehicle Description SummaryVehicle Development TeamVehicle Development Technical Operations Vehicle Engineering CenterVehicle Integration EngineerVehicle Information SystemVehicle Line ExecutiveVehicle Launch ManagerVehicle and Manufacturing Requirements Review Voice of CustomerVoice of DesignVehicle Synthesis,Analysis,and Simulation Vehicle System EngineerVehicle Technical SpecificationWorldwide Benchmarking and Business Analysis Wide Open ThrottleWorldwide PurchasingProgram CommencementConcept ApprovalPrograme ApprovalEngineering ReleaseProduct & Process ValidationPre-PilotPilot。

凯斯工程机械美国伯灵顿

的工厂,携手凯斯纽荷兰农业

机械中国哈尔滨工厂在“世界

级制造”(WCM )项目中双双获

得铜级认证。

获得此次认证是

凯斯纽荷兰工业旗下全球品

牌———凯斯工程机械、凯斯农业机械与纽荷兰农业机取得的又一重要里程碑,再度力证了公司追求世界级卓越制造的决心。

位于美国爱荷华州的伯灵顿工厂生产凯斯挖掘装载机、越野叉车、履带式推土机以及凯斯和纽荷兰割台,并拥有一个业界领先的研发中心。

伯灵顿工厂位于密西西比河畔,占地百万平方英尺,拥有约600名员工,设备生产历史可追溯至1937年。

伯灵顿工厂还拥有一个占地400英亩的试验场,位于距离工厂以北10英里处。

哈尔滨工厂占地40万平方米,在中国东北同类制造工厂中规模领先。

哈尔滨工厂生产凯斯与纽荷兰品牌先进的农业机械设备,包括拖拉机、联合收割机、割台、打捆机以及其他设备。

工厂雇佣约350名员工,于三年前加入“世界级制造”项目,起初只有核心人员参与其中,随后逐渐扩大至全厂工作人员。

世界级制造是制造业工厂和生产流程综合管理的全球最高标准之一,它基于支柱体系

的持续改进,旨在通过设立零伤害、零缺陷、零故障和零浪费等目标来消除生产过程中的浪费和损失。

世界级制造通过定期的第三方审计对各支柱进行

评估,得出每家工厂的总分,作为铜级、银级和金级三个认证等级的基础。

世界级制造评审认为伯灵顿工厂和哈尔滨工厂均在包含员工发展和环境在内的多个生产和管理方面实现了改进,并体现了一致性,授予铜级认证。

姻凯斯纽荷兰哈尔滨工厂剑指世界级制造

□关群

. All Rights Reserved.。

美国卡特彼勒公司(Caterpillar,履带拖拉机公司)美国卡特彼勒公司官方网站:/ 英文美国卡特彼勒公司中文网站:/ 中文美国卡特彼勒公司简介美国卡特彼勒公司(NYSE: CAT)成立于1925年,卡特彼勒公司总部位于美国伊利诺州。

是世界上最大的工程机械和矿山设备生产厂家、燃气发动机和工业用燃气轮机生产厂家之一,也是世界上最大的柴油机厂家之一。

80几年以来,卡特彼勒公司一直致力于全球的基础设施建设,并与全球代理商紧密合作,在各大洲积极推进持续变革。

卡特彼勒2005 年销售和收入达到363.4 亿美元,是建筑机械、矿用设备、柴油和天然气发动机以及工业用燃气轮机领域的技术领导者和全球领先制造商。

2005 年的销售和收入达363.4 亿美元,比2004 年增加了60.3 亿美元(提高了20%)。

该增长源自37.2 亿美元的销售增加额、18.27 亿美元的价格变现增加额、3.63 亿美元金融产品收入增加额。

大约有一半的销售额产生于美国境外的客户,这使得卡特彼勒得以保持全球供应商和美国主要出口商的稳固地位。

6 Sigma管理6 Sigma 的长期成果将在我们培养的未来领导精英中得以体现。

作为行业领导者,我们将面临日益复杂的问题,而这些领导精英将时刻准备着去解决这些问题。

如今,已有30,000 多员工参与到 6 Sigma 中,并正在为塑造卡特彼勒的明天贡献自己的力量。

Caterpillar代理商网络卡特彼勒的全球代理商网络为客户提供了关键的有竞争性的平台,使客户可以与他们认识并信赖的人打交道。

公司所有的销售代理几乎都是独立的当地公司。

许多代理商与客户保持了至少横跨两代人的业务关系。

卡特彼勒的代理商遍布200 多个国家,为客户提供设备、服务和金融业务。

此外还通过全球1500 多个网点提供租赁服务。

Caterpillar公司治理卡特彼勒一向以诚信为本,这是公司的基本传统,也是我们最可宝贵的财产之一。

访问公司治理部分,这是您了解公司治理实践的可靠信息来源。