C4_HVAC SPECIFICATION_2009_R0

- 格式:pdf

- 大小:347.45 KB

- 文档页数:18

SECTION 23 05 29HANGERS AND SUPPORTS FOR HVAC PIPING AND EQUIPMENT******************************************Throughout this document you will find these ‘specifier notes’ or links to specific electronic resources to better serve your needs. If you have any questions or comments, please contact your local Eaton B-Line Division sales representative, email ***************** or call (618) 654-2184.******************************************PART 1GENERAL1.1SUMMARYA.The work covered under this section consists of the furnishing of all necessary labor, supervision,materials, equipment, and services to completely execute the pipe hanger and supports asdescribed in this specification.1.2REFERENCESA.American Society of Mechanical Engineers:1.ASME B31.1 - Power Piping.2.ASME B31.5 - Refrigeration Piping.3.ASME B31.9 - Building Services Piping.B.ASTM International:1.ASTM B633 - Specification for Electrodeposited Coatings of Zinc on Iron and Steel2.ASTM A123 - Specification for Zinc (Hot-Galvanized) Coatings on Products Fabricatedfrom Rolled, Pressed, and Forged Steel Shapes, Plates, Bars, and Strip3.ASTM A653 – Specification for Steel Sheet, Zinc-Coated by the Hot-Dip Process4.ASTM A1011 - Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural,High-Strength Low-Alloy and High-Strength Low-Alloy with Improved Formability(Formerly ASTM A570)C.Manufacturers Standardization Society of the Valve and Fittings Industry:1.MSS SP 58 - Pipe Hangers and Supports - Materials, Design and Manufacturer.2.MSS SP 69 - Pipe Hangers and Supports - Selection and Application.3.MSS SP 89 - Pipe Hangers and Supports - Fabrication and Installation Practices.D.NFPA1.NFPA 13 – Standard for the Installation of Sprinkler Systems1.3DEFINITIONSA.Firestopping (Through-Penetration Protection System): Sealing or stuffing material or assemblyplaced in spaces between and penetrations through building materials to arrest movement of fire,smoke, heat, and hot gases through fire rated construction.1.4SUBMITTALSA.Submit product data on all hanger and support devices, including shields and attachmentmethods. Product data to include, but not limited to materials, finishes, approvals, load ratings,and dimensional information.1.5QUALITY ASSURANCEA. Hangers and supports used in fire protection piping systems shall be listed and labeled byUnderwriters Laboratories.B. Steel pipe hangers and supports shall have the manufacturer’s name, part number, andapplicable size stamped in the part itself for identification.C. Hangers and supports shall be designed and manufactured in conformance with MSSSP 58.D. Supports for sprinkler piping shall be in conformance with NFPA 13.1.6QUALIFICATIONS******************************************Include the following paragraph if a list of manufacturers is not included or when substitutions are allowed to define applicable requirements. [] denotes a variable or choice******************************************A.Manufacturer: Company specializing in manufacturing Products specified in this section withminimum [_____] years of documented experience, and with service facilities within [_____]miles of Project.1.7PRE-INSTALLATION MEETINGSA.Section 01 30 00 - Administrative Requirements: Pre-installation meeting.B.Convene a minimum of [_____] week(s) prior to commencing work of this section.1.8DELIVERY, STORAGE, AND HANDLINGA.Section 01 60 00 - Product Requirements: Requirements for transporting, handling, storing, andprotecting products.B.Accept materials on site in original factory packaging, labeled with manufacturer's identification.C.Protect from weather and construction traffic, dirt, water, chemical, and damage, by storing inoriginal packaging.PART 2PRODUCTS2.1ACCEPTABLE MANUFACTURERSA.Subject to compliance with these specifications, wire basket cable tray systems to be installedshall be as manufactured by the following:1.Eaton’s B-Line Division. 509 West Monroe Street, Highland, IL, 62249, USA. Phone:(618)654-2184 or email *****************2.Engineer approved equivalent2.2PIPE HANGERS AND SUPPORTSA.Hangers1.Uninsulated pipes 2 inch and smaller:a.Adjustable steel swivel ring (band type) hanger, B-Line series B3170.b.Adjustable steel swivel J-hanger, B-Line series B3690.c.Malleable iron ring hanger, B-Line series B3198R or hinged ring hanger, B3198H.d.Malleable iron split-ring hanger with eye socket, B-Line series B3173 with B3222.e.Adjustable steel clevis hanger, B-Line series B3104 or B3100.2.Uninsulated pipes 2-1/2 inch and larger:a.Adjustable steel clevis hanger, B-Line series B3100.b.Pipe roll with sockets, B-Line series B3114.c.Adjustable steel yoke pipe roll, B-Line series B3110.3.Insulated pipe- Hot or steam piping:a. 2 inch and smaller pipes: use adjustable steel clevis with galvanized sheet metal shield.B-Line series B3100 with B3151 series.b.2-1/2 inch and larger pipes:1)Adjustable steel yoke pipe roll with pipe covering protection saddle. B-Line seriesB3110 with B3160-B3165 series.2)Pipe roll with sockets with pipe covering protection saddle, B-Line series B3114with B3160-B3165 series.4.Insulated pipe – Cold or chilled water piping:a. 5 inch and smaller pipes: use adjustable steel clevis with galvanized sheet metal shield.B-Line series B3100 with B3151 solutions.b. 6 inch and larger pipes:1)Pipe roll with sockets with pipe covering protection saddle, B-Line series B3114with B3160-B3165 series.2)Steel yoke pipe roll with pipe covering protection saddle. B-Line series B3110with B3160-B3165 solutions.B.Pipe Clamps1.When flexibility in the hanger assembly is required due to horizontal movement, use pipeclamps with weldless eye nuts, B-Line series B3140 or B3142 with B3200. For insulatedlines use double bolted pipe clamps, B-Line series B3144 or B3146 with B3200.C.Multiple or Trapeze Hanger1.Trapeze hangers shall be constructed from 12-gauge roll formed ASTM A1011 SS Grade 33structural steel channel, 1-5/8 inch by 1-5/8 inch minimum, B-Line series B22 strut orstronger as required.2.Mount pipes to trapeze with 2-piece pipe straps sized for outside diameter of pipe, B-Lineseries B2000 solutions.3.For pipes subjected to axial movement:a.Strut mounted roller support, B-Line series B3126. Use pipe protection shield orsaddles on insulated lines.b.Strut mounted pipe guide, B-Line series B2417.D.Wall Supports1.Pipes 4 inch and smaller:a.Carbon steel hook, B-Line series B3191.b.Carbon steel J-hanger, B-Line series B3690.2.Pipes larger than 4 inches:a.Welded strut bracket and pipe straps, B-Line series B3064 and B2000 solutions.b.Welded steel brackets, B-Line series B3066 or B3067, with roller chair or adjustablesteelyoke pipe roll. B-Line series B3120 or B3110. Use pipe protection shield or saddles oninsulated lines.E.Floor Supports1.Hot piping under 6 inches and all cold piping:a.Carbon steel adjustable pipe saddle and nipple attached to steel base stand sized for pipeelevation. B-Line series B3093 and B3088T or B3090 and B3088. Pipe saddle shall bescrewed or welded to appropriate base stand.2.Hot piping 6 inch and larger:a. [Adjustable] Roller stand with base plate, B-Line series B3117SL [or B3118SL]b.Adjustable roller support and steel support sized for elevation, B-Line series B3124F.Vertical Supports1.Steel riser clamp sized to fit outside diameter of pipe, B-Line series B3373.G.Copper Tubing Supports1.Hangers shall be sized to fit copper tubing outside diameters.a.Adjustable steel swivel ring (band type) hanger, B-Line series B3170CT.b.Malleable iron ring hanger, B-Line series B3198RCT or hinged ring hangerB3198HCT.c.Malleable iron split-ring hanger with eye socket, B-Line series B3173CT withB3222.d.Adjustable steel clevis hanger, B-Line series B3104CT.2.For supporting vertical runs use epoxy painted or plastic-coated riser clamps,B-Line series B3373CT or B3373CTC.3.For supporting copper tube to strut use epoxy painted pipe straps sized for copper tubing, B-Line series B2000 solutions, or plastic inserted vibration isolation clamps, B-Line seriesBVT products.H.Plastic Pipe Supports1.V-Bottom clevis hanger with galvanized 18-gauge continuous support channel, B-Line seriesB3106 and B3106V, to form a continuous support system for plastic pipe or flexible tubing.I.Supplementary Structural Supports1.Design and fabricate supports using structural quality steel bolted framing materials asmanufactured by Cooper B-Line, Inc. (DBA Eaton). Channels shall be roll formed, 12-gauge ASTM A1011 SS Grade 33 steel, 1-5/8 inch by 1-5/8 inch or greater as required byloading conditions. Submit designs for pipe tunnels, pipe galleries, etc., to engineer forapproval. Use clamps and fittings designed for use with the2.3UPPER ATTACHMENTSA.Beam Clamps1.Beam clamps shall be used where piping is to be suspended from building steel. Clamp typeshall be selected on the basis of load to be supported, and load configuration.2.C-Clamps shall have locknuts and cup point set screws, B-Line series B351L, or B3036L.Top flange c-clamps shall be used when attaching a hanger rod to the top flange of structuralshapes, B-Line series B3034 or B3033. Refer to manufacturer’s recommendation forsetscrew torque. Retaining straps shall be used to maintain the clamps position on the beamwhere required.3.Center loaded beam clamps shall be used where specified. Steel clamps shall be B-Lineseries B3050, or B3055. Malleable iron or forged steel beam clamps with cross bolt shall beB-Line series B3054 or B3291-B3297 solutions as required to fit beams.B.Concrete Inserts1.Cast in place spot concrete inserts shall be used where applicable; either steel or malleableiron body, B-Line series B2500 or B3014. Spot inserts shall allow for lateral adjustment andhave means for attachment to forms. Select inserts to suit threaded hanger rod sizes, B-Lineseries N2500 or B3014N solutions.2.Continuous concrete inserts shall be used where applicable. Channels shall be 12 gauge,ASTM A1011 SS Grade 33 structural quality carbon steel, complete with styrofoam insertsand end caps with nail holes for attachment to forms. The continuous concrete insert shallhave a load rating of 2,000 lbs/ft. in concrete, B-Line series B22I, 32I, or 52I. Selectchannel nuts suitable for strut and rod sizes.2.4VIBRATION ISOLATION AND SUPPORTSA.For refrigeration, air conditioning, hydraulic, pneumatic, and other vibrating system applications,use a clamp that has a vibration dampening insert and a nylon inserted locknut. For copper andsteel tubing use B-Line series BVT series Vibra-Clamp™, for pipe sizes use BVP series.B.For larger tubing or piping subjected to vibration, use neoprene or spring hangers as required.C.For base mounted equipment use vibration pads, molded neoprene mounts, or spring mounts asrequired.D.Vibration isolation products as manufactured by Cooper B-Line, Inc. (DBA Eaton)Vibratrol systems.2.5ACCESSORIESA.Hanger Rods shall be threaded both ends, or continuous threaded rods of circular cross section.Use adjusting locknuts at upper attachments and hangers. No wire, chain, or perforated straps areallowed.B.Shields shall be 180-degree galvanized sheet metal, 12 inch minimum length, 18-gauge minimumthickness, designed to match outside diameter of the insulated pipe, B-Line series B3151.C.Pipe protection saddles shall be formed from carbon steel, 1/8-inch minimum thickness, sized forinsulation thickness. Saddles for pipe sizes greater than 12 inches shall have a center support rib.2.6FINISHESA.Indoor Finishes1.Hangers and clamps for support of bare copper piping shall be coated with copper coloredepoxy paint, B-Line series Dura-Copper™. Additional PVC coating of the epoxy paintedhanger shall be used where necessary.2.Hangers for other than bare copper pipe shall be zinc plated in accordance with ASTM B633OR shall have an electro-deposited green epoxy finish, B-Line series Dura Green™.3.Strut channels shall be pre-galvanized in accordance with ASTM A653 SS Grade 33 G90OR have an electro-deposited green epoxy finish, B-Line series Dura Green.B.Outdoor and Corrosive Area Finishes1.Hangers and strut located outdoors shall be hot dip galvanized after fabrication inaccordance with ASTM A123. All hanger hardware shall be hot dip galvanized or stainlesssteel. Zinc plated hardware is not acceptable for outdoor or corrosive use.2.Hangers and strut located in corrosive areas shall be type 304 [316] stainless steel withstainless steel hardware.PART 3EXECUTION3.1PIPE HANGERS AND SUPPORTSA.Pipe shall be adequately supported by pipe hanger and supports specified in PART 2PRODUCTS. Hangers for insulated pipes shall be sized to accommodate insulation thickness.B.Horizontal steel piping shall be supported in accordance with MSS SP-69 Tables 3 and 4,excerpts of which follow below:NOMINAL PIPE SIZE ROD DIAMETER MAXIMUM SPACING(INCHES) (INCHES) (FEET)1/2 to 1-1/4 3/8 71-1/2 3/8 92 3/8 102-1/2 1/2 113 1/2 123-1/2 1/2 134 5/8 145 5/8 166 3/4 178 3/4 1910 7/8 2212 7/8 2314 1 2516 1 27C.Horizontal copper tubing shall be supported in accordance with MSS SP-69 Tables 3 and 4,excerpts of which follow below:NOMINAL PIPE SIZE ROD DIAMETER MAXIMUM SPACING(INCHES) (INCHES) (FEET)1/2 to 3/4 3/8 51 3/8 61-1/4 3/8 71-1/2 3/8 82 3/8 82-1/2 1/2 93 1/2 103-1/2 1/2 114 1/2 125 1/2 136 5/8 148 3/4 16D.Provide means of preventing dissimilar metal contact such as plastic-coated hangers, coppercolored epoxy paint, or non-adhesive isolation tape- B-Line series Iso-pipe. Galvanized feltisolators sized for copper tubing may also be used, B-Line series B3195CT.E.Support horizontal cast iron pipe adjacent to each hub, with 5 feet maximum spacingbetween hangers.F.Install hangers to provide a minimum of 1/2 inch space between finished covering andadjacent work.G.Place a hanger within 12 inches of each horizontal elbow.H.Support vertical piping independently of connected horizontal piping. Support verticalpipes at every [other] floor. Wherever possible, locate riser clamps directly below pipecouplings or shear lugs.I.Where several pipes can be installed in parallel and at the same elevation, provide trapeze hangersas specified in section 2.02 C. Trapeze hangers shall be spaced according to the smallest pipesize or install intermediate supports according to schedule in section 3.01B.J.Do not support piping from other pipes, ductwork or other equipment that is notbuilding structure.3.2CONCRETE INSERTSA.Provide inserts for placement in formwork before concrete is poured.B.Provide inserts for suspending hangers from reinforced concrete slabs and sides of reinforcedconcrete beams.C.Where concrete slabs form finished ceilings, provide inserts to be flush with slab surface.D.Provide hooked rod to concrete reinforcement section for inserts carrying pipe over 4 inches.END OF SECTION。

Restore your peace of mindYour HVAC system has to be dependableYour facility depends on an efficient, reliable HVAC system for employee comfort and well-being. In many cases, critical process applications will be shut down in the event of a HVAC failure. It is essential to adopt a predictive rather than a reactive approach when it comes to maintenance.Your energy costs are likely to be a large budget item needing careful management and efficient coils will deliver significant savings.Warning signsThe most common failure mode is a coil leak, shutting down your HVAC system and possibly your site operation. But long before a leak develops, your system is likely to suffer a gradual loss of performance accompanied by a gradual increase in energy consumption.Coils are the most sensitive partNo matter what the brand of your equipment is, the most likely point of failure will be the heat exchangers, such as water coils or steam coils, situated indoors or outdoors. Coils lifetime is limited by nature. By necessity, they are constructed with thin metals for efficient heat transfer. These metals are under constant attack on the inside and outside by contaminants, the environment and the stress of continuous heat/cool cycles.Causes of coil damageDirt-encrusted finsThe large surface area and narrow gaps between coil fins causes dirt accumulation and incrustation.By insulating the fins, this dirt can prevent effective heat exchange as well as causing moisture carryover.Neglected maintenanceIf coils are not inspected and cleaned as recommended by the manufacturer, contaminants like dust, debris, mould and bacteria can accumulate. This can dramatically reduce coil lifespan.Tube foulingThe gradual build-up of contaminant deposits within the coil tubing acts as insulation, reducing the ability of the coil to transfer heat. Sludge build-up will also reduce the internal diameter of the tube resulting in a water pressure drop. Corrosive elements in water can perforate the coil from the inside.Thermal cyclingRepeated rise and fall in temperature can also separate fins and tubes affecting thermal performance. It can also create friction between tubes and other metal components leading to premature wear.Environmental attackEnvironmental conditions can weaken a coil’s structure, causing premature failure. Air pollution can create acids that attack tubes and fins, especially the air-borne salt that is common in coastal areas. Water which collects on coils in winter can freeze and expand causing severe damage.And…Other causes of coil damage can include extreme operating conditions such as excessive temperature, pressure, vibration or cycling. If the coils were not correctly specified at the outset, or are of an obsolete design, then system functionality will be jeopardized.The solution is Trane SureFit TM coilsTrane is your single source of expertise• On-site inspection• Performance assessment• Diagnosis• Specification and quotation for replacement • Supply, installation and commissioning• Future service and maintenance Sure to fitFollowing a site inspection performed by a qualified service engineer, recommendations on corrective actions will be provided. When the specification is approved, we will provide rapid delivery and installation of competitively priced coils built to the right specification for your equipment, whatever the brand or application may be.High-quality coilsTrane’s expertise and attention to detail will ensure your SureFit TM replacement coils fit your application perfectly and perform as promised. Peace of mind comes from the assurance of years of trouble-free operation.Coils for any application, equipment or brandRegardless of your equipment’s manufacturer, you can rely on Trane to provide a replacement that will improve efficiency, reduce energy costs and get your system up and running fast. Competitively priced coils Trane’s extensive experience and manufacturing expertise gives us the capability to design, build and distribute high quality coils at a reasonable cost. In addition, Trane´s large distribution network will provide efficient local support.100 years of experienceWith a century of leadership in coil engineering and manufacturing, Trane can guide you through the coil selection process. Your Trane representative has the expertise to ensure coils both fit your application and deliver the promise of performance and reliability.6Making buildings better for lifePerformanceTrane SureFit TM replacement coils are designed, engineered, built and tested to be solid performers with the longest possible life. Regardless of the equipment or application, Trane SureFit TM replacement coils will help it perform at its best.InnovationFounded a century ago on the belief that imagination and inspiration can overcome any obstacle, the Trane legacy of technological breakthroughs has made it an industry legend. Today’s Trane SureFit TM coils are the product of nearly 100 years of innovations to maximize performance, efficiency, reliability and longevity.CommitmentTrane's reputation depends both on our products’ performance as well as our relationships with customers. The Trane commitment to your satisfaction begins the moment you call us and is maintained throughout the coil manufacturing, delivery, installation, and their life span.KnowledgeTo become and remain an industry leader requires a full understanding of existing knowledge and a never-ending quest for new discoveries. For one hundred years, Trane has built and maintained its leadership status in the HVAC industry by employing the brightest and most inquisitive engineers and design experts—all of whom share a singular passion to knowand explore the ever-evolving technology that improves the systems of our customers.7Trane SureFit coilsEvaporators and condensers for• H ot or cold water • Steam • RefrigerantA choice of design options• Tube wall thickness • Number of circuits • Fin spacingA choice of protective coatings• Epoxy coated fins• Complete anti-corrosion treatmentA choice of materials• Aluminium • Copper • Stainless steelStandalone and duct applicationAir handlersTerminal units and fan coilsUnit ventilatorsWater source heat pumpsSplit systemsPackaged rooftop unitsSelf-containedAir cooled chillersHot water✓✓✓✓✓✓Chilled water✓✓✓✓✓✓Steam✓✓✓✓✓✓Evaporator✓✓✓✓✓✓✓ ✓Condenser✓✓✓✓✓✓Heat recovery✓✓✓✓✓✓Contact your nearest Trane sales office now, for more information or a quotation.Services Portfolio• Validate installation• Engineering checklist for optimal start up•Verify and record design operational parametersTrane Elite Start™•Comprehensive service agreements for HVAC systems • Improve reliability and efficiency • Improve cost of ownershipTrane Select™ Agreements• Foundation for high performance buildings • Benchmarking baseline parameters• Monitor and adjust system critical parametersTrane Extended Start• Solutions for sustainable high performance buildings • Maintain system fitness• Optimize system performanceTrane Controls Services• Comprehensive OEM parts • State of the art logistics• Factory authorized techniciansGenuine Parts and Repair Services• System enhancement service solutions• Reliability – Energy – Environmental Solutions • I mprove comfort and operating efficiencyTrane Care™ Services• Inspect chiller operating conditions• Evaluate basic and critical parameters• Recommend upgrade and improvement solutionsTrane Chiller Health Check Program• Remote monitoring with professional advantage • Address key operational challenges• Critical alarm management and event logTrane Intelligent Services• Planned maintenance• Minimize downtime and extend equipment life • Reduce operating costsTrane Service Agreements• Temporary cooling solutions• Reliable equipment and fast service • All building purposesTrane Rental ServicesHigh Performance BuildingsEfficient Systems Turnkey SolutionsControls Services Your Mission. Realized. Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.Trane bvba, Lenneke Marelaan 6, 1932 Sint-Stevens-Woluwe, Belgium, ON 0888.048.262 - RPR BrusselsTrane® is a brand of Ingersoll Rand®. Ingersoll Rand (NYSE:IR) advances the quality of life by creating comfortable, sustainable and efficient environments. Our people and our family of brands—including Ingersoll Rand®, Trane®,Thermo King® and Club Car® — work together to enhance the quality and comfort of air in homes and buildings; transport and protect food and perishables; and increase industrial productivity and efficiency. We are a global business committed to a world of sustainable progress and enduring results.© 2014 Trane – All rights reserved COIL-SLB006-E4 January 2014We are committed to using environmentally conscious print practices that reduce waste.。

暖通词汇英汉对照Hot water system: 热水系统Water supply system: 自来水系统Sewer system: 污水系统Rain-water system: 雨水系统Municipal pipe: 市政管网Fire hydrant: 室内消火栓Wash basin and valve:洗脸盆和阀门Sanitary and valve: 卫生洁具Urinal : 小便斗Gully :雨水口Manhole: 一般指管网末端最大的雨污水井(表示人可以进去检修)Washbasin:洗脸盆Sink:洗涤盆Closet pan:坐式大便器Eastern closet:蹲式大大便器Rain water catch basin:雨水边井Plan: 平面图Elevation: 立面图Section :剖面Foundation plan: 基础平面图Details: 详图Updated: 最新的,更新的Fire hydrant: 室内消火栓Specification: 说明书,规范Profile: 剖面M&E-mechanical and electrical:机电专业M&E utility room: 机电设备房Architecture: 建筑专业Civil and structure: 结构专业Client: 业主LDI: lead design institute :设计院Curriculum vitae (CV): 个人简历Project manager(PM):项目经理constructer manager(CM): 现场经理costing manager(CM):预算经理lay out: 平面布局schematic diagram : 示意图,原理图Weighbridge: 地磅,电子称Mechanical ventilation: 机械通风Natural ventilation: 自然通风Split unit air conditioning : 分体式空调HV AC-heating ventilating and air conditioning: 暖通空调专业Technical Specification: 技术说明书,技术规范Profile: 剖面MAU:新风机组(make-up air unit)FCU: fan-coil unit 风机盘管机组AHU: air handing unit空气处理单元,组合式空调机V A V: variable air volume 变风量FFU: Fan Filter Unit风机过滤单元(洁净室常用)Chiller: 冷水机组V ariable frequency: 变频Air-cooled heat pump unit: 风冷热泵机组GMP:good manufacture practice 优良制造标准,多用于制药、食品行业Fire protection system: 防火系统Portable fire extinguisher: 便携式灭火器Fire hydrant: 室外消火栓Hose reel: 室内消火栓Cast-iron pipe: 铸铁管Fire pump: 消防水泵Fire tank:消防水箱(水池)Diesel pump: 柴油机组泵Duty pump and spare pump: 消防泵和备用泵Galvanized steel pipe: 镀锌钢管Municipal pipe: 市政管网Fire break glass: 碎玻璃按钮Alarm bell: 消防警铃Fire pump : 消防泵Jockey pump: 稳压泵Sump pump: 潜污泵Septic tank : 化粪池Fire monitor: 消防炮thermal 热的,热量的heat 热compressor 压缩机condenser 冷凝器throttling device 节流装置evaporator 蒸发器refrigerant 制冷剂suck 吸取absorb 吸收force … into压入discharge 排出suction 吸气exhaust 排气cooling coil 冷却盘管fan-coil units 风机盘管air cycle 空气循环surface 表面passage 通道saturated vapor 饱和蒸汽superheated vapor 过热蒸汽mixture 混合物pressure 压力temperature 温度process 过程remove 驱散coil walls 盘管壁dissipate 驱散liquid 液体vapor 蒸汽central air-conditioning 中央空调系统heat-supply network 热网(热力网)substation 热力站heat source 热源空调设备英文简称FCU :风机盘管 fan coil unitAHU :空气处理单元 (空气处理机) air handling unitFAU :新风处理单元 fresh air unitHVAC:供热通风与空气调节 heating ventilating and air conditioning DCC :干盘管(干式盘管)Dry cooling coilFFU:风机过滤单元 Fan filter unitMAU :新风空调箱 Make up air handling unit scheduleAHU:空气处理单元 Air handling unitHEPA:高效空气过滤器 High efficiency pariculate airRAC:循环组合空调单元 Recirculation air cabinet unit scheduleC/R:洁净室无尘室 Clean roomULPA:超高空气效过滤器 Ultra low penetration air filterAS :风淋室Air shower PB:传递箱 Pass boxCB:净化工作台Clean bench RD :泄压风门Relief damper CH.:制冷机C.D. :冷凝水管C.T. :冷却塔CAV :新风量控制箱EAF :排风机EAD :排风管EAG :排风口EAL :排风百叶FAG :新风口FAL :新风百叶FAF :补风机F.A. :新风FAD :新风管F.D.:防火阀HC :加热盘管FP :风机盘管HX :热交换器N.R.D.:风管止回阀P.A.:经过处理的新风PDA:新风管(经过处理的新风)PAU:新风机(带处理功能)PAL:新风百叶R.A.:回风RAD:回风管RAG:回风口Hot water system: 热水系统Water supply system: 自来水系统Sewer system: 污水系统Rain-water system: 雨水系统Municipal pipe: 市政管网Fire hydrant: 室内消火栓Wash basin and valve:洗脸盆和阀门Sanitary and valve: 卫生洁具Urinal : 小便斗Gully :雨水口Manhole: 一般指管网末端最大的雨污水井(表示人可以进去检修)Washbasin:洗脸盆Sink:洗涤盆Closet pan:坐式大便器Eastern closet:蹲式大大便器Rain water catch basin:雨水边井Plan: 平面图Elevation: 立面图Section :剖面Foundation plan: 基础平面图Details: 详图Updated: 最新的,更新的Fire hydrant: 室内消火栓Specification: 说明书,规范Pro file:剖面M&E-mechanical and electrical:机电专业M&E utility room: 机电设备房Architecture: 建筑专业Civil and structure: 结构专业Client: 业主LDI: lead design institute :设计院Curriculum vitae (CV): 个人简历Project manager(PM):项目经理constructer manager(CM): 现场经理costing manager(CM):预算经理lay out: 平面布局schematic diagram : 示意图,原理图Weighbridge: 地磅,电子称Mechanical ventilation: 机械通风Natural ventilation: 自然通风Split unit air conditioning : 分体式空调HVAC-heating ventilating and air conditioning: 暖通空调专业Technical Specification: 技术说明书,技术规范Pro file:剖面MAU:新风机组(make-up air unit)FCU: fan-coil unit 风机盘管机组AHU: air handing unit空气处理单元,组合式空调机VAV: variable air volume 变风量FFU: Fan Filter Unit风机过滤单元(洁净室常用)Chiller: 冷水机组Variable frequency: 变频Air-cooled heat pump unit: 风冷热泵机组GMP:good manufacture practice 优良制造标准,多用于制药、食品行业Fire protection system: 防火系统Portable fire extinguisher: 便携式灭火器Fire hydrant: 室外消火栓Hose reel: 室内消火栓Cast-iron pipe: 铸铁管Fire pump: 消防水泵Fire tank:消防水箱(水池)Diesel pump: 柴油机组泵Duty pump and spare pump: 消防泵和备用泵Galvanized steel pipe: 镀锌钢管Municipal pipe: 市政管网Fire break glass: 碎玻璃按钮Alarm bell: 消防警铃Fire pump : 消防泵Jockey pump: 稳压泵Sump pump: 潜污泵Septic tank : 化粪池Fire monitor: 消防炮。

![HomePlug_GreenPHY_Overview[1]](https://uimg.taocdn.com/6ad550edaeaad1f346933f0c.webp)

The HomePlug® Green PHY (GP) Specification is anew powerline technology designed to the specific requirements of Smart Grid applications, while interoperating with HomePlug AV products and the IEEE 1901 standard. It was developed in cooperation with major utilities with the goal of dramatically reducing power consumption and cost.The Green PHY Specification will be published and available for download from HomePlug’s website in June, 2010.HomePlug Green PHY SpecificationHomePlug GP targets smart grid applications such as HVAC/thermostats, smart meters, home appliances and plug-in electric hybrid vehicles. HomePlug GP has been developed in cooperation with major utility companies including Consumers Energy, Duke Energy, Pacific Gas & Electric, and Southern California Edison to help optimize the specification for real-world deployments.“The Smart Grid continues to be a major focus for HomePlug with the GP specification at the center ofour efforts,” said Rob Ranck, president of the HomePlug Powerline Alliance. “Our new GP spec meets the specific performance and interoperability requirements solicited from utilities and appliance manufacturers.”“HomePlug GP is a trimmed down, lower data rate, lower power version of HomePlug AV, making it easier for multiple silicon suppliers to produce Green PHY chips with relative ease and speed. Backwards interoperability allows use of current HomePlug AV chips to deploy prototypes and early implementations now.”HomePlug GP has ample bandwidth to support critical functionality such as IP networking, but with power consumption an am estimated 75% lower than HomePlug AV, with similar cost savings projected. Certified chips and products are expected to ship in the first half of 2011. HomePlug GP was developed to be a certification profile of the IEEE 1901 PLC standard. This means that products based on HomePlug GP will be fully interoperablewith HomePlug AV and IEEE 1901 products and will be included in HomePlug’s well-established Compliance and Interoperability Certification Logo program.Working with the IndustryThe HomePlug Powerline Alliance is committed to working with the industry in support of Smart Grid interoperability initiatives. Atheros Communications, Inc. has been awarded a $4.5 million grant by the U.S. Department of Energy for HomePlug GP development. Atheros is the only semiconductor company to receive such a grant under the $3.4 billion Smart Grid Investment Grant program for modernization of the U.S. power grid. The HomePlug Powerline Alliance has also worked with the ZigBee Alliance to develop the ZigBee/HomePlug Smart Energy Profile, a commonapplication layer enabling interoperability between applications which may run in ZigBee wireless and HomePlug powerline devices. The ZigBee/HomePlug Smart Energy Profile has also been named in theNational Institute for Standards and Technology Smart Grid interoperability standards roadmap.HomePlug devices account for over 80 percent of the world’s broadband powerline communications market, and over 45 million devices have shipped to date.About the Smart GridDevelopment of a smart grid involves overlaying a unified two-way communications capability on the existing power delivery infrastructure to provide the right information to the right entity – whether appliances in homes, transmission and distribution equipment or utilities – at the right time to take actions beneficial to the entire system. The smart grid should optimize power supply and delivery, minimize losses, be “self-healing” and enable next-generation energy efficiency and demand response applications.The Smart Grid infrastructure requires an open standard for two-way communications between many different transmission and distribution devices, appliances and other end-use devices, along with an advanced metering infrastructure (AMI), the two-way communications between a utility and its customers, and smart interconnections to distributed energy resources.The emerging Smart Grid will facilitate charging stationsfor plug-in hybrid electric vehicles (PHEVs) that can be plugged into electrical outlets – ultimately at homes and public places – for recharging.The Smart Grid will enable dynamic energy management that, along with smart energy-efficient end-use devices, advanced building control systems, and smart distributed energy resources will yield energy savings and peak demand reductions greater than what could otherwise be realized. A Smart Grid would potentially link all of these elements together and provide constant communications between a utility and its customers to optimize energy efficiency and mitigate emissions.The Alliance operates the powerline networking industry’s largest Compliance and Interoperability Certification Program to ensure true multi-vendor co-existence and interoperability. It has certified more than 190 products and will begin certifying IEEE 1901 products in 2010.Smart thermostats that communicate over home electrical wiring give users more control over their energy usage.Key Features of HomePlug Green PHY HomePlug Green PHY will be interoperable with HomePlug AV, IEEE 1901 (expected to become a certification profile of IEEE 1901) and the HomePlug AV2 Specification for next generation broadband (now under development).HomePlug Green PHY Enables Smart Homes While the smart grid comprises a variety of new technologies that would allow more efficient usage of energy on a local and national scale, it will ultimately enable Home Area Networks(HANs) inside homes and give homeowners more control over their individual energy usage and electricity rates. A HAN inside the home means home appliances can communicate with the power meter to determine themost economical times to run.The smart home’s HAN communicates through the smart meter to the smart grid WAN.In addition to Green PHY-enabled smart meters, consumers can expect the development of in-home displays to allow them to program their big Green PHY-enabled appliances. In addition to many different “smart” appliances in the home, companies are developing Programmable Communicating Thermostats (PCTs) that put monitoring and control of the HVAC system in the consumer’s hands. Also, charging stations for homes and public places are in development; these will also have powerline communications capability to inform the customer of the current rate or allow the home owner to program when the electric vehicle should be charged.Green PHY Features • Operate with 75% less power consumption(than current HomePlug AV implementations) • Reduce total Bill of Materials by 75% (from current HomePlug AV implementations) • Provide Internet (IP) networking (802.2, IPv6) support• Provide 256 Kbps minimum effectivenetworking throughput.• Provide 10 Mbps peak PHY rateKey Technical Working Group Contributors Arkados, Atheros Communications, Cisco, Corporate Systems, Duke Energy, GE Energy, Gigle Networks, Marvell, NEC Electronics, PG&E, Renesas, SPiDCOM, ST Microelectronics, and Watteco.About the HomePlug Powerline AllianceFounded in 2000, the HomePlug Powerline Alliance, Inc. is an industry-led initiative with 70 member companies that creates specifications and certification logo programs for using the powerlines for reliable home networking and Smart Grid applications. The Alliance accelerates worldwide adoption for HomePlug technology by collaboratingwith international standards organizations such as the IEEE and through market development and user education programs. Sponsor members include Atheros Communications (ATHR); Cisco (CSCO); Comcast (CMCSK); Duke Energy (DUK), GE Energy, an affiliate of General Electric Co. (NYSE: GE); Gigle Networks; Motorola, Inc. (MOT); Renesas Electronics Corporation (TSE: 6723); SPiDCOM Technologies, and ST Microelectronics (STM). Contributor members include Arkados (OTCBB: AKDS) and Corporate Systems Engineering. For more information, visit .HomePlug Powerline Alliance, Inc. 5200 SW Macadam Avenue, Suite 470 Portland, Oregon 97239 USATel: +1.503.766.2516 Fax: +1.503.863.3881。

A/D/V Analysis/Development/Validation 分析/发展/验证9 e# I. ~# ]- W- W% b9 mAA Approve Architecture 审批体系: z* [! @0 |, I, K6 \7 c1 dACD Actual Completion Date 实际完成日期! V# [; E( m9 f: c+ AALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购9 r/ C# y$ j3 fAPI Advanced Product Information 先进的产品信息$ a! _. A- d! P' n( f+ ~APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时% O6 S2 @) [% U- s: P) WBIQ Building in Quality 制造质量 N! ^4 D8 j( H/ z* N' s" VBIW Body In White 白车身6 I& ~( h. e9 p/ o5 w' f$ j( @8 VBOD Bill of Design 设计清单BOE Bill of Equipment 设备清单4 G6 I2 U2 ?$ J( NBOL Bill of Logistic 装载清单, T/ |% s1 [6 @ w. P/ mBOM Bill of Material 原料清单& e' _% `- ]7 B7 H/ b7 PBOP Bill of Process 过程清单BPD Business Plan Deployment 业务计划实施2 ]2 e, Z- O$ a3 aCAD Computer-Aided Design 计算机辅助设计4 y! C- U* Z9 ~ W1 N+ WCAE Computer-Aided Engineering 计算机辅助工程(软件)- V+ {/ @/ ~- @4 D M% ?6 rCARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进8 ?2 \ q% A/ K* F% pCIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪7 f2 @. s( h, v9 ]) r4 FCPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接# C. T- w) o- r# B9 VCS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格% a. {; E" z" iCVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析2 E1 L% a, @, H$ p% n2 sDAP Design Analysis Process 设计分析过程DES Design Center 设计中心/ @1 P4 b4 Z6 K. mDFA Design for Assembly 装配设计& n; p) ?1 d6 A9 }5 wDOE Design Of Experiments 试验设计$ d$ A3 ?$ x y& aDOL Die Operation Line-Up 冲模业务排行! s+ _- F6 G- ~* IDPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆# c: I! s6 [- ]1 z7 ]* Y. g: l9 zENG Engineering 工程技术、工程学. n9 H5 w( a' d9 v+ \, wEOA End of Acceleration 停止加速" H9 I" [) n: S$ b( FEPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告% l; a- o# O1 n- _: p% X3 S FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FMEA Failure Mode and Effects Analysis 失效形式及结果分析$ F E0 c, S& M( `3 X- B: |/ ~ FPS Fixed Point Stop 定点停* ^& i' F( K \( h: m9 U$ C0 S) a7 IFTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率* C. w: m6 c. P. @6 Q. z. B: k! oGA General Assembly 总装GA Shop General Assembly Shop 总装车间; G! v; s& r4 Z4 ]/ v" t7 gPaint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间1 s0 p8 W0 \9 P) hGCA Global Customer Audit 全球顾客评审- U! @9 a) L: ?! \. ^1 OGD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查0 n3 J9 R4 T' y$ lGM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太7 p7 H% d* ~2 W6 X: KGME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作: Z( M9 f# @$ ?GMIQ General Motors Initial Quality 通用汽车初始质量+ g; I8 V1 H: W. ?9 E# Y# ^ GMPTG General Motors Powertrain Group 通用汽车动力组0 F* ]; u! U4 b: O. X- i6 JGMS Global Manufacturing System 通用全球制造系统( S: t- D) }5 \, C# t8 KGP General Procedure 通用程序( t6 F5 q2 N. S: |( A' w- ~GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部9 L# W1 I& [- F/ i4 Q: N7 HHV AC Heating, Ventilation ,and Air Conditioning 加热、通风及空调5 a, i1 B- R7 N* F9 RI/P Instrument Panel 仪表板: ~0 g& V4 W, ~% L6 sIC Initiate Charter 初始租约5 y6 ^* l: C7 x7 F+ q/ uICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析8 B' x: `) o. o- Z+ s5 [- u: W" ~ ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要 N% x) ] K3 S0 Z: N9 u4 NIPC International Product Center 国际产品中心; g8 [0 b! w$ K* i/ @IPTV Incidents Per Thousand Vehicles 每千辆车的故障率3 Y% v/ P& T+ G" o e& xIQS Initial Quality Survey 初始质量调查+ d/ L5 y, S7 z! a5 H( O8 vIR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUV A International Uniform Vehicle Audit 国际统一车辆审核" P6 `% O" V' ^2 G% `JES Job Element Sheet 工作要素单6 T8 |0 ?* K5 | IJIS Job Issue Sheet 工作要素单: R( I1 C4 S3 T/ \5 iJIT Just in Time 准时制- r# J6 j; a$ G7 H1 c/ b' @+ QJPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性( h* r: v" g wKCDS Key Characteristics Designation System 关键特性标识系统- ?3 u0 m. |& ^2 xKPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区1 L: D0 S' {/ r4 C8 F2 \) sMFG Manufacturing Operations 制造过程% k0 k4 R3 {9 C- BMIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师; g2 Q) q; }5 M9 @% a5 F3 x. ^MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书1 f G: n e1 G' yMNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表& L6 }$ z U s# k GMPS Material Planning System 原料计划系统+ }8 m8 u/ i" N; r- d' lMRD Material Required Date 物料需求日期1 j! @$ B2 h: \2 j: ]0 F! F; QMSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程+ ~' [0 _& }+ \9 C+ z1 u( F; O/ LMSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范; Q% j$ S" Y3 B4 L. Z9 IMVSS Motor Vehicle Safety Standards 汽车发动机安全标准# s- x8 F8 e/ b: g( ]2 m" Z/ ONAMA North American Market Analysis 北美市场分析8 Q0 w1 F8 R9 v) xNAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输7 K$ A& s. x* j/ E1 J4 zNC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书: r8 n8 T, x, uNSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案$ k0 t5 w, {2 c8 iOSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件5 K+ w, Q/ C2 Y1 B0 R2 }PAD Product Assembly Document 产品装配文件& k5 Z5 J9 a9 N& b7 KPARTS Part Readiness Tracking System 零件准备跟踪系统- w- E$ B2 T. r A* \3 T% P* U$ N: k5 TPC Problem Communication 问题信息PCPA Process Control Plan Audit 过程控制计划审核PCL Production Control and Logistics 生产控制和支持 E" f5 e* m5 K' H) E2 q* YPCM Process Control Manager 工艺控制负责人" X; N2 s5 r# N; T. I, TPCR Problem Communication Report 问题交流报告8 Y/ @% Q9 B& b. k8 O: R0 y& Z, {! ?PDC Portfolio Development Center 证券发展中心 Z) L% x: ]2 C/ O! A _PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组, H3 c) ~, d- {+ TPED Production Engineering Department 产品工程部1 @; t+ I) F( dPEP Product Evaluation Program 产品评估程序4 p7 `/ g+ H/ w% |0 jPER Personnel 人员0 o5 G G* j; g0 dPET Program Execution Team 项目执行小组PGM Program Management 项目管理: E4 g% ^* m, \4 rPI People Involement 人员参与) \# N: o. k( Z7 L% O! S4 f! T BPIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组) \6 p2 i5 D% v0 fPOMS Production Order Management System 产品指令管理小组: u! _% f K: s$ G( ^0 w0 P* n POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估: v4 g4 {! D- `- s" xPR/R Problem Reporting and Resolution 问题报告和解决" o1 P% U( v& a; d' g+ e0 ?9 u+ [PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会" O7 O: }5 l$ ^" S3 A+ x( K9 nPST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行6 v# M7 \8 h7 N* A7 OPUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型1 ]4 ~& B2 U# |0 ~2 d4 C/ MQA Quality Audit 质量评审7 u, J, K8 R, q3 k, fQAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性" B( y+ A+ ]# t/ o: {' ~) VQCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师3 g; z" S- c! C" [4 [QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置5 g; y- F, P3 U" U* h. |QRD Quality, Reliability,andDurability 质量、可靠性和耐久力6 B8 ^: R/ C3 h" B$ c7 fQS Quality System 质量体系6 ?* U; z. [2 ]# R- J, cQUA Quality 质量2 b( N9 z. @/ `$ VRC Review Charter 评估特许RCD Required Completion Date 必须完成日期3 g3 S* G* O7 SRFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估9 ]- b* t) V0 Z) W% KRPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定 V! W" l! ` l6 A- S5 f1 t1 c5 n- _RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理% P, ^& @8 C( }5 L- ^SDC Strategic Decision Center 战略决策中心& L I! @6 Y$ n' P/ MSF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单4 y }- |) D: B9 ]5 a, ^SIP Stansardized Inspection Process 标准化检验过程) A$ x* u" V7 v6 ^SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期1 T6 S' K) F! q' D1 [( ^SMART 8 H3 _. v# F0 H9 ]SMBP Synchronous Math-Based Process 理论同步过程1 x- }! s8 H6 c4 TSME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验2 \5 F, X. v( A, ]7 rSOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计% n4 o; l {0 m! F ^2 X9 _9 M SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织; _/ X) X6 q& WSPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制3 ^) g- T. q9 Z4 c2 B% S7 |SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师, ^* N$ U$ ~! o x; }SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充 _* ^2 U, E3 W" {8 USSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位6 V9 r( j: r/ {( f6 G( XSWE Simulated Work Environment 模拟工作环境" K+ C7 r0 ` |: k/ L3 n! k TAG Timing Analysis Group 定时分析组3 i. j6 j e) r9 k& d sTBD To Be Determined 下决定& l1 _5 ]1 ^3 M6 N! m6 g8 ETCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心* ~* r& e- G3 TTDMF Text Data Management Facility 文本数据管理设备6 `! I4 E7 W( ?- R/ e TG Tooling 工具' R0 |7 o, e+ I$ DTIMS Test Incident Management System 试验事件管理系统% e- r; u/ v/ t) Q TIR Test Incident Report 试验事件报告# b% l: u! P% U$ P; W% lTMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验+ h' k0 \6 ^3 JTPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统1 ]; U# Y) _. gUAW United Auto Workers 班组! ^; W* p1 o9 {UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布% Z! N* L; e4 G) l( p; \ UPC Uniform Parts Classification 统一零件分级7 M) j4 }# q, c. r2 JV AE Vehicle Assembly Engineer 车辆装配工程师4 k- V# a0 N. n* l2 O% f) q V APIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组V ASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心6 r, `" T% I$ \VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管8 E8 t2 U3 D4 F0 \9 ^- \+ XVLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC V oice of Customer 顾客的意见# K' m- }" P! X! J& m" X* _VOD V oice of Design 设计意见; A, x$ ~% ]' T: z( [VS Validation Station 确认站# _$ e; I# Y9 ?3 @1 s, [+ {VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书' H/ B' E# [ D0 q ?2 C$ iWBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析/ h. L b6 J8 m; J' e WOT Wide Open Throttle 压制广泛开放6 T& Z6 t% V8 w( k; yWPO Work Place Organization 工作场地布置0 @( t6 j7 C/ b5 d* R, WWWP Worldwide Purchasing 全球采购$ k/ ], G D! E! C( K3 g* rCOMMWIP Correction 纠错浪费$ C; a3 b& \ D' x. l. T! E; kOverproduction 过量生产浪费Material Flow 过度物料移动浪费! w9 i/ ~- m" F$ \Motion 过度移动浪费, x/ ^- C: u+ |Waiting 等待浪费& {+ j' X ]8 z" g' H! pInventory 过度库存浪费. ]1 n& ]* G2 H# }& x) G7 bProcessing 过度加工浪费。

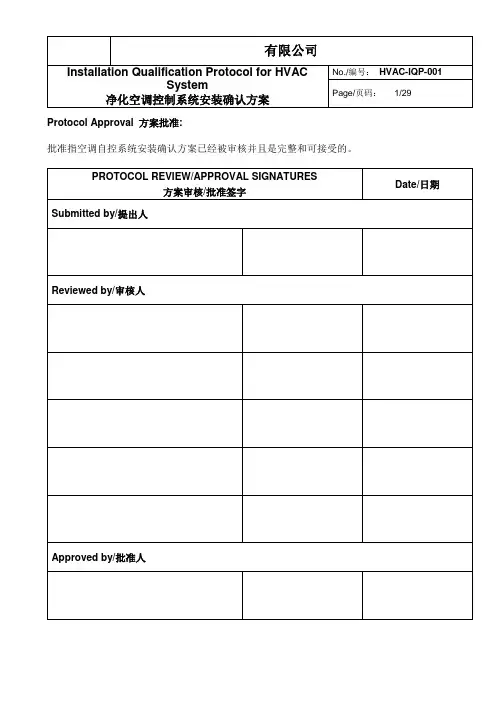

Protocol Approval 方案批准:批准指空调自控系统安装确认方案已经被审核并且是完整和可接受的。

Content目录1.Purpose目的 (3)2.Scope范围 (3)3.Responsibilities职责 (3)4.References参考资料 (5)5.Abbreviations缩略语 (5)6.Instruction介绍 (5)6.1.厂房概要 (5)6.2.HVAC系统描述 (6)6.3.控制系统描述 (6)7.Pre-requirements before Starting IQ 安装确认前的准备工作 (7)8.Qualification Plan 验证计划 (7)9.IQ 实施 (8)9.1.先决条件 (8)9.2.文件确认 (10)9.3.控制系统硬件架构的确认 (12)9.4.关键仪表检查 (15)9.5.接线和电气图的确认 (19)9.6.控制系统软件配置检查 (21)9.7.静态人机界面的确认 (24)9.8.公用设施的确认 (26)10.Deviation and Changes 偏差和变更 (28)1.1验证偏差 (28)1.2变更控制 (29)1. Purpose目的厂房一洁净区房间是依照中国GMP D级区药品生产厂房设计标准设计,质检楼微生物实验室是依照中国GMP C级区药品生产厂房设计标准设计。

各项指标:●能够满足URS;●符合车间产品生产工艺和GMP相应洁净度级别的要求。

●确保设计符合中国GMP的要求。

●满足相关设计规范、功能规范的要求与确认。

2. Scope范围本设计方案适用于洁净房间的空调自控系统的安装确认。

3. Responsibilities职责4. References参考资料4.1. (CFDA) 中国GMP 2010年版4.2. 欧盟药品法规第4卷GMP(人用和兽用药品)4.3. 欧盟GMP的附录11-计算机化系统4.4. 欧盟GMP的附录15-验证和确认4.5. ( (GAMP5) 良好自动化生产实践指南-遵从GXP计算机化系统监管的风险管理方法,第5版4.6. 用户需求说明5. Abbreviations缩略语6. Instruction介绍6.1. 厂房概要各技术区具体面积和洁净级别见下表:6.2. H VAC系统描述净化空调系统HVAC主要有组合式空气处理机组、排风机组、回风系统、风管和管件风阀、高效过滤器、监测传感和上位机控制系统组成。

Refrigeration compressor lubrication demands the highest quality raw materials and formulation expertiseto assure proper lubrication and lubricant life as required by OEMs. Parker Guardian is developed, tested and qualified as our lubricants meet or exceed the industry standards. You can be assured the Guardian POE will perform in any and all commercial systems and in all compressor types and brands. Special formulas can be developed to suit your needs.Parker Guardian high performance HFC compressor lubricants are based on synthetic Polyol Ester (POE). The lubricants are designed to provide excellent miscibility and oil return from the evaporator to the compressor.Characteristics:• Excellent miscibility with HFC refrigerants.• Superior performance in low temperature systems• Better lubricity than comparable mineral oils. High dielectric strength allows oil/refrigerant mixture to serve as an insulator between the motor windings and the body in the compressor.• No floc point (low temperature systems separation of residual waxes), as previously observed in mineral oils.• Any refrigerant application in whicha superior lubricant is desired or isrequired to meet OEM specifications.• Refer to SDS sheet for furtherinformation. SDS sheets are availableat your local wholesaler, online at/coolparts andby e-mailing SVDTechSupport@.Purpose and Application:The VPOE series is a highly engineeredsynthetic polyolester used in a varietyof HVAC&R applications due to itsbroad spectrum of viscosities. Itis precisely formulated to ensureexcellent lubricity, wear, and anti-foaming characteristics.Benefits:• Precision manufacturing maintainsprecise viscosity for optimallubrication• Uniquely formulated to improvelubricity, reducing wear andprotecting the bearing surfaces andother moving components withinthe compressor.• Packaged in sealed metal containersfor extended shelf life and moisturecontrol.• Containers from 1 quart to 55 gallondrum to suit the smallest jobs to thelargest• OEM tested and approved for peaceof mindMade in the USAForm P-497 / 92016© 2016 Parker Hannifin CorporationParker Hannifin CorporationA/C & Refrigeration Aftermarket206 Lange Drive • Washington, MO 63090 USA phone 636 239 1111 • fax 636 239 /coolparts⚠WARNING – USER RESPONSIBILITYFailure or improper selection or improper use of the products described herein or related items can cause death, personal injury and property damage.This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.NON-WARRANTY – All data, statements and recommendations contained herein are based upon the best information available and are believed to be reliable. However, no warranty, either expressed or implied, is made concerning the application of this product since the customer’s use cannot be controlled. Statements concerning the use of this product should not be construed as suggestions, recommendations or inducements that it be used in violation of patent rights or in violation of any applicable laws or regulations. Product improvement is a continuous process at Virginia, therefore, product specifications may change without notice.The table below provides a guide for Residential Air Conditioning as well as Industrial and Commercial Refrigeration andAir Conditioning.POE LubricantComplementary products Parker ETK Acid Test Kit or the Sporlan TA-1 Acid Test Kit are suitable for use with the Parker Guardian Series. For more detailed analysis use the OA-1 Test Kit which provides complete analysis in 48 hours with recom-mendations for correcting out of specification parameters.。

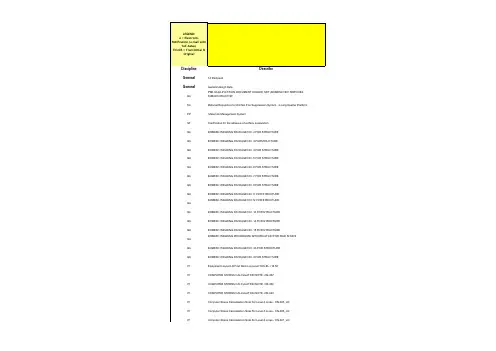

e = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline DescribeGeneral All RecipientGeneral General design DataQA PRE-QUALIFICATION DOCUMENT HUAWEI NDT (BOMESC NDT SERVICES SUBCONTRACTORSA Material Requisition for Kitchen Fire Suppression System - Living Quarter Platform PP Materials Management SystemST Clarification for the abrasive of surface preparationQA BOMESC WELDING PACKAGE NO. 2 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 3 FORSTRUCTUREQA BOMESC WELDING PACKAGE NO. 4 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 5 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 6 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 7 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 8 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO.11 FOR STRUCTUREQABOMESC WELDING PACKAGE NO.12 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 13 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 14 FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 15 FOR STRUCTUREQA BOMESC WELDING PROCEDURE SPECIFICATION FOR SKID SHOESQA BOMESC WELDING PACKAGE NO. 3A FOR STRUCTUREQA BOMESC WELDING PACKAGE NO. 4 FOR STRUCTUREPI Equipment Layout LQ First Deck Layout at TOS.EL.+16.50PI COMPUTER STRESS CALCULATION NOTE -CN-007PI COMPUTER STRESS CALCULATION NOTE -CN-002PI COMPUTER STRESS CALCULATION NOTE -CN-020PI Computer Stress Calculatation Note For Level-3 Lines - CN-005_LQPI Computer Stress Calculatation Note For Level-3 Lines - CN-006_LQPI Computer Stress Calculatation Note For Level-3 Lines - CN-021_LQe = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describe℃e = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describee = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline DescribeLEGEND:e = ElectronicNotification (e-mail withfull datas)TN+OR = Transmittal &OriginalDiscipline Describe。

欧洲变压器标准(EN Transformer standards)Measureme ntof tur ns ratio on atran sformer used ina couplerEN 50152-3-3-2001 铁路应用固定装置交流开关的特殊要求第3-3部分:专门用于交流牵引系统的测量、控制和保护装置单相Railway applicati ons -Fixedin stallati ons- Particularrequireme nts for a.c.switchgear -Part 3-3: Measurement, con trol and protection devices for specificuse in a.c. tracti onsystems- Sin gle-phasein ductive voltage transformersEN 50180-1997 充液变压器用1kV 至36kV和250A 至1.25kA的套管Bush ings above 1 kVup to 36 kV and from250 A to 3,15 kA forliquid filled transformersEN 50181-1997 不包括充液变压器在内的设备用1kV 至36kV和250A 至1.25kA的插入套管Plug-i n typebushi ngs above 1 kVup to 36 kV and from250 A to 1,25 kA forequipment other thanliquid filledtran sformersEN 50216-1-2002 电源变压器及电抗器配件第1 部分:总则Power tran sformer andreactor fittings -Part 1:GeneralEN 50216-2-2002 电源变压器及电抗器配件第2 部分:带保油箱的充液式变压器和电抗器的气动Power tran sformer andreactor fittings -Part 2:Gas and oil actuatedrelay for liquidimmersedEN 50243-2002 充液变压器24kV和36kV 以及5kA和8kV的室外套管Outdoor bushings for24 kV and 36 kV andfor 5 kA and 8 kA, forliquid filled transformersEN 50299-2002 最咼电压为72.5kV 至550KV设备的变压器和电抗器用油浸电缆连接组件Oil-immersed cableconn ecti on assembliesfor tran sformers andreactors hav ing highestvoltage for equipme ntU<(l ndex)m> from 72,5kV to 550 kVEN 50329-2003 铁路应用牵引变压器Railway applicati ons -Fixed in stallati ons -Tracti ontran sformersEN 50336-2002 不大于36kV的变压器和电抗器电缆箱的套筒Bush ings for transformers and reactorcable boxes not exceeding 36 kVEN 50386-2002 注液变压器用1kV及以下和250 A 至5 kA的套管Bush ings up to 1 kVand from 250 A to 5 kA,for liquid filled transformersEN 50387-2002 注液变压器用1kV及以下和1.25 kA 至5 kA的母线套管Busbar bush ings up to1 kV and from 1,25 kAto 5 kA, for liquid filledtran sformersEN 60044-3-2003 仪器变压器第3部分:组合式变压器In strume nt transformers - Part 3:Combi ned transformers (IEC 60044-3:2002) / Note: Endorseme nt n oticeEN 60044-8-2002 仪器变压器第8部分:电流变压器In strume nttran sformers - Part8: Electro nic curre nttran sformers (IEC60044-8:2002) / Note:En dorseme nt n oticeEN60076-1-1997+A1-2000+A12-2002 电力变压器第1部分:总则Power tran sformers -Part 1: General (IEC60076-1:1993,modified)EN 60076-10-2001 电力变压器第10部分:声级的测定Power tran sformers -Part 10:Determ ination of soundlevels (IEC 60076-10:2001)EN 60076-2-1997 电力变压器第2部分:温升Power tran sformers -Part 2: Temperaturerise (IEC 60076-2:1993,modified)EN 60076-3-2001 电力变压器第3部分:绝缘水平、电介质试验和空气中的外间隙Power tran sformers -Part 3: In sulati onlevels, dielectric testsand exter nal clearances in air (IEC 60076-3:2000 + Corrigendum2000)EN 60076-4-2002 电力变压器第4部分:闪电脉冲和开关脉冲试验指南电力变压器和电抗器Power tran sformers -Part 4: Guide to thelight ning impulse andswitch ing impulse testing;Power tran sformersand reactors (IEC60076-4:2002) /Note: En dorseme nt noticeEN 60076-5-2000 电力变压器第5部分:承受短路的能力(IEC60076-5:2000 )Power tran sformers -Part 5: Ability to withstand short circuit (IEC60076-5:2000)EN 60146-1-3-1993 半导体变换器第1-3部分:变压器和电抗器Semic on ductor convertors- Gen eralrequireme nts and linecommutated convertors- Part 1-3: Transformers and reactors(IEC 60146-1-3:1991)EN 60310-1996 铁路应用运输车辆的牵引变压器和电感器Railwayapplicati ons -Tracti ontran sformers and inductors on rolli ng stock(IEC 60310:1991,modified)EN 60417-1/prAAA-2002 用于5945型小型变压器的图形符号:变压器绝缘、短路试验修改草案AAAIEC 60417: Graphicalsymbol for use on smalltran sformers 5945 Pr:Isolat ing tran sformer,short-circuit proofEN 60417-1/prAAAC-2002 用于5947型小型变压器的图形符号:变压器绝缘安全、短路试验修改草案AAACIEC 60417: Graphicalsymbol for use on smalltran sformers 5947 Pr:Safety isolati ng transformer, short-circuitproofEN 60417-1/prAAAD-2002 用于小型变压器5948型的图形符号:变压器绝缘微扰衰减法、总则修改草案AAADIEC 60417: Graphicalsymbol for use on smalltran sformers 5948 Pr:Perturbati on atte nuatio n压器绝缘总则图形符号修改草案AAU small tran sformers 5221/02: Isolat ing tran sformer, gen eralEN 60417-1/prAAV-2002 用于小型变压器5222/02 型变压器绝缘总则图形符号修改草案AAVIEC 60417: Graphicalsymbol for use on smalltran sformers 5222/02:Isolat ing tran sformer,gen eralEN 60417-1/prAAW-2002 用于小型变压器5941型自动转换器总则图形符号修改草案AAWIEC 60417: Graphicalsymbol for use on smalltran sformers 5941 Pr:Auto-tra nsformer, generalEN 60417-1/prAAX-2002 用于小型变压器5942型自动转换器非短路试验图形符号修改草案AAXIEC 60417: Graphicalsymbol for use on smalltran sformers 5942 Pr:Auto-tra nsformer, non-short-circuit proofEN 60417-1/prAAY-2002 用于小型变压器5221/02 型自动转换器短路试验图形符号修改草案AAYIEC 60417: Graphicalsymbol for use on smalltran sformers 5943 Pr:Auto-tra nsformer,short-circuit proofEN 60417-1/prAAZ-2002 用于小型变压器5944型变压器绝缘非短路试验图形符号修改草案AAZIEC 60417: Graphicalsymbol for use on smalltran sformers 5944 Pr:Isolat ing tran sformer,non-short-circuit proofEN 60598-2-6-1994+A1-1997 灯具第2分:特殊要求第6:内装变压器的Luminaires - Part 2:Particular requireme nts-感器的叠片铁心包第2部分:用YEE2叠片铁芯的电性能tran sformers and in ductors for use in telecom mun icatio n and electr onic equipme nt - Part 2: Electrical characteristics for cores using YEE 2 lam in ati ons (IEC 61021-2:1995)EN 61050-1992+A1-1995 空载输出电压超过1000V的管形放电用变压器规范(一般叫做氖管变压器)一般要求和安全要求Tran sformers fortubular discharge lampshav ing a no-loadoutput voltage exceeding 1000 V (ge nerallycalled neon-transformers); gen eraland safety requirements (IEC 61050:1991 +corrige ndum 1992,modified)EN 61203-1994 电工用合成有机酯设备中变压器酯类的维护指南Syn thetic orga nicesters for electricalpurposes -Guide formaintenance of transformer esters inequipme nt (IEC61203:1992)EN 61248-1-1997 电子和电信设备用变压器和电感器第1部分:通用规范Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 1: Gen ericspecificati on (IEC61248-1:1996)EN 61248-2-1997 电子和电信设备用变压器和电感Tran sformers and inductors for use in器第2部分:采用能力批准程序的信号变压器分规范electro nic and telecom mun icatio n equipme nt - Part 2: Sect ional specification for signal transformers on the basis of the capability approval procedure (IEC 61248-2:1996)EN 61248-3-1997 电子和电信设备用变压器和电感器第3部分:采用能力批准程序的电源变压器分规范Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 3: Sect ionalspecification for powertran sformers on thebasis of the capabilityapproval procedure(IEC 61248-3:1996)EN 61248-4-1997 电子和电信设备用变压器和电感器第4部分:采用能力批准程序的转换供电方式(SMPS的开关电源变压器分规范Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 4: Sect ionalspecification for powertran sformers forswitched mode powersupplies (SMPS) on thebasis of the capabilityapproval procedure(IEC 61248-4:1996)EN 61248-5-1997 电子和电信设备用变压器和电感器第5部分:采用能力批准程序的脉冲变压器Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 5:分规范Sect ional specificationfor pulse tran sformerson the basis of thecapability approvalprocedure (IEC 61248-5:1996)EN 61248-6-1997 电子和电信设备用变压器和电感器第6部分:采用能力批准程序的电感器分规范Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 6: Sect ionalspecification for inductors on the basis ofthe capability approvalprocedure (IEC 61248-6:1996)EN 61248-7-1997 电子和电信设备用变压器和电感器第7部分:采用能力批准程序的高频电感器和中频变压器分规范Tran sformers and inductors for use inelectro nic and telecommun icatio n equipme nt- Part 7: Sect ionalspecification for high-freque ncy in ductorsand in termediatefreque ncy transformerson the basis of thecapability approvalprocedure (IEC 61248-7:1997)EN 61378-1-1998 交流器变压器第1部分:工业用变流变压器Conv ertortran sformers - Part 1:Tran sformers for industrial applicati ons(IEC 61378-1-1997)cable boxes on the high-voltage an d/or low-voltage side - Sectio n 3: Cable boxesHD 428.3 S1-1994 50 Hz、50 至2500 kVA、设备最咼电压不超过36 kV的三相油浸式配电变压器第3部分:设备最咼电压等于36 kVThree phase oil-immersed distributio ntran sformers 50 Hz,from 50 to 2500 kVAwith highest voltage forequipme nt not exceeding 36 kV- Part 3:Suppleme ntaryrequireme nts for transformers with highestvoltage for equipme ntequal to 36 kVHD 428.4 S1-1994 50 Hz、50 至2500 kVA、设备最咼电压不超过36 kV的三相油浸式配电变压器第4部分:负载非正弦电流变压器Three phase oil-immersed distributio ntran sformers 50 Hz,from 50 to 2500 kVAwith highest voltage forequipme nt not exceeding 36 kV- Part 4:Determ ination of thepower rati ng of a transformer loaded withnon-sinu soidal currentsHD 428.6 S1-2002 50 Hz、50 至2500 kVA、设备最咼电压不超过36 kV的三相油浸式配电变压器第6部分:关于加压波纹外壳的Three phase oil-immersed distributio ntran sformers 50 Hz,from 50 kVA to 2500kVA with highestvoltage for的最高电压Um大于1kV的设备用的电源变压器和电抗器的使用和特殊设计特点for particular desig n features for power tran sformers and reactors with highest voltage for equipme nt Um exceedi ng 1 kV, perma nen tly in corporated in build ingsprEN 60076-11-2002 电力变压器第11部分:干式变压器IEC 60076-11: Powertran sformers - Part 11:Dry-type tran sformersprEN 60076-8-1997 电力变压器第8部分:应用指南IEC 60076-8: Powertran sformers - Application guideprEN 60296-2003 变压器和开关设备用未使用过的矿物绝缘油规范IEC 60296, Ed. 3:Fluids for electrotech nical applicati ons - Unused min eral in sulati ngoils for tran sformersand switchgearprEN 60310-2003 铁路应用运输车辆的牵引变压器和电感器Railway applicati ons -Tracti on tran sformersand in ductors on boardrolli ng stockprEN 60989-1994 单独变压器自藕变压器、可变频率变压器和电抗器Separati ng transformers, autotransformers, variable transformers and reactors(IEC 60989:1991,modified)prEN 62041-2003 电源变压器、供电部件和类似部件电磁兼容要求IEC 62041, Ed. 1:Power tran sformers,power supply un its,reactors and similarproducts - EMCrequireme nts编号中文名称英文名称。