Biodegradable polymers as solid substrate and biofilm carrier for denitrification in recirculated aq

- 格式:pdf

- 大小:469.38 KB

- 文档页数:11

专利名称:Biodegradable polymer scaffold 发明人:CHANTAL E. HOLY,MOLLY S.SHOICHET,JOHN E. DAVIES申请号:AU1138099申请日:19981113公开号:AU749041B2公开日:20020620专利内容由知识产权出版社提供摘要:A polymer scaffold is provided having an extensively interconnected macroporous network with macropores having microporous struts as walls. Macropore diameter ranges from about 0.5 to about 3.5 mm. The polymer may be a biocompatible, biodegradable polymer such as poly(lactide-co-glycolide) containing 75% polylactide and 25% polyglycolide. The polymer scaffold is prepared by mixing a liquid polymer with particles, precipitating the liquid polymer with a non-solvent for the liquid polymer and dissolving the particles with a solvent to form the macroporous polymer scaffold which preferably has porosity greater than 50%. The surface of the polymer scaffold may be modified by acid or base treatment, or by collagen or calcium phosphate deposition. The polymer scaffold has utility for tissue engineering, particularly as a scaffold for in vitro and in vivo cell growth.申请人:BONETEC CORPORATION更多信息请下载全文后查看。

替代物料英文专业术语In the field of materials science and engineering, the use of alternative materials has become increasingly important. The development of new and innovative materials has led to the need for a comprehensive understanding and usage of alternative material terminologies. In this article, we will explore some commonly used English professional terminologies related to alternative materials.1. Substitutes:In the context of materials, the term "substitutes" refers to materials that can replace or perform the same function as another material. It implies that the substitute material can be used as an alternative in a specific application or context. For example, carbon fiber can be used as a substitute for steel in certain structural applications due to its high strength and lightweight properties.2. Alternatives:Similar to substitutes, the term "alternatives" refers to materials that can be used in place of another material. However, the concept of alternatives is more broad, often including a wider range of choices. For instance, in the packaging industry, paper or biodegradable polymers can be considered as alternatives to conventional plastic packaging materials.3. Eco-friendly materials:In recent years, there has been a growing demand for eco-friendly materials, which are also known as environmentally friendly or greenmaterials. These materials are designed and manufactured with the aim of minimizing negative environmental impacts, such as reducing carbon footprint or decreasing waste generation. Bamboo, for example, is considered an eco-friendly alternative to traditional hardwoods due to its rapid growth and regenerative properties.4. Renewable materials:Renewable materials are derived from natural resources that can be replenished over time. These materials offer an alternative to non-renewable resources, such as fossil fuels. Examples of renewable materials include bio-based plastics made from corn or sugarcane, which can be used as substitutes for petroleum-based plastics.5. Recycled materials:Recycled materials are obtained from the processing of waste materials into new products. These materials provide an alternative to the extraction and production of raw materials. Recycled plastics, for example, can be used as an alternative to virgin plastics in various applications, contributing to waste reduction and resource conservation.6. Biodegradable materials:Biodegradable materials are capable of decomposing naturally and returning to the environment without causing harm. They offer an alternative to non-biodegradable materials, such as conventional plastics that persist in the environment for hundreds of years. PLA (polylactic acid) is a biodegradable alternative to conventional plastics and is commonly used in packaging and disposable products.7. Sustainable materials:Sustainable materials are those that consider the long-term environmental, social, and economic impacts throughout their lifecycle. These materials are designed to meet present needs without compromising the ability of future generations to meet their own needs. Examples of sustainable materials include responsibly sourced timber and low-carbon concrete alternatives, which aim to reduce environmental impacts associated with construction and building materials.8. Low-emission materials:Low-emission materials, as the name suggests, are materials that have reduced emissions of pollutants during their production, use, or disposal. These materials are often used as alternatives to high-emission materials, such as volatile organic compounds (VOCs) in paints and coatings. Water-based paints, for instance, are considered low-emission alternatives to solvent-based paints.In conclusion, the use of alternative materials has gained significant attention in various industries. Understanding and utilizing the appropriate professional terminologies related to alternative materials is essential for effective communication and knowledge exchange. The terminologies discussed in this article provide a basis for discussing and exploring the diverse range of materials available as substitutes, alternatives, or eco-friendly options in numerous applications.。

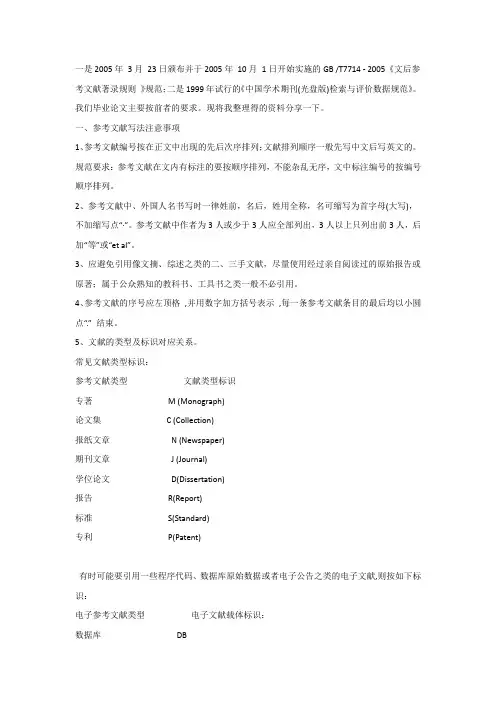

一是2005年3月23日颁布并于2005年10月1日开始实施的GB /T7714 - 2005《文后参考文献著录规则》规范;二是1999年试行的《中国学术期刊(光盘版)检索与评价数据规范》。

我们毕业论文主要按前者的要求。

现将我整理得的资料分享一下。

一、参考文献写法注意事项1、参考文献编号按在正文中出现的先后次序排列;文献排列顺序一般先写中文后写英文的。

规范要求:参考文献在文内有标注的要按顺序排列,不能杂乱无序,文中标注编号的按编号顺序排列。

2、参考文献中、外国人名书写时一律姓前,名后,姓用全称,名可缩写为首字母(大写),不加缩写点“·”。

参考文献中作者为3人或少于3人应全部列出,3人以上只列出前3人,后加“等”或“et al”。

3、应避免引用像文摘、综述之类的二、三手文献,尽量使用经过亲自阅读过的原始报告或原著;属于公众熟知的教科书、工具书之类一般不必引用。

4、参考文献的序号应左顶格,并用数字加方括号表示,每一条参考文献条目的最后均以小圆点“.” 结束。

5、文献的类型及标识对应关系。

常见文献类型标识:参考文献类型文献类型标识专著M (Monograph)论文集 C (Collection)报纸文章 N (Newspaper)期刊文章 J (Journal)学位论文 D(Dissertation)报告R(Report)标准S(Standard)专利P(Patent)有时可能要引用一些程序代码、数据库原始数据或者电子公告之类的电子文献,则按如下标识:电子参考文献类型电子文献载体标识:数据库DB计算机程序 CP电子公告EB电子文献类型标识载体类型标识代码磁带(magnetic tape) MT磁盘(disk) DK光盘(CD-ROM) CD联机网络(online) OL另外:对于专著、论文集中的析出文献(析出文献:即出版物的一部分, 是指那些存在于宿主文献( 即源文献) 中的, 依靠宿主文献并与宿主文献共同发行的宿主文献的一个组成部分, 需依赖包含它们的宿主文献的标识, 才能获得对它们自身的书目标识和检索。

pH-Responsive Biodegradable Polymers for Intracellular Drug DeliveryA. Proposed area of researchThe aim of this proposed PhD project is to develop and evaluate pH responsive, endosomolytic polymers for efficient intracellular delivery of biological drug payloads.There is a need to better understand the mechanisms of entry into the cell cytoplasm and nucleus in order to design optimal delivery systems for biological molecules. On the one hand, this would open up significant opportunities to deliver potent drug payloads against intracellular targets to positively impact human health. In addition the project aims to develop a more general understanding of the rules governing the uptake of biological molecules into cells.This project proposes to investigate the use of synthetic, biodegradable polymers for intracellular delivery of drug payloads (including siRNA, therapeutic peptide and antibody) against a well-validated intracellular drug target, such as Bcl-2. The novel pH- responsive polymers have been designed by Dr Rongjun Chen’sLab to mimic the activity of viruses, both in their cell entry and endosomal escape mechanisms. Using cancer cell lines (Jurkat or HL-60 cells) as a model system, the polymers would be tested with a variety of different biological payloads in a quantitative comparison of their ability to enter the cell and trigger apoptosis and subsequently cell death. With an efficient model system established, there would then be scope to optimize the systemin terms of the kinetics and mechanisms of cell entry, cytoplasmic and nuclear localization, and the biodegradation of the polymers. There would also be scope to explore the efficiency in other cell systems and with further intracellular targets. This multidisciplinary project is at the interface of Chemistry, Biology and Medicine, and will provide the student with a real opportunity to be involved in the development and evaluation of new nanomedicines.B. BackgroundAdvances in genomics and proteomics have enabled the development of macrodrugs, such as nucleic acids and proteins, with potential for the treatment of a wide variety of diseases. Amongst other problems, their clinical applications may be greatly impairedby low cellular uptake and lysosomal degradation before they can reach their target organelles or cell nuclei. In order to achieve efficient intracellular delivery of such biological molecules, delivery systems are required to enable high cell entry via endocytosis and efficient release into the cytoplasm by endosomal membrane disruption under mildly acidic conditions.Recombinant viruses and fusogenic viral peptides have been used to mediate gene transfection, but their clinical use is potentially limited by safety issues and difficultiesin large-scale production. A variety of synthetic polymers have therefore been developed as non-viral vectors. Cationic polyethyleneimine, poly(2- (dimethylamino)ethyl methacrylate) and polyamidoamine dendrimers mediate gene delivery through the ‘proton sponge ’effect, but suffer from c y y a t o n t d o x r e i c l i a t ivelylow transduction efficiencies. The intensively studied vinyl-based anionic polymers, poly(a-alkylacrylic acid)s, display pH-responsive membrane disruptive behavior, butthey are not biodegradable, thus low molecular weights have to be strictly required toallow renal excretion and their clinical applications are seriously limited.Dr Rongjun Chen’sLab has recently developed a class of novel, biodegradable, pH- responsive polymers to mimic factors that enable efficient viral transfection, but theyare safe, easy to manufacture and have more controllable structures. The parent polymer is a polyamide, poly(L-lysine isophthalamide), which was based on polycondensation of diacyl chlorides and natural metabolite tri-functional amino acids containing both - αa nd ω-amine groups. Hydrophobic amino acids and/or poly(ethylene glycol) were grafted onto its pendant carboxylic acid groups to manipulate its amphiphilicity and structure. The metabolite-derived biomimetic polymers can undergopH-mediated coil-globule changes in conformation. This property enables these polymers to be significantly membrane-disruptive within pH range typical of endosomal compartments, but necessarily non-toxic at physiological pH. Based on previous successful intracellular delivery of the model-drugs such as calcein, dextran (with molecular weight ranging from 3kDa to 70kDa), and therapeutic protein apoptin and siRNA, it is thought that these polymers may be able to deliver a wide variety of different biological molecules (nucleic acids and proteins) into cells for the treatment of various diseases including cancers.C. Applicant ’s work preparation in ChinaThe applicant is an expected bachelor majoring in Polymer Science and Engineering from Beijing University of Chemical Technology (BUCT). After four years of undergraduate studies (2007-2011), I have obtained a strong research background in organic chemistry, polymer physics and chemistry, physical chemistry, etc. Working inthe State Key Laboratory of Polymer Physics and Chemistry in the Institute of Chemistryof Chinese Academy of Science f or more than half of a year has set up my mind in researching polymer drug carriers. Our group cast our eyes towards synthesizing graft copolymers with amino acids as the main monomers, to create a novel carrier which isboth pH and temperature sensitive.We had synthesized a polymer brush from Z-lysine and 2-Bromoisobutyryl bromidethrough ring-opening polymerization. Then we grafted specific temperature sensitive residues onto the polymer brush via atomic transfer radical polymerization, followed by characterization and theoretical analysis of the polymers.In addition, I was a Research Assistant in the state key laboratory of Beijing University of Chemical Technology, working on the characterization of copolymers by NMR. I was alsoa Research Assistant in the Environmental Materials Laboratory of China Building Materials Academy, working on synthesis of FEVE coating. These research experiences have enriched my knowledge and experimental skills for polymer synthesis and enabledme to operate many facilities deftly, such as NMR, GPC,FTIR,vacuum glove box and rotary evaporator.In the summer of 2010, I was selected to attend the program -Cambridg“e S B u U m C m T e r School ”in the Ui v nersi t y of Cambridge. During the three weeks in the UK, I visited the Department of Chemical Engineering and Biotechnology and did experiments relevantto my research its labs. In Cambridge, I also did a case study about the biopharmaceutical market. This deepened my understanding of commercial prospectsof drug delivery technologies, such as the demands of different patients for drug delivery systems and competitiveness of different health testing equipments. Besidesthe University of Cambridge, I also visited the University of Oxford, Imperial College London, University of Birmingham, and University of Loughborough. I also establishedthe contact with Dr Rongjun Chen who is the Group Leader of Biomaterials and Drug Delivery Group at the University of Leeds when I was in the UK, and have been communicating with him via emails since then, discussing about polymer synthesis and characterization and drug delivery research.I believe the above mentioned academic backgrounds and various relevant experiences have prepared myself well for the PhD study on polymer drug delivery research for the treatment of various diseases including cancers in Dr Rongjun Chen’sLab at the University of Leeds.D. Aim of overseas studyThe aim of my PhD study is to apply polymer nanotechnology to drug delivery in orderto improve the safety and pharmaceutical efficacy of drugs that need precise intracellular delivery. I will design and synthesize biodegradable amino acid-based polymer vectors, which are efficient, safe, cost-effective and amenable to large-scale manufacturing. I will then evaluate the polymer-based targeted intracellular delivery of biological drug payloads (including siRNA, therapeutic peptide and antibody) against awell-validated intracellular drug target, such as Bcl-2, for cancer treatment. The intention is to combine the highly novel chemistry expertise surrounding the deliverypolymer with the biological expertise around the discovery and development of a variety of drug payloads. The novel polymer delivery technology to be developed will open the door to a wide variety of cytoplasmic and nuclear targets, previously thoughtto be inaccessible to biological therapy for various disease including cancers.In addition, I will investigate the fundamental mechanisms of the interaction between polymers/polymer-drug entities and different membrane models (artificial lipid membranes, erythrocytes and more complex nucleated mammalian cells) and obtain a better understanding of the rules controlling the uptake of macromolecules into cells.E. Research methodsThe project would break down into discrete stages as described below:(1) Polymer synthesisAmino acid derivatives (e.g. lysine derivative) will be used to carry out the N- Carboxyanhydride ring opening polymerization in order to obtain a polymer brush, which could be the backbone of target polymer. Then environmentally (e.g. pH and temperature) responsive groups will be grafted to the main chain by ATRP or Michael Addition, etc. Fluorescent polymers would be prepared by coupling organic fluorophores (e.g. fluorescein isothiocyanate and Cy5) onto the polymers. Cleavable linker chemistry (e.g. disulfide bond) would be introduced onto the polymer backbonefor drug conjugation. Polyethylene glycol would be added to the polymers to increase their biocompatibility and bioavailability.(2) Characterization of polymersThe structures, molecular weights and compositions of the synthesized peptide polymers will be characterized by NMR, mass spectrometry, GPCand HPLCetc. Their physicochemical properties tested by UV-visible spectroscopy, fluorescence spectroscopy, dynamic light scattering, zeta potential analysis and electron microscopy, and their membrane disruptive activity tested in a well established haemolysis model system.(3) Testing of biological payloads in the model cell systemsiRNA, therapeutic peptide and antibody payloads against Bcl-2 would be tested in the model cellular system for their biological potency. There are known model systemsin which Bcl-2 antagonists are active, such as in Jurkat or HL-60 cells, where the assays for apoptosis and cell proliferation are well established. For this stage of testing, the siRNA payload would be delivered by standard cationic lipid transfection, while the peptide and antibody would be encoded on expression plasmids, delivered via lentiviral transfection.(4) Combination of polymer delivery and biological payloadsBiological payloads such as siRNA, therapeutic peptide and antibody would be directly conjugated onto the polymer delivery system through cleavable linkage. siRNA payload could also be complexed with the stimuli-responsive anionic polymers via the use of cationic packaging modules (e.g. cationic polymers, lipids or ions). At this stage different chemistries could be explored and the combination efficiency and reproducibility assessedby biophysical analysis. Control reagents will also be prepared, e.g. using existing delivery technology systems such as TAT peptides, for later comparison.(5) Testing of polymer-payload conjugates/complexes in the model cell systemIn the model cell system the polymer-payload entities would be compared for their biological potency in dose titration and time course studies to compare the different payloads. Confocal microscopy would be used to study the mechanisms and kinetics of cell uptake and to visualise the distribution of polymers and payloads within the cell compartments. Flow cytometry would be used for quantitative analysis of cell uptake.(6) Biomembrane activity and cytotoxicityThe distinct but closely related research is to understand the activity of nano-systems at the biological membrane level. Dr Rongjun Chen has established production collaborations with Prof Nelson (Centre for Molecular Nanoscince/School of Chemistry, University of Leeds) on interaction of polymers with electrochemical lipid model membrane systems. Cytotoxicity of the polymers and/or polymer-payload entities towards model cell lines will be tested by MTT assay for metabolic activity, propidium iodide assay for membrane integrity, TEM for morphology of intracellular compartments and Comet assay for DNA damage.(7) Extending the polymer systemWith the model delivery system established, the aim is to optimise delivery to both cytoplasm and nucleus, in particular optimising endosomal release through careful study of the fate of polymers with different chemical modifications by confocal microscopy. There are further opportunities to optimise the biodegradation of the polymer through chemical changes as well as to look within different cellular systems and to look at other intracellular and nuclear targets.F. Schedule of researchPeriod of Study: 36 months from 1st October, 2011Programme: Full-timeMaximum time limit for submission of PhD thesis 30th September, 2015.The detailed schedule for different research stages shown in the above Section E is shown in the Table 1 Work plan.G. Introduction of work in China after graduationAfter obtaining my PhD degree from University of Leeds, I will return to Beijing University of Chemical Technology starting my academic career in the Department of Biomaterials of the College of Materials Science and Engineering. I will maintain my collaborative network including my PhD supervisor Dr Rongjun Chen in Leeds and other scientists/engineers/clinicians within and outside of the University Leeds. I will devote myself in the research area of drug delivery and biological therapy for various diseases including cancers. This area of research in nanomedicine aligns well with the research strategies of Beijing University of Chemical Technology, and will also have considerable potential to make a very positive impact upon the development of biotechnology in China. After I return to China at the end of my studies, the multidisciplinary knowledge and skills at the interface of Chemistry, Biology and Medicine, and excellent scientific capabilities that I will have developed will make me succeed in my academic career to the great benefit of Chinese Biotechnology and develop new potential nanomedicinesto positively impact human health in China and worldwide.Specifically speaking, the PhD research will enable me to have a good understanding of the basic science surrounding drug delivery through a systematic assessmentof both the delivery component and the payload component in a general biological system. Current knowledge of intracellular drug delivery is not well-developed and this project aims to shed light on this area. This PhD project fits the concept of taking novel tools into biological systems to advance the fundamental understanding of complex biological processes and translate basic research into new and improved healthcare qualities and practice. It supports knowledge exchange between academia and industry. In addition, the area of research in nanomedicine within Beijing University of Chemical Technology would help catalyze/enhance cross-faculty interactions/collaborations with researchersin the areas of drug delivery, molecular imaging, polymer chemistry, drug design, nanoparticle synthesis and characterisation, computational modeling of membrane activity, nanotoxicology, physics, cell biology, and medicine, therefore facilitating translational research from basic sciences into healthcare initiatives.The projected total market for nanotechnology-enabled drug delivery is predicted to rise to $26 billion by 2012. The area of research in drug delivery and therapy is of strategic interest to biopharmaceutical and healthcare sectors as it would enable new opportunities to make potent and specific drugs to intracellular targets which are currently inaccessible with existing technologies. The key knowledge and research skills developed from my PhD project will be of interest to all nanotechnology, drug delivery and medical scientists anxious to generate much superior disease treatments leading to substantial savings in healthcare budget, better health and improved quality of life.Table 1. Work planTASK Oct 2011–Sep 2012 Oct 2012–Sep 2013 Oct 2013–Sep 2014 Oct 2014–Sep 2015Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q1 Q3 Q4 Q1 Q2 Q3 Q4(1) Polymer synthesis(2) Characterization of polymers(3) Testing of biological payloadsin the model cell system(4) Combination of polymerdelivery and biological payloads(5) Testing of polymer-payloadconjugates/complexes in themodel cell system(6) Biomembrane activity andcytotoxicity(7) Extending the polymer system(8) Writing up PhD thesisApproval by PhD supervisorSignatureName Dr Rongjun ChenPosition Group Leader of Biomaterials and Drug Delivery Group, BHRC Senior Translational Research Fellow,Centre for Molecular Nanoscience, School of Chemistry, University of Leeds, UKTime 12 March 2011Page of 778。

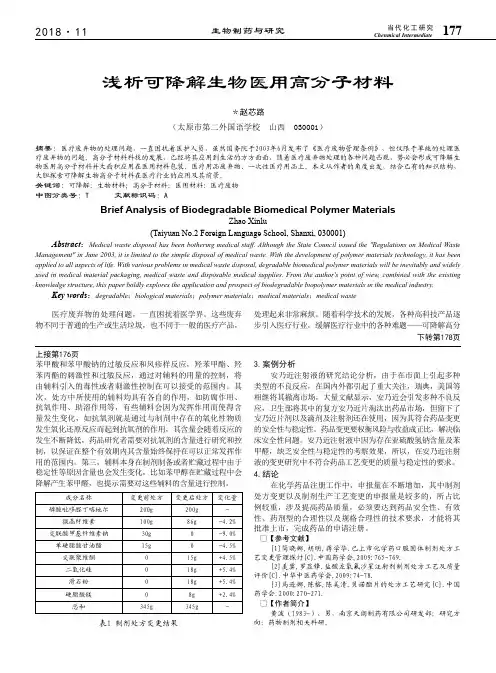

生物制药与研究2018·11177Chenmical Intermediate当代化工研究浅析可降解生物医用高分子材料*赵芯路(太原市第二外国语学校 山西 030001)摘要:医疗废弃物的处理问题,一直困扰着医护人员,虽然国务院于2003年6月发布了《医疗废物管理条例》,但仅限于单纯的处理医疗废弃物的问题。

高分子材料科技的发展,已经将其应用到生活的方方面面,随着医疗废弃物处理的各种问题凸现,势必会形成可降解生物医用高分子材料并大面积应用在医用材料包装、医疗用品废弃物、一次性医疗用品上。

本文从作者的角度出发,结合已有的知识结构,大胆探索可降解生物高分子材料在医疗行业的应用及其前景。

关键词:可降解;生物材料;高分子材料;医用材料;医疗废物中图分类号:T 文献标识码:ABrief Analysis of Biodegradable Biomedical Polymer MaterialsZhao Xinlu(Taiyuan No.2 Foreign Language School, Shanxi, 030001)Abstract :Medical waste disposal has been bothering medical staff. Although the State Council issued the "Regulations on Medical WasteManagement" in June 2003, it is limited to the simple disposal of medical waste. With the development of polymer materials technology, it has been applied to all aspects of life. With various problems in medical waste disposal, degradable biomedical polymer materials will be inevitably and widely used in medical material packaging, medical waste and disposable medical supplies. From the author's point of view, combined with the existing knowledge structure, this paper boldly explores the application and prospect of biodegradable biopolymer materials in the medical industry.Key words :degradable ;biological materials ;polymer materials ;medical materials ;medical waste医疗废弃物的处理问题,一直困扰着医学界。

bpi认证在北美,BPI(Biodegradable Products Institute,可生物降解产品研究院)是为可堆肥产品和包装提供认证的领导者。

可生物降解产品研究所院(BPI) 是一个由来自政府、工业界和学术界的关键个人和团体组成的非营利性协会。

BPI 认证计划应用基于科学的测试来证明材料将在市政或商业设施中堆肥,并且不会在土壤中留下有毒或挥之不去的塑料残留物。

BPI认证的意义当包装获得BPI 认证时,客户以及工业级的堆肥商可以保证其可堆肥性已通过合适的测试,消费者可以毫不犹豫地把包装扔进堆肥箱!BPI 认证意味着人们可以就如何处理他们购买的产品及其包装做出更明智的决定。

通过BPI认证产品或包装的过程是全面的,涉及多个步骤,可能需要许多个月才能完成。

但是,如果没有这种以细节为导向的测试,像从BPI获得的那些认证就不会具有让人们对他们所购买的产品感到放心的感觉。

BPI认证产品范围按照产品类别,可分为农用地膜、袋子(咖啡袋、垃圾袋、封口袋等)、组件(胶粘剂、涂料、咖啡胶囊、墨水、色母粒等)、餐饮类用具(纸杯、围裙、接触食物的手套等)、纤维模压制品(食物容器、托盘、披萨盒等)、包装材料(纸板、薄膜、一次性包装袋)、树脂(吹塑树脂、热成型树脂、注塑树等)BPI认证测试要获得BPI认证,产品必须通过ASTM D6400或ASTM D6868规定的测试,ASTM D6400 Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities 用于在市政或工业设施中进行有氧堆肥的塑料标签的标准规范ASTM D6868 Standard Specification for Labeling of End Items that Incorporate Plasticsand Polymers as Coatings or Additives with Paper and Other Substrates Designed to be Aerobically Composted in Municipal or Industrial Facilities 将塑料和聚合物作为涂层或添加剂与纸和其他设计用于在市政或工业设施中进行好氧堆肥的基质相结合的最终产品的标签标准规范BPI认证测试内容包括:生物降解测试:测量材料中的有机碳被微生物消耗的固有能力,并表明该材料或物品不会在自然界积累。

关于材料塑料的英语作文Title: The Role and Impact of Plastics in Modern Society。

Plastics, ubiquitous in our modern lives, play a multifaceted role in various sectors, ranging from packaging and construction to healthcare and transportation. However, their widespread use also raises concernsregarding environmental sustainability and human health. In this essay, we will delve into the significance, benefits, challenges, and potential solutions associated with plastics.Firstly, let us acknowledge the significance of plastics. These versatile materials have revolutionized industries worldwide due to their durability, flexibility, and cost-effectiveness. In the realm of packaging, plastics offer lightweight and durable alternatives to traditional materials like glass and metal, reducing transportation costs and energy consumption. Moreover, plastics play acrucial role in modern medicine, facilitating advancementsin drug delivery systems, medical devices, and prosthetics, thereby enhancing healthcare outcomes and patient comfort.Despite their undeniable benefits, plastics pose significant challenges, primarily concerning environmental sustainability. The durability of plastics, a boon in many applications, becomes a curse when it comes to disposal. Single-use plastics, in particular, contribute to pollution, clogging waterways, harming marine life, and degrading ecosystems. Moreover, the production of plastics relies heavily on non-renewable fossil fuels, exacerbating climate change and resource depletion.To address these challenges, various strategies have been proposed. Recycling represents a promising approach to mitigate the environmental impact of plastics. By diverting plastics from landfills and incinerators, recycling conserves resources, reduces energy consumption, and minimizes pollution. However, challenges such as limited recycling infrastructure, contamination of recyclable materials, and low consumer awareness hinder theeffectiveness of recycling initiatives.In addition to recycling, innovations in material science offer potential solutions to the plastic crisis. Biodegradable plastics, derived from renewable sources such as plant-based polymers, present a more sustainable alternative to traditional plastics. These bioplastics decompose naturally, reducing the burden on landfills and ecosystems. Furthermore, advances in polymer chemistry enable the development of recyclable plastics with enhanced properties, such as improved durability and biodegradability.Education and awareness also play a vital role in addressing the plastic problem. By promoting eco-friendly habits, such as reducing plastic consumption, reusing products, and properly disposing of waste, individuals can contribute to a more sustainable future. Moreover, advocating for policy changes, such as plastic bans or extended producer responsibility schemes, can incentivize businesses to adopt more environmentally friendly practices and products.In conclusion, plastics represent a double-edged sword in modern society, offering unparalleled convenience and versatility while posing significant environmental and health risks. To ensure a sustainable future, concerted efforts are needed to address the challenges associated with plastics through recycling, innovation, education, and policy intervention. By embracing these solutions, we can harness the benefits of plastics while minimizing their negative impacts on the planet and future generations.。

浅析生物可降解高分子材料的开发利用中英文对照Development and use of biodegradable polymer materials in English我国目前的高分子材料生产和使用已跃居世界前列,每年产生几百万吨废旧物。

如此多的高聚物迫切需要进行生物可降解,以尽量减少对人类及环境的污染。

生物可降解材料,是指在自然界微生物,如细菌、霉菌及藻类作用下,可完全降解为低分子的材料。

这类材料储存方便,只要保持干燥,不需避光,应用范围广,可用于地膜、包装袋、医药等领域。

生物可降解的机理大致有以下3 种方式:生物的细胞增长使物质发生机械性破坏;微生物对聚合物作用产生新的物质;酶的直接作用,即微生物侵蚀高聚物从而导致裂解。

按照上述机理,现将目前研究的几种主要的可生物可降解的高分子材料介绍如下。

China's current polymer materials production and use has leapt to the forefront of the world, millions of tons of waste materials generated each year. So many of the urgent need for biodegradable polymers, in order to reduce the pollution to human and environment. Biodegradable materials, refers to the natural microorganisms, such as bacteria, fungi and algae function, can be completely degraded into low molecular materials. This kind of material storage is convenient, as long as keep dry, without dark, wide application range, can be used for plastic film, packaging bags, medicine and other fields. Biodegradable mechanism can be summarized in the following 3 ways: biological cell growth of material mechanical damage; microorganism to produce new substances on the polymer; direct role in enzyme, namely microbial attack polymers resulting in cracking. According to the mechanism, the present study several main can be biodegradable polymer materials is introduced as follows.1、生物可降解高分子材料概念及降解机理1, the concept and the degradation mechanism of biodegradable polymer materials生物可降解高分子材料是指在一定的时间和一定的条件下,能被微生物或其分泌物在酶或化学分解作用下发生降解的高分子材料。

Development of Biodegradable Polymers随着环境保护意识的普及,越来越多的人开始考虑可持续性发展的问题。

其中,塑料污染问题成为了人们关注的焦点之一。

单一使用传统塑料制品不仅会造成废弃物的海洋污染,还会对环境和自然生态系统造成长期的影响。

因此,寻找一种替代品已经成为了当今科技界的迫切需求。

生物降解聚合物 (Biodegradable Polymers), 顾名思义,是一种能够降解的塑料类材料,可以通过生物学降解进入大自然而不会对环境造成污染。

生物降解聚合物因其具有环境友好、低污染等优点,近年来得到了更广泛的关注和应用。

生物降解聚合物的基本原理是,将生物降解物质(如淀粉类、纤维素等)与聚合物进行共混,通过物理或化学交联、接枝等技术,使材料具有特定的物理和化学性质,在使用后经过生物降解或自然降解过程被分解。

生物降解聚合物的使用不仅可以提高环境保护意识,还可以有效解决传统塑料产品产生的污染问题。

随着环保意识的增强,生物降解聚合物市场的需求也在逐年扩大。

在消费市场方面,生物降解聚合物可以用于塑料袋、餐具、饮料杯、纸巾等一次性消费品,替代传统的非降解性聚合物。

而在工业领域,生物降解聚合物可以用于制造土工布、果蔬包装材料等。

目前,市场上已经有多种生物降解聚合物可供选择,比如聚乳酸(PLA)、聚羟基脂肪酸酯(PHA)、聚己内酯(PCL)等。

PLA是当前生物降解聚合物市场中份额较大的一种,它由玉米、木薯等植物淀粉经过加工后得到。

与传统聚合物相比,PLA具有相似的物理和化学性质,但在使用后可以在自然条件下降解,对环境污染十分小。

PHB是一种天然合成的生物降解聚合物,其性能与普通塑料相似,并具有良好的光学性能和优良的拉伸性能。

PCL是一种在酯化反应中得到的聚合物,具有可降解、生物相容性等优点。

当然,生物降解聚合物在应用中还面临着一些挑战。

首先,价格仍然是制约其大规模应用的主要因素。

因为制造生物降解聚合物需要的折算成聚合物的单价或数倍于传统聚合物,生产成本过高,导致其市场价格偏高。

生物可降解聚合物在药用辅料方面的研究进展(图文)论文导读:生物可降解聚合物(BiodegradablePolymers)系指在生物体内能被降解或酶解,生成的小分子物质被机体吸收并排出体外的一类高分子材料。

天然可降解聚合物包括淀粉、纤维素、聚糖、甲壳素、壳聚糖及其衍生物等。

关键词:生物可降解聚合物,降解机理,壳聚糖,聚酯类生物可降解聚合物(BiodegradablePolymers)系指在生物体内能被降解或酶解,生成的小分子物质被机体吸收并排出体外的一类高分子材料。

该类聚合物作为药物载体时,可使释药时程持续几天乃至几年,研究、开发该类聚合物已成为药物传递系统领域的研究“热点”。

1 生物可降解聚合物的降解机理[1]生物可降解聚合物的降解分为本体降解(均相降解)和表面降解(异相降解)。

本体降解过程是降解在整个材料内同时发生。

表面降解是降解先从表面发生,由表及里,高分子材料在体内降解涉及的反应有水解、酶解、氧化等。

对大多数生物降解材料,尤其是合成的高分子材料。

降解过程主要是水解反应,其形式为:直线型高分子主链内不稳定键断裂;主链为线型而带侧链的高分子侧链基团的水解;交联网状高分子内不稳定交联链的断裂;通过以上3种形式使聚合物分子变小,达到降解的目的。

影响水解反应的因素主要有(1)分子链是否有易水解的键。

如酸酐和原酸酯最易水解,其次为酯键和酰胺键。

(2)材料的结晶性、分子量等。

例如结晶性的聚乳酸[P(L-LA)]降解要慢于非晶态的聚乳酸[P(DL-LA)] 。

(3)亲水/疏水性以及环境中pH值等。

由于疏水性聚合物吸水量少,故降解速度慢,而亲水性聚合物可吸收大量水分,降解速率加快。

特别是含有羟基、羧基的高分子。

不仅因为其较强的亲水性。

而且由于其本身的自催化作用。

所以比较容易降解。

另外不同pH值下聚合物的降解速率也是不同的。

论文大全。

聚酯在碱性和酸性环境中降解较快,而在中性介质中降解最慢。

2.生物降解聚合物生物可降解聚合物按来源可分为天然和合成两大类。

pH-Responsive Biodegradable Polymers for Intracellular Drug DeliveryA。

Proposed area of researchThe aim of this proposed PhD project is to develop and evaluate pH responsive, endosomolytic polymers for efficient intracellular delivery of biological drug payloads。

There is a need to better understand the mechanisms of entry into the cell cytoplasm and nucleus in order to design optimal delivery systems for biological molecules. On the one hand, this would open up significant opportunities to deliver potent drug payloads against intracellular targets to positively impact human health. In addition the project aims to develop a more general understanding of the rules governing the uptake of biological molecules into cells。

This project proposes to investigate the use of synthetic, biodegradable polymers for intracellular delivery of drug payloads (including siRNA,therapeutic peptide and antibody)against a well—validated intracellular drug target,such as Bcl—2。

第45卷 第9期 包 装 工 程2024年5月PACKAGING ENGINEERING ·105·收稿日期:2024-03-18基金项目:上海市青浦区科学技术协会学会咨询项目(QPXHB23-04) 生物可降解高分子材料增韧共混改性研究进展陈晨1,潘宇飞1*,于绍凤2,李军1,熊露璐3(1.上海工程技术大学,上海 201620;2. 上海现代农业园区发展有限公司,上海 201717;3.上海大觉包装制品有限公司,上海 201706)摘要:目的 综述国内外生物可降解塑料共混改性的常用策略,为高品质生物可降解塑料的工业化开发提供思路与理论方法。

方法 共混改性是高分子材料改性的常用策略,因其具有高效、经济的特点而被广泛采用,本文针对生物可降解高分子材料增韧共混改性策略,选取聚乳酸(PLA )、对苯二甲酸-己二酸丁二醇酯(PBAT )、聚丁二酸丁二醇酯(PBS )作为对象,对增韧共混改性研究现状进行归纳、总结和分析,同时对比各自的增韧改性效果及优点和不足。

结论 以生物可降解塑料取代不可降解塑料可以在很大程度上缓解当前的环境污染问题,在未来地膜和包覆材料中具有广阔的应用前景。

关键词:生物可降解;增韧;改性中图分类号:TB33 文献标志码:A 文章编号:1001-3563(2024)09-0105-08 DOI :10.19554/ki.1001-3563.2024.09.013Development Status of Polymer Materials Plastics Toughening andBlending ModificationCHEN Chen 1, PAN Yufei 1*, YU Shaofeng 2, LI Jun 1, XIONG Lulu 3(1. Shanghai University of Engineering Science, Shanghai 201620, China; 2. Shanghai Modern Agricultural Park Development Co., Ltd., Shanghai 201717, China; 3. Shanghai Dajue Packaging Products Co., Ltd.,Shanghai 201706, China)ABSTRACT: The work aims to review the commonly used strategies for blending and modifying biodegradable plastics at home and abroad, and provide ideas and theoretical methods for the industrial development of high- quality biodegradable plastics. Based on the fact that blending modification was a commonly used strategy for polymer material modification, which was widely adopted due to its high efficiency and economic characteristics, this article focused on the biodegradable polymer materials. Poly (lactic acid) (PLA), butylene terephthalate (PBAT), and polybutylene succinate (PBS) were selected as objects to summarize, conclude and analyze the current research status of toughening blending modification. At the same time, the toughening and modification effects, advantages and disadvantages of each were compared. In conclusion, replacing non degradable plastics with biodegradable plastics can greatly alleviate current environmental pollution problems. It has broad application prospects in future plastic films and coating materials.KEY WORDS: biodegradable; toughening; modification为了改善环境问题,越来越多的研究人员开始探索一种能够在较短时间内分解的绿色环保新型材料。

生物降解塑料中英文对照Poly(Butylene-Succinate) PBS 聚丁二酸丁二醇酯Poly(butylene succinate-co-butylene adipate) PBSA丁二酸丁二醇酯-己二酸丁二醇酯共聚物poly(butylene succinate-co-terephthalate)s PBST聚丁二酸/对苯二甲酸丁二醇酯Soft biodegradable material technology 软性生分解材料技术Photodegradable Plastics光降解性塑胶Disintegradable Plastics 崩解性塑胶Biodegradable Materials生物可分解材料Bio-Polymer生物高分子聚合物Green Plastics绿色塑胶Aliphatic-Aromatic Polyester Copolymers 脂肪族—芳香族聚酯的嵌段分子聚合物Aliphatic Polyesters脂肪族聚酯CPLA, Polylactide Aliphatic Polyester Copolymers 聚乳酸—脂肪族聚酯的嵌段分子聚合物Polycaprolactone PCL 聚己内酯Polyhydroxyalkanoates PHA聚羟基羧酸酯Poly-beta-hydroxybutyrate PHB聚羟基丁酸酯Polyhydroxybutyrate-valerate PHBV聚羟基戊酸酯Polylactide PLA聚乳酸poly(butylene adipate-co-terephthalate) (PBAT) 己二酸-对苯二甲酸-丁二酯共聚物(PBAT) Poly(butylene Succinate-co-butylene Fumarate) 聚(琥珀酸丁二醇酯-共-富马酸丁二醇酯)目前可降解塑料除了PLA还有哪些种类?降解塑料(degradable plastic)是指,在规定环境条件下,经过一段时间和包含一个或更多步骤,导致材料化学结构的显著变化而损失某些性能(如完整性、分子量、结构或机械强度)和/或发生破碎的塑料。

B I O D E G R A D A B L E P O L Y M E R SR.CHANDRA,RENU RUSTGIDepartment of Polymer Technology and Applied Chemistry,Delhi College ofEngineering,Delhi-110006,India1273PergamonProg.Polym.Sci.,Vol.23,1273–1335,1998Copyright ᭧1998Elsevier Science Ltd Printed in Great Britain.All rights reserved.0079–6700/98$−see front matterS0079–6700(97)00039–7C O N T E N T S1.General introduction12742.Natural biodegradable polymers12752.1.Polysaccharides12752.1.1.Starch12762.1.2.Cellulose12792.1.3.Chitin and chitosan12822.1.4.Alginic acid12822.2.Polypeptides of natural origin12822.2.1.Gelatin12822.3.Bacterial polyesters12833.Polymer with hydrolyzable backbones12843.1.Polyesters12863.2.Polycaprolactone12863.3.Polyamides12863.4.Polyurethanes and polyureas12873.5.Polyanhydrides12873.6.Poly(amide-enamine)s12874.Polymers with carbon backbones12884.1.Poly(vinyl alcohol)and poly(vinyl acetate)12884.2.Polyacrylates12895.Factors affecting biodegradation12895.1.Effect of polymer structure12895.2.Effect of polymer morphology12905.3.Effects of radiation and chemical treatments12915.4.Effect of molecular weight12926.Mode of biodegradation12936.1.Microorganisms12926.1.1.Fungi12926.1.2.Bacteria12946.2.Enzymes12946.2.1.Physical factors affecting the activity of enzymes12956.2.2.Enzyme mechanisms12956.2.2.1.Biological oxidation12956.2.2.2.Biological hydrolysis12961274R.CHANDRA and R.RUSTGI7.Test methods and standards for biodegradable polymers12967.1.Modified sturm test12977.2.Closed bottle test12997.3.Petri dish screen12997.4.Environmental chamber method13007.5.Soil burial test13018.Polymer modification to facilitate biodegradation13029.Blends of biodegradable and non-degradable polymers13049.1.Polyethylene and starch blends13059.2.Modified polyethylene and starch blends131610.Applications131910.1.Medical applications131910.1.1.Surgical sutures131910.1.2.Bonefixation devices132010.1.3.Vascular grafts132010.1.4.Adhesion prevention132010.1.5.Artificial skin132110.1.6.Drug delivery systems132110.2.Agricultural applications132310.2.1.Agricultural mulches132310.2.2.Controlled release of agricultural chemicals132410.2.3.Agricultural planting containers132510.3.Packaging1325 References13261.I N T R O D U C T I O NBiodegradable polymers are a newly emergingfield.A vast number of biodegradable polymers have been synthesized recently and some microorganisms and enzymes capable of degrading them have been identified.In developing countries,environmental pollution by synthetic polymers has assumed dangerous proportions.As a result,attempts have been made to solve these problems be including biodegradability into polymers in everyday use through slight modifications of their structures.Biodegradation is a natural process by which organic chemicals in the environment are converted to simpler compounds,mineralized and redistributed through elemental cycles such as the carbon,nitrogen and sulphur cycles.Biodegradation can only occur within the biosphere as microorganisms play a central role in the biodegradation process.A number of standards authorities have sought to produce definitions for biodegradable plastics and some of these are provided below:ISO472:1988—A plastic designed to undergo a significant change in its chemical structure under specific environmental conditions resulting in a loss of some properties that may vary as measured by standard test methods appropriate to the plastics and application in a period of time that determines its classification.The change in chemical structure results from the action of naturally occurring microorganisms.ASTM sub-committee D20.96proposal—Degradable plastics are plastic materials that undergo bond scission in the backbone of a polymer through chemical,biological and/orphysical forces in the environment at a rate which leads to fragmentation or disintegra-tion of the plastics.Japanese Biodegradable Plastic Society 1draft proposal—Biodegradable plastics are polymeric materials which are changed into lower molecular weight compounds where at least one step in the degradation process is through metabolism in the presence of naturally occurring organisms.DIN 103.2working group on biodegradable polymers—Biodegradation of a plastic material is a process leading to naturally occurring metabolic end products.General definition of biodegradation—It is a process whereby bacteria,fungi,yeasts and their enzymes consume a substance as a food source so that its original form disappears.Under appropriate conditions of moisture,temperature and oxygen availability,bio-degradation is a relatively rapid process.Biodegradation for limited periods is a reason-able target for the complete assimilation and disappearance of an article leaving no toxic or environmentally harmful residue.Biodegradable polymers are useful for various applications in medical,agriculture,drug release and packaging fields.2.N A T U R A L B I O D E G R A D A B L E P O L Y M E R SBiopolymers are polymers formed in nature during the growth cycles of all organisms;hence,they are also referred to as natural polymers.Their synthesis generally involves enzyme-catalyzed,chain growth polymerization reactions of activated monomers,which are typically formed within cells by complex metabolic processes.2.1.PolysaccharidesFor materials applications,the principal polysaccharides of interest are cellulose and starch,but increasing attention is being given to the more complex carbohydrate polymers produced by bacteria and fungi,especially to polysaccharides such as xanthan,curdlan,pullulan and hyaluronic acid.These latter polymers generally contain more than one type of carbohydrate unit,and in many cases these polymers have regularly arranged branched structures.Starch,for example,is a physical combination of branched and linear polymers (amylopectin and amylose,respectively),but it contains only a single type of carbohydrate,glucose.Both cellulose and starch are composed of hundreds or thousands of d -glucopyranoside repeating units.These units are linked together by acetal bonds formed between the hemi-acetal carbon atom,C 1,of the cyclic glucose structure in one unit and a hydroxyl group at either the C 3(for cellulose and amylose)or the C 6(for the branch units in amylopectin)atoms in the adjacent unit.This type of structure occurs because in aqueous solution,glucose can exist in either the acyclic aldehyde or cyclic hemiacetal form,and the latter form is the structure that become incorporated into the polysaccharide.Also,the cyclic form can exist as one of two isomers,the a -isomer with an axial OH group on the ring or the b -isomer with an equatorial OH group.In starch the glucopyranoside ring is present in the a -form while in cellulose the repeating units exist in the b -form.Because of this difference,enzymes that catalyze acetal hydrolysis reactions during the biodegradation of each of these two1275BIODEGRADABLE POLYMERSpolysaccharides are different and are not interchangeable.Fig.1shows the structures of some polysaccharides.2.1.1.StarchStarch is a polymer which occurs widely in plants.The principal crops used for its produc-tion include potatoes,corn and rice.In all of these plants,starch is produced in the form of granules,which vary in size and somewhat in composition from plant to plant.In general,the linear polymer,amylose,makes up about 20wt%of the granule,and the branched polymer,amylopectin,the remainder.Amylose is crystalline and can have a number average molecular weight as high as 500000,but it is soluble in boiling water.Amylopectin is insoluble in boiling water,but in their use in foods,both fractions are readily hydrolyzed at the acetal link by enzymes.The a -1,4-link in both components of starch is attacked by amylases (Fig.2a)and the a -1,6-link in amylopectin is attacked by glucosidases.Starch has been widely used as a raw material in film production because of increasing prices and decreasing availability of conventional film-forming resins.2Starch films possess low permeability and are thus attractive materials for food packaging.Starch is also usefulforFig.1.Structures of polysaccharides.1276R.CHANDRA and R.RUSTGImaking agricultural mulch films because it degrades into harmless products when placed in contact with soil microorganisms.Research on starch includes investigation of its water adsorptive capacity,the chemical modification of the molecule,its behaviour under agitation and high temperature,and its resistance to thermomechanical shear.Although starch is a polymer,its stability under stress is not high.At temperatures higher than 150ЊC,the glucoside links start to break,and above 250ЊC the starch grain endothermally collapses.At low temperatures,a phenomenon known as retrogradation is observed.This is a reorganization of the hydrogen bonds and analigningFig.2.Enzymatic hydrolysis of (a)starch and (b)cellulose.1277BIODEGRADABLE POLYMERS1278R.CHANDRA and R.RUSTGIof the molecular chains during cooling.In extreme cases under10ЊC,precipitation is observed.Thus,though starch can be dispersed into hot water and cast asfilms,the above phenomenon causes brittleness in thefilm.In its application in biodegradable plastics,starch is either physically mixed in with its native granules,kept intact,or melted and blended on a molecular level with the appropriate polymer.In either form,the fraction of starch in the mixture which is accessible to enzymes can be degraded by either,or both,amylases and glucosidases.The starch molecule has two important functional groups,the–OH group that is susceptible to substitution reactions and the C–O–C bond that is susceptible to chain breakage.The hydroxyl group of glucose has a nucleophilic character.By reaction of its–OH group,modification of various properties can be obtained.One example is the reaction with silane to improve its dispersion in poly-ethylene.3Crosslinking or bridging of the–OH groups changes the structure into a network while increasing the viscosity,reducing water retention and increasing its resistance to thermomechanical shear.Acetylated starch does have several advantages as a structuralfibre orfilm-forming polymer as compared to native starch.The acetylation of starch is a well-known reaction and is a relatively easy derivative to synthesize.4Starch acetate is considerably more hydro-phobic than is starch and has been shown to have better retention of tensile properties in aqueous environments.Another advantage is that starch acetate has an improved solubility compared to starch and is easily cast intofilms from simple solvents.The degree of acetyla-tion is easily controlled by transesterification,allowing polymers to be produced with a range of hydrophobicities.Starch has been acetylated5[with a high content(70%)of linear amylose]and its enzymatic degradation studied.Starch acetate was prepared by acetylation of starch with a pyridine/acetic anhydride mixture and cast intofilms from solutions of90% formic acid.A series offilms with a range of acetyl content were then exposed to buffered amylase solutions.It was found that with a sufficient acetyl content,the wet strength of the films was maintained in the aqueous solutions,but that the acetyl content was sufficiently low to permit degradation by a mixture of alpha and beta amylases within a period of1h.These films might be useful as membranes in bioreactors which could then be degraded by the addition of enzymes to the system.Starch has been used for many years as an additive to plastic for various purposes.Starch was added as afiller6to various resin systems to makefilms that were impermeable to water but permeable to water vapour.Starch as a biodegradablefiller in LDPE was reported.7,8A starch-filled polyethylenefilm was prepared9which becomes porous after the extraction of the starch.This porousfilm can be readily invaded by microorganisms and rapidly saturated with oxygen,thereby increasing polymer degradation by biological and oxidative pathways.Otey et al.10in a study on starch-basedfilms,found that a starch–polyvinyl alcoholfilm could be coated with a thin layer of water-resistant polymer to give a degradable agricultural mulchingfilm.Starch-based polyethylenefilms were formu-lated11,12and consisted of up to40%starch,urea,ammonia and various portions of low-density polyethylene(LDPE)and poly(ethylene-co-acrylic acid)(EAA).The EAA acted as a compatibilizer,forming a complex between the starch and the PE in the presence of ammonia.The resulting blend could be cast or blown intofilms,and had physical properties approaching those of LDPE.Three techniques were used to incorporate large amounts of starch as afiller into dis-posable polyvinyl chloride(PVC)plastics.13In thefirst technique,a starch xanthate solutionwas prepared by mixing starch with aqueous NaOH and then adding a small amount of carbon disulphide (usually 0.1mol CS 2per mol starch).To this starch–xanthate solution,a PVC latex was added.The starch–xanthate and PVC resins were then coprecipitated by adding NaNO 2and alum.The fine powder obtained from this was blended with dioctyl phthalate (DOP).In the second technique (a concentration method),whole starch was gelatinized by heating in water before mixing into the PVC latex.After removing the water,dry product was mixed with DOP.In the third method,starch was dry-blended with PVC and DOP.These films appear to be useful for a variety of agricultural applications.14The possibility of chemically combining starch or starch-derived products with commer-cial resins in such a manner that the starch would serve as both a filler and a crosslinking agent may provide a feasible approach for incorporating starch into plastics.Since isocyanates are highly reactive with hydroxyl groups,they can be used to prepare a number of reactive resins that crosslink with starch.The addition of starch to isocyanate resins considerably reduced costs and improved solvent resistance and strength properties.15Starch can be modified with nonpolar groups,such as fatty esters,before the isocyanate reaction to improve the degree of reactivity.16A method was developed 17to incorporate starch as a filler and crosslinking agent in diisocyanate-modified polyesters to yield elasto-mers.Dosmann and Steel 18added starch to urethane systems to yield shock-absorbing foams.Bennett et al .19reported that 10–40%of a rigid urethane foam formulation can be starch.These studies demonstrated that starch products cause foams to be more flame resistant and more readily attacked by soil microorganisms.2.1.2.CelluloseMany polymer researchers are of the opinion that polymer chemistry had its origins with the characterization of cellulose.Cellulose was isolated for the first time some 150years ago.Cellulose differs in some respects from other polysaccharides produced by plants,the molecular chain being very long and consisting of one repeating unit (cellobiose).Naturally,it occurs in a crystalline state.From the cell walls,cellulose is isolated in microfibrils by chemical extraction.In all forms,cellulose is a very highly crystalline,high molecular weight polymer,which is infusible and insoluble in all but the most aggressive,hydrogen bond-breaking solvents such as N -methylmorpholine-N -oxide.Because of its infusibility and insolubility,cellulose is usually converted into derivatives to make it more processable.Some fungi can secrete enzymes that catalyze oxidation reactions of either cellulose itself or the lower molecular weight oligomers produced from the enzymatic hydrolysis of cellu-lose.Of these,the peroxidases can provide hydrogen peroxide for free radical attack on the C 2–C 3positions of cellulose to form ‘aldehyde’cellulose,which is very reactive and can hydrolyze to form lower molecular weight fragments (Fig.2b)while other oxidative enzymes can oxidize glucose and related oligomers to glucuronic acids.Bacteria also secrete both endo-and exoenzymes,some of which form complexes that act jointly in degrading cellulose to form carbohydrate nutrients which the microorganisms utilize for survival.20,21Aerobic soil environments generally contain a consortia of several different type of degrading bacteria and fungi which operate cooperatively.Primary microorganisms degrade cellulose to glucose and cellodextrins,a portion of which they utilize,and secondary1279BIODEGRADABLE POLYMERS1280R.CHANDRA and R.RUSTGImicroorganisms,which provide enzymes that degrade the cellodextrins to glucose,which they consume.By consuming glucose the latter assist in the growth of the primary micro-organism because they prevent the build-up of the cellodextrins,which can inhibit glucanases if they are present in the environment at high concentrations.Thefinal products from aerobic biodegradation are ultimately CO2and water.In anaerobic environments,a variety offinal products are formed,including CO2hydrogen, methane,hydrogen sulphide and ammonia.CO2can be formed by oxidative reactions which utilize inorganic compounds,such as sulphate and nitrate ions,in the environment as oxidizing agents.Hydrogen produced by some anaerobic bacteria can be utilized by autotrophic bacteria to reduce oxidized compounds and CO2to form either acetic acid or methane.Cellulose has received more attention than any other polymer since it is attacked by a wide variety of microorganisms,and since it is often used in textiles without additives to complicate the interpretation of results.Cellulose represents an appreciable fraction of the waste products that make up sewage and refuse.It is fortunate that it does decom-pose readily.Fermentation of cellulose has been suggested as a source of chemicals such as ethanol and acetic acid,but this has not achieved any commercial importance to date.All of the important derivatives of cellulose are reaction products of one or more of the three hydroxyl groups,which are present in each glucopyranoside repeating unit,including: (1)ethers,e.g.methyl cellulose and hydroxyl-ethyl cellulose;(2)esters,e.g.cellulose acetate and cellulose xanthate,which is used as a soluble intermediate for processing cellulose into eitherfibre orfilm forms,during which the cellulose is regenerated by controlled hydrolysis; and(3)acetals,especially the cyclic acetal formed between the C2and C3hydroxyl groups and butyraldehyde.The biodegradation of cellulose is complicated,because cellulose exists together with lignin,for example,in wood cell walls.White-rot fungi secrete exocellular peroxidases to degrade lignin preferentially and,to a lesser extent,cellulases to degrade the polysaccharides in order to produce simple sugars which serve as nutrients for these microorganisms.Brown-rot fungi secrete enzymes for the degradation of cellulose and the hemicelluloses.Soft-rot fungi,also degrade principally these two types of polysaccharides.Cellulose esters represent a class of polymers that have the potential to participate in the carbon cycle via microbiologically catalyzed de-esterification and decomposition of the resulting cellulose and organic acids.Cellulose acetate is currently used in high volume applications ranging fromfibres,tofilms,to injection moulding thermoplastics.It has the physical properties and relatively low material costs that have tended to exclude other biodegradable polymers from being widely accepted in the marketplace.Gardener et al.22have developed a series of cellulose acetatefilms,differing in their degree of substitution,that were evaluated in this bench-scale system.In addition, commercially available biodegradable polymers such as poly(hydroxybutyrate-co-valerate) (PHBV)and polycaprolactone(PCL)were included as points of reference.Based onfilm disintegration andfilm weight loss,cellulose acetates,having degrees of substitution less than approximately2.20,compost at rates comparable to that of PHBV.NMR and GPC analyses of compostedfilms indicate that low molecular weight fractions are removed preferentially from the more highly substituted and slower degrading cellulose acetates.Reese23presented evidence of esterase activity on soluble cellulose acetates with a lowdegree of substitution (DS,0.76sites esterified per anhydroglucose monomer).A pure culture of Pestalotiopsis Westerdijkii Quarter Master (QM)381was reported to completely utilize this low DS cellulose ester.However,Reese did not find any evidence that the fully sub-stituted cellulose triacetate could be biodegraded.Cantor and Mechalas 24found evidence of esterase activity on reverse osmosis membranes composed of cellulose acetate (DS 2.5).Using infrared analysis,up to 50%deacylation was detected on the desalinating surface.No reduction in acylation was detected with cellulose triacetate.Dong Gue et al .25recently presented evidence of anaerobic biodegradation of cellulose acetate (DS 1.7)with about 9%weight loss over a 60-day period.Recently,Buchanan et al .26,27presented evidence support-ing the inherent biodegradability of cellulose acetate with naturally occurring micro-organisms in activated sludge and in aerobic microbial cultures.Komarck et al .28studied biodegradation of radiolabelled cellulose acetate and cellulose propionate with a naturally derived mixed microbial culture derived from activated sludge.Radiolabelled cellulose esters were synthesized with either [1-14C]-acetate or [1-14C]-pro-pionate and back hydrolyzed to the desired degree of substitution (DS)ranging from 1.77to2.64.Biodegradation was measured in an in vitro aerobic culture system that was designed to capture 14CO 2produced by the aerobic microbial metabolism of the cellulose esters.Micro-organisms were able to extensively degrade cellulose [1-14C]-acetate (CA)with DS values ranging from 1.85to 2.57over periods of 14–31days.More than 80%of the original 14C-polymeric carbon was biodegraded to 14CO 2for CA substrates with a DS of 1.85.CA polymers with a DS of 2.07and 2.57yielded over 60%conversion to 14CO 2.The amount of biodegradation that was observed for cellulose [1-14C]-propionate with DS values of 2.11,2.44and 2.64were lower than the corresponding acetyl ester and ranged from 0.09to 1.1%.However,cellulose [1-14C]-propionate with a DS of 1.77and 1.84underwent very rapid degradation in the mixed culture system,with 70–80%conversion of the labelled polymeric carbon metabolized to 14CO 2in 29days.The high level of microbial utilization of carbon from both cellulose esters and its conversion to CO 2confirms the biodegradability of these polymers and the potential they have for total mineralization in natural,microbiologically active environments.The biodegradation of cellulose ethers has been studied extensively and it is known that cellulose ethers with a DS of less than 1will degrade due to attack of microorgan-isms at the unsubstituted residues of the polymers.The ether linkages on the cellulose backbone are considered resistant to microbial attack.By contrast,there have been conflicting reports concerning the biodegradation potential of cellulose esters.Stutzen-berger and Kahler 29have reported that cellulose acetate (CA)is a poor substrate,because of its extreme resistance to microbial attack.However,Reese 23has isolated cellulolytic filtrates,which deacetylated soluble CA (DS =0.76)and insoluble cellobiose octaacetate.Further-more,Cantor and Mechalas 24have demonstrated that CA reverse-osmosis membranes with a DS of 2.5suffer losses in semipermeability due to microbial attack.These reports suggest that the synergistic action of esterase and cellulase-producing microorganisms act in concert to degrade CA.One possible mechanistic pathway would involve attack by cellulase enzymes on the unsubstituted residues in the polymer backbone.Enzymatic cleavage of the acetyls by esterase (or simple chemical hydrolysis)would then serve to expose additional unsubstituted residues,which could also be digested by the action of cellulase enzymes which further would serve eventually to degrade CA completely in the environment.1281BIODEGRADABLE POLYMERS1282R.CHANDRA and R.RUSTGI2.1.3.Chitin and chitosanChitin is a macromolecule found in the shells of crabs,lobsters,shrimps and insects.It consists of2-acetamide-2-deoxy-b-d-glucose through the b-(1-4)-glycoside linkage.Chitin can be degraded by chitinase.Chitinfibres have been utilized for making artificial skin and absorbable sutures.30Chitin is insoluble in its native form but chitosan,the partly deacetyl-ated form,is water soluble.The materials are biocompatible and have antimicrobial activities as well as the ability to absorb heavy metal ions.They alsofind applications in the cosmetic industry because of their water-retaining and moisturizing ing chitin and chitosan as carriers,a water-soluble prodrug has been synthesized.31Modified chitosans have been prepared with various chemical and biological properties.32 N-Carboxymethylchitosan and N-carboxybutylchitosan have been prepared for use in cos-metics and in wound treatment.33Chitin derivatives can also be used as drug carriers,34and a report of the use of chitin in absorbable sutures shows that chitins have the lowest elongation among suture materials consisting of chitin,poly(glycolic acid)(PGA),plain catgut and chromic catgut.35The tissue reaction of chitin is similar to that of PGA.2.1.4.Alginic acidMany polysaccharides in solution form gels upon the introduction of counterions.The degree of cross-linking is dependent on various factors such as pH,type of counterion,and the functional charge density of these polymers.Alginates have been studied extensively for their ability to form gels in the presence of divalent cations.36–41Alginate is a binary linear heteropolymer containing1,4-linked a-l-guluronic acid and b-d-mannuronic acid.Alginic acid forms water-soluble salts with monovalent cations,low molecular weight amines,and quaternary ammonium compounds.It becomes water-insoluble in the presence of polyvalent cations such as Ca2+,Be2+,Cu2+,Al3+and Fe3+. Alginate gels have been used widely in controlled release drug delivery systems.Alginates have been used to encapsulate various herbicides,microorganisms and cells.2.2.Polypeptides of natural originThe proteins that have found applications as materials are,for the most part,neither soluble nor fusible without degradation,so they are used in the form in which they are found in nature.This description is especially true for thefibrous proteins wool,silk and collagen.All proteins are specific copolymers with regular arrangements of different types of a-amino acids,so the biosynthesis of proteins is an extremely complex process involving many different types of enzymes.In contrast,the enzymatic degradation of proteins,with general purpose proteases,is a relatively straightforward,amide hydrolysis reaction.2.2.1.GelatinGelatin,an animal protein,consists of19amino acids joined by peptide linkages and can be hydrolyzed by a variety of the proteolytic enzymes to yield its constituent amino acids or peptide components.42This nonspecificity is a desirable factor in intentional biodegradation. Gelatin is a water-soluble,biodegradable polymer with extensive industrial,pharmaceutical,and biomedical uses,has been employed for coatings and microencapsulating various drugs,43–49and for preparing biodegradable hydrogels.50–53A method was developed to prepare a simple,flexible gelatin film-based artificial skin that could adhere to an open wound and protect it against fluid loss and infection.The approach used was to mix polyglycerols,either as it is or after epoxizing them with epichlorohydrin,with commercially available gelatin and to cast films on teflon-covered trays.52The films were tough and adhered to open wounds spontaneously.They could be loaded with bioactive molecules,such as growth factors and antibiotics that would be released over several days.The films could be sterilized with g -rays or prepared under sterile conditions.Chemical modification of natural polymers by grafting serves the twofold purpose of utilizing renewable,naturally derived products such as proteins,as replacements for petroleum-based polymers and as biodegradable compositions which can be tailored for the slower or faster rates of degradation.In order to extend the application of grafting for the modification of natural polymers,T.Kuwajima et al .54grafted methyl methacrylate onto gelatins by radical initiators and studied these in aqueous solution at temperatures between 60and 80ЊC.Among the initiators used (peroxysulphates,a ,a Ј-azobisisobutylonitrile,and benzoyl peroxide),potassium peroxysulphate was found to be the most efficient in this particular graft polymerization.From kinetic data with this initiator,it was shown that:(1)the efficiency of grafting is higher at lower temperatures;(2)a sharp increase in the efficiency of grafting occurs at the later period of the polymerization at high temperature,which is attributable to the combination of the homopolymer and the backbone gelatin;and (3)generally,the number of branches was small and the molecular weight of the branched polymer was high in this polymerization.Kumar et al .55prepared gelatin-g-poly(ethyl acrylate)in an aqueous medium,using K 2S 2O 8as an initiator.The composition of the graft copolymer was dependent upon the temperature and duration of the reaction.The number of grafting sites was small and the molecular weight of the grafted poly(ethylacrylate)branches was high.Three copolymer samples with grafting efficiencies of 33.3,61.0and 84.0%were tested for their microbial susceptibility in a synthetic medium employing a mixed inoculum of Bacillus subtilis,Pseudomonas aeruginosa ,and Serratia marcescens .The weight losses were found to be 12,10.1and 6.0%,respectively,after six weeks of incubation.The extent of degradation seems to decrease with increasing grafting efficiency.There was initial rapid weight loss accompanied by an exponential increase in the bacterial population and pH of the culture medium during the first week.Nitrogen analysis also showed the polymer utilization.A parallel set of experiments,carried out by employing the samples as the only source of both carbon and nitrogen,showed a marginal but definite increase in the utilization of the polymer.2.3.Bacterial polyestersThe natural polyesters,which are produced by a wide variety of bacteria as intracellular reserve materials,are receiving increased attention for possible applications as biodegrad-able,melt processable polymers which can be produced from renewable resources.The members of this family of thermoplastic biopolymers,which have the general structure given below,can show variation in their material properties from rigid brittle plastics,to flexible plastics with good impact properties to strong tough elastomers,depending on the size of the pendant alkyl group,R,and the composition of the polymer.56–581283BIODEGRADABLE POLYMERS。

《功能高分子材料》复习题一、功能高分子材料按其功能性可以分为几类?功能高分子可从以下几个方面分类:1. 力学功能材料:1) 强化功能材料,如超高强材料、高结晶材料等;2) 弹性功能材料,如热塑性弹性体等。

2. 化学功能材料:1) 分离功能材料,如分离膜、离子交换树脂、高分子络合物等;2) 反应功能材料,如高分子催化剂、高分子试剂;3) 生物功能材料,如固定化酶、生物反应器等。

3. 物理化学功能材料:1) 耐高温高分子,高分子液晶等;2) 电学功能材料,如导电性高分子、超导高分子,感电子性高分子等;3) 光学功能材料,如感光高分子、导光性高分子,光敏性高分子等;4) 能量转换功能材料,如压电性高分子、热电性高分子等。

4. 生物化学功能材料:1) 人工脏器用材料,如人工肾、人工心肺等;2) 高分子药物,如药物活性高分子、缓释性高分子药物、高分子农药等;3) 生物分解材料,如可降解性高分子材料等。

二、说明离子交换树脂的类型及作用机理?试述离子交换树脂的主要用途。

1.阳离子交换树脂。

机理:解离出阳离子、并与外来阳离子进行交换;R-SO3H + M+—— R-SO3M+ H+2.阴离子交换树脂。

机理:解离出阴离子、并与外来阴离子进行交换。

RN+H3OH- + X-——RN+H3X- + OH-3.应用:1)水处理:包括水质的软化、水的脱盐和高纯水的制备。

2)冶金工业:分离、提纯和回收铀、钍等超铀元素、稀土金属、重金属、轻金属、贵金属和过渡金属。

3)原子能工业:包括核燃料的分离、提纯、精制、回收等,还是原子能工业废水去除放射性污染处理的主要方法。

4)海洋资源利用:从海洋生物(例如海带)中提取碘、溴、镁等重要化工原料,用以海水制取淡水。

5)食品工业:制糖、酿酒、烟草、乳品、饮料、调味品等食品加工中都有广泛地应用。

6)医药工业:例如在药物生产中用于药剂的脱盐、吸附分离、中和及中草药有效成分的提取等。

7)化学工业:在化学实验、化工生产上是重要的单元操作,普遍用于多种无机、有机化合物的分离、提纯、浓缩和回收等。